DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3971 of 5267

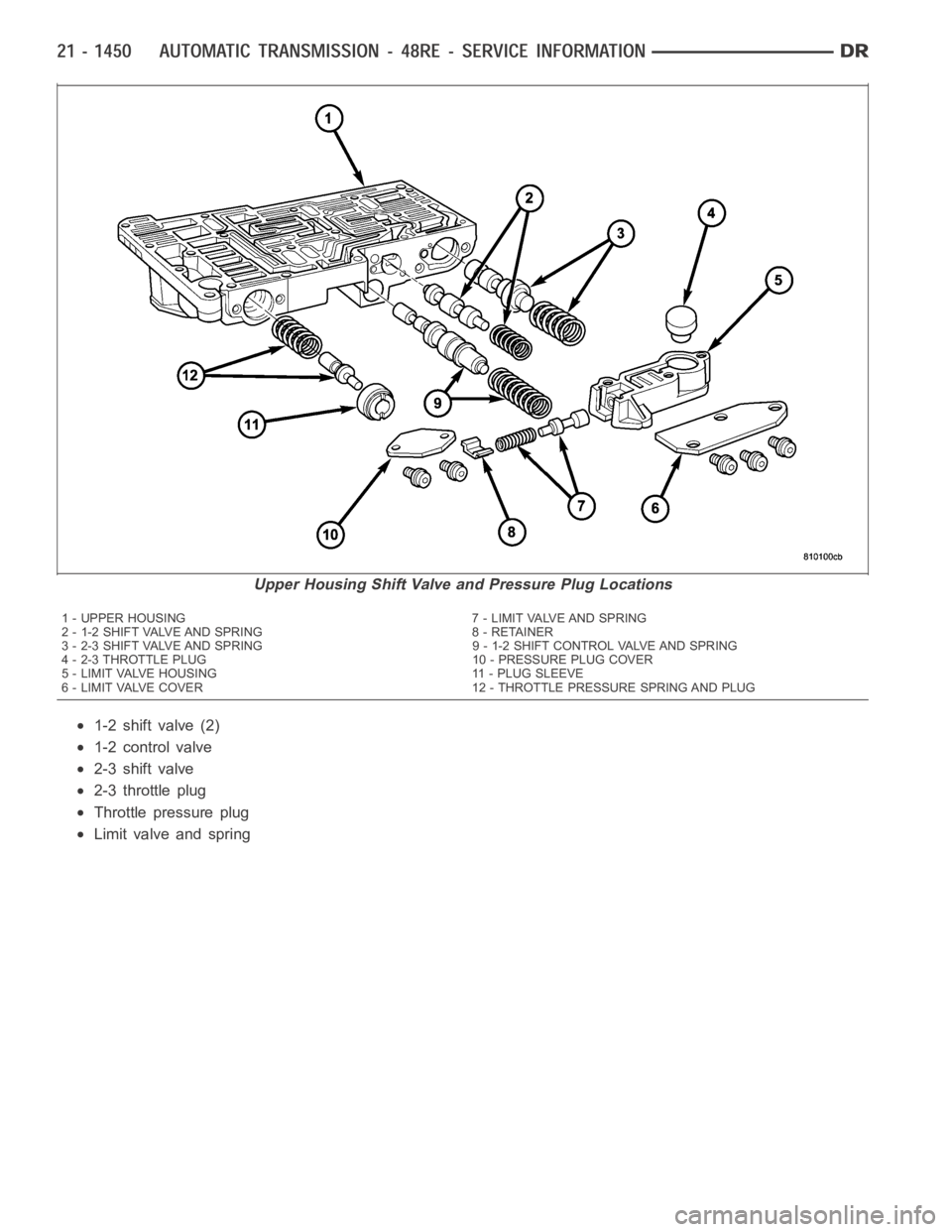

1-2 shift valve (2)

1-2 control valve

2-3 shift valve

2-3 throttle plug

Throttlepressureplug

Limit valve and spring

Upper Housing Shift Valve and Pressure Plug Locations

1 - UPPER HOUSING 7 - LIMIT VALVE AND SPRING

2 - 1-2 SHIFT VALVE AND SPRING 8 - RETAINER

3 - 2-3 SHIFT VALVE AND SPRING 9 - 1-2 SHIFT CONTROL VALVE AND SPRING

4 - 2-3 THROTTLE PLUG 10 - PRESSURE PLUG COVER

5 - LIMIT VALVE HOUSING 11 - PLUG SLEEVE

6 - LIMIT VALVE COVER 12 - THROTTLE PRESSURE SPRING AND PLUG

Page 3972 of 5267

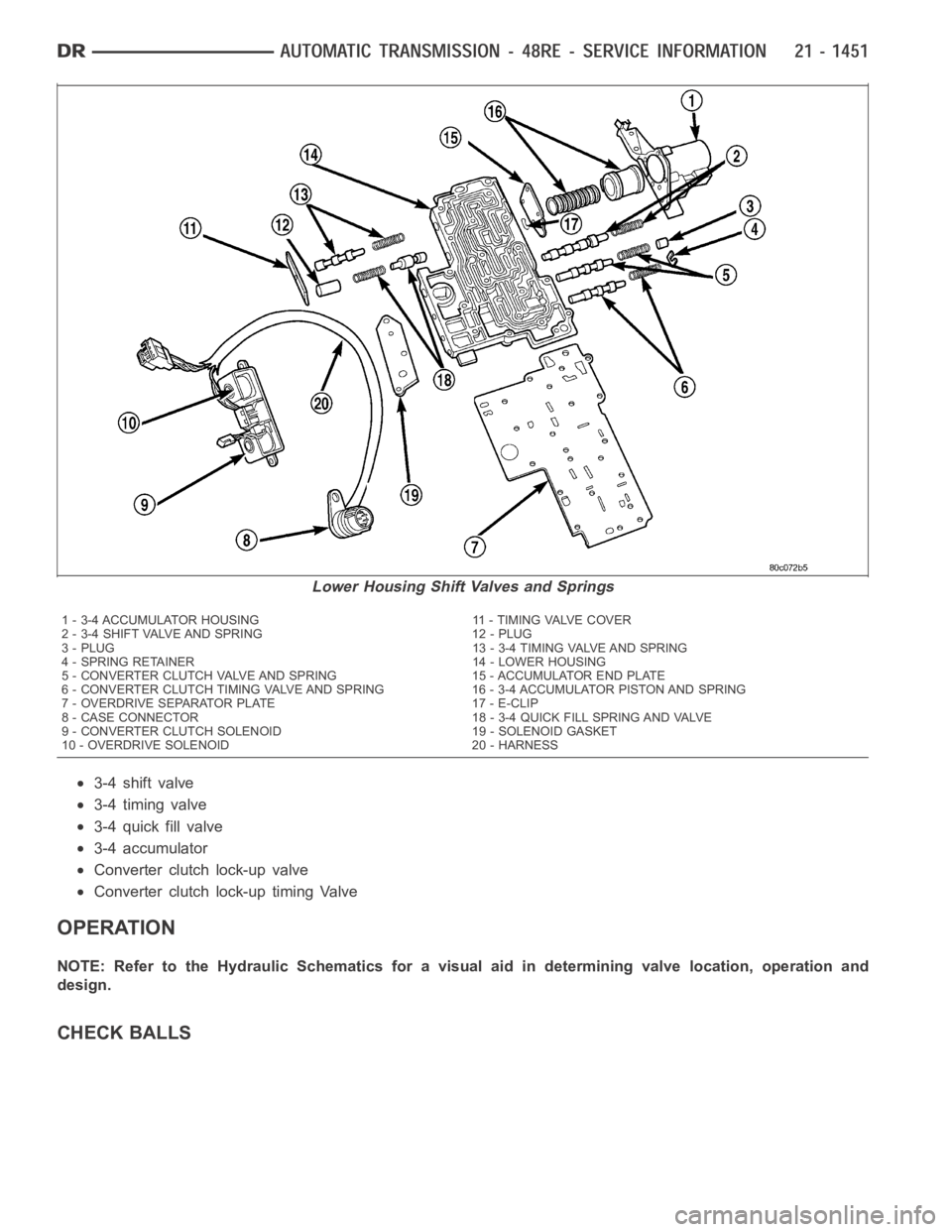

3-4 shift valve

3-4 timing valve

3-4 quick fill valve

3-4 accumulator

Converter clutch lock-up valve

Converter clutch lock-up timing Valve

OPERATION

NOTE: Refer to the Hydraulic Schematics for a visual aid in determining valve location, operation and

design.

CHECK BALLS

Lower Housing Shift Valves and Springs

1 - 3-4 ACCUMULATOR HOUSING 11 - TIMING VALVE COVER

2 - 3-4 SHIFT VALVE AND SPRING 12 - PLUG

3 - PLUG 13 - 3-4 TIMING VALVE AND SPRING

4 - SPRING RETAINER 14 - LOWER HOUSING

5 - CONVERTER CLUTCH VALVE AND SPRING 15 - ACCUMULATOR END PLATE

6 - CONVERTER CLUTCH TIMING VALVE AND SPRING 16 - 3-4 ACCUMULATOR PISTON ANDSPRING

7 - OVERDRIVE SEPARATOR PLATE 17 - E-CLIP

8 - CASE CONNECTOR 18 - 3-4 QUICK FILL SPRING AND VALVE

9 - CONVERTER CLUTCH SOLENOID 19 - SOLENOID GASKET

10 - OVERDRIVE SOLENOID 20 - HARNESS

Page 3973 of 5267

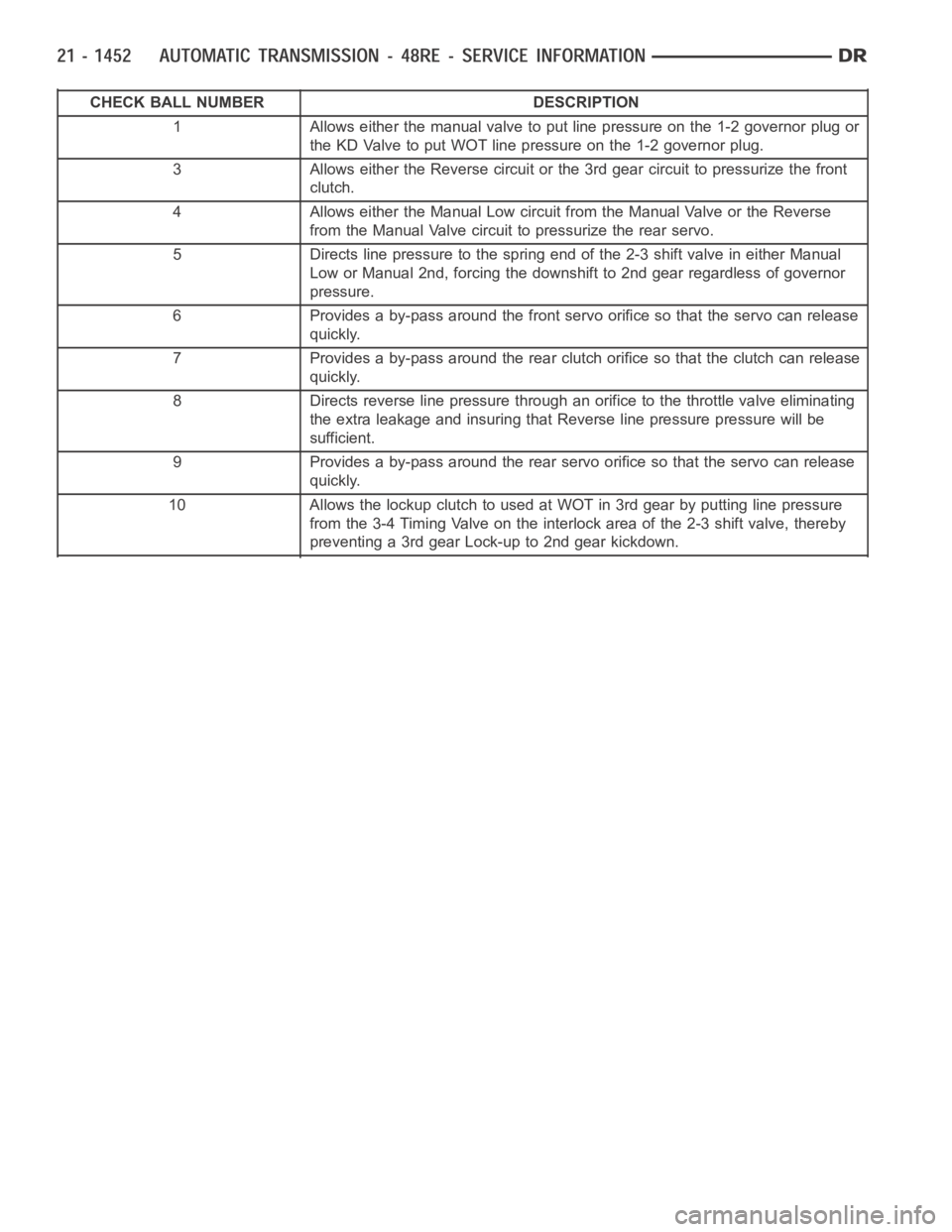

CHECK BALL NUMBER DESCRIPTION

1 Allows either the manual valve to put line pressure on the 1-2 governor plugor

the KD Valve to put WOT line pressure on the 1-2 governor plug.

3 Allows either the Reverse circuit or the 3rd gear circuit to pressurize thefront

clutch.

4 Allows either the Manual Low circuit from the Manual Valve or the Reverse

from the Manual Valve circuit to pressurize the rear servo.

5 Directs line pressure to the spring end of the 2-3 shift valve in either Manual

Low or Manual 2nd, forcing the downshift to 2nd gear regardless of governor

pressure.

6 Provides a by-pass around the front servo orifice so that the servo can release

quickly.

7 Provides a by-pass around the rear clutch orifice so that the clutch can release

quickly.

8 Directs reverse line pressure through an orifice to the throttle valve eliminating

the extra leakage and insuring that Reverse line pressure pressure will be

sufficient.

9 Provides a by-pass around the rear servo orifice so that the servo can release

quickly.

10 AllowsthelockupclutchtousedatWOTin3rdgearbyputtinglinepressure

from the 3-4 Timing Valve on the interlock area of the 2-3 shift valve, thereby

preventing a 3rd gear Lock-up to 2nd gear kickdown.

Page 3974 of 5267

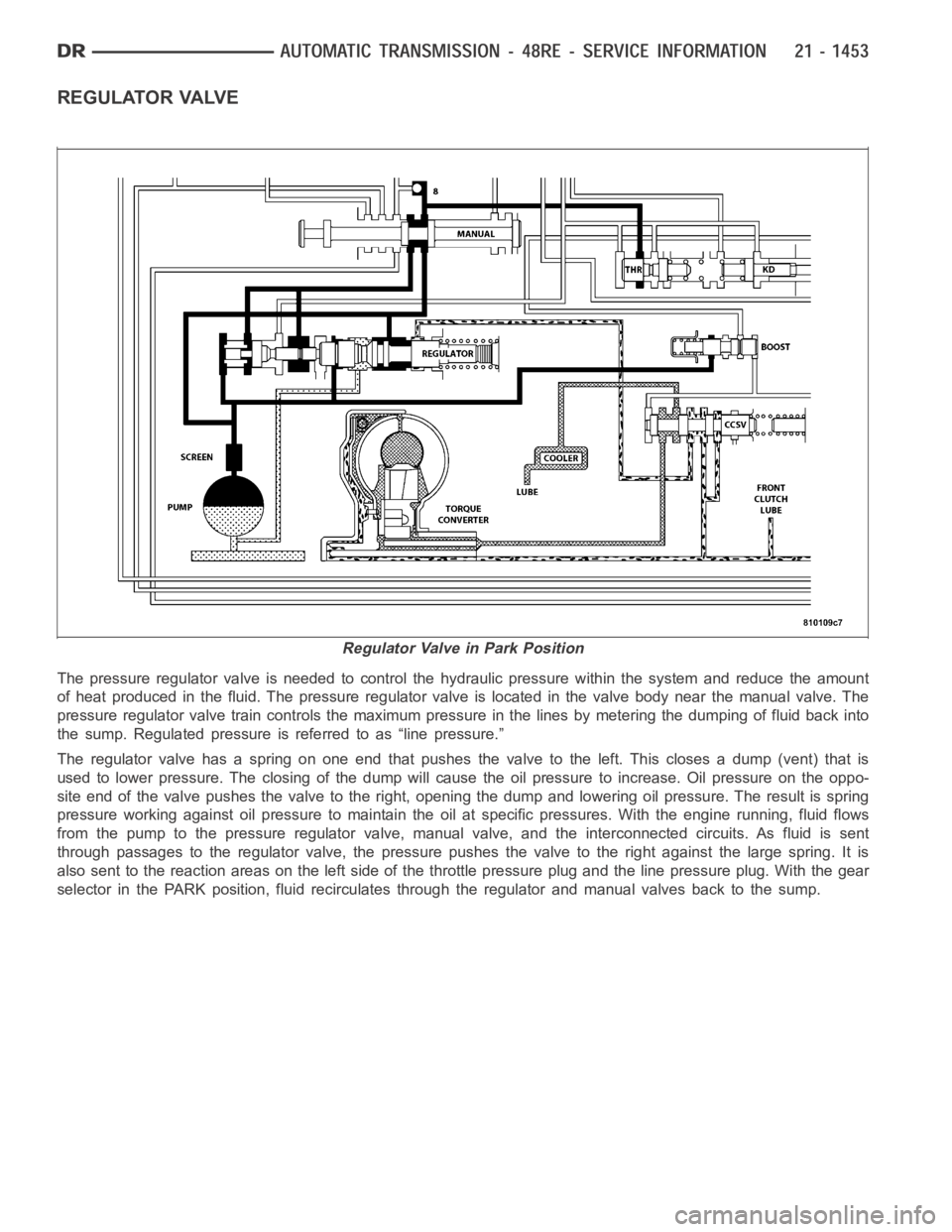

REGULATOR VALVE

The pressure regulator valve is needed to control the hydraulic pressure within the system and reduce the amount

of heat produced in the fluid. The pressure regulator valve is located in the valve body near the manual valve. The

pressure regulator valve train controls the maximum pressure in the linesby metering the dumping of fluid back into

the sump. Regulated pressure is referred to as “line pressure.”

The regulator valve has a spring on one end that pushes the valve to the left.This closes a dump (vent) that is

used to lower pressure. The closing of the dump will cause the oil pressure to increase. Oil pressure on the oppo-

site end of the valve pushes the valve to the right, opening the dump and lowering oil pressure. The result is spring

pressure working against oil pressureto maintain the oil at specific pressures. With the engine running, fluid flows

from the pump to the pressure regulator valve, manual valve, and the interconnected circuits. As fluid is sent

through passages to the regulator valve, the pressure pushes the valve to the right against the large spring. It is

also sent to the reaction areas on the left side of the throttle pressure plug and the line pressure plug. With the gear

selector in the PARK position, fluid recirculates through the regulator and manual valves back to the sump.

Regulator Valve in Park Position

Page 3975 of 5267

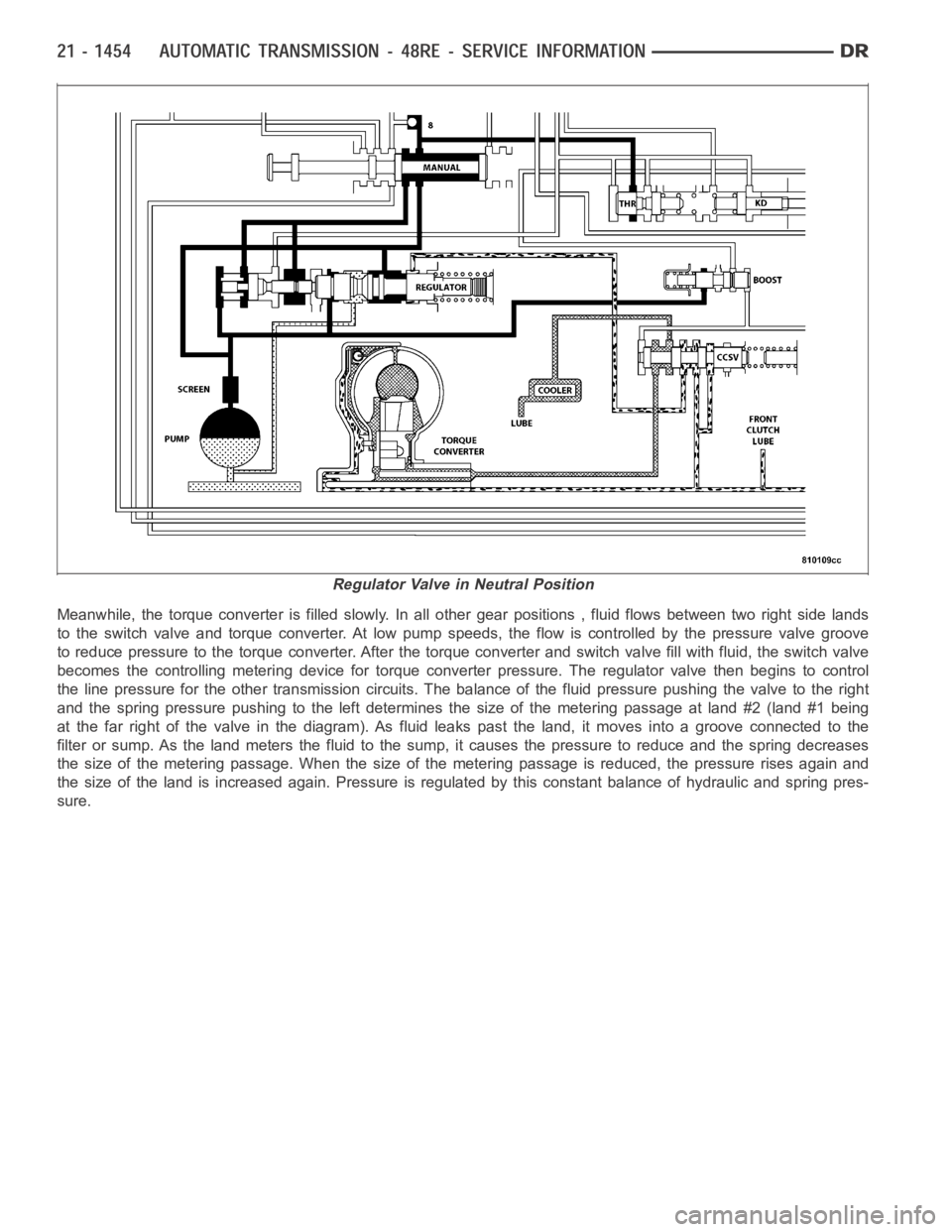

Meanwhile, the torque converter is filled slowly. In all other gear positions , fluid flows between two right side lands

to the switch valve and torque converter. At low pump speeds, the flow is controlled by the pressure valve groove

to reduce pressure to the torque converter. After the torque converter andswitch valve fill with fluid, the switch valve

becomes the controlling metering device for torque converter pressure. The regulator valve then begins to control

the line pressure for the other transmission circuits. The balance of the fluid pressure pushing the valve to the right

and the spring pressure pushing to the left determines the size of the metering passage at land #2 (land #1 being

at the far right of the valve in the diagram). As fluid leaks past the land, itmoves into a groove connected to the

filter or sump. As the land meters the fluid to the sump, it causes the pressure to reduce and the spring decreases

the size of the metering passage. When the size of the metering passage is reduced, the pressure rises again and

the size of the land is increased again. Pressure is regulated by this constant balance of hydraulic and spring pres-

sure.

Regulator Valve in Neutral Position

Page 3976 of 5267

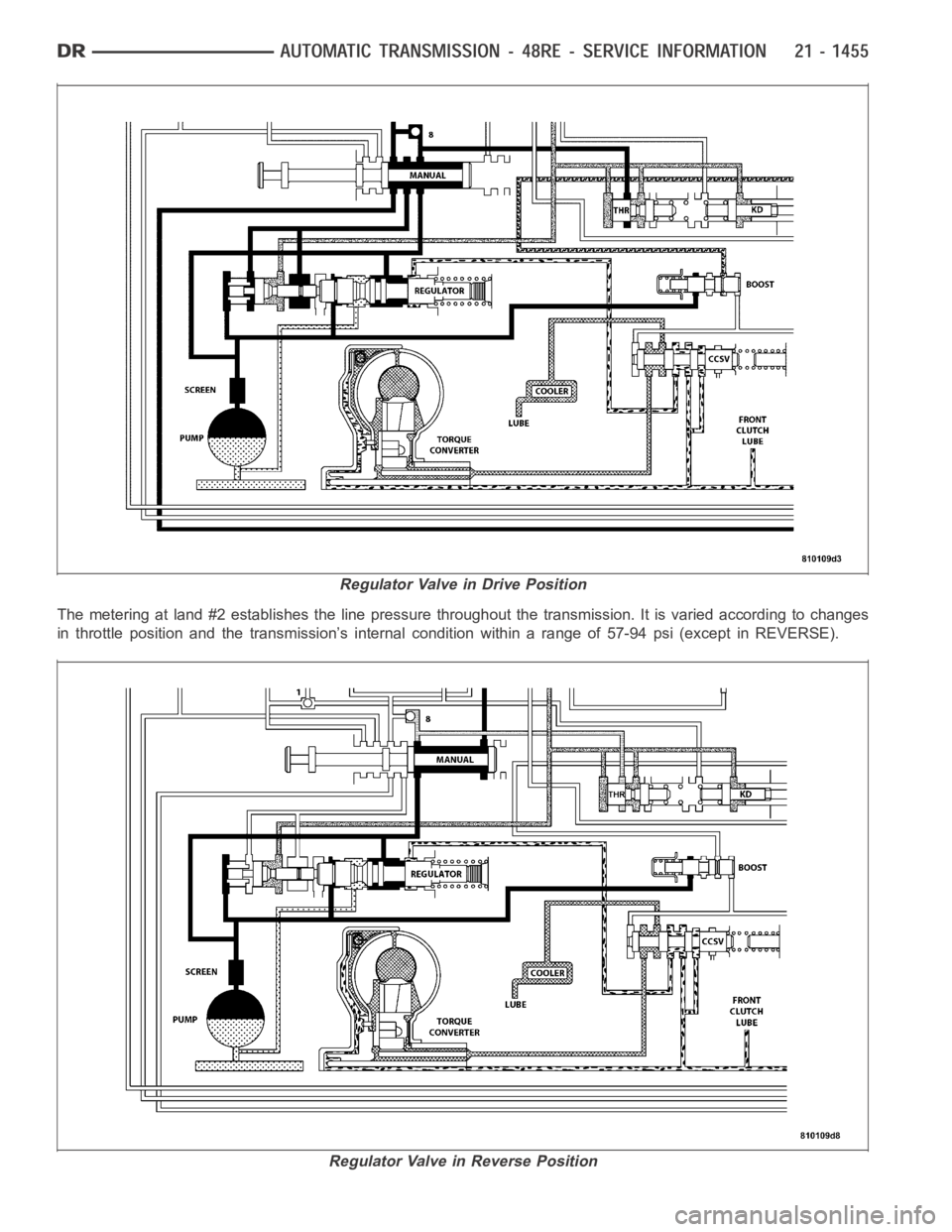

The metering at land #2 establishes the line pressure throughout the transmission. It is varied according to changes

in throttle position and the transmission’s internal condition within a range of 57-94 psi (except in REVERSE).

Regulator Valve in Drive Position

Regulator Valve in Reverse Position

Page 3977 of 5267

The regulated line pressure in REVERSEis held at much higher pressures than in the other gear positions: 145-280

psi. The higher pressure for REVERSE isachieved by the manual valve blocking the supply of line pressure to the

reaction area left of land #4. With this pressure blocked, there is less area for pressure to act on to balance the

force of the spring on the right. This allows line pressure to push the valvetrain to the right, reducing the amount

of fluid returned to the pump’s inlet, increasing line pressure.

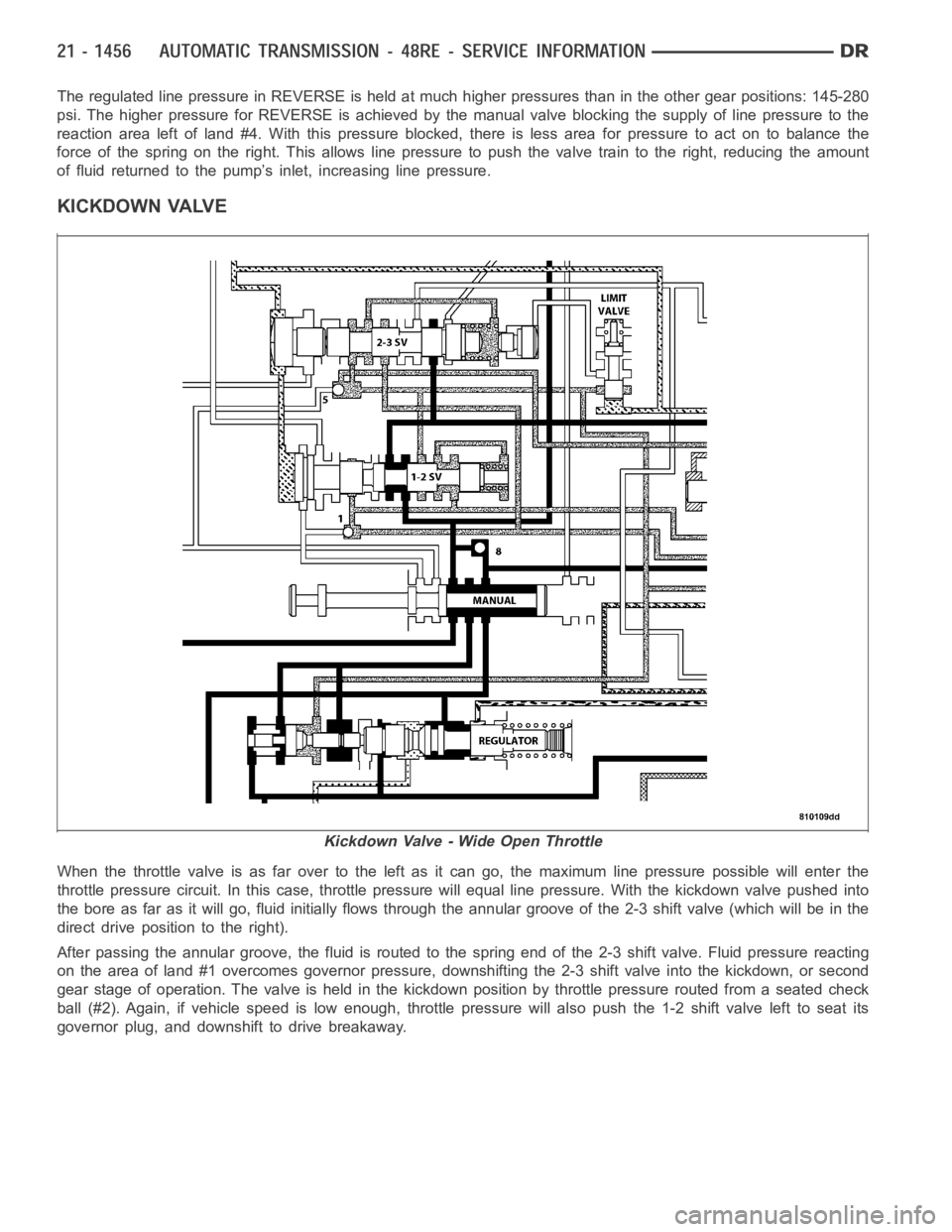

KICKDOWN VALVE

When the throttle valve is as far over to the left as it can go, the maximum line pressure possible will enter the

throttle pressure circuit. In this case, throttle pressure will equal line pressure. With the kickdown valve pushed into

the bore as far as it will go, fluid initially flows through the annular groove of the 2-3 shift valve (which will be in the

direct drive position to the right).

After passing the annular groove, the fluid is routed to the spring end of the 2-3 shift valve. Fluid pressure reacting

on the area of land #1 overcomes governor pressure, downshifting the 2-3 shift valve into the kickdown, or second

gear stage of operation. The valve is held in the kickdown position by throttle pressure routed from a seated check

ball (#2). Again, if vehicle speed is low enough, throttle pressure will also push the 1-2 shift valve left to seat its

governor plug, and downshift to drive breakaway.

Kickdown Valve - Wide Open Throttle

Page 3978 of 5267

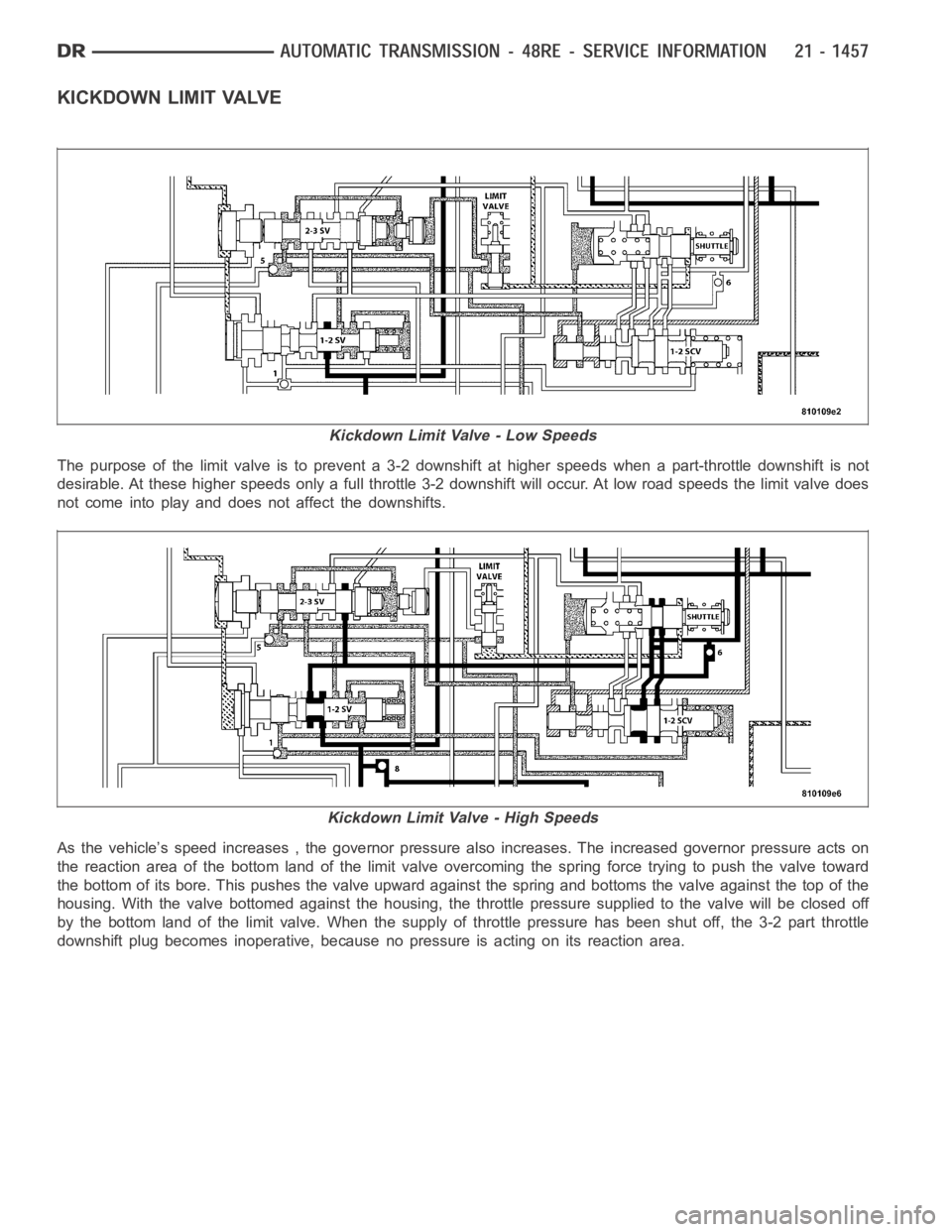

KICKDOWN LIMIT VALVE

The purpose of the limit valve is to prevent a 3-2 downshift at higher speedswhen a part-throttle downshift is not

desirable. At these higher speeds only a full throttle 3-2 downshift will occur. At low road speeds the limit valve does

not come into play and does not affect the downshifts.

As the vehicle’s speed increases , the governor pressure also increases. The increased governor pressure acts on

the reaction area of the bottom land of the limit valve overcoming the spring force trying to push the valve toward

the bottom of its bore. This pushes the valve upward against the spring and bottoms the valve against the top of the

housing. With the valve bottomed against the housing, the throttle pressure supplied to the valve will be closed off

by the bottom land of the limit valve. When the supply of throttle pressure has been shut off, the 3-2 part throttle

downshift plug becomes inoperative, because no pressure is acting on its reaction area.

Kickdown Limit Valve - Low Speeds

Kickdown Limit Valve - High Speeds

Page 3979 of 5267

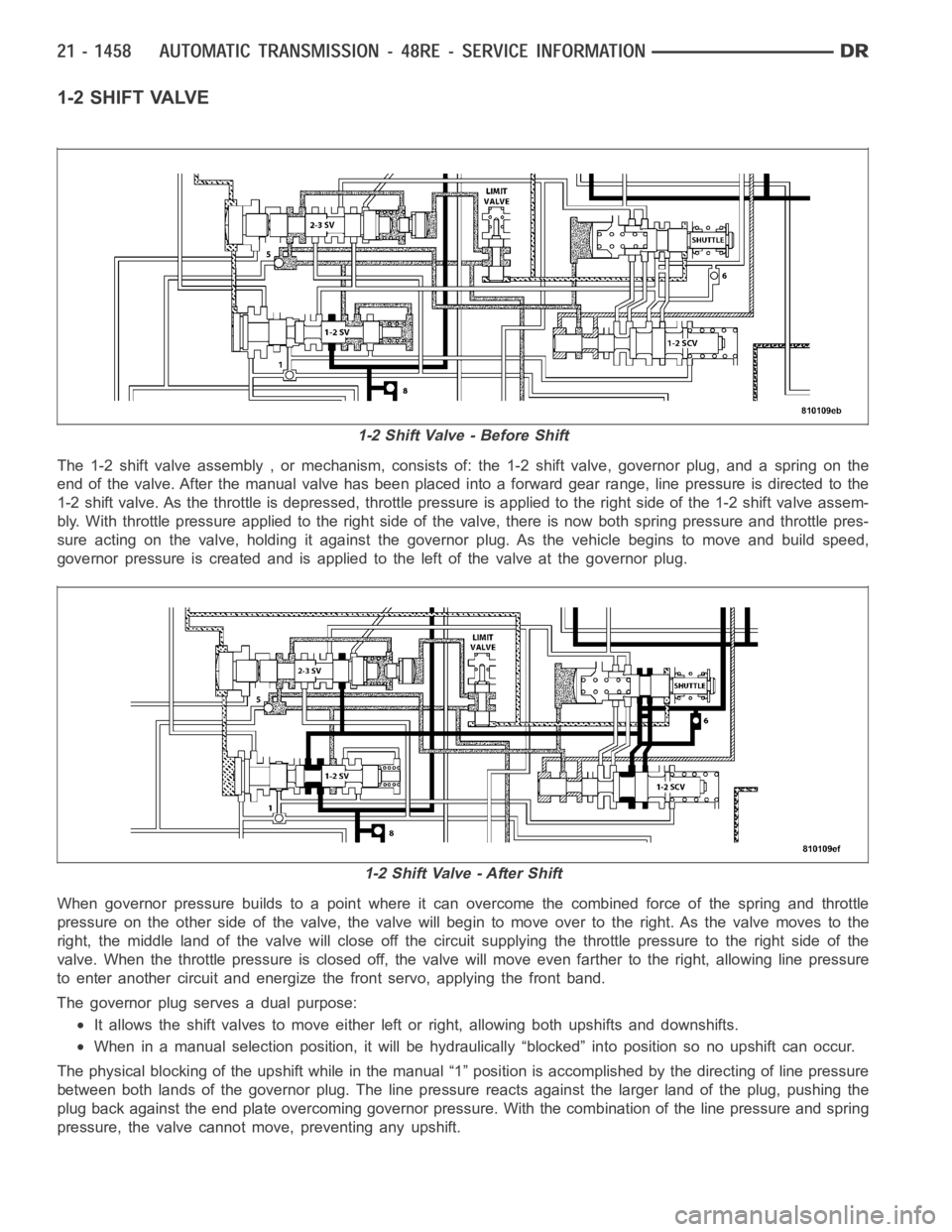

1-2 SHIFT VALVE

The 1-2 shift valve assembly , or mechanism, consists of: the 1-2 shift valve, governor plug, and a spring on the

end of the valve. After the manual valve has been placed into a forward gear range, line pressure is directed to the

1-2 shift valve. As the throttle is depressed, throttle pressure is applied to the right side of the 1-2 shift valve assem-

bly. With throttle pressure applied to the right side of the valve, there isnow both spring pressure and throttle pres-

sure acting on the valve, holding it against the governor plug. As the vehicle begins to move and build speed,

governor pressure is created and is applied to the left of the valve at the governor plug.

When governor pressure builds to a point where it can overcome the combinedforce of the spring and throttle

pressureontheothersideofthevalve,thevalvewillbegintomoveovertothe right. As the valve moves to the

right, the middle land of the valve will close off the circuit supplying thethrottle pressure to the right side of the

valve. When the throttle pressure is closed off, the valve will move even farther to the right, allowing line pressure

to enter another circuit and energize the front servo, applying the front band.

The governor plug serves a dual purpose:

It allows the shift valves to move either left or right, allowing both upshifts and downshifts.

When in a manual selection position, it will be hydraulically “blocked” into position so no upshift can occur.

The physical blocking of the upshift while in the manual “1” position is accomplished by the directing of line pressure

between both lands of the governor plug. The line pressure reacts against the larger land of the plug, pushing the

plug back against the end plate overcoming governor pressure. With the combination of the line pressure and spring

pressure, the valve cannot move, preventing any upshift.

1-2 Shift Valve - Before Shift

1-2ShiftValve-AfterShift

Page 3980 of 5267

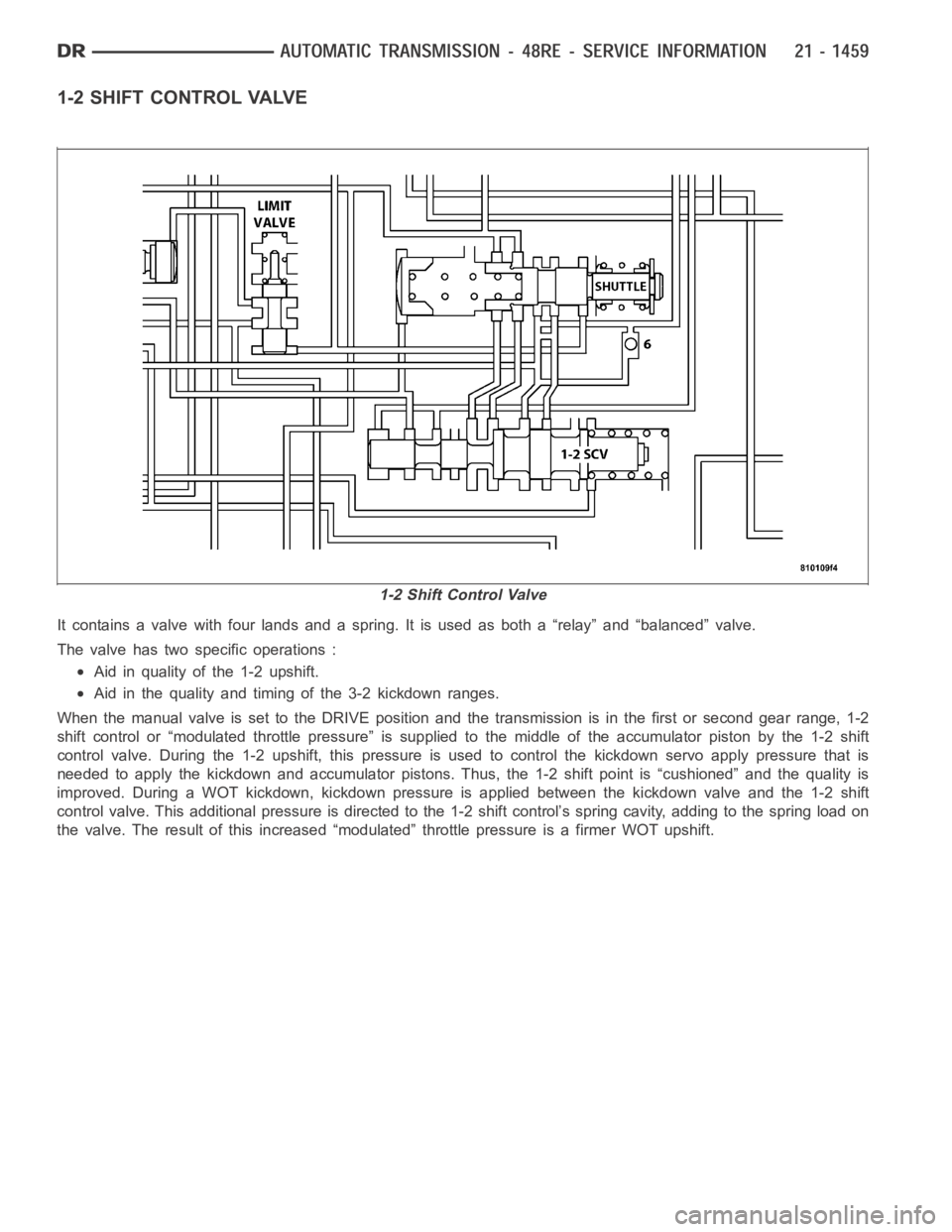

1-2 SHIFT CONTROL VALVE

It contains a valve with four lands and a spring. It is used as both a “relay” and “balanced” valve.

The valve has two specific operations :

Aid in quality of the 1-2 upshift.

Aid in the quality and timing of the 3-2 kickdown ranges.

When the manual valve is set to the DRIVE position and the transmission is inthe first or second gear range, 1-2

shift control or “modulated throttle pressure” is supplied to the middle of the accumulator piston by the 1-2 shift

control valve. During the 1-2 upshift, this pressure is used to control thekickdown servo apply pressure that is

needed to apply the kickdown and accumulator pistons. Thus, the 1-2 shift point is “cushioned” and the quality is

improved. During a WOT kickdown, kickdown pressure is applied between thekickdown valve and the 1-2 shift

control valve. This additional pressure is directed to the 1-2 shift control’s spring cavity, adding to the spring load on

the valve. The result of this increased “modulated” throttle pressure is afirmer WOT upshift.

1-2 Shift Control Valve