ECU DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5146 of 5267

CONDENSER-A/C

DESCRIPTION

The A/C condenser is located in the front of the engine compartment behind the grille. The A/C condenser is a heat

exchanger that allows the high-pressure refrigerant gas being dischargedbytheA/Ccompressortogiveupitsheat

to the air passing over the condenser fins, which causes the refrigerant tocool and change to a liquid state.

OPERATION

When air passes through the fins of the A/C condenser, the high-pressure refrigerant gas within the A/C condenser

gives up its heat. The refrigerant then condenses as it leaves the A/C condenser and becomes a high-pressure

liquid. The volume of air flowing over the condenser fins is critical to theproper cooling performance of the A/C

system. Therefore, it is important that there are no objects placed in front of the radiator grille openings at the front

of the vehicle or foreign material on the condenser fins that might obstruct proper air flow. Also, any factory-installed

air seals or shrouds must be properly reinstalled following radiator or A/C condenser service.

The A/C condenser cannot be repaired and, if faulty or damaged, it must be replaced.

REMOVAL

3.7L/4.7L/5.7L ENGINES

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

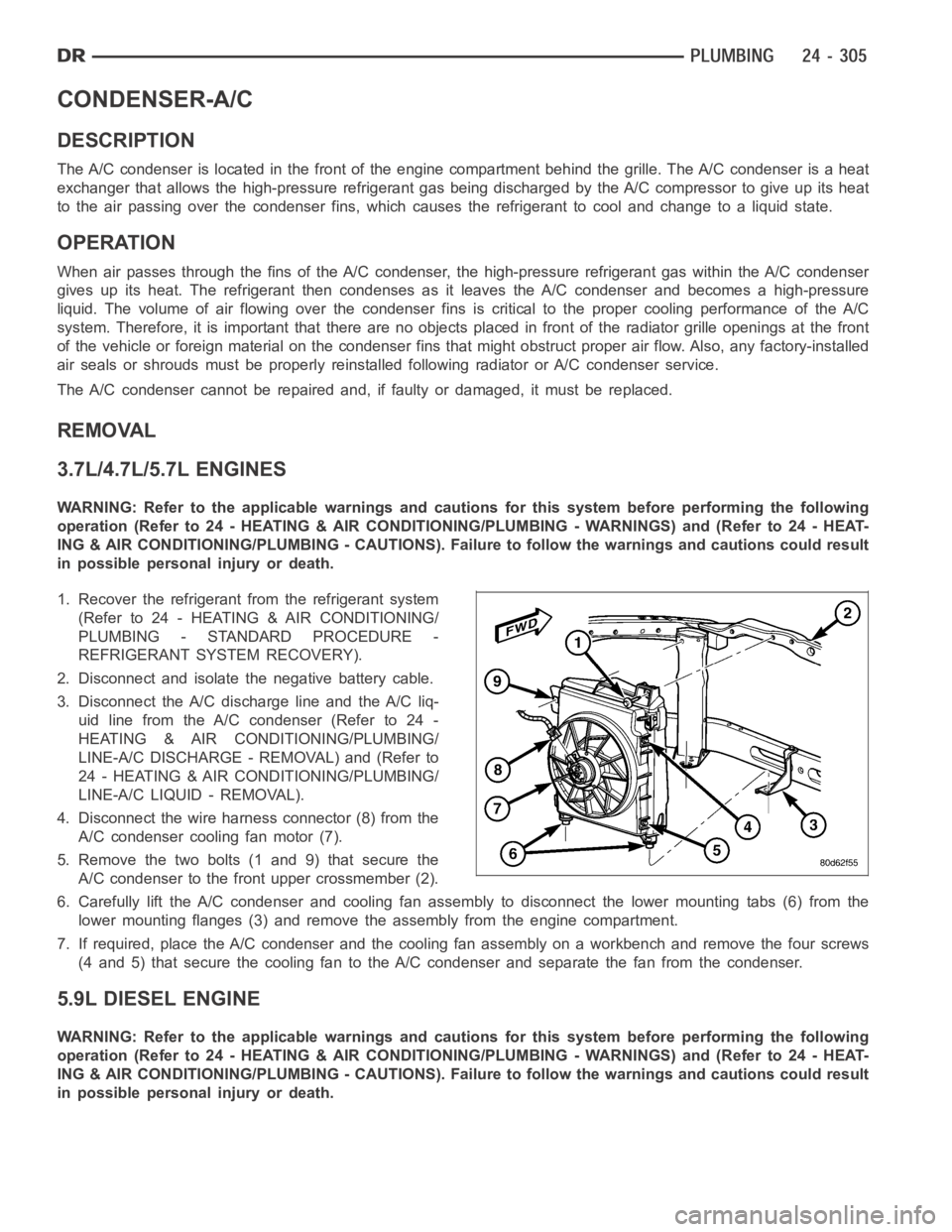

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Disconnect the A/C discharge line and the A/C liq-

uidlinefromtheA/Ccondenser(Referto24-

HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C DISCHARGE - REMOVAL) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C LIQUID - REMOVAL).

4. Disconnect the wire harness connector (8) from the

A/C condenser cooling fan motor (7).

5. Remove the two bolts (1 and 9) that secure the

A/C condenser to the front upper crossmember (2).

6. Carefully lift the A/C condenser and cooling fan assembly to disconnectthe lower mounting tabs (6) from the

lower mounting flanges (3) and remove the assembly from the engine compartment.

7. If required, place the A/C condenser and the cooling fan assembly on a workbench and remove the four screws

(4 and 5) that secure the cooling fan to the A/C condenser and separate the fan from the condenser.

5.9L DIESEL ENGINE

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

Page 5147 of 5267

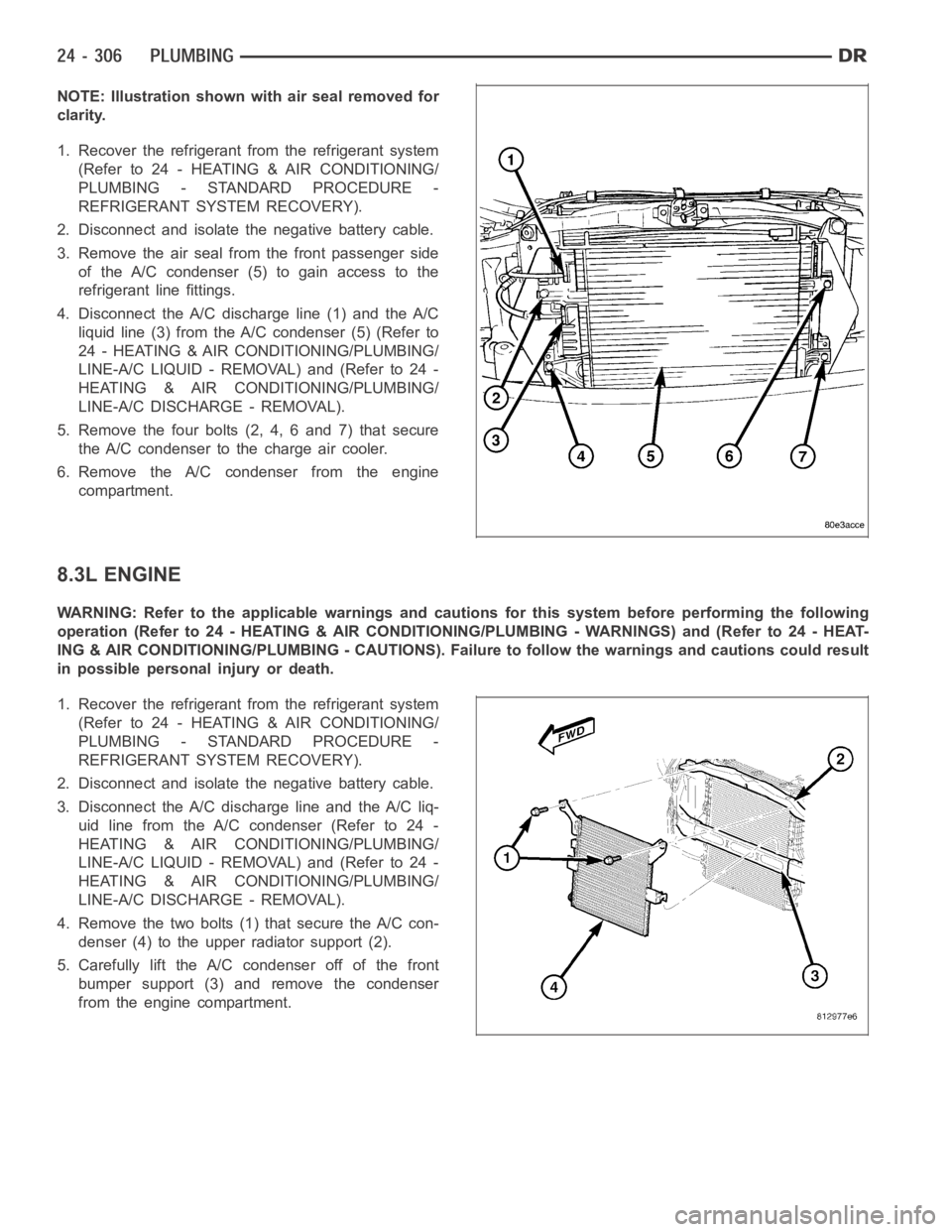

NOTE: Illustration shown with air seal removed for

clarity.

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Remove the air seal from the front passenger side

of the A/C condenser (5) to gain access to the

refrigerant line fittings.

4. Disconnect the A/C discharge line (1) and the A/C

liquid line (3) from the A/C condenser (5) (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C LIQUID - REMOVAL) and (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C DISCHARGE - REMOVAL).

5. Remove the four bolts (2, 4, 6 and 7) that secure

the A/C condenser to the charge air cooler.

6. Remove the A/C condenser from the engine

compartment.

8.3L ENGINE

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Disconnect the A/C discharge line and the A/C liq-

uidlinefromtheA/Ccondenser(Referto24-

HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C LIQUID - REMOVAL) and (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C DISCHARGE - REMOVAL).

4. Remove the two bolts (1) that secure the A/C con-

denser (4) to the upper radiator support (2).

5. Carefully lift the A/C condenser off of the front

bumper support (3) and remove the condenser

from the engine compartment.

Page 5148 of 5267

INSTALLATION

3.7L/4.7L/5.7L ENGINES

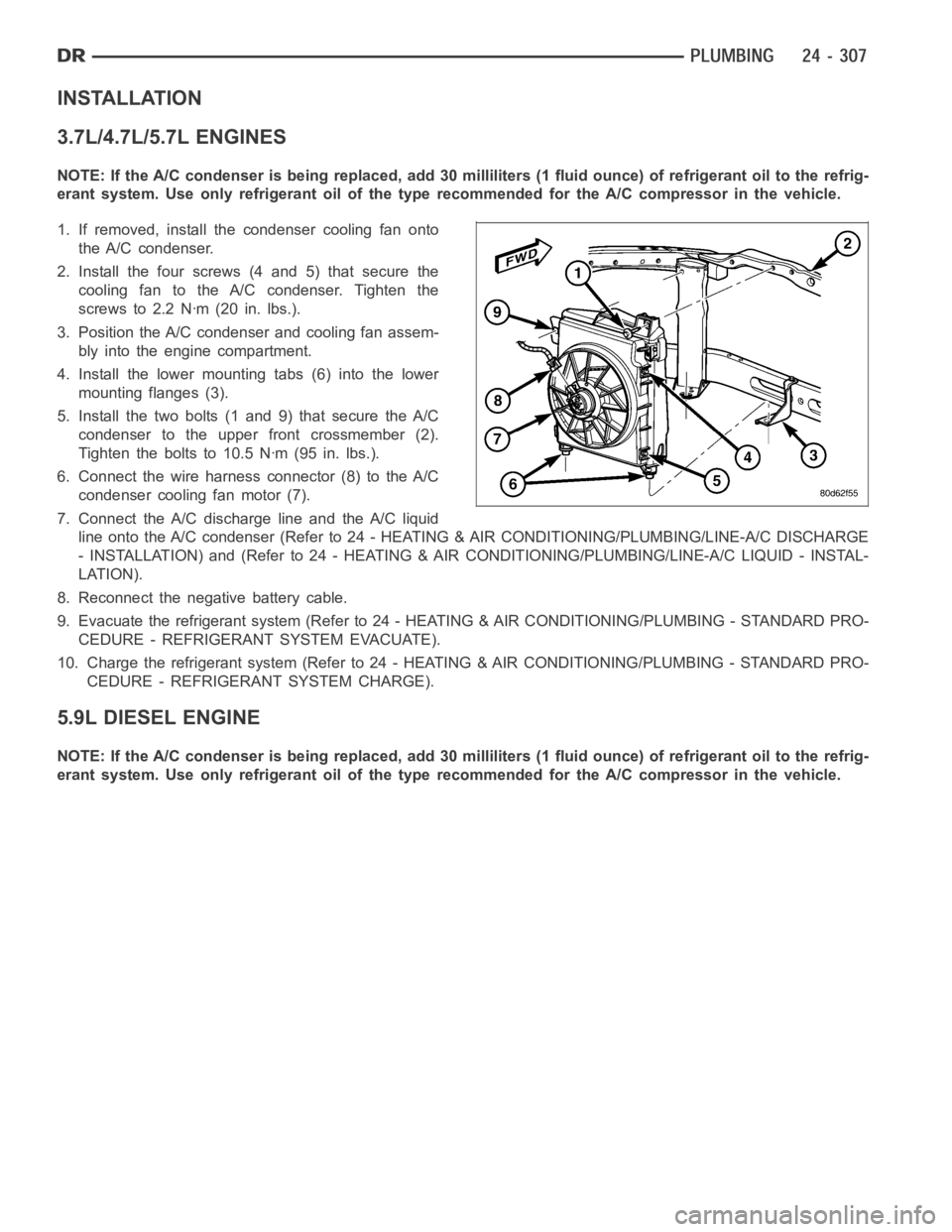

NOTE: If the A/C condenser is being replaced, add 30 milliliters (1 fluid ounce) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type recommended for the A/C compressor in the vehicle.

1. If removed, install the condenser cooling fan onto

the A/C condenser.

2. Install the four screws (4 and 5) that secure the

cooling fan to the A/C condenser. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

3. Position the A/C condenser and cooling fan assem-

bly into the engine compartment.

4. Install the lower mounting tabs (6) into the lower

mounting flanges (3).

5. Install the two bolts (1 and 9) that secure the A/C

condenser to the upper front crossmember (2).

Tighten the bolts to 10.5 Nꞏm (95 in. lbs.).

6. Connect the wire harness connector (8) to the A/C

condenser cooling fan motor (7).

7. Connect the A/C discharge line and the A/C liquid

line onto the A/C condenser (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C DISCHARGE

- INSTALLATION) and (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C LIQUID - INSTAL-

LATION).

8. Reconnect the negative battery cable.

9. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE).

10. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

5.9L DIESEL ENGINE

NOTE: If the A/C condenser is being replaced, add 30 milliliters (1 fluid ounce) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type recommended for the A/C compressor in the vehicle.

Page 5149 of 5267

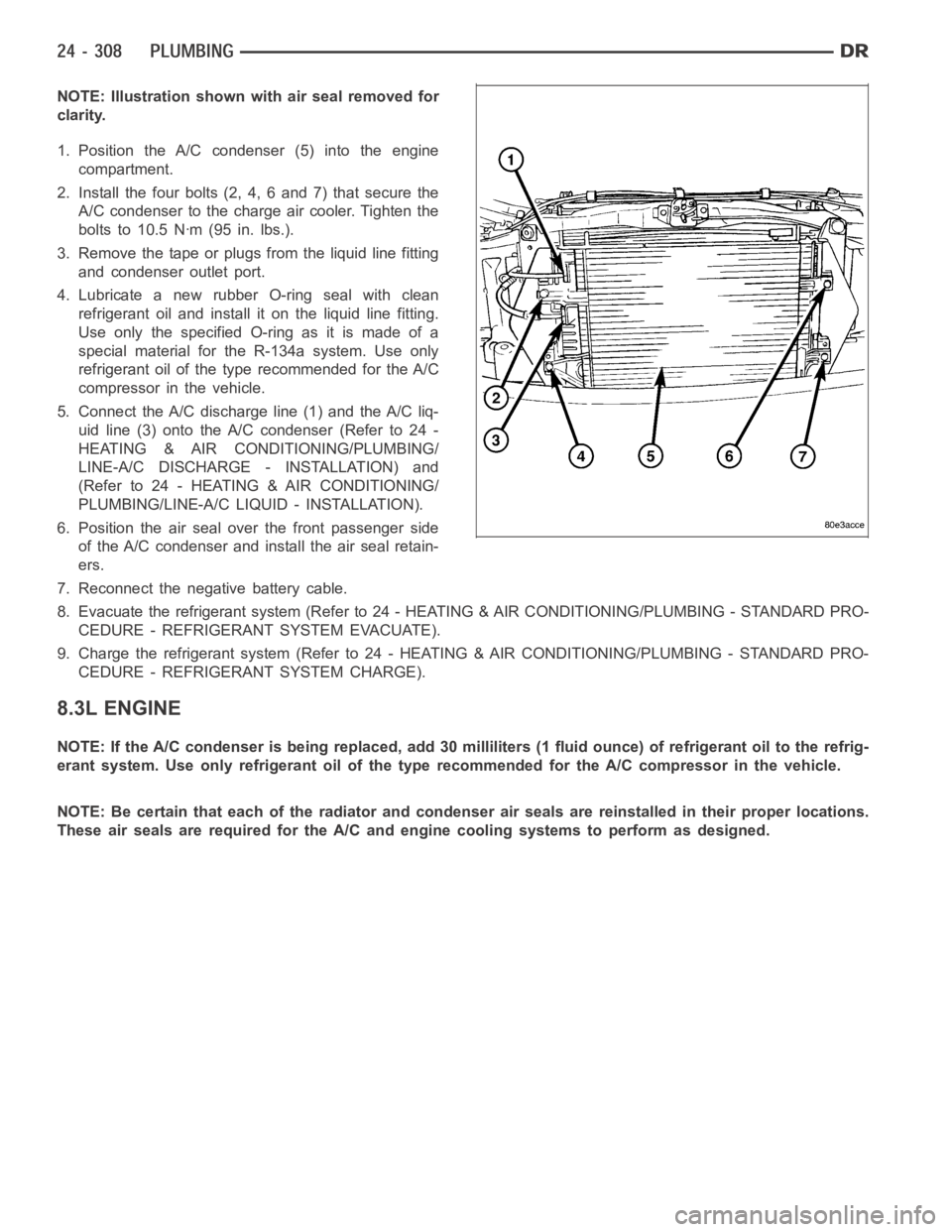

NOTE: Illustration shown with air seal removed for

clarity.

1. Position the A/C condenser (5) into the engine

compartment.

2. Install the four bolts (2, 4, 6 and 7) that secure the

A/C condenser to the charge air cooler. Tighten the

bolts to 10.5 Nꞏm (95 in. lbs.).

3. Remove the tape or plugs from the liquid line fitting

and condenser outlet port.

4. Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

UseonlythespecifiedO-ringasitismadeofa

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

5. Connect the A/C discharge line (1) and the A/C liq-

uid line (3) onto the A/C condenser (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C DISCHARGE - INSTALLATION) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/LINE-A/C LIQUID - INSTALLATION).

6. Position the air seal over the front passenger side

of the A/C condenser and install the air seal retain-

ers.

7. Reconnect the negative battery cable.

8. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE).

9. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

8.3L ENGINE

NOTE: If the A/C condenser is being replaced, add 30 milliliters (1 fluid ounce) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type recommended for the A/C compressor in the vehicle.

NOTE: Be certain that each of the radiator and condenser air seals are reinstalled in their proper locations.

These air seals are required for the A/C and engine cooling systems to perform as designed.

Page 5150 of 5267

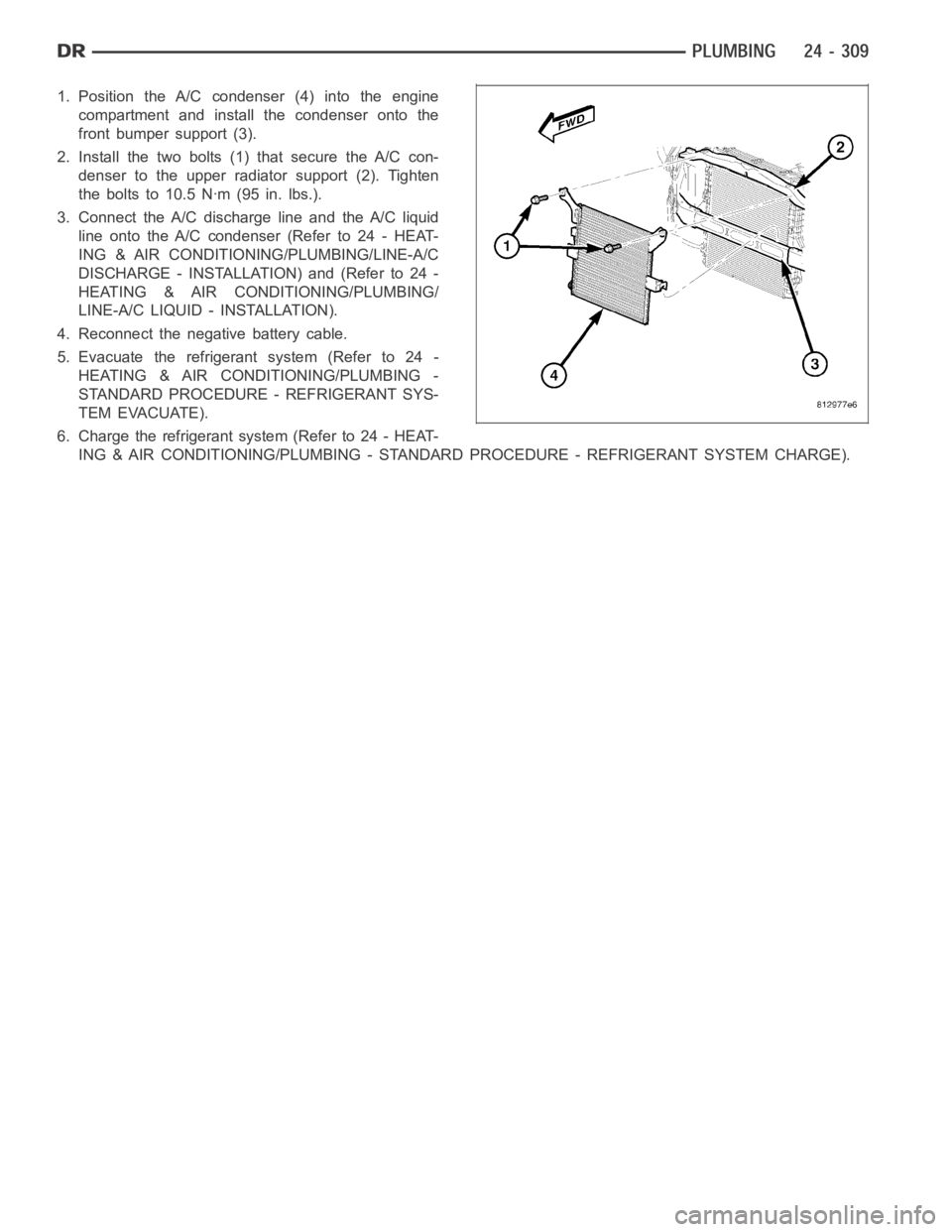

1. Position the A/C condenser (4) into the engine

compartment and install the condenser onto the

front bumper support (3).

2. Install the two bolts (1) that secure the A/C con-

denser to the upper radiator support (2). Tighten

the bolts to 10.5 Nꞏm (95 in. lbs.).

3. Connect the A/C discharge line and the A/C liquid

line onto the A/C condenser(Referto24-HEAT-

ING & AIR CONDITIONING/PLUMBING/LINE-A/C

DISCHARGE - INSTALLATION) and (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C LIQUID - INSTALLATION).

4. Reconnect the negative battery cable.

5. Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

6. Charge the refrigerant system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STANDARD PROCEDURE - REFRIGERANT SYSTEM CHARGE).

Page 5151 of 5267

CORE-HEATER

DESCRIPTION

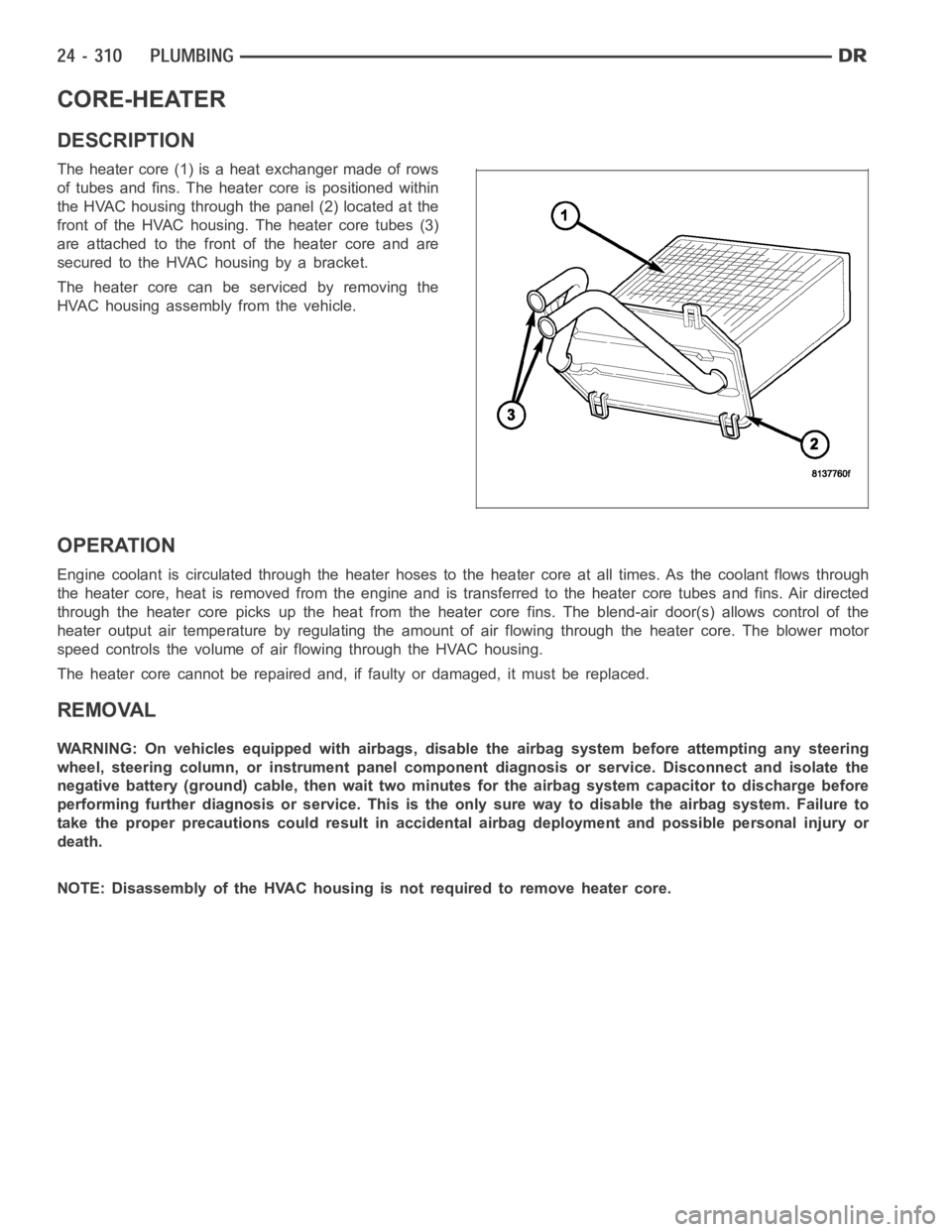

The heater core (1) is a heat exchanger made of rows

of tubes and fins. The heater core is positioned within

the HVAC housing through the panel (2) located at the

front of the HVAC housing. The heater core tubes (3)

are attached to the front of the heater core and are

secured to the HVAC housing by a bracket.

The heater core can be serviced by removing the

HVAC housing assembly from the vehicle.

OPERATION

Engine coolant is circulated through the heater hoses to the heater core atall times. As the coolant flows through

the heater core, heat is removed from the engine and is transferred to the heater core tubes and fins. Air directed

through the heater core picks up the heat from the heater core fins. The blend-air door(s) allows control of the

heater output air temperature by regulating the amount of air flowing through the heater core. The blower motor

speed controls the volume of air flowing through the HVAC housing.

The heater core cannot be repaired and, if faulty or damaged, it must be replaced.

REMOVAL

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

negative battery (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. This is the only sure way to disable the airbag system. Failure to

take the proper precautions could result in accidental airbag deploymentand possible personal injury or

death.

NOTE: Disassembly of the HVAC housing is not required to remove heater core.

Page 5152 of 5267

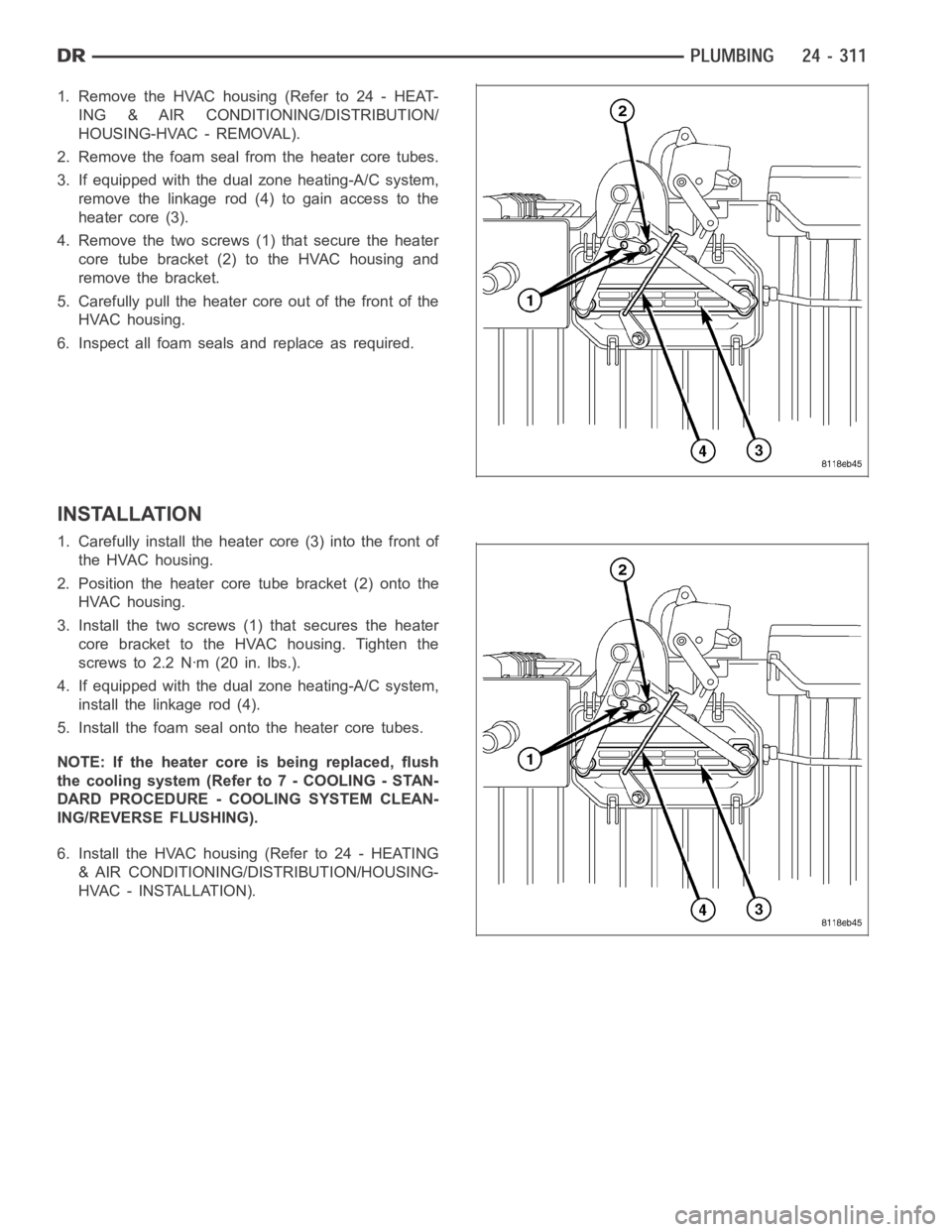

1. RemovetheHVAChousing(Referto24-HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/

HOUSING-HVAC - REMOVAL).

2. Remove the foam seal from the heater core tubes.

3. If equipped with the dual zone heating-A/C system,

remove the linkage rod (4) to gain access to the

heater core (3).

4. Remove the two screws (1) that secure the heater

core tube bracket (2) to the HVAC housing and

remove the bracket.

5. Carefully pull the heater core out of the front of the

HVAC housing.

6. Inspect all foam seals and replace as required.

INSTALLATION

1. Carefully install the heater core (3) into the front of

the HVAC housing.

2. Position the heater core tube bracket (2) onto the

HVAC housing.

3. Install the two screws (1) that secures the heater

core bracket to the HVAC housing. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

4. If equipped with the dual zone heating-A/C system,

install the linkage rod (4).

5. Install the foam seal onto the heater core tubes.

NOTE: If the heater core is being replaced, flush

the cooling system (Refer to 7 - COOLING - STAN-

DARD PROCEDURE - COOLING SYSTEM CLEAN-

ING/REVERSE FLUSHING).

6. Install the HVAC housing (Refer to 24 - HEATING

& AIR CONDITIONING/DISTRIBUTION/HOUSING-

HVAC - INSTALLATION).

Page 5161 of 5267

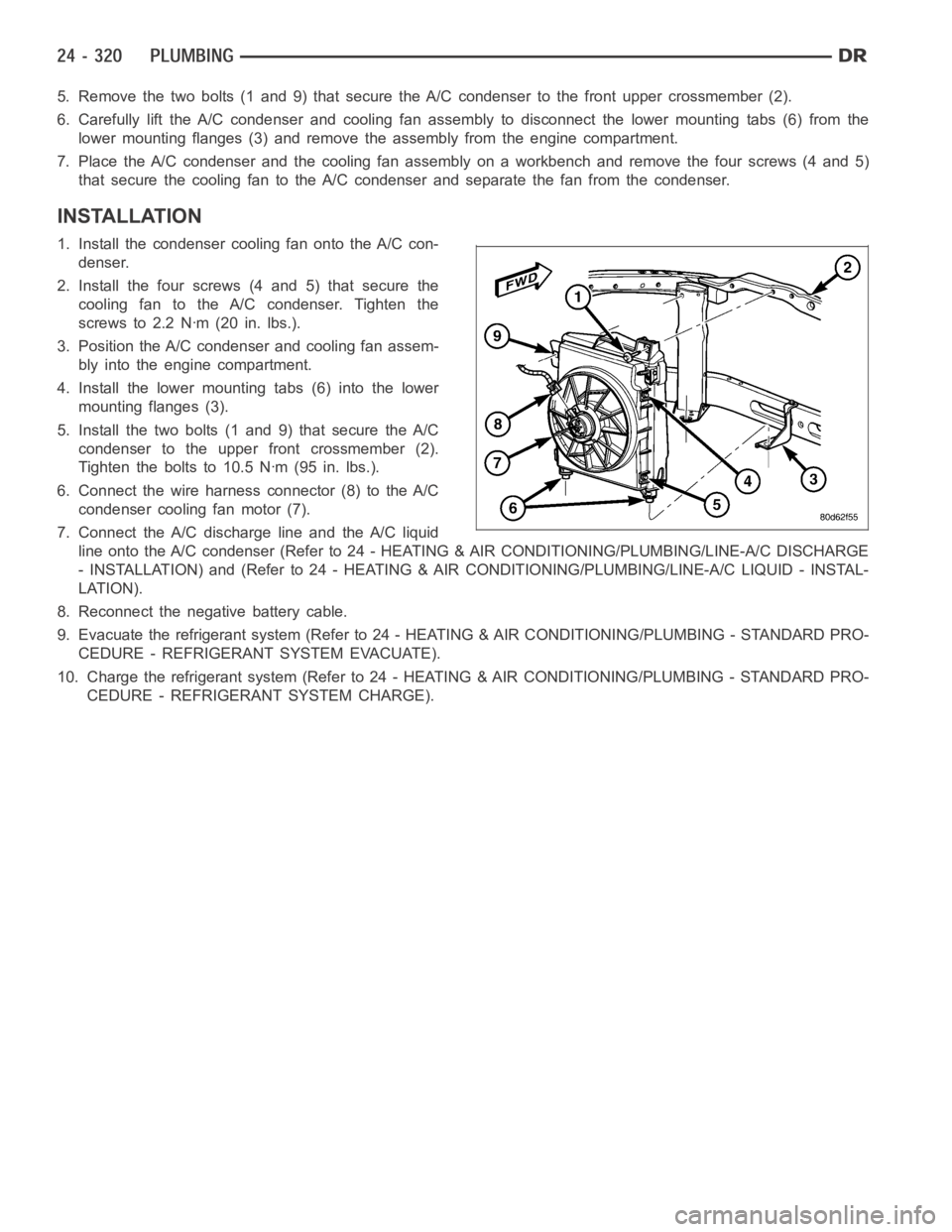

5. Remove the two bolts (1 and 9) that secure the A/C condenser to the front upper crossmember (2).

6. Carefully lift the A/C condenser and cooling fan assembly to disconnectthe lower mounting tabs (6) from the

lower mounting flanges (3) and remove the assembly from the engine compartment.

7. Place the A/C condenser and the cooling fan assembly on a workbench and remove the four screws (4 and 5)

that secure the cooling fan to the A/C condenser and separate the fan from the condenser.

INSTALLATION

1. Install the condenser cooling fan onto the A/C con-

denser.

2. Install the four screws (4 and 5) that secure the

cooling fan to the A/C condenser. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

3. Position the A/C condenser and cooling fan assem-

bly into the engine compartment.

4. Install the lower mounting tabs (6) into the lower

mounting flanges (3).

5. Install the two bolts (1 and 9) that secure the A/C

condenser to the upper front crossmember (2).

Tighten the bolts to 10.5 Nꞏm (95 in. lbs.).

6. Connect the wire harness connector (8) to the A/C

condenser cooling fan motor (7).

7. Connect the A/C discharge line and the A/C liquid

line onto the A/C condenser (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C DISCHARGE

- INSTALLATION) and (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C LIQUID - INSTAL-

LATION).

8. Reconnect the negative battery cable.

9. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE).

10. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

Page 5162 of 5267

LINE-A/C DISCHARGE

DESCRIPTION

The A/C discharge line is the refrigerant line that goes from the A/C compressor to the A/C condenser and has an

integral fitting for the A/C pressure transducer (Refer to 24 - HEATING & AIR CONDITIONING/CONTROLS/TRANS-

DUCER-A/C PRESSURE - DESCRIPTION).

The A/C discharge line for the 5.9L Diesel engine is serviced as an assemblywith the suction line.

The A/C discharge line for the 8.3L engine is secured to the top of fan shroudby two retainers.

CAUTION: Use only O-ring seals specified for the vehicle. Failure to use correct O-ring seal will cause the

refrigerant system connection to leak.

The A/C discharge line has no serviceable parts except the rubber O-ring seals. The O-ring seals used on the

connections are made from a special type of rubber not affected by R-134a refrigerant. The O-ring seals must be

replaced whenever the A/C discharge line is removed and installed.

If the A/C discharge line is found to be leaking or is damaged, it must be replaced.

REMOVAL

3.7L/4.7L ENGINES

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

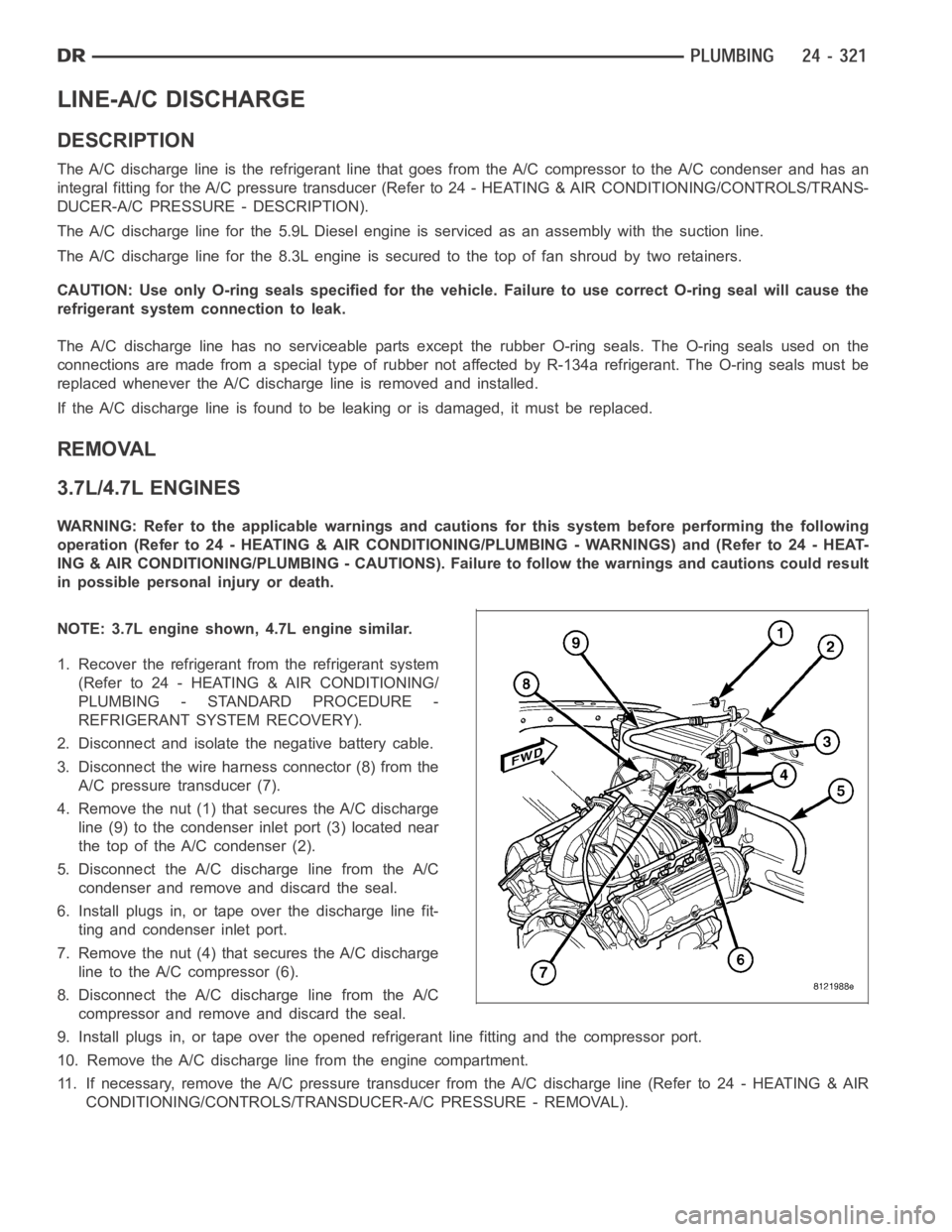

NOTE: 3.7L engine shown, 4.7L engine similar.

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Disconnect the wire harness connector (8) from the

A/C pressure transducer (7).

4. Remove the nut (1) that secures the A/C discharge

line (9) to the condenser inlet port (3) located near

the top of the A/C condenser (2).

5. Disconnect the A/C discharge line from the A/C

condenser and remove and discard the seal.

6. Install plugs in, or tape over the discharge line fit-

ting and condenser inlet port.

7. Remove the nut (4) that secures the A/C discharge

line to the A/C compressor (6).

8. Disconnect the A/C discharge line from the A/C

compressor and remove and discard the seal.

9. Install plugs in, or tape over the opened refrigerant line fitting and the compressor port.

10. Remove the A/C discharge line from the engine compartment.

11. If necessary, remove the A/C pressure transducer from the A/C dischargeline(Referto24-HEATING&AIR

CONDITIONING/CONTROLS/TRANSDUCER-A/C PRESSURE - REMOVAL).

Page 5163 of 5267

5.7L ENGINE

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

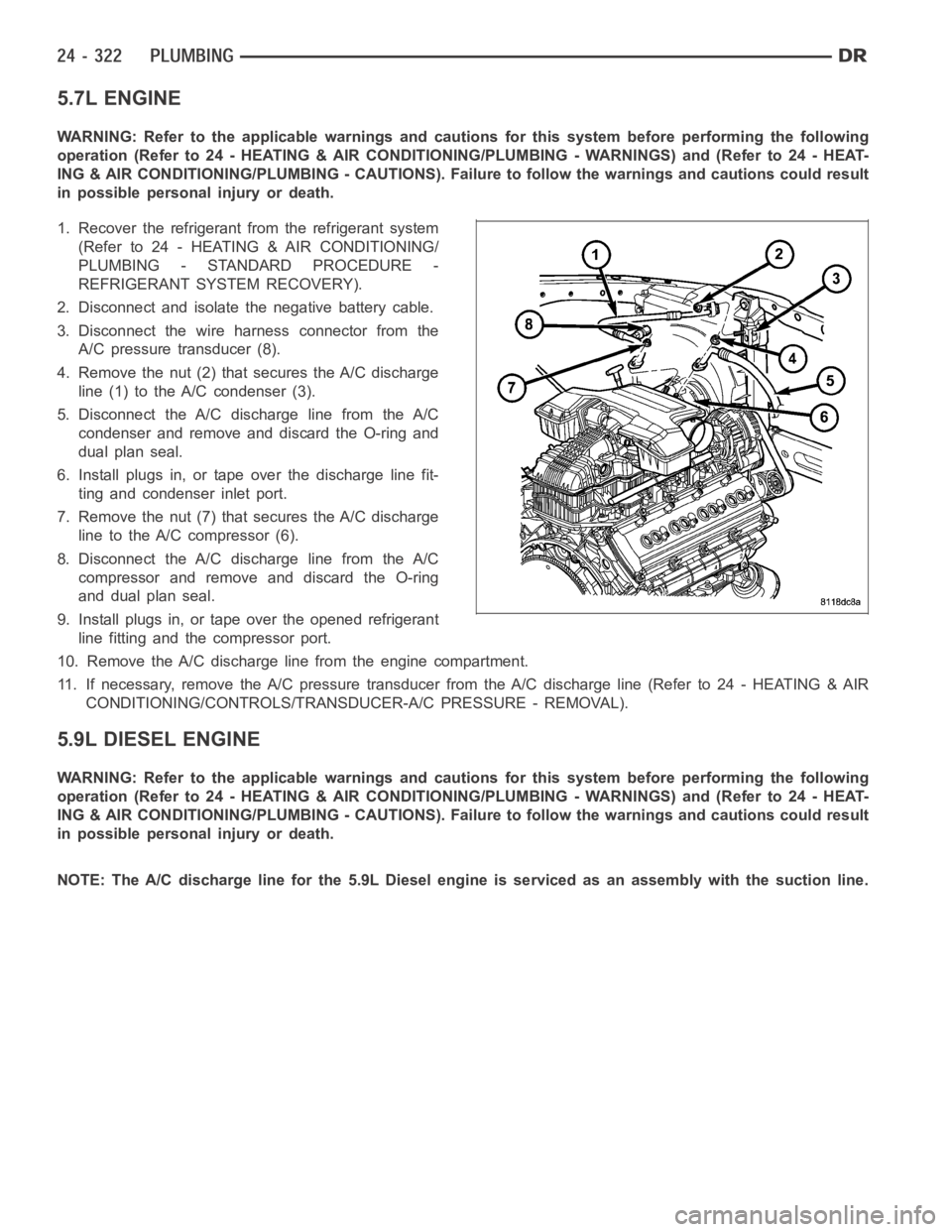

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Disconnect the wire harness connector from the

A/C pressure transducer (8).

4. Remove the nut (2) that secures the A/C discharge

line (1) to the A/C condenser (3).

5. Disconnect the A/C discharge line from the A/C

condenser and remove and discard the O-ring and

dual plan seal.

6. Install plugs in, or tape over the discharge line fit-

ting and condenser inlet port.

7. Remove the nut (7) that secures the A/C discharge

line to the A/C compressor (6).

8. Disconnect the A/C discharge line from the A/C

compressor and remove and discard the O-ring

and dual plan seal.

9. Install plugs in, or tape over the opened refrigerant

line fitting and the compressor port.

10. Remove the A/C discharge line from the engine compartment.

11. If necessary, remove the A/C pressure transducer from the A/C dischargeline(Referto24-HEATING&AIR

CONDITIONING/CONTROLS/TRANSDUCER-A/C PRESSURE - REMOVAL).

5.9L DIESEL ENGINE

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

NOTE: The A/C discharge line for the 5.9L Diesel engine is serviced as an assembly with the suction line.