change time DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1471 of 5267

9.(C3) A/C CLUTCH RELAY OUTPUT CIRCUIT OPEN

Turn the ignition off.

Disconnect the A/C Clutch harness connector.

Remove the A/C Clutch Relay.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the (C3) A/C Clutch Relay Output circuit betweenthe IPM and the A/C Clutch Coil.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 10

No>>

Repair the open in the (C3) A/C Clutch Relay Output circuit.

Perform BODY VERIFICATION TEST - VER 1.

10.(A17) FUSED B+ CIRCUIT OPEN

Turn the ignition off.

Remove the A/C Clutch Relay.

NOTE: Check connectors - Clean/repair as necessary.

Measure the voltage of the Fused B+ circuit at the A/C Clutch Relay connector.

Is the voltage above 11.0 volts?

Ye s>>

Go To 11

No>>

Repair the open in the Fused B+ circuit. The open may be in the IMP.

Perform BODY VERIFICATION TEST - VER 1.

11 .A/C CLUTCH RELAY

If there are no possible causes remaining, view repair.

Repair

Replace the A/C Clutch Relay.

Perform BODY VERIFICATION TEST - VER 1.

12.A/CSELECTSWITCHSTATUSINHVAC

Ignition on, engine not running.

With the scan tool in the HVAC, under the Monitors screen, read the A/C Select Switch state.

While monitoring the scan tool screen, turn the A/C switch on and off a few times.

Does the A/C Select State change on the HVAC Monitors screen.

Ye s>>

Check for any related TSBs. Replace and program the PCM in accordance with the Service Information

as long as no BUS problems exist.

Perform BODY VERIFICATION TEST - VER 1.

No>>

Replace the A/C-Heater Control module.

Perform BODY VERIFICATION TEST - VER 1.

Page 1572 of 5267

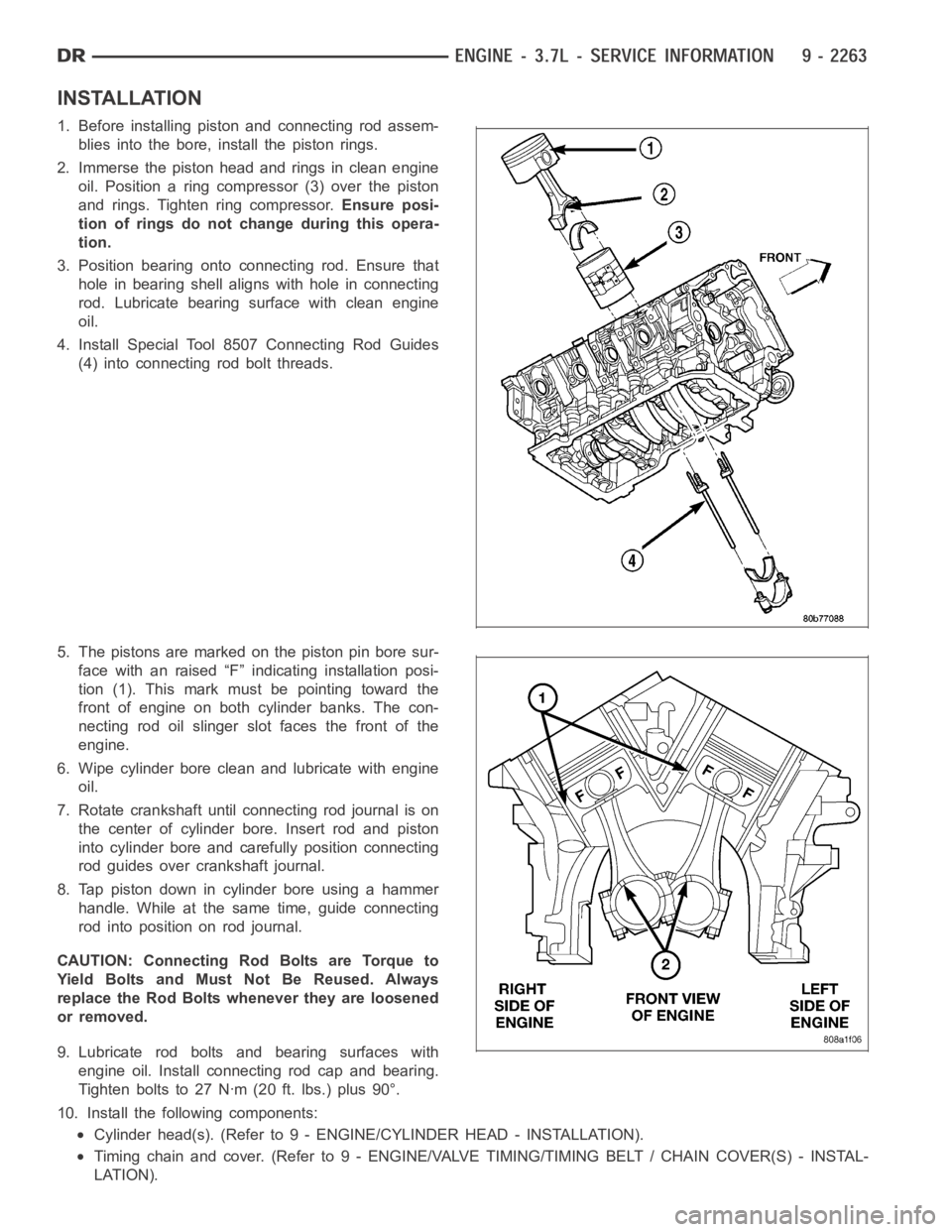

INSTALLATION

1. Before installing piston and connecting rod assem-

blies into the bore, install the piston rings.

2. Immerse the piston head and rings in clean engine

oil. Position a ring compressor (3) over the piston

and rings. Tighten ring compressor.Ensure posi-

tion of rings do not change during this opera-

tion.

3. Position bearing onto connecting rod. Ensure that

hole in bearing shell aligns with hole in connecting

rod. Lubricate bearing surface with clean engine

oil.

4. Install Special Tool 8507 Connecting Rod Guides

(4) into connecting rod bolt threads.

5. The pistons are marked on the piston pin bore sur-

face with an raised “F” indicating installation posi-

tion (1). This mark must be pointing toward the

front of engine on both cylinder banks. The con-

necting rod oil slinger slot faces the front of the

engine.

6. Wipe cylinder bore clean and lubricate with engine

oil.

7. Rotate crankshaft until connecting rod journal is on

the center of cylinder bore. Insert rod and piston

into cylinder bore and carefully position connecting

rod guides over crankshaft journal.

8. Tap piston down in cylinder bore using a hammer

handle. While at the same time, guide connecting

rodintopositiononrodjournal.

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

9. Lubricate rod bolts and bearing surfaces with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 27 Nꞏm (20 ft. lbs.) plus 90°.

10. Install the following components:

Cylinder head(s). (Refer to 9 - ENGINE/CYLINDER HEAD - INSTALLATION).

Timing chain and cover. (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) - INSTAL-

LATION).

Page 1598 of 5267

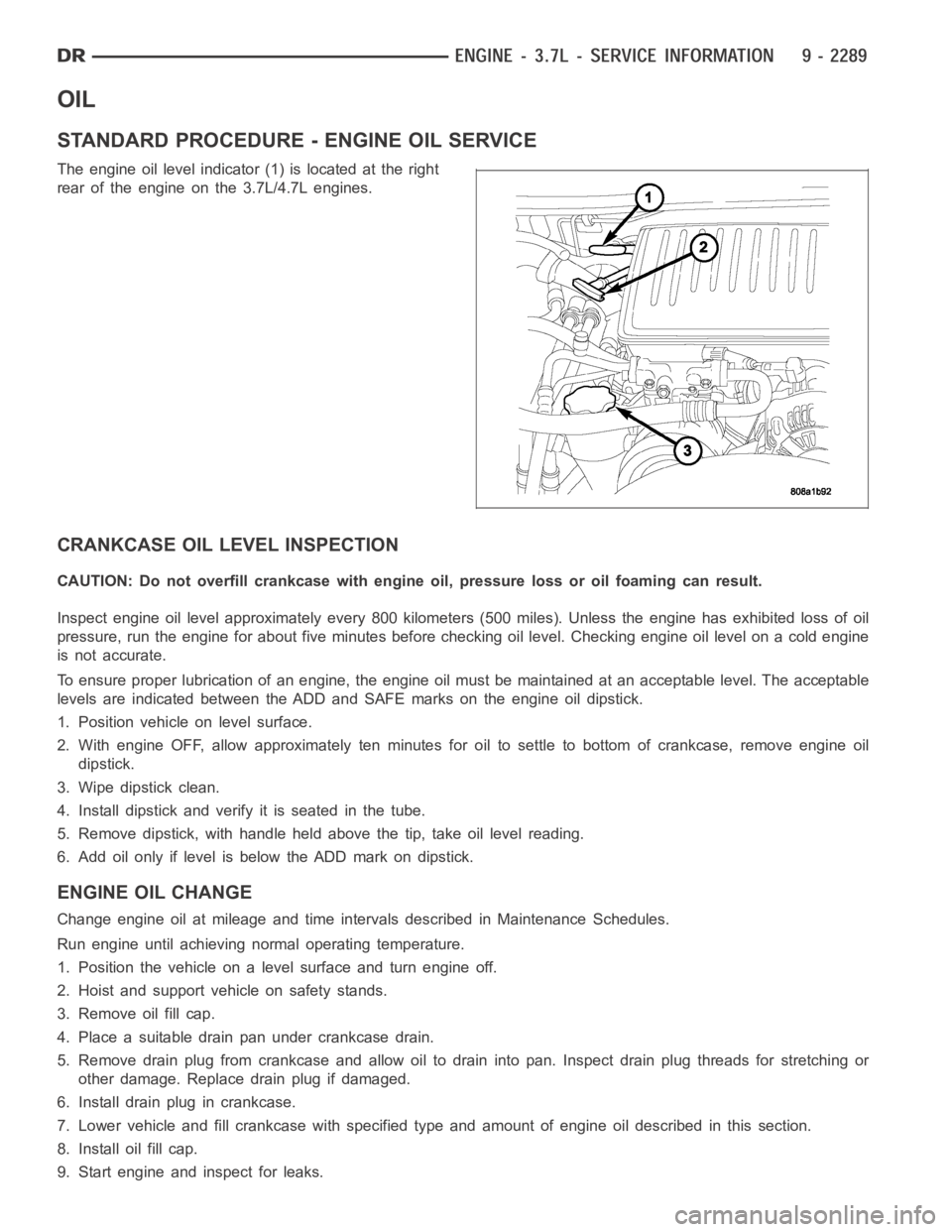

OIL

STANDARD PROCEDURE - ENGINE OIL SERVICE

The engine oil level indicator (1) is located at the right

rear of the engine on the 3.7L/4.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil, pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800 kilometers (500 miles).Unless the engine has exhibited loss of oil

pressure, run the engine for about five minutes before checking oil level.Checking engine oil level on a cold engine

is not accurate.

To ensure proper lubrication of an engine, the engine oil must be maintained at an acceptable level. The acceptable

levels are indicated between the ADD and SAFE marks on the engine oil dipstick.

1. Position vehicle on level surface.

2. With engine OFF, allow approximately ten minutes for oil to settle to bottom of crankcase, remove engine oil

dipstick.

3. Wipe dipstick clean.

4. Install dipstick and verify it is seated in the tube.

5. Remove dipstick, with handle held above the tip, take oil level reading.

6. Add oil only if level is below the ADD mark on dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals described in Maintenance Schedules.

Run engine until achieving normal operating temperature.

1. Position the vehicle on a level surface and turn engine off.

2. Hoist and support vehicle on safety stands.

3. Remove oil fill cap.

4. Place a suitable drain pan under crankcase drain.

5. Remove drain plug from crankcase and allow oil to drain into pan. Inspectdrain plug threads for stretching or

other damage. Replace drain plug if damaged.

6. Install drain plug in crankcase.

7. Lower vehicle and fill crankcase with specified type and amount of engine oil described in this section.

8. Install oil fill cap.

9. Start engine and inspect for leaks.

Page 1723 of 5267

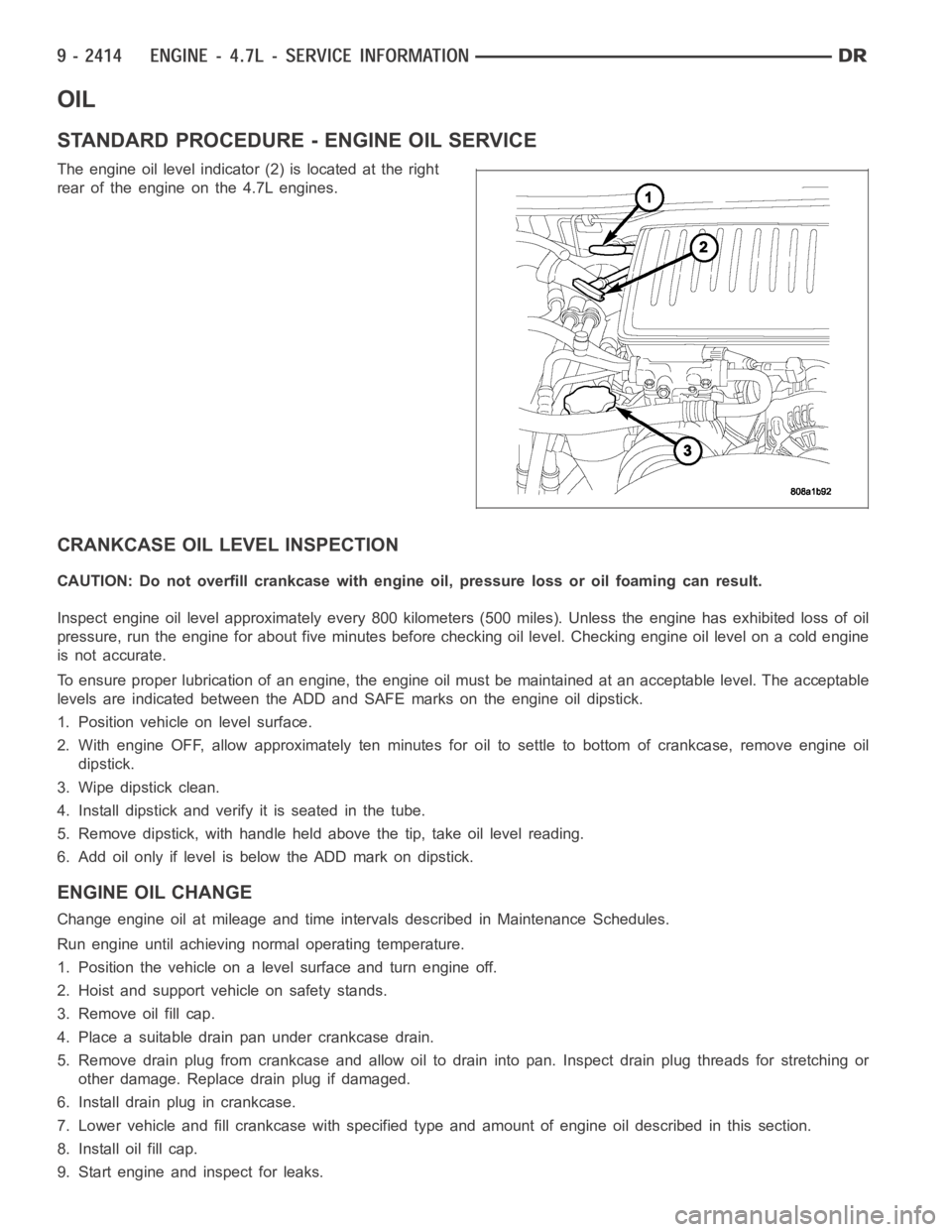

OIL

STANDARD PROCEDURE - ENGINE OIL SERVICE

The engine oil level indicator (2) is located at the right

rear of the engine on the 4.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil, pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800 kilometers (500 miles).Unless the engine has exhibited loss of oil

pressure, run the engine for about five minutes before checking oil level.Checking engine oil level on a cold engine

is not accurate.

To ensure proper lubrication of an engine, the engine oil must be maintained at an acceptable level. The acceptable

levels are indicated between the ADD and SAFE marks on the engine oil dipstick.

1. Position vehicle on level surface.

2. With engine OFF, allow approximately ten minutes for oil to settle to bottom of crankcase, remove engine oil

dipstick.

3. Wipe dipstick clean.

4. Install dipstick and verify it is seated in the tube.

5. Remove dipstick, with handle held above the tip, take oil level reading.

6. Add oil only if level is below the ADD mark on dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals described in Maintenance Schedules.

Run engine until achieving normal operating temperature.

1. Position the vehicle on a level surface and turn engine off.

2. Hoist and support vehicle on safety stands.

3. Remove oil fill cap.

4. Place a suitable drain pan under crankcase drain.

5. Remove drain plug from crankcase and allow oil to drain into pan. Inspectdrain plug threads for stretching or

other damage. Replace drain plug if damaged.

6. Install drain plug in crankcase.

7. Lower vehicle and fill crankcase with specified type and amount of engine oil described in this section.

8. Install oil fill cap.

9. Start engine and inspect for leaks.

Page 1810 of 5267

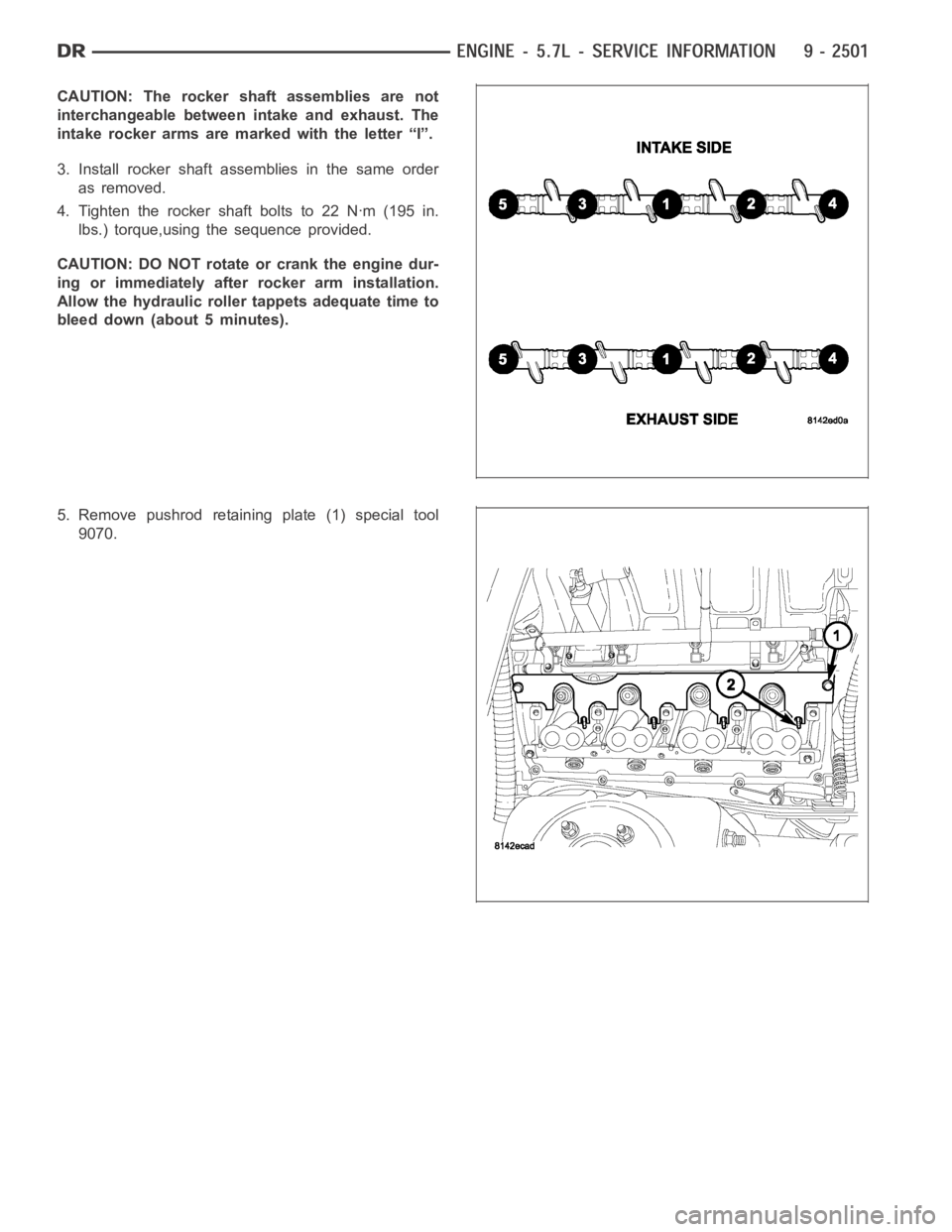

CAUTION: The rocker shaft assemblies are not

interchangeable between intake and exhaust. The

intake rocker arms are marked with the letter “I”.

3. Install rocker shaft assemblies in the same order

as removed.

4. Tighten the rocker shaft bolts to 22 Nꞏm (195 in.

lbs.) torque,using the sequence provided.

CAUTION: DO NOT rotate or crank the engine dur-

ing or immediately after rocker arm installation.

Allow the hydraulic roller tappets adequate time to

bleed down (about 5 minutes).

5. Remove pushrod retaining plate (1) special tool

9070.

Page 1858 of 5267

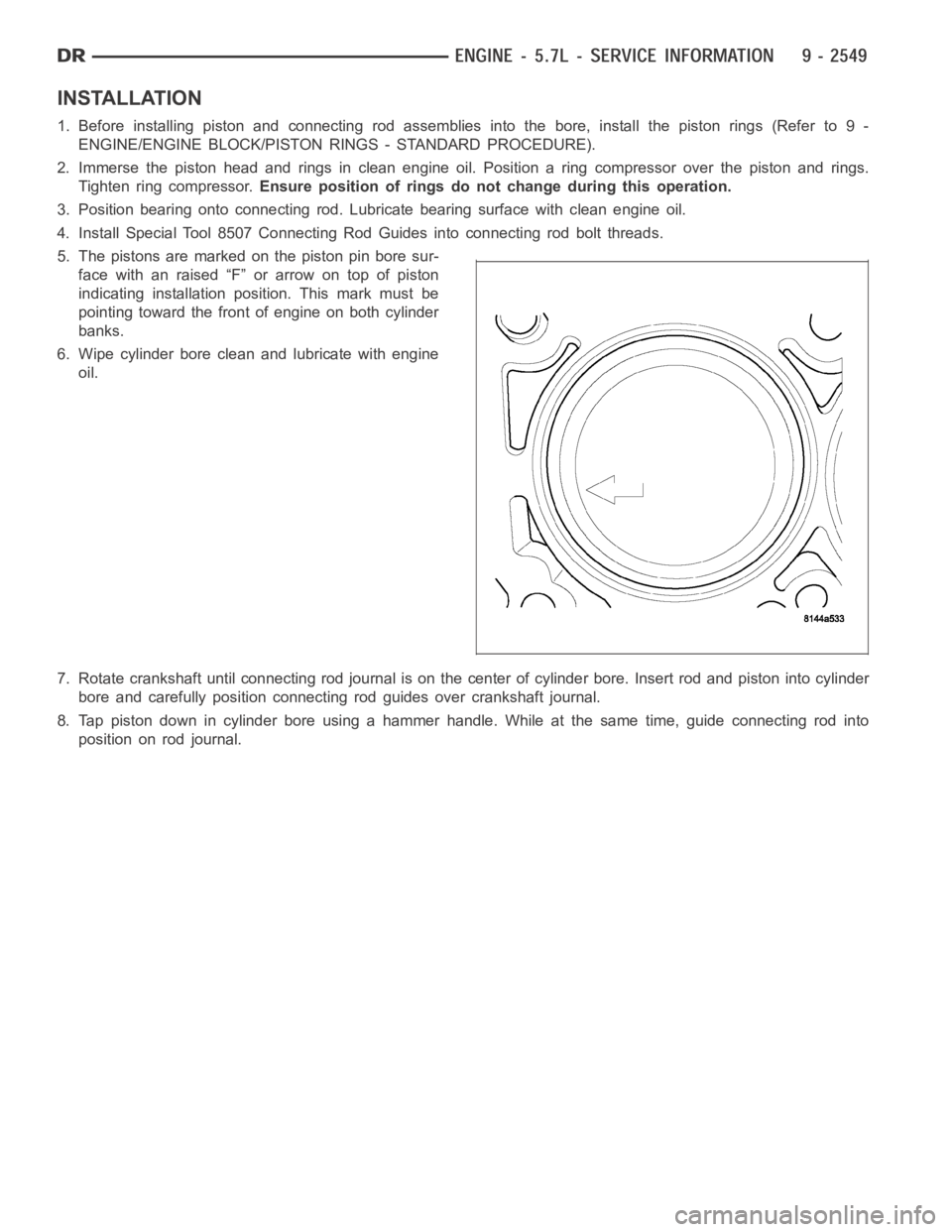

INSTALLATION

1. Before installing piston and connecting rod assemblies into the bore, install the piston rings (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON RINGS - STANDARD PROCEDURE).

2. Immerse the piston head and rings in clean engine oil. Position a ring compressor over the piston and rings.

Tighten ring compressor.Ensure position of rings do not change during this operation.

3. Position bearing onto connecting rod. Lubricate bearing surface with clean engine oil.

4. Install Special Tool 8507 Connecting Rod Guides into connecting rod bolt threads.

5. The pistons are marked on the piston pin bore sur-

face with an raised “F” or arrow on top of piston

indicating installation position. This mark must be

pointing toward the front of engine on both cylinder

banks.

6. Wipe cylinder bore clean and lubricate with engine

oil.

7. Rotate crankshaft until connecting rod journal is on the center of cylinder bore. Insert rod and piston into cylinder

bore and carefully position connecting rod guides over crankshaft journal.

8. Tap piston down in cylinder bore using a hammer handle. While at the same time, guide connecting rod into

position on rod journal.

Page 1877 of 5267

OIL

STANDARD PROCEDURE - ENGINE OIL SERVICE

The engine oil level indicator is located at the left hand of the engine on the 5.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil, pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800 kilometers (500 miles).Unless the engine has exhibited loss of oil

pressure, run the engine for about ten minutes before checking oil level. Checking engine oil level on a cold engine

is not accurate.

To ensure proper lubrication of an engine, the engine oil must be maintained at an acceptable level. The acceptable

levels are indicated between the ADD and SAFE marks on the engine oil dipstick.

1. Position vehicle on level surface.

2. With engine OFF, allow approximately five minutes for oil to settle to bottom of crankcase, remove engine oil

dipstick.

3. Wipe dipstick clean.

4. Install dipstick and verify it is seated in the tube.

5. Remove dipstick, with handle held above the tip, take oil level reading.

6. Add oil only if level is below the ADD mark on dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals described in Maintenance Schedules (Refer to LUBRICATION &

MAINTENANCE/MAINTENANCESCHEDULES - DESCRIPTION).

Run engine until achieving normal operating temperature.

1. Position the vehicle on a level surface and turn engine off.

2. Hoist and support vehicle on safety stands.

3. Remove oil fill cap.

4. Place a suitable drain pan under crankcase drain.

5. Remove drain plug from crankcase and allow oil to drain into pan. Inspectdrain plug threads for stretching or

other damage. Replace drain plug if damaged.

6. Install drain plug in crankcase. Torque to 34 Nꞏm ( 25 ft. lbs.).

7. Lower vehicle and fill crankcase with specified type and amount of engine oil described in this section.

8. Install oil fill cap.

9. Start engine and inspect for leaks.

10. Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used engine oil after it has been drained from a vehicle engine. Refer to

the WARNING at beginning of this section.

Page 1997 of 5267

LUBRICATION

DESCRIPTION

A gear driven gerotor type oil pump is mounted behind the front gear cover inthe lower right portion on the engine.

OPERATION

A gerotor style oil pump draws oil from the crankcase through the suction tube and delivers it through the block

where it enters the oil cooler cover and pressure regulator valve. When oilpressure exceeds 517 kPa (75 PSI), the

valve opens exposing the dump port, which routes excess oil back to the oil pump.

At the same time, oil is directed to a cast in passage in the oil cooler cover,leading to the oil cooler element. As the

oil travels through the element plates, it is cooled by engine coolant traveling past the outside of the plates. It is

then routed to the oil filter head and through a full flow oil filter. If a plugged filter is encountered, the filter by-pass

valve opens, allowing unfiltered oil to lubricate the engine. This condition can be avoided by frequent oil and filter

changes, per the maintenance schedules found in the owners manual. The by-pass valve is calibrated to open when

it sees a pressure drop of more than 345 kPa (50 psi) across the oil filter.

The oil filter head then divides the oil between the engine and the turbocharger. The turbocharger receives filtered,

cooled and pressurized oil through a supply line from the filter head. The oil lubricates the turbocharger and returns

to the pan by way of a drain tube connecting the bottom of the turbocharger toa tube in the cylinder block.

Page 2088 of 5267

OIL

STANDARD PROCEDURE

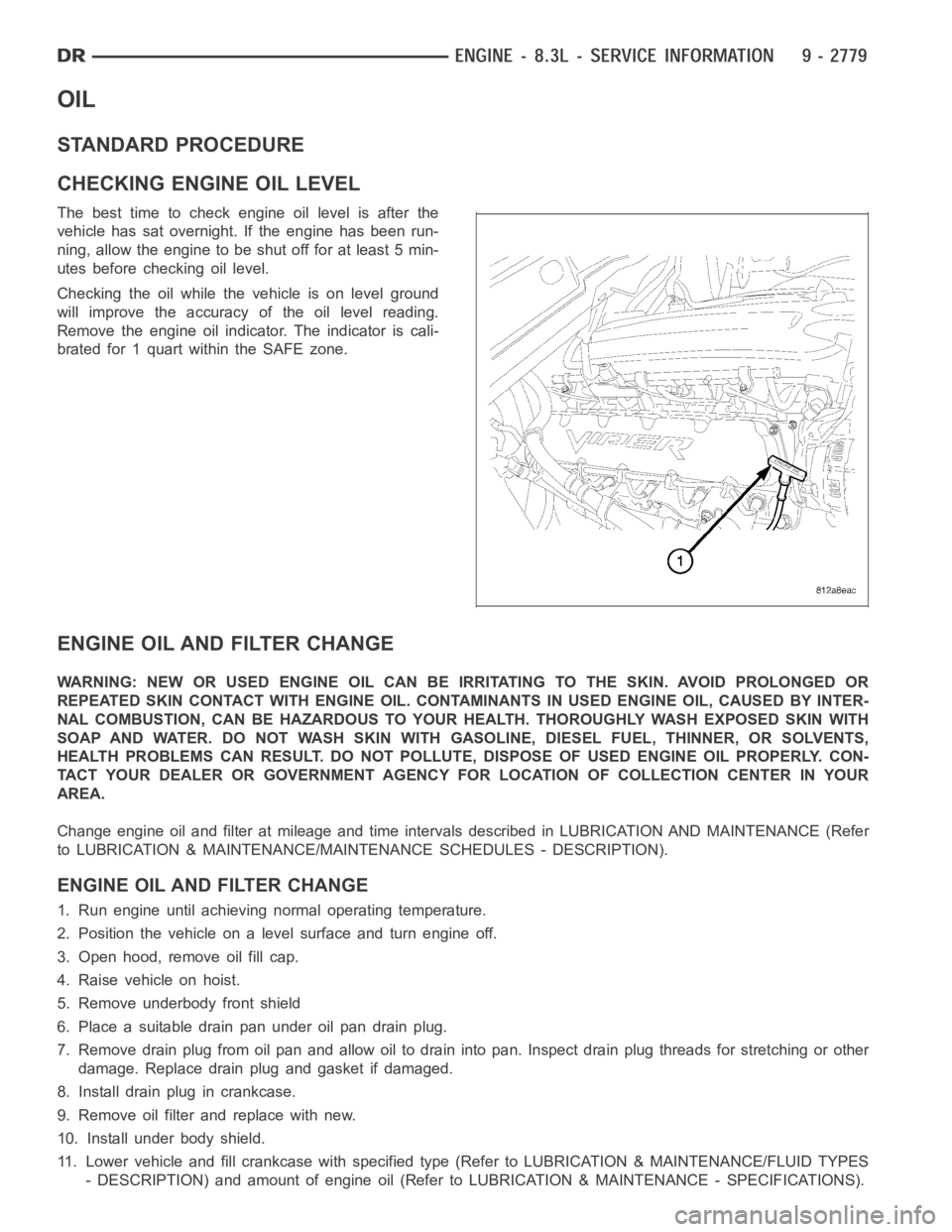

CHECKING ENGINE OIL LEVEL

The best time to check engine oil level is after the

vehicle has sat overnight. If the engine has been run-

ning, allow the engine to be shut off for at least 5 min-

utes before checking oil level.

Checking the oil while the vehicle is on level ground

will improve the accuracy of the oil level reading.

Remove the engine oil indicator. The indicator is cali-

brated for 1 quart within the SAFE zone.

ENGINE OIL AND FILTER CHANGE

WARNING: NEW OR USED ENGINE OIL CAN BE IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL. CONTAMINANTS IN USED ENGINE OIL, CAUSED BY INTER-

NAL COMBUSTION, CAN BE HAZARDOUS TO YOUR HEALTH. THOROUGHLY WASH EXPOSED SKIN WITH

SOAP AND WATER. DO NOT WASH SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR SOLVENTS,

HEALTH PROBLEMS CAN RESULT. DO NOT POLLUTE, DISPOSE OF USED ENGINE OIL PROPERLY. CON-

TACT YOUR DEALER OR GOVERNMENT AGENCY FOR LOCATION OF COLLECTION CENTER INYOUR

AREA.

Change engine oil and filter at mileage and time intervals described in LUBRICATION AND MAINTENANCE (Refer

to LUBRICATION & MAINTENANCE/MAINTENANCE SCHEDULES - DESCRIPTION).

ENGINE OIL AND FILTER CHANGE

1. Run engine until achieving normal operating temperature.

2. Position the vehicle on a level surface and turn engine off.

3. Open hood, remove oil fill cap.

4. Raise vehicle on hoist.

5. Remove underbody front shield

6. Place a suitable drain pan under oil pan drain plug.

7. Remove drain plug from oil pan and allow oil to drain into pan. Inspect drain plug threads for stretching or other

damage. Replace drain plug and gasket if damaged.

8. Install drain plug in crankcase.

9. Remove oil filter and replace with new.

10. Install under body shield.

11. Lower vehicle and fill crankcase with specified type (Refer to LUBRICATION & MAINTENANCE/FLUID TYPES

- DESCRIPTION) and amount of engine oil (Refer to LUBRICATION & MAINTENANCE - SPECIFICATIONS).

Page 2315 of 5267

higher altitude, because the air density changes with altitude. It will also help to correct for varying barometric pres-

sure. Barometric pressure and altitude have a direct inverse correlation; as altitude goes up, barometric goes down.

At key-on, the PCM powers up and looks at MAP voltage, and based upon the voltage it sees, it knows the current

barometric pressure (relative to altitude). Once the engine starts, the PCM looks at the voltage again, continuously

every 12 milliseconds, and compares the current voltage to what it was at key-on. The difference between current

voltage and what it was at key-on, is manifold vacuum.

During key-on (engine not running) the sensor reads (updates) barometricpressure. A normal range can be

obtained by monitoring a known good sensor.

As the altitude increases, the air becomes thinner (less oxygen). If a vehicleisstartedanddriventoaverydifferent

altitude than where it was at key-on, the barometric pressure needs to be updated. Any time the PCM sees Wide

Open Throttle (WOT), based upon Throttle Position Sensor (TPS) angle and RPM, it will update barometric pressure

in the MAP memory cell. With periodic updates, the PCM can make its calculations more effectively.

The PCM uses the MAP sensor input to aid in calculating the following:

Manifold pressure

Barometric pressure

Engine load

Injector pulse-width

Spark-advance programs

Shift-point strategies (certain automatic transmissions only)

Idle speed

Decel fuel shutoff

The MAP sensor signal is provided from asingle piezoresistive element located in the center of a diaphragm. The

element and diaphragm are both made ofsilicone. As manifold pressure changes, the diaphragm moves causing

the element to deflect, which stresses the silicone. When silicone is exposed to stress, its resistance changes. As

manifold vacuum increases, the MAP sensor input voltage decreases proportionally. The sensor also contains elec-

tronics that condition the signal and provide temperature compensation.

The PCM recognizes a decrease in manifold pressure by monitoring a decrease in voltage from the reading stored

in the barometric pressure memory cell. The MAP sensor is a linear sensor; meaning as pressure changes, voltage

changes proportionately. The range of voltage output from the sensor is usually between 4.6 volts at sea level to as

low as 0.3 volts at 26 in. of Hg. Barometric pressure is the pressure exertedby the atmosphere upon an object. At

sea level on a standard day, no storm, barometric pressure is approximately 29.92 in Hg. For every 100 feet of

altitude, barometric pressure drops 0.10 in. Hg. If a storm goes through, it can change barometric pressure from

what should be present for that altitude. You should know what the average pressure and corresponding barometric

pressure is for your area.