ECU DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5114 of 5267

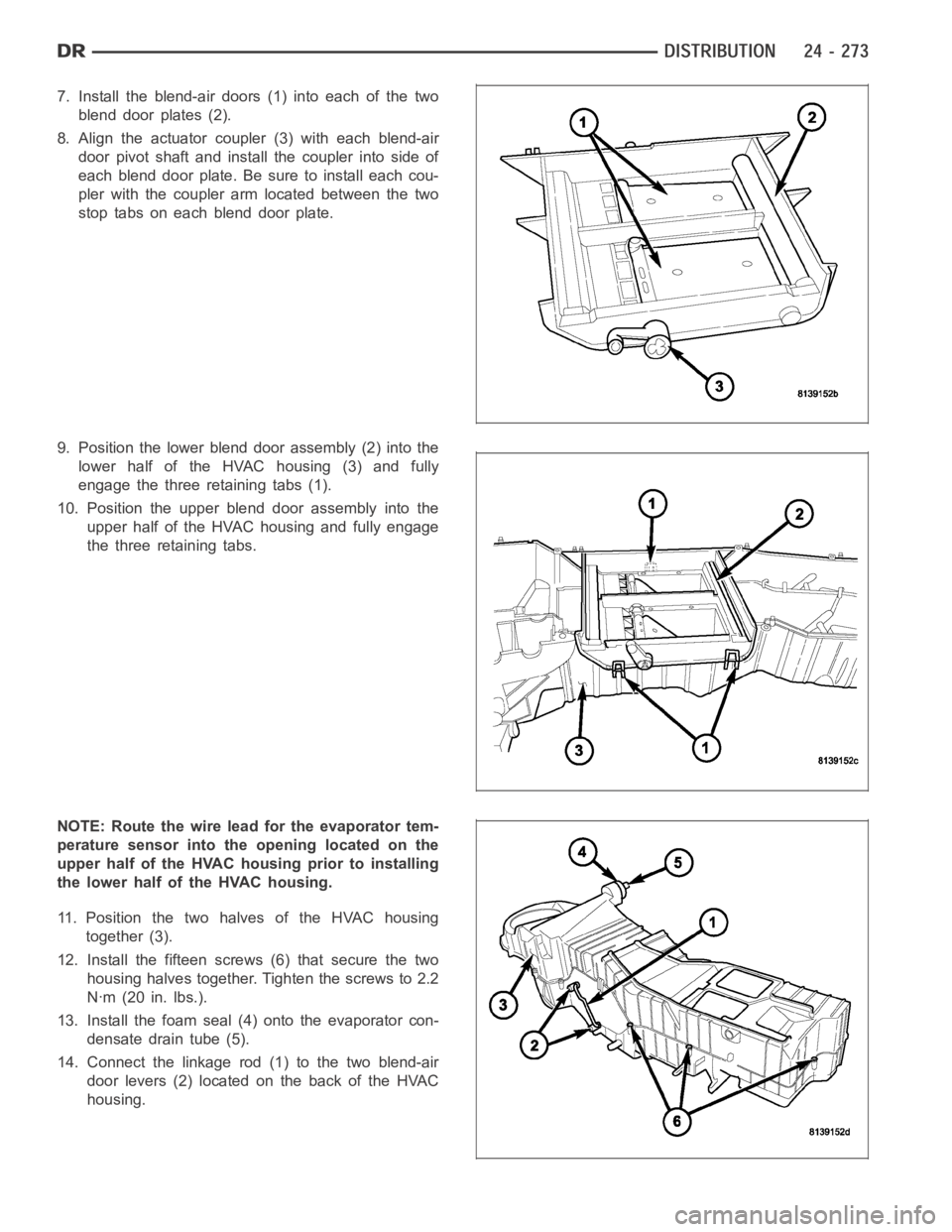

7. Install the blend-air doors (1) into each of the two

blend door plates (2).

8. Align the actuator coupler (3) with each blend-air

door pivot shaft and install the coupler into side of

each blend door plate. Be sure to install each cou-

pler with the coupler arm located between the two

stop tabs on each blend door plate.

9. Position the lower blend door assembly (2) into the

lower half of the HVAC housing (3) and fully

engage the three retaining tabs (1).

10. Position the upper blend door assembly into the

upper half of the HVAC housing and fully engage

the three retaining tabs.

NOTE: Route the wire lead for the evaporator tem-

perature sensor into the opening located on the

upper half of the HVAC housing prior to installing

the lower half of the HVAC housing.

11. Position the two halves of the HVAC housing

together (3).

12. Install the fifteen screws (6) that secure the two

housing halves together. Tighten the screws to 2.2

Nꞏm (20 in. lbs.).

13. Install the foam seal (4) onto the evaporator con-

densate drain tube (5).

14. Connect the linkage rod (1) to the two blend-air

door levers (2) located on the back of the HVAC

housing.

Page 5115 of 5267

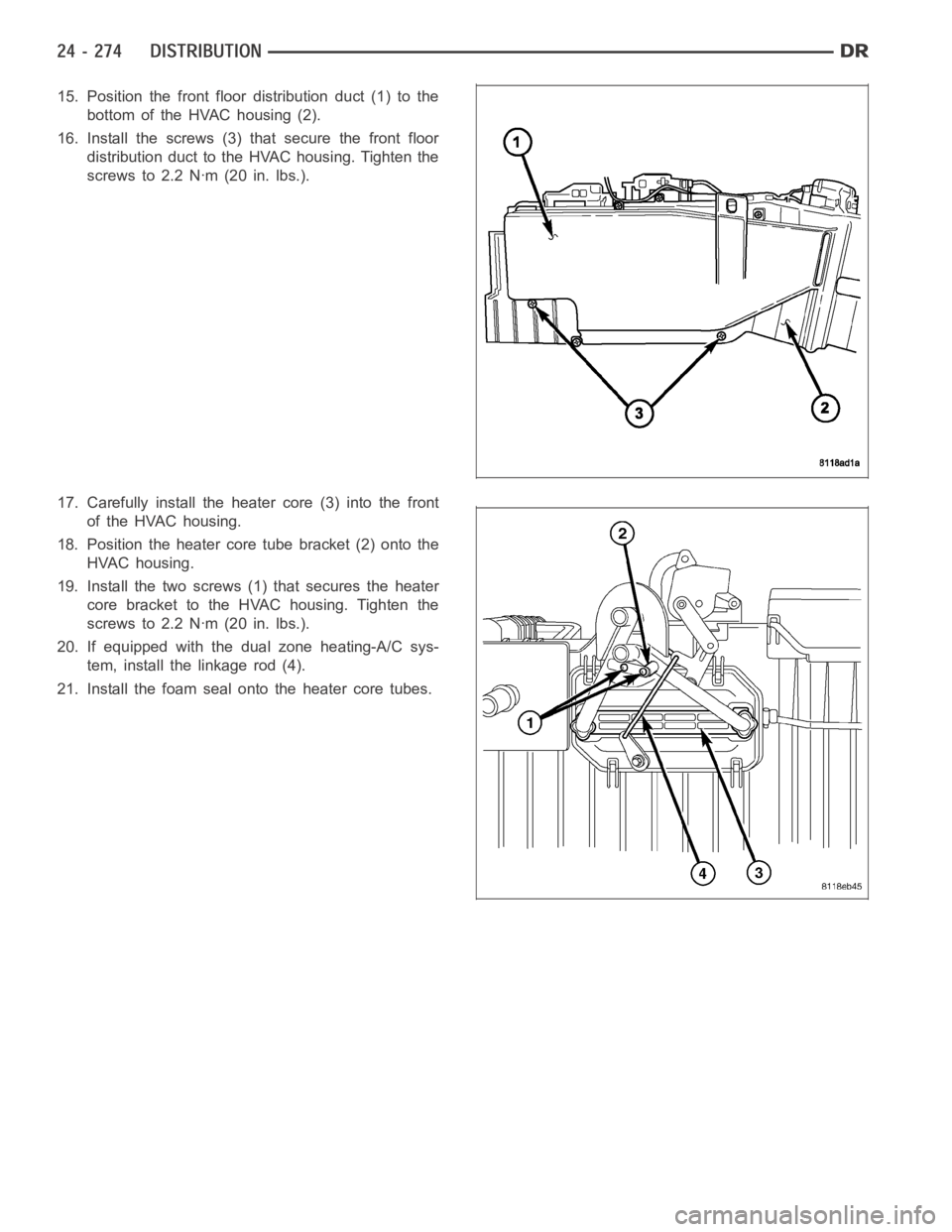

15. Position the front floor distribution duct (1) to the

bottom of the HVAC housing (2).

16. Install the screws (3) that secure the front floor

distribution duct to the HVAC housing. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

17. Carefully install the heater core (3) into the front

of the HVAC housing.

18. Position the heater core tube bracket (2) onto the

HVAC housing.

19. Install the two screws (1) that secures the heater

core bracket to the HVAC housing. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

20. If equipped with the dual zone heating-A/C sys-

tem, install the linkage rod (4).

21. Install the foam seal onto the heater core tubes.

Page 5116 of 5267

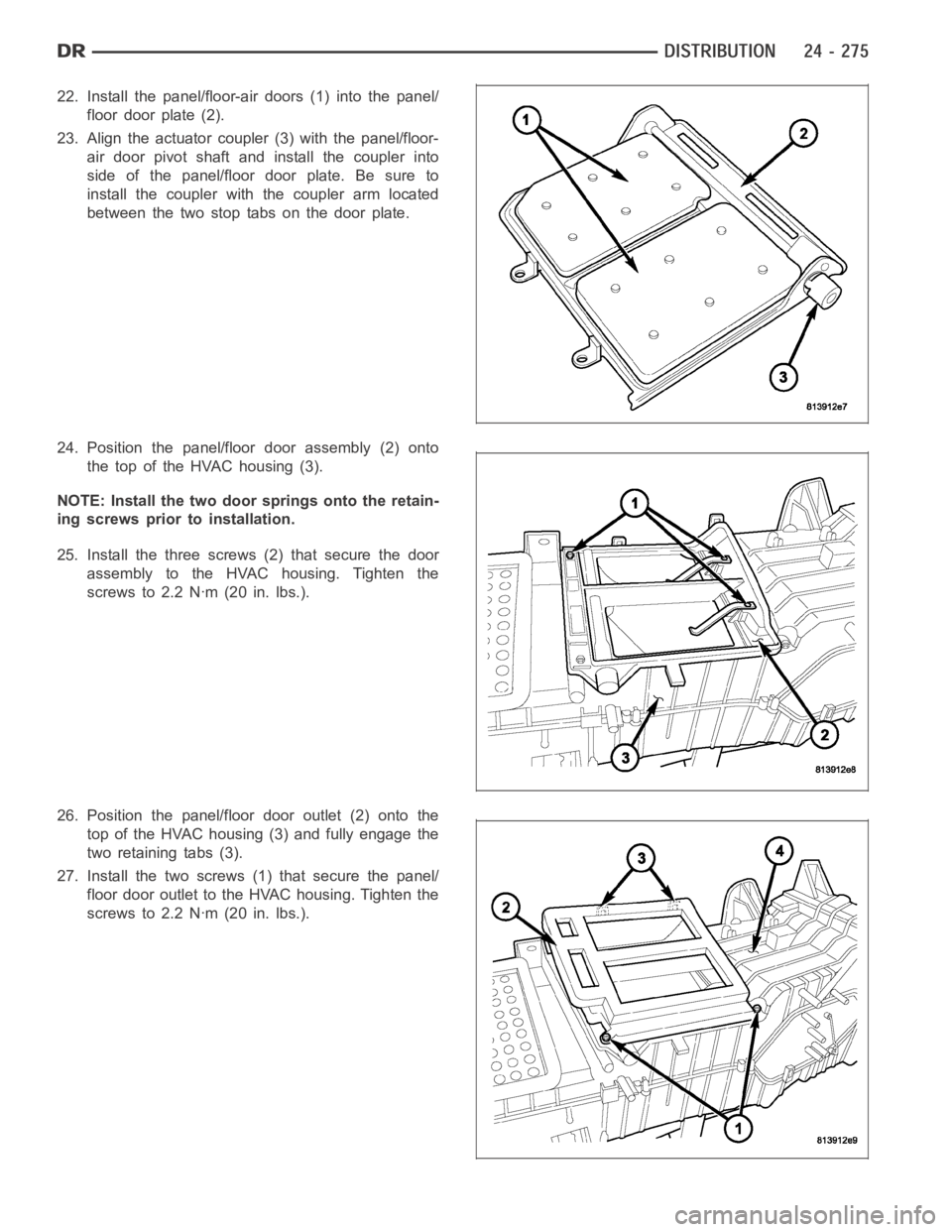

22. Install the panel/floor-air doors (1) into the panel/

floor door plate (2).

23. Align the actuator coupler (3) with the panel/floor-

air door pivot shaft and install the coupler into

side of the panel/floor door plate. Be sure to

install the coupler with the coupler arm located

between the two stop tabs on the door plate.

24. Position the panel/floor door assembly (2) onto

the top of the HVAC housing (3).

NOTE: Install the two door springs onto the retain-

ing screws prior to installation.

25. Install the three screws (2) that secure the door

assembly to the HVAC housing. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

26. Position the panel/floor door outlet (2) onto the

top of the HVAC housing (3) and fully engage the

two retaining tabs (3).

27. Install the two screws (1) that secure the panel/

floor door outlet to the HVAC housing. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

Page 5117 of 5267

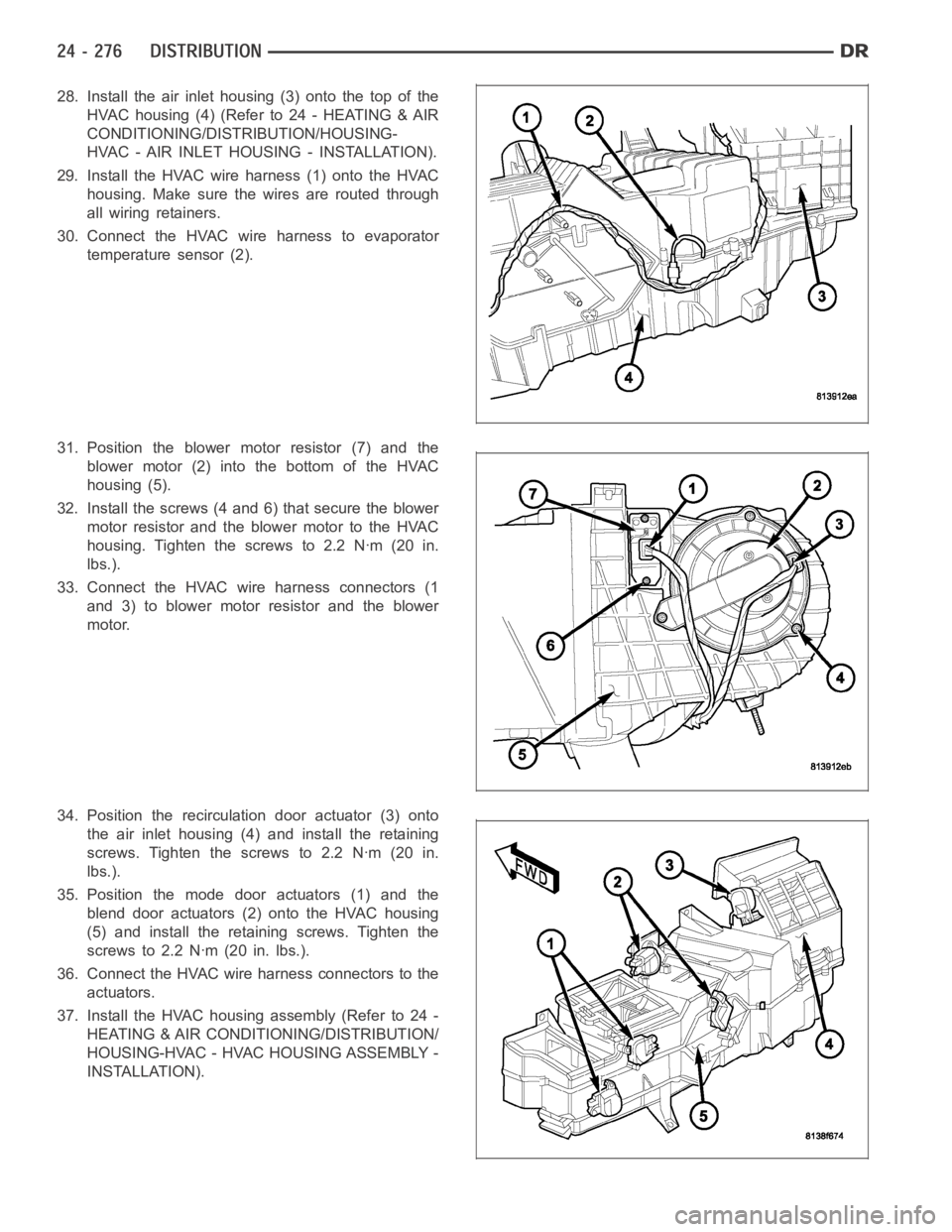

28. Install the air inlet housing (3) onto the top of the

HVAC housing (4) (Refer to 24 - HEATING & AIR

CONDITIONING/DISTRIBUTION/HOUSING-

HVAC - AIR INLET HOUSING - INSTALLATION).

29. Install the HVAC wire harness (1) onto the HVAC

housing. Make sure the wires are routed through

all wiring retainers.

30. Connect the HVAC wire harness to evaporator

temperature sensor (2).

31. Position the blower motor resistor (7) and the

blower motor (2) into the bottom of the HVAC

housing (5).

32. Install the screws (4 and 6) that secure the blower

motor resistor and the blower motor to the HVAC

housing. Tighten the screws to 2.2 Nꞏm (20 in.

lbs.).

33. Connect the HVAC wire harness connectors (1

and 3) to blower motor resistor and the blower

motor.

34. Position the recirculation door actuator (3) onto

the air inlet housing (4) and install the retaining

screws. Tighten the screws to 2.2 Nꞏm (20 in.

lbs.).

35. Position the mode door actuators (1) and the

blend door actuators (2) onto the HVAC housing

(5) and install the retaining screws. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

36. Connect the HVAC wire harness connectors to the

actuators.

37. Install the HVAC housing assembly (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HOUSING-HVAC - HVAC HOUSING ASSEMBLY -

INSTALLATION).

Page 5119 of 5267

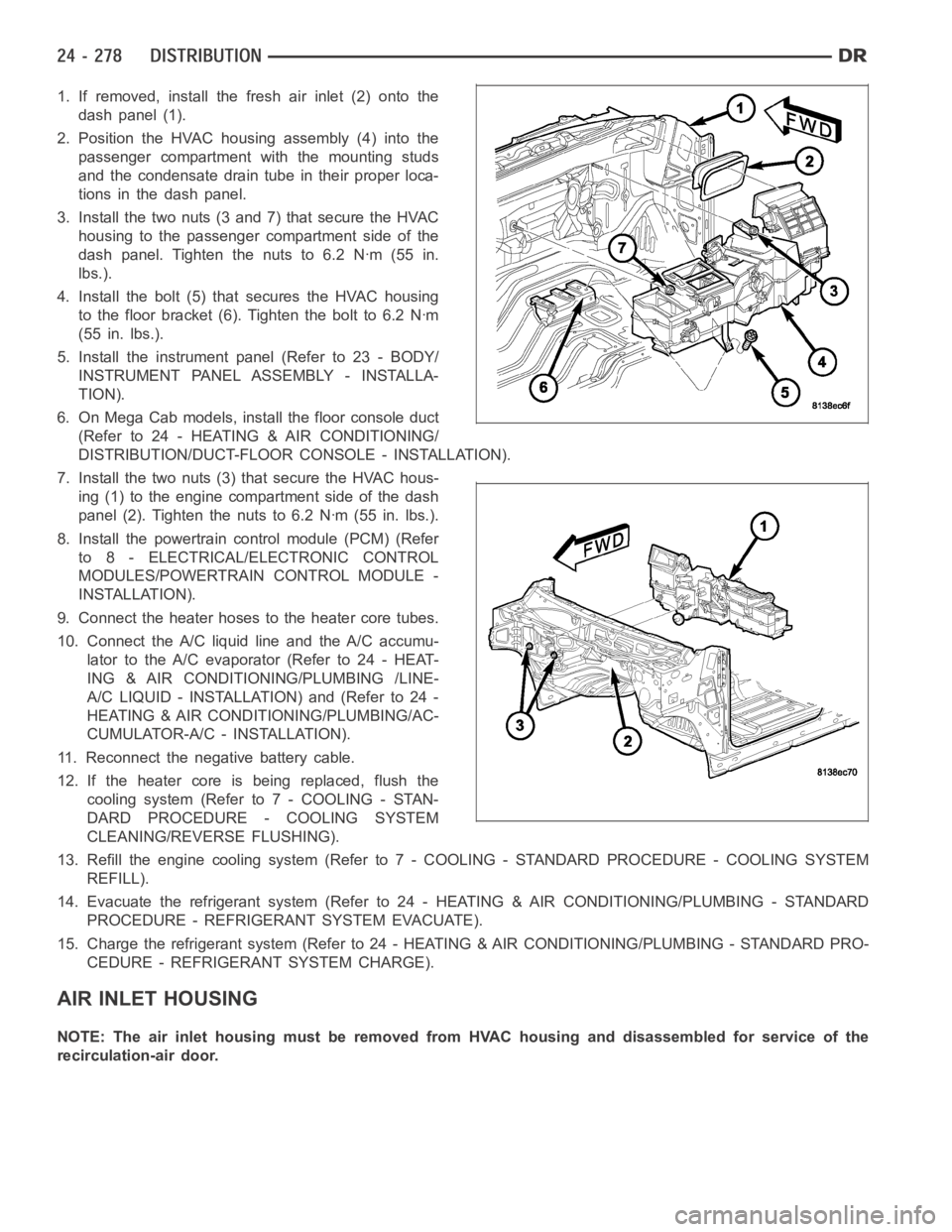

1. If removed, install the fresh air inlet (2) onto the

dash panel (1).

2. Position the HVAC housing assembly (4) into the

passenger compartment with the mounting studs

and the condensate drain tube in their proper loca-

tions in the dash panel.

3. Install the two nuts (3 and 7) that secure the HVAC

housing to the passenger compartment side of the

dash panel. Tighten the nuts to 6.2 Nꞏm (55 in.

lbs.).

4. Install the bolt (5) that secures the HVAC housing

to the floor bracket (6). Tighten the bolt to 6.2 Nꞏm

(55 in. lbs.).

5. Install the instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL ASSEMBLY - INSTALLA-

TION).

6. On Mega Cab models, install the floor console duct

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/DUCT-FLOOR CONSOLE - INSTALLATION).

7. Install the two nuts (3) that secure the HVAC hous-

ing (1) to the engine compartment side of the dash

panel (2). Tighten the nuts to 6.2 Nꞏm (55 in. lbs.).

8. Install the powertrain control module (PCM) (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

INSTALLATION).

9. Connect the heater hoses to the heater core tubes.

10. Connect the A/C liquid line and the A/C accumu-

lator to the A/C evaporator (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING /LINE-

A/C LIQUID - INSTALLATION) and (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR-A/C - INSTALLATION).

11. Reconnect the negative battery cable.

12. If the heater core is being replaced, flush the

coolingsystem(Referto7-COOLING-STAN-

DARD PROCEDURE - COOLING SYSTEM

CLEANING/REVERSE FLUSHING).

13. Refill the engine cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE - COOLING SYSTEM

REFILL).

14. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM EVACUATE).

15. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

AIR INLET HOUSING

NOTE: The air inlet housing must be removed from HVAC housing and disassembled for service of the

recirculation-air door.

Page 5120 of 5267

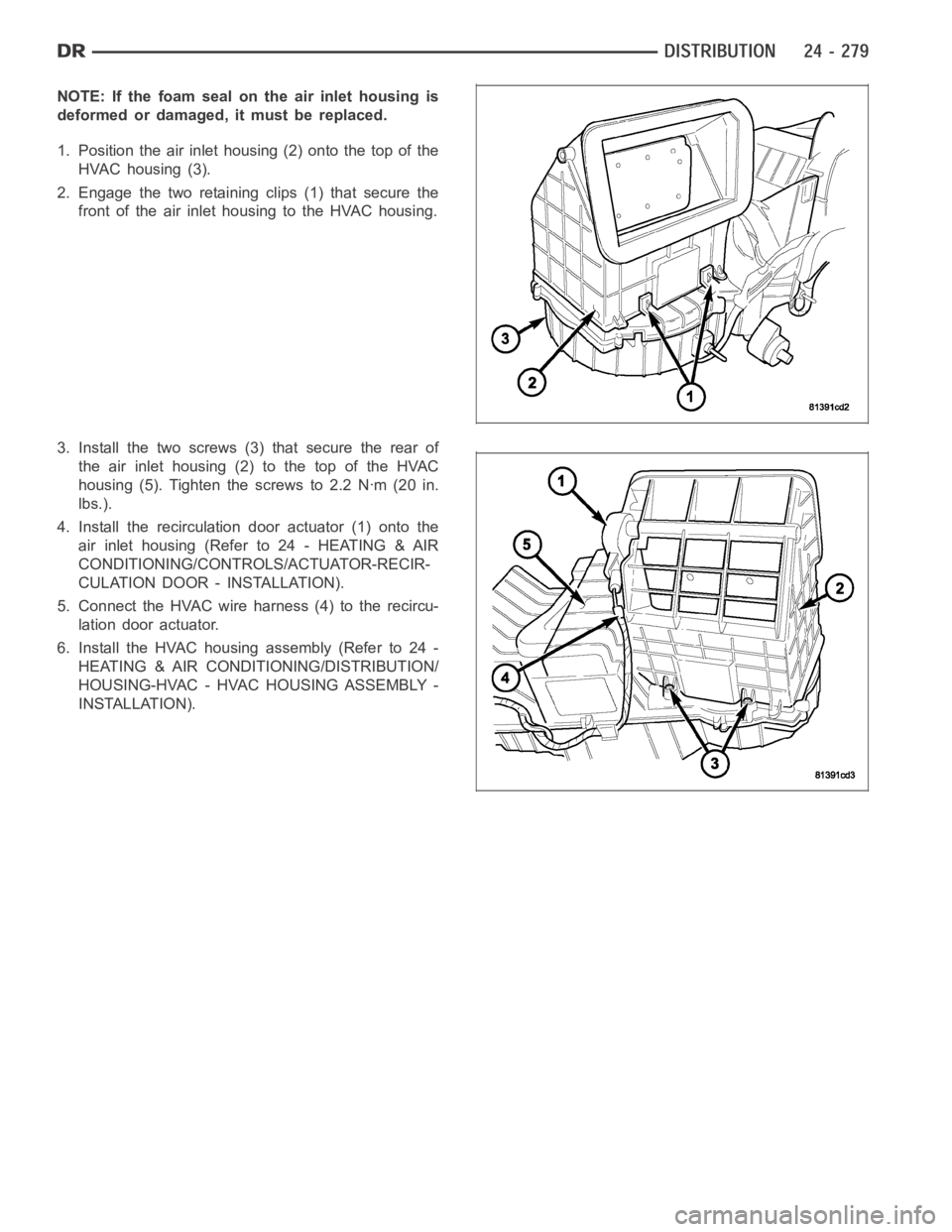

NOTE: If the foam seal on the air inlet housing is

deformed or damaged, it must be replaced.

1. Position the air inlet housing (2) onto the top of the

HVAC housing (3).

2. Engage the two retaining clips (1) that secure the

front of the air inlet housing to the HVAC housing.

3. Install the two screws (3) that secure the rear of

the air inlet housing (2) to the top of the HVAC

housing (5). Tighten the screws to 2.2 Nꞏm (20 in.

lbs.).

4. Install the recirculation door actuator (1) onto the

air inlet housing (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/ACTUATOR-RECIR-

CULATION DOOR - INSTALLATION).

5. Connect the HVAC wire harness (4) to the recircu-

lation door actuator.

6. Install the HVAC housing assembly (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HOUSING-HVAC - HVAC HOUSING ASSEMBLY -

INSTALLATION).

Page 5121 of 5267

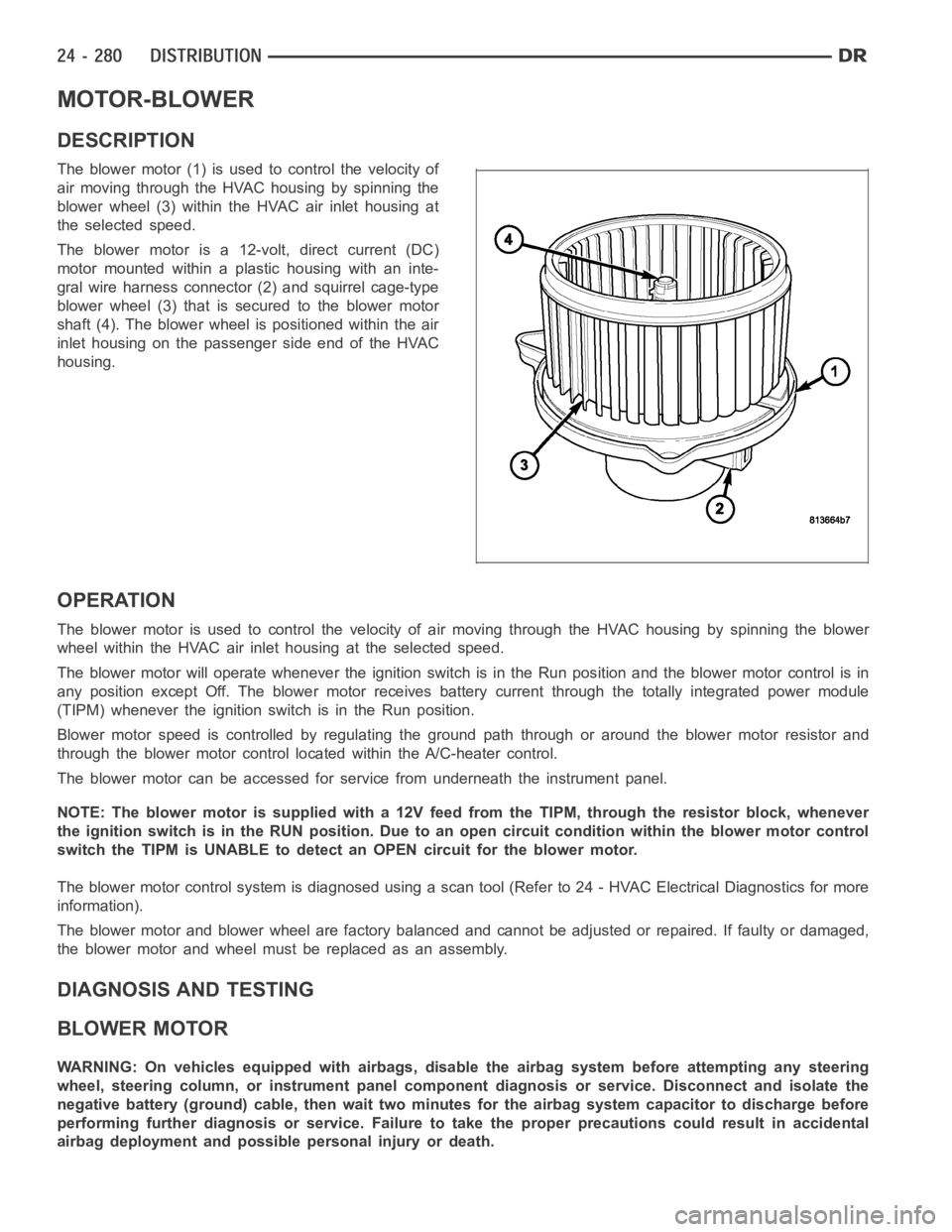

MOTOR-BLOWER

DESCRIPTION

The blower motor (1) is used to control the velocity of

air moving through the HVAC housing by spinning the

blower wheel (3) within the HVAC air inlet housing at

the selected speed.

The blower motor is a 12-volt, direct current (DC)

motormountedwithinaplastichousingwithaninte-

gral wire harness connector (2) and squirrel cage-type

blower wheel (3) that is secured to the blower motor

shaft (4). The blower wheel is positioned within the air

inlet housing on the passenger side end of the HVAC

housing.

OPERATION

The blower motor is used to control the velocity of air moving through the HVAC housing by spinning the blower

wheel within the HVAC air inlet housing at the selected speed.

The blower motor will operate whenever the ignition switch is in the Run position and the blower motor control is in

any position except Off. The blower motor receives battery current through the totally integrated power module

(TIPM) whenever the ignition switch is in the Run position.

Blower motor speed is controlled by regulating the ground path through or around the blower motor resistor and

through the blower motor control located within the A/C-heater control.

The blower motor can be accessed for service from underneath the instrument panel.

NOTE: The blower motor is supplied with a 12V feed from the TIPM, through theresistor block, whenever

the ignition switch is in the RUN position. Due to an open circuit conditionwithin the blower motor control

switch the TIPM is UNABLE to detect an OPEN circuit for the blower motor.

The blower motor control system is diagnosed using a scan tool (Refer to 24 -HVAC Electrical Diagnostics for more

information).

The blower motor and blower wheel are factory balanced and cannot be adjusted or repaired. If faulty or damaged,

the blower motor and wheel must be replaced as an assembly.

DIAGNOSIS AND TESTING

BLOWER MOTOR

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

negative battery (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. Failure to take the proper precautions could result in accidental

airbag deployment and possible personal injury or death.

Page 5123 of 5267

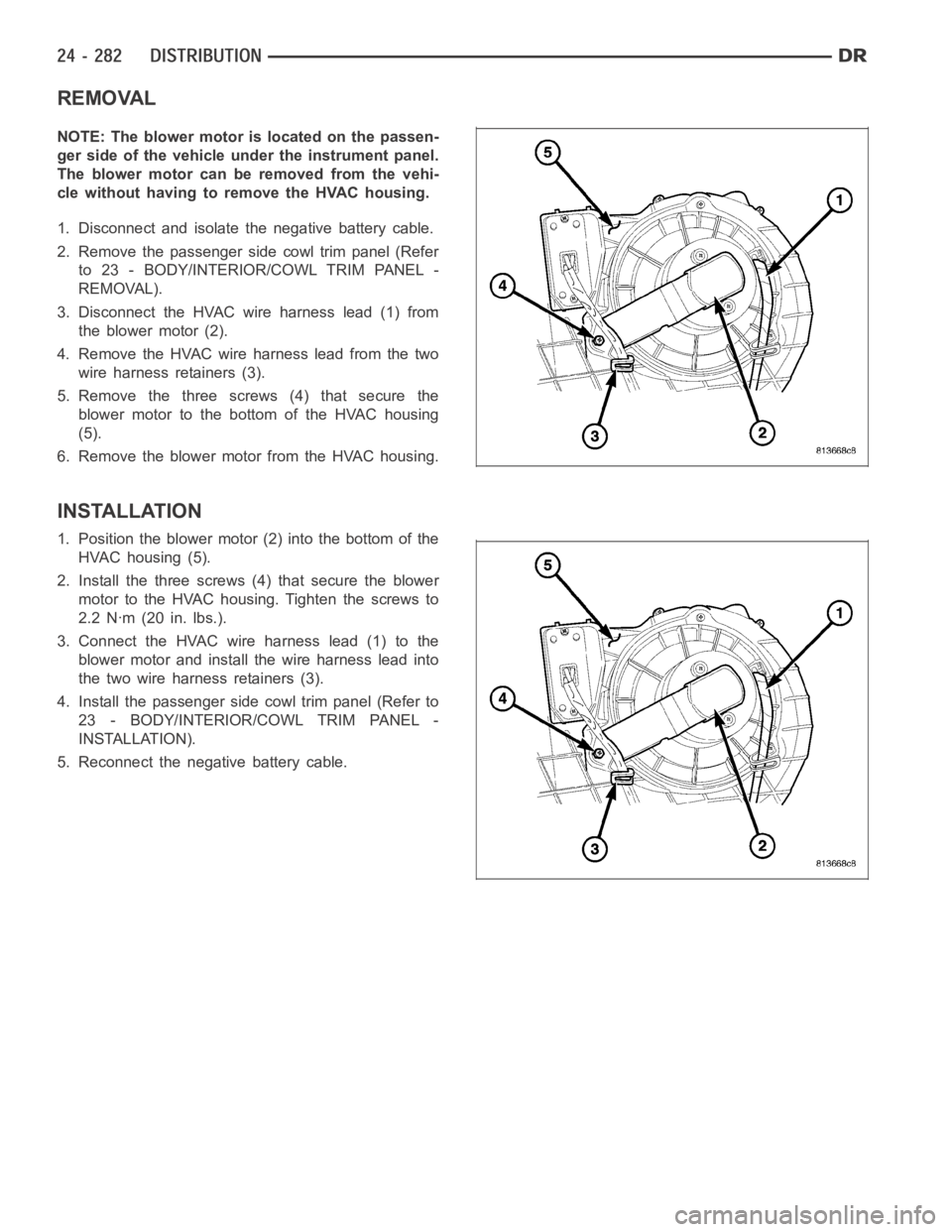

REMOVAL

NOTE: The blower motor is located on the passen-

ger side of the vehicle under the instrument panel.

The blower motor can be removed from the vehi-

cle without having to remove the HVAC housing.

1. Disconnect and isolate the negative battery cable.

2. Remove the passenger side cowl trim panel (Refer

to 23 - BODY/INTERIOR/COWL TRIM PANEL -

REMOVAL).

3. Disconnect the HVAC wire harness lead (1) from

the blower motor (2).

4. Remove the HVAC wire harness lead from the two

wire harness retainers (3).

5. Remove the three screws (4) that secure the

blower motor to the bottom of the HVAC housing

(5).

6. Remove the blower motor from the HVAC housing.

INSTALLATION

1. Position the blower motor (2) into the bottom of the

HVAC housing (5).

2. Install the three screws (4) that secure the blower

motor to the HVAC housing. Tighten the screws to

2.2 Nꞏm (20 in. lbs.).

3. Connect the HVAC wire harness lead (1) to the

blower motor and install the wire harness lead into

the two wire harness retainers (3).

4. Install the passenger side cowl trim panel (Refer to

23 - BODY/INTERIOR/COWL TRIM PANEL -

INSTALLATION).

5. Reconnect the negative battery cable.

Page 5127 of 5267

PLUMBING

DESCRIPTION

The A/C refrigerant lines and hoses are used to carry the refrigerant between the various A/C system components.

The refrigerant lines and hoses for the R-134a system on this vehicle consist of a barrier-hose design with a nylon

tube sandwiched between rubber layers. The nylon tube helps to contain theR-134a refrigerant, which has a

smaller molecular structure than R-12 refrigerant. The ends of the refrigerant lines are made from lightweight alu-

minum or steel, and commonly use braze-less fittings.

Any kinks or sharp bends in the refrigerant lines and hoses will reduce the capacity of the entire A/C system and

can reduce the flow of refrigerant in the system. The radius of all bends in the flexible hose refrigerant lines should

be at least ten times the diameter of the hose and the refrigerant lines should be routed so they are at least 80

millimeters (3 inches) away from the exhaust manifold(s) and exhaust pipe(s).

OPERATION

High pressures are produced in the refrigerant system when the A/C compressor is operating. Extreme care must

be exercised to make sure that each of the refrigerant system connections is pressure-tight and leak free. It is a

good practice to inspect all flexible hose refrigerant lines at least oncea year to make sure they are in good con-

dition and properly routed.

The refrigerant lines and hoses are coupled to other A/C system componentswith block-type fittings. An O-ring seal,

or a flat steel gasket with an integral O-ring (dual plane seal), is used to mate the refrigerant line fittings with A/C

system components to ensure the integrity of the refrigerant system.

The refrigerant lines and hoses cannot be repaired and, if faulty or damaged, they must be replaced.

WARNING

WARNING: The A/C system contains refrigerant under high pressure. Repairs should only be performed by

qualified service personnel. Severe personal injury or death may result from improper service procedures.

WARNING: Avoid breathing the refrigerant and refrigerant oil vapor or mist. Exposure may irritate the eyes,

nose, and/or throat. Wear eye protection when servicing the A/C refrigerant system. Serious eye injury can

result from direct contact with the refrigerant. If eye contact occurs, seek medical attention immediately.

WARNING: Do not expose the refrigerant to open flame. Poisonous gas is createdwhenrefrigerantis

burned. An electronic leak detector is recommended. Severe personal injury or death may result from

improper service procedures.

WARNING: If accidental system discharge occurs, ventilate the work area before resuming service. Large

amounts of refrigerant released in a closed work area will displace the oxygen and cause suffocation and

death.

WARNING: The evaporation rate of R-134a refrigerant at average temperature and altitude is extremely high.

As a result, anything that comes in contact with the refrigerant will freeze. Always protect the skin or del-

icate objects from direct contact with the refrigerant.

WARNING: The R-134a service equipment or the vehicle refrigerant system should not be pressure tested or

leak tested with compressed air. Some mixtures of air and R-134a have been shown to be combustible at

elevated pressures. These mixtures are potentially dangerous, and may result in fire or explosion causing

property damage, personal injury or death.

Page 5133 of 5267

ACCUMULATOR-A/C

DESCRIPTION

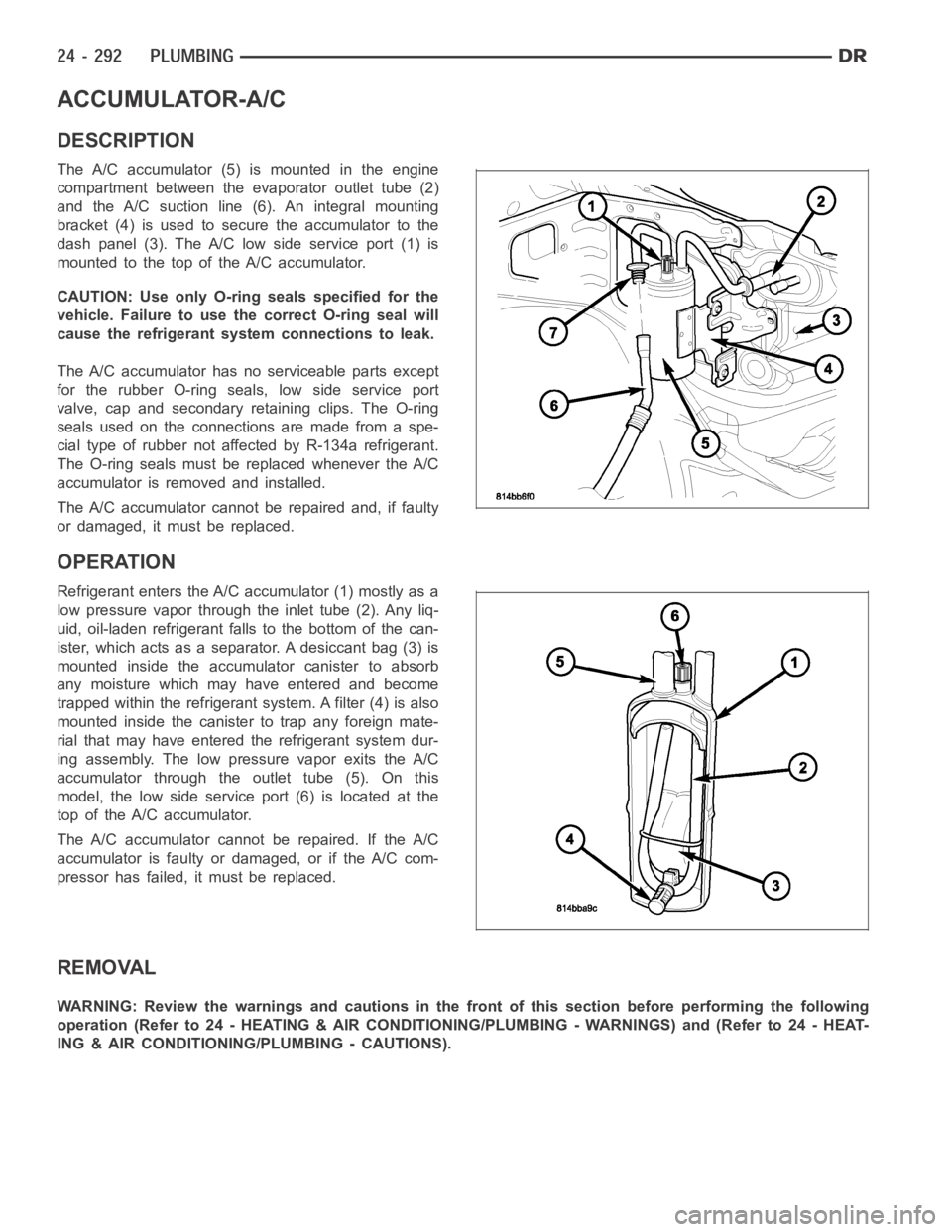

The A/C accumulator (5) is mounted in the engine

compartment between the evaporator outlet tube (2)

and the A/C suction line (6). An integral mounting

bracket (4) is used to secure the accumulator to the

dash panel (3). The A/C low side service port (1) is

mountedtothetopoftheA/Caccumulator.

CAUTION: Use only O-ring seals specified for the

vehicle. Failure to use the correct O-ring seal will

cause the refrigerant system connections to leak.

The A/C accumulator has no serviceable parts except

for the rubber O-ring seals, low side service port

valve, cap and secondary retaining clips. The O-ring

seals used on the connections are made from a spe-

cial type of rubber not affected by R-134a refrigerant.

The O-ring seals must be replaced whenever the A/C

accumulator is removed and installed.

The A/C accumulator cannot be repaired and, if faulty

or damaged, it must be replaced.

OPERATION

Refrigerant enters the A/C accumulator (1) mostly as a

low pressure vapor through the inlet tube (2). Any liq-

uid, oil-laden refrigerant falls to the bottom of the can-

ister, which acts as a separator. A desiccant bag (3) is

mounted inside the accumulator canister to absorb

any moisture which may have entered and become

trapped within the refrigerant system. A filter (4) is also

mounted inside the canister to trap any foreign mate-

rial that may have entered the refrigerant system dur-

ing assembly. The low pressure vapor exits the A/C

accumulator through the outlet tube (5). On this

model, the low side service port (6) is located at the

top of the A/C accumulator.

The A/C accumulator cannot be repaired. If the A/C

accumulator is faulty or damaged, or if the A/C com-

pressor has failed, it must be replaced.

REMOVAL

WARNING: Review the warnings and cautions in the front of this section before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS).