torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2494 of 5267

SWITCH-POWER STEERING PRESSURE

DESCRIPTION

A pressure sensing switch is used in the power steering system. It is mounted on the high-pressure steering hose.

This switch will only be used onHD vehicleswith the 5.7L engines. There is no pressure switch used for the 3.7L,

4.7L, 5.9LDiesel engine or the5.7L LD vehiclepump.

OPERATION

The switch is used on the 5.7L V-8 enginesHD vehicles only.

The power steering pressure switch provides an input to the Powertrain Control Module (PCM). This input is pro-

vided during periods of high steering pump load and low engine rpm; such as during parking maneuvers. The PCM

increases the idle speed through the Idle Air Control (IAC) motor. This is done to prevent the engine from stalling

under the increased load.

When steering pump pressure exceeds 3275 kPa ± 690 kPa (475 psi ± 100 psi), the Normally Closed (NC) switch

will open and the PCM will increase the engine idle speed. This will preventthe engine from stalling.

When pump pressure drops to approximately 1379 kPa (200 psi), the switch circuit will re-close and engine idle

speed will return to its previous setting.

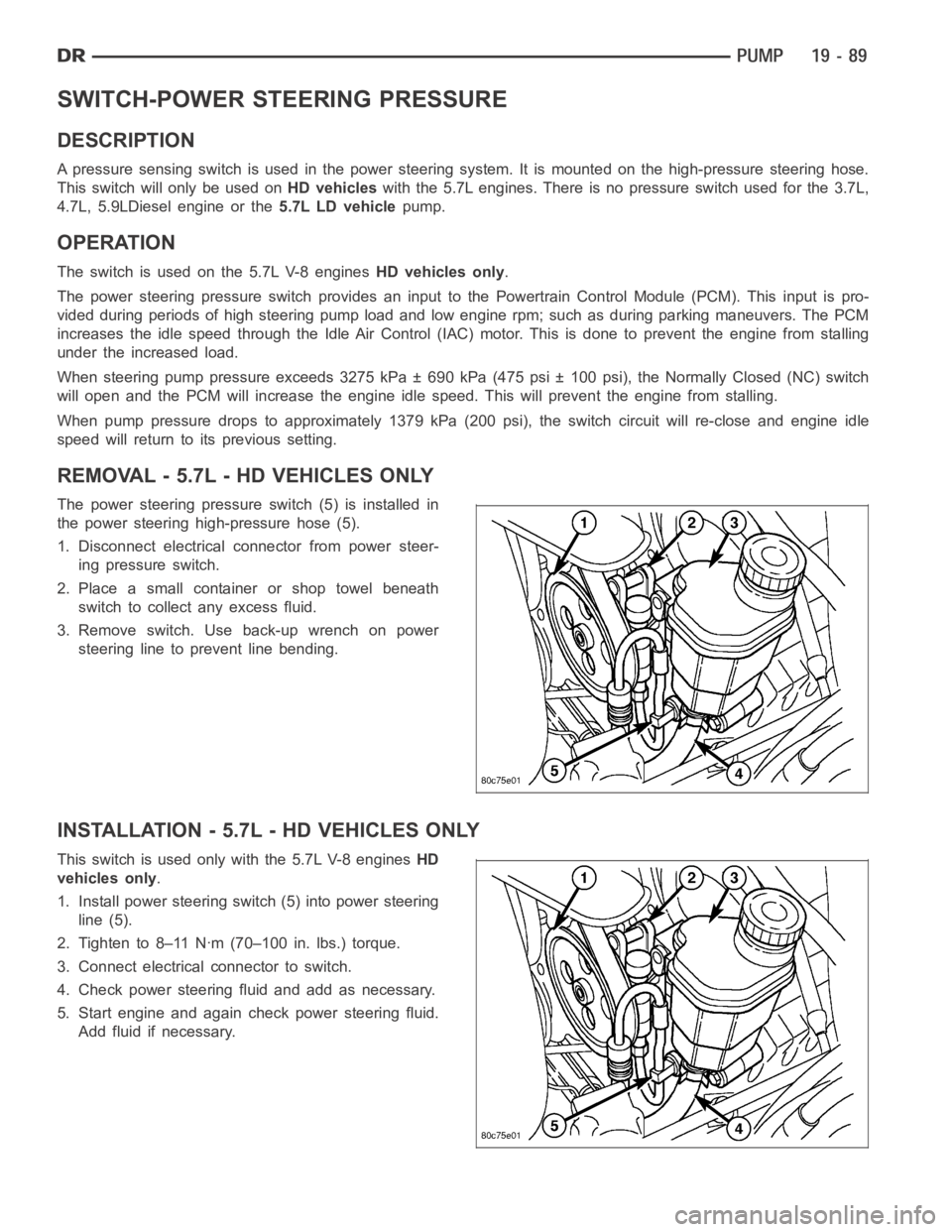

REMOVAL - 5.7L - HD VEHICLES ONLY

The power steering pressureswitch (5) is installed in

the power steering high-pressure hose (5).

1. Disconnect electrical connector from power steer-

ing pressure switch.

2. Place a small container or shop towel beneath

switch to collect any excess fluid.

3. Remove switch. Use back-up wrench on power

steering line to prevent line bending.

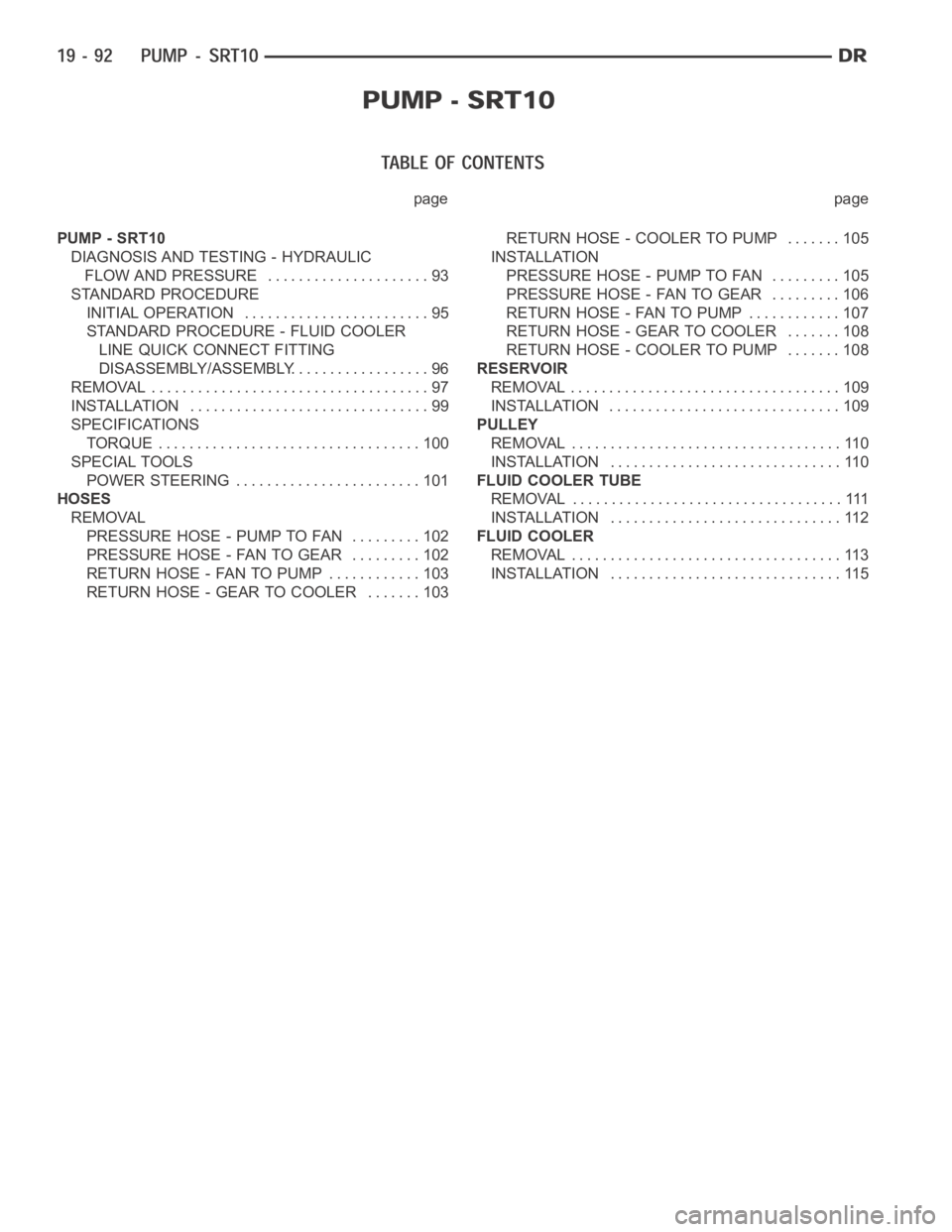

INSTALLATION - 5.7L - HD VEHICLES ONLY

This switch is used only with the 5.7L V-8 enginesHD

vehicles only.

1. Install power steering switch (5) into power steering

line (5).

2. Tighten to 8–11 Nꞏm (70–100 in. lbs.) torque.

3. Connect electrical connector to switch.

4. Check power steering fluid and add as necessary.

5. Start engine and again check power steering fluid.

Add fluid if necessary.

Page 2497 of 5267

page page

PUMP - SRT10

DIAGNOSIS AND TESTING - HYDRAULIC

FLOW AND PRESSURE ..................... 93

STANDARD PROCEDURE

INITIAL OPERATION ........................ 95

STANDARD PROCEDURE - FLUID COOLER

LINE QUICK CONNECT FITTING

DISASSEMBLY/ASSEMBLY. ................. 96

REMOVAL .................................... 97

INSTALLATION ............................... 99

SPECIFICATIONS

TORQUE .................................. 100

SPECIAL TOOLS

POWER STEERING ........................ 101

HOSES

REMOVAL

PRESSURE HOSE - PUMP TO FAN ......... 102

PRESSURE HOSE - FAN TO GEAR ......... 102

RETURN HOSE - FAN TO PUMP ............ 103

RETURN HOSE - GEAR TO COOLER ....... 103RETURN HOSE - COOLER TO PUMP ....... 105

INSTALLATION

PRESSURE HOSE - PUMP TO FAN ......... 105

PRESSURE HOSE - FAN TO GEAR ......... 106

RETURN HOSE - FAN TO PUMP ............ 107

RETURN HOSE - GEAR TO COOLER ....... 108

RETURN HOSE - COOLER TO PUMP ....... 108

RESERVOIR

REMOVAL ................................... 109

INSTALLATION .............................. 109

PULLEY

REMOVAL ................................... 110

INSTALLATION .............................. 110

FLUID COOLER TUBE

REMOVAL ................................... 111

INSTALLATION .............................. 112

FLUID COOLER

REMOVAL ................................... 113

INSTALLATION .............................. 115

Page 2504 of 5267

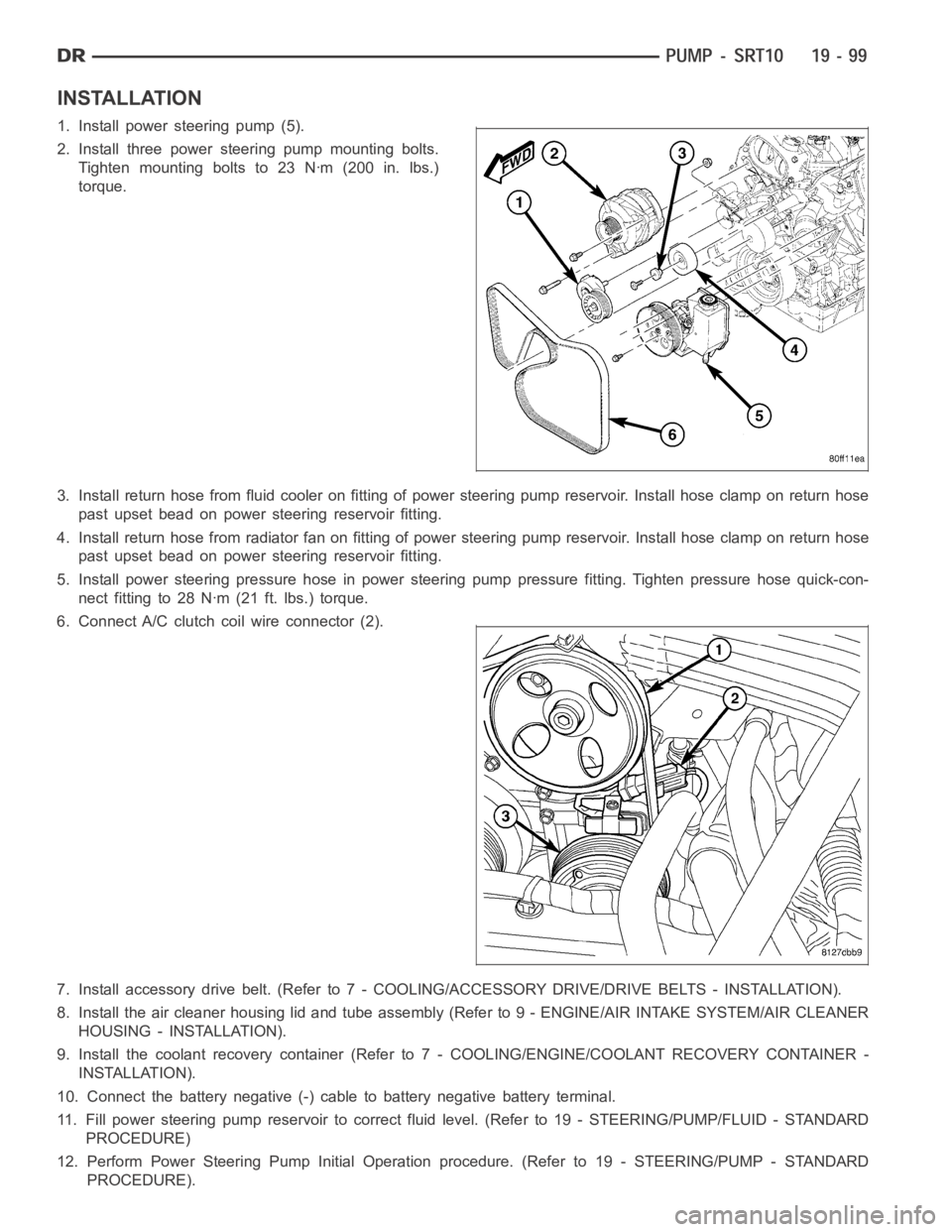

INSTALLATION

1. Install power steering pump (5).

2. Install three power steering pump mounting bolts.

Tighten mounting bolts to 23 Nꞏm (200 in. lbs.)

torque.

3. Install return hose from fluid cooler on fitting of power steering pump reservoir. Install hose clamp on return hose

past upset bead on power steering reservoir fitting.

4. Install return hose from radiator fan on fitting of power steering pump reservoir. Install hose clamp on return hose

past upset bead on power steering reservoir fitting.

5. Install power steering pressure hose in power steering pump pressure fitting. Tighten pressure hose quick-con-

nect fitting to 28 Nꞏm (21 ft. lbs.) torque.

6. Connect A/C clutch coil wire connector (2).

7. Install accessory drive belt. (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

8. Install the air cleaner housing lid and tube assembly (Refer to 9 - ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

9. Install the coolant recovery container (Refer to 7 - COOLING/ENGINE/COOLANT RECOVERY CONTAINER -

INSTALLATION).

10. Connect the battery negative (-) cable to battery negative battery terminal.

11. Fill power steering pump reservoir to correct fluid level. (Refer to 19- STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

12. Perform Power Steering Pump Initial Operation procedure. (Refer to 19- STEERING/PUMP - STANDARD

PROCEDURE).

Page 2505 of 5267

13. Check for leaks at all hose connections.

SPECIFICATIONS

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Power Steering Line nuts 28 21 —

Power Steering Pump

Mounting Bolts23 17 200

Page 2510 of 5267

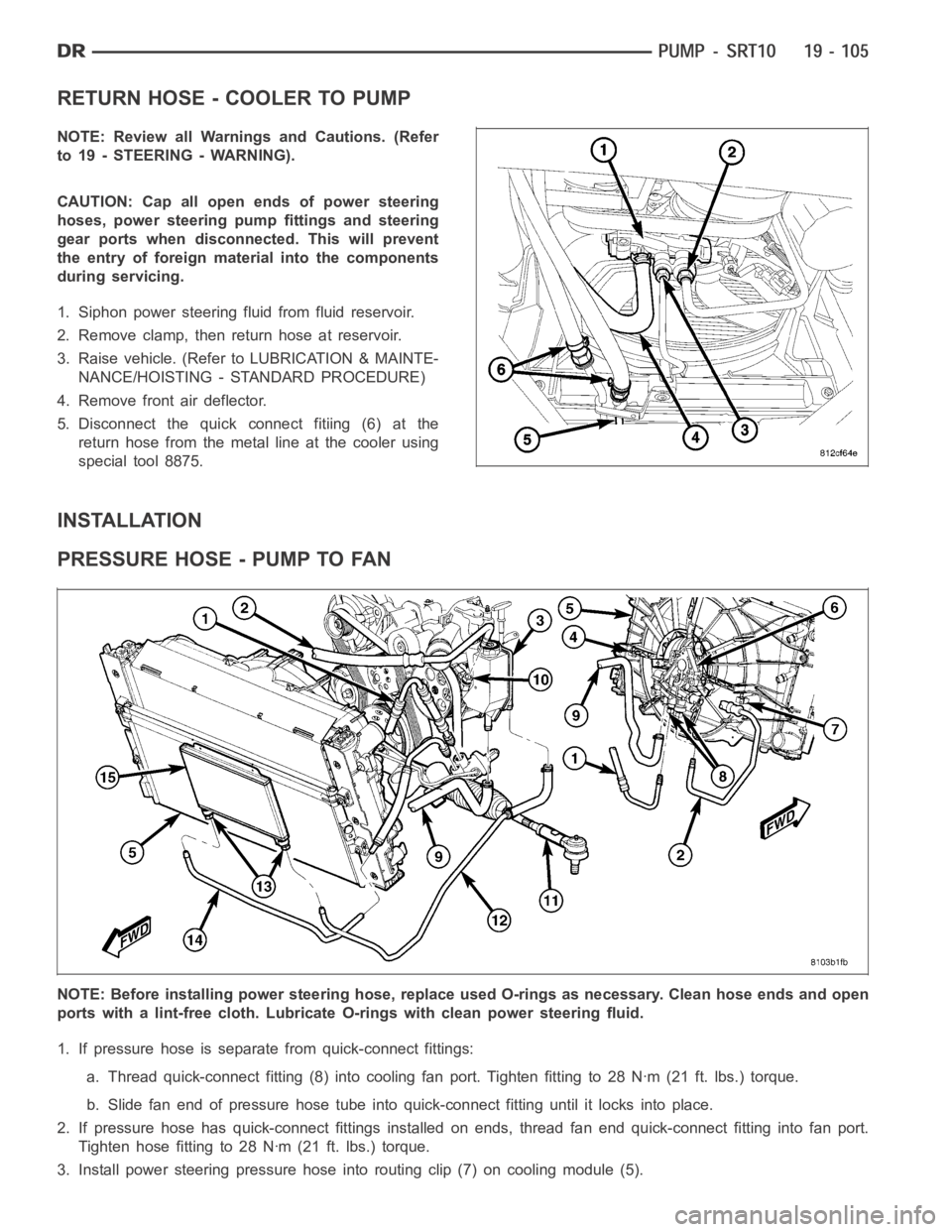

RETURN HOSE - COOLER TO PUMP

NOTE: Review all Warnings and Cautions. (Refer

to 19 - STEERING - WARNING).

CAUTION: Cap all open ends of power steering

hoses, power steering pump fittings and steering

gear ports when disconnected. This will prevent

the entry of foreign material into the components

during servicing.

1. Siphon power steering fluid from fluid reservoir.

2. Remove clamp, then return hose at reservoir.

3. Raise vehicle. (Refer to LUBRICATION & MAINTE-

NANCE/HOISTING - STANDARD PROCEDURE)

4. Remove front air deflector.

5. Disconnect the quick connect fitiing (6) at the

return hose from the metal line at the cooler using

special tool 8875.

INSTALLATION

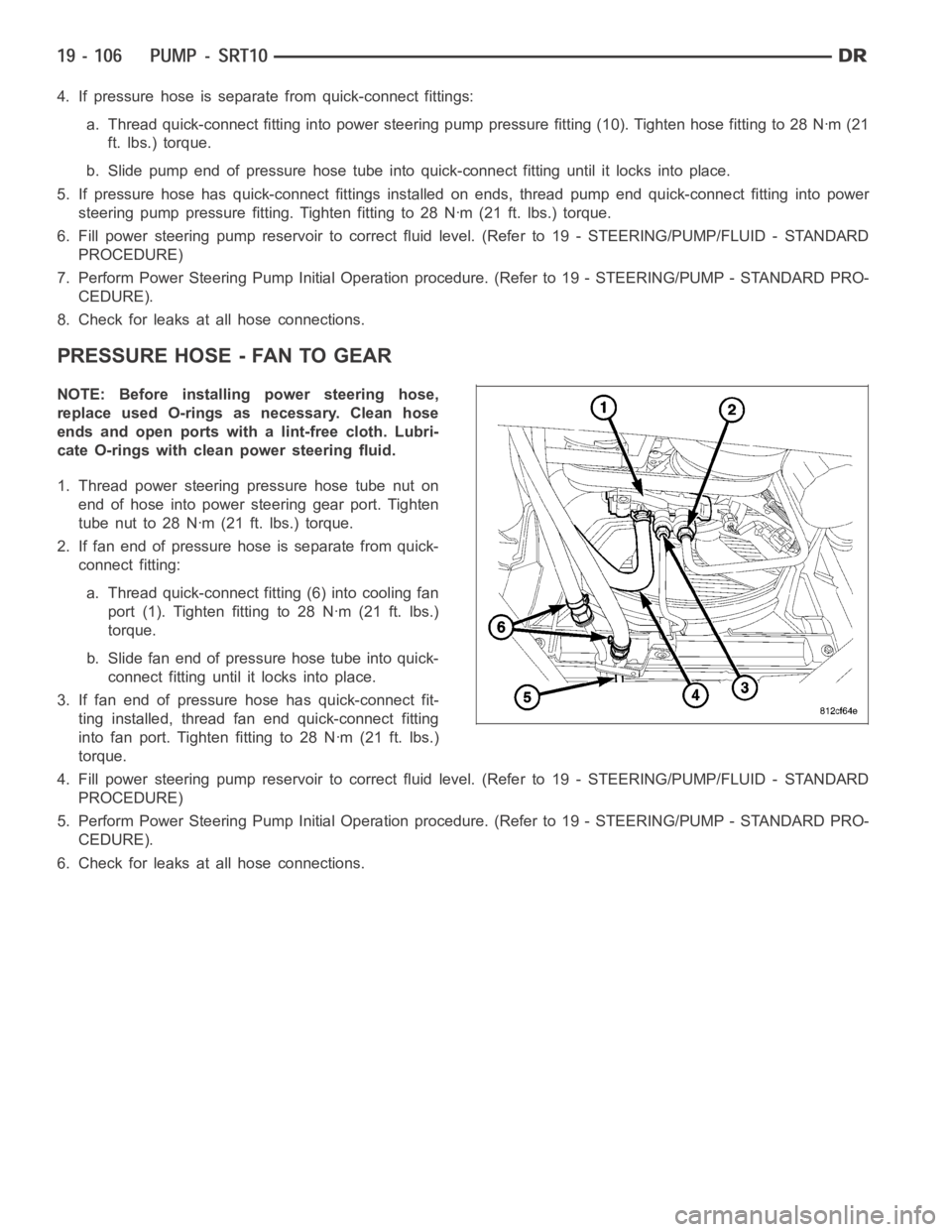

PRESSURE HOSE - PUMP TO FAN

NOTE: Before installing power steering hose, replace used O-rings as necessary. Clean hose ends and open

ports with a lint-free cloth. Lubricate O-rings with clean power steeringfluid.

1. If pressure hose is separate from quick-connect fittings:

a. Thread quick-connect fitting (8) into cooling fan port. Tighten fittingto28Nꞏm(21ft.lbs.)torque.

b. Slide fan end of pressure hose tube into quick-connect fitting until it locks into place.

2. If pressure hose has quick-connect fittings installed on ends, thread fan end quick-connect fitting into fan port.

Tighten hose fitting to 28 Nꞏm (21 ft. lbs.) torque.

3. Install power steering pressure hose into routing clip (7) on cooling module (5).

Page 2511 of 5267

4. If pressure hose is separate from quick-connect fittings:

a. Thread quick-connect fitting into power steering pump pressure fitting (10). Tighten hose fitting to 28 Nꞏm (21

ft. lbs.) torque.

b. Slide pump end of pressure hose tube into quick-connect fitting until itlocks into place.

5. If pressure hose has quick-connect fittings installed on ends, thread pump end quick-connect fitting into power

steering pump pressure fitting. Tighten fitting to 28 Nꞏm (21 ft. lbs.) torque.

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

7. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

8. Check for leaks at all hose connections.

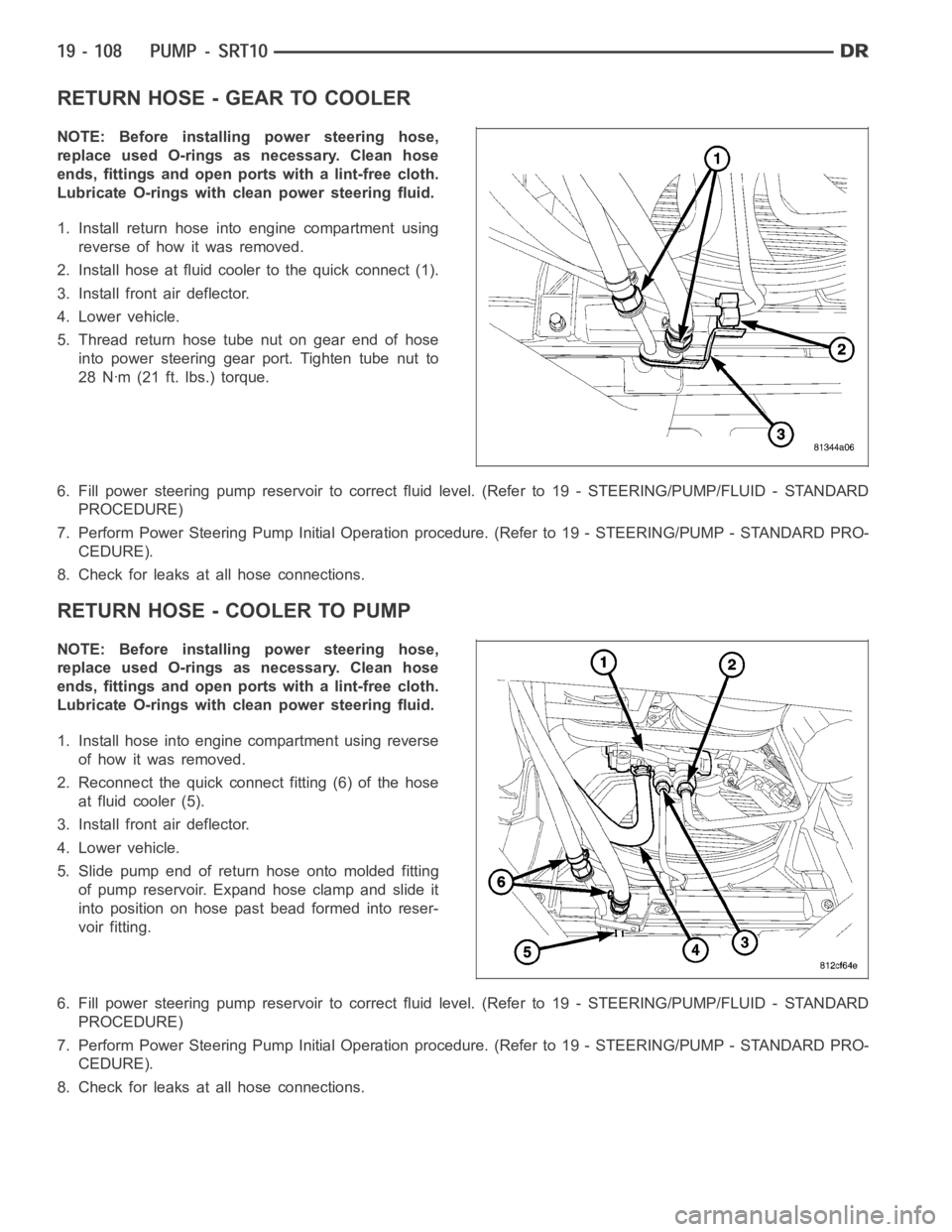

PRESSURE HOSE - FAN TO GEAR

NOTE: Before installing power steering hose,

replace used O-rings as necessary. Clean hose

ends and open ports with a lint-free cloth. Lubri-

cate O-rings with clean power steering fluid.

1. Thread power steering pressure hose tube nut on

end of hose into power steering gear port. Tighten

tube nut to 28 Nꞏm (21 ft. lbs.) torque.

2. If fan end of pressure hose is separate from quick-

connect fitting:

a. Thread quick-connect fitting (6) into cooling fan

port (1). Tighten fitting to 28 Nꞏm (21 ft. lbs.)

torque.

b. Slide fan end of pressure hose tube into quick-

connect fitting until it locks into place.

3. If fan end of pressure hose has quick-connect fit-

ting installed, thread fan end quick-connect fitting

into fan port. Tighten fitting to 28 Nꞏm (21 ft. lbs.)

torque.

4. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

5. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

6. Check for leaks at all hose connections.

Page 2513 of 5267

RETURN HOSE - GEAR TO COOLER

NOTE: Before installing power steering hose,

replace used O-rings as necessary. Clean hose

ends, fittings and open ports with a lint-free cloth.

Lubricate O-rings with clean power steering fluid.

1. Install return hose into engine compartment using

reverse of how it was removed.

2. Install hose at fluid cooler to the quick connect (1).

3. Install front air deflector.

4. Lower vehicle.

5. Thread return hose tube nut on gear end of hose

into power steering gear port. Tighten tube nut to

28 Nꞏm (21 ft. lbs.) torque.

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

7. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

8. Check for leaks at all hose connections.

RETURN HOSE - COOLER TO PUMP

NOTE: Before installing power steering hose,

replace used O-rings as necessary. Clean hose

ends, fittings and open ports with a lint-free cloth.

Lubricate O-rings with clean power steering fluid.

1. Install hose into engine compartment using reverse

of how it was removed.

2. Reconnect the quick connect fitting (6) of the hose

at fluid cooler (5).

3. Install front air deflector.

4. Lower vehicle.

5. Slide pump end of return hose onto molded fitting

of pump reservoir. Expand hose clamp and slide it

into position on hose past bead formed into reser-

voir fitting.

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

7. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

8. Check for leaks at all hose connections.

Page 2586 of 5267

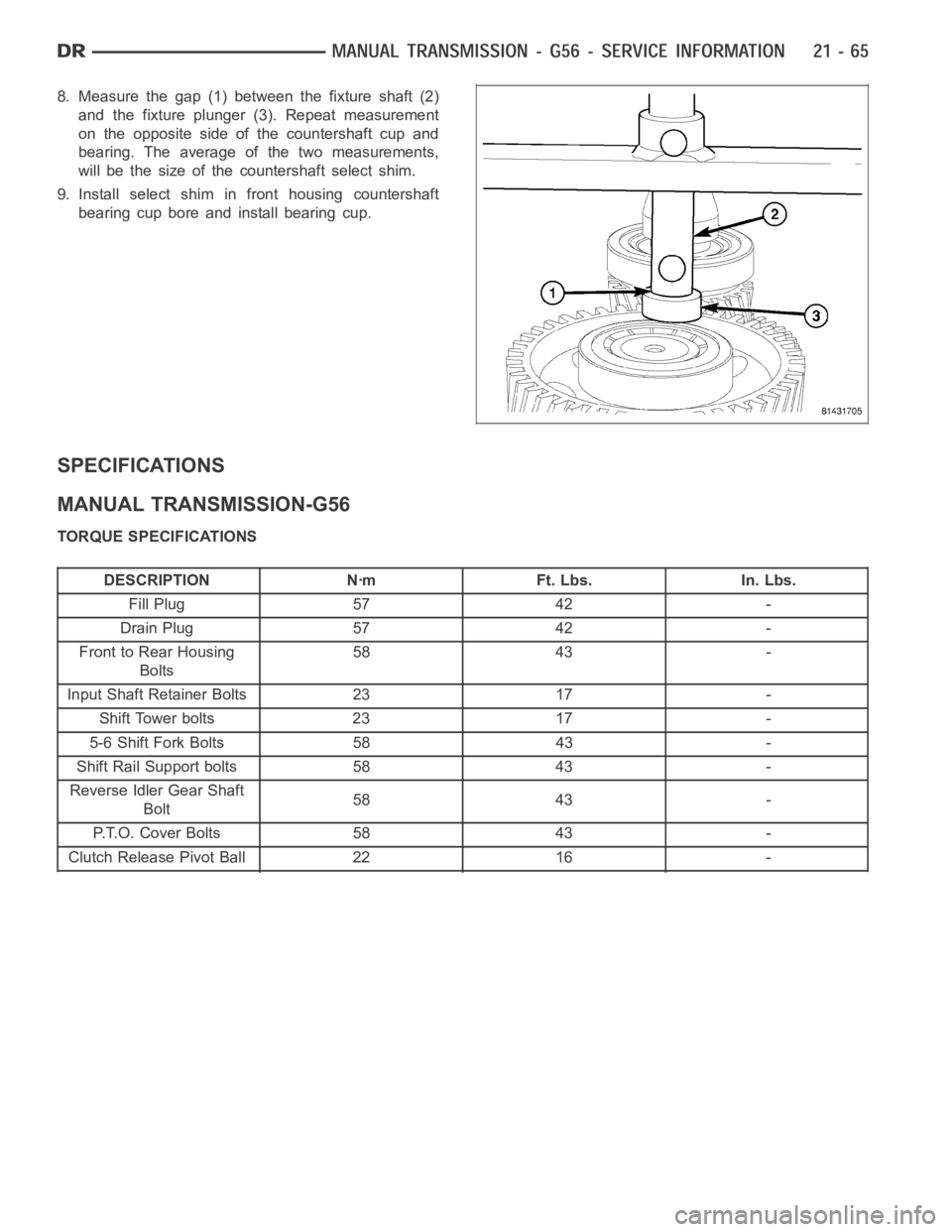

8. Measure the gap (1) between the fixture shaft (2)

and the fixture plunger (3). Repeat measurement

on the opposite side of the countershaft cup and

bearing. The average of the two measurements,

will be the size of the countershaft select shim.

9. Install select shim in front housing countershaft

bearing cup bore and install bearing cup.

SPECIFICATIONS

MANUAL TRANSMISSION-G56

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Fill Plug 57 42 -

Drain Plug 57 42 -

Front to Rear Housing

Bolts58 43 -

Input Shaft Retainer Bolts 23 17 -

Shift Tower bolts 23 17 -

5-6 Shift Fork Bolts 58 43 -

Shift Rail Support bolts 58 43 -

Reverse Idler Gear Shaft

Bolt58 43 -

P.T.O. Cover Bolts 58 43 -

Clutch Release Pivot Ball 22 16 -

Page 2657 of 5267

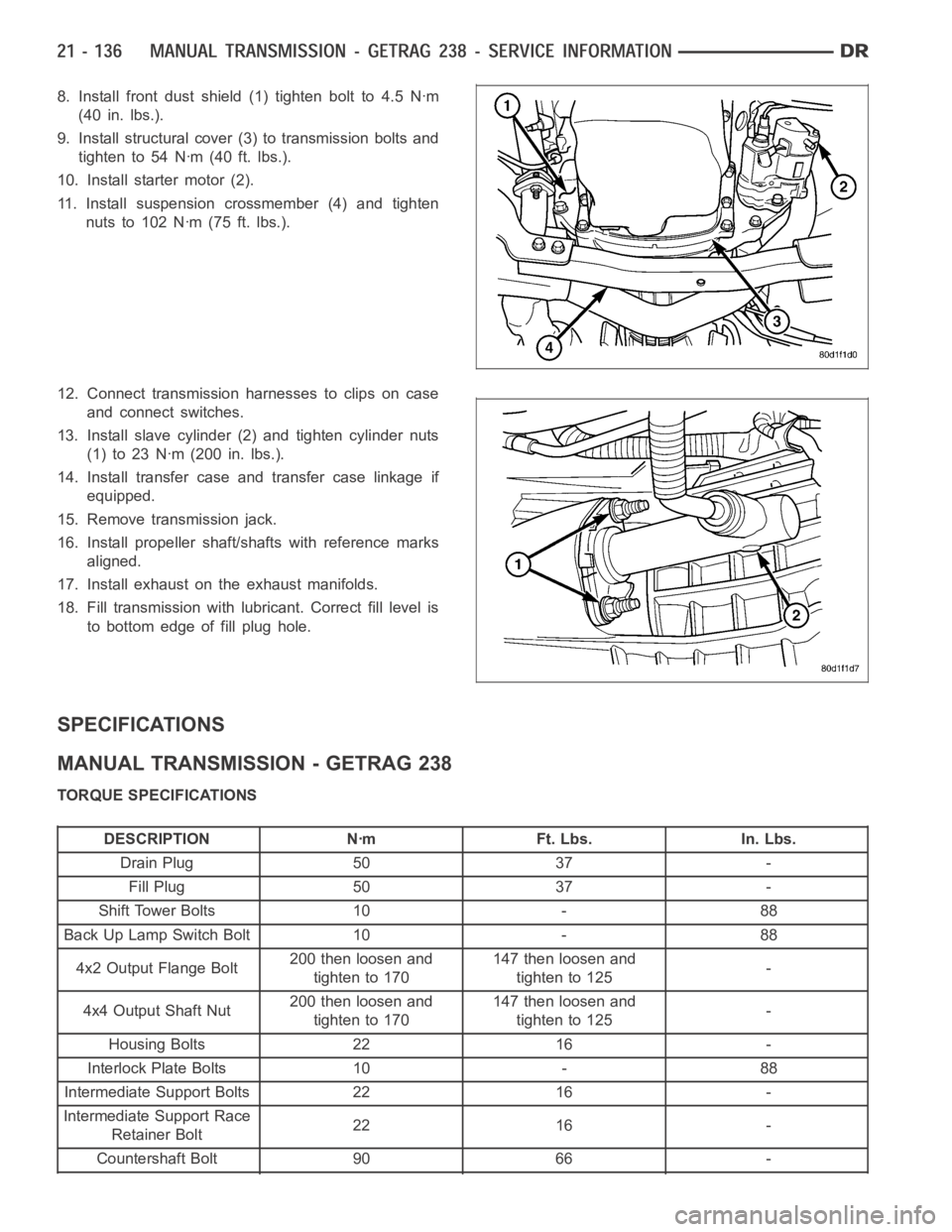

8. Install front dust shield (1) tighten bolt to 4.5 Nꞏm

(40 in. lbs.).

9. Install structural cover (3) to transmission bolts and

tighten to 54 Nꞏm (40 ft. lbs.).

10. Install starter motor (2).

11. Install suspension crossmember (4) and tighten

nuts to 102 Nꞏm (75 ft. lbs.).

12. Connect transmission harnesses to clips on case

and connect switches.

13. Install slave cylinder (2) and tighten cylinder nuts

(1)to23Nꞏm(200in.lbs.).

14. Install transfer case and transfer case linkage if

equipped.

15. Remove transmission jack.

16. Install propeller shaft/shafts with reference marks

aligned.

17. Install exhaust on the exhaust manifolds.

18. Fill transmission with lubricant. Correct fill level is

to bottom edge of fill plug hole.

SPECIFICATIONS

MANUAL TRANSMISSION - GETRAG 238

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Drain Plug 50 37 -

Fill Plug 50 37 -

Shift Tower Bolts 10 - 88

Back Up Lamp Switch Bolt 10 - 88

4x2 Output Flange Bolt200 then loosen and

tighten to 170147 then loosen and

tighten to 125-

4x4 Output Shaft Nut200 then loosen and

tighten to 170147 then loosen and

tighten to 125-

Housing Bolts 22 16 -

Interlock Plate Bolts 10 - 88

Intermediate Support Bolts 22 16 -

Intermediate Support Race

Retainer Bolt22 16 -

Countershaft Bolt 90 66 -

Page 2711 of 5267

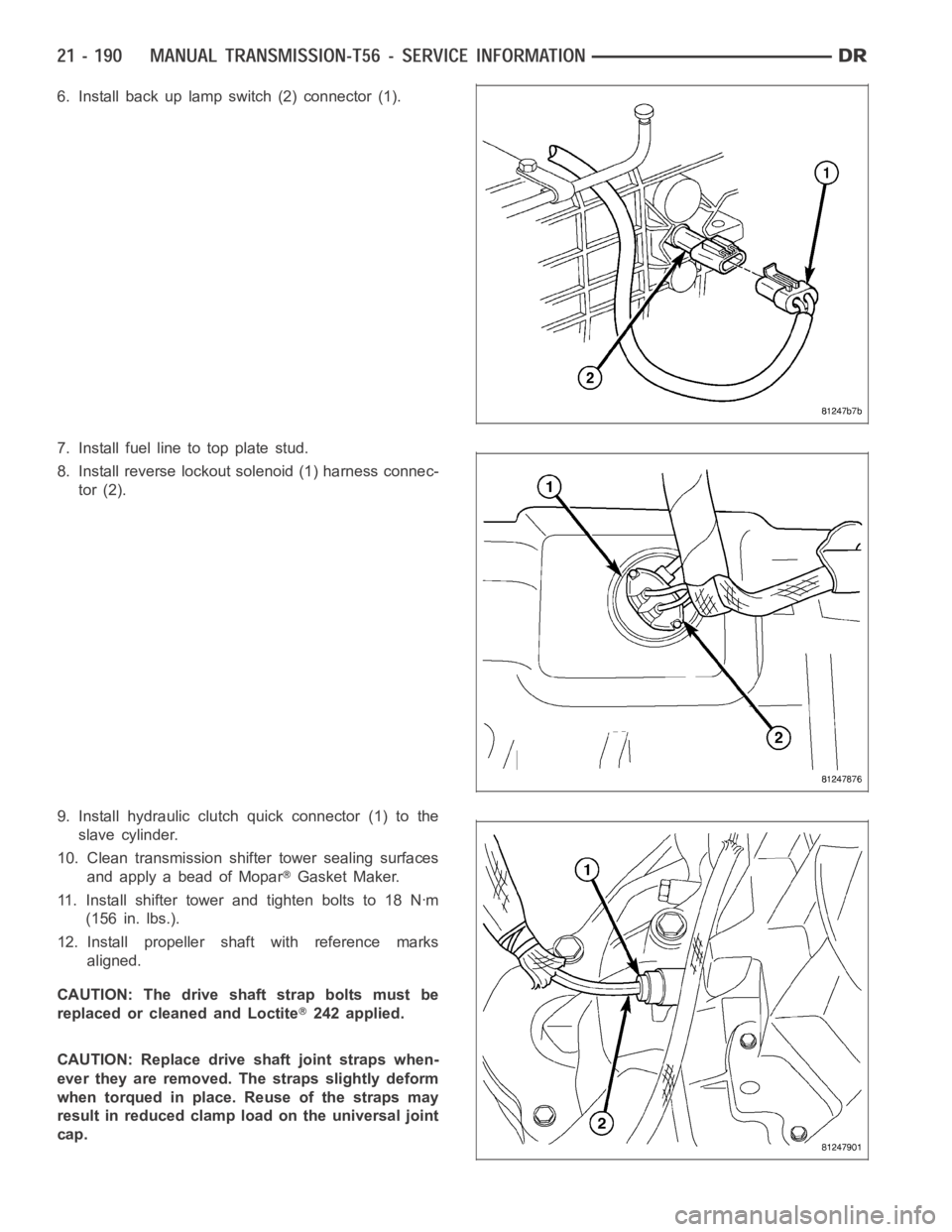

6. Install back up lamp switch (2) connector (1).

7. Install fuel line to top plate stud.

8. Install reverse lockout solenoid (1) harness connec-

tor (2).

9. Install hydraulic clutch quick connector (1) to the

slave cylinder.

10. Clean transmission shifter tower sealing surfaces

and apply a bead of Mopar

Gasket Maker.

11. Install shifter tower and tighten bolts to 18 Nꞏm

(156 in. lbs.).

12. Install propeller shaft with reference marks

aligned.

CAUTION: The drive shaft strap bolts must be

replaced or cleaned and Loctite

242 applied.

CAUTION: Replace drive shaft joint straps when-

ever they are removed. The straps slightly deform

when torqued in place. Reuse of the straps may

result in reduced clamp load on the universal joint

cap.