torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3099 of 5267

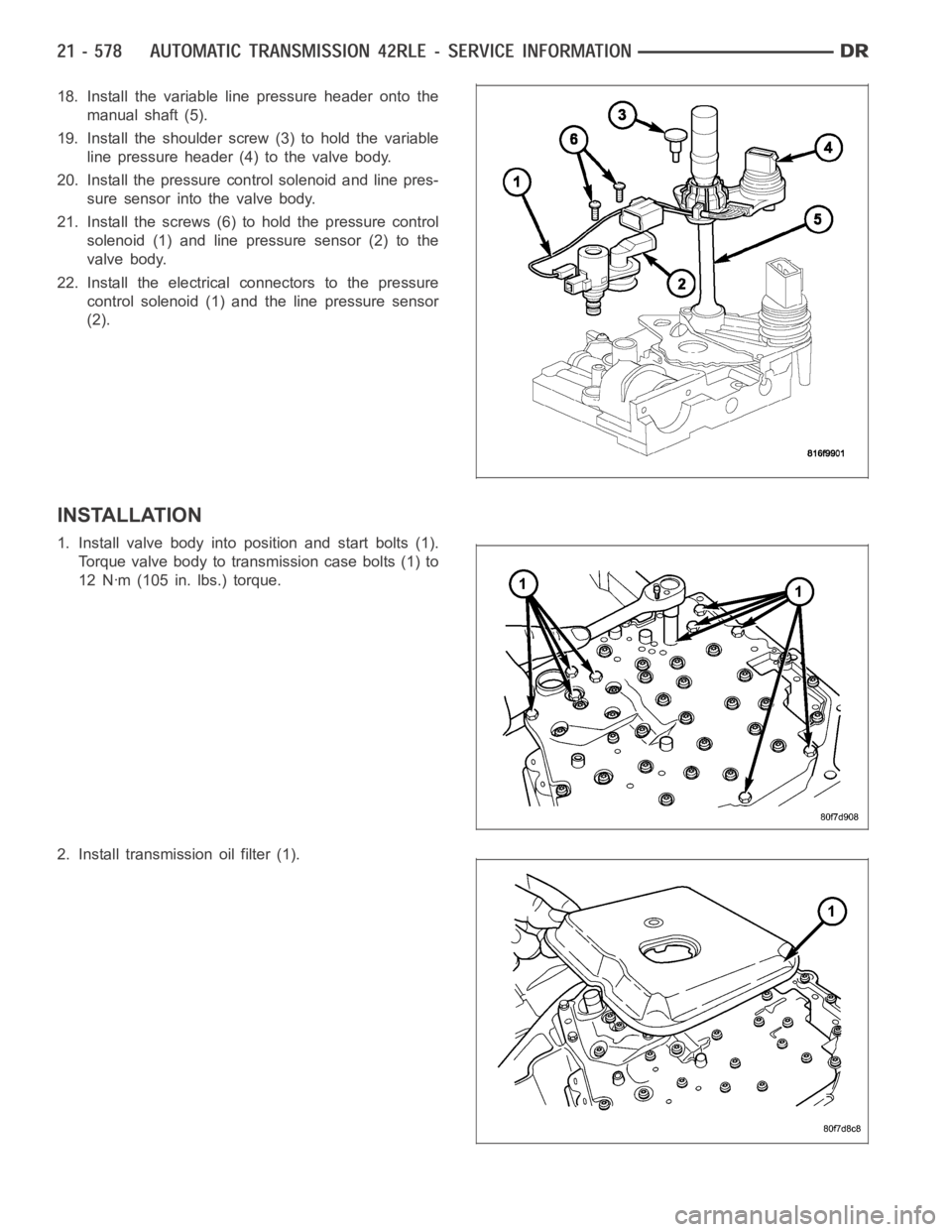

18. Install the variable line pressure header onto the

manual shaft (5).

19. Install the shoulder screw (3) to hold the variable

line pressure header (4) to the valve body.

20. Install the pressure control solenoid and line pres-

sure sensor into the valve body.

21. Install the screws (6) to hold the pressure control

solenoid (1) and line pressure sensor (2) to the

valve body.

22. Install the electrical connectors to the pressure

control solenoid (1) and the line pressure sensor

(2).

INSTALLATION

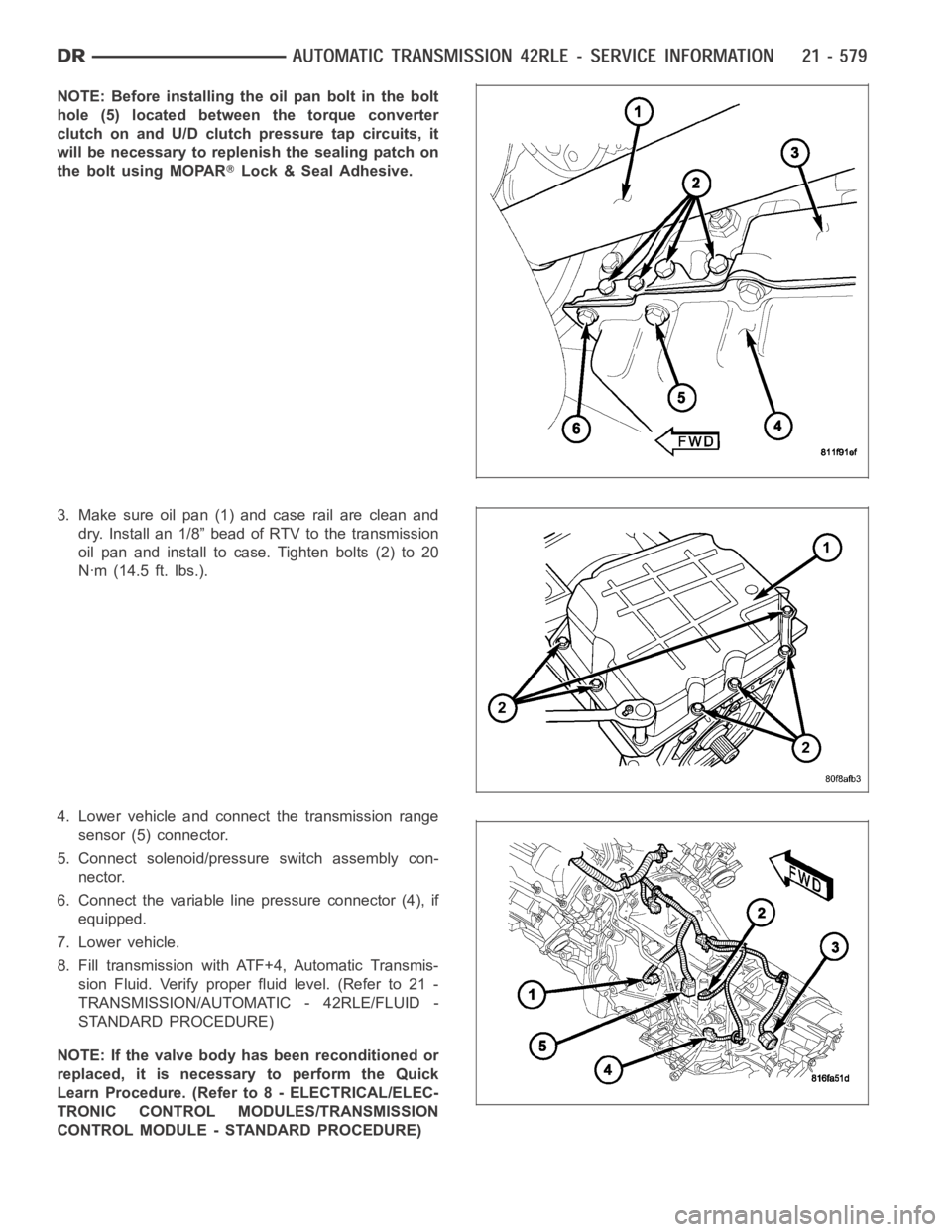

1. Install valve body into position and start bolts (1).

Torque valve body to transmission case bolts (1) to

12 Nꞏm (105 in. lbs.) torque.

2. Install transmission oil filter (1).

Page 3100 of 5267

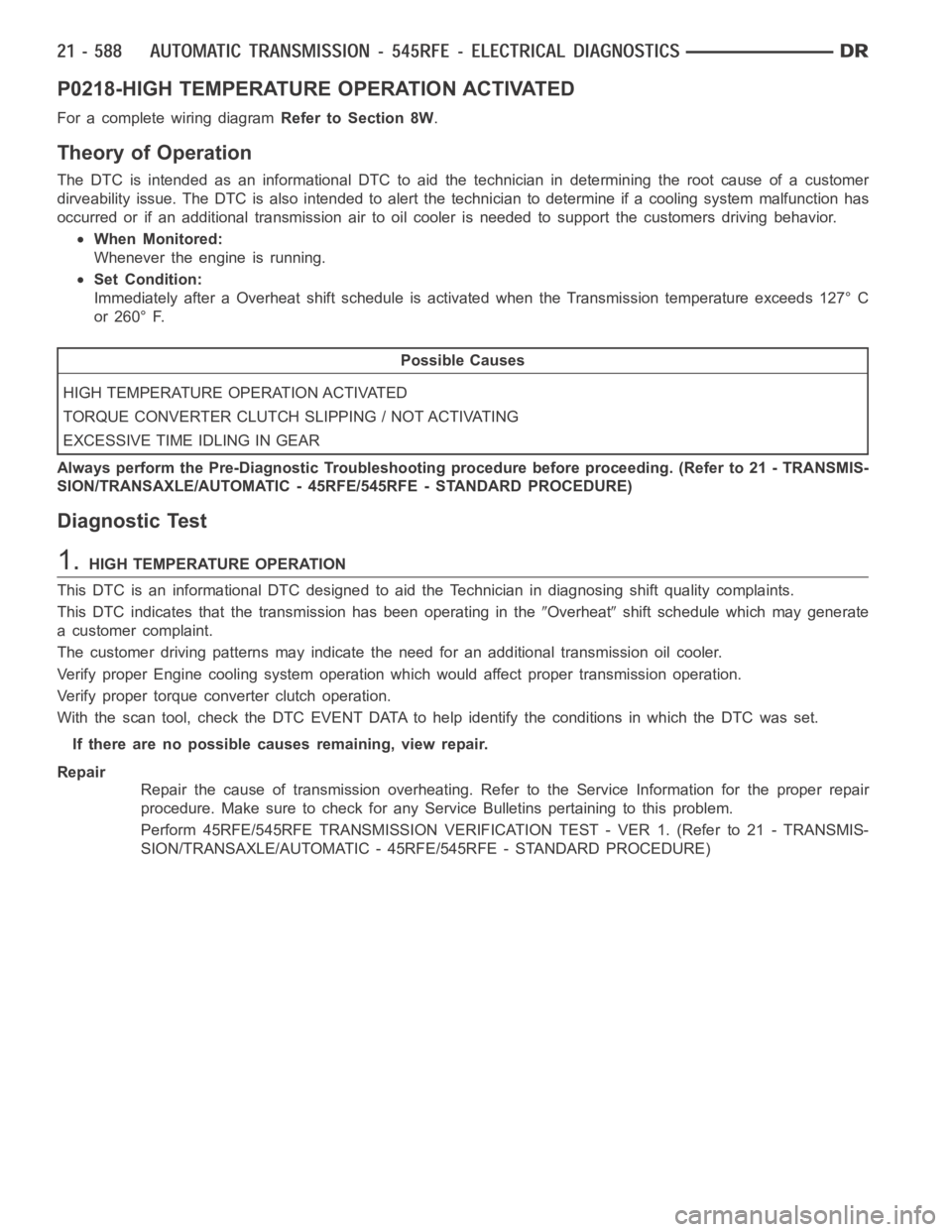

NOTE: Before installing the oil pan bolt in the bolt

hole (5) located between the torque converter

clutch on and U/D clutch pressure tap circuits, it

will be necessary to replenish the sealing patch on

the bolt using MOPAR

Lock & Seal Adhesive.

3. Make sure oil pan (1) and case rail are clean and

dry. Install an 1/8” bead of RTV to the transmission

oil pan and install to case. Tighten bolts (2) to 20

Nꞏm (14.5 ft. lbs.).

4. Lower vehicle and connect the transmission range

sensor (5) connector.

5. Connect solenoid/pressure switch assembly con-

nector.

6. Connect the variable line pressure connector (4), if

equipped.

7. Lower vehicle.

8. Fill transmission with ATF+4, Automatic Transmis-

sion Fluid. Verify proper fluid level. (Refer to 21 -

TRANSMISSION/AUTOMATIC - 42RLE/FLUID -

STANDARD PROCEDURE)

NOTE: If the valve body has been reconditioned or

replaced, it is necessary to perform the Quick

Learn Procedure. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

Page 3109 of 5267

P0218-HIGH TEMPERATURE OPERATION ACTIVATED

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The DTC is intended as an informational DTC to aid the technician in determining the root cause of a customer

dirveability issue. The DTC is also intended to alert the technician to determine if a cooling system malfunction has

occurred or if an additional transmission air to oil cooler is needed to support the customers driving behavior.

When Monitored:

Whenever the engine is running.

Set Condition:

Immediately after a Overheat shift schedule is activated when the Transmission temperature exceeds 127° C

or 260° F.

Possible Causes

H I G H T E M P E R AT U R E O P E R AT I O N A C T I VAT E D

TORQUE CONVERTER CLUTCH SLIPPING / NOT ACTIVATING

EXCESSIVE TIME IDLING IN GEAR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.HIGH TEMPERATURE OPERATION

This DTC is an informational DTC designed to aid the Technician in diagnosing shift quality complaints.

This DTC indicates that the transmission has been operating in the

Overheatshift schedule which may generate

a customer complaint.

The customer driving patterns may indicate the need for an additional transmission oil cooler.

Verify proper Engine cooling system operation which would affect proper transmission operation.

Verify proper torque converter clutch operation.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

If there are no possible causes remaining, view repair.

Repair

Repair the cause of transmission overheating. Refer to the Service Information for the proper repair

procedure. Make sure to check for any Service Bulletins pertaining to thisproblem.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3124 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set when the desired transmission temperature does not reacha normal operating temperature

within a given time frame. Time is variable due to ambient temperature. Approximate times are starting tem-

perature to warm up time: (-40° F / -40° C - 35 min) (-20° F / -28° C - 25 min) (20°F / -6.6° C - 20 min) (60°

F/15.5°C-10min)

Possible Causes

RELATED DTC’S PRESENT

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Temperature Sensor is a variable resistor that changes with temperature, or otherwise known as

a thermister. The temperature of the transmission fluid can affect a variety of electronically controlled transmission

operations such as shift quality, torque converter lock-up, and when and/or if certain OBDII or system self-diagnostic

test are performed. The Powertrain Control Module (PCM) substitutes a calculated transmission temperature value

if a fault is detected in the Transmission Temperature Sensor circuit.

Diagnostic Test

1.DETERMINE IF RELATED DTC’S ARE PRESENT

With the scan tool, check Transmission DTC’s.

Are there any other related Transmission Temperature Sensor DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF DTC IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0711.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 4

3.TRANSMISSION TEMPERATURE SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 3127 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage drops below0.078 volts for the period of

0.45 seconds.

Possible Causes

RELATED DTC’S PRESENT

(T54) TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO GROUND

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Temperature Sensor is a variable resistor that changes with temperature, or otherwise known as

a thermister. The temperature of the transmission fluid can affect a variety of electronically controlled transmission

operations such as shift quality, torque converter lock-up, and when and/or if certain OBDII or system self-diagnostic

test are performed. The Powertrain Control Module (PCM) substitutes a calculated transmission temperature value

if a fault is detected in the Transmission Temperature Sensor circuit.

Diagnostic Test

1.DETERMINE IF RELATED DTC’S ARE PRESENT

With the scan tool, check Transmission DTC’s.

Are there any line pressure sensor or throttle position sensor DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0712.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 5

3.TRANSMISSION TEMPERATURE SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 3130 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage rises above4.94 volts for the period of 0.45

seconds.

Possible Causes

RELATED DTC’S PRESENT

(T54) TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO OTHER CIRCUITS

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Temperature Sensor is a variable resistor that changes with temperature, or otherwise known as

a thermister. The temperature of the transmission fluid can affect a variety of electronically controlled transmission

operations such as shift quality, torque converter lock-up, and when and/or if certain OBDII or system self-diagnostic

test are performed. The Powertrain Control Module (PCM) substitutes a calculated transmission temperature value

if a fault is detected in the Transmission Temperature Sensor circuit.

Diagnostic Test

1.DETERMINE IF RELATED DTC’S ARE PRESENT

With the scan tool, check Transmission DTC’s.

Are there any line pressure sensor or throttle position sensor DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF DTC IS CURRENT

With the scan tool, check the STARTS SINCE SET counter for P0713.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 5

3.TRANSMISSION TEMPERATURE SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 3133 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage fluctuatesor changes abruptly within a pre-

determined period of time.

Possible Causes

RELATED DTC’S PRESENT

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Temperature Sensor is a variable resistor that changes with temperature, or otherwise known as

a thermister. The temperature of the transmission fluid can affect a variety of electronically controlled transmission

operations such as shift quality, torque converter lock-up, and when and/or if certain OBDII or system self-diagnostic

test are performed. The Powertrain Control Module (PCM) substitutes a calculated transmission temperature value

if a fault is detected in the Transmission Temperature Sensor circuit.

Diagnostic Test

1.DETERMINE IF RELATED DTC’S ARE PRESENT

With the scan tool, check Transmission DTC’s.

Are there any line pressure sensor or throttle position sensor DTCs present?

Ye s>> Refer to the Transmission category and perform the appropriate symptom.(Referto21-TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0714.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 4

3.TRANSMISSION TEMPERATURE SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 3174 of 5267

P0740-TCC OUT OF RANGE

For a complete wiring diagramRefer to Section 8W

When Monitored:

During Electronically Modulated Converter Clutch (EMCC) Operation.

Set Condition:

Transmission must be in EMCC, with input speed greater than 1750 RPM. TCC-LR Solenoid achieves the

maximum duty cycle and can not pull engine speed within 60 RPM of input speed. Also when the transmission

is in FEMCC and the engine slips TCC less than 100 RPM for 10 seconds. This DTCcantakeuptofive

minutes of problem identification before illuminating the MIL.

Possible Causes

RELATED DTC P0750 PRESENT

L/R SOLENOID

TCC SWITCH VALVE STUCK

T C C R E G U L AT O R VA LV E S T U C K

INPUT SHAFT SEAL RING CUT

TORQUE CONVERTER AND/OR INTERNAL TRANSMISSION

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

When in 2nd, 2nd Prime, 3rd, 4th or 5th gear, the torque converter clutch (TCC) can be engaged when certain

conditions are met. The TCC piston is electronically modulated by increasing the duty cycle of the LR Solenoid until

the torque converter slip difference (difference between engine and transmission input speed) is within 60 RPM.

Then the LR solenoid is fully energized(FEMCC – 100% duty cycle). Torque converter slip is monitored in FEMCC

to ensure adequate clutch capacity.

Diagnostic Test

1.CHECKFORRELATEDDTCP0750

With the scan tool, read transmission DTCs.

Is the DTC P0750 present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF DTC P0740 IS CURRENT

With the scan tool, Read and RECORD ALL Transmission DTC’s. After recording DTCs, erase DTCs.

Drive the vehicle until the transmission temperature is at least 43° C or 110° F and the engine temperature at least

49° C or 120° F.

Perform the following steps 3 times.

Drive the vehicle to the speed of at least 88 Kmh or 55 mph.

Allow 4th or 5th gear to engage for at least 10 seconds.

Close the throttle.

Tip back into the throttle until the TPS angle is between 25 and 29 degrees.

NOTE: If the throttle angle goes over 30 degrees, you must close the throttleandtryagain.

Did the TCC engage during any of the attempts, Engine speed approximately equal to input speed?

Ye s>>

Go To 3

No>>

Go To 4

Page 3175 of 5267

3.CHECK WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time. Usingthe schematics as a guide, inspect the

wiring and connectors specific to this circuit. Wiggle the wires while checking for shorts and open circuits.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorts and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

4.CHECK THE LR SOLENOID

With the scan tool, check for other transmission DTC’s.

Are the DTCs P1775 and P0841 present also?

Ye s>>

Replace Transmission Solenoid/TRS Assembly per the Service Information. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE/TRANS SOLENOID/TRS ASSY - REMOVAL)

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 5

5.CHECK THE TORQUE CONVERTER AND/OR INTERNAL TRANSMISSION

Repair internal transmission as necessary.

Check for the following possible causes. Refer to the Service informationfor the proper repair procedures.

Inspect the Transmission Oil Pump and Valve Body.

If no problems are found, replace the Transmission Solenoid/TRS Assembly.

Check the Torque Converter Switch Valve and the Torque Converter Clutch Control Valve for sticking in the bore.

Check the Teflon seal rings on the input shaft. Note: If one of the seal ringsis , the loose piece will often lodge in

the TCC switch valve, causing it to stick in it bore.

View repair

Repair

In all cases, replace the Torque Converter. Make sure to check all other possible causes in addition to

the Torque Converter.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3219 of 5267

When Monitored:

Continuously while driving in a forward gear.

Set Condition:

The PCM continuously monitors Actual Line Pressure and compares it to DesiredLinePressure.IftheActual

Line Pressure is more than 10 psi below Desired Line Pressure, this DTC willset.

Possible Causes

CHECK FOR RELATED DTC’S

LOW FLUID LEVEL

(F856) 5-VOLT SUPPLY CIRCUIT OPEN

POOR LINE PRESSURE SENSOR CONNECTION

(F856) 5-VOLT SUPPLY CIRCUIT SHORT TO GROUND

(F856) 5-VOLT SUPPLY CIRCUIT SHORT TO VOLTAGE

(T118) PRESSURE CONTROL SOLENOID CONTROL CIRCUIT SHORT TO ANOTHER CIRCUIT

INTERNAL TRANSMISSION

LINE PRESSURE SENSOR

CRACKED, PLUGGED, OR MISINSTALLED PRIMARY OIL FILTER

STUCK OR STICKING MAIN REGULATOR VALVE

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is measured by the Line Pressure Sensor (LPS) and regulationis achieved by changing the duty

cycle of the Pressure Control Solenoid (PCS) controlled by the Transmission Control System. (5% duty cycle =

solenoid off = Max line pressure, 62%duty cycle = solenoid on = Min line pressure). The Transmission Control

System calculates the desired line pressure based on inputs from both the engine and transmission.

The Transmission Control System calculates torque input to the transmission and uses it as the primary input to the

desired line pressure calculation. This is called Torque Based Line Pressure. In addition, the line pressure is set to

a preset level 827 or 931kPa (120 or 135 psi) during shifts and in Park and Neutral to ensure consistent shift qual-

ity. The desired line pressure is continuously being compared to the actual line pressure. If the actual line pressure

is consistently lower than the target while driving, the line pressure lowDTC P0868 will set.

Diagnostic Test

1.CHECKFORRELATEDDTCS

With the scan tool, check for other transmission DTCs

Is the DTC P0932 present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2