change time DODGE RAM SRT-10 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2336 of 5267

OPERATION

The 5.7L V-8 engine does not use a separate Throttle Position Sensor (TPS) on the throttle body.

The 3-wire TPS provides the Powertrain Control Module (PCM) with an input signal (voltage) that represents the

throttle blade position of the throttle body. The sensor is connected to the throttle blade shaft. As the position of the

throttle blade changes, the output voltage of the TPS changes.

The PCM supplies approximately 5 volts to the TPS. The TPS output voltage (input signal to the PCM) represents

the throttle blade position. The PCM receives an input signal voltage fromthe TPS. This will vary in an approximate

range of from .26 volts at minimum throttle opening (idle), to 4.49 volts atwide open throttle. Along with inputs from

other sensors, the PCM uses the TPS input to determine current engine operating conditions. In response to engine

operating conditions, the PCM will adjust fuel injector pulse width and ignition timing.

The PCM needs to identify the actions and position of the throttle blade at all times. This information is needed to

assist in performing the following calculations:

Ignition timing advance

Fuel injection pulse-width

Idle (learned value or minimum TPS)

Off-idle (0.06 volt)

Wide Open Throttle (WOT) open loop (2.608 volts above learned idle voltage)

Deceleration fuel lean out

Fuel cutoff during cranking at WOT (2.608 volts above learned idle voltage)

A/C WOT cutoff (certain automatic transmissions only)

REMOVAL

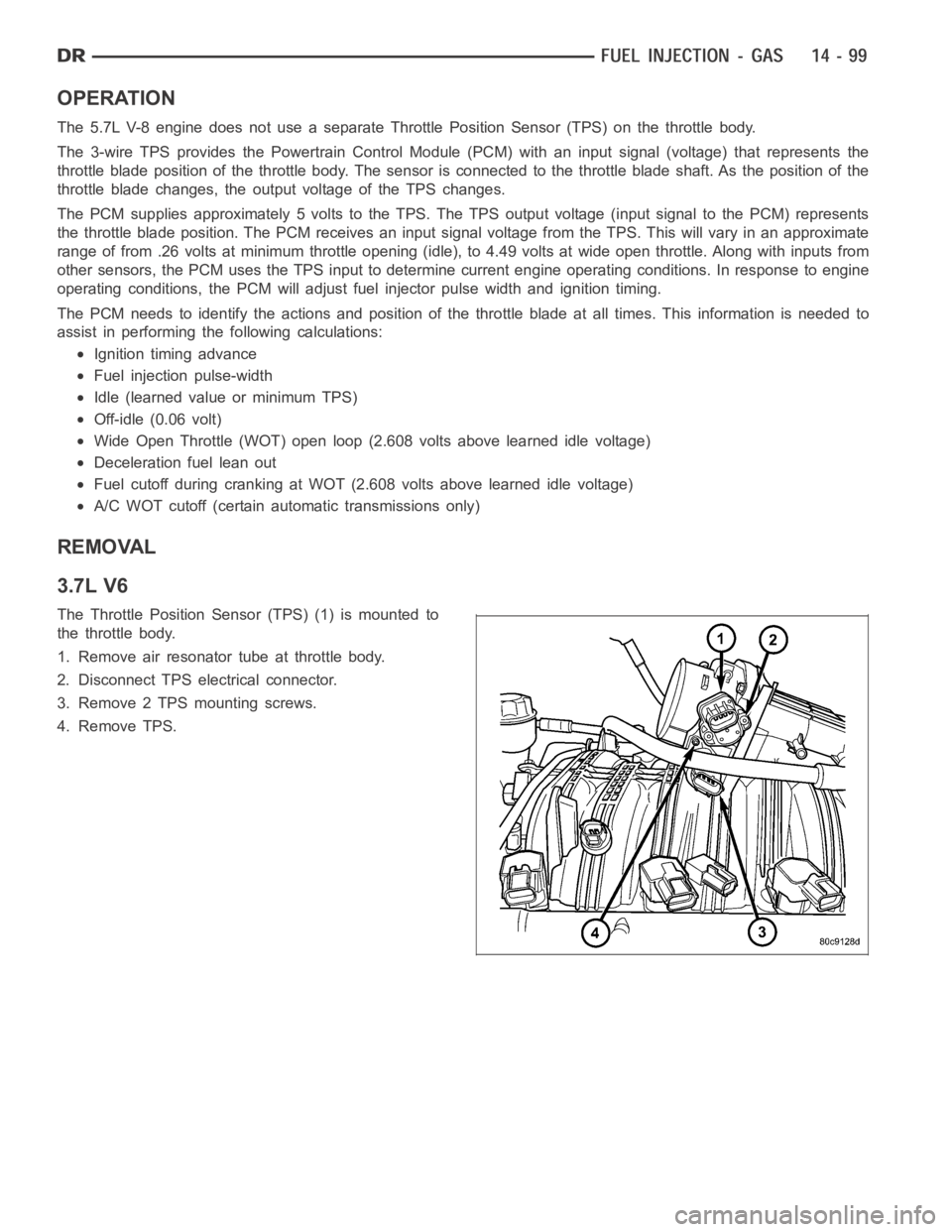

3.7L V6

The Throttle Position Sensor (TPS) (1) is mounted to

the throttle body.

1. Remove air resonator tube at throttle body.

2. Disconnect TPS electrical connector.

3. Remove 2 TPS mounting screws.

4. Remove TPS.

Page 2380 of 5267

SENSOR-CAMSHAFT POSITION

DESCRIPTION

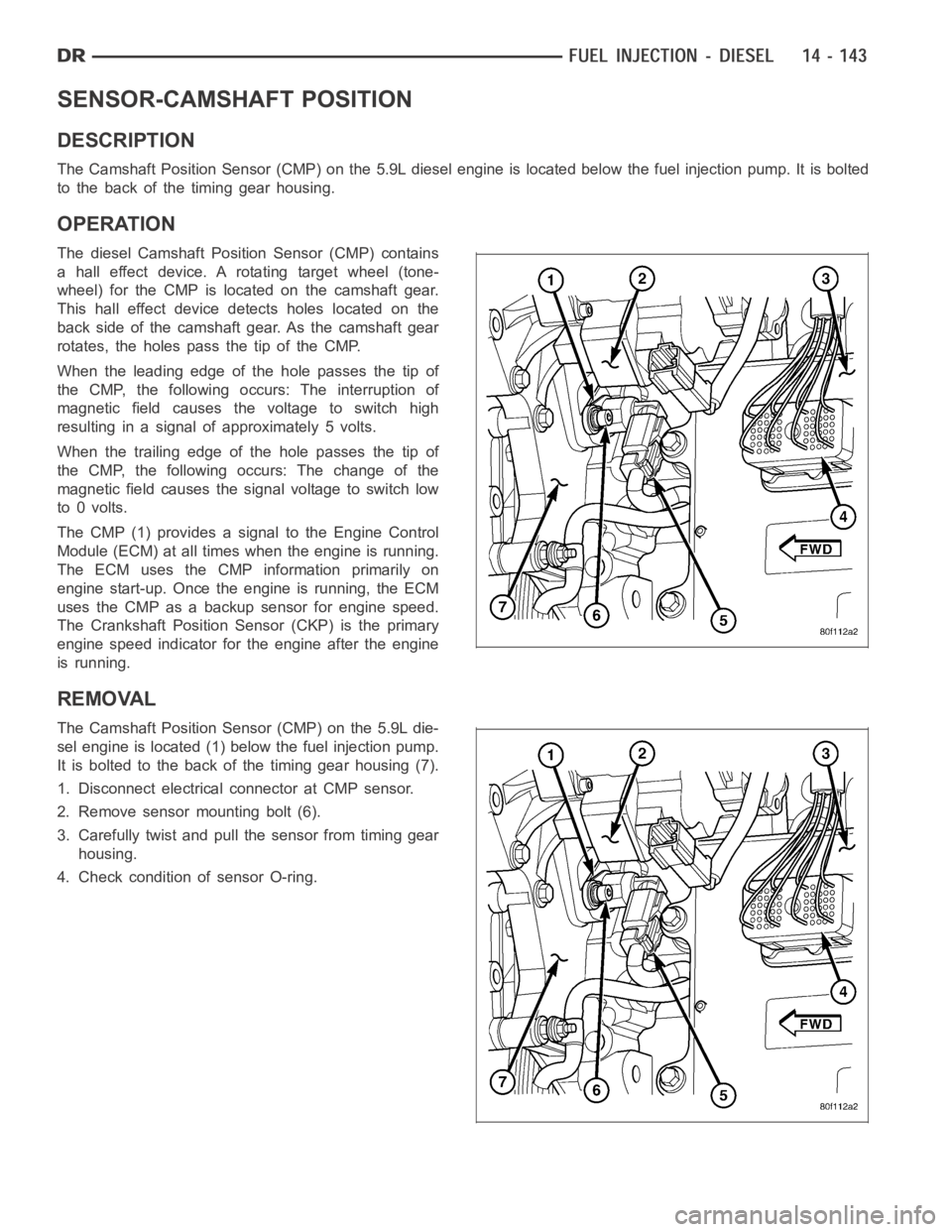

The Camshaft Position Sensor (CMP) on the 5.9L diesel engine is located below the fuel injection pump. It is bolted

to the back of the timing gear housing.

OPERATION

The diesel Camshaft Position Sensor (CMP) contains

a hall effect device. A rotating target wheel (tone-

wheel) for the CMP is located on the camshaft gear.

This hall effect device detects holes located on the

back side of the camshaft gear. As the camshaft gear

rotates, the holes pass the tip of the CMP.

When the leading edge of the hole passes the tip of

the CMP, the following occurs: The interruption of

magnetic field causes the voltage to switch high

resulting in a signal of approximately 5 volts.

When the trailing edge of the hole passes the tip of

the CMP, the following occurs: The change of the

magnetic field causes the signal voltage to switch low

to 0 volts.

The CMP (1) provides a signal to the Engine Control

Module (ECM) at all times when the engine is running.

TheECMusestheCMPinformationprimarilyon

engine start-up. Once the engine is running, the ECM

uses the CMP as a backup sensor for engine speed.

The Crankshaft Position Sensor (CKP) is the primary

engine speed indicator for the engine after the engine

is running.

REMOVAL

The Camshaft Position Sensor (CMP) on the 5.9L die-

sel engine is located (1) below the fuel injection pump.

It is bolted to the back of the timing gear housing (7).

1. Disconnect electrical connector at CMP sensor.

2. Remove sensor mounting bolt (6).

3. Carefully twist and pull the sensor from timing gear

housing.

4. Check condition of sensor O-ring.

Page 2382 of 5267

SENSOR-CRANKSHAFT POSITION

DESCRIPTION

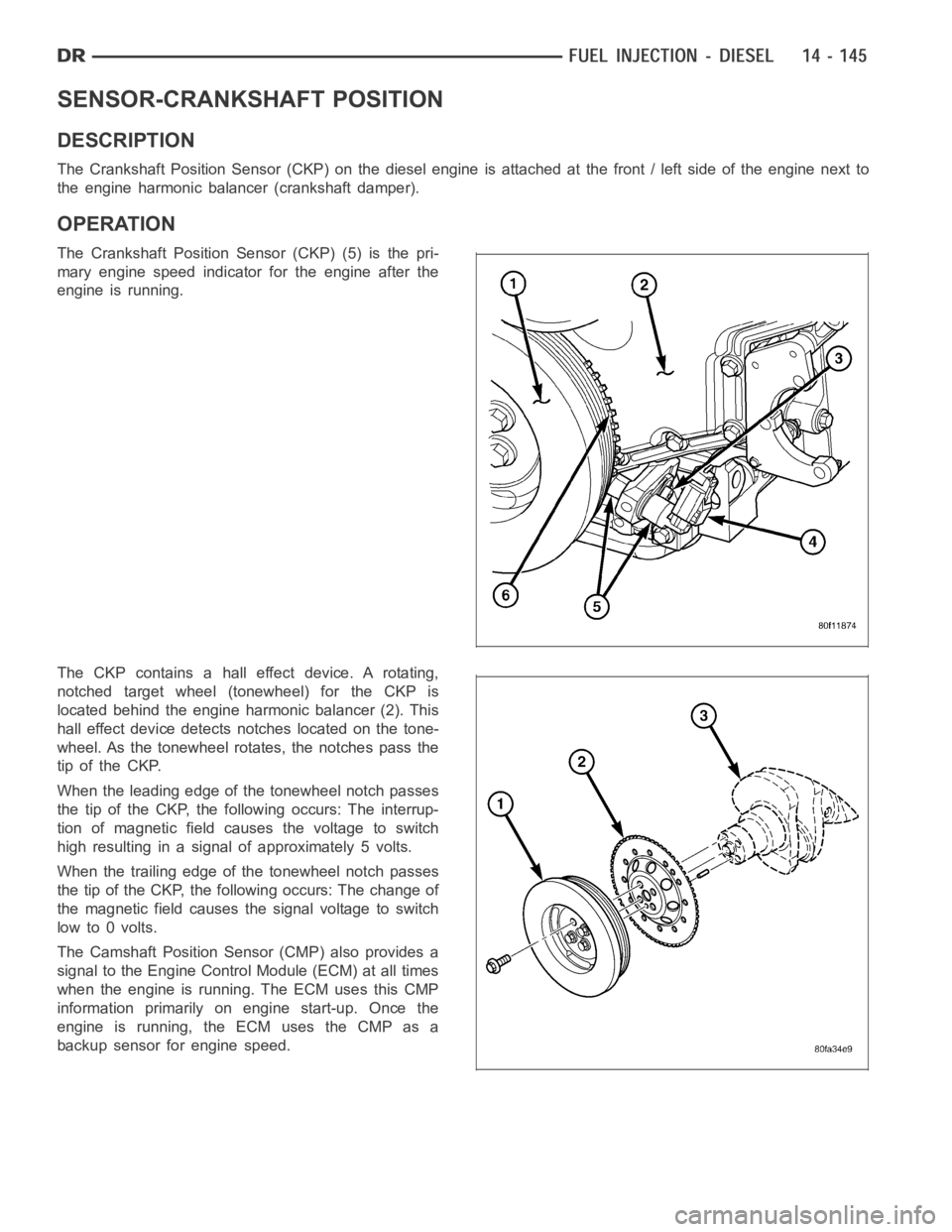

The Crankshaft Position Sensor (CKP) on the diesel engine is attached at thefront/leftsideoftheenginenextto

the engine harmonic balancer (crankshaft damper).

OPERATION

The Crankshaft Position Sensor (CKP) (5) is the pri-

mary engine speed indicator for the engine after the

engine is running.

The CKP contains a hall effect device. A rotating,

notched target wheel (tonewheel) for the CKP is

located behind the engine harmonic balancer (2). This

hall effect device detects notches located on the tone-

wheel. As the tonewheel rotates, the notches pass the

tip of the CKP.

When the leading edge of the tonewheel notch passes

the tip of the CKP, the following occurs: The interrup-

tion of magnetic field causes the voltage to switch

high resulting in a signal of approximately 5 volts.

When the trailing edge of the tonewheel notch passes

the tip of the CKP, the following occurs: The change of

the magnetic field causes the signal voltage to switch

lowto0volts.

The Camshaft Position Sensor (CMP) also provides a

signal to the Engine Control Module (ECM) at all times

when the engine is running. The ECM uses this CMP

information primarily on engine start-up. Once the

engine is running, the ECM uses the CMP as a

backup sensor for engine speed.

Page 2731 of 5267

3.CHECK THE THROTTLE POSITION SENSOR OPERATION

Ignition on, engine not running.

With the scan tool, under Transmission Sensors, monitor the TPS voltage inthe following step.

Slowly open and close the throttle while checking for erratic voltage changes.

Did the TPS voltage change smooth and consistent?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. Check for Ser-

vice Information Tune-ups or Service Bulletins for any possible causes that may apply. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Replace the Throttle Position Sensor per the Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

Pay particular attention to the TPS signal and sensor ground circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 2757 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage fluctuatesor changes abruptly within a pre-

determined period of time.

Possible Causes

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The temperature sensor is used to sense the temperature of the transmission fluid. Transmission fluid temperature

can affect shift quality, torque converter operation and when or if some diagnostics are run. A failed temperature

sensor could affect the OBD diagnostics. If a problem occurs in the transmission temperature sensor circuit, trans-

mission temperature will be based on a calculated value.

1.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, view DTCs.

Is the status Active for this DTC or is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 2

No>>

Go To 3

2.CHECK THE PCM AND WIRING WITH THE TRANSMISSION SIMULATOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool , monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Compare the scan tool readings with the numbers listed on the TransmissionSimulator.

Do the readings on the Transmission Simulator match a non-fluctuating scan tool reading ± 0.2 volts?

Ye s>>

Replace Transmission Solenoid/Pressure Switch Assembly per the ServiceInformation.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. Check for any

Service Information Tune-ups or Service Bulletins for any possible causes that may apply. If no prob-

lems are found, replace the PCM per the Service Information. With the scan tool, perform QUICK

LEARN.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2869 of 5267

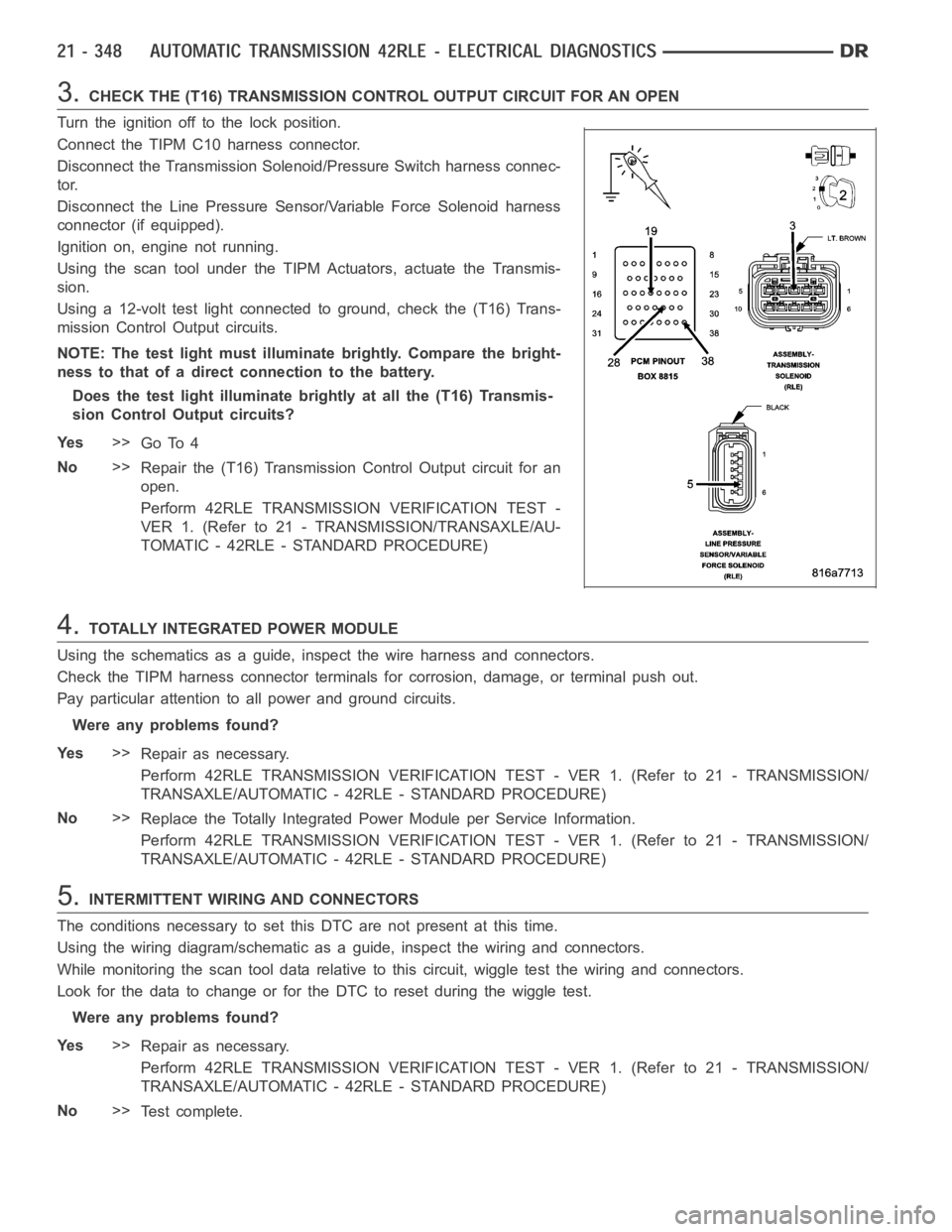

3.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Connect the TIPM C10 harness connector.

Disconnect the Transmission Solenoid/Pressure Switch harness connec-

tor.

Disconnect the Line Pressure Sensor/Variable Force Solenoid harness

connector (if equipped).

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the Transmis-

sion.

Using a 12-volt test light connected to ground, check the (T16) Trans-

mission Control Output circuits.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly at all the (T16) Transmis-

sion Control Output circuits?

Ye s>>

Go To 4

No>>

Repair the (T16) Transmission Control Output circuit for an

open.

Perform 42RLE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE - STANDARD PROCEDURE)

4.TOTALLY INTEGRATED POWER MODULE

Using the schematics as a guide, inspect the wire harness and connectors.

Check the TIPM harness connector terminals for corrosion, damage, or terminal push out.

Pay particular attention to all power and ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 2872 of 5267

3.TOTALLY INTEGRATED POWER MODULE

Using the schematics as a guide, inspect the wire harness and connectors.

Check the TIPM harness connector terminals for corrosion, damage, or terminal push out

Pay particular attention to all power and ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 2875 of 5267

3.TOTALLY INTEGRATED POWER MODULE

Using the schematics as a guide, inspect the wire harness and connectors.

Check the TIPM harness connector terminals for corrosion, damage, or terminal push out.

Pay particular attention to all power and ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3015 of 5267

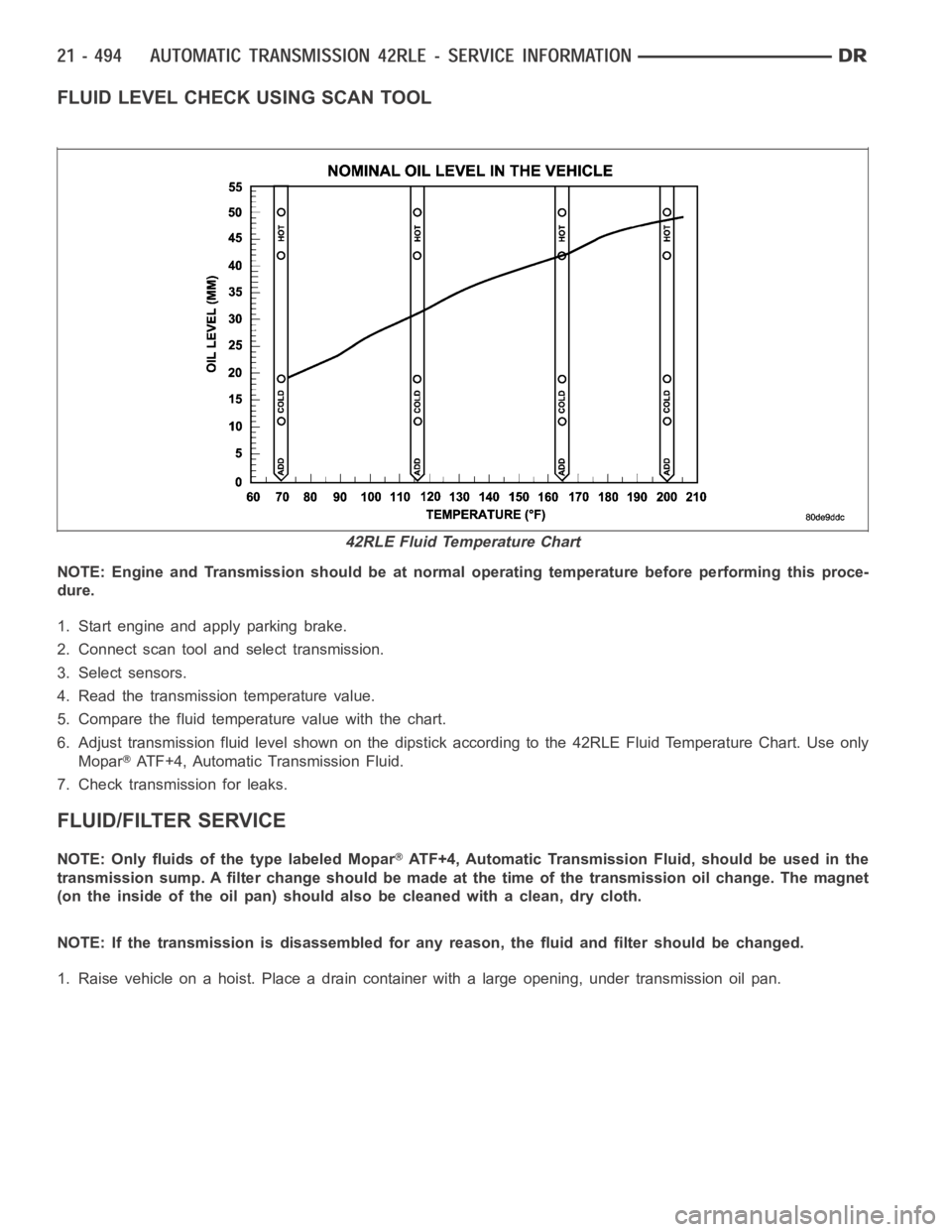

FLUID LEVEL CHECK USING SCAN TOOL

NOTE: Engine and Transmission should be at normal operating temperature before performing this proce-

dure.

1. Start engine and apply parking brake.

2. Connect scan tool and select transmission.

3. Select sensors.

4. Read the transmission temperature value.

5. Compare the fluid temperature value with the chart.

6. Adjust transmission fluid level shown on the dipstick according to the 42RLE Fluid Temperature Chart. Use only

Mopar

ATF+4, Automatic Transmission Fluid.

7. Check transmission for leaks.

FLUID/FILTER SERVICE

NOTE: Only fluids of the type labeled MoparATF+4, Automatic Transmission Fluid, should be used in the

transmission sump. A filter change should be made at the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned with a clean, dry cloth.

NOTE: If the transmission is disassembled for any reason, the fluid and filter should be changed.

1. Raise vehicle on a hoist. Place a drain container with a large opening, under transmission oil pan.

42RLE Fluid Temperature Chart

Page 3108 of 5267

3.CHECK THROTTLE POSITION SENSOR OPERATION

Ignition On, Engine Not Running.

With the scan tool, under Transmission Sensors, monitor the TPS voltage inthe following step.

Slowly open and close the throttle while checking for erratic voltage changes.

IfequippedwithETC,usetheETCThrottleFollowertestinthescantooltocheck for erratic voltage changes.

Was the TPS voltage change smooth and consistent?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Throttle Position Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set the DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wiring and connectors while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .