DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3931 of 5267

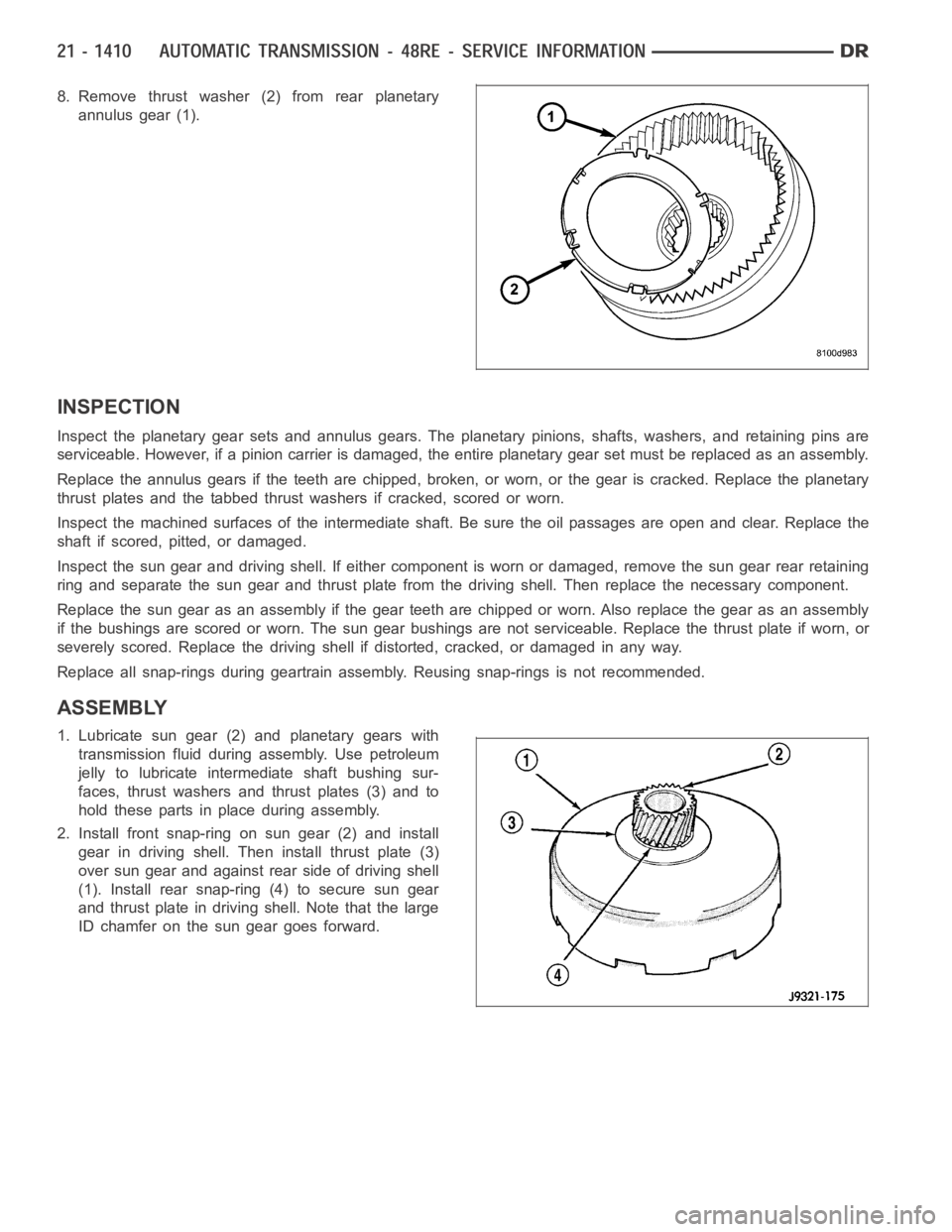

8. Remove thrust washer (2) from rear planetary

annulus gear (1).

INSPECTION

Inspect the planetary gear sets and annulus gears. The planetary pinions,shafts, washers, and retaining pins are

serviceable. However, if a pinion carrier is damaged, the entire planetarygearsetmustbereplacedasanassembly.

Replace the annulus gears if the teeth are chipped, broken, or worn, or the gear is cracked. Replace the planetary

thrust plates and the tabbed thrust washers if cracked, scored or worn.

Inspect the machined surfaces of the intermediate shaft. Be sure the oil passages are open and clear. Replace the

shaft if scored, pitted, or damaged.

Inspect the sun gear and driving shell. If either component is worn or damaged, remove the sun gear rear retaining

ring and separate the sun gear and thrust plate from the driving shell. Thenreplace the necessary component.

Replace the sun gear as an assembly if the gear teeth are chipped or worn. Also replace the gear as an assembly

if the bushings are scored or worn. The sun gear bushings are not serviceable. Replace the thrust plate if worn, or

severely scored. Replace the driving shell if distorted, cracked, or damaged in any way.

Replace all snap-rings during geartrain assembly. Reusing snap-rings isnot recommended.

ASSEMBLY

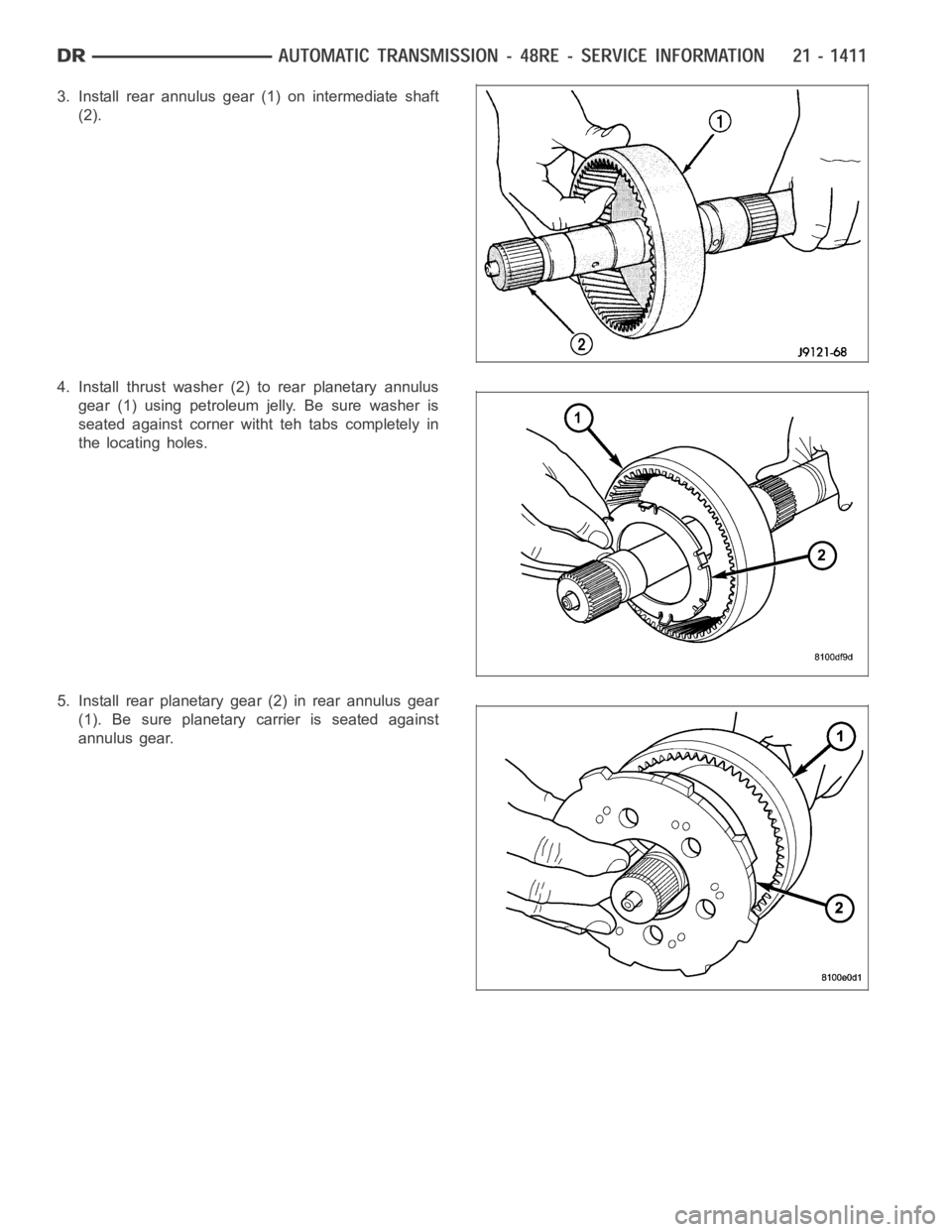

1. Lubricate sun gear (2) and planetary gears with

transmission fluid during assembly. Use petroleum

jelly to lubricate intermediate shaft bushing sur-

faces, thrust washers and thrust plates (3) and to

hold these parts in place during assembly.

2. Install front snap-ring on sun gear (2) and install

gear in driving shell. Then install thrust plate (3)

over sun gear and against rear side of driving shell

(1). Install rear snap-ring (4) to secure sun gear

and thrust plate in driving shell. Note that the large

ID chamfer on the sun gear goes forward.

Page 3932 of 5267

3. Install rear annulus gear (1) on intermediate shaft

(2).

4. Install thrust washer (2) to rear planetary annulus

gear (1) using petroleum jelly. Be sure washer is

seated against corner witht teh tabs completely in

the locating holes.

5. Install rear planetary gear (2) in rear annulus gear

(1). Be sure planetary carrier is seated against

annulus gear.

Page 3933 of 5267

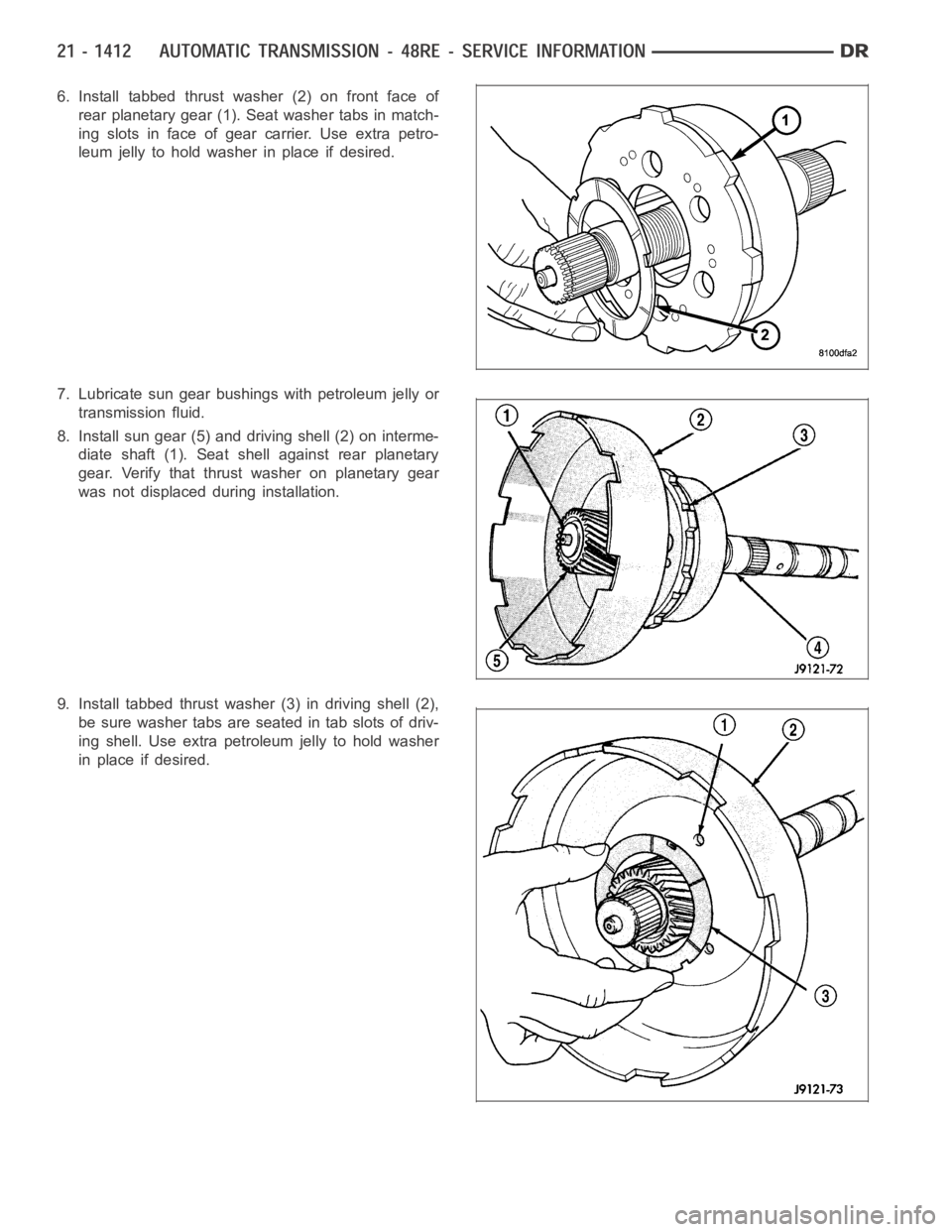

6. Install tabbed thrust washer (2) on front face of

rear planetary gear (1). Seat washer tabs in match-

ing slots in face of gear carrier. Use extra petro-

leum jelly to hold washer in place if desired.

7. Lubricate sun gear bushings with petroleum jelly or

transmission fluid.

8. Install sun gear (5) and driving shell (2) on interme-

diate shaft (1). Seat shell against rear planetary

gear. Verify that thrust washer on planetary gear

was not displaced during installation.

9. Install tabbed thrust washer (3) in driving shell (2),

be sure washer tabs are seated in tab slots of driv-

ing shell. Use extra petroleum jelly to hold washer

in place if desired.

Page 3934 of 5267

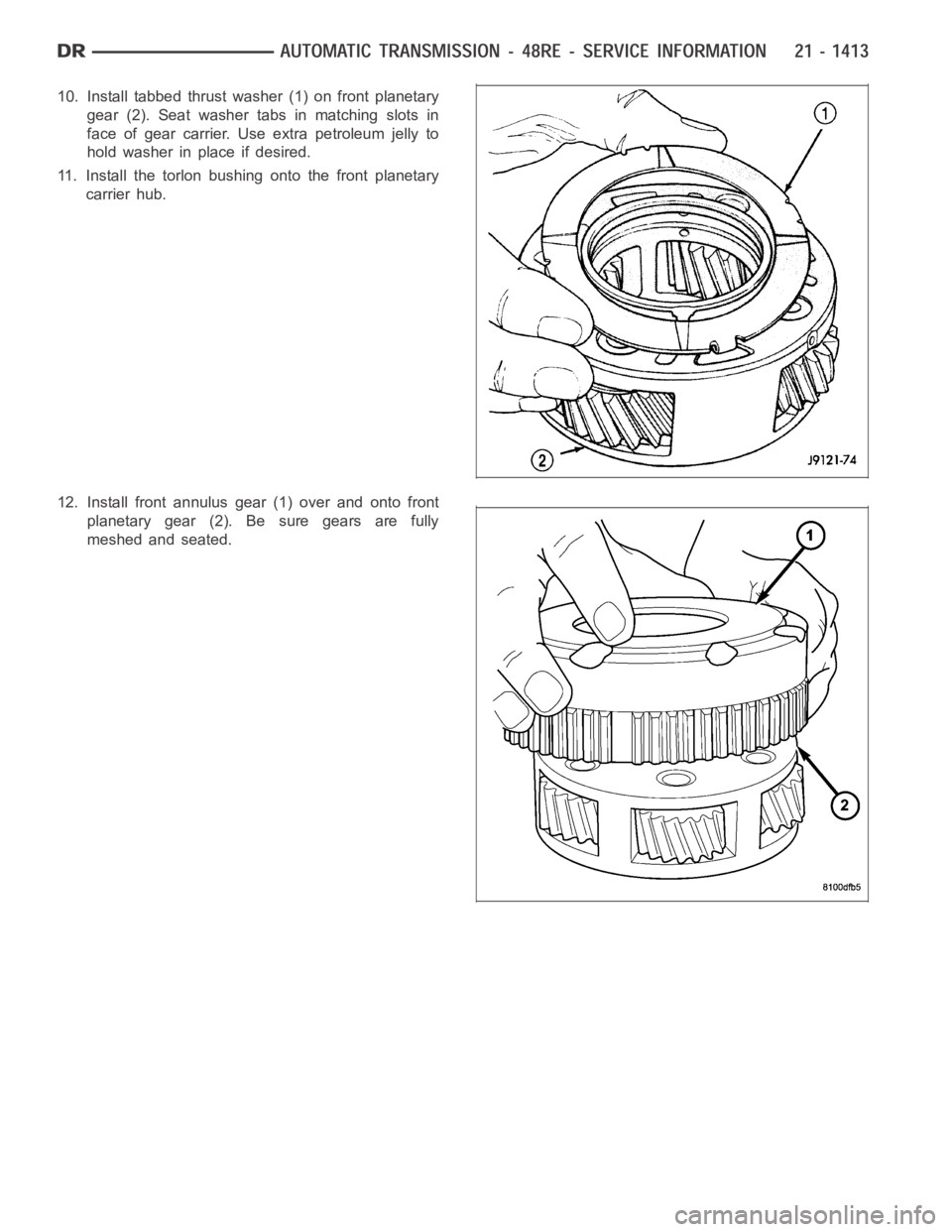

10. Install tabbed thrust washer (1) on front planetary

gear (2). Seat washer tabs in matching slots in

face of gear carrier. Use extra petroleum jelly to

hold washer in place if desired.

11. Install the torlon bushing onto the front planetary

carrier hub.

12. Install front annulus gear (1) over and onto front

planetary gear (2). Be sure gears are fully

meshed and seated.

Page 3935 of 5267

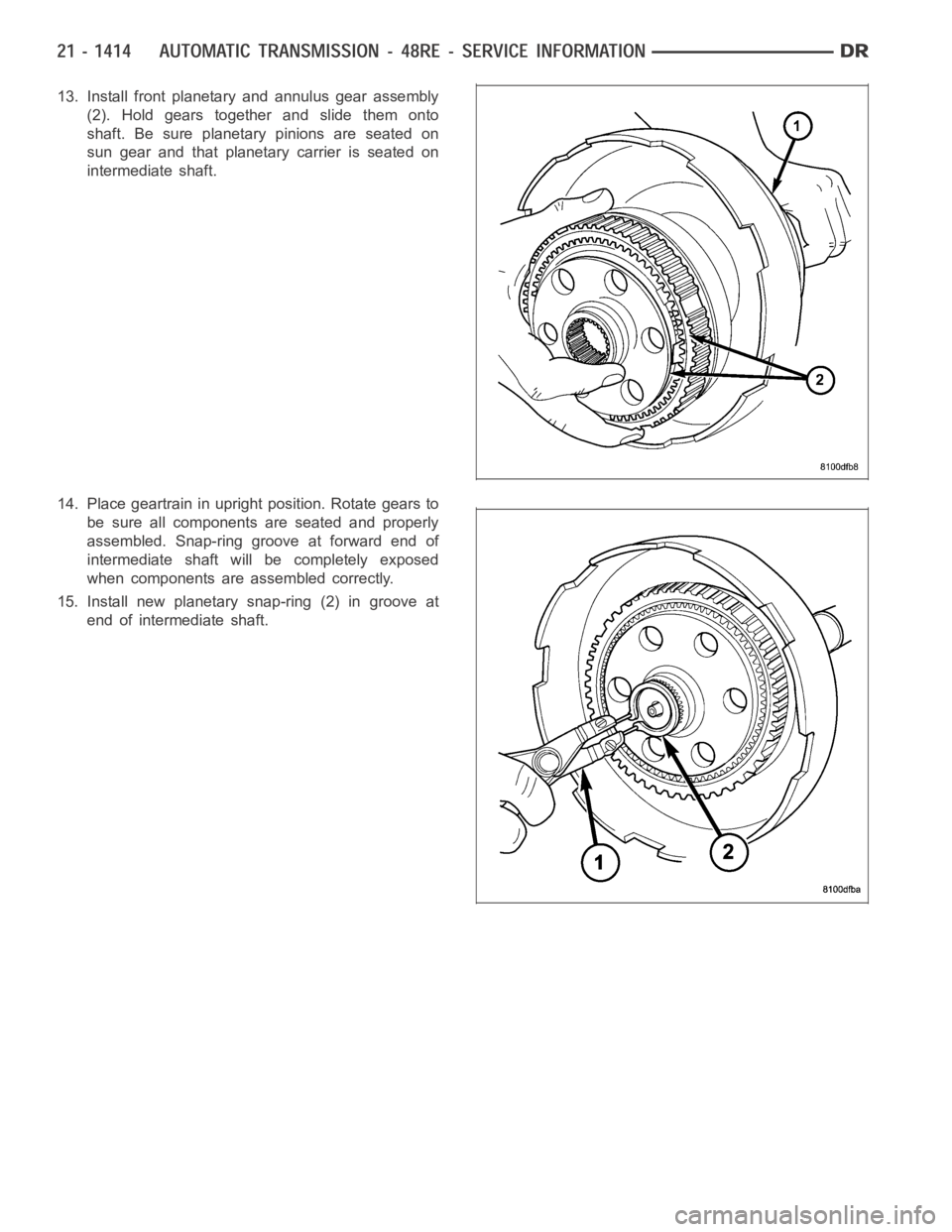

13. Install front planetary and annulus gear assembly

(2). Hold gears together and slide them onto

shaft. Be sure planetary pinions are seated on

sun gear and that planetary carrier is seated on

intermediate shaft.

14. Place geartrain in upright position. Rotate gears to

be sure all components are seated and properly

assembled. Snap-ring groove at forward end of

intermediate shaft will be completely exposed

when components are assembled correctly.

15. Install new planetary snap-ring (2) in groove at

end of intermediate shaft.

Page 3936 of 5267

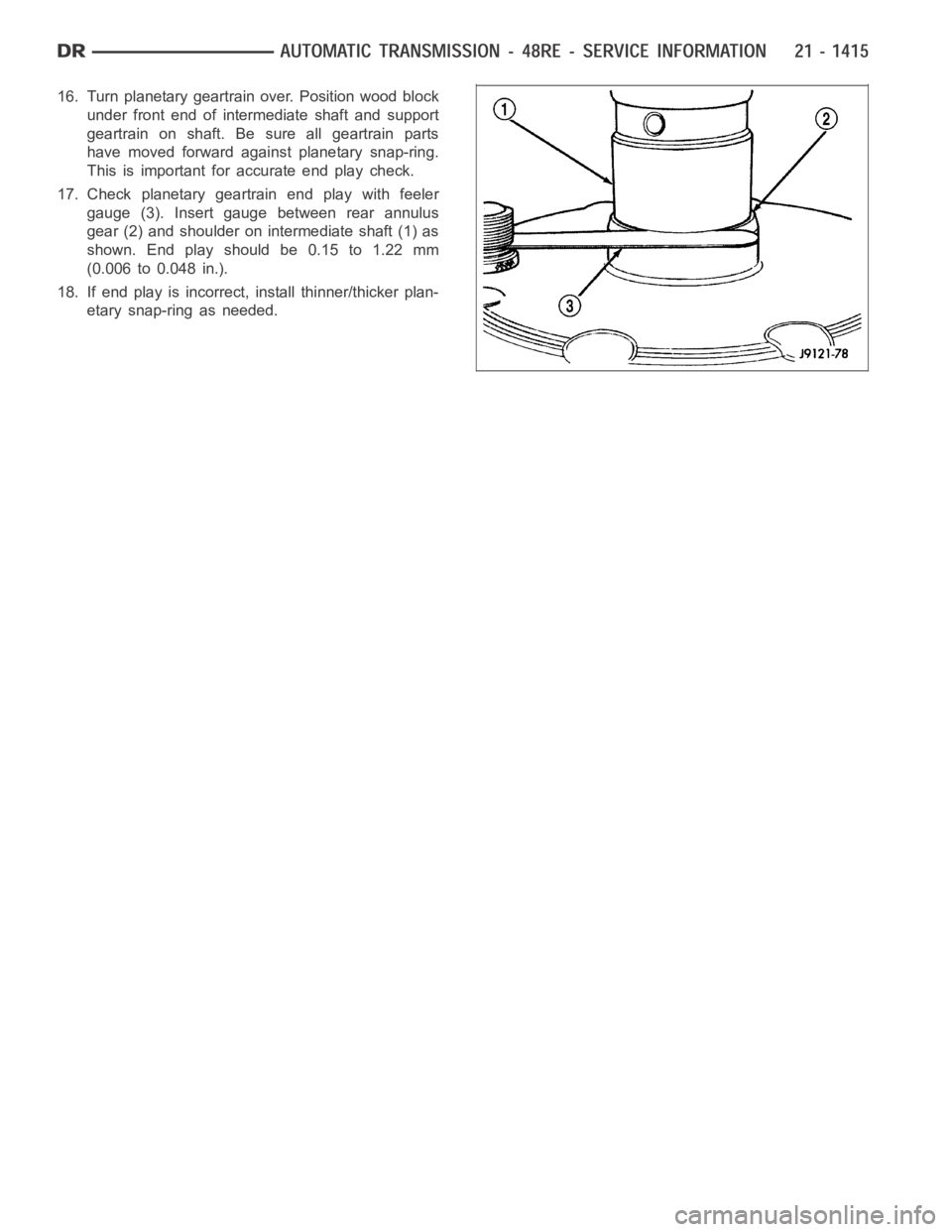

16. Turn planetary geartrain over. Position wood block

under front end of intermediate shaft and support

geartrain on shaft. Be sure all geartrain parts

have moved forward against planetary snap-ring.

This is important for accurate end play check.

17. Check planetary geartrain end play with feeler

gauge (3). Insert gauge between rear annulus

gear (2) and shoulder on intermediate shaft (1) as

shown. End play should be 0.15 to 1.22 mm

(0.006 to 0.048 in.).

18. If end play is incorrect, install thinner/thicker plan-

etary snap-ring as needed.

Page 3937 of 5267

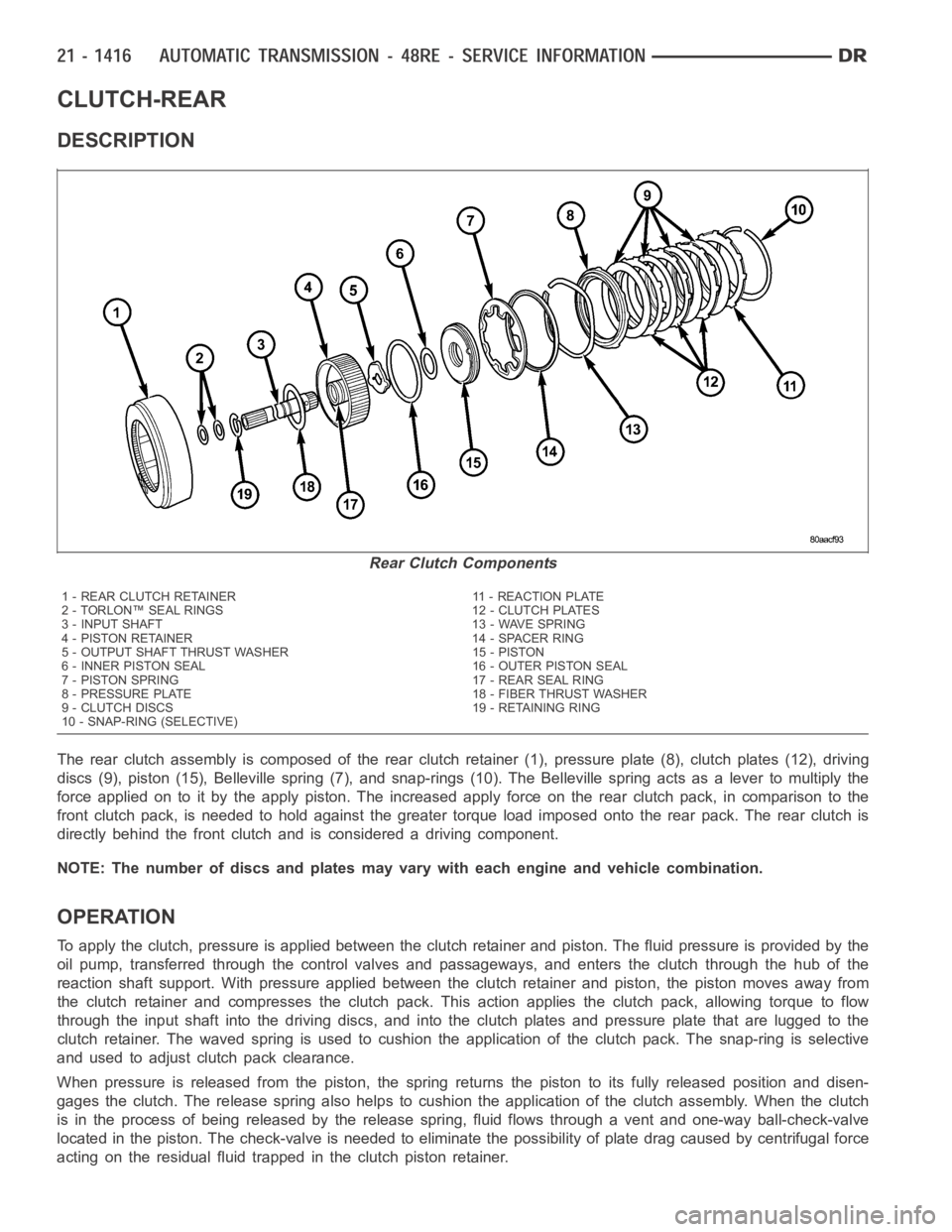

CLUTCH-REAR

DESCRIPTION

The rear clutch assembly is composed of the rear clutch retainer (1), pressure plate (8), clutch plates (12), driving

discs (9), piston (15), Belleville spring (7), and snap-rings (10). The Belleville spring acts as a lever to multiply the

force applied on to it by the apply piston. The increased apply force on the rear clutch pack, in comparison to the

front clutch pack, is needed to hold against the greater torque load imposed onto the rear pack. The rear clutch is

directly behind the front clutch and is considered a driving component.

NOTE: The number of discs and plates may vary with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between the clutch retainer and piston. The fluid pressure is provided by the

oil pump, transferred through the control valves and passageways, and enters the clutch through the hub of the

reaction shaft support. With pressure applied between the clutch retainer and piston, the piston moves away from

the clutch retainer and compresses the clutch pack. This action applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and into the clutch plates and pressure plate that are lugged to the

clutch retainer. The waved spring is used to cushion the application of theclutch pack. The snap-ring is selective

and used to adjust clutch pack clearance.

When pressure is released from the piston, the spring returns the piston toits fully released position and disen-

gages the clutch. The release spring also helps to cushion the applicationof the clutch assembly. When the clutch

is in the process of being released by the release spring, fluid flows through a vent and one-way ball-check-valve

located in the piston. The check-valve is needed to eliminate the possibility of plate drag caused by centrifugal force

acting on the residual fluid trapped in the clutch piston retainer.

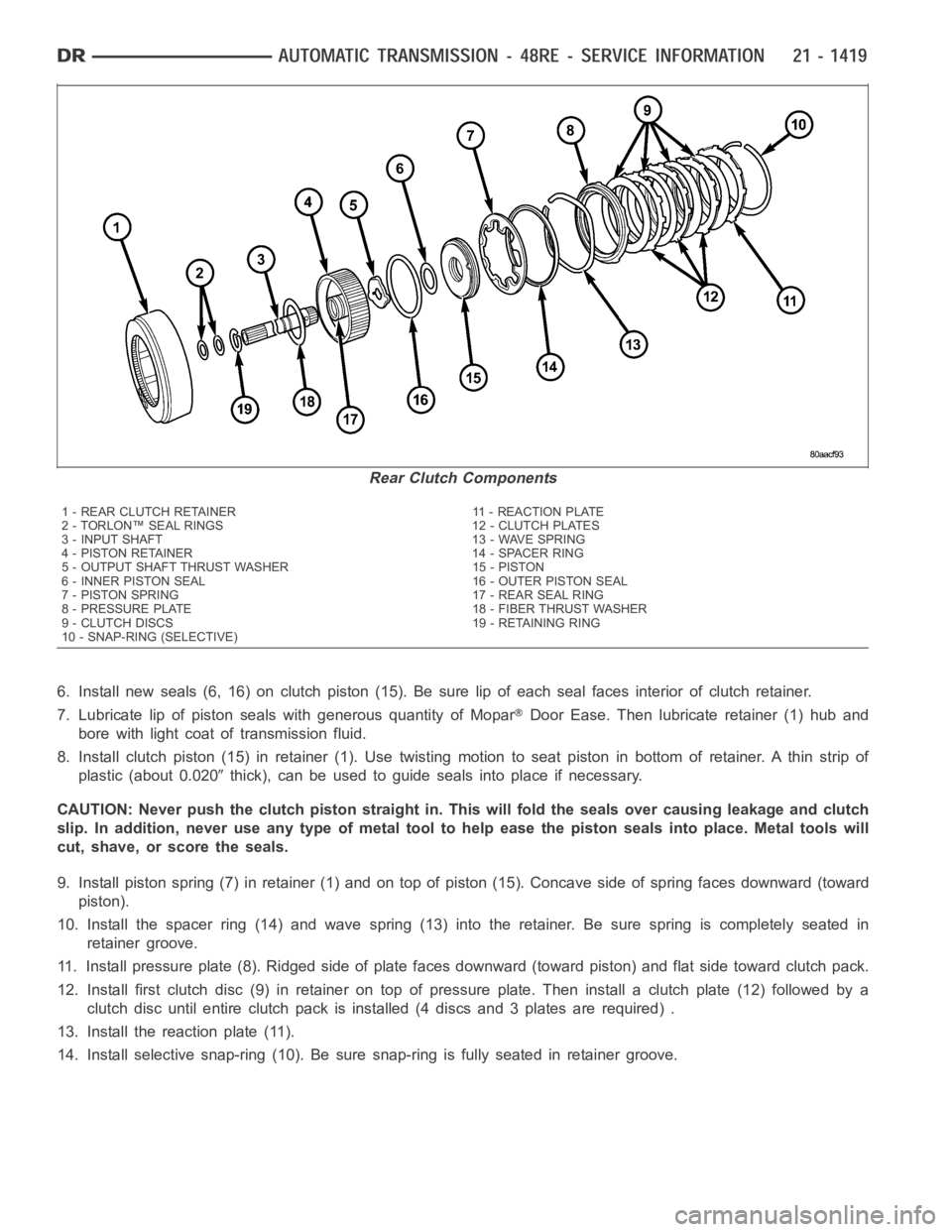

Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLON™ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)

Page 3938 of 5267

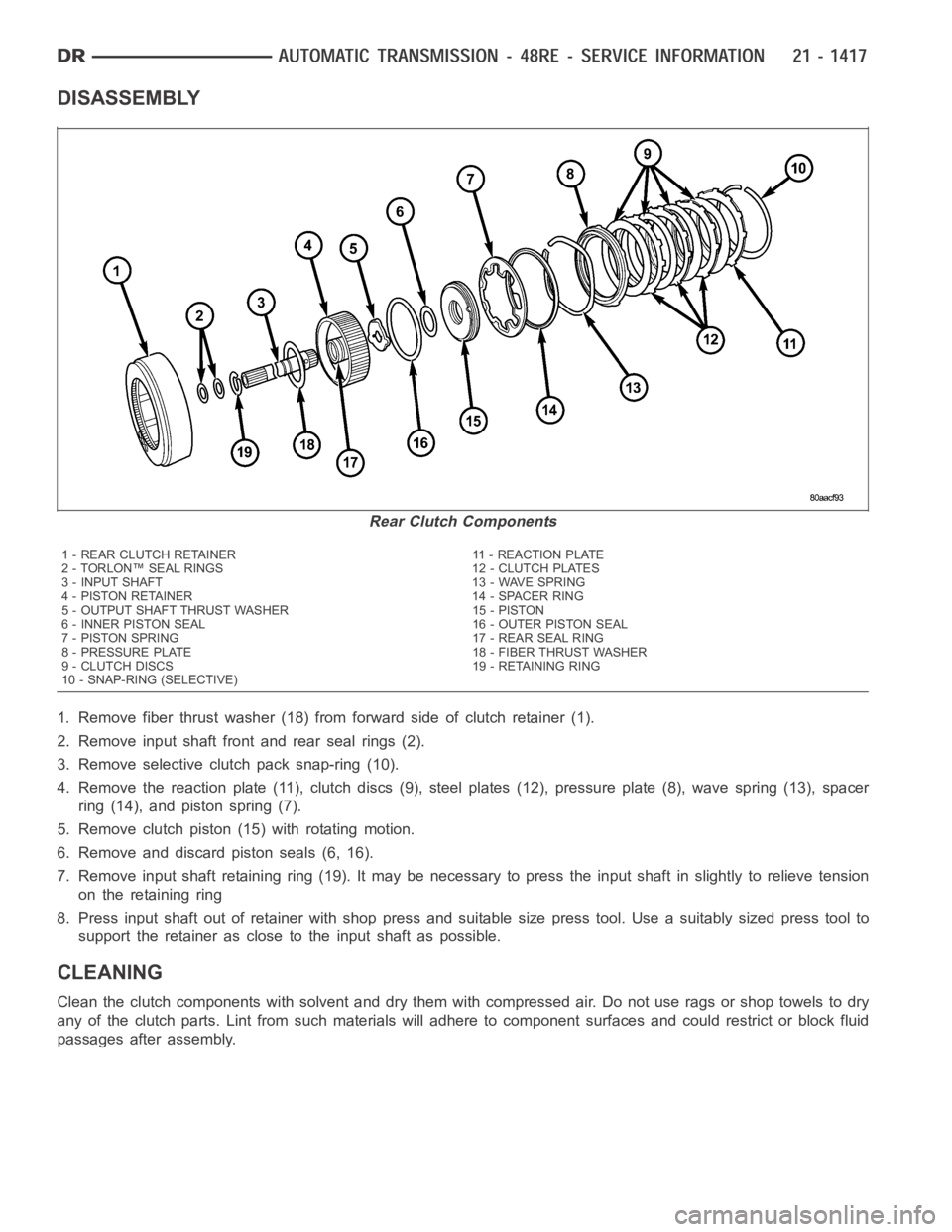

DISASSEMBLY

1. Remove fiber thrust washer (18) from forward side of clutch retainer (1).

2. Remove input shaft front and rear seal rings (2).

3. Remove selective clutch pack snap-ring (10).

4. Remove the reaction plate (11), clutch discs (9), steel plates (12), pressure plate (8), wave spring (13), spacer

ring (14), and piston spring (7).

5. Remove clutch piston (15) with rotating motion.

6. Remove and discard piston seals (6, 16).

7. Remove input shaft retaining ring (19). It may be necessary to press the input shaft in slightly to relieve tension

on the retaining ring

8. Press input shaft out of retainer with shop press and suitable size presstool. Use a suitably sized press tool to

support the retainer as close to the input shaft as possible.

CLEANING

Clean the clutch components with solvent and dry them with compressed air.Do not use rags or shop towels to dry

any of the clutch parts. Lint from such materials will adhere to component surfaces and could restrict or block fluid

passages after assembly.

Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLON™ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)

Page 3939 of 5267

INSPECTION

Replace the clutch discs if warped, worn, scored, burned/charred, the lugs are damaged, or if the facing is flaking

off. Replace the top and bottom pressure plates if scored, warped, or cracked. Be sure the driving lugs on the

pressure and clutch plates are also in good condition. The lugs must not be bent, cracked or damaged in any way.

Replace the piston spring and wave spring if either part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The clutch and pressure plates should slide freely in the slots. Replace

the retainer if the grooves are worn or damaged. Also check action of the check balls in the retainer and piston.

Each check ball must move freely and not stick.

Replace the retainer bushing if worn, scored, or doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for nicks or scratches. Minor scratches can be removed with crocus

cloth. However, replace the piston and/or retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and metal output shaft thrust washer. Replace either washer if worn or

damaged.

Check condition of the seal rings on the input shaft and clutch retainer hub. Replace the seal rings only if worn,

distorted, or damaged. The input shaft front seal ring is teflon with chamfered ends. The rear ring is metal with

interlocking ends.

Check the input shaft for wear, or damage. Replace the shaft if worn, scoredor damaged in any way.

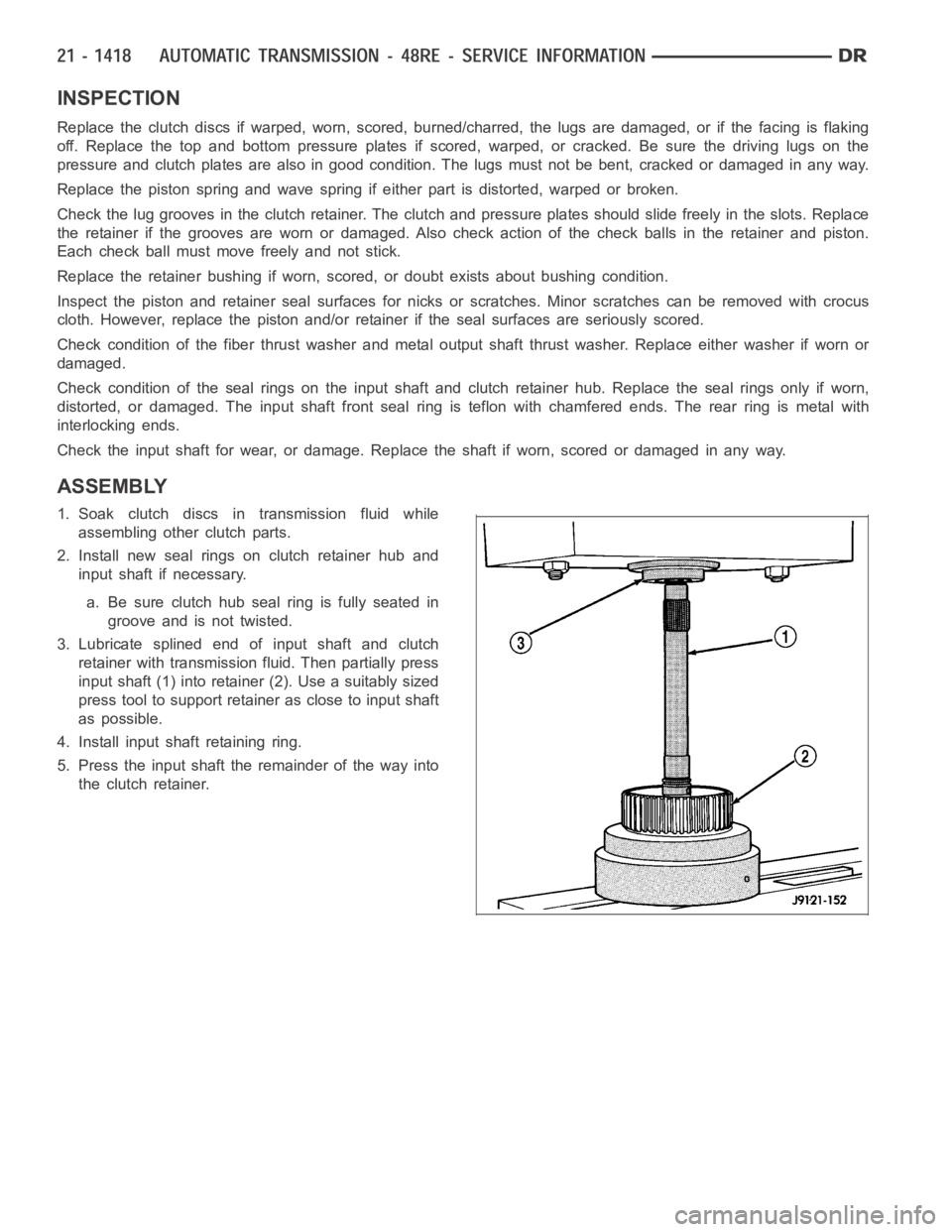

ASSEMBLY

1. Soak clutch discs in transmission fluid while

assembling other clutch parts.

2. Install new seal rings on clutch retainer hub and

input shaft if necessary.

a. Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

3. Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then partially press

input shaft (1) into retainer (2). Use a suitably sized

press tool to support retainer as close to input shaft

as possible.

4. Install input shaft retaining ring.

5. Press the input shaft the remainder of the way into

the clutch retainer.

Page 3940 of 5267

6. Install new seals (6, 16) on clutch piston (15). Be sure lip of each seal faces interior of clutch retainer.

7. Lubricate lip of piston seals with generous quantity of Mopar

Door Ease. Then lubricate retainer (1) hub and

bore with light coat of transmission fluid.

8. Install clutch piston (15) in retainer (1). Use twisting motion to seat piston in bottom of retainer. A thin strip of

plastic (about 0.020

thick), can be used to guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in. This will fold the sealsover causing leakage and clutch

slip. In addition, never use any type of metal tool to help ease the piston seals into place. Metal tools will

cut, shave, or score the seals.

9. Install piston spring (7) in retainer (1) and on top of piston (15). Concave side of spring faces downward (toward

piston).

10. Install the spacer ring (14) and wave spring (13) into the retainer. Be sure spring is completely seated in

retainer groove.

11. Install pressure plate (8). Ridged side of plate faces downward (toward piston) and flat side toward clutch pack.

12. Install first clutch disc (9) in retainer on top of pressure plate. Theninstall a clutch plate (12) followed by a

clutch disc until entire clutch pack is installed (4 discs and 3 plates are required) .

13. Install the reaction plate (11).

14. Install selective snap-ring (10). Be sure snap-ring is fully seated inretainer groove.

Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLON™ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)