DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3991 of 5267

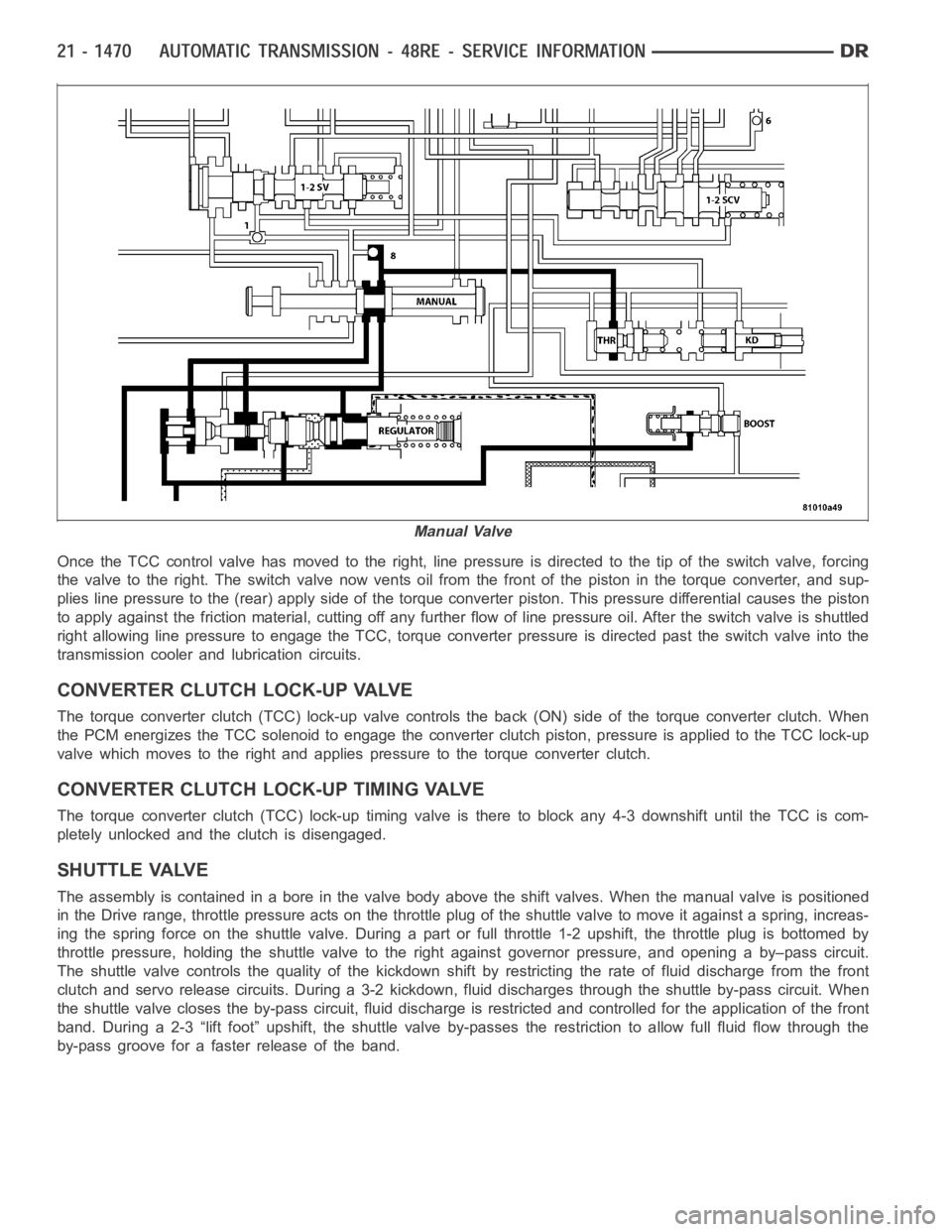

Once the TCC control valve has moved to the right, line pressure is directedto the tip of the switch valve, forcing

the valve to the right. The switch valve now vents oil from the front of the piston in the torque converter, and sup-

plies line pressure to the (rear) apply side of the torque converter piston. This pressure differential causes the piston

to apply against the friction material, cutting off any further flow of line pressure oil. After the switch valve is shuttled

right allowing line pressure to engage the TCC, torque converter pressureis directed past the switch valve into the

transmission cooler and lubrication circuits.

CONVERTER CLUTCH LOCK-UP VALVE

The torque converter clutch (TCC) lock-up valve controls the back (ON) side of the torque converter clutch. When

the PCM energizes the TCC solenoid to engage the converter clutch piston, pressure is applied to the TCC lock-up

valve which moves to the right and applies pressure to the torque converterclutch.

CONVERTER CLUTCH LOCK-UP TIMING VALVE

The torque converter clutch (TCC) lock-up timing valve is there to block any 4-3 downshift until the TCC is com-

pletely unlocked and the clutch is disengaged.

SHUTTLE VALVE

The assembly is contained in a bore in the valve body above the shift valves.When the manual valve is positioned

in the Drive range, throttle pressure acts on the throttle plug of the shuttle valve to move it against a spring, increas-

ing the spring force on the shuttle valve. During a part or full throttle 1-2upshift, the throttle plug is bottomed by

throttle pressure, holding the shuttle valve to the right against governor pressure, and opening a by–pass circuit.

The shuttle valve controls the quality of the kickdown shift by restricting the rate of fluid discharge from the front

clutch and servo release circuits. During a 3-2 kickdown, fluid discharges through the shuttle by-pass circuit. When

the shuttle valve closes the by-pass circuit, fluid discharge is restricted and controlled for the application of the front

band. During a 2-3 “lift foot” upshift, the shuttle valve by-passes the restriction to allow full fluid flow through the

by-pass groove for a faster release of the band.

Manual Valve

Page 3992 of 5267

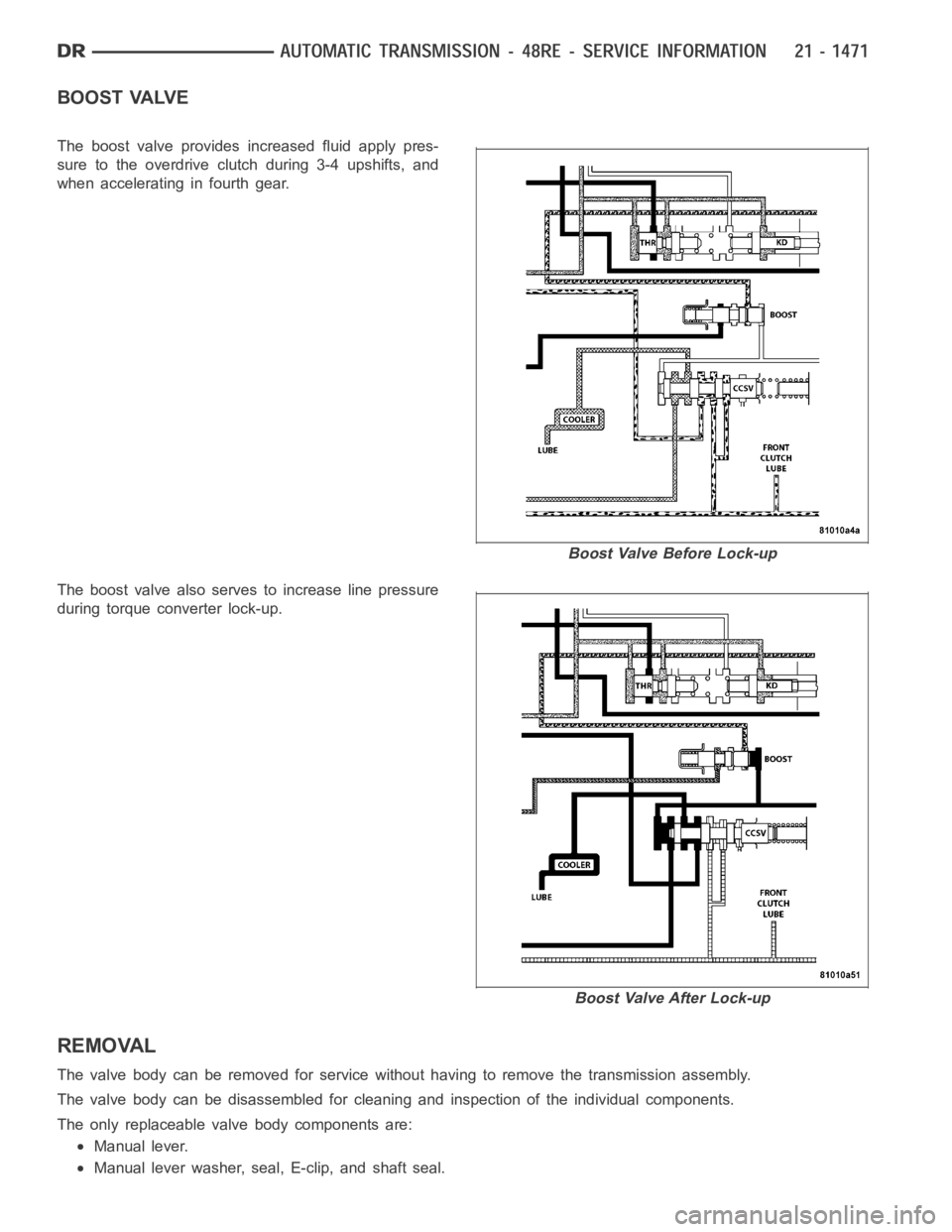

BOOST VALVE

The boost valve provides increased fluid apply pres-

sure to the overdrive clutch during 3-4 upshifts, and

when accelerating in fourth gear.

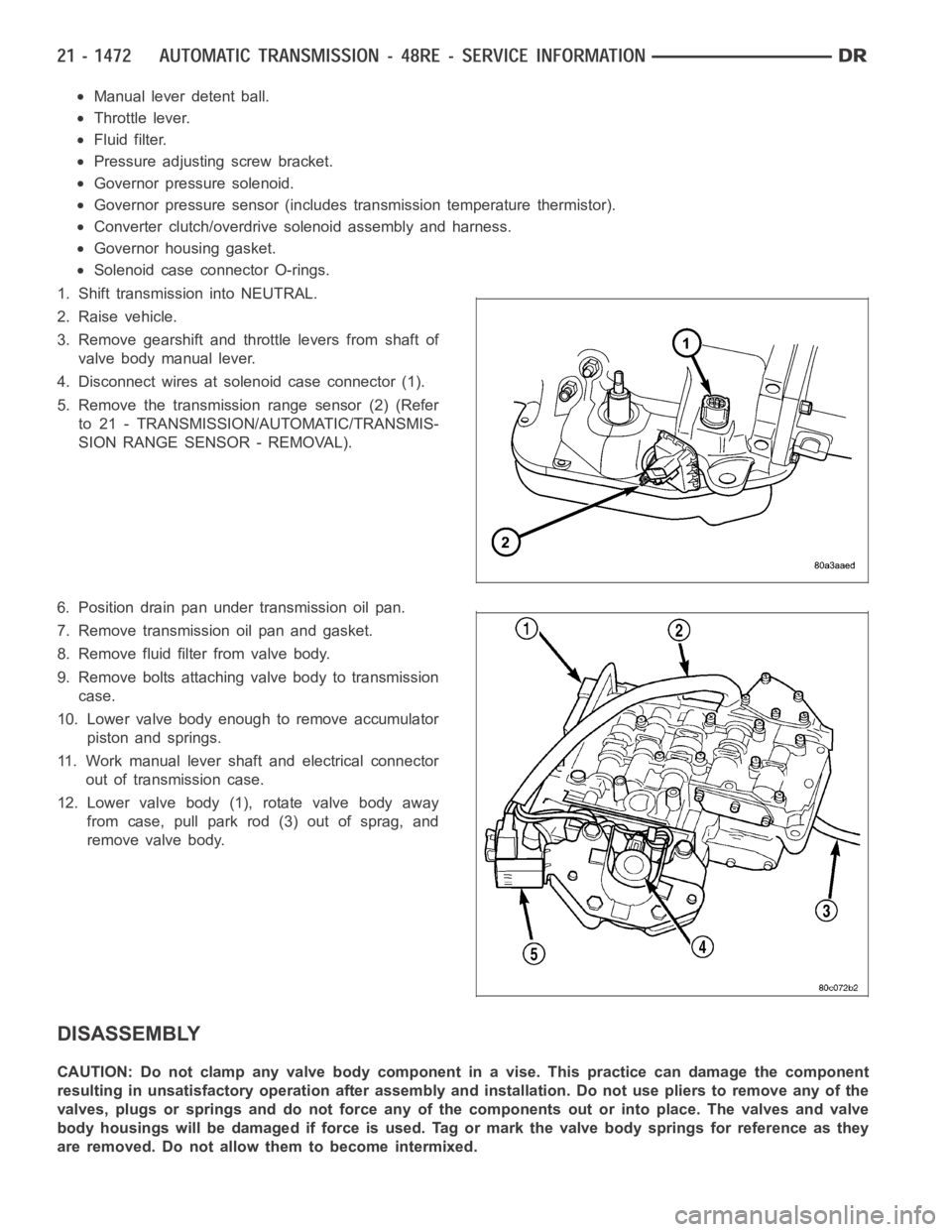

Theboostvalvealsoservestoincreaselinepressure

during torque converter lock-up.

REMOVAL

The valve body can be removed for service without having to remove the transmission assembly.

The valve body can be disassembled for cleaning and inspection of the individual components.

The only replaceable valve body components are:

Manual lever.

Manual lever washer, seal, E-clip, and shaft seal.

Boost Valve Before Lock-up

Boost Valve After Lock-up

Page 3993 of 5267

Manual lever detent ball.

Throttle lever.

Fluid filter.

Pressure adjusting screw bracket.

Governor pressure solenoid.

Governor pressure sensor (includes transmission temperature thermistor).

Converter clutch/overdrive solenoid assembly and harness.

Governor housing gasket.

Solenoid case connector O-rings.

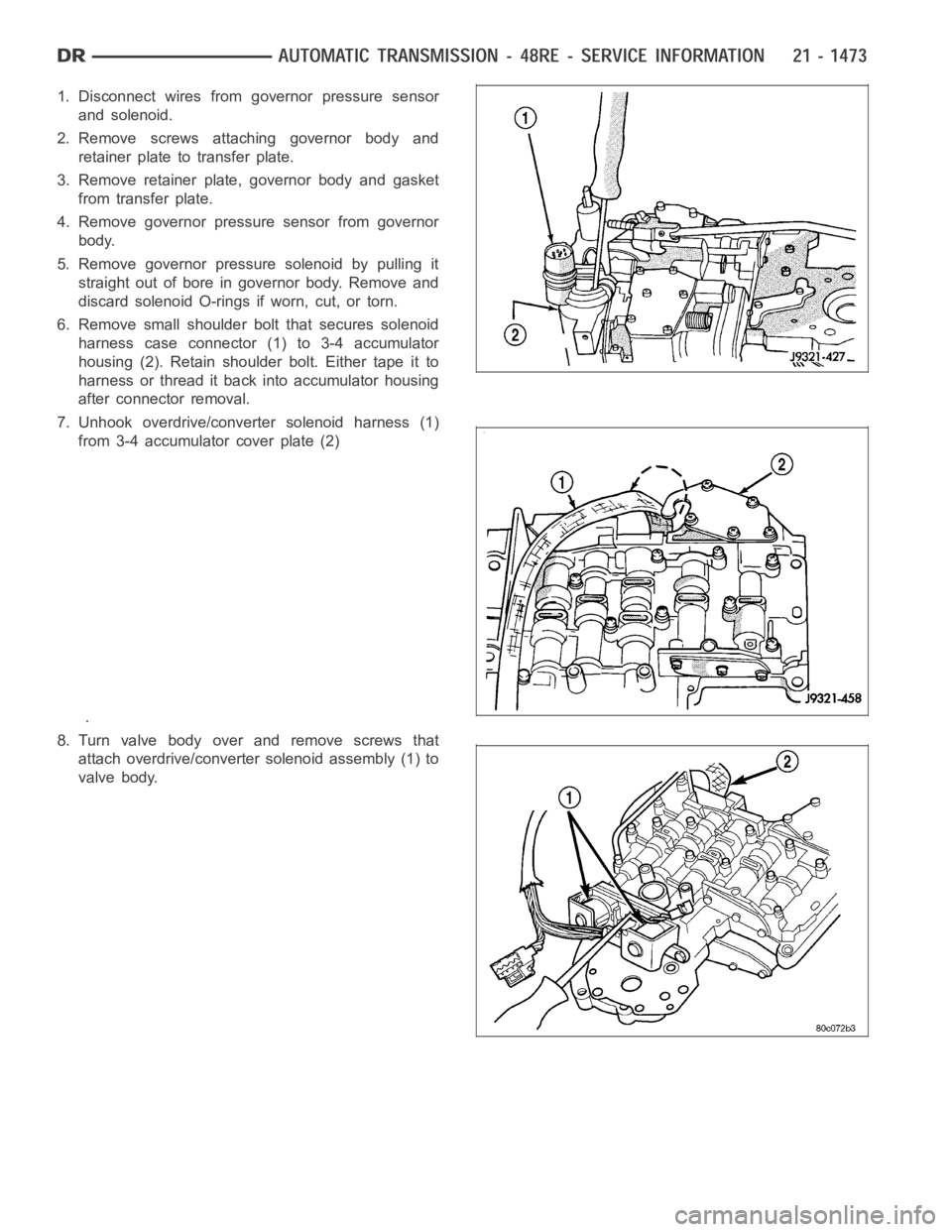

1. Shift transmission into NEUTRAL.

2. Raise vehicle.

3. Remove gearshift and throttle levers from shaft of

valve body manual lever.

4. Disconnect wires at solenoid case connector (1).

5. Remove the transmission range sensor (2) (Refer

to 21 - TRANSMISSION/AUTOMATIC/TRANSMIS-

SION RANGE SENSOR - REMOVAL).

6. Position drain pan under transmission oil pan.

7. Remove transmission oil pan and gasket.

8. Remove fluid filter from valve body.

9. Remove bolts attaching valve body to transmission

case.

10. Lower valve body enough to remove accumulator

piston and springs.

11. Work manual lever shaft and electrical connector

out of transmission case.

12. Lower valve body (1), rotate valve body away

from case, pull park rod (3) out of sprag, and

remove valve body.

DISASSEMBLY

CAUTION: Do not clamp any valve body component in a vise. This practice can damage the component

resulting in unsatisfactory operation after assembly and installation.Do not use pliers to remove any of the

valves, plugs or springs and do not force any of the components out or into place. The valves and valve

body housings will be damaged if force is used. Tag or mark the valve body springs for reference as they

are removed. Do not allow them to become intermixed.

Page 3994 of 5267

1. Disconnect wires from governor pressure sensor

and solenoid.

2. Remove screws attaching governor body and

retainer plate to transfer plate.

3. Remove retainer plate, governor body and gasket

from transfer plate.

4. Remove governor pressure sensor from governor

body.

5. Remove governor pressure solenoid by pulling it

straight out of bore in governor body. Remove and

discard solenoid O-rings if worn, cut, or torn.

6. Remove small shoulder bolt that secures solenoid

harness case connector (1) to 3-4 accumulator

housing (2). Retain shoulder bolt. Either tape it to

harness or thread it back into accumulator housing

after connector removal.

7. Unhook overdrive/converter solenoid harness (1)

from 3-4 accumulator cover plate (2)

.

8. Turn valve body over and remove screws that

attach overdrive/converter solenoid assembly (1) to

valve body.

Page 3995 of 5267

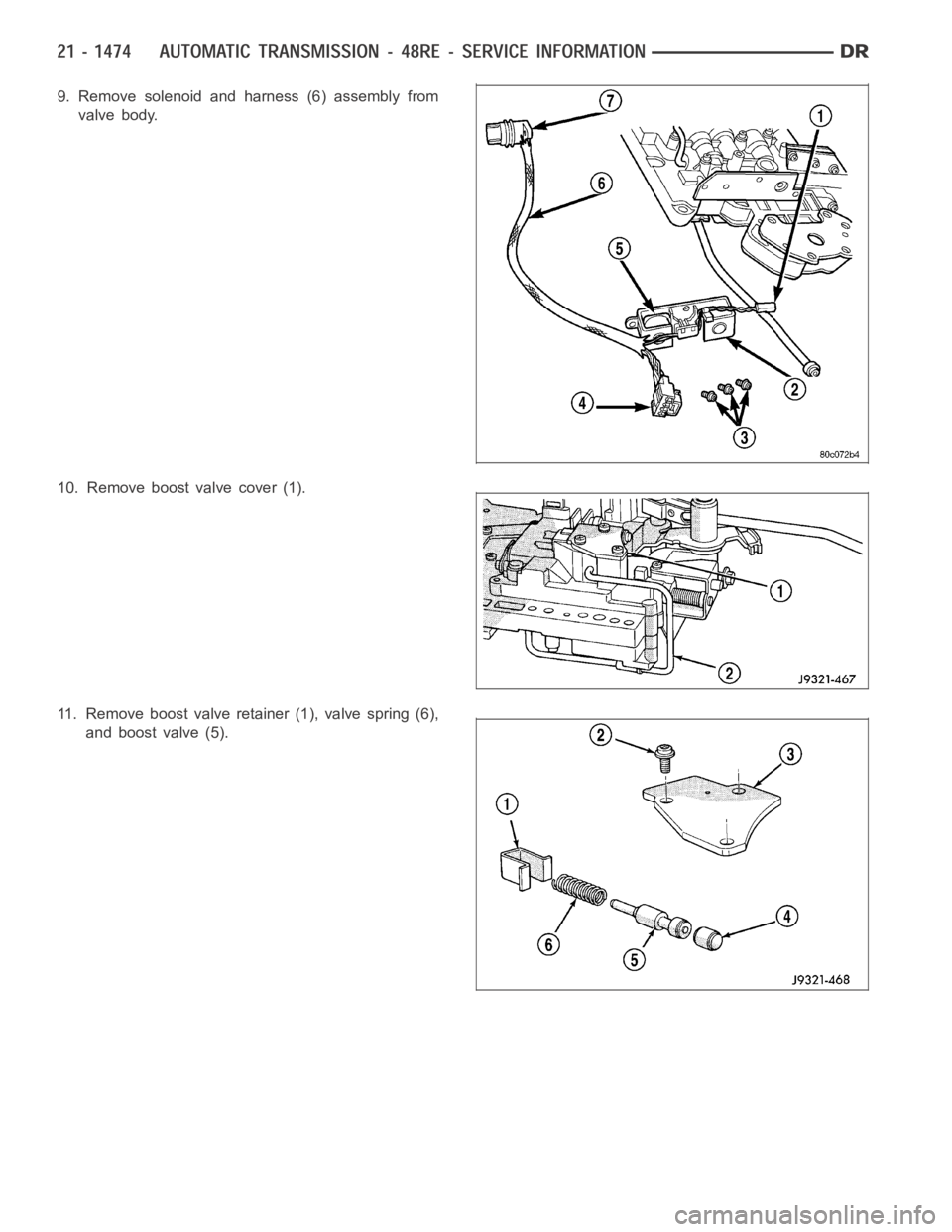

9. Remove solenoid and harness (6) assembly from

valve body.

10. Remove boost valve cover (1).

11. Remove boost valve retainer (1), valve spring (6),

and boost valve (5).

Page 3996 of 5267

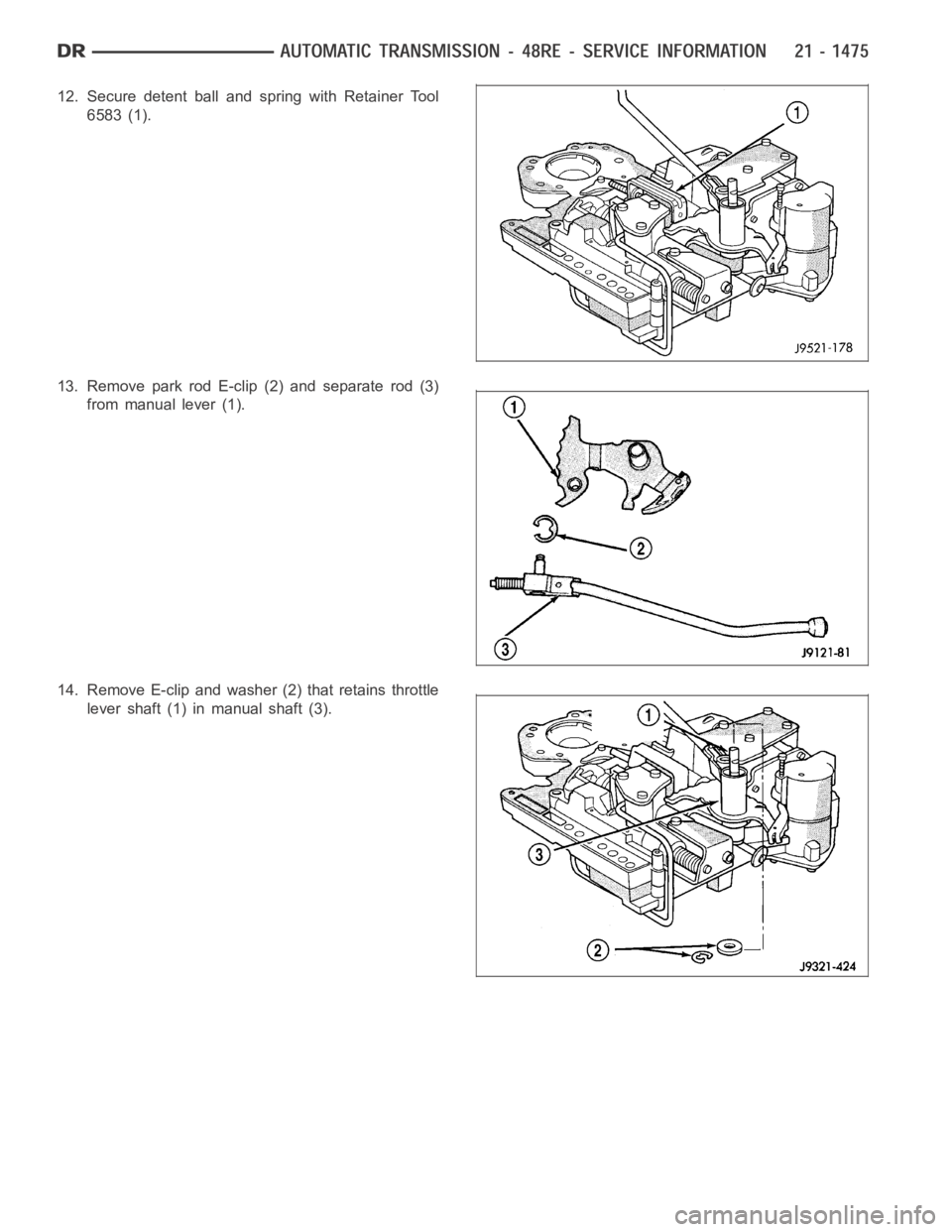

12. Secure detent ball and spring with Retainer Tool

6583 (1).

13. Remove park rod E-clip (2) and separate rod (3)

from manual lever (1).

14. Remove E-clip and washer (2) that retains throttle

lever shaft (1) in manual shaft (3).

Page 3997 of 5267

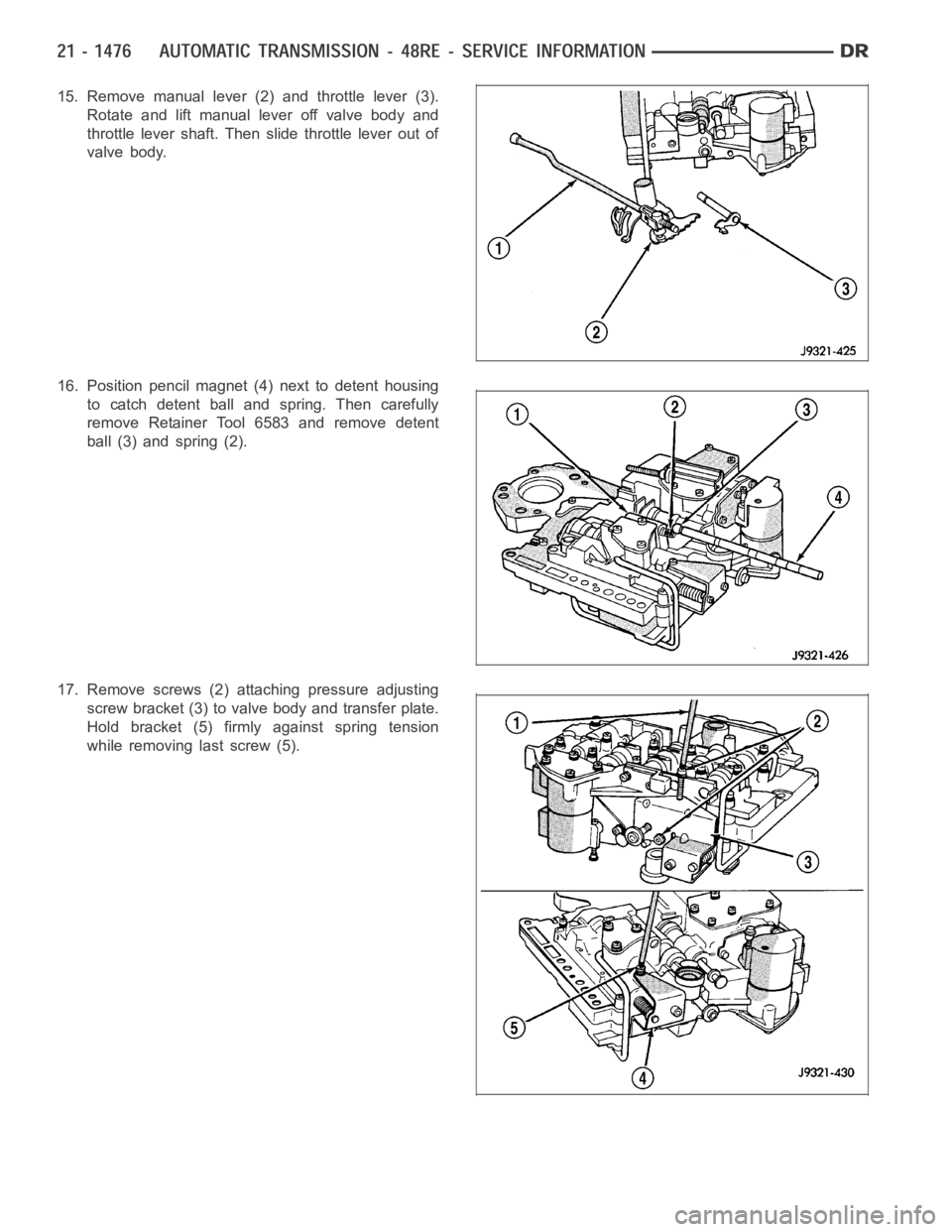

15. Remove manual lever (2) and throttle lever (3).

Rotate and lift manual lever off valve body and

throttle lever shaft. Then slide throttle lever out of

valve body.

16. Position pencil magnet (4) next to detent housing

to catch detent ball and spring. Then carefully

remove Retainer Tool 6583 and remove detent

ball (3) and spring (2).

17. Remove screws (2) attaching pressure adjusting

screw bracket (3) to valve body and transfer plate.

Hold bracket (5) firmly against spring tension

while removing last screw (5).

Page 3998 of 5267

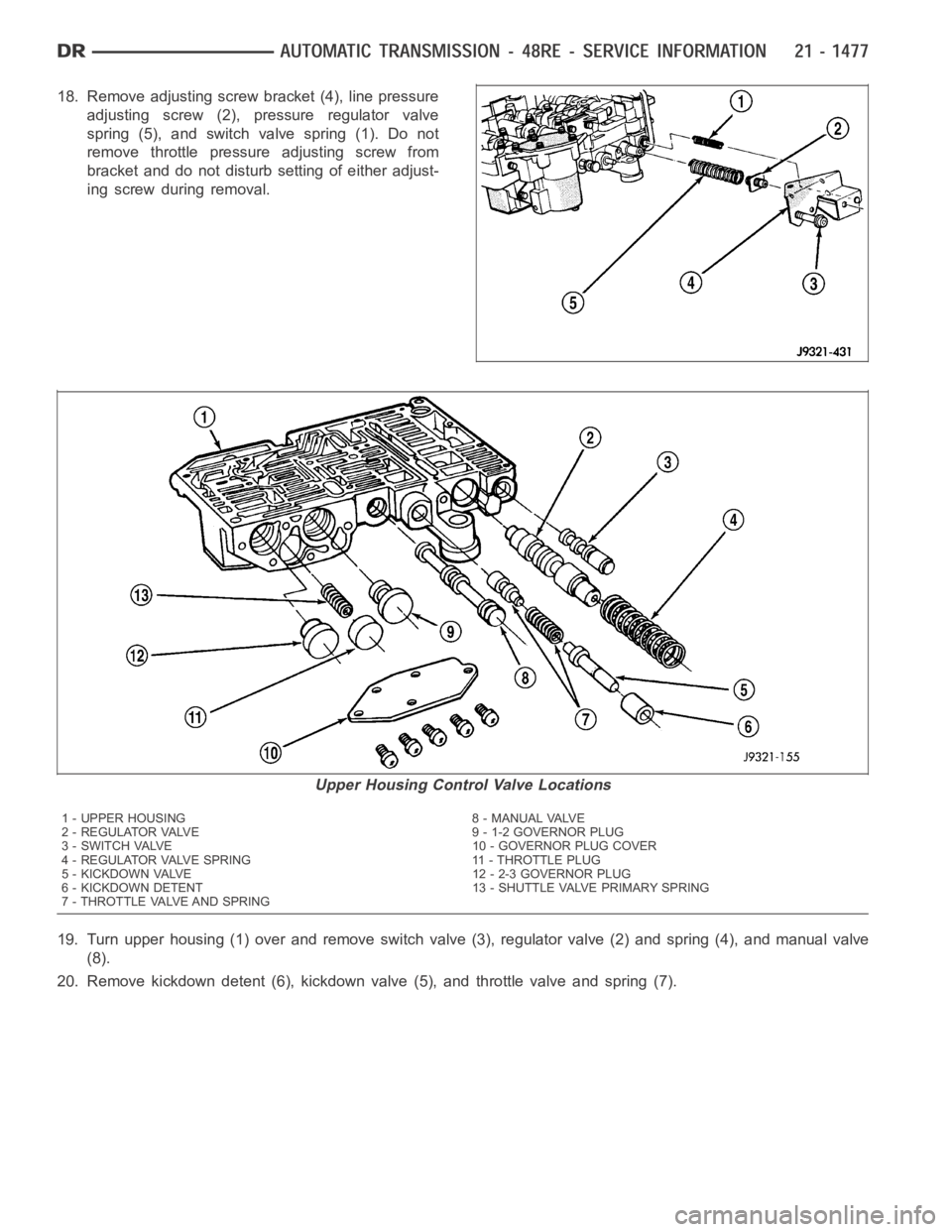

18. Remove adjusting screw bracket (4), line pressure

adjusting screw (2), pressure regulator valve

spring (5), and switch valve spring (1). Do not

remove throttle pressure adjusting screw from

bracket and do not disturb setting of either adjust-

ing screw during removal.

19. Turn upper housing (1) over and remove switch valve (3), regulator valve (2) and spring (4), and manual valve

(8).

20. Remove kickdown detent (6), kickdown valve (5), and throttle valve andspring (7).

Upper Housing Control Valve Locations

1 - UPPER HOUSING 8 - MANUAL VALVE

2 - REGULATOR VALVE 9 - 1-2 GOVERNOR PLUG

3 - SWITCH VALVE 10 - GOVERNOR PLUG COVER

4 - REGULATOR VALVE SPRING 11 - THROTTLE PLUG

5 - KICKDOWN VALVE 12 - 2-3 GOVERNOR PLUG

6 - KICKDOWN DETENT 13 - SHUTTLE VALVE PRIMARY SPRING

7 - THROTTLE VALVE AND SPRING

Page 3999 of 5267

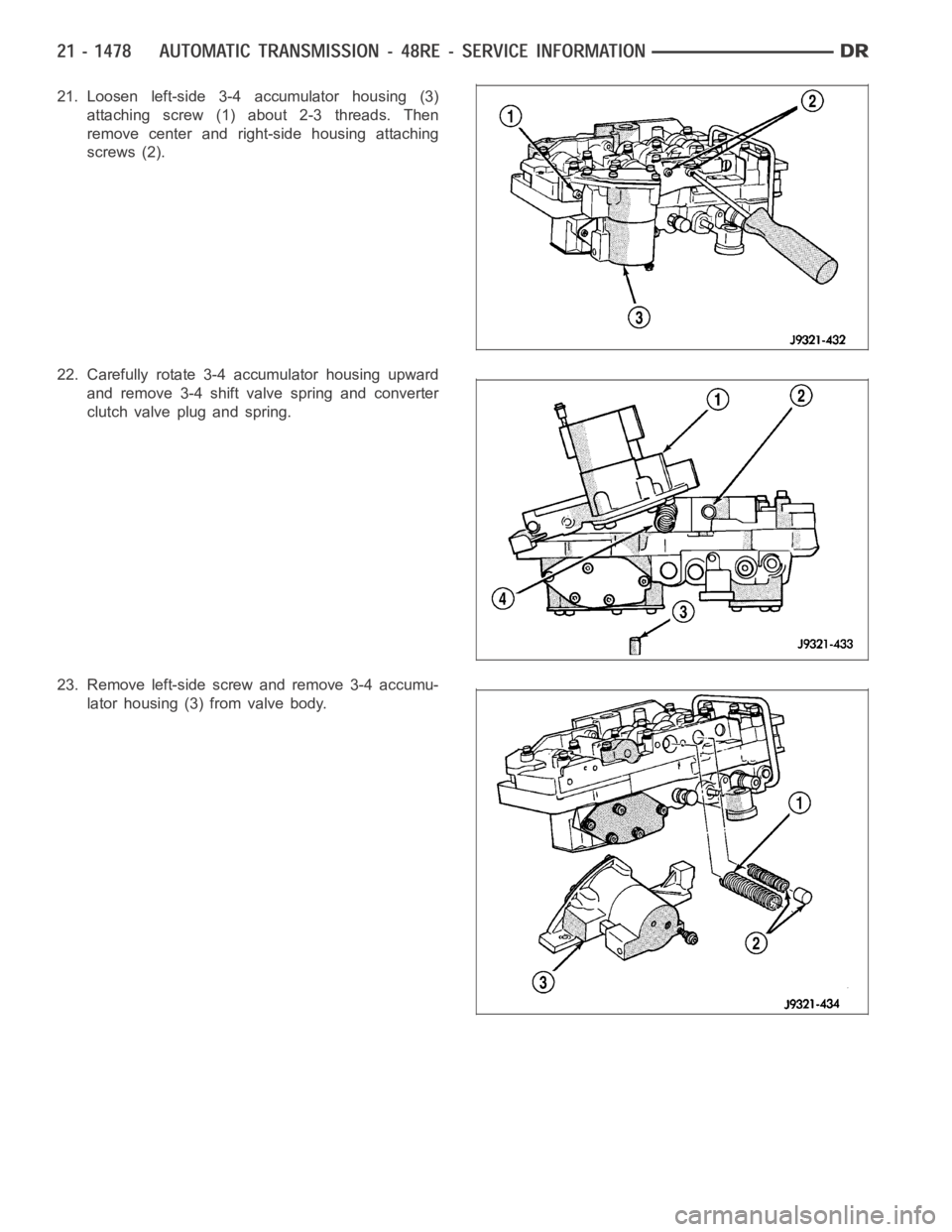

21. Loosen left-side 3-4 accumulator housing (3)

attaching screw (1) about 2-3 threads. Then

remove center and right-side housing attaching

screws (2).

22. Carefully rotate 3-4 accumulator housing upward

and remove 3-4 shift valve spring and converter

clutch valve plug and spring.

23. Remove left-side screw and remove 3-4 accumu-

lator housing (3) from valve body.

Page 4000 of 5267

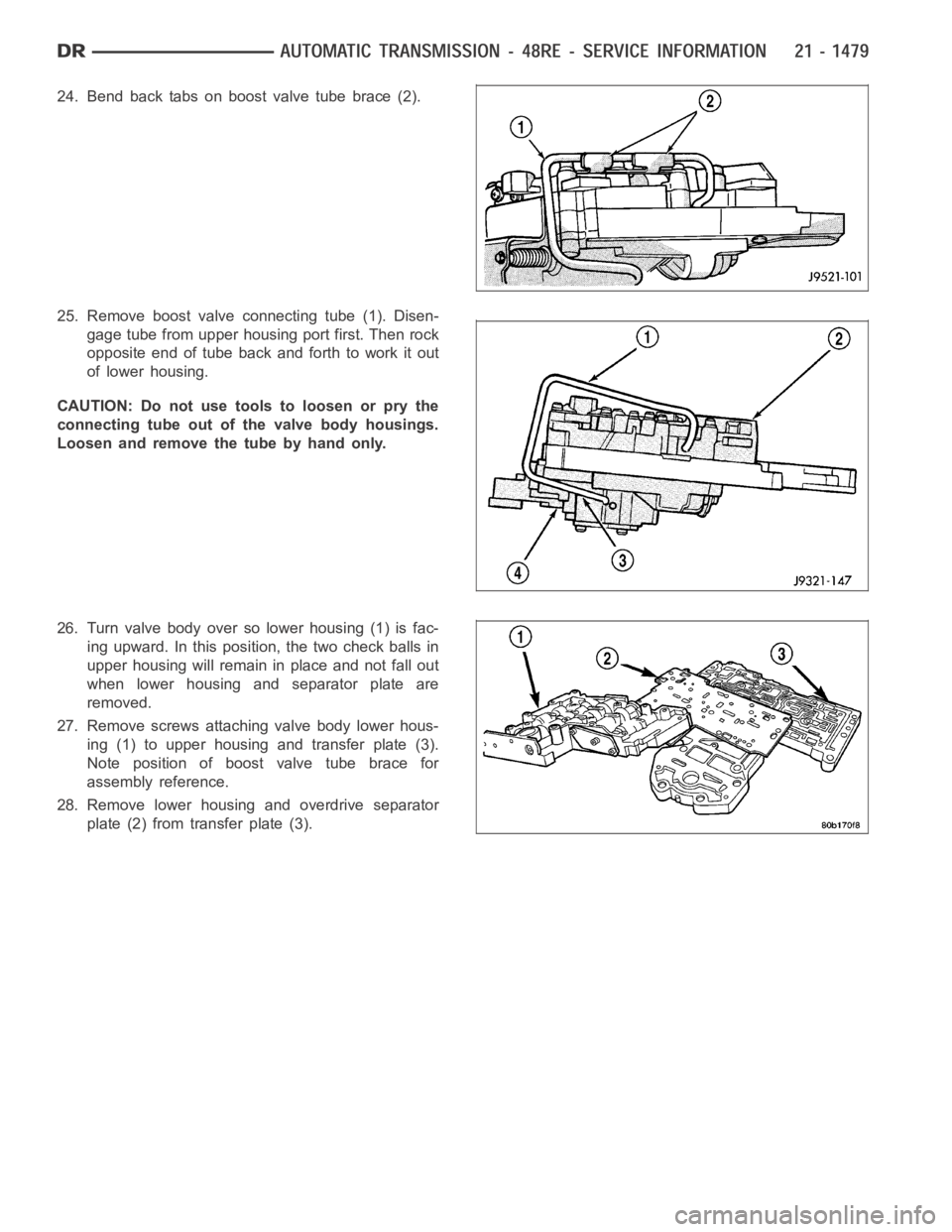

24. Bend back tabs on boost valve tube brace (2).

25. Remove boost valve connecting tube (1). Disen-

gage tube from upper housing port first. Then rock

opposite end of tube back and forth to work it out

of lower housing.

CAUTION: Do not use tools to loosen or pry the

connecting tube out of the valve body housings.

Loosen and remove the tube by hand only.

26. Turn valve body over so lower housing (1) is fac-

ing upward. In this position, the two check balls in

upper housing will remain in place and not fall out

when lower housing and separator plate are

removed.

27. Remove screws attaching valve body lower hous-

ing (1) to upper housing and transfer plate (3).

Note position of boost valve tube brace for

assembly reference.

28. Remove lower housing and overdrive separator

plate (2) from transfer plate (3).