DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3941 of 5267

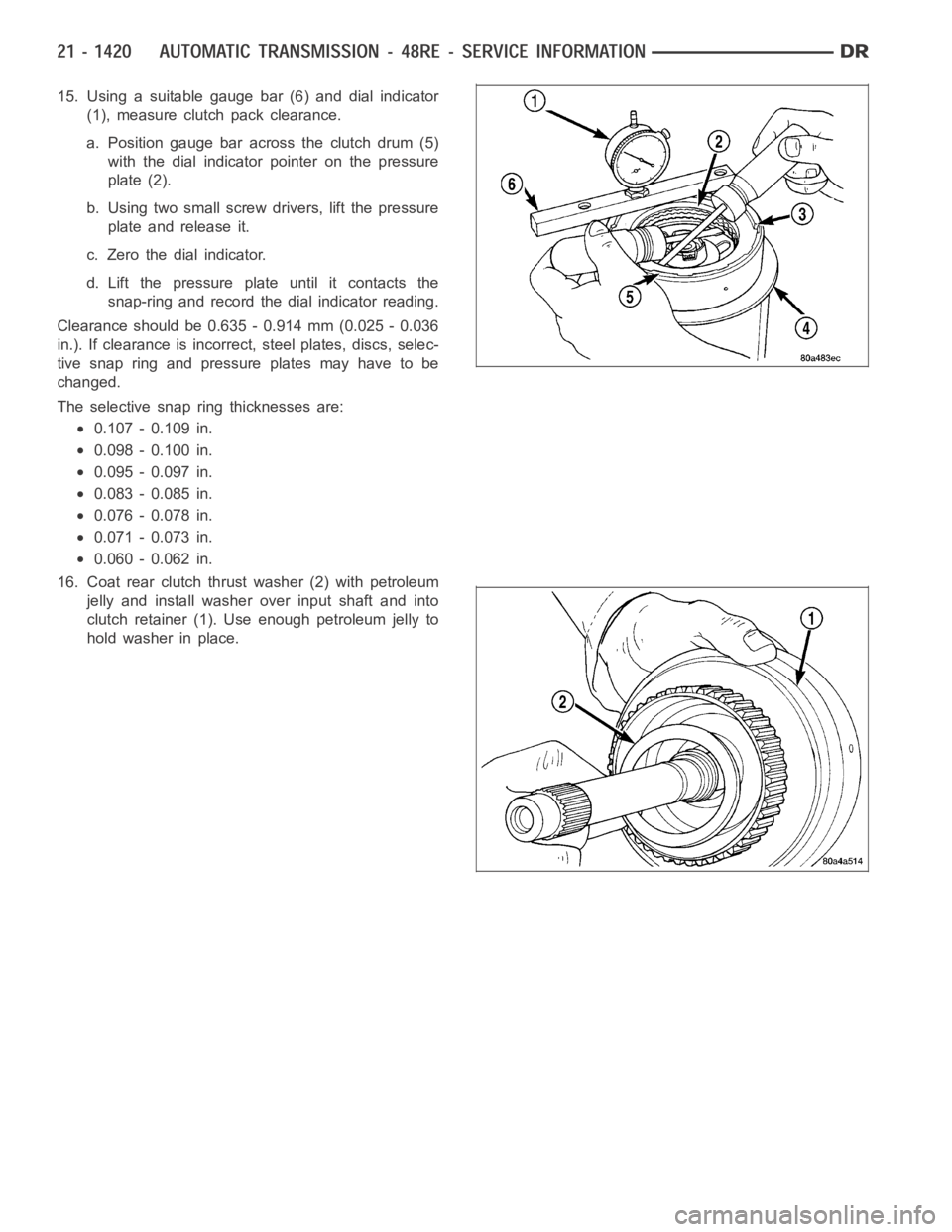

15. Using a suitable gauge bar (6) and dial indicator

(1), measure clutch pack clearance.

a. Position gauge bar across the clutch drum (5)

with the dial indicator pointer on the pressure

plate (2).

b. Using two small screw drivers, lift the pressure

plate and release it.

c. Zero the dial indicator.

d. Lift the pressure plate until it contacts the

snap-ring and record the dial indicator reading.

Clearance should be 0.635 - 0.914 mm (0.025 - 0.036

in.). If clearance is incorrect, steel plates, discs, selec-

tive snap ring and pressure plates may have to be

changed.

The selective snap ring thicknesses are:

0.107 - 0.109 in.

0.098 - 0.100 in.

0.095 - 0.097 in.

0.083 - 0.085 in.

0.076 - 0.078 in.

0.071 - 0.073 in.

0.060 - 0.062 in.

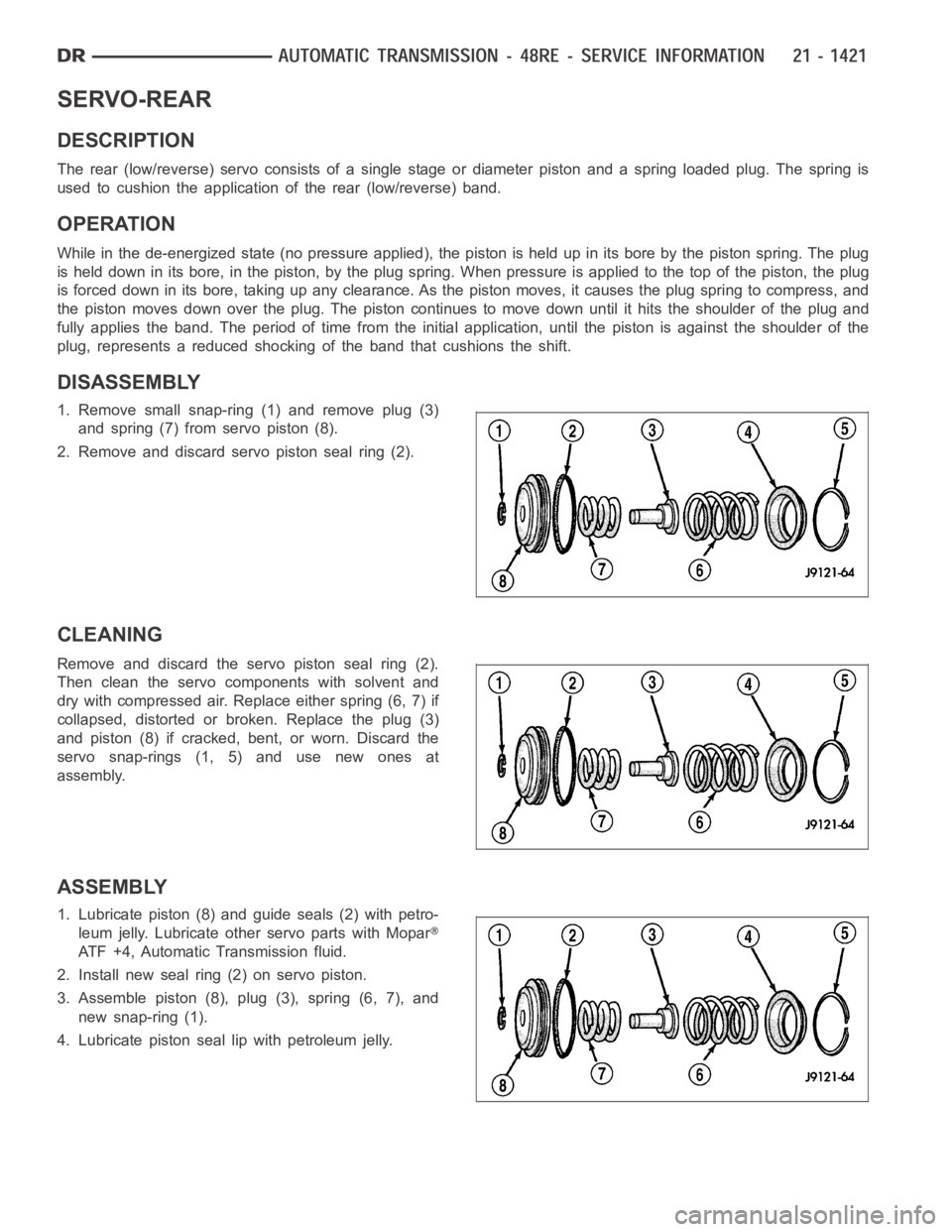

16. Coat rear clutch thrust washer (2) with petroleum

jelly and install washer over input shaft and into

clutch retainer (1). Use enough petroleum jelly to

hold washer in place.

Page 3942 of 5267

SERVO-REAR

DESCRIPTION

The rear (low/reverse) servo consists of a single stage or diameter pistonand a spring loaded plug. The spring is

used to cushion the application of the rear (low/reverse) band.

OPERATION

While in the de-energized state (no pressure applied), the piston is held up in its bore by the piston spring. The plug

is held down in its bore, in the piston, by the plug spring. When pressure is applied to the top of the piston, the plug

is forced down in its bore, taking up any clearance. As the piston moves, it causes the plug spring to compress, and

the piston moves down over the plug. The piston continues to move down untilit hits the shoulder of the plug and

fully applies the band. The period of time from the initial application, until the piston is against the shoulder of the

plug, represents a reduced shocking of the band that cushions the shift.

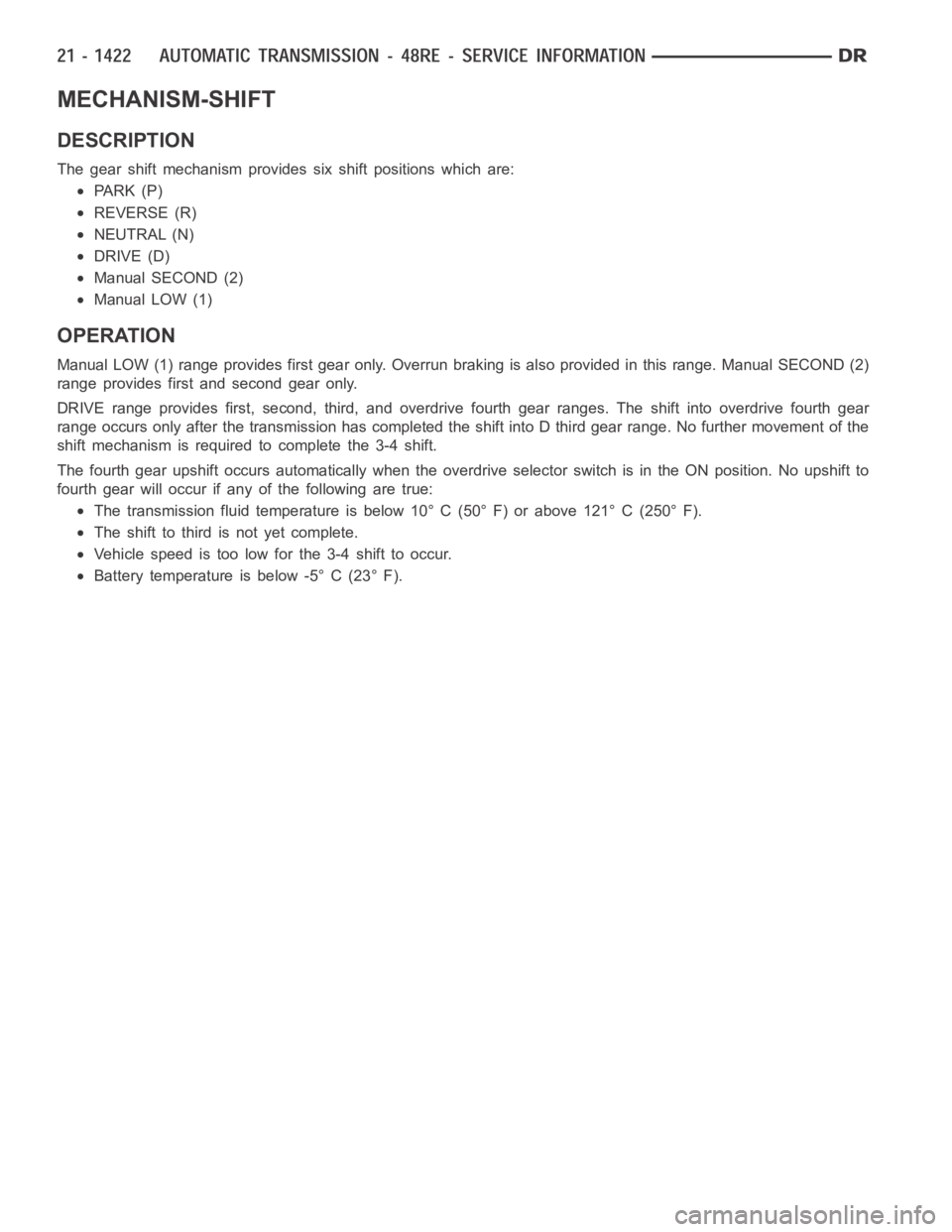

DISASSEMBLY

1. Remove small snap-ring (1) and remove plug (3)

and spring (7) from servo piston (8).

2. Remove and discard servo piston seal ring (2).

CLEANING

Remove and discard the servo piston seal ring (2).

Then clean the servo components with solvent and

dry with compressed air. Replace either spring (6, 7) if

collapsed, distorted or broken. Replace the plug (3)

and piston (8) if cracked, bent, or worn. Discard the

servo snap-rings (1, 5) and use new ones at

assembly.

ASSEMBLY

1. Lubricate piston (8) and guide seals (2) with petro-

leum jelly. Lubricate other servo parts with Mopar

ATF +4, Automatic Transmission fluid.

2. Install new seal ring (2) on servo piston.

3. Assemble piston (8), plug (3), spring (6, 7), and

new snap-ring (1).

4. Lubricate piston seal lip with petroleum jelly.

Page 3943 of 5267

MECHANISM-SHIFT

DESCRIPTION

The gear shift mechanism provides six shift positions which are:

PA R K ( P )

REVERSE (R)

NEUTRAL (N)

DRIVE (D)

Manual SECOND (2)

Manual LOW (1)

OPERATION

Manual LOW (1) range provides first gear only. Overrun braking is also provided in this range. Manual SECOND (2)

range provides first and second gear only.

DRIVE range provides first, second, third, and overdrive fourth gear ranges. The shift into overdrive fourth gear

range occurs only after the transmission has completed the shift into D third gear range. No further movement of the

shift mechanism is required to complete the 3-4 shift.

The fourth gear upshift occurs automatically when the overdrive selectorswitch is in the ON position. No upshift to

fourth gear will occur if any of the following are true:

The transmission fluid temperature is below 10° C (50° F) or above 121° C (250° F).

The shift to third is not yet complete.

Vehicle speed is too low for the 3-4 shift to occur.

Battery temperature is below -5° C (23° F).

Page 3944 of 5267

SENSOR-SPEED

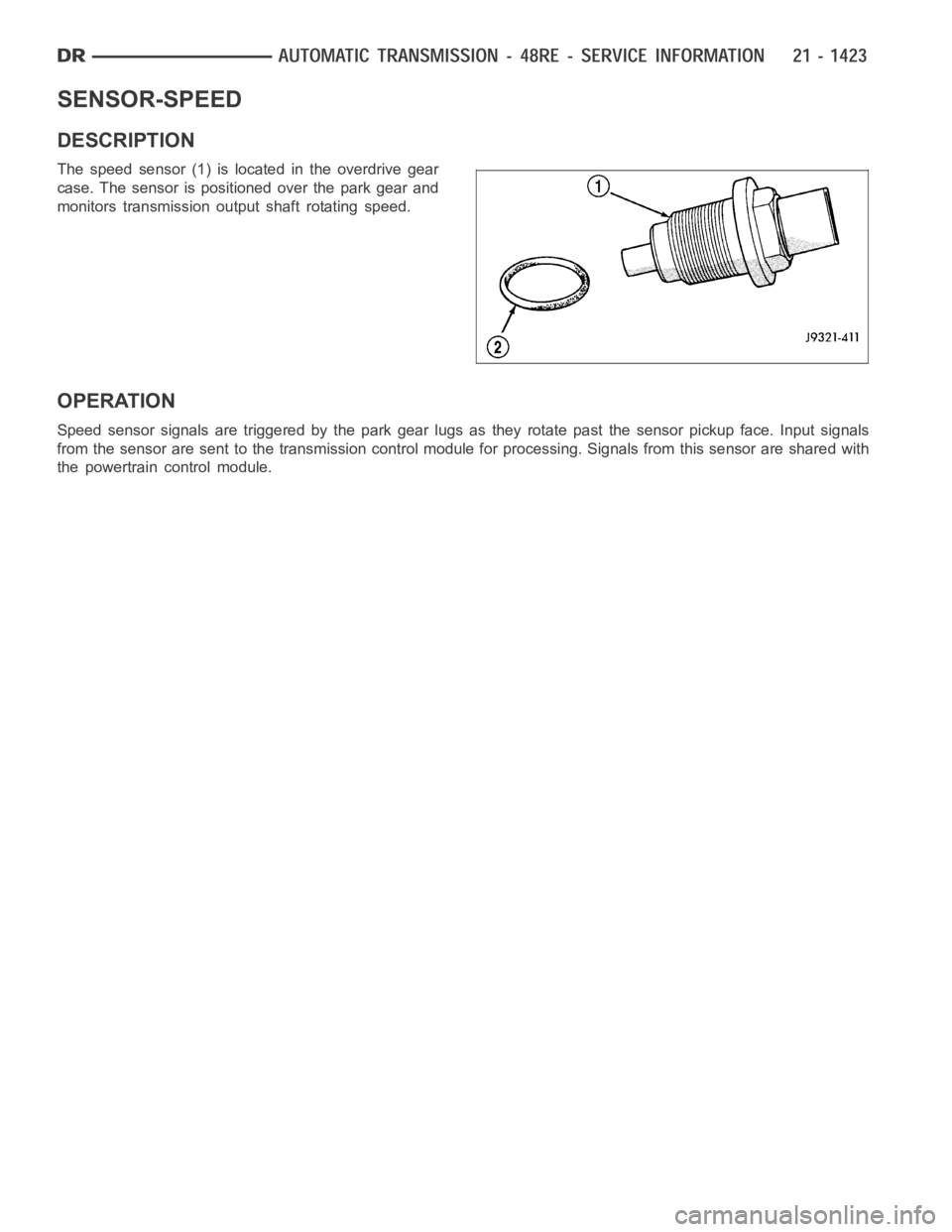

DESCRIPTION

The speed sensor (1) is located in the overdrive gear

case. The sensor is positioned over the park gear and

monitors transmission output shaft rotating speed.

OPERATION

Speed sensor signals are triggered by the park gear lugs as they rotate pastthe sensor pickup face. Input signals

from the sensor are sent to the transmission control module for processing. Signals from this sensor are shared with

the powertrain control module.

Page 3945 of 5267

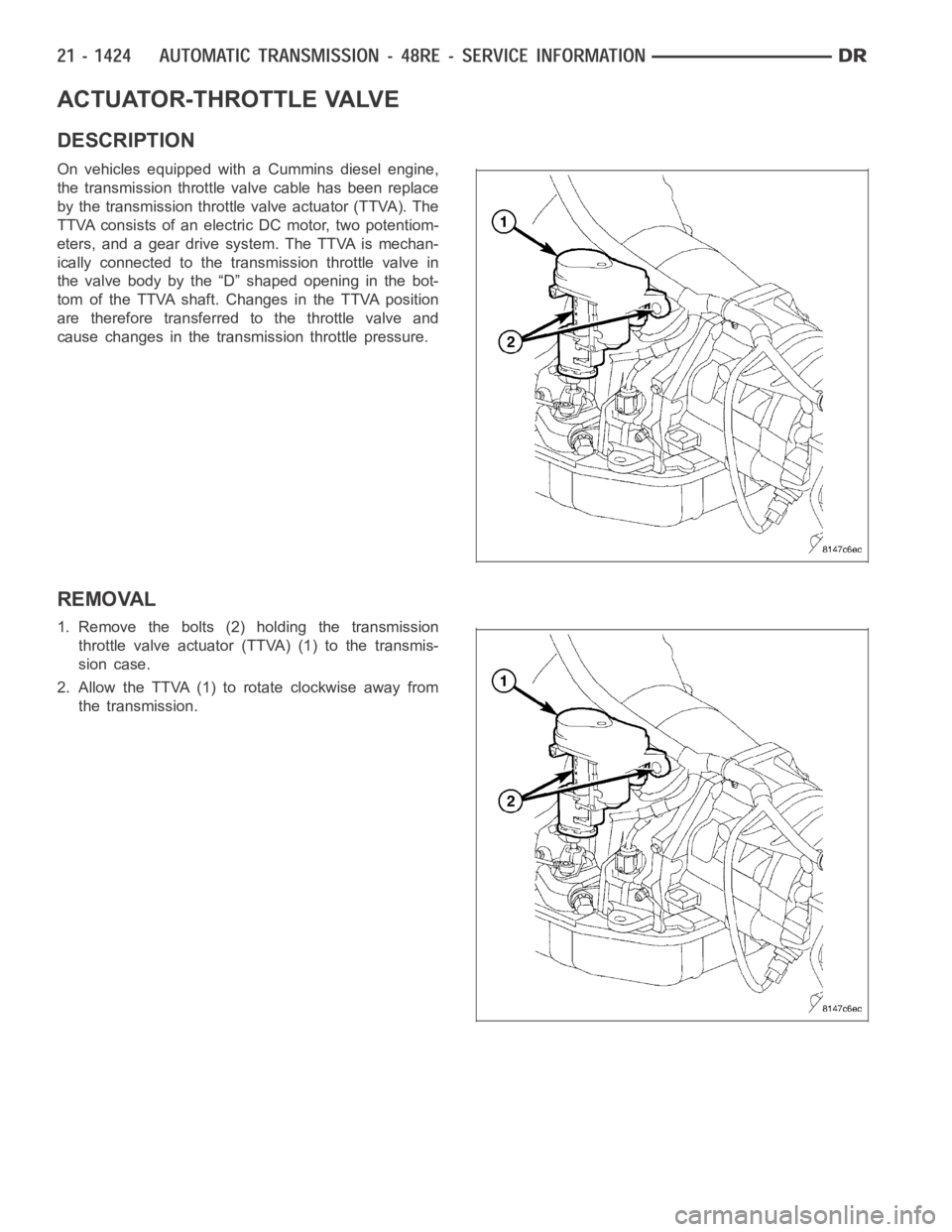

ACTUATOR-THROTTLE VALVE

DESCRIPTION

On vehicles equipped with a Cummins diesel engine,

the transmission throttle valve cable has been replace

by the transmission throttle valve actuator (TTVA). The

TTVA consists of an electric DC motor, two potentiom-

eters, and a gear drive system. The TTVA is mechan-

ically connected to the transmission throttle valve in

the valve body by the “D” shaped opening in the bot-

tom of the TTVA shaft. Changes in the TTVA position

are therefore transferred to the throttle valve and

cause changes in the transmission throttle pressure.

REMOVAL

1. Remove the bolts (2) holding the transmission

throttle valve actuator (TTVA) (1) to the transmis-

sion case.

2. Allow the TTVA (1) to rotate clockwise away from

the transmission.

Page 3946 of 5267

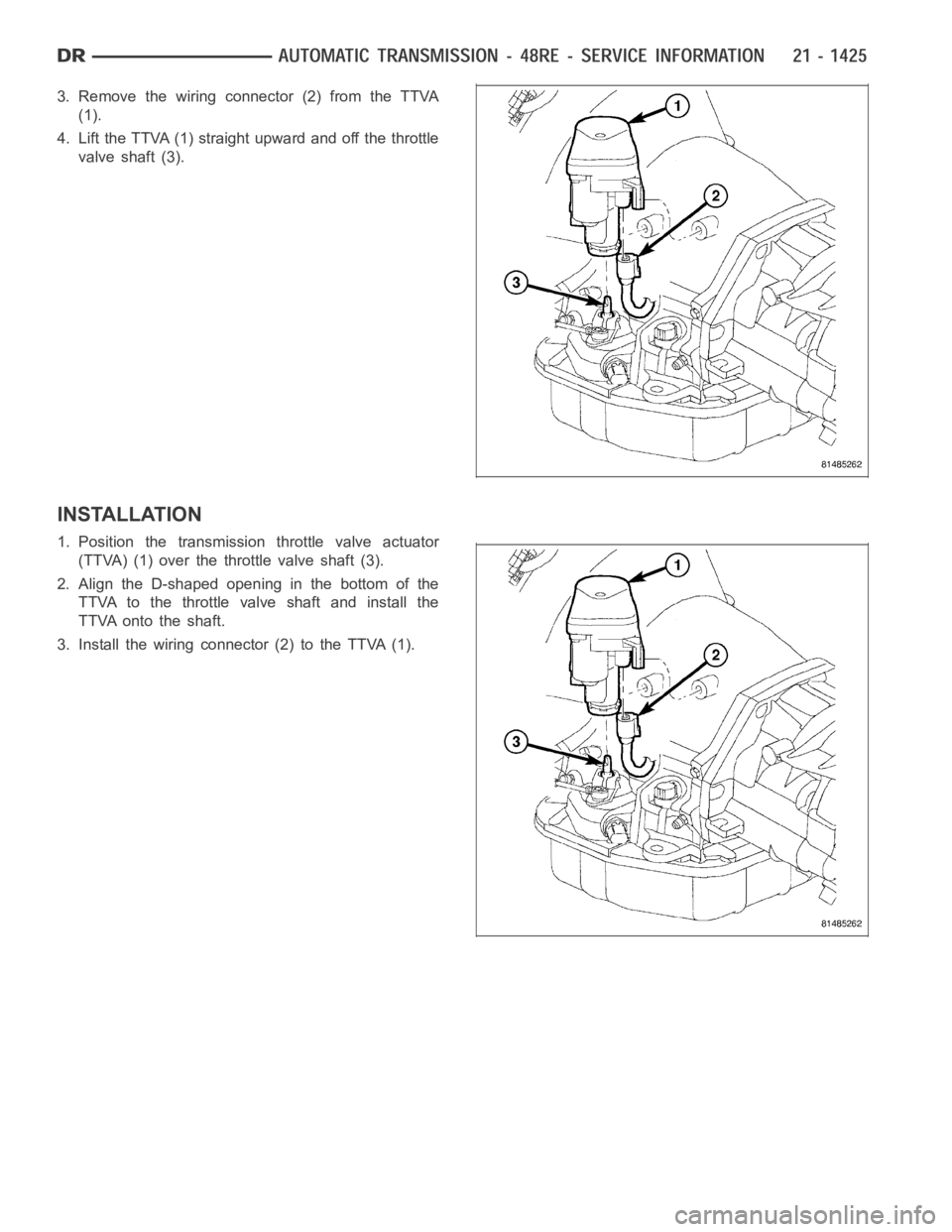

3. Remove the wiring connector (2) from the TTVA

(1).

4. Lift the TTVA (1) straight upward and off the throttle

valve shaft (3).

INSTALLATION

1. Position the transmission throttle valve actuator

(TTVA) (1) over the throttle valve shaft (3).

2. Align the D-shaped opening in the bottom of the

TTVA to the throttle valve shaft and install the

TTVA onto the shaft.

3. Install the wiring connector (2) to the TTVA (1).

Page 3947 of 5267

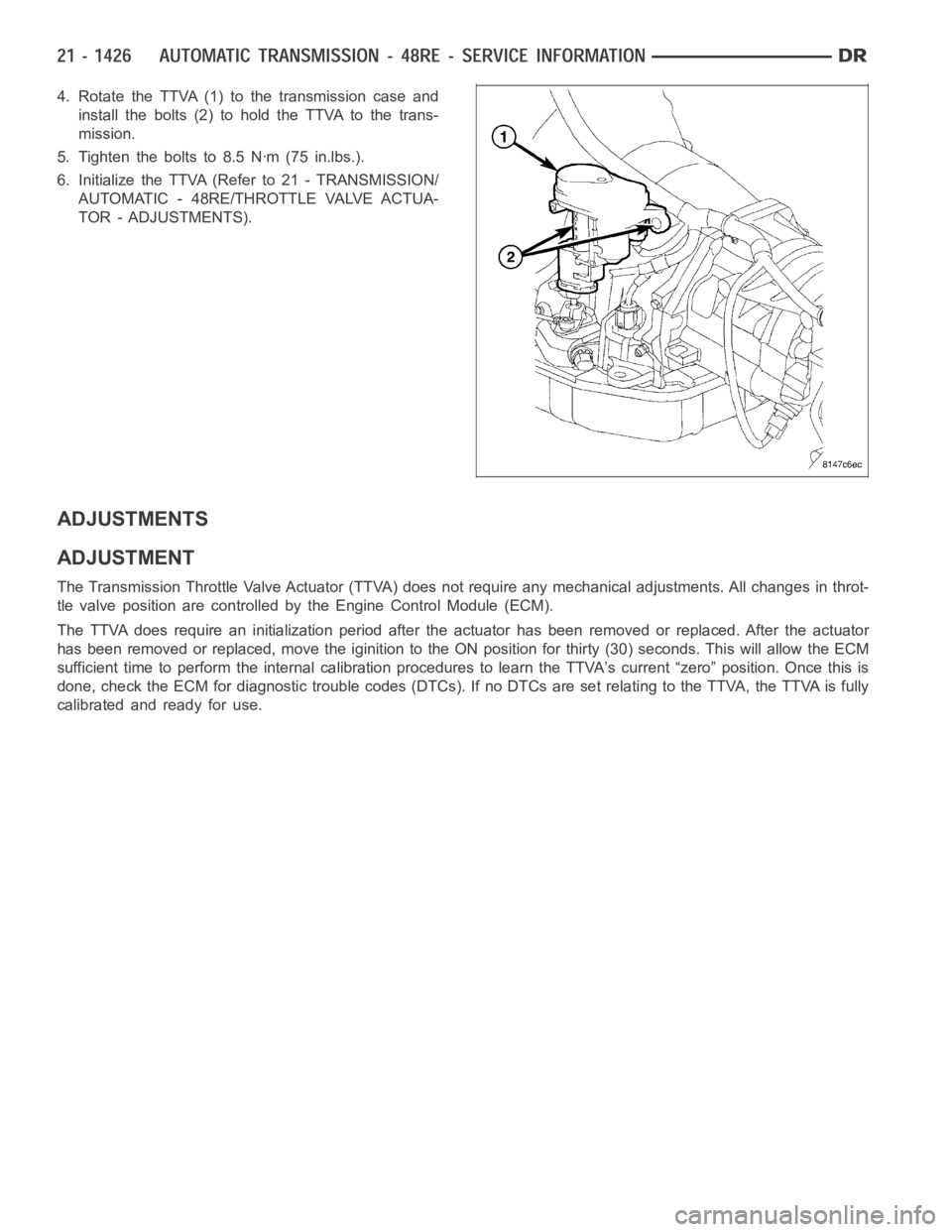

4. Rotate the TTVA (1) to the transmission case and

install the bolts (2) to hold the TTVA to the trans-

mission.

5. Tighten the bolts to 8.5 Nꞏm (75 in.lbs.).

6. Initialize the TTVA (Refer to 21 - TRANSMISSION/

AUTOMATIC - 48RE/THROTTLE VALVE ACTUA-

TOR - ADJUSTMENTS).

ADJUSTMENTS

ADJUSTMENT

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the iginition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position. Once this is

done, check the ECM for diagnostic trouble codes (DTCs). If no DTCs are set relating to the TTVA, the TTVA is fully

calibrated and ready for use.

Page 3948 of 5267

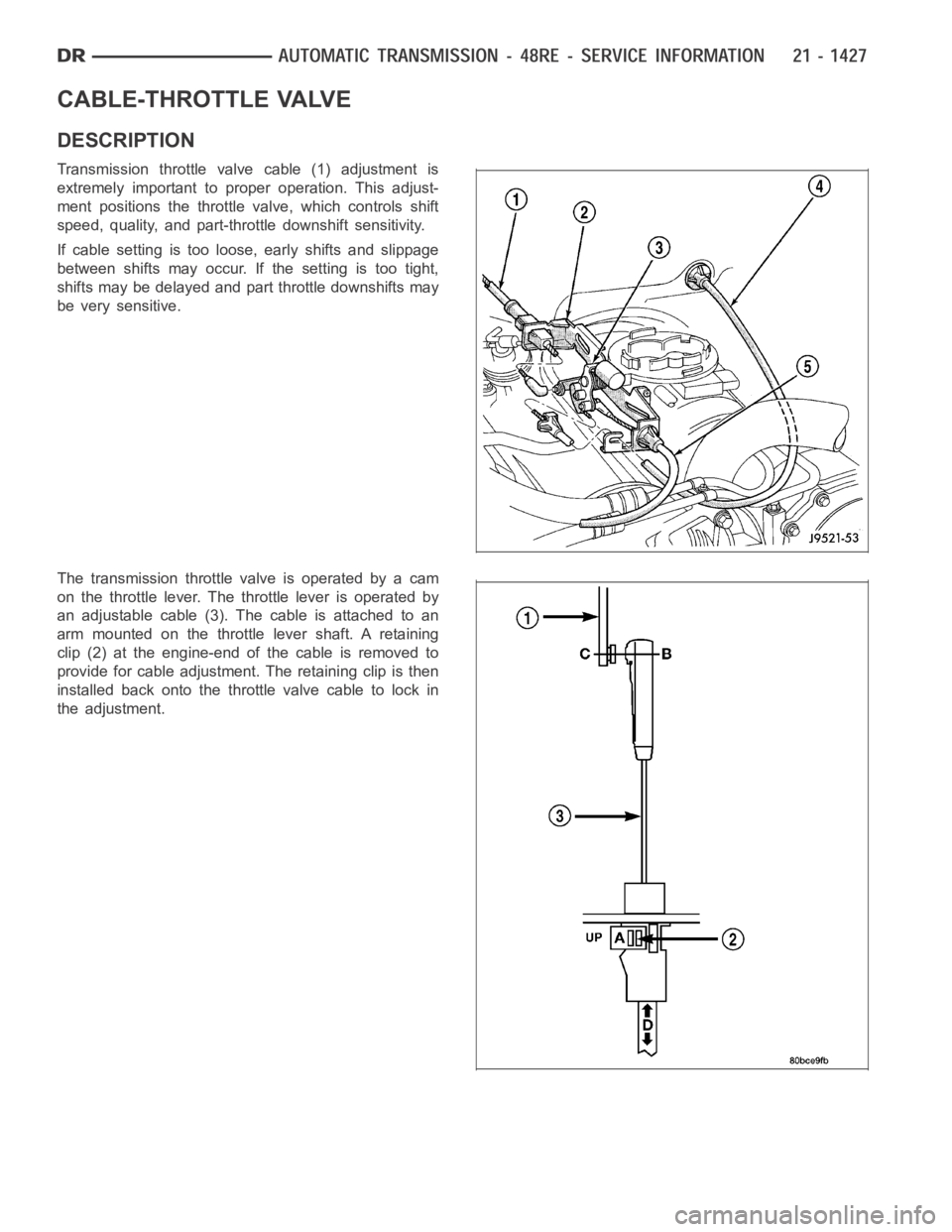

CABLE-THROTTLE VALVE

DESCRIPTION

Transmission throttle valve cable (1) adjustment is

extremely important to proper operation. This adjust-

ment positions the throttle valve, which controls shift

speed, quality, and part-throttle downshift sensitivity.

If cable setting is too loose, early shifts and slippage

between shifts may occur. If the setting is too tight,

shifts may be delayed and part throttle downshifts may

be very sensitive.

The transmission throttlevalveisoperatedbyacam

on the throttle lever. The throttle lever is operated by

an adjustable cable (3). The cable is attached to an

arm mounted on the throttle lever shaft. A retaining

clip (2) at the engine-end of the cable is removed to

provide for cable adjustment. The retaining clip is then

installedbackontothethrottlevalvecabletolockin

the adjustment.

Page 3949 of 5267

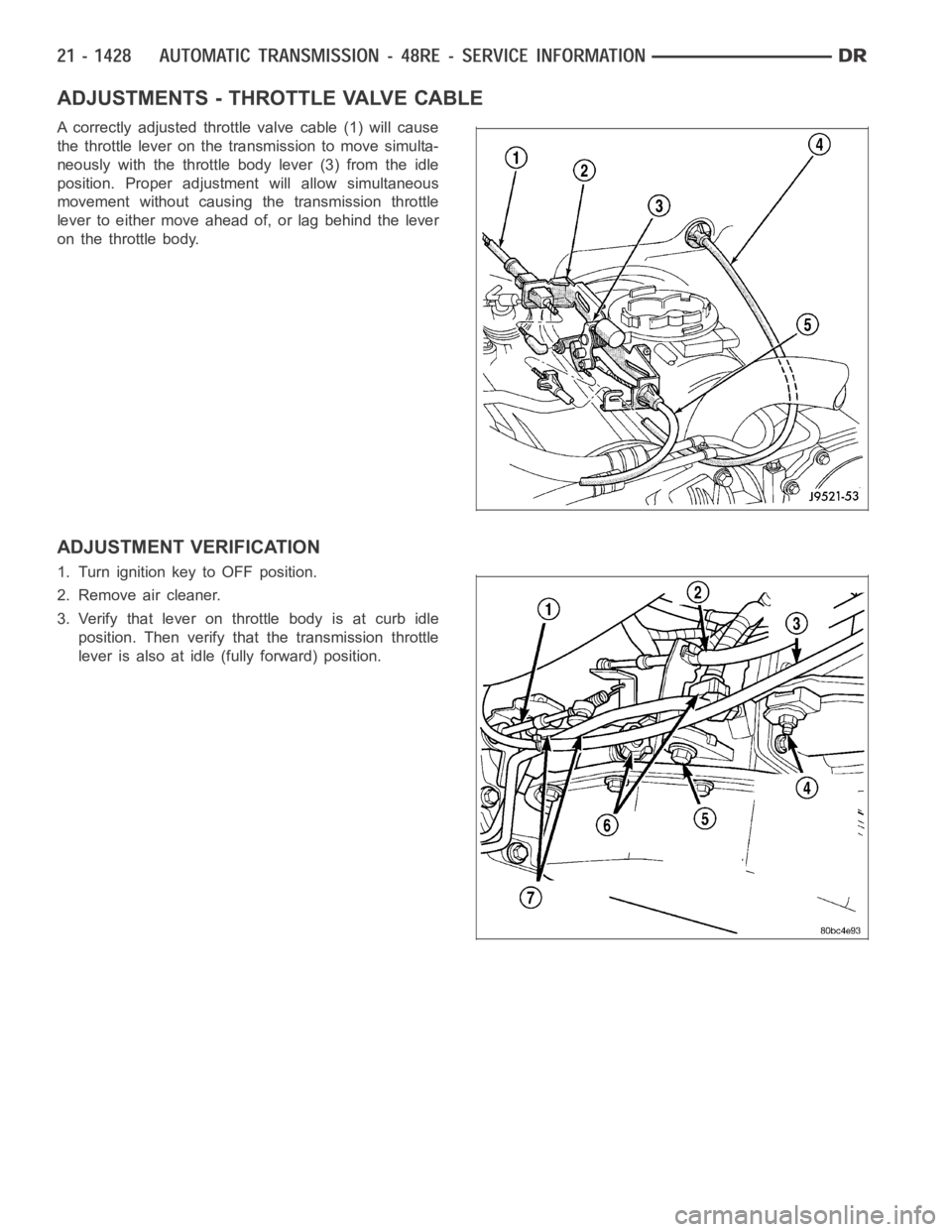

ADJUSTMENTS - THROTTLE VALVE CABLE

A correctly adjusted throttle valve cable (1) will cause

the throttle lever on the transmission to move simulta-

neously with the throttle body lever (3) from the idle

position. Proper adjustment will allow simultaneous

movement without causing the transmission throttle

lever to either move ahead of, or lag behind the lever

on the throttle body.

ADJUSTMENT VERIFICATION

1. Turn ignition key to OFF position.

2. Remove air cleaner.

3. Verify that lever on throttle body is at curb idle

position. Then verify that the transmission throttle

lever is also at idle (fully forward) position.

Page 3950 of 5267

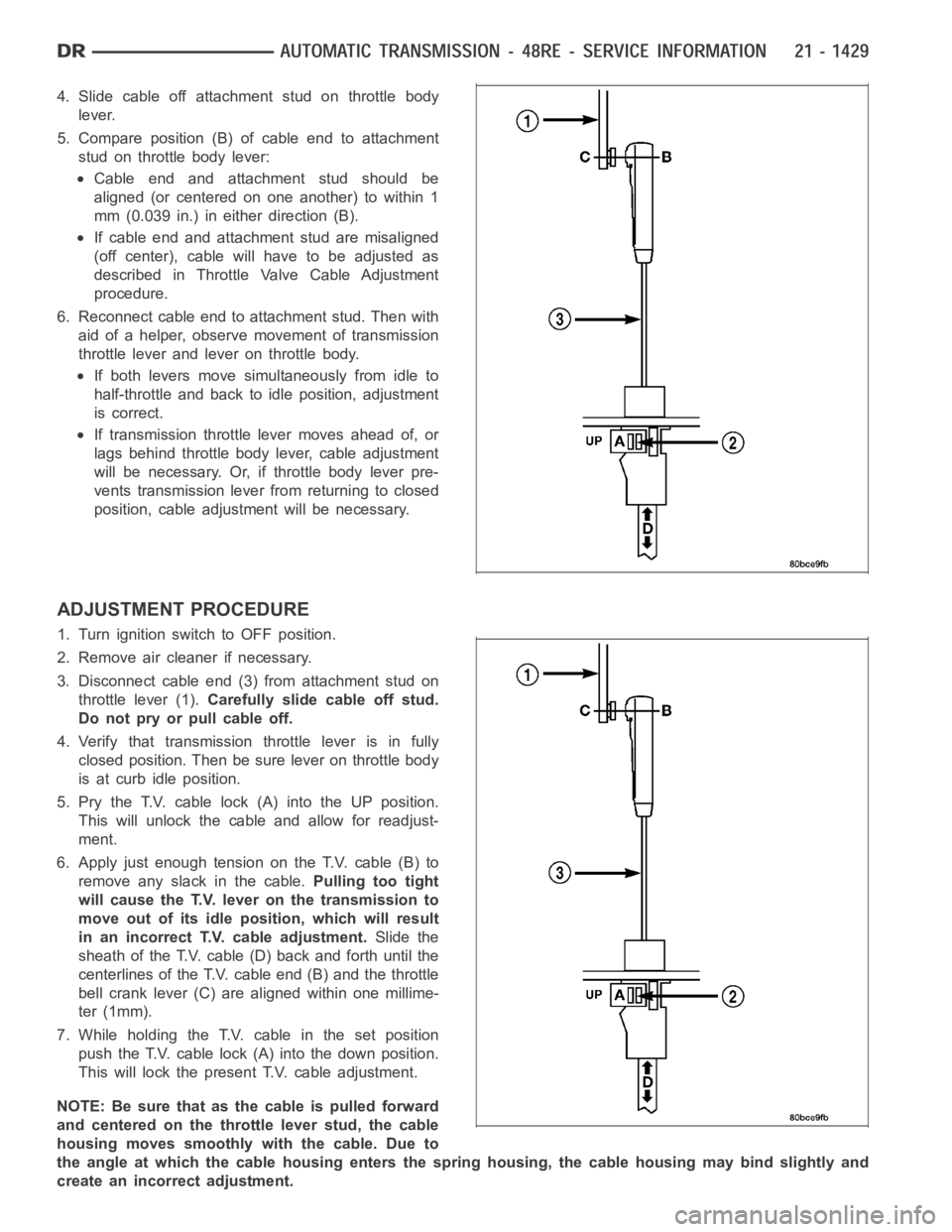

4. Slide cable off attachment stud on throttle body

lever.

5. Compare position (B) of cable end to attachment

stud on throttle body lever:

Cable end and attachment stud should be

aligned (or centered on one another) to within 1

mm (0.039 in.) in either direction (B).

If cable end and attachment stud are misaligned

(off center), cable will have to be adjusted as

described in Throttle Valve Cable Adjustment

procedure.

6. Reconnect cable end to attachment stud. Then with

aid of a helper, observe movement of transmission

throttle lever and lever on throttle body.

If both levers move simultaneously from idle to

half-throttle and back to idle position, adjustment

is correct.

If transmission throttle lever moves ahead of, or

lags behind throttle body lever, cable adjustment

will be necessary. Or, if throttle body lever pre-

vents transmission lever from returning to closed

position, cable adjustment will be necessary.

ADJUSTMENT PROCEDURE

1. Turn ignition switch to OFF position.

2. Remove air cleaner if necessary.

3. Disconnect cable end (3) from attachment stud on

throttle lever (1).Carefully slide cable off stud.

Do not pry or pull cable off.

4. Verify that transmission throttle lever is in fully

closed position. Then be sure lever on throttle body

is at curb idle position.

5. Pry the T.V. cable lock (A) into the UP position.

This will unlock the cable and allow for readjust-

ment.

6. Apply just enough tension on the T.V. cable (B) to

remove any slack in the cable.Pulling too tight

will cause the T.V. lever on the transmission to

move out of its idle position, which will result

in an incorrect T.V. cable adjustment.Slide the

sheath of the T.V. cable (D) back and forth until the

centerlines of the T.V. cable end (B) and the throttle

bell crank lever (C) are aligned within one millime-

ter (1mm).

7. While holding the T.V. cable in the set position

push the T.V. cable lock (A) into the down position.

This will lock the present T.V. cable adjustment.

NOTE:Besurethatasthecableispulledforward

and centered on the throttle lever stud, the cable

housing moves smoothly with the cable. Due to

the angle at which the cable housing enters the spring housing, the cable housing may bind slightly and

create an incorrect adjustment.