fuse DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1408 of 5267

4.ASD RELAY

Install a substitute relay for the ASD Relay.

Attempt to startthe vehicle.

Did the engine start?

Ye s>>

Replace the ASD Relay.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No>>

Go To 5

5.(A14) FUSED B+ CIRCUITS

Turn the ignition off.

Remove the ASD Relay from the PDC.

Using a 12-volt test light, probe the (A14) Fused B+ circuits at the ASD Relay connector in the PDC.

Does the test light illuminate brightly?

Ye s>>

Go To 6

No>>

Repair the open or short to ground in the (A14) Fused B+ circuits. Inspect the related fuse and repair

as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

6.(K342) ASD RELAY OUTPUT CIRCUIT OPEN

Disconnect the PCM harness connectors.

Measure the resistance of the (K342) ASD Relay Output circuit from the ASD Relay cavity in the PDC to the PCM

harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the open in the (K342)ASD Relay Output circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1436 of 5267

When Monitored:

Ignition on and engine running.

Set Condition:

An open or shorted condition in the Hydraulic Fan Solenoid control circuitis detected by the Powertrain Control

Module.

Possible Causes

RADIATOR FAN INOP

(K342) FUSED ASD RELAY OUTPUT CIRCUIT

(C240) COOLING FAN CONTROL CIRCUIT OPEN

(C240) COOLING FAN CONTROL CIRCUIT SHORTED TO GROUND

HYDRAULIC FAN

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.RADIATOR FAN INOP

Ignition on, engine not running.

With the scan tool, perform the Hydraulic Fan Solenoid Test found under Engine Test and Systems Test.

Does the Radiator Fan operate properly?

Ye s>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

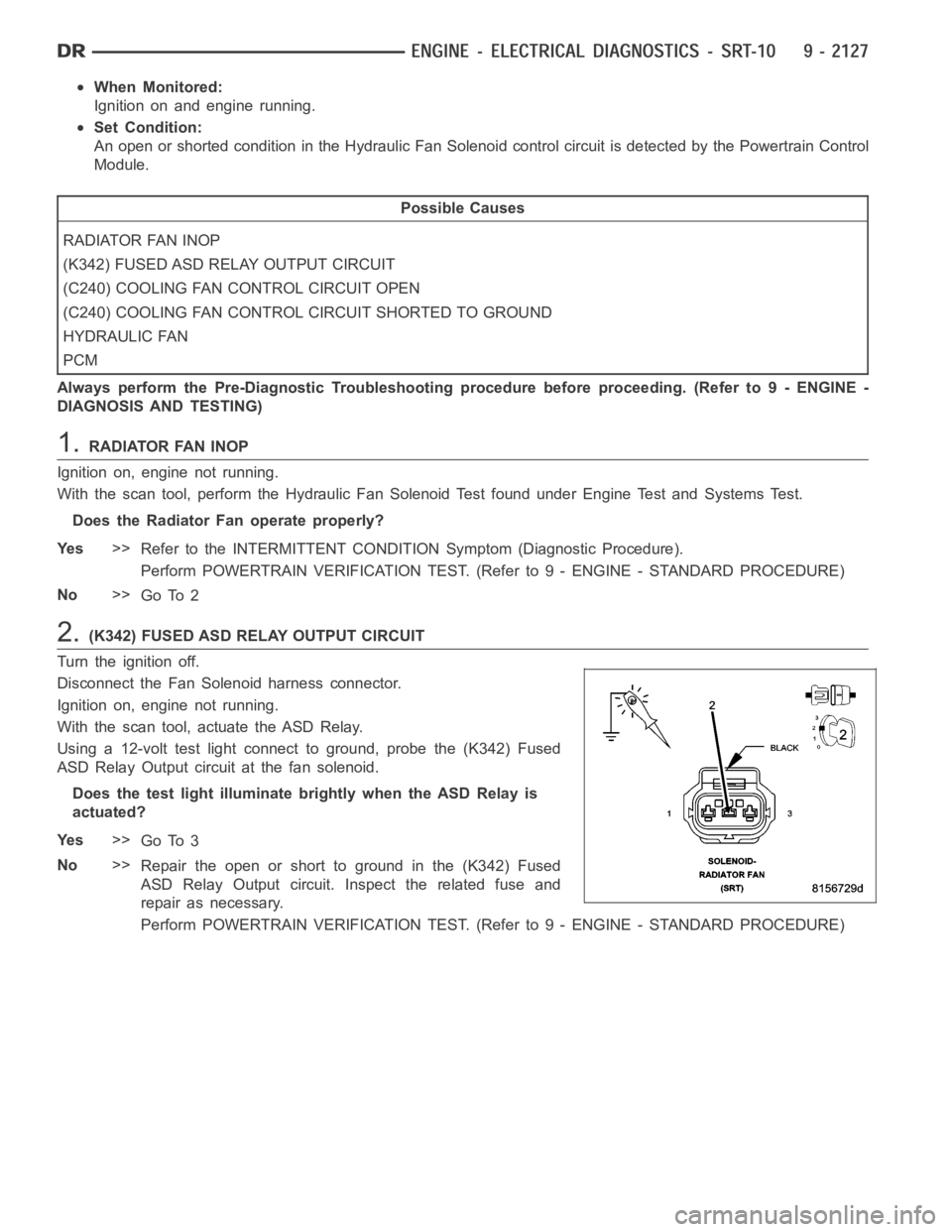

2.(K342) FUSED ASD RELAY OUTPUT CIRCUIT

Turn the ignition off.

Disconnect the Fan Solenoid harness connector.

Ignition on, engine not running.

With the scan tool, actuate the ASD Relay.

Using a 12-volt test light connect to ground, probe the (K342) Fused

ASD Relay Output circuit at the fan solenoid.

Does the test light illuminate brightly when the ASD Relay is

actuated?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (K342) Fused

ASD Relay Output circuit. Inspect the related fuse and

repair as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1437 of 5267

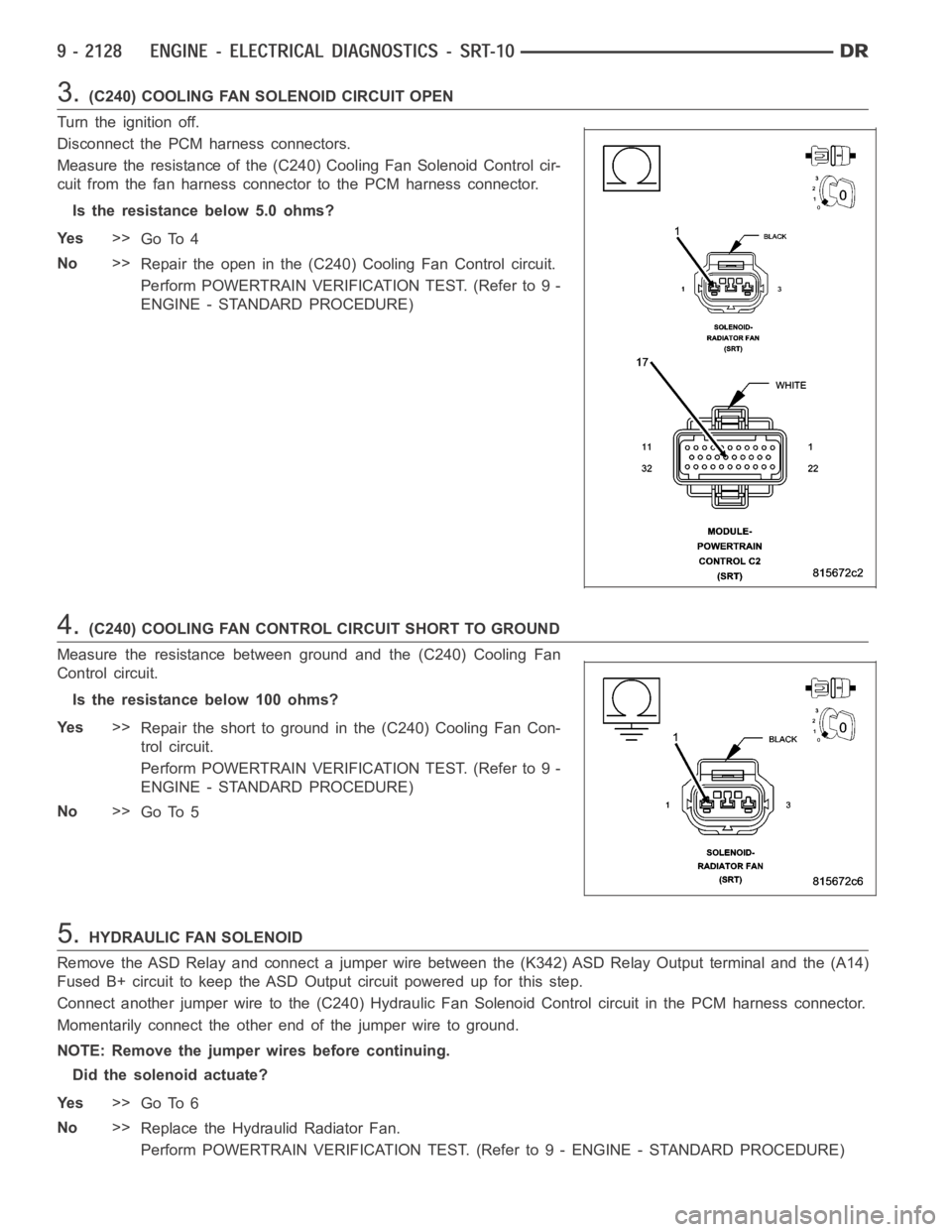

3.(C240) COOLING FAN SOLENOID CIRCUIT OPEN

Turn the ignition off.

Disconnect the PCM harness connectors.

Measure the resistance of the (C240) Cooling Fan Solenoid Control cir-

cuit from the fan harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 4

No>>

Repair the open in the (C240) Cooling Fan Control circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

4.(C240) COOLING FAN CONTROL CIRCUIT SHORT TO GROUND

Measure the resistance between ground and the (C240) Cooling Fan

Control circuit.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (C240) Cooling Fan Con-

trol circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.HYDRAULIC FAN SOLENOID

Remove the ASD Relay and connect a jumper wire between the (K342) ASD Relay Output terminal and the (A14)

Fused B+ circuit to keep the ASD Output circuit powered up for this step.

Connect another jumper wire to the (C240) Hydraulic Fan Solenoid Control circuit in the PCM harness connector.

Momentarily connect the other end of the jumper wire to ground.

NOTE: Remove the jumper wires before continuing.

Did the solenoid actuate?

Ye s>>

Go To 6

No>>

Replace the Hydraulid Radiator Fan.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1460 of 5267

P1696-PCM FAILURE EEPROM WRITE DENIED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on and battery voltage greater than 10 volts.

Set Condition:

An attempt to program/write to the internal EEPROM failed, also checks at powerdown.

Possible Causes

SRI MILEAGE INVALID

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.SCAN TOOL DISPLAYS WRITE FAILURE

Ignition on, engine not running.

With the scan tool, perform the SRI Memory Test.

Does the scan tool display Write Failure?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.SCAN TOOL DISPLAYS WRITE REFUSED

With the scan tool, perform the SRI Memory Test.

Does the scan tool display Write Refused?

Ye s>>

Go To 3

No>>

Go To 4

3.PCM REFUSED 2ND TEST

With the scan tool, perform the SRI Memory Test a second time.

NOTE: Retest the SRI Memory two more times.

Does the scan tool display Write Refused again?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

4.SCAN TOOL DISPLAYS SRI MILEAGE INVALID

With the scan tool, perform the SRI Memory Test.

Does the scan tool display SRI Mileage Invalid?

Ye s>>

Update the mileage and retest the SRI Memory.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

Page 1463 of 5267

Possible Causes

(A103) FUSED B+ CIRCUIT

(Z429) BRAKE LAMP SWITCH GROUND CIRCUIT OPEN

BRAKE LAMP SWITCH

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT OPEN

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT SHORT TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.SCAN TOOL DOES NOT SHOW BRAKE SW PRESSED OR RELEASED

Ignition on, engine not running.

With the scan tool in Inputs/Outputs, read the Brake Switch state.

While observing the scan tool display, press and release the brake pedal several times.

Does the scan tool display Brake Switch PRESSED and RELEASED?

Ye s>>

The Brake Lamp Switch is operating properly at this time.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.(A103) FUSED B+ CIRCUIT OPEN

Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Using a 12-volt test light connected to ground, probe the (A103) Fused

B+ circuit at the Brake Lamp Switch harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (A103) Fused B+

circuit. Check and replace fuses as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 1469 of 5267

Possible Causes

A/C SELECT CIRCUIT OPEN

A/C SELECT IN HVAC

PCM

A/C REQUEST CIRCUIT OPEN

REFRIGERATION SYSTEM NOT PROPERLY CHARGED

HIGH PRESS CUT-OFF SWITCH

LOW PRESSURE SWITCH

A/CCLUTCHCOIL

A/C COMPRESSOR CLUTCH GROUND CIRCUIT OPEN

(C3) A/C CLUTCH RELAY OUTPUT CIRCUIT OPEN

FUSED B+ CIRCUIT OPEN

A/CCLUTCHRELAY

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.DTC AND COMMUNICATION PRESENT

Ignition on, engine not running.

Verify that communication with the HVAC and PCM is available over the BUS.

With the scan tool, check for DTCs in the PCM and HVAC module.

Are any A/C DTC’s or communication failures present?

Ye s>>

Diagnose the related DTC(s) or BUS failure before continuing.

Perform BODY VERIFICATION TEST - VER 1.

No>>

Go To 2

2.A/C SELECT CIRCUIT OPEN

Engine running.

With the scan tool, read the A/C Select status in the PCM.

Turn the A/C Switch on and off a few times.

Does the A/C Select state change?

Ye s>>

Go To 3

No>>

Go To 12

3.A/C REQUEST CIRCUIT OPEN

Engine Running.

Turn the A/C system on and the fan on high.

With the scan tool in Inputs/Outputs, read the A/C request state.

Does the A/C request state change?

Ye s>>

Go To 4

No>>

Repair the open in the A/C Request circuit.

Perform BODY VERIFICATION TEST - VER 1.

Page 1471 of 5267

9.(C3) A/C CLUTCH RELAY OUTPUT CIRCUIT OPEN

Turn the ignition off.

Disconnect the A/C Clutch harness connector.

Remove the A/C Clutch Relay.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the (C3) A/C Clutch Relay Output circuit betweenthe IPM and the A/C Clutch Coil.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 10

No>>

Repair the open in the (C3) A/C Clutch Relay Output circuit.

Perform BODY VERIFICATION TEST - VER 1.

10.(A17) FUSED B+ CIRCUIT OPEN

Turn the ignition off.

Remove the A/C Clutch Relay.

NOTE: Check connectors - Clean/repair as necessary.

Measure the voltage of the Fused B+ circuit at the A/C Clutch Relay connector.

Is the voltage above 11.0 volts?

Ye s>>

Go To 11

No>>

Repair the open in the Fused B+ circuit. The open may be in the IMP.

Perform BODY VERIFICATION TEST - VER 1.

11 .A/C CLUTCH RELAY

If there are no possible causes remaining, view repair.

Repair

Replace the A/C Clutch Relay.

Perform BODY VERIFICATION TEST - VER 1.

12.A/CSELECTSWITCHSTATUSINHVAC

Ignition on, engine not running.

With the scan tool in the HVAC, under the Monitors screen, read the A/C Select Switch state.

While monitoring the scan tool screen, turn the A/C switch on and off a few times.

Does the A/C Select State change on the HVAC Monitors screen.

Ye s>>

Check for any related TSBs. Replace and program the PCM in accordance with the Service Information

as long as no BUS problems exist.

Perform BODY VERIFICATION TEST - VER 1.

No>>

Replace the A/C-Heater Control module.

Perform BODY VERIFICATION TEST - VER 1.

Page 1477 of 5267

Possible Causes

HARNESS INSPECTION

HYDRAULIC FAN

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.FAN OPERATION

Ignition on, engine not running.

With the scan tool select Engine Test, Systems Test, and Hydraulic Fan Solenoid Test.

Actuate the Hydraulic Fan Solenoid Test.

Does the fan operate properly?

Ye s>>

Te s t C o m p l e t e .

No>>

Go To 2

2.HARNESS INSPECTION

Turn the ignition off.

Check to see if the fan wire harness is properly connected at the upper rightcorner of the fan shroud.

Check to see if the fan wire harness is properly connected at the fan solenoidonthefanmotor.

Check the harness for continuity from the Hydraulic Fan Relay to the solenoid.

Inspect connector terminals for proper pin fit and corrosion.

Inspect the related fuse and relay.

Were any problems found?

Ye s>>

Repair any defective wire harness concerns.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

3.HYDRAULIC FAN

Turn the ignition off.

Inspect the hydraulic circuit for leaks and repair as necessary.

Were any problems found?

Ye s>>

Repair the Hydraulic leaks and/or replace the Hydraulic Fan assembly.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1479 of 5267

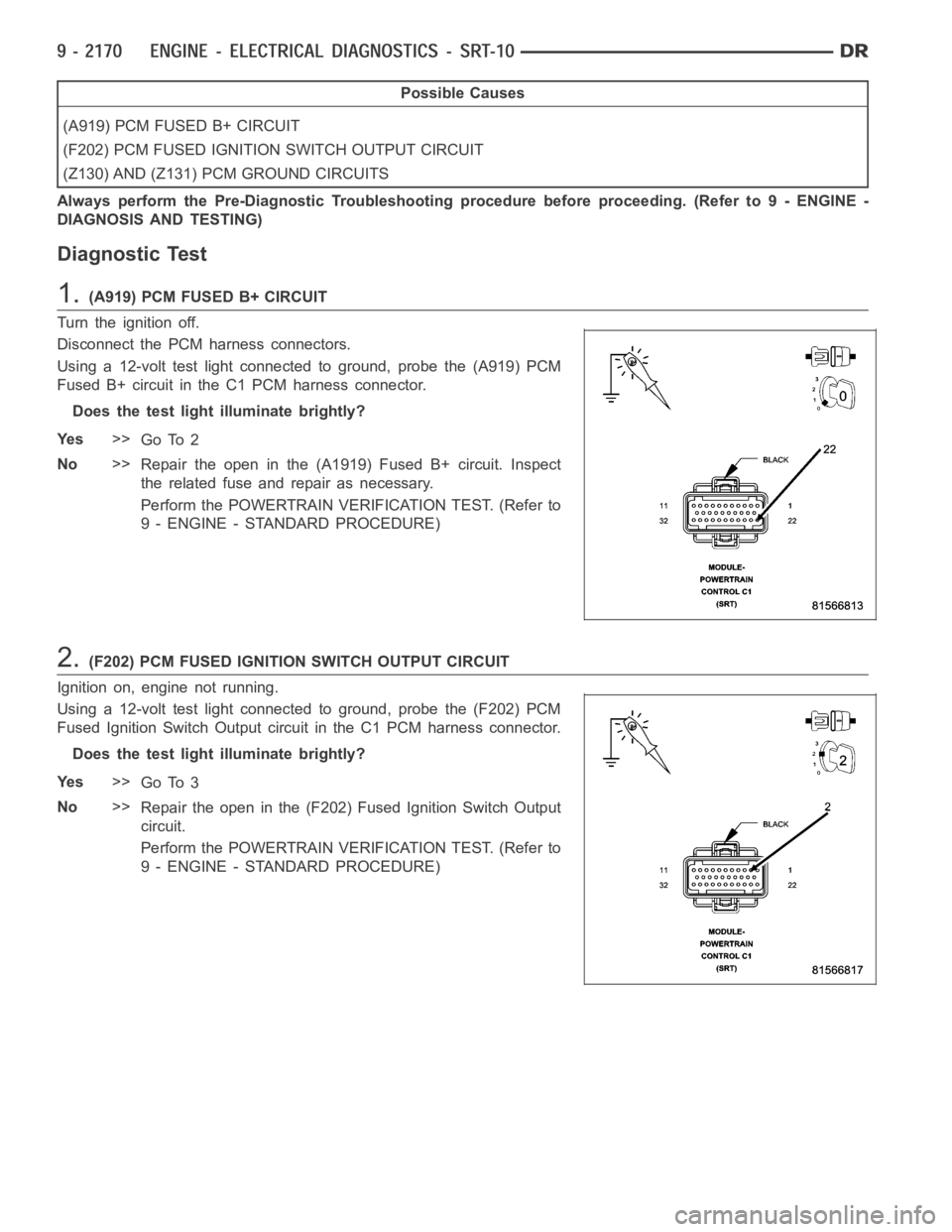

Possible Causes

(A919) PCM FUSED B+ CIRCUIT

(F202) PCM FUSED IGNITION SWITCH OUTPUT CIRCUIT

(Z130) AND (Z131) PCM GROUND CIRCUITS

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.(A919) PCM FUSED B+ CIRCUIT

Turn the ignition off.

Disconnect the PCM harness connectors.

Using a 12-volt test light connected to ground, probe the (A919) PCM

Fused B+ circuit in the C1 PCM harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 2

No>>

Repair the open in the (A1919) Fused B+ circuit. Inspect

the related fuse and repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

2.(F202) PCM FUSED IGNITION SWITCH OUTPUT CIRCUIT

Ignition on, engine not running.

Using a 12-volt test light connected to ground, probe the (F202) PCM

Fused Ignition Switch Output circuit in the C1 PCM harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open in the (F202) Fused Ignition Switch Output

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 1909 of 5267

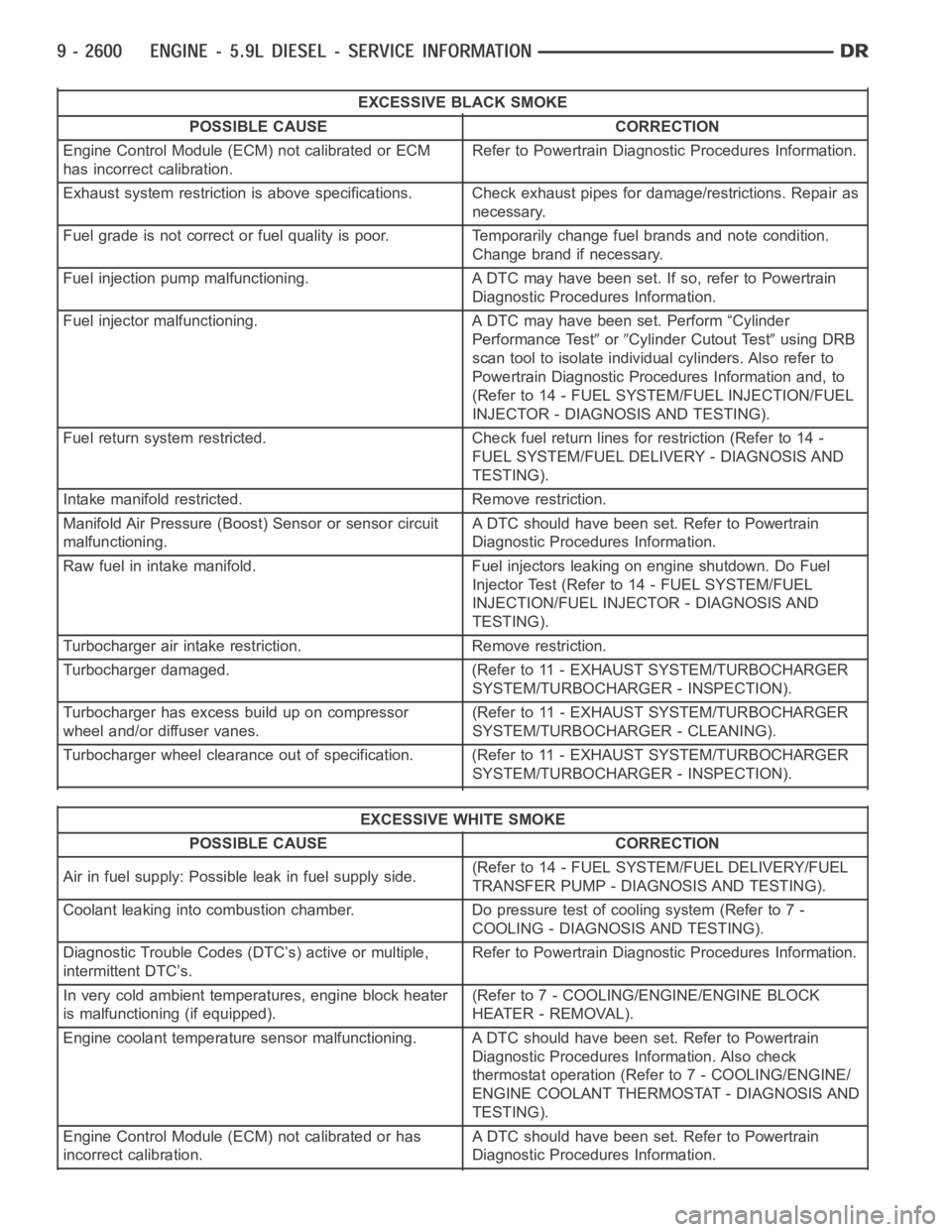

EXCESSIVE BLACK SMOKE

POSSIBLE CAUSE CORRECTION

Engine Control Module (ECM) not calibrated or ECM

has incorrect calibration.Refer to Powertrain Diagnostic Procedures Information.

Exhaust system restriction is above specifications. Check exhaust pipesfor damage/restrictions. Repair as

necessary.

Fuel grade is not correct or fuel quality is poor. Temporarily change fuel brands and note condition.

Change brand if necessary.

Fuel injection pump malfunctioning. A DTC may have been set. If so, refer toPowertrain

Diagnostic Procedures Information.

Fuel injector malfunctioning. A DTC may have been set. Perform “Cylinder

Performance Test

orCylinder Cutout Testusing DRB

scan tool to isolate individual cylinders. Also refer to

Powertrain Diagnostic Procedures Information and, to

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL

INJECTOR - DIAGNOSIS AND TESTING).

Fuel return system restricted. Check fuel return lines for restriction (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Intake manifold restricted. Remove restriction.

Manifold Air Pressure (Boost) Sensor or sensor circuit

malfunctioning.A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information.

Raw fuel in intake manifold. Fuel injectors leaking on engine shutdown. DoFuel

Injector Test (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/FUEL INJECTOR - DIAGNOSIS AND

TESTING).

Turbocharger air intake restriction. Remove restriction.

Turbocharger damaged. (Refer to 11 - EXHAUST SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER - INSPECTION).

Turbocharger has excess build up on compressor

wheel and/or diffuser vanes.(Refer to 11 - EXHAUST SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER - CLEANING).

Turbocharger wheel clearance out of specification. (Refer to 11 - EXHAUSTSYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER - INSPECTION).

EXCESSIVE WHITE SMOKE

POSSIBLE CAUSE CORRECTION

Air in fuel supply: Possible leak in fuel supply side.(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL

TRANSFER PUMP - DIAGNOSIS AND TESTING).

Coolant leaking into combustion chamber. Do pressure test of cooling system (Refer to 7 -

COOLING - DIAGNOSIS AND TESTING).

Diagnostic Trouble Codes (DTC’s) active or multiple,

intermittent DTC’s.Refer to Powertrain Diagnostic Procedures Information.

In very cold ambient temperatures, engine block heater

is malfunctioning (if equipped).(Refer to 7 - COOLING/ENGINE/ENGINE BLOCK

HEATER - REMOVAL).

Engine coolant temperature sensor malfunctioning. A DTC should have beenset. Refer to Powertrain

Diagnostic Procedures Information. Also check

thermostat operation (Refer to 7 - COOLING/ENGINE/

ENGINE COOLANT THERMOSTAT - DIAGNOSIS AND

TESTING).

Engine Control Module (ECM) not calibrated or has

incorrect calibration.A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information.