fuse DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 443 of 5267

Possible Causes

(A919) PCM FUSED B+ CIRCUIT

PCM NO RESPONSE

(F202) (F1) (T751) PCM FUSED IGNITION SWITCH OUTPUT CIRCUITS

(Z130) (Z131) PCM GROUND CIRCUITS

CRANKSHAFT POSITION SENSOR

(F855) 5-VOLT SENSOR OPEN/SHORTED

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

(F856) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

PCM

Diagnostic Test

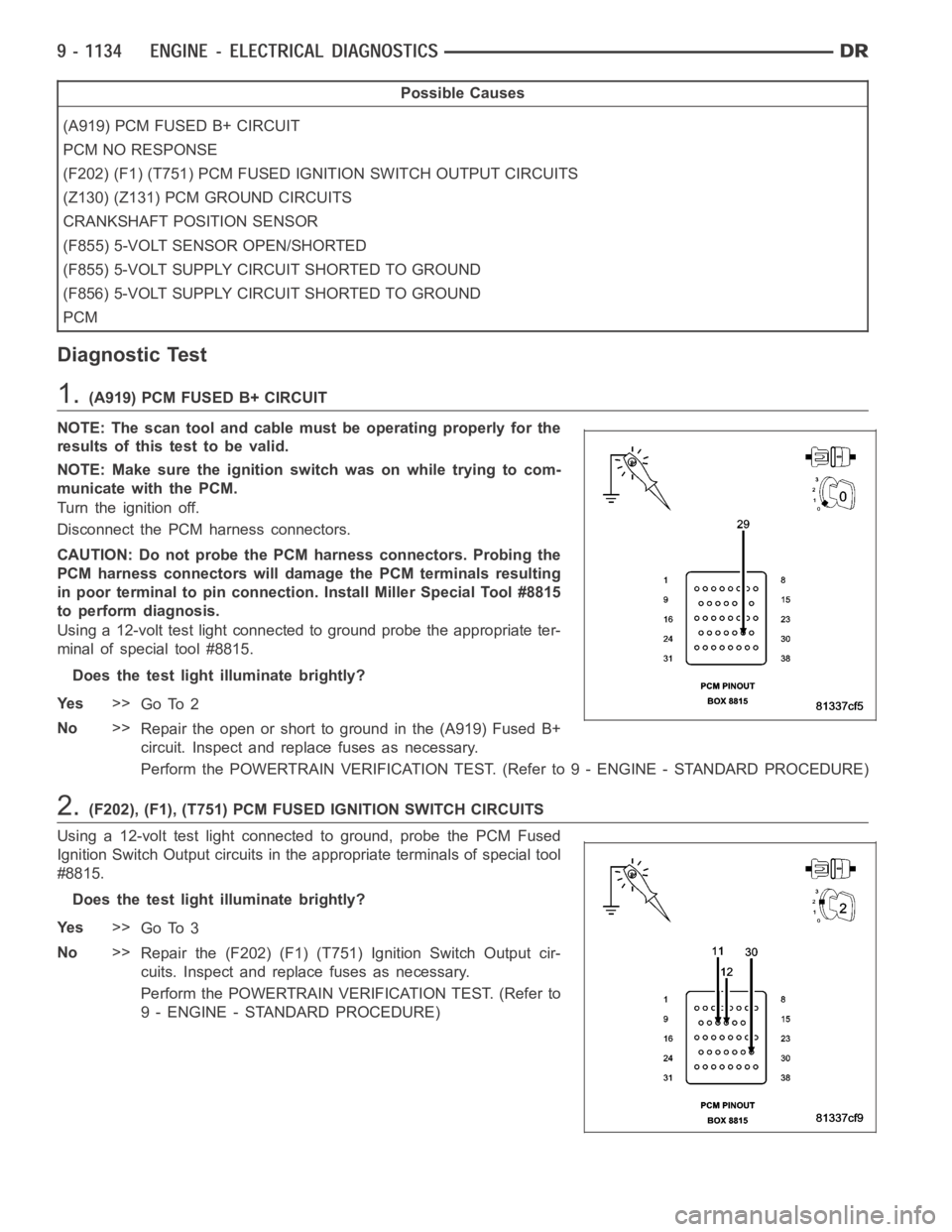

1.(A919) PCM FUSED B+ CIRCUIT

NOTE: The scan tool and cable must be operating properly for the

resultsofthistesttobevalid.

NOTE: Make sure the ignition switch was on while trying to com-

municate with the PCM.

Turn the ignition off.

Disconnect the PCM harness connectors.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Using a 12-volt test light connected to ground probe the appropriate ter-

minal of special tool #8815.

Does the test light illuminate brightly?

Ye s>>

Go To 2

No>>

Repair the open or short to ground in the (A919) Fused B+

circuit. Inspect and replace fuses as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

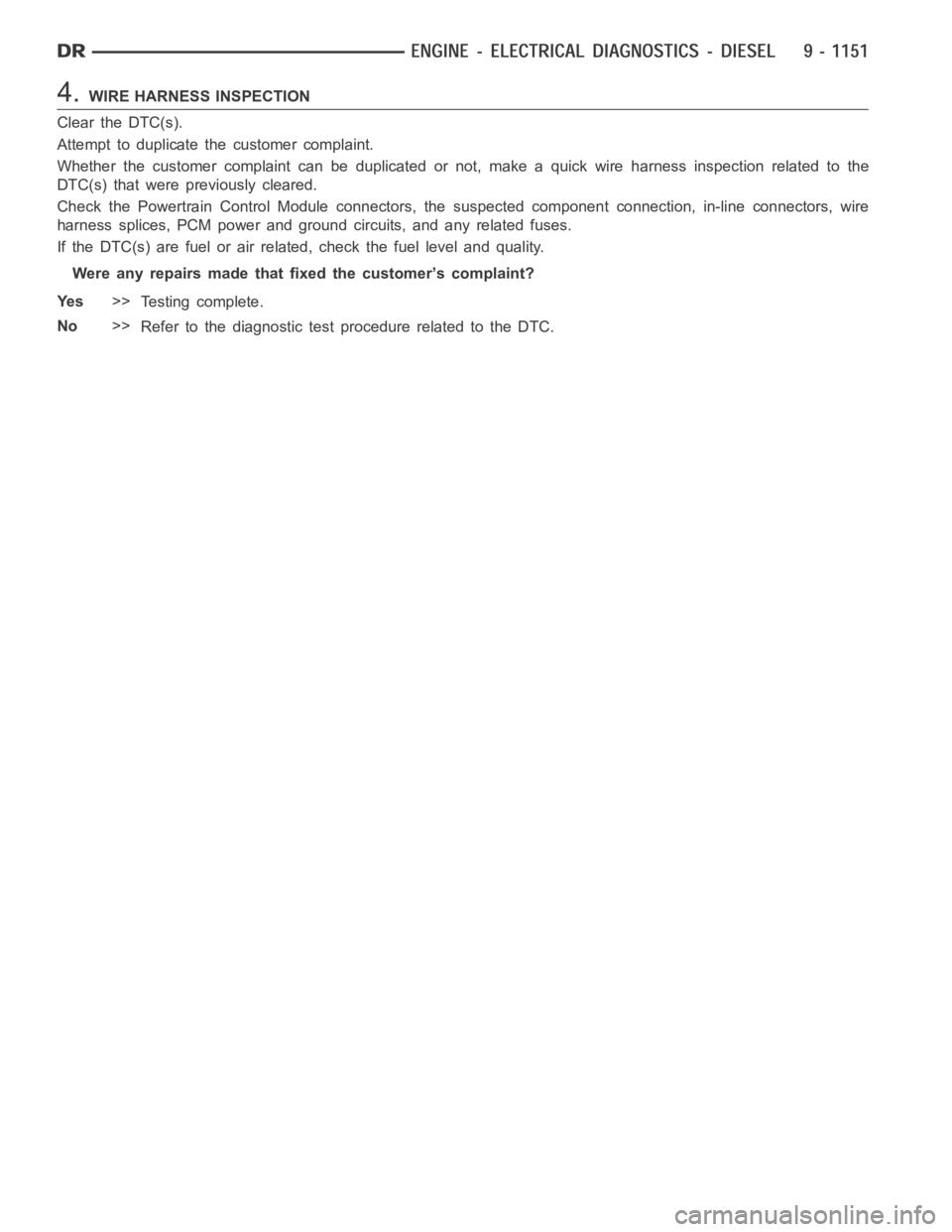

2.(F202), (F1), (T751) PCM FUSED IGNITION SWITCH CIRCUITS

Using a 12-volt test light connected to ground, probe the PCM Fused

Ignition Switch Output circuits in the appropriate terminals of special tool

#8815.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the (F202) (F1) (T751) Ignition Switch Output cir-

cuits. Inspect and replace fuses as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 460 of 5267

4.WIRE HARNESS INSPECTION

Clear the DTC(s).

Attempt to duplicate the customer complaint.

Whether the customer complaint can be duplicated or not, make a quick wire harness inspection related to the

DTC(s) that were previously cleared.

Check the Powertrain Control Module connectors, the suspected componentconnection, in-line connectors, wire

harness splices, PCM power and ground circuits, and any related fuses.

If the DTC(s) are fuel or air related, check the fuel level and quality.

Were any repairs made that fixed the customer’s complaint?

Ye s>>

Testing complete.

No>>

Refer to the diagnostic test procedure related to the DTC.

Page 581 of 5267

When Monitored:

When the ignition is on.

Set Condition:

The ECM detects an open or short circuit in the Wastegate solenoid circuit.

Possible Causes

DAMAGED WIRING HARNESS OR CONNECTORS

WASTEGATE SOLENOID

(F504) FUSED IGNITION SWITCH OUTPUT OPEN

(K139) WASTEGATE SOLENOID DRIVER CIRCUIT OPEN

(K139) WASTEGATE SOLENOID CIRCUIT SHORTED TO GROUND

(K139) WASTEGATE SOLENOID DRIVER SHORTED TO VOLTAGE

(K139) WASTEGATE SOLENOID DRIVER CIRCUIT SHORTED TO ANOTHER CIRCUIT

ECM

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

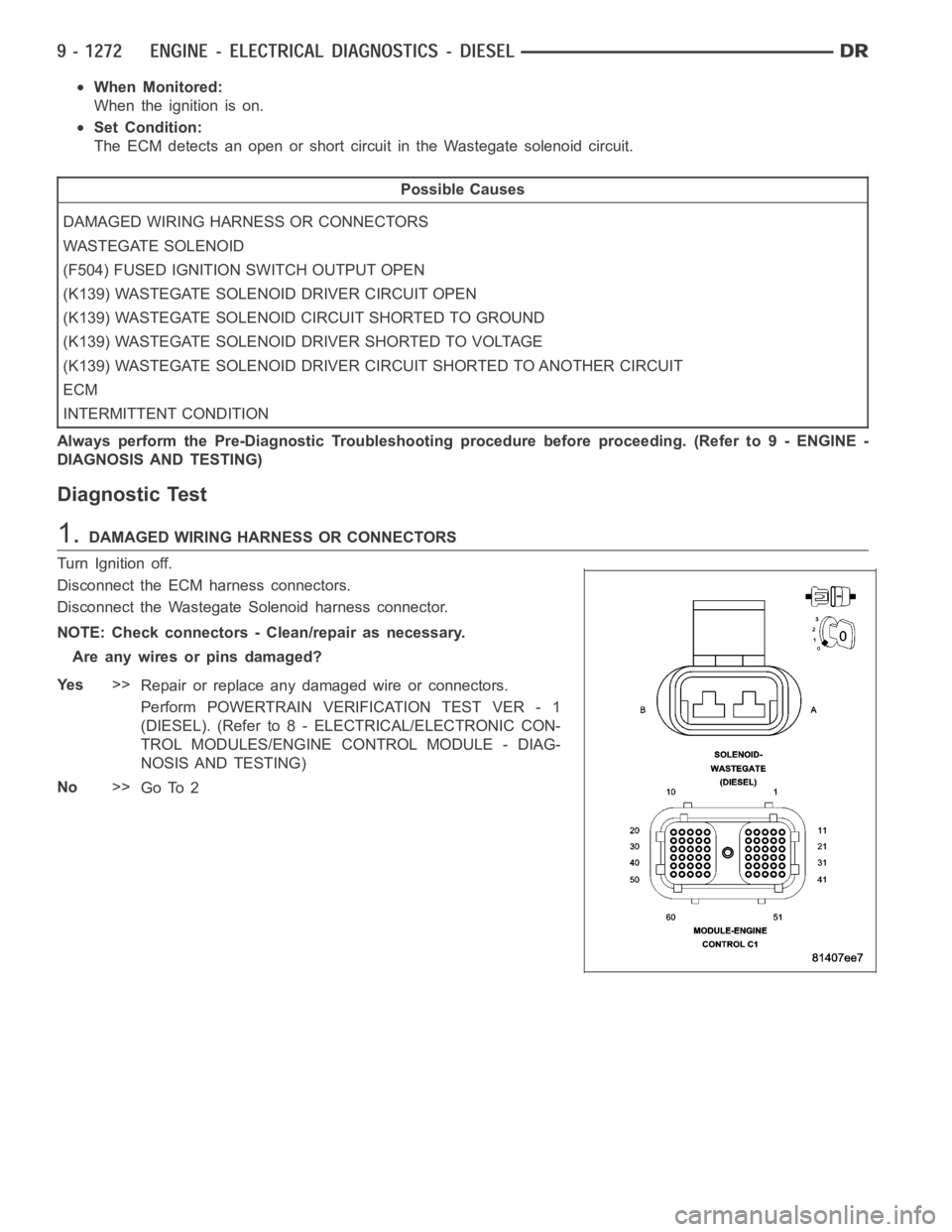

1.DAMAGED WIRING HARNESS OR CONNECTORS

Turn Ignition off.

Disconnect the ECM harness connectors.

Disconnect the Wastegate Solenoid harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Areanywiresorpinsdamaged?

Ye s>>

Repair or replace any damaged wire or connectors.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 2

Page 582 of 5267

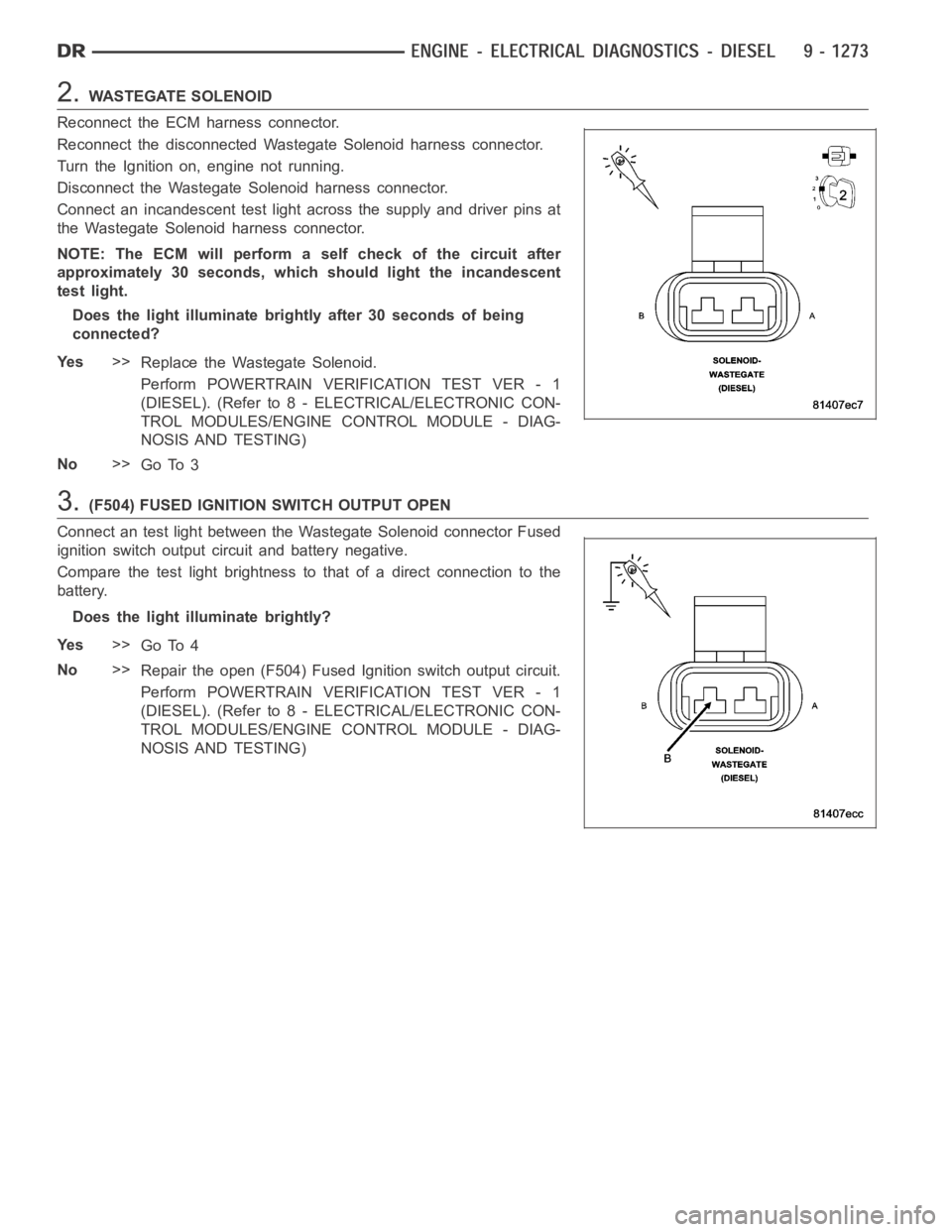

2.WASTEGATE SOLENOID

Reconnect the ECM harness connector.

Reconnect the disconnected Wastegate Solenoid harness connector.

Turn the Ignition on, engine not running.

Disconnect the Wastegate Solenoid harness connector.

Connect an incandescent test light across the supply and driver pins at

the Wastegate Solenoid harness connector.

NOTE: The ECM will perform a self check of the circuit after

approximately 30 seconds, which should light the incandescent

test light.

Does the light illuminate brightly after 30 seconds of being

connected?

Ye s>>

Replace the Wastegate Solenoid.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 3

3.(F504) FUSED IGNITION SWITCH OUTPUT OPEN

Connect an test light between the Wastegate Solenoid connector Fused

ignition switch output circuit and battery negative.

Compare the test light brightness to that of a direct connection to the

battery.

Does the light illuminate brightly?

Ye s>>

Go To 4

No>>

Repair the open (F504) Fused Ignition switch output circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 645 of 5267

P0381-WAIT TO START LAMP INOPERATIVE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on.

Set Condition:

The cluster sends a signal to the ECM that it has detected a failed wait to start lamp.

Possible Causes

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

WAIT-TO-START LIGHT BULB

WIRING/CONNECTOR PROBLEM

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.WAIT-TO-START LAMP DOES NOT COME ON

Turn the ignition off.

While watching the wait-to-start lamp, turn the ignition key on.

Did the wait-to-start lamp light?

Ye s>>

Go To 2

No>>

Go To 3

2.WAIT-TO-START LAMP STAYS ON ALL THE TIME

Turn the ignition off.

While watching the wait-to-start lamp, turn the ignition key on.

Does the wait-to-start lamp stay on all the time?

Ye s>>

Go To 3

No>>

Wait-to-start Lamp operating normally. Test passed.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 646 of 5267

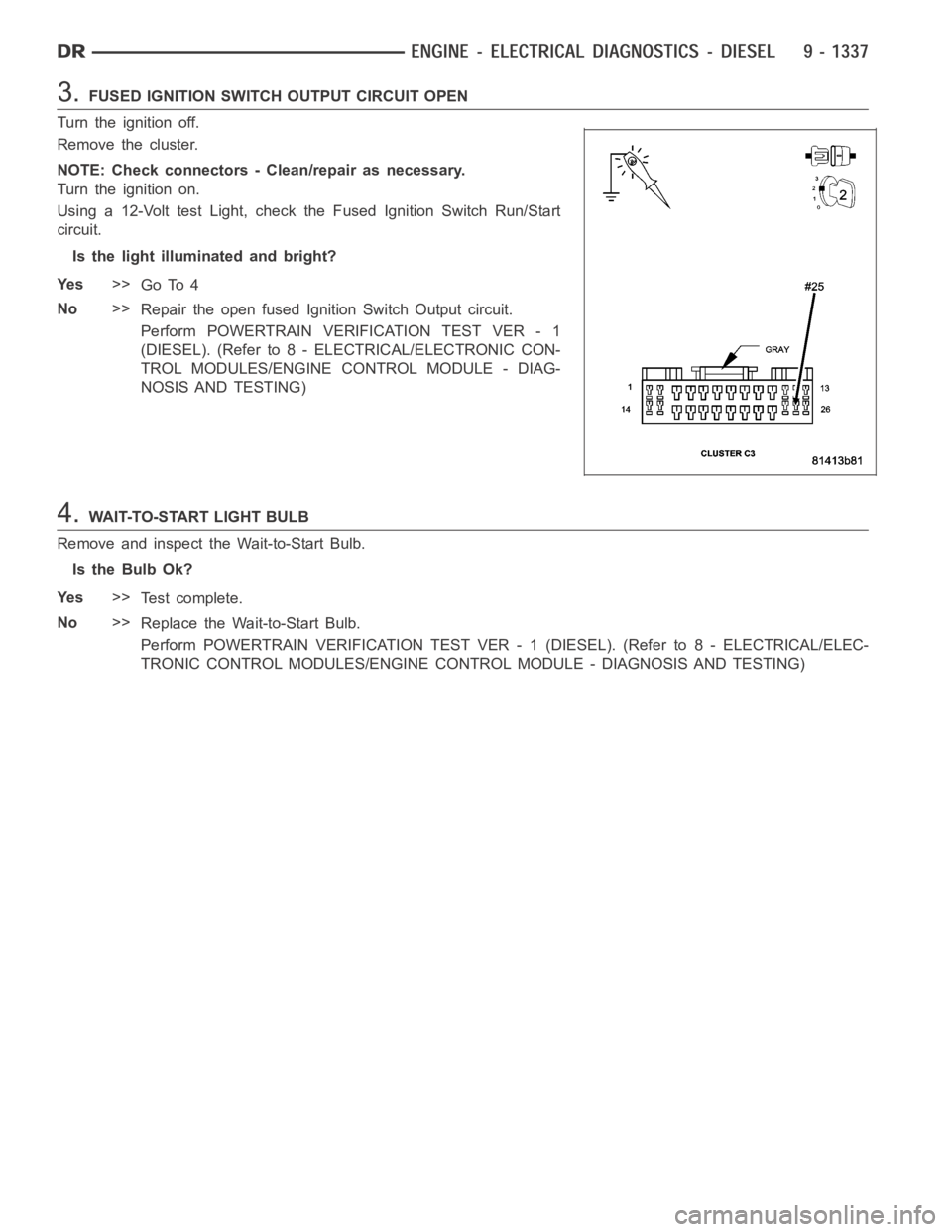

3.FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

Turn the ignition off.

Remove the cluster.

NOTE: Check connectors - Clean/repair as necessary.

Turn the ignition on.

Using a 12-Volt test Light, check the Fused Ignition Switch Run/Start

circuit.

Is the light illuminated and bright?

Ye s>>

Go To 4

No>>

Repair the open fused Ignition Switch Output circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

4.WAIT-TO-START LIGHT BULB

Remove and inspect the Wait-to-Start Bulb.

Is the Bulb Ok?

Ye s>>

Te s t c o m p l e t e .

No>>

Replace the Wait-to-Start Bulb.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 657 of 5267

P0477-LOW VOLTAGE ON THE ENGINE BRAKE DRIVER

For a complete wiring diagramRefer to Section 8W.

When Monitored:

When the ignition is on.

Set Condition:

When the signal from the engine brake driver output does not match the signal from the engine brake driver

feedback.

Possible Causes

WIRING HARNESS

ENGINE BRAKE DRIVER RELAY

FUSED B+ OPEN

ENGINE BRAKE DRIVER SIGNAL CIRCUIT OPEN

INTERMITTENT CONDITION

ENGINE BRAKE DRIVER SIGNAL CIRCUIT SHORTED TO BATTERY NEGATIVE

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.RELAY CLICKING

Turn the engine off (ignition on).

With the scan tool, actuate the exhaust brake relay.

Can you hear the Relay clicking?

Ye s>>

Go To 2

No>>

Go To 3

2.WIRING HARNESS

With the scan tool, actuate the exhaust brake relay.

While the relay is clicking, wiggle the wiring harness and connectors throughout the circuit.

Does this interrupt the clicking?

Ye s>>

Repair or replace the wiring harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 3

3.Engine Brake Driver Relay

Remove the Engine Brake Driver Relay.

Check connectors - Clean/repair as necessary.

Measure the resistance between terminals 86 and 85 of the engine brake relay.

Is the resistance less than 100 Ohms?

Ye s>>

Go To 4

No>>

Replace the Engine Brake Driver Relay.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 658 of 5267

4.FUSED B+ OPEN

Ignition on, engine not running.

Measure the voltage of the Fused B+ Supply circuit at the Engine Brake Relay.

Is the voltage within 10% of battery voltage?

Ye s>>

Go To 5

No>>

Repair the open B+ circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.ENGINE BRAKE DRIVER SIGNAL CIRCUIT OPEN

Turn the ignition off.

Disconnect the ECM harness connectors.

Check connectors - Clean/repair as necessary.

Measure the resistance of the Engine Brake Driver signal circuit between the Relay harness connector and the ECM

harness connector.

Is the resistance less than 10 Ohms?

Ye s>>

Go To 6

No>>

Repair the open Engine Brake driver circuit open from relay to ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.ENGINE BRAKE DRIVER SIGNAL CIRCUIT SHORTED TO BATTERY NEGATIVE

Measure the resistance of the Engine Brake Driver signal circuit between the Relay connector and battery negative.

Is the resistance greater than 100k Ohms?

Ye s>>

Go To 7

No>>

Repair Engine brake driver shorted to Battery negative.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.ECM

Reconnect the ECM harness connectors.

Using the scan tool, actuate the Engine Brake Driver Relay.

While monitoring with the scan tool, use a jumper wire to connect 12 volts tothe relay signal circuit with the relay

disconnected.

Did the DTC P0478?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diagnostic Procedure). (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

No>>

Replace ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 759 of 5267

4.FUSED BATTERY SUPPLY

Connect the ECM and TIPM connectors.

Ignition on, engine not running.

Using a back probing tool 6801, back probe the A/C clutch logic pin in the TIPM logic connector.

Usinga12volttestlightconnectedtobatterypositive,checkthetransmission logic circuit at the TIPM connector

while actuating the A/C clutch circuit with the Electronic Service Tool.

NOTE: The test light must illuminate brightly.

Compare the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Go To 5

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.TIPM

Using a back probing tool, back probe the A/C clutch power pin from the TIPM power connector.

Using a 12 volt test light connected to battery positive, check the transmission power circuit at the TIPM connector

while actuating the A/C clutch circuit with the Electronic Service Tool.

NOTE: The test light must illuminate brightly.

Compare the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Te s t c o m p l e t e .

Perform Intermittent Condition test. (Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

No>>

Replace the TIPM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 869 of 5267

When Monitored:

Continuous - key on or key off.

Set Condition:

Loss of voltage detected at the ECM for a calibrated amount of time.

Possible Causes

POOR CONNECTIONS AT THE BATTERIES

LOW BATTERY VOLTAGE

OPEN FUSED B+ TO ECM

OPEN GROUND CIRCUIT

BATTERY + SHORTED TO OTHER CIRCUITS

RETURN CIRCUIT SHORTED

BATTERY + SHORTED TO GROUND

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.POOR CONNECTIONS AT THE BATTERIES

Visually inspect the wiring at the battery for damaged wires, or corrosion.

Are the connections tight and free of corrosion?

Ye s>>

Go To 2

No>>

Repair the poor connections at the batteries.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

2.L O W B AT T E RY V O LTA G E

Measure the voltage between the positive and negative posts of the batteries.

Is the battery voltages both above 12 volts?

Ye s>>

Go To 3

No>>

Recharge or replace the battery (s).

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)