torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2974 of 5267

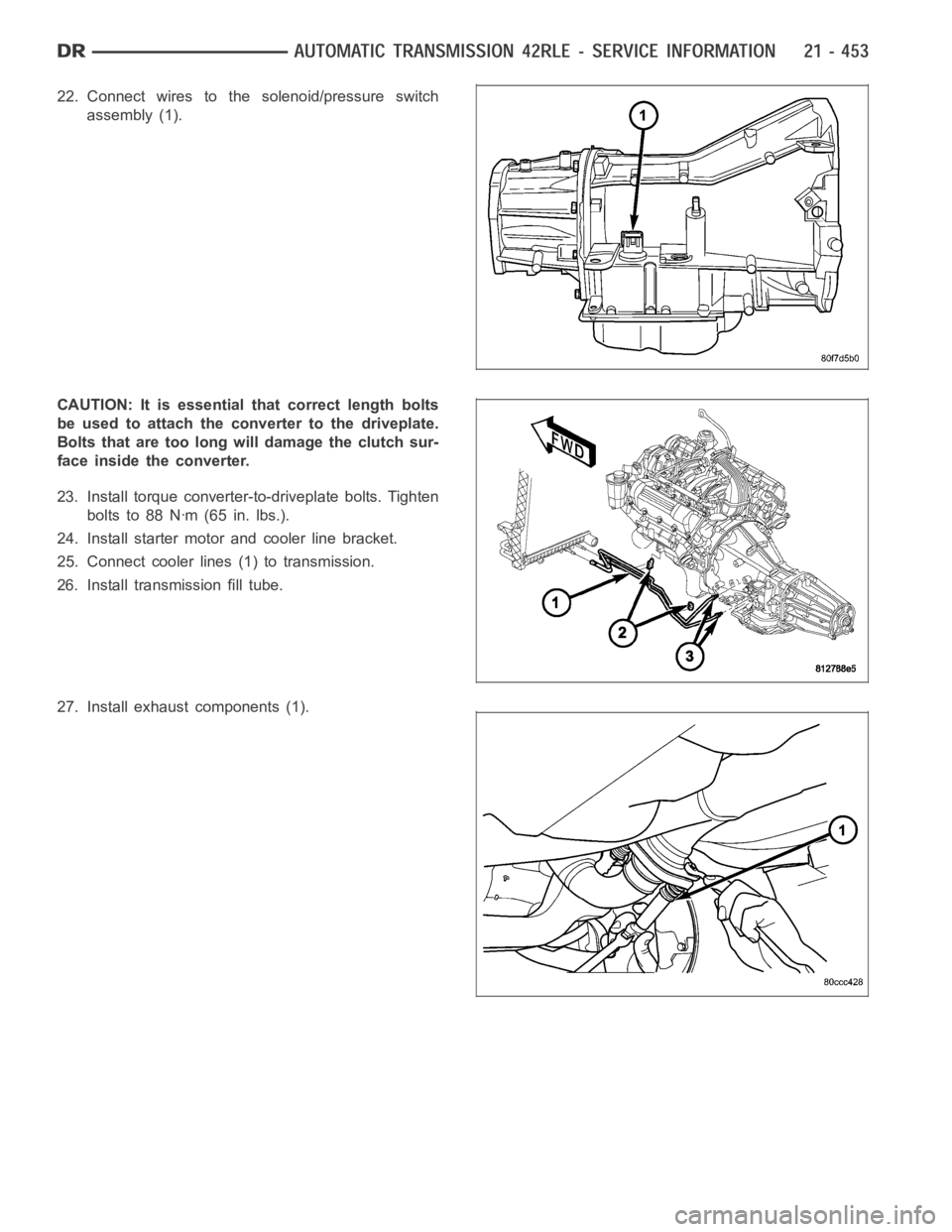

22. Connect wires to the solenoid/pressure switch

assembly (1).

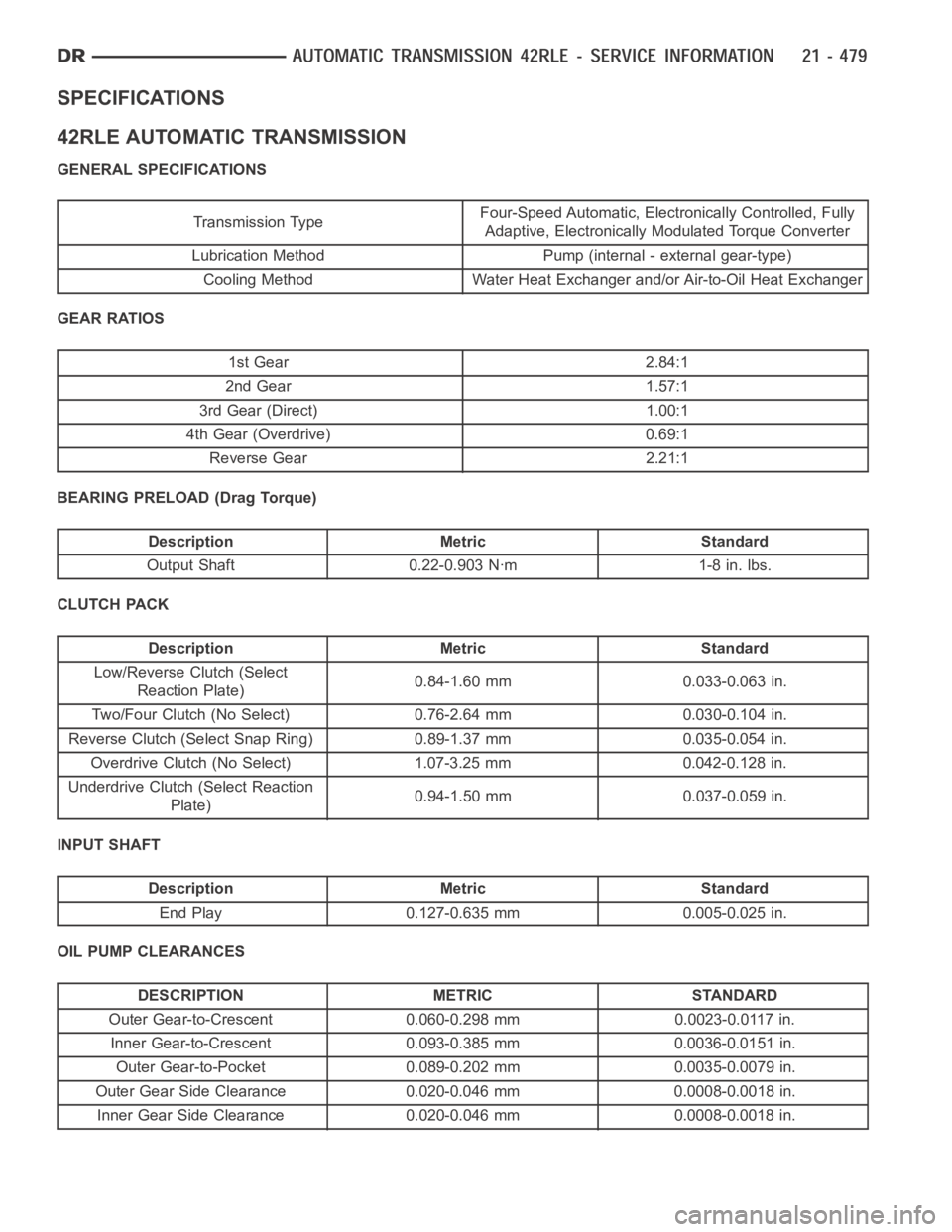

CAUTION: It is essential that correct length bolts

be used to attach the converter to the driveplate.

Bolts that are too long will damage the clutch sur-

face inside the converter.

23. Install torque converter-to-driveplate bolts. Tighten

boltsto88Nꞏm(65in.lbs.).

24. Install starter motor and cooler line bracket.

25. Connect cooler lines (1) to transmission.

26. Install transmission fill tube.

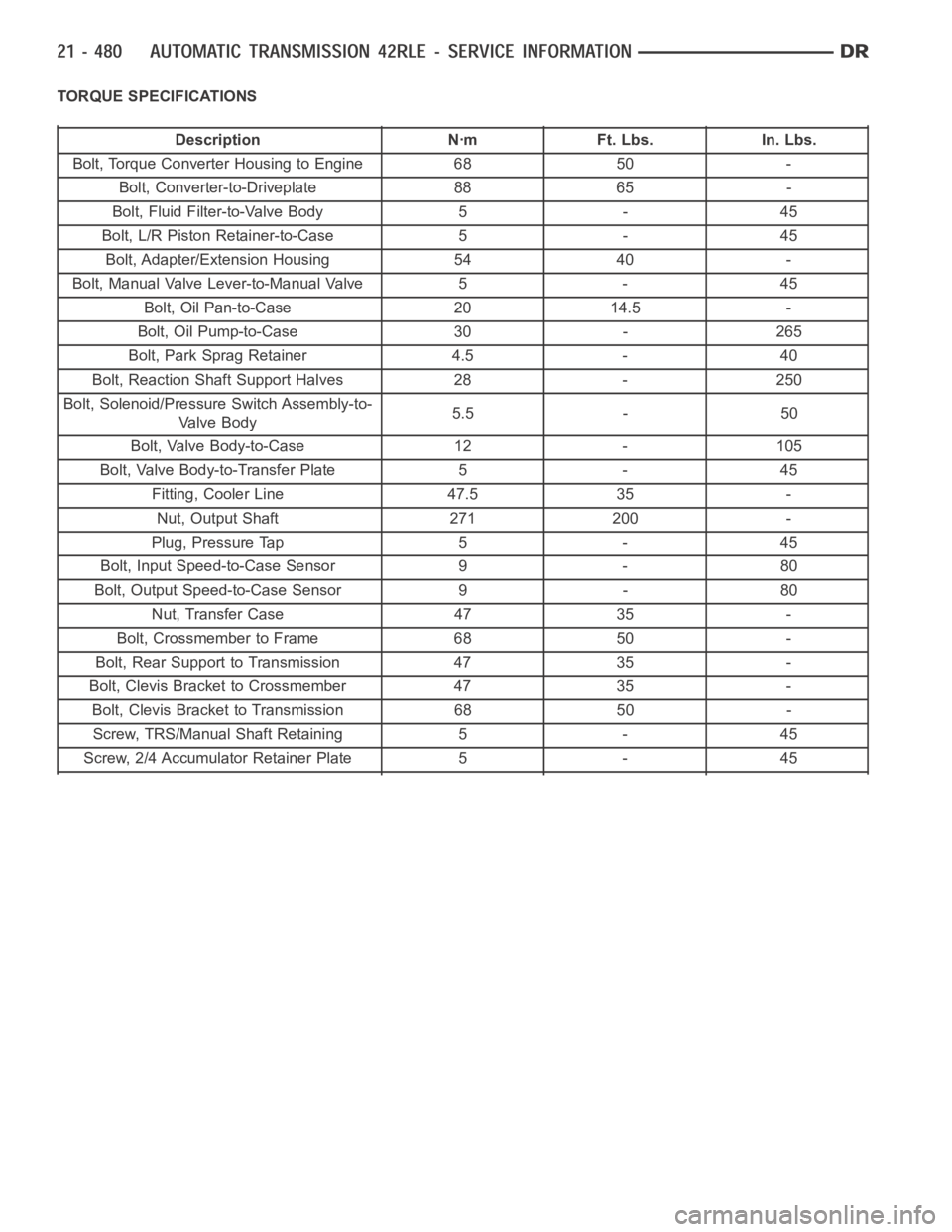

27. Install exhaust components (1).

Page 3000 of 5267

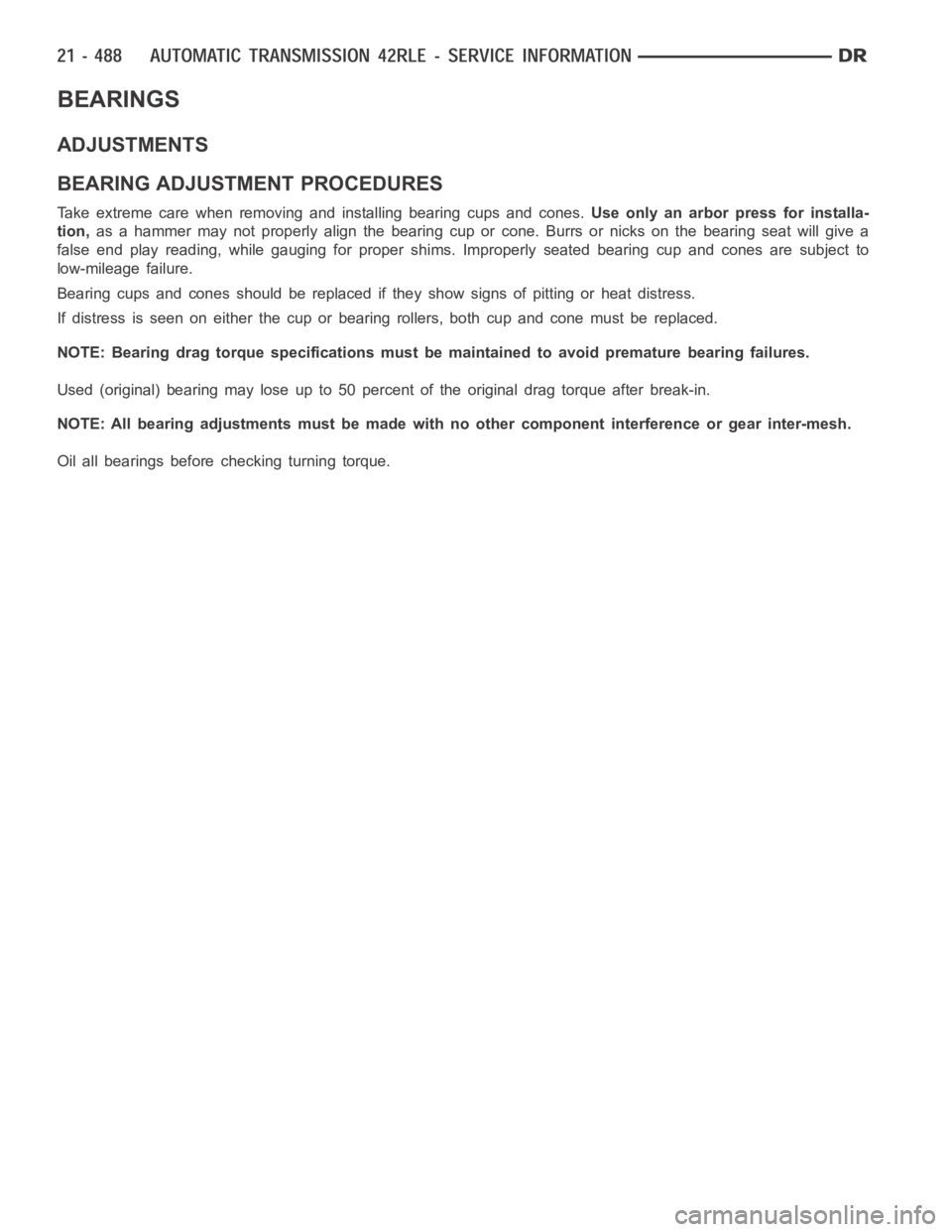

SPECIFICATIONS

42RLE AUTOMATIC TRANSMISSION

GENERAL SPECIFICATIONS

Transmission TypeFour-Speed Automatic, Electronically Controlled, Fully

Adaptive, Electronically Modulated Torque Converter

Lubrication Method Pump (internal - external gear-type)

Cooling Method Water Heat Exchanger and/or Air-to-Oil Heat Exchanger

GEAR RATIOS

1st Gear 2.84:1

2nd Gear 1.57:1

3rd Gear (Direct) 1.00:1

4th Gear (Overdrive) 0.69:1

Reverse Gear 2.21:1

BEARING PRELOAD (Drag Torque)

Description Metric Standard

Output Shaft 0.22-0.903 Nꞏm 1-8 in. lbs.

CLUTCH PACK

Description Metric Standard

Low/Reverse Clutch (Select

Reaction Plate)0.84-1.60 mm 0.033-0.063 in.

Two/Four Clutch (No Select) 0.76-2.64 mm 0.030-0.104 in.

Reverse Clutch (Select Snap Ring) 0.89-1.37 mm 0.035-0.054 in.

Overdrive Clutch (No Select) 1.07-3.25 mm 0.042-0.128 in.

Underdrive Clutch (Select Reaction

Plate)0.94-1.50 mm 0.037-0.059 in.

INPUT SHAFT

Description Metric Standard

End Play 0.127-0.635 mm 0.005-0.025 in.

OIL PUMP CLEARANCES

DESCRIPTION METRIC STANDARD

Outer Gear-to-Crescent 0.060-0.298 mm 0.0023-0.0117 in.

Inner Gear-to-Crescent 0.093-0.385 mm 0.0036-0.0151 in.

Outer Gear-to-Pocket 0.089-0.202 mm 0.0035-0.0079 in.

Outer Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

Inner Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

Page 3001 of 5267

TORQUE SPECIFICATIONS

Description Nꞏm Ft. Lbs. In. Lbs.

Bolt, Torque Converter Housing to Engine 68 50 -

Bolt, Converter-to-Driveplate 88 65 -

Bolt, Fluid Filter-to-Valve Body 5 - 45

Bolt, L/R Piston Retainer-to-Case 5 - 45

Bolt, Adapter/Extension Housing 54 40 -

Bolt, Manual Valve Lever-to-Manual Valve 5 - 45

Bolt, Oil Pan-to-Case 20 14.5 -

Bolt, Oil Pump-to-Case 30 - 265

Bolt, Park Sprag Retainer 4.5 - 40

Bolt, Reaction Shaft Support Halves 28 - 250

Bolt, Solenoid/Pressure Switch Assembly-to-

Valve Body5.5 - 50

Bolt, Valve Body-to-Case 12 - 105

Bolt, Valve Body-to-Transfer Plate 5 - 45

Fitting, Cooler Line 47.5 35 -

Nut, Output Shaft 271 200 -

Plug, Pressure Tap 5 - 45

Bolt, Input Speed-to-Case Sensor 9 - 80

Bolt, Output Speed-to-Case Sensor 9 - 80

Nut, Transfer Case 47 35 -

Bolt, Crossmember to Frame 68 50 -

Bolt, Rear Support to Transmission 47 35 -

Bolt, Clevis Bracket to Crossmember 47 35 -

Bolt, Clevis Bracket to Transmission 68 50 -

Screw, TRS/Manual Shaft Retaining 5 - 45

Screw, 2/4 Accumulator Retainer Plate 5 - 45

Page 3009 of 5267

BEARINGS

ADJUSTMENTS

BEARING ADJUSTMENT PROCEDURES

Take extreme care when removing andinstalling bearing cups and cones.Use only an arbor press for installa-

tion,as a hammer may not properly align the bearing cup or cone. Burrs or nicks on the bearing seat will give a

false end play reading, while gauging for proper shims. Improperly seatedbearing cup and cones are subject to

low-mileage failure.

Bearing cups and cones should be replaced if they show signs of pitting or heat distress.

If distress is seen on either the cup or bearing rollers, both cup and cone must be replaced.

NOTE: Bearing drag torque specifications must be maintained to avoid premature bearing failures.

Used (original) bearing may lose up to 50 percent of the original drag torque after break-in.

NOTE: All bearing adjustments must be made with no other component interference or gear inter-mesh.

Oil all bearings before checking turning torque.

Page 3014 of 5267

FLUID AND FILTER

DIAGNOSIS AND TESTING

CAUSES OF BURNT FLUID

Burnt, discolored fluid is a result of overheating which has two primary causes.

1. A result of restricted fluid flow through the main and/or auxiliary cooler. This condition is usually the result of a

faulty or improperly installed drainback valve, a damaged oil cooler, or severe restrictions in the coolers and lines

caused by debris or kinked lines.

2. Heavy duty operation with a vehicle not properly equipped for this type of operation. Trailer towing or similar high

load operation will overheat the transmission fluid if the vehicle is improperly equipped. Such vehicles should

have an auxiliary transmission fluid cooler, a heavy duty cooling system,and the engine/axle ratio combination

needed to handle heavy loads.

EFFECTS OF INCORRECT FLUID LEVEL

Alowfluidlevelallowsthepumptotakeinairalongwiththefluid.Airinthe fluid will cause fluid pressures to be

low and develop slower than normal. If the transmission is overfilled, thegears churn the fluid into foam. This aer-

ates the fluid and causing the same conditions occurring with a low level. In either case, air bubbles cause fluid

overheating, oxidation, and varnish buildup which interferes with valveand clutch operation. Foaming also causes

fluid expansion which can result in fluid overflow from the transmission vent or fill tube. Fluid overflow can easily be

mistaken for a leak if inspection is not careful.

FLUID CONTAMINATION

Transmission fluid contamination is generally a result of:

adding incorrect fluid

failure to clean dipstick and fill tube when checking level

engine coolant entering the fluid

internal failure that generates debris

overheat that generates sludge (fluid breakdown)

failure to replace contaminated converter after repair

The use of non-recommended fluids can result in transmission failure. Theusual results are erratic shifts, slippage,

abnormal wear and eventual failure due to fluid breakdown and sludge formation. Avoid this condition by using rec-

ommended fluids only.

The dipstick cap and fill tube should be wiped clean before checking fluid level. Dirt, grease and other foreign mate-

rial on the cap and tube could fall into the tube if not removed beforehand. Take the time to wipe the cap and tube

clean before withdrawing the dipstick.

Engine coolant in the transmission fluid is generally caused by a cooler malfunction. The only remedy is to replace

the radiator as the cooler in the radiator is not a serviceable part. If coolant has circulated through the transmission,

an overhaul is necessary.

The torque converter should also be replaced whenever a failure generatessludge and debris. This is necessary

because normal converter flushing procedures will not remove all contaminants.

STANDARD PROCEDURE

FLUID LEVEL CHECK

The transmission sump has a dipstick to check oil similar to most automatictransmissions. It is located on the left

side of the engine. Be sure to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the PARK and NEUTRAL positions. Place the selector lever in PARK to be sure

that the fluid level check is accurate.The engine should be running at idle speed for at least one minute, with

the vehicle on level ground.At normal operating temperature (approximately 82° C or 180° F), the fluidlevel is

correct if it is in the HOT region (cross-hatched area) on the oil level indicator. The fluid level should be in COLD

region at 21° C (70° F) fluid temperature. Adjust fluid level as necessary.Use only Mopar

ATF+4, Automatic Trans-

mission Fluid.

Page 3016 of 5267

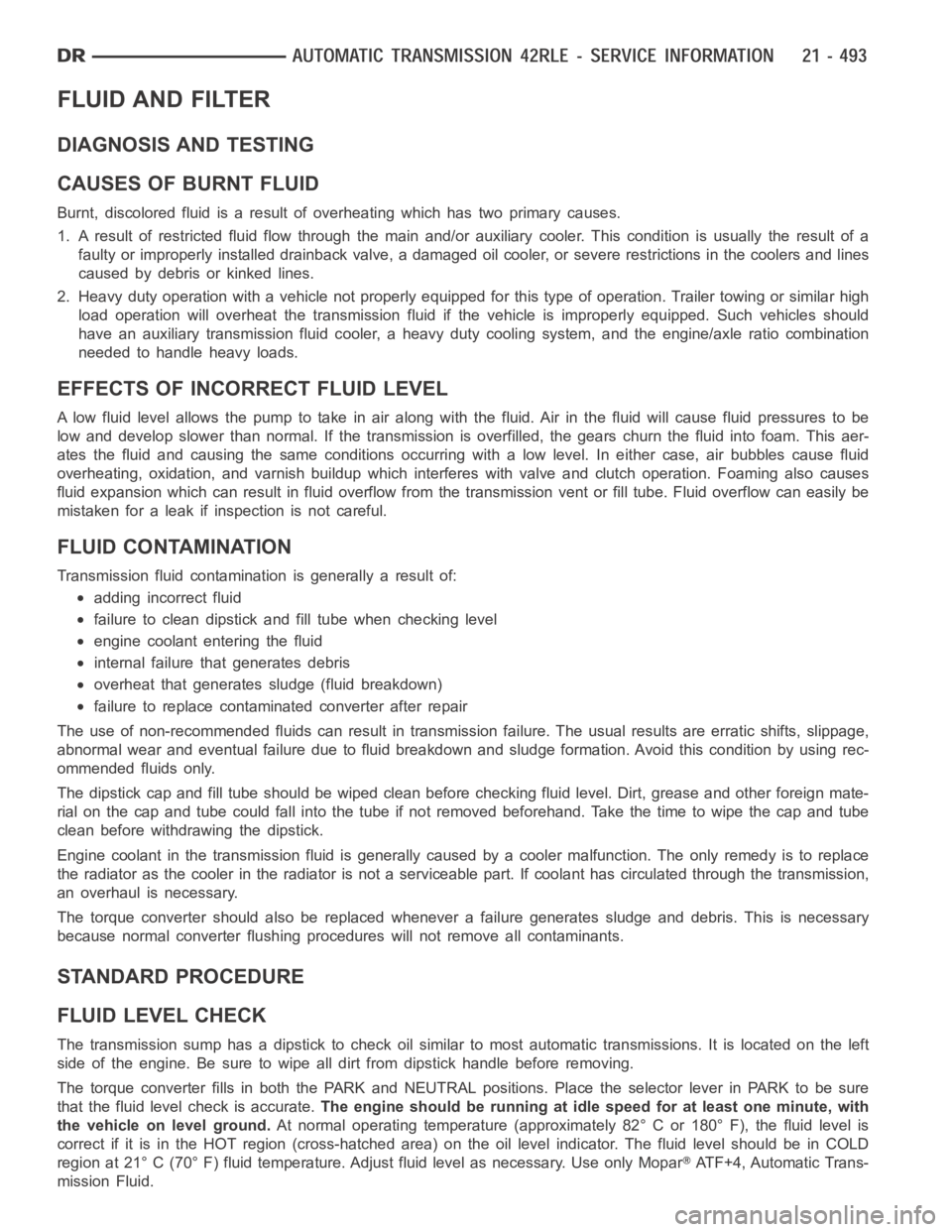

NOTE: One of the oil pan bolts (5) has a sealing

patch applied from the factory. Separate this bolt

for reuse.

2. Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove

the oil pan.

3. Install a new filter and o-ring on bottom of the valve

body and tighten retaining screws to 5 Nꞏm (45 in.

lbs.).

NOTE: Before installing the oil pan bolt (5) in the

bolt hole located between the torque converter

clutch on and U/D clutch pressure tap circuits, it

will be necessary to replentish the sealing patch

on the bolt using Mopar

Lock & Seal Adhesive.

4. Clean the oil pan and magnet. Reinstall pan using

new Mopar

Silicone Adhesive sealant. Tighten oil

pan bolts to 20 Nꞏm (14.5 ft. lbs.).

5. Pour four quarts of Mopar

AT F + 4 , A u t o m a t i c

Transmission Fluid, through the dipstick opening.

6. Start engine and allow to idle for at least one minute. Then, with parkingand service brakes applied, move selec-

tor lever momentarily to each position, ending in the park or neutral position.

7. Check the transmission fluid level and add an appropriate amount to bring the transmission fluid level to 3mm

(1/8 in.) below the lowest mark on the dipstick.

8. Recheck the fluid level after the transmission has reached normal operating temperature, 82° C (180°F).

9. To prevent dirt from entering transmission, make certain that dipstickis fully seated into the dipstick opening.

TRANSMISSION FILL

To avoid overfilling transmission after a fluid change or overhaul, perform the following procedure:

1. Remove dipstick and insert clean funnel in transmission fill tube.

2. Add following initial quantity of Mopar

ATF+4totransmission:

a. If only fluid and filter were changed, add3 pints (1-1/2 quarts)of ATF +4 to transmission.

b. If transmission was completely overhauled, torque converter was replaced or drained, and cooler was

flushed, add12 pints (6 quarts)of ATF +4 to transmission.

3. Apply parking brakes.

4. Start and run engine at normal curb idle speed.

5. Apply service brakes, shift transmission through all gear ranges then back to NEUTRAL, set parking brake, and

leave engine running at curb idle speed.

6. Remove funnel, insert dipstick andcheck fluid level. If level is low,add fluid to bring level to MIN mark on

dipstick.Check to see if the oil level is equal on both sides of the dipstick. If one side is noticably higher than

the other, the dipstick has picked up some oil from the dipstick tube. Allowthe oil to drain down the dipstick tube

and re-check.

7. Drive vehicle until transmission fluid is at normal operating temperature.

8. With the engine running at curb idle speed, the gear selector in NEUTRAL,and the parking brake applied, check

the transmission fluid level.

CAUTION: Do not overfill transmission, fluid foaming and shifting problems can result.

9. Add fluid to bring level up to MAX arrow mark.

When fluid level is correct, shut engine off, release park brake, remove funnel, and install dipstick in fill tube.

Page 3044 of 5267

SENSOR-INPUT SPEED

DESCRIPTION

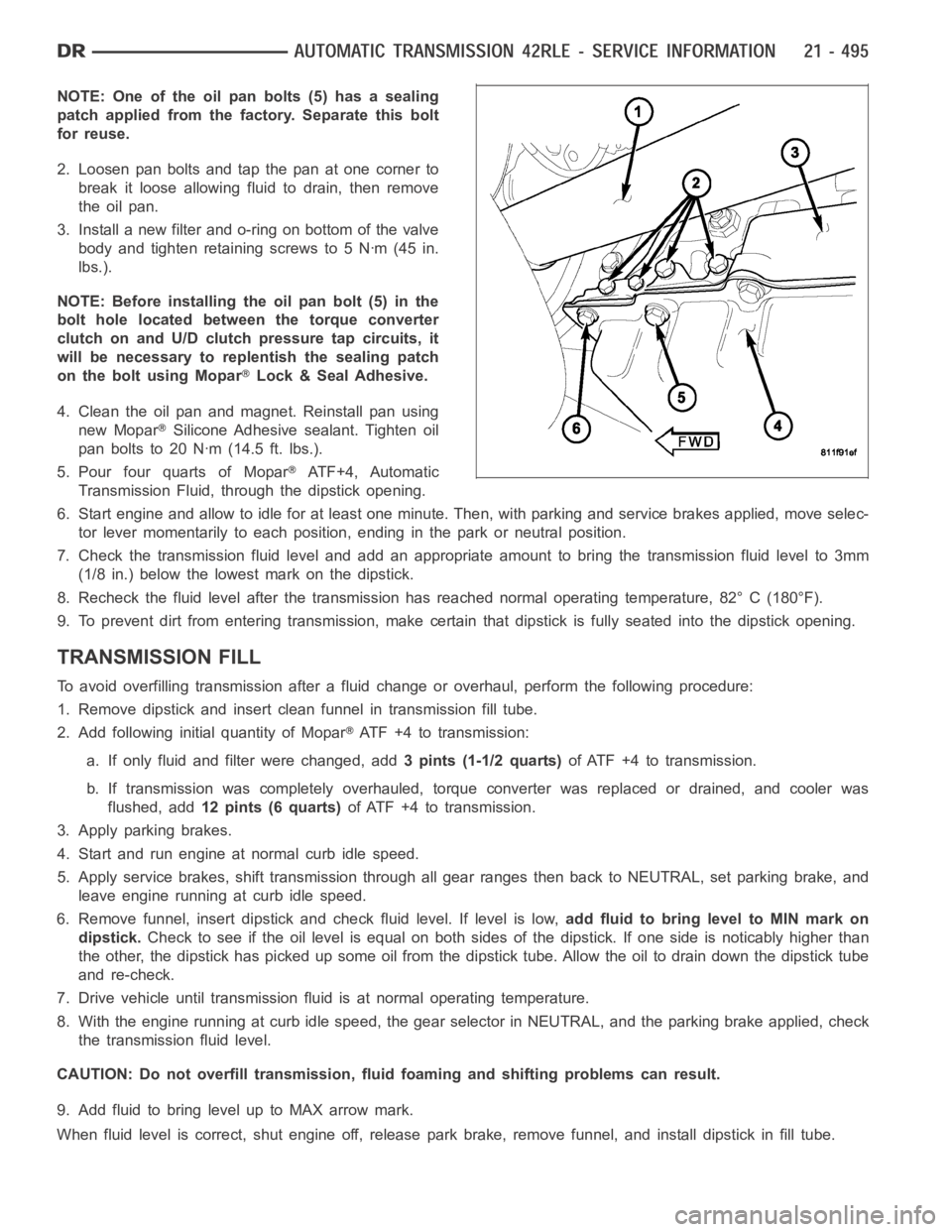

The Input (1) and Output (2) Speed Sensors are two-

wire magnetic pickup devices that generate AC signals

as rotation occurs. They are mounted in the left side

of the transmission case and are considered primary

inputs to the Transmission Control Module (TCM).

OPERATION

The Input Speed Sensor provides information on how fast the input shaft is rotating. As the teeth of the input clutch

hub pass by the sensor coil, an AC voltage is generated and sent to the TCM. The TCM interprets this information

as input shaft rpm.

The Output Speed Sensor generates an AC signal in a similar fashion, thoughitscoilisexcitedbyrotationofthe

rear planetary carrier lugs. The TCM interprets this information as outputshaftrpm.

The TCM compares the input and output speed signals to determine the following:

Transmission gear ratio

Speed ratio error detection

CVI calculation

The TCM also compares the input speed signal and the engine speed signal to determine the following:

Torque converter clutch slippage

Torque converter element speed ratio

REMOVAL

1. Raise vehicle.

2. Place a suitable fluid catch pan under the transmis-

sion.

3. Remove the wiring connector from the input speed

sensor.

NOTE: The speed sensor bolt has a sealing patch

applied from the factory. Be sure to reuse the

same bolt.

4. Remove the bolt holding the input speed sensor to

the transmission case.

5. Remove the input speed sensor from the transmis-

sion case.

Page 3046 of 5267

SENSOR-VARIABLE LINE PRESSURE

DESCRIPTION

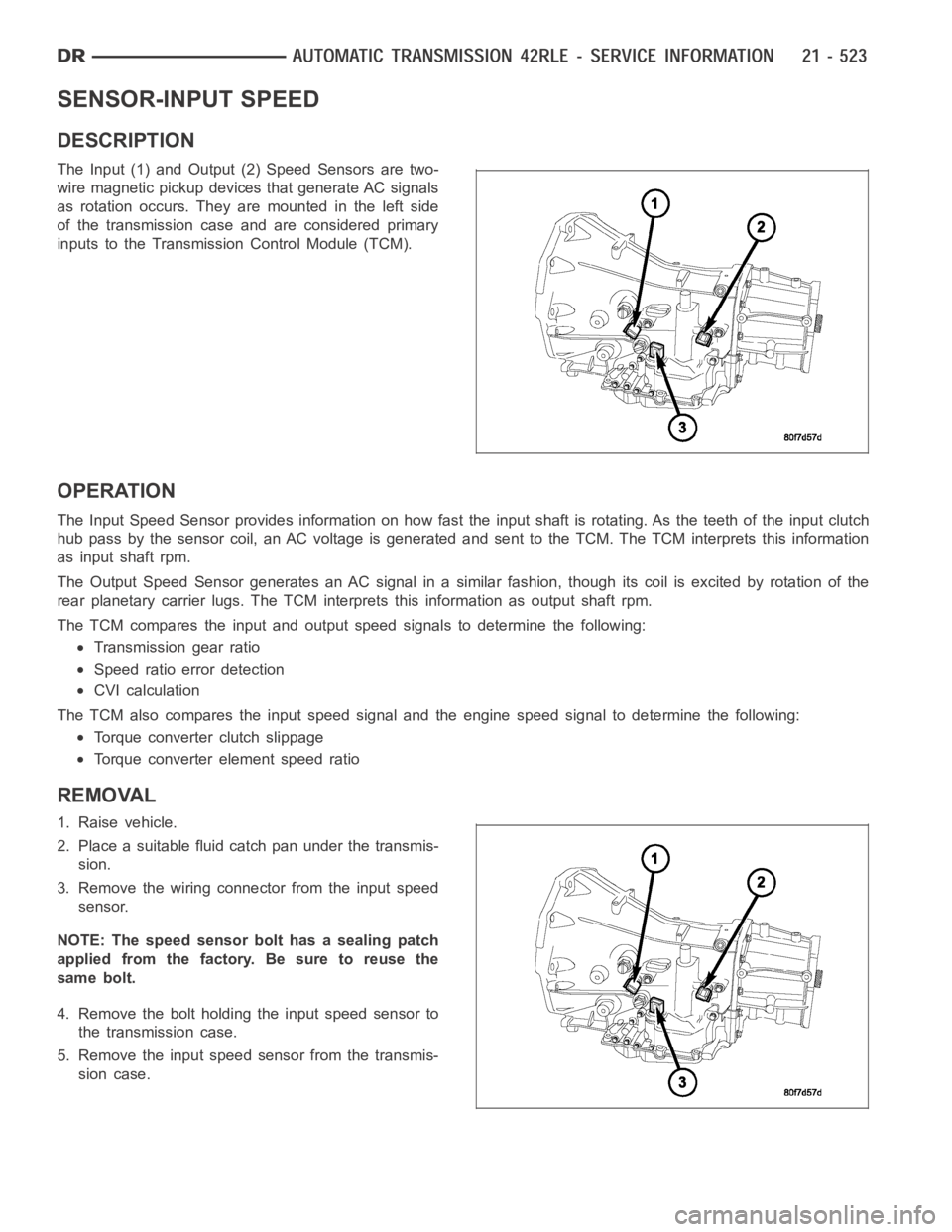

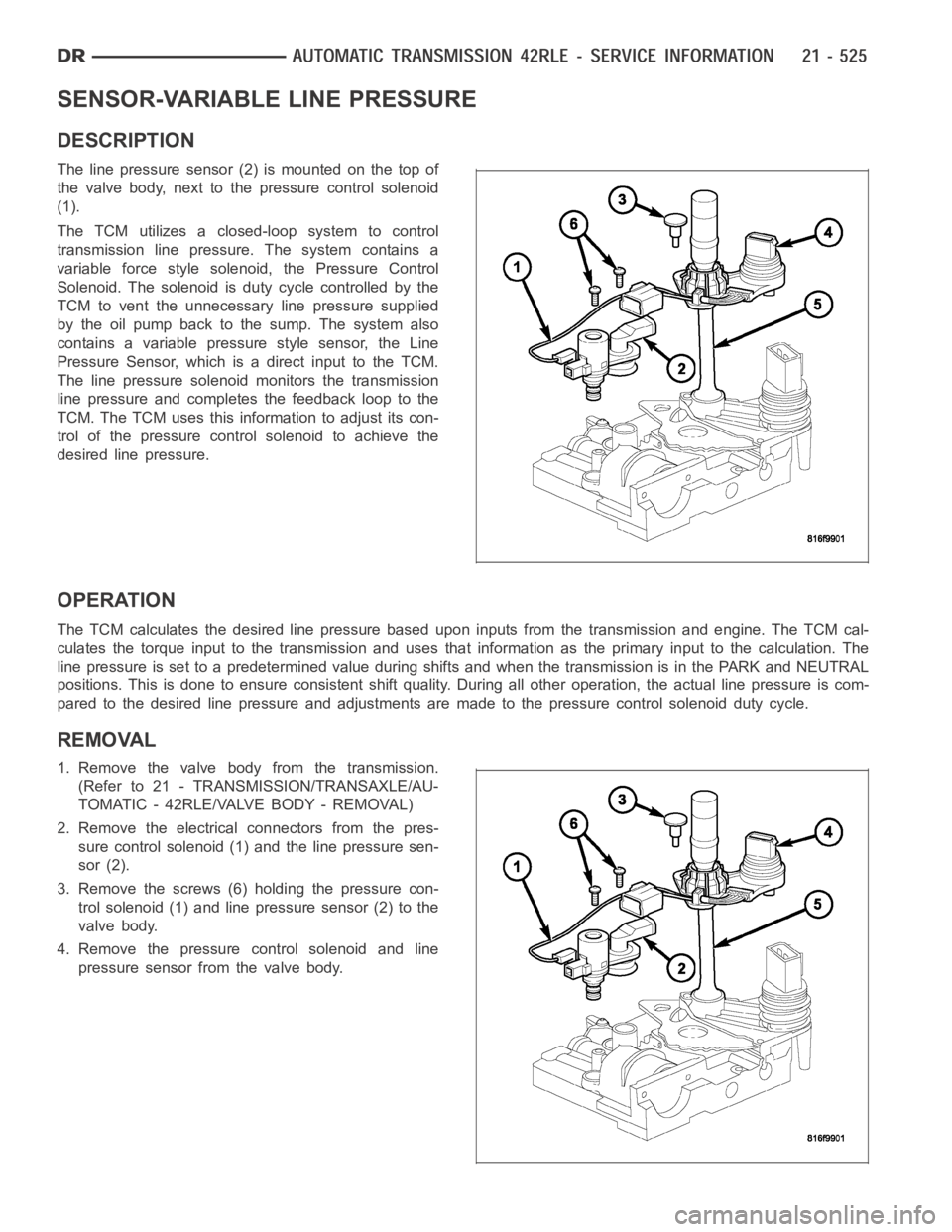

The line pressure sensor (2) is mounted on the top of

the valve body, next to the pressure control solenoid

(1).

The TCM utilizes a closed-loop system to control

transmission line pressure. The system contains a

variable force style solenoid, the Pressure Control

Solenoid. The solenoid is duty cycle controlled by the

TCM to vent the unnecessary line pressure supplied

by the oil pump back to the sump. The system also

contains a variable pressure style sensor, the Line

Pressure Sensor, which is a direct input to the TCM.

The line pressure solenoid monitors the transmission

line pressure and completes the feedback loop to the

TCM. The TCM uses this information to adjust its con-

trol of the pressure control solenoid to achieve the

desired line pressure.

OPERATION

The TCM calculates the desired line pressure based upon inputs from the transmission and engine. The TCM cal-

culates the torque input to the transmission and uses that information as the primary input to the calculation. The

line pressure is set to a predetermined value during shifts and when the transmission is in the PARK and NEUTRAL

positions. This is done to ensure consistent shift quality. During all other operation, the actual line pressure is com-

pared to the desired line pressure and adjustments are made to the pressurecontrol solenoid duty cycle.

REMOVAL

1. Remove the valve body from the transmission.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE/VALVE BODY - REMOVAL)

2. Remove the electrical connectors from the pres-

sure control solenoid (1) and the line pressure sen-

sor (2).

3. Remove the screws (6) holding the pressure con-

trol solenoid (1) and line pressure sensor (2) to the

valve body.

4. Remove the pressure control solenoid and line

pressure sensor from the valve body.

Page 3048 of 5267

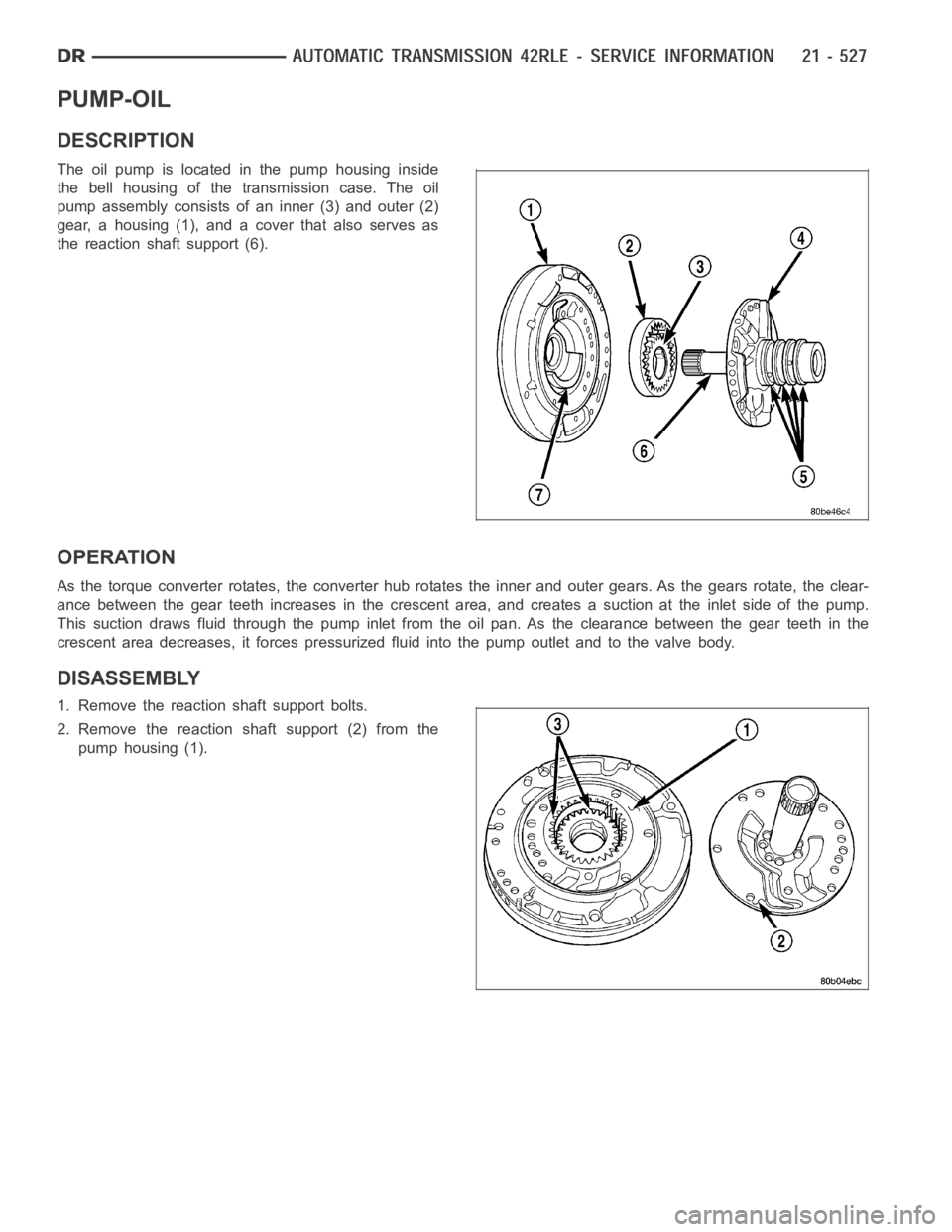

PUMP-OIL

DESCRIPTION

The oil pump is located in the pump housing inside

the bell housing of the transmission case. The oil

pump assembly consists of an inner (3) and outer (2)

gear, a housing (1), and a cover that also serves as

the reaction shaft support (6).

OPERATION

As the torque converter rotates, the converter hub rotates the inner and outer gears. As the gears rotate, the clear-

ance between the gear teeth increases in the crescent area, and creates a suction at the inlet side of the pump.

This suction draws fluid through the pump inlet from the oil pan. As the clearance between the gear teeth in the

crescent area decreases, it forces pressurized fluid into the pump outletand to the valve body.

DISASSEMBLY

1. Remove the reaction shaft support bolts.

2. Remove the reaction shaft support (2) from the

pump housing (1).

Page 3050 of 5267

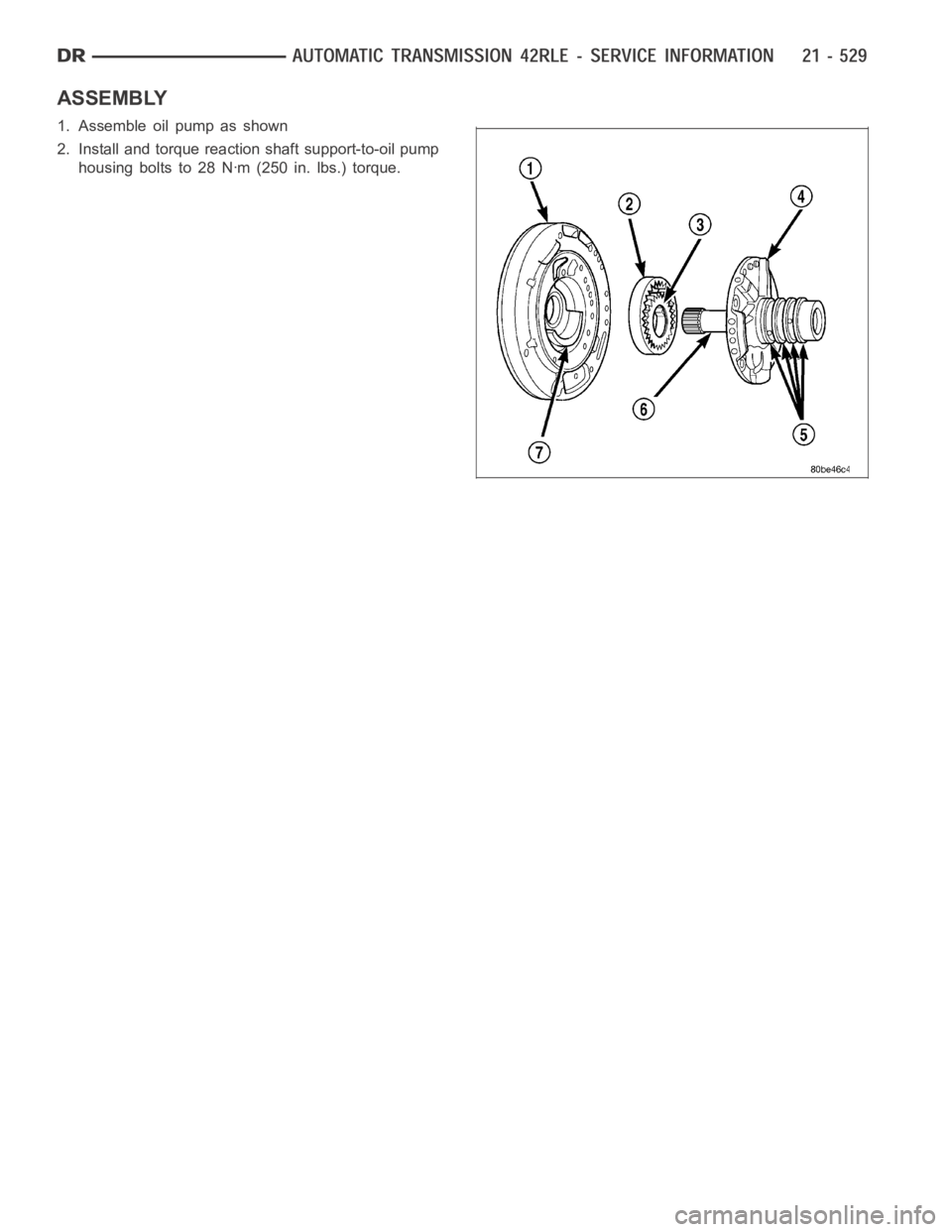

ASSEMBLY

1. Assemble oil pump as shown

2. Install and torque reaction shaft support-to-oil pump

housing bolts to 28 Nꞏm (250 in. lbs.) torque.