torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2928 of 5267

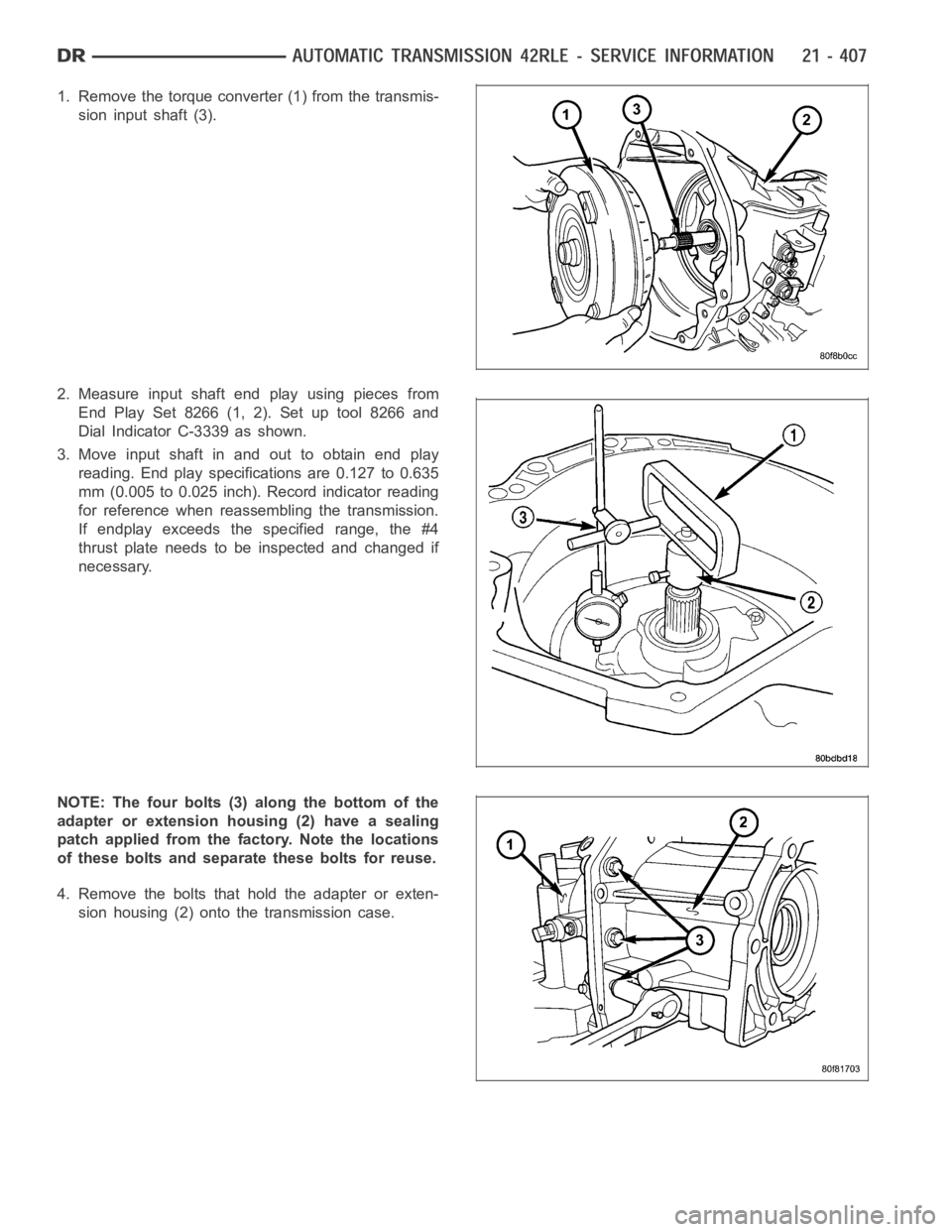

1. Remove the torque converter (1) from the transmis-

sion input shaft (3).

2. Measure input shaft end play using pieces from

End Play Set 8266 (1, 2). Set up tool 8266 and

Dial Indicator C-3339 as shown.

3. Move input shaft in and out to obtain end play

reading. End play specifications are 0.127 to 0.635

mm (0.005 to 0.025 inch). Record indicator reading

for reference when reassembling the transmission.

If endplay exceeds the specified range, the #4

thrust plate needs to be inspected and changed if

necessary.

NOTE: The four bolts (3) along the bottom of the

adapter or extension housing (2) have a sealing

patch applied from the factory. Note the locations

of these bolts and separate these bolts for reuse.

4. Remove the bolts that hold the adapter or exten-

sion housing (2) onto the transmission case.

Page 2950 of 5267

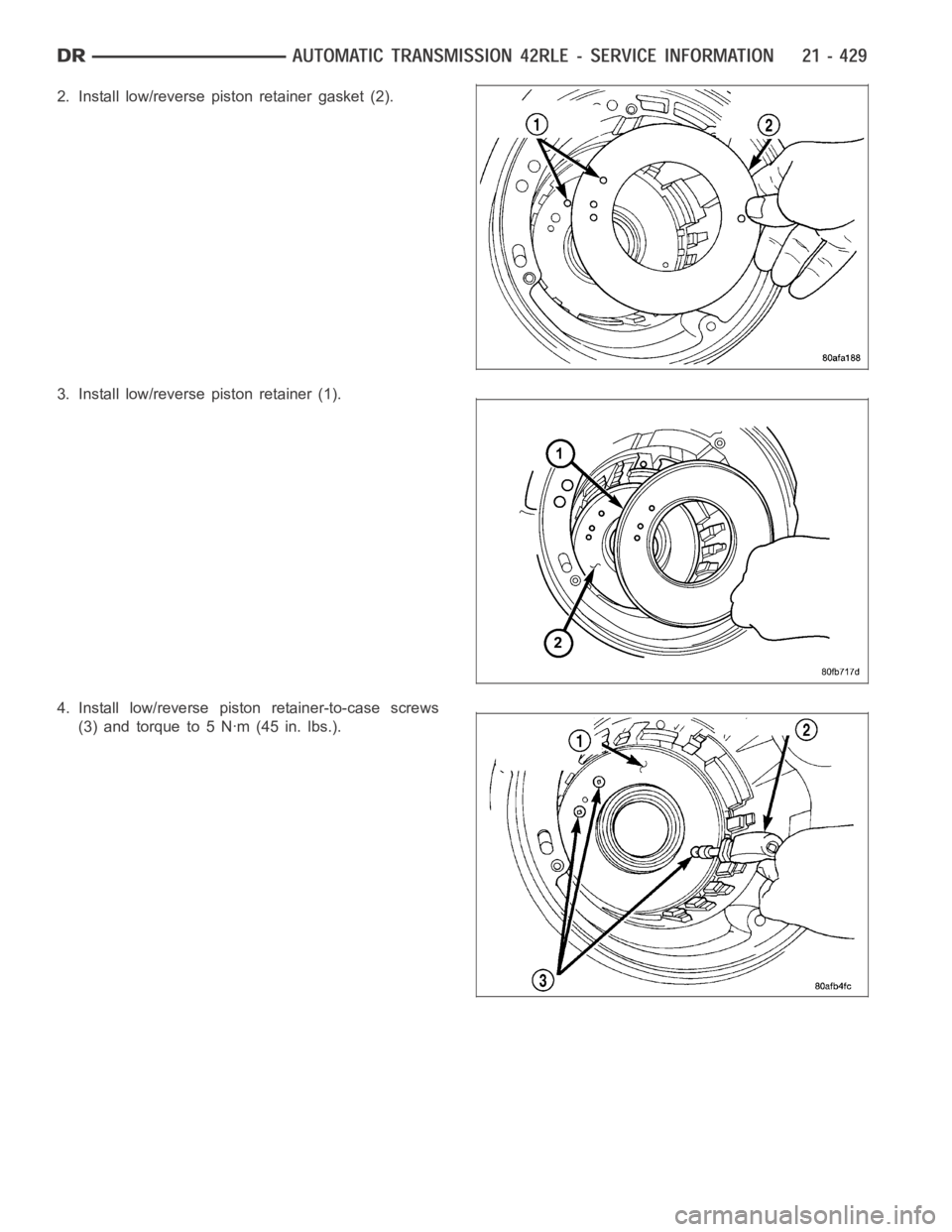

2. Install low/reverse piston retainer gasket (2).

3. Install low/reverse piston retainer (1).

4. Install low/reverse piston retainer-to-case screws

(3) and torque to 5 Nꞏm (45 in. lbs.).

Page 2951 of 5267

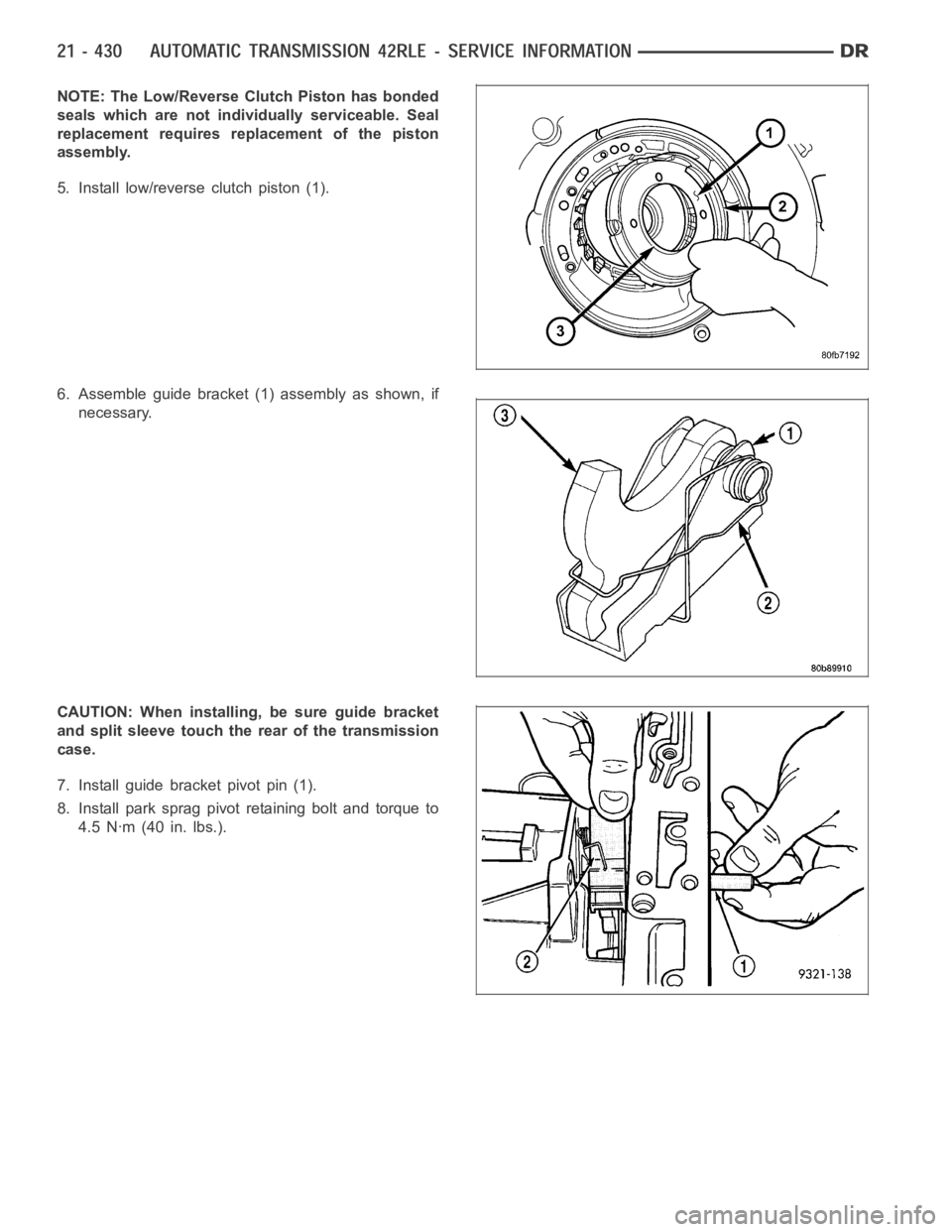

NOTE: The Low/Reverse Clutch Piston has bonded

seals which are not individually serviceable. Seal

replacement requires replacement of the piston

assembly.

5. Install low/reverse clutch piston (1).

6. Assemble guide bracket (1) assembly as shown, if

necessary.

CAUTION: When installing, be sure guide bracket

and split sleeve touch the rear of the transmission

case.

7. Install guide bracket pivot pin (1).

8. Install park sprag pivot retaining bolt and torque to

4.5 Nꞏm (40 in. lbs.).

Page 2955 of 5267

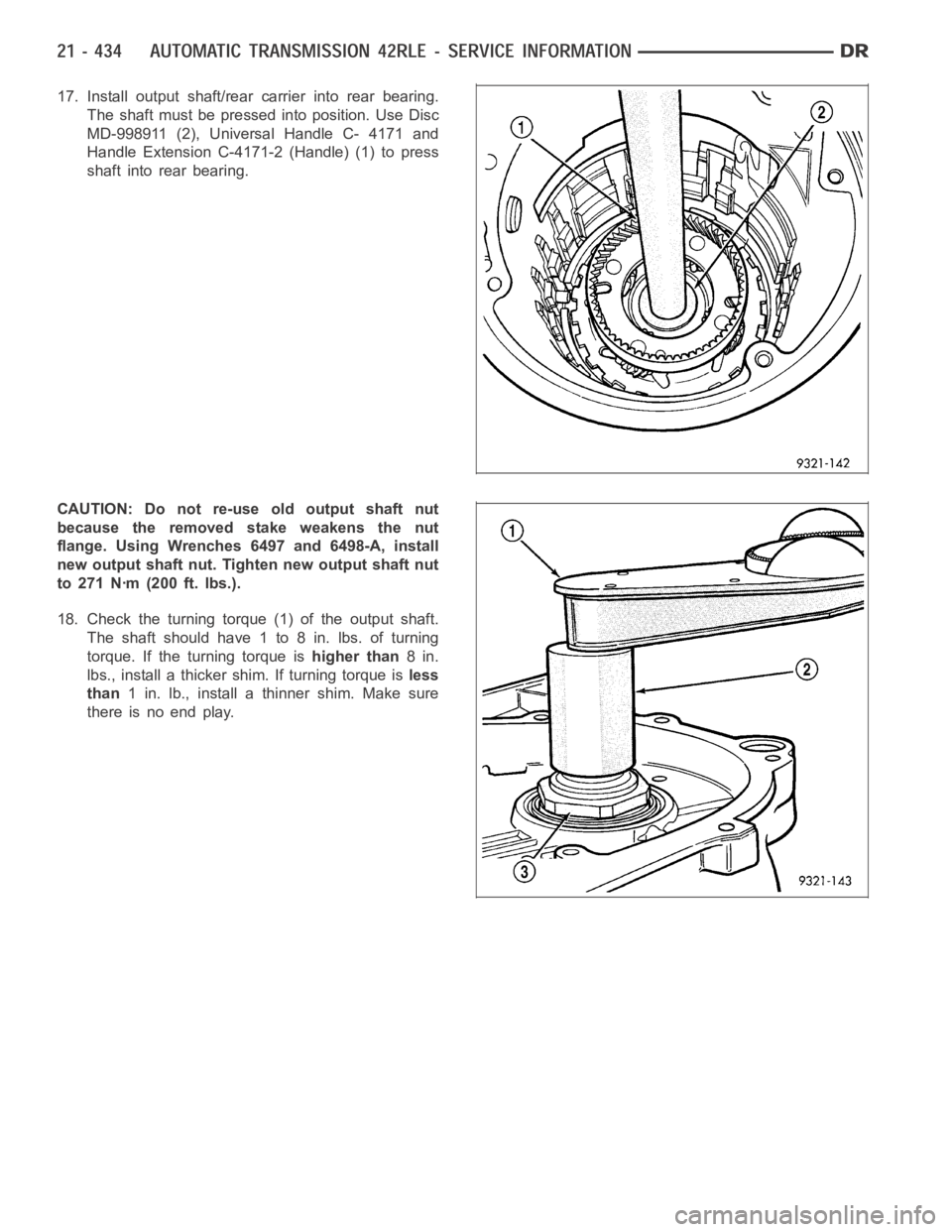

17. Install output shaft/rear carrier into rear bearing.

The shaft must be pressed into position. Use Disc

MD-998911 (2), Universal Handle C- 4171 and

Handle Extension C-4171-2 (Handle) (1) to press

shaft into rear bearing.

CAUTION: Do not re-use old output shaft nut

because the removed stake weakens the nut

flange. Using Wrenches 6497 and 6498-A, install

new output shaft nut. Tighten new output shaft nut

to 271 Nꞏm (200 ft. lbs.).

18. Check the turning torque (1) of the output shaft.

The shaft should have 1 to 8 in. lbs. of turning

torque. If the turning torque ishigher than8in.

lbs., install a thicker shim. If turning torque isless

than1 in. lb., install a thinner shim. Make sure

there is no end play.

Page 2956 of 5267

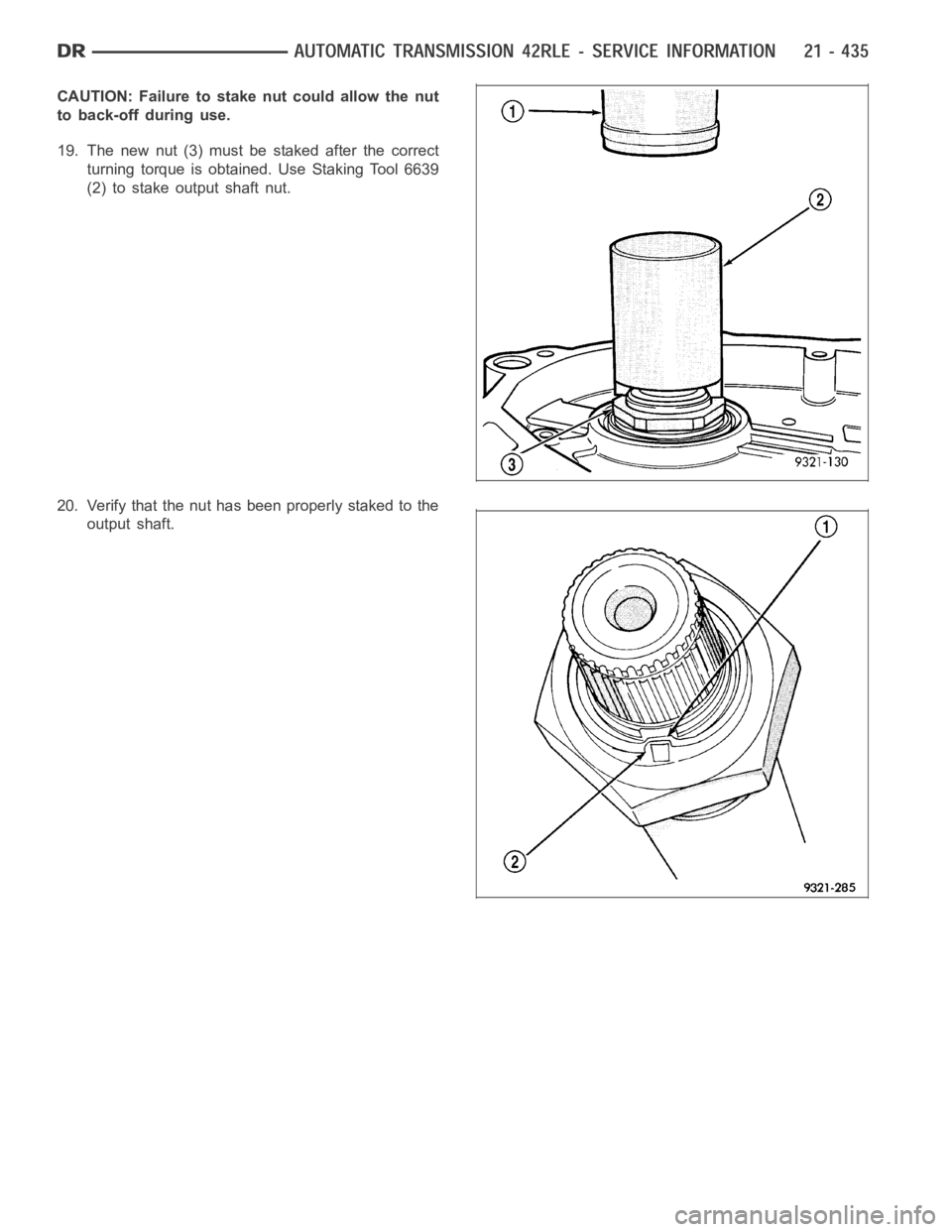

CAUTION: Failure to stake nut could allow the nut

to back-off during use.

19. The new nut (3) must be staked after the correct

turning torque is obtained. Use Staking Tool 6639

(2) to stake output shaft nut.

20. Verify that the nut has been properly staked to the

output shaft.

Page 2965 of 5267

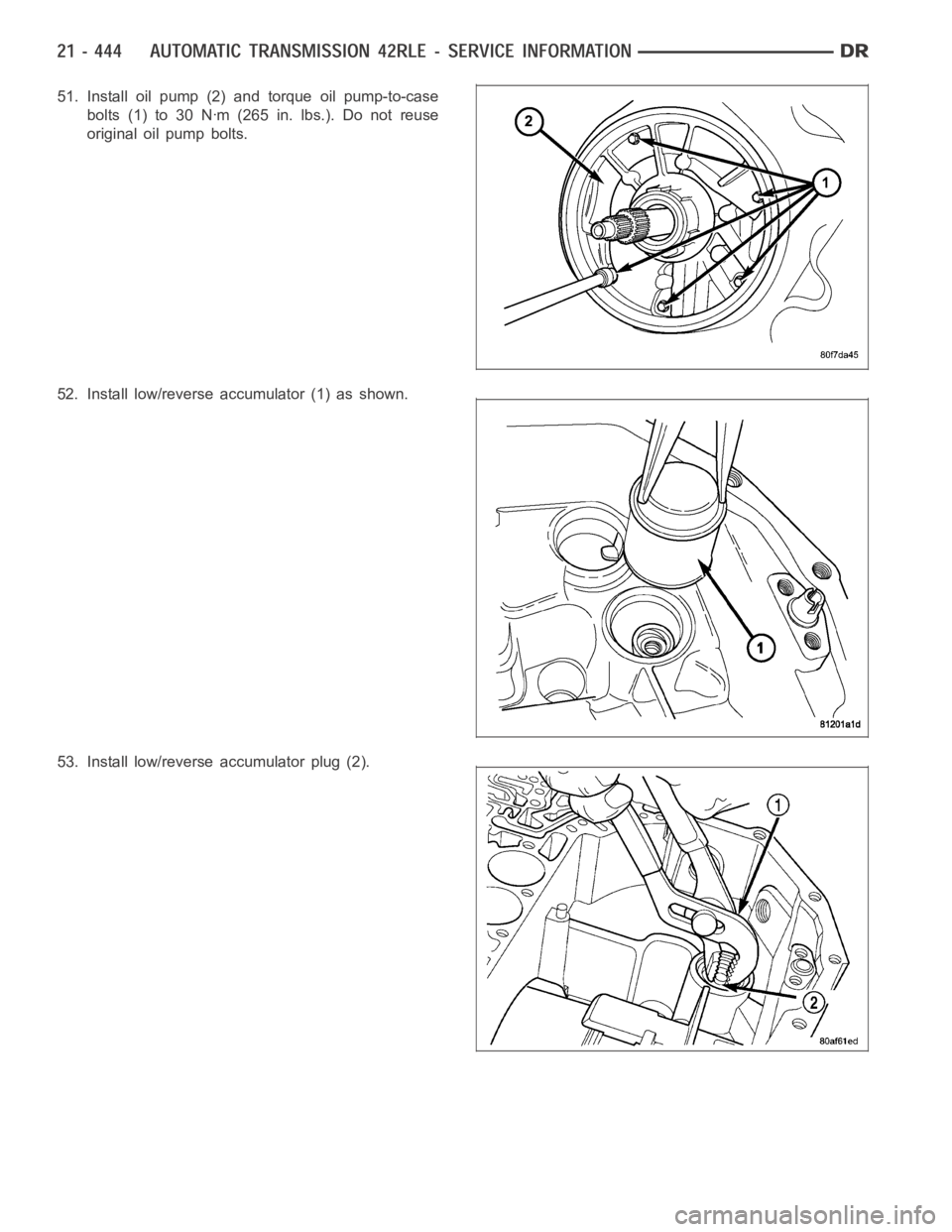

51. Install oil pump (2) and torque oil pump-to-case

bolts (1) to 30 Nꞏm (265 in. lbs.). Do not reuse

original oil pump bolts.

52. Install low/reverse accumulator (1) as shown.

53. Install low/reverse accumulator plug (2).

Page 2967 of 5267

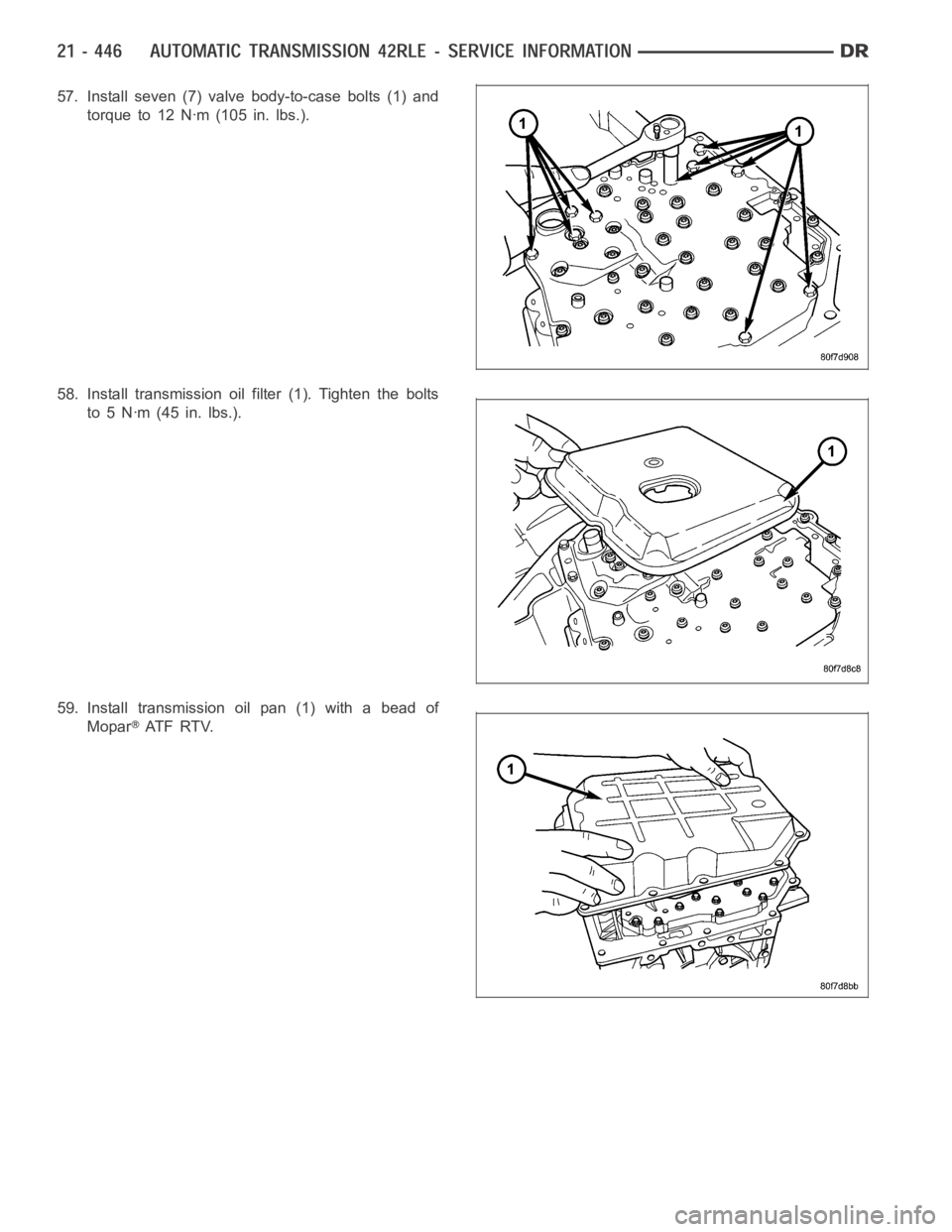

57. Install seven (7) valve body-to-case bolts (1) and

torque to 12 Nꞏm (105 in. lbs.).

58. Install transmission oil filter (1). Tighten the bolts

to5Nꞏm(45in.lbs.).

59. Install transmission oil pan (1) with a bead of

Mopar

AT F R T V.

Page 2968 of 5267

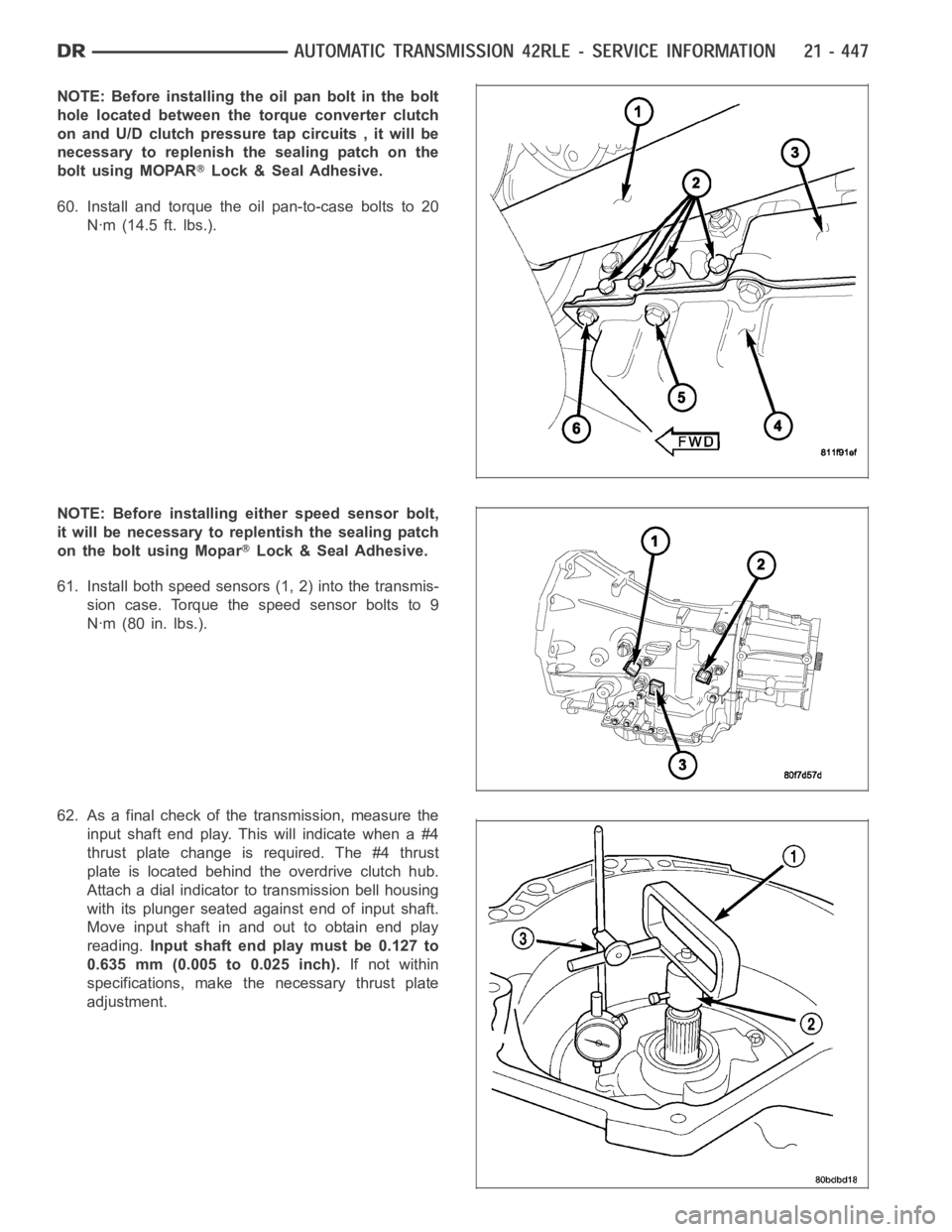

NOTE: Before installing the oil pan bolt in the bolt

hole located between the torque converter clutch

on and U/D clutch pressure tap circuits , it will be

necessary to replenish the sealing patch on the

bolt using MOPAR

Lock & Seal Adhesive.

60. Install and torque the oil pan-to-case bolts to 20

Nꞏm (14.5 ft. lbs.).

NOTE: Before installing either speed sensor bolt,

it will be necessary to replentish the sealing patch

on the bolt using Mopar

Lock & Seal Adhesive.

61. Install both speed sensors (1, 2) into the transmis-

sion case. Torque the speed sensor bolts to 9

Nꞏm (80 in. lbs.).

62. As a final check of the transmission, measure the

input shaft end play. This will indicate when a #4

thrust plate change is required. The #4 thrust

plate is located behind the overdrive clutch hub.

Attach a dial indicator to transmission bell housing

with its plunger seated against end of input shaft.

Move input shaft in and out to obtain end play

reading.Input shaft end play must be 0.127 to

0.635 mm (0.005 to 0.025 inch).If not within

specifications, make the necessary thrust plate

adjustment.

Page 2972 of 5267

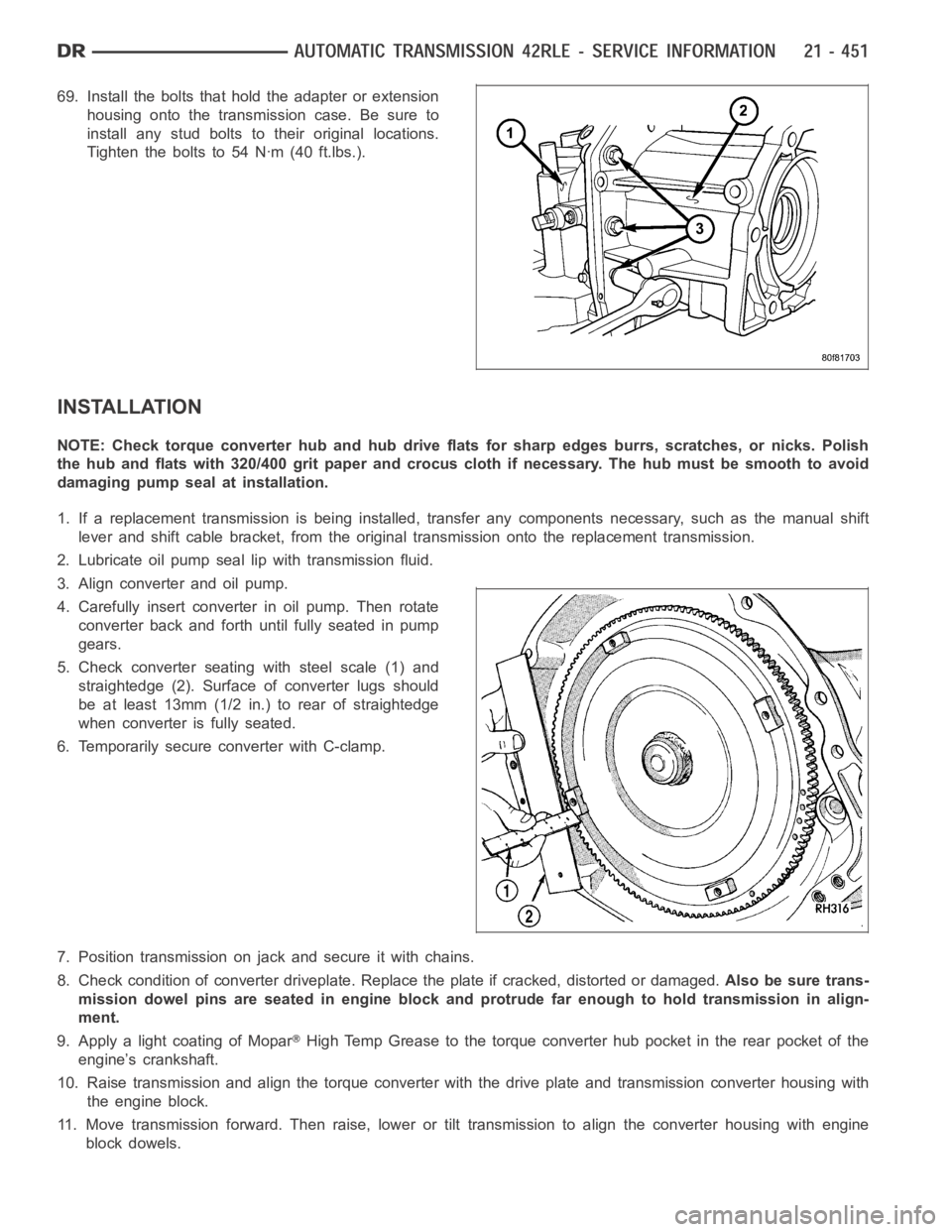

69. Install the bolts that hold the adapter or extension

housing onto the transmission case. Be sure to

install any stud bolts to their original locations.

Tighten the bolts to 54 Nꞏm (40 ft.lbs.).

INSTALLATION

NOTE: Check torque converter hub and hub drive flats for sharp edges burrs,scratches, or nicks. Polish

the hub and flats with 320/400 grit paper and crocus cloth if necessary. Thehub must be smooth to avoid

damaging pump seal at installation.

1. If a replacement transmission is being installed, transfer any components necessary, such as the manual shift

lever and shift cable bracket, from the original transmission onto the replacement transmission.

2. Lubricate oil pump seal lip with transmission fluid.

3. Align converter and oil pump.

4. Carefully insert converter in oil pump. Then rotate

converter back and forth until fully seated in pump

gears.

5. Check converter seating with steel scale (1) and

straightedge (2). Surface of converter lugs should

be at least 13mm (1/2 in.) to rear of straightedge

when converter is fully seated.

6. Temporarily secure converter with C-clamp.

7. Position transmission on jack and secure it with chains.

8. Check condition of converter driveplate. Replace the plate if cracked,distorted or damaged.Also be sure trans-

mission dowel pins are seated in engine block and protrude far enough to holdtransmissioninalign-

ment.

9. Apply a light coating of Mopar

High Temp Grease to the torque converter hub pocket in the rear pocket of the

engine’s crankshaft.

10. Raise transmission and align the torque converter with the drive plateand transmission converter housing with

the engine block.

11. Move transmission forward. Then raise, lower or tilt transmission to align the converter housing with engine

block dowels.

Page 2973 of 5267

12. Carefully work transmission forward and over engine block dowels until converter hub is seated in crankshaft.

Verify that no wires, or the transmission vent hose, have become trapped between the engine block and the

transmission.

13. Install two bolts to attach the transmission to the engine.

14. Install remaining torque converter housing to engine bolts. Tighten to 68 Nꞏm (50 ft.lbs.).

15. Install transfer case, if equipped. Tighten transfer case nuts to 35 Nꞏm (26 ft.lbs.).

16. Install rear transmission crossmember. Tighten crossmember to framebolts to 68 Nꞏm (50 ft.lbs.).

17. Install rear support to transmission. Tighten bolts to 47 Nꞏm (35 ft.lbs.).

18. Lower transmission onto crossmember and install bolts attaching transmission mount to crossmember. Tighten

clevis bracket to crossmember bolts to 47 Nꞏm (35 ft.lbs.). Tighten the clevis bracket to rear support bolt to 68

Nꞏm (50 ft.lbs.).

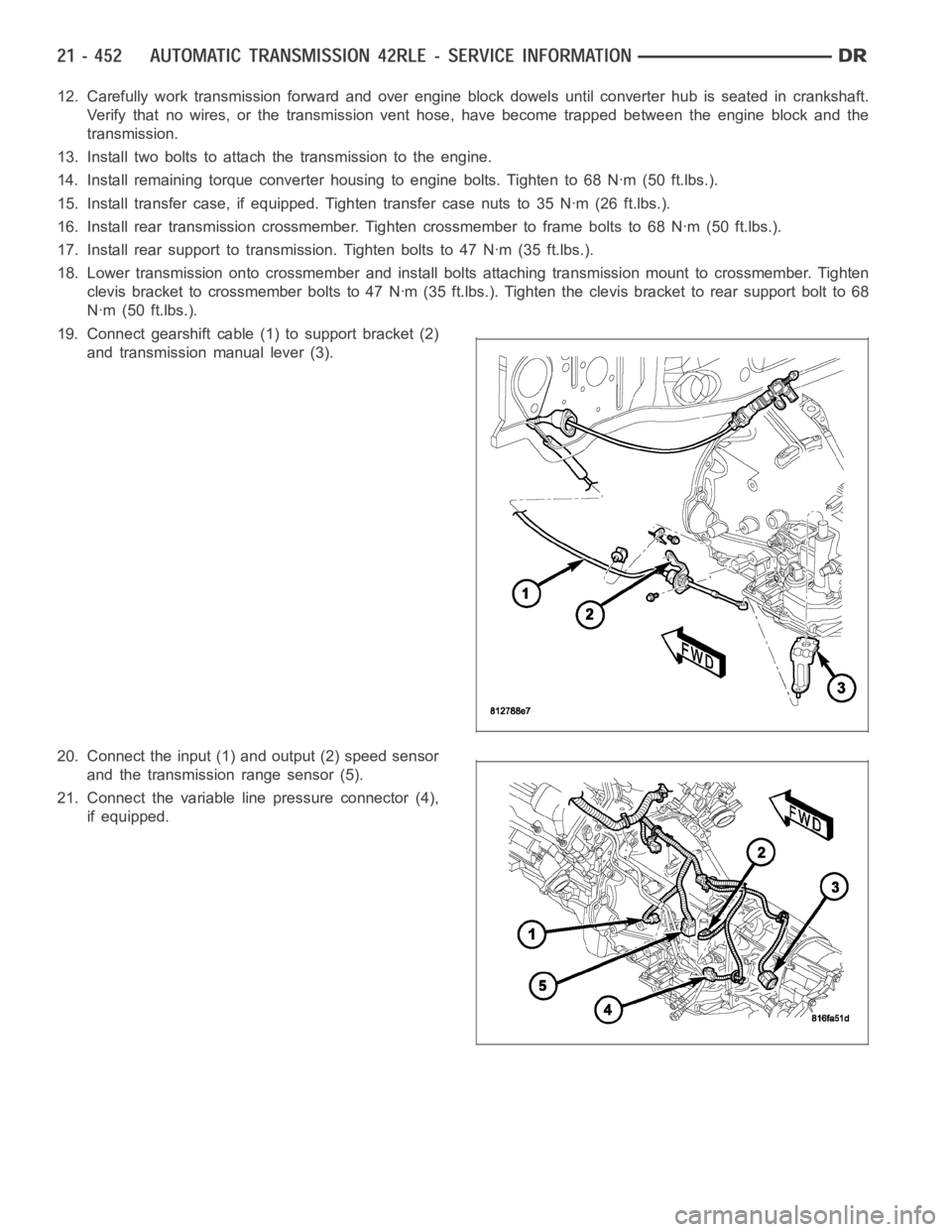

19. Connect gearshift cable (1) to support bracket (2)

and transmission manual lever (3).

20. Connect the input (1) and output (2) speed sensor

and the transmission range sensor (5).

21. Connect the variable line pressure connector (4),

if equipped.