torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3788 of 5267

CLEANING ................................. 1389

INSPECTION ............................... 1389

ASSEMBLY . ............................... 1390

INSTALLATION ............................. 1400

RETAINER-OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON

DESCRIPTION ............................. 1402

OPERATION ............................... 1402

DISASSEMBLY ............................. 1402

CLEANING ................................. 1403

INSPECTION ............................... 1403

ASSEMBLY . ............................... 1403

SHAFT-PLANETARY GEARTRAIN/OUTPUT

DESCRIPTION ............................. 1407

OPERATION ............................... 1407

DISASSEMBLY ............................. 1407

INSPECTION ............................... 1410

ASSEMBLY ................................ 1410

CLUTCH-REAR

DESCRIPTION ............................. 1416

OPERATION ............................... 1416

DISASSEMBLY ............................. 1417

CLEANING ................................. 1417

INSPECTION ............................... 1418

ASSEMBLY ................................ 1418

SERVO-REAR

DESCRIPTION ............................. 1421

OPERATION ............................... 1421

DISASSEMBLY ............................. 1421

CLEANING ................................. 1421

ASSEMBLY ................................ 1421

MECHANISM-SHIFT

DESCRIPTION ............................. 1422

OPERATION ............................... 1422

SENSOR-SPEED

DESCRIPTION ............................. 1423

OPERATION ............................... 1423

ACTUATOR-THROTTLE VALVE

DESCRIPTION ............................. 1424

REMOVAL ................................. 1424

INSTALLATION ............................. 1425

ADJUSTMENTS

ADJUSTMENT ............................ 1426

CABLE-THROTTLE VALVE

DESCRIPTION ............................. 1427ADJUSTMENTS - THROTTLE VALVE CABLE . . 1428

CONVERTER-TORQUE

DESCRIPTION ............................. 1431

OPERATION ............................... 1435

REMOVAL ................................. 1436

INSTALLATION ............................. 1437

VALVE-TORQUE CONVERTER DRAINBACK

DESCRIPTION

GAS ENGINES ........................... 1438

DIESEL ENGINE .......................... 1438

OPERATION

GAS ENGINES ........................... 1438

DIESEL ENGINE .......................... 1438

STANDARD PROCEDURE

GAS ENGINES ........................... 1438

DIESEL ENGINE .......................... 1438

SWITCH-TOW/HAUL OVERDRIVE

DESCRIPTION ............................. 1440

OPERATION ............................... 1440

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS ................. 1440

REMOVAL ................................. 1440

INSTALLATION ............................. 1441

SENSOR-TRANSMISSION RANGE

DESCRIPTION ............................. 1442

OPERATION ............................... 1442

DIAGNOSIS AND TESTING - TRANSMISSION

RANGE SENSOR (TRS) ................... 1443

REMOVAL ................................. 1444

INSTALLATION ............................. 1445

SENSOR-TRANSMISSION TEMPERATURE

DESCRIPTION ............................. 1447

OPERATION ............................... 1447

BODY-VALVE

DESCRIPTION ............................. 1448

OPERATION ............................... 1451

REMOVAL ................................. 1471

DISASSEMBLY ............................. 1472

CLEANING ................................. 1485

INSPECTION ............................... 1485

ASSEMBLY................................ 1486

INSTALLATION ............................. 1497

ADJUSTMENTS - VALVE BODY .............. 1498

Page 3791 of 5267

The 48RE is a four speed fully automatic transmissions with an electronic governor. The 48RE is equipped with a

lock-up clutch in the torque converter. First through third gear ranges are provided by the clutches, bands, over-

running clutch, and planetary gear sets in the transmission. Fourth gear range is provided by the overdrive unit that

contains an overdrive clutch, direct clutch, planetary gear set, and overrunning clutch.

The transmission contains a front, rear, and direct clutch which functionas the input driving components. It also

contains the kickdown (front) and the low/reverse (rear) bands which, along with the overrunning clutch and over-

drive clutch, serve as the holding components. The driving and holding components combine to select the neces-

sary planetary gear components, in the front, rear, or overdrive planetary gear set, transfer the engine power from

the input shaft through to the output shaft.

The valve body is mounted to the lower side of the transmission and containsthe valves to control pressure reg-

ulation, fluid flow control, and clutch/band application. The oil pump ismounted at the front of the transmission and

is driven by the torque converter hub. The pump supplies the oil pressure necessary for clutch/band actuation and

transmission lubrication.

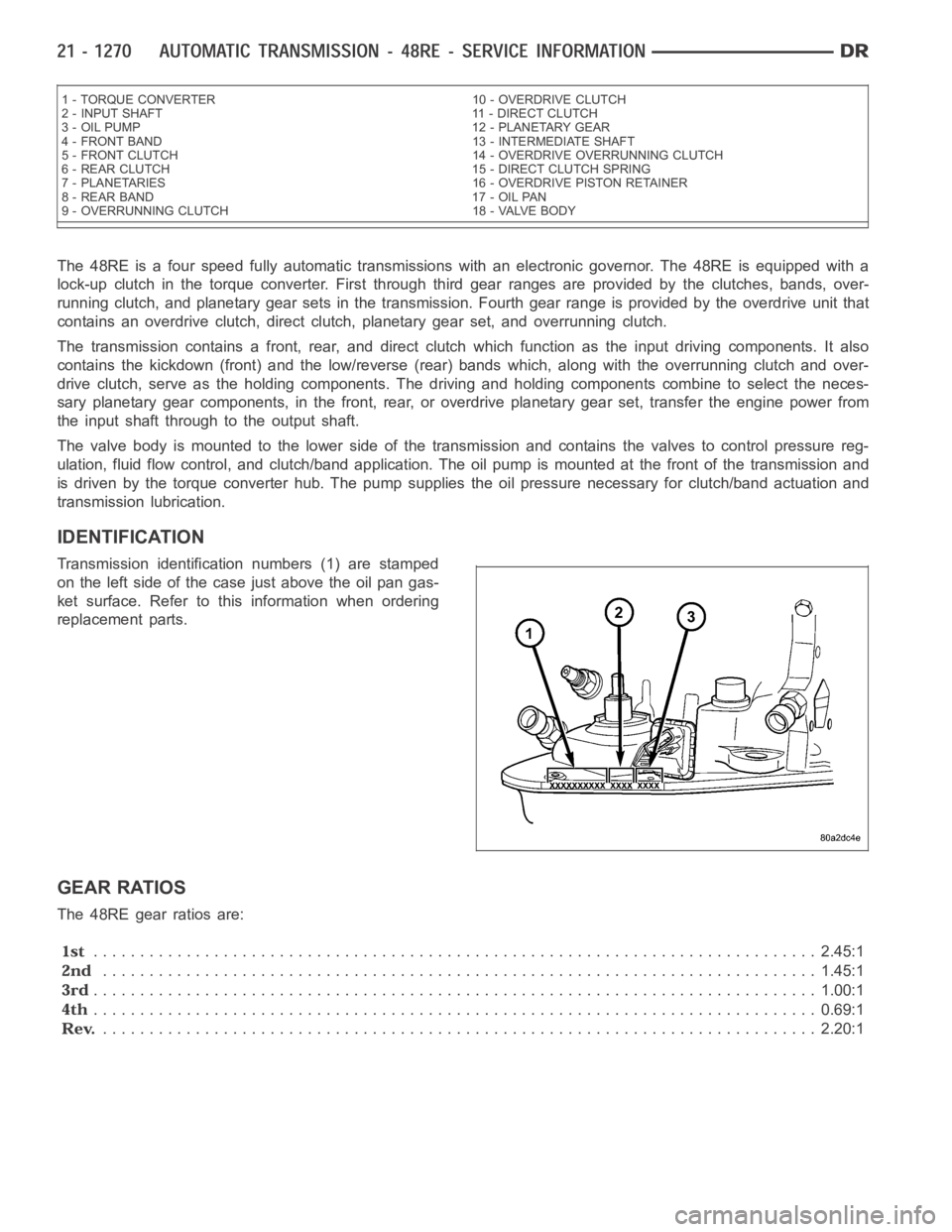

IDENTIFICATION

Transmission identification numbers (1) are stamped

on the left side of the case just above the oil pan gas-

ket surface. Refer to this information when ordering

replacement parts.

GEAR RATIOS

The 48RE gear ratios are:

.............................................................................. 2.45:1

............................................................................. 1.45:1

.............................................................................. 1.00:1

.............................................................................. 0.69:1

............................................................................. 2.20:1

1 - TORQUE CONVERTER 10 - OVERDRIVE CLUTCH

2 - INPUT SHAFT 11 - DIRECT CLUTCH

3 - OIL PUMP 12 - PLANETARY GEAR

4 - FRONT BAND 13 - INTERMEDIATE SHAFT

5 - FRONT CLUTCH 14 - OVERDRIVE OVERRUNNING CLUTCH

6 - REAR CLUTCH 15 - DIRECT CLUTCH SPRING

7 - PLANETARIES 16 - OVERDRIVE PISTON RETAINER

8 - REAR BAND 17 - OIL PAN

9 - OVERRUNNING CLUTCH 18 - VALVE BODY

Page 3792 of 5267

OPERATION

The application of each driving or holding component is controlled by the valve body based upon the manual lever

position, throttle pressure, and governor pressure. The governor pressure is a variable pressure input to the valve

body and is one of the signals that a shift is necessary. First through fourth gear are obtained by selectively apply-

ing and releasing the different clutches and bands. Engine power is thereby routed to the various planetary gear

assemblies which combine with the overrunning clutch assemblies to generate the different gear ratios. The torque

converter clutch is hydraulically applied and is released when fluid is vented from the hydraulic circuit by the torque

converter control (TCC) solenoid on the valve body. The torque converter clutch is controlled by the Powertrain

Control Module (PCM). The torque converter clutch engages in fourth gear,and in third gear under various condi-

tions, such as when the O/D switch is OFF, when the vehicle is cruising on a level surface after the vehicle has

warmed up. The torque converter clutch can also be engaged in the MANUAL SECOND gear position if high trans-

mission temperatures are sensed by the PCM. The torque converter clutch will disengage momentarily when an

increase in engine load is sensed by the PCM, such as when the vehicle beginsto go uphill or the throttle pressure

is increased. The torque converter clutch feature increases fuel economyand reduces the transmission fluid tem-

perature.

Since the overdrive clutch is applied in fourth gear only and the direct clutch is applied in all ranges except fourth

gear, the transmission operation for park, neutral, and first through third gear will be described first. Once these

powerflows are described, the third to fourth shift sequence will be described.

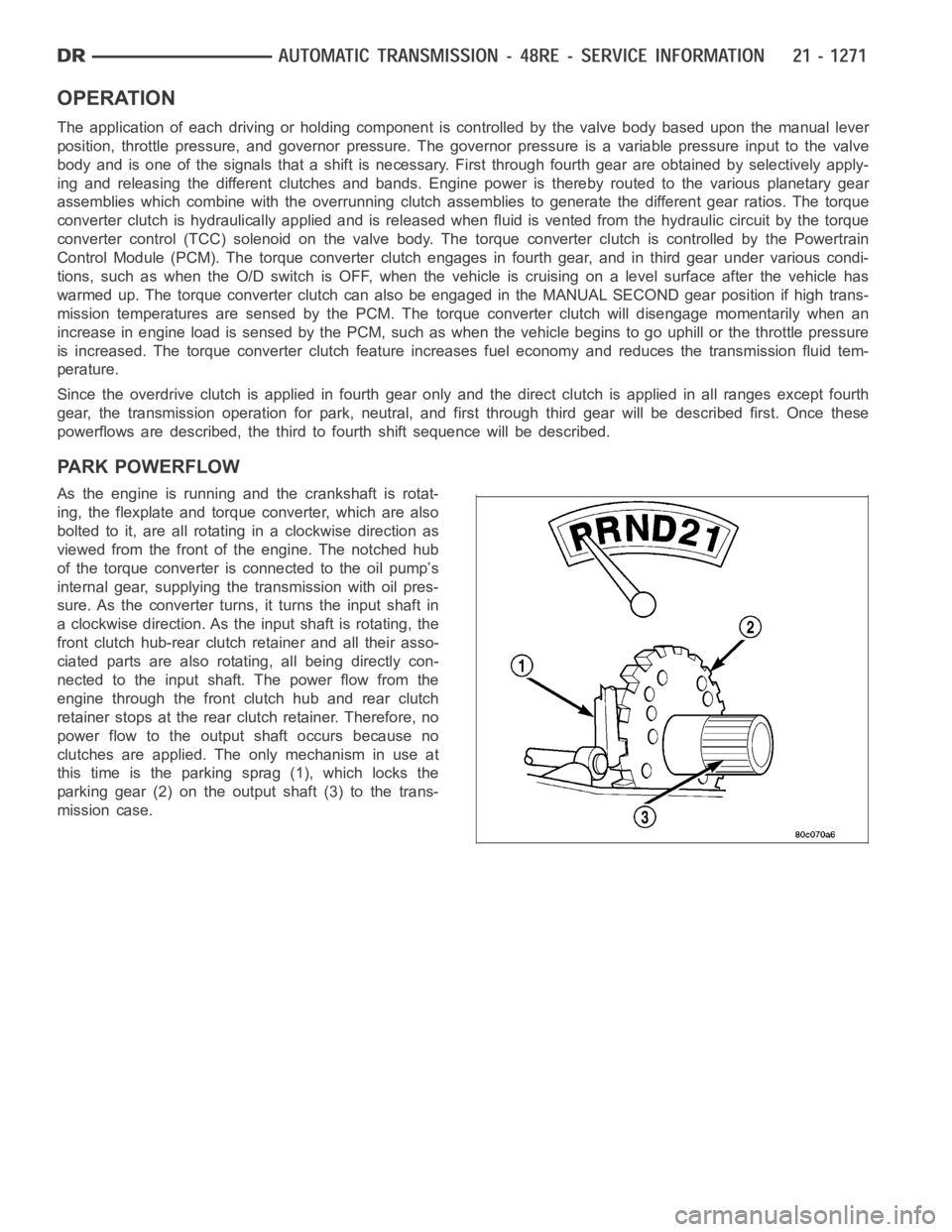

PARK POWERFLOW

As the engine is running and the crankshaft is rotat-

ing, the flexplate and torque converter, which are also

bolted to it, are all rotating in a clockwise direction as

viewed from the front of the engine. The notched hub

of the torque converter is connected to the oil pump’s

internal gear, supplying the transmission with oil pres-

sure. As the converter turns, it turns the input shaft in

a clockwise direction. As the input shaft is rotating, the

front clutch hub-rear clutch retainer and all their asso-

ciated parts are also rotating, all being directly con-

nected to the input shaft. The power flow from the

engine through the front clutch hub and rear clutch

retainer stops at the rear clutch retainer. Therefore, no

power flow to the output shaft occurs because no

clutches are applied. The only mechanism in use at

this time is the parking sprag (1), which locks the

parking gear (2) on the output shaft (3) to the trans-

mission case.

Page 3794 of 5267

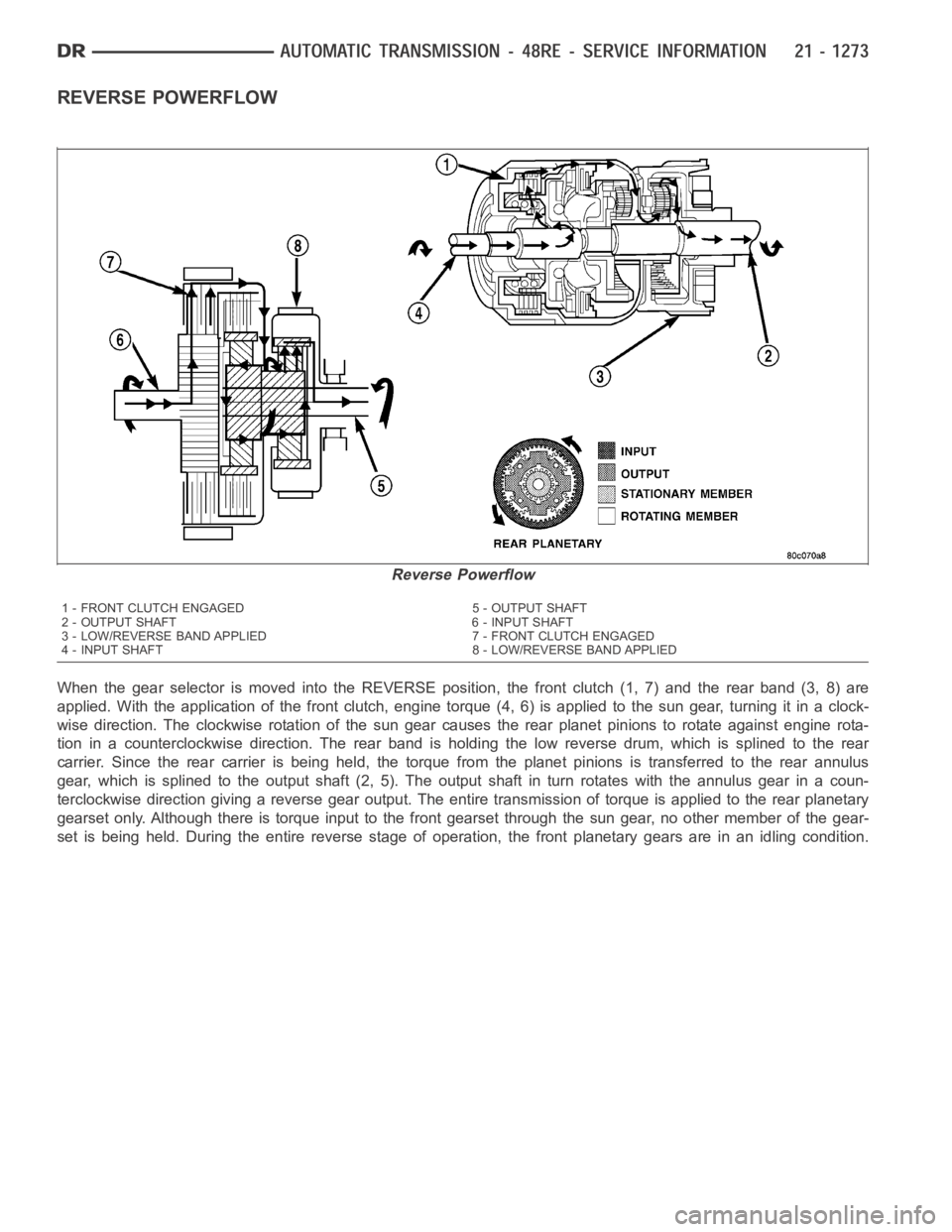

REVERSE POWERFLOW

When the gear selector is moved into the REVERSE position, the front clutch(1, 7) and the rear band (3, 8) are

applied. With the application of the front clutch, engine torque (4, 6) is applied to the sun gear, turning it in a clock-

wise direction. The clockwise rotation of the sun gear causes the rear planet pinions to rotate against engine rota-

tion in a counterclockwise direction. The rear band is holding the low reverse drum, which is splined to the rear

carrier. Since the rear carrier is being held, the torque from the planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft (2, 5). The output shaft in turn rotates with the annulus gear in a coun-

terclockwise direction giving a reverse gear output. The entire transmission of torque is applied to the rear planetary

gearset only. Although there is torque input to the front gearset through the sun gear, no other member of the gear-

set is being held. During the entire reverse stage of operation, the front planetary gears are in an idling condition.

Reverse Powerflow

1 - FRONT CLUTCH ENGAGED 5 - OUTPUT SHAFT

2 - OUTPUT SHAFT 6 - INPUT SHAFT

3 - LOW/REVERSE BAND APPLIED 7 - FRONT CLUTCH ENGAGED

4 - INPUT SHAFT 8 - LOW/REVERSE BAND APPLIED

Page 3795 of 5267

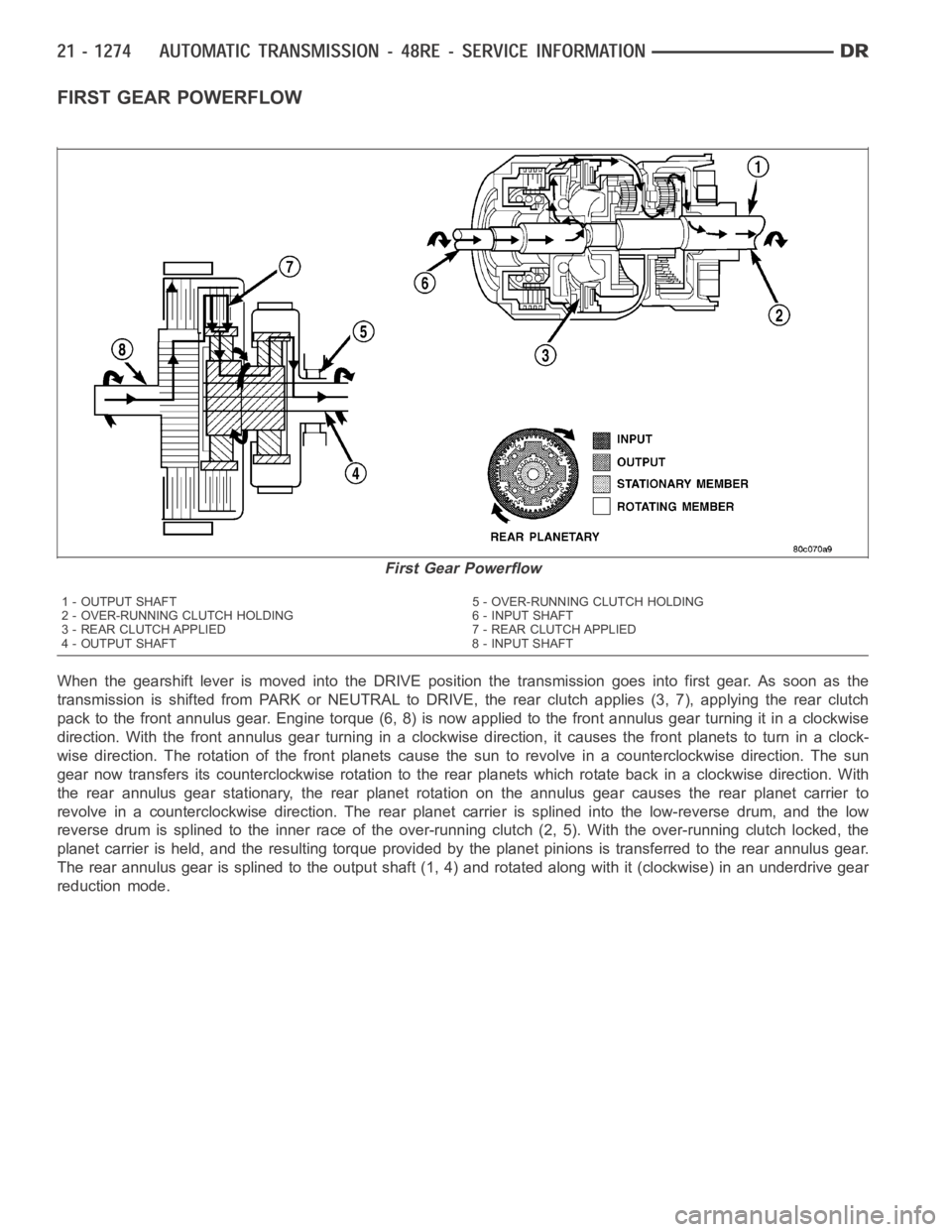

FIRST GEAR POWERFLOW

When the gearshift lever is moved into the DRIVE position the transmissiongoes into first gear. As soon as the

transmission is shifted from PARK or NEUTRAL to DRIVE, the rear clutch applies (3, 7), applying the rear clutch

pack to the front annulus gear. Engine torque (6, 8) is now applied to the front annulus gear turning it in a clockwise

direction. With the front annulus gear turning in a clockwise direction, it causes the front planets to turn in a clock-

wise direction. The rotation of the front planets cause the sun to revolve in a counterclockwise direction. The sun

gear now transfers its counterclockwise rotation to the rear planets which rotate back in a clockwise direction. With

the rear annulus gear stationary, the rear planet rotation on the annulus gear causes the rear planet carrier to

revolve in a counterclockwise direction. The rear planet carrier is splined into the low-reverse drum, and the low

reverse drum is splined to the inner race of the over-running clutch (2, 5).With the over-running clutch locked, the

planet carrier is held, and the resulting torque provided by the planet pinions is transferred to the rear annulus gear.

The rear annulus gear is splined to the output shaft (1, 4) and rotated alongwith it (clockwise) in an underdrive gear

reduction mode.

First Gear Powerflow

1 - OUTPUT SHAFT 5 - OVER-RUNNING CLUTCH HOLDING

2 - OVER-RUNNING CLUTCH HOLDING 6 - INPUT SHAFT

3 - REAR CLUTCH APPLIED 7 - REAR CLUTCH APPLIED

4 - OUTPUT SHAFT 8 - INPUT SHAFT

Page 3796 of 5267

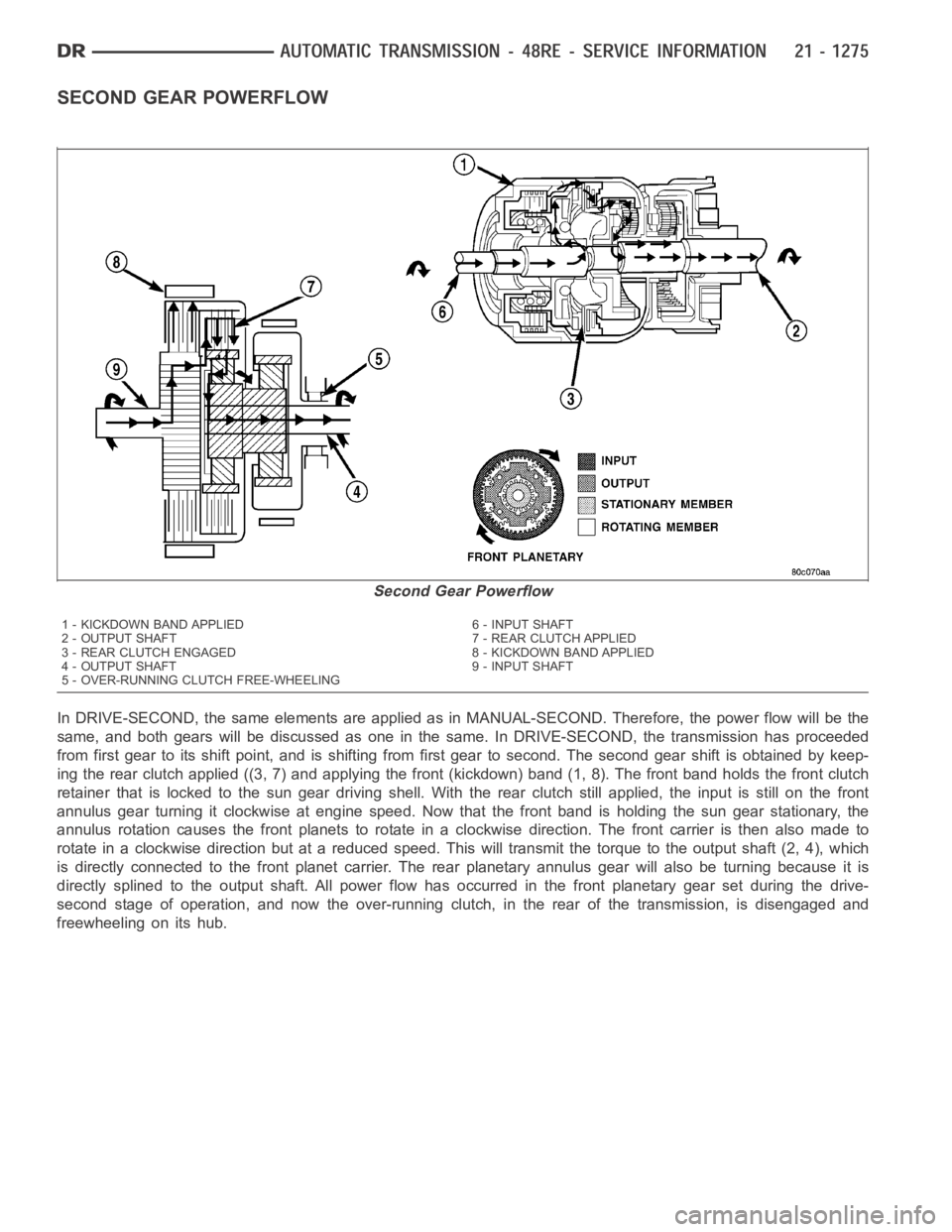

SECOND GEAR POWERFLOW

In DRIVE-SECOND, the same elements are applied as in MANUAL-SECOND. Therefore, the power flow will be the

same, and both gears will be discussed as one in the same. In DRIVE-SECOND, the transmission has proceeded

from first gear to its shift point, and is shifting from first gear to second. The second gear shift is obtained by keep-

ing the rear clutch applied ((3, 7) and applying the front (kickdown) band (1, 8). The front band holds the front clutch

retainer that is locked to the sun gear driving shell. With the rear clutch still applied, the input is still on the front

annulus gear turning it clockwise at engine speed. Now that the front band is holding the sun gear stationary, the

annulus rotation causes the front planets to rotate in a clockwise direction. The front carrier is then also made to

rotate in a clockwise direction but at a reduced speed. This will transmit the torque to the output shaft (2, 4), which

is directly connected to the front planet carrier. The rear planetary annulus gear will also be turning because it is

directly splined to the output shaft. All power flow has occurred in the front planetary gear set during the drive-

second stage of operation, and now the over-running clutch, in the rear of the transmission, is disengaged and

freewheeling on its hub.

Second Gear Powerflow

1 - KICKDOWN BAND APPLIED 6 - INPUT SHAFT

2 - OUTPUT SHAFT 7 - REAR CLUTCH APPLIED

3 - REAR CLUTCH ENGAGED 8 - KICKDOWN BAND APPLIED

4 - OUTPUT SHAFT 9 - INPUT SHAFT

5 - OVER-RUNNING CLUTCH FREE-WHEELING

Page 3797 of 5267

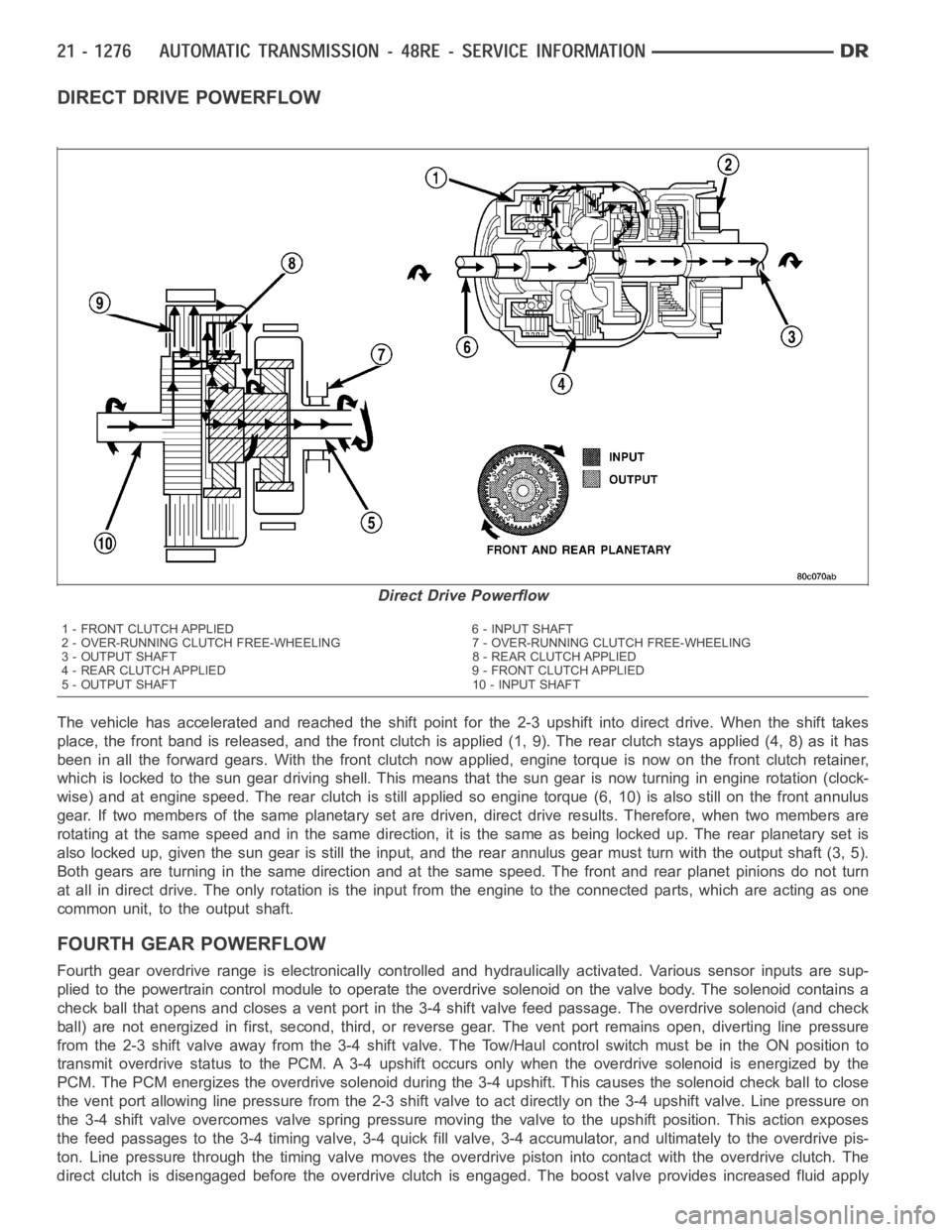

DIRECT DRIVE POWERFLOW

The vehicle has accelerated and reached the shift point for the 2-3 upshiftinto direct drive. When the shift takes

place, the front band is released, and the front clutch is applied (1, 9). The rear clutch stays applied (4, 8) as it has

been in all the forward gears. With the front clutch now applied, engine torque is now on the front clutch retainer,

which is locked to the sun gear drivingshell. This means that the sun gear isnow turning in engine rotation (clock-

wise) and at engine speed. The rear clutch is still applied so engine torque(6, 10) is also still on the front annulus

gear. If two members of the same planetary set are driven, direct drive results. Therefore, when two members are

rotating at the same speed and in the same direction, it is the same as being locked up. The rear planetary set is

also locked up, given the sun gear is still the input, and the rear annulus gear must turn with the output shaft (3, 5).

Both gears are turning in the same direction and at the same speed. The frontand rear planet pinions do not turn

at all in direct drive. The only rotation is the input from the engine to the connected parts, which are acting as one

common unit, to the output shaft.

FOURTHGEARPOWERFLOW

Fourth gear overdrive range is electronically controlled and hydraulically activated. Various sensor inputs are sup-

plied to the powertrain control module to operate the overdrive solenoid on the valve body. The solenoid contains a

check ball that opens and closes a vent port in the 3-4 shift valve feed passage. The overdrive solenoid (and check

ball) are not energized in first, second, third, or reverse gear. The vent port remains open, diverting line pressure

from the 2-3 shift valve away from the 3-4 shift valve. The Tow/Haul controlswitch must be in the ON position to

transmit overdrive status to the PCM. A 3-4 upshift occurs only when the overdrive solenoid is energized by the

PCM. The PCM energizes the overdrive solenoid during the 3-4 upshift. Thiscauses the solenoid check ball to close

the vent port allowing line pressure from the 2-3 shift valve to act directly on the 3-4 upshift valve. Line pressure on

the 3-4 shift valve overcomes valve spring pressure moving the valve to theupshift position. This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick fill valve, 3-4 accumulator, and ultimately to the overdrive pis-

ton. Line pressure through the timing valve moves the overdrive piston into contact with the overdrive clutch. The

direct clutch is disengaged before the overdrive clutch is engaged. The boost valve provides increased fluid apply

Direct Drive Powerflow

1 - FRONT CLUTCH APPLIED 6 - INPUT SHAFT

2 - OVER-RUNNING CLUTCH FREE-WHEELING 7 - OVER-RUNNING CLUTCH FREE-WHEELING

3 - OUTPUT SHAFT 8 - REAR CLUTCH APPLIED

4 - REAR CLUTCH APPLIED 9 - FRONT CLUTCH APPLIED

5 - OUTPUT SHAFT 10 - INPUT SHAFT

Page 3803 of 5267

Front Clutch Air Test

Place one or two fingers on the clutch housing and apply air pressure through front clutch apply passage. Piston

movement can be felt and a soft thump heard as the clutch applies.

Rear Clutch Air Test

Place one or two fingers on the clutch housing and apply air pressure through rear clutch apply passage. Piston

movement can be felt and a soft thump heard as the clutch applies.

Front Servo Air Test

Apply air pressure to the front servo apply passage. The servo rod should extend and cause the band to tighten

around the drum. Spring pressure should release the servo when air pressure is removed.

Rear Servo Air Test

Apply air pressure to the rear servo apply passage. The servo rod should extend and cause the band to tighten

around the drum. Spring pressure should release the servo when air pressure is removed.

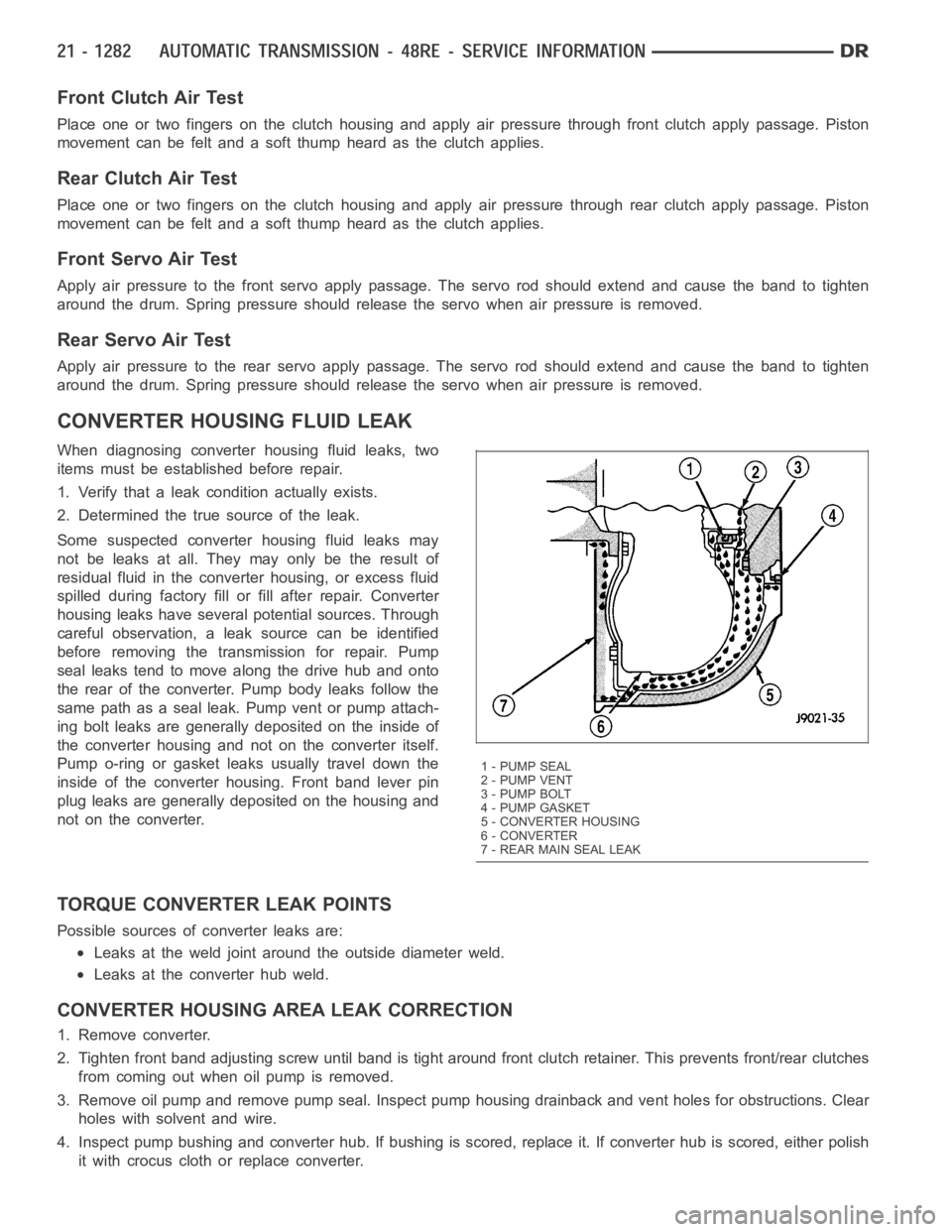

CONVERTER HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks, two

items must be established before repair.

1. Verify that a leak condition actually exists.

2. Determined the true source of the leak.

Some suspected converter housing fluid leaks may

not be leaks at all. They may only be the result of

residual fluid in the converter housing, or excess fluid

spilled during factory fill or fill after repair. Converter

housing leaks have several potential sources. Through

careful observation, a leak source can be identified

before removing the transmission for repair. Pump

seal leaks tend to move along the drive hub and onto

the rear of the converter. Pump body leaks follow the

same path as a seal leak. Pump vent or pump attach-

ing bolt leaks are generally deposited on the inside of

the converter housing and not on the converter itself.

Pump o-ring or gasket leaks usually travel down the

inside of the converter housing. Front band lever pin

plug leaks are generally deposited on the housing and

not on the converter.

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

Leaks at the weld joint around the outside diameter weld.

Leaks at the converter hub weld.

CONVERTER HOUSING AREA LEAK CORRECTION

1. Remove converter.

2. Tighten front band adjusting screw until band is tight around front clutch retainer. This prevents front/rear clutches

from coming out when oil pump is removed.

3. Remove oil pump and remove pump seal. Inspect pump housing drainback andvent holes for obstructions. Clear

holes with solvent and wire.

4. Inspect pump bushing and converter hub. If bushing is scored, replace it. If converter hub is scored, either polish

it with crocus cloth or replace converter.

1 - PUMP SEAL

2-PUMPVENT

3-PUMPBOLT

4 - PUMP GASKET

5 - CONVERTER HOUSING

6 - CONVERTER

7 - REAR MAIN SEAL LEAK

Page 3804 of 5267

5. Install new pump seal, O-ring, and gasket. Replace oil pump if cracked, porous or damaged in any way. Be sure

to loosen the front band before installing the oil pump, damage to the oil pump seal may occur if the band is still

tightened to the frontclutch retainer.

6. Loosen kickdown lever pin access plug three turns. Apply Loctite™ 592, orPermatex

No. 2 to plug threads and

tightenplugto17Nꞏm(150in.lbs.)torque.

7. Adjust front band.

8. Lubricate pump seal and converter hub with transmission fluid or petroleum jelly and install converter.

9. Install transmission and converter housing dust shield.

10. Lower vehicle.

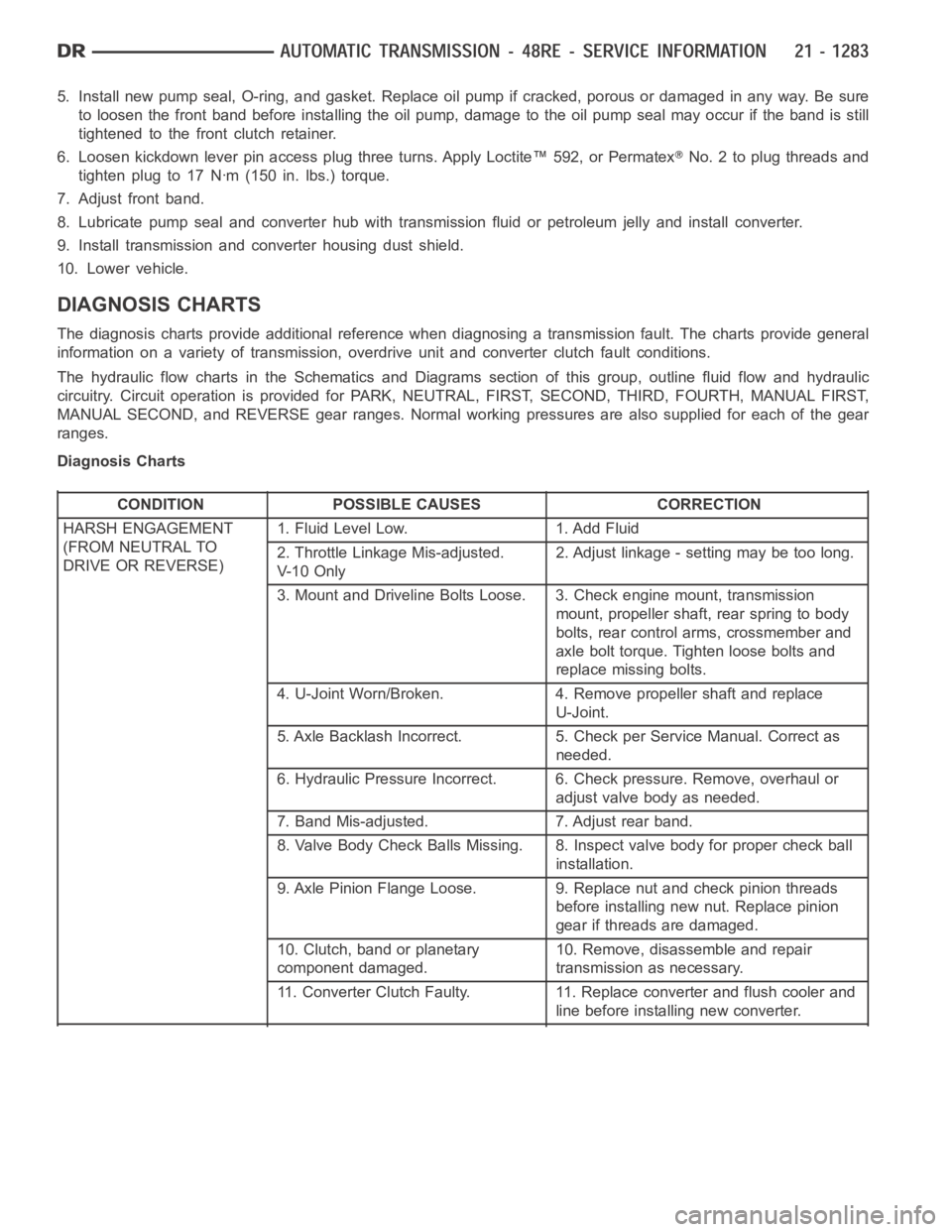

DIAGNOSIS CHARTS

The diagnosis charts provide additional reference when diagnosing a transmission fault. The charts provide general

information on a variety of transmission, overdrive unit and converter clutch fault conditions.

The hydraulic flow charts in the Schematics and Diagrams section of this group, outline fluid flow and hydraulic

circuitry. Circuit operation is provided for PARK, NEUTRAL, FIRST, SECOND, THIRD, FOURTH, MANUAL FIRST,

MANUAL SECOND, and REVERSE gear ranges. Normal working pressures are alsosupplied for each of the gear

ranges.

Diagnosis Charts

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Add Fluid

2. Throttle Linkage Mis-adjusted.

V- 1 0 O n l y2. Adjust linkage - setting may be too long.

3. Mount and Driveline Bolts Loose. 3. Check engine mount, transmission

mount, propeller shaft, rear spring to body

bolts, rear control arms, crossmember and

axle bolt torque. Tighten loose bolts and

replace missing bolts.

4. U-Joint Worn/Broken. 4. Remove propeller shaft and replace

U-Joint.

5. Axle Backlash Incorrect. 5. Check per Service Manual. Correct as

needed.

6. Hydraulic Pressure Incorrect. 6. Check pressure. Remove, overhaul or

adjust valve body as needed.

7. Band Mis-adjusted. 7. Adjust rear band.

8. Valve Body Check Balls Missing. 8. Inspect valve body for proper check ball

installation.

9. Axle Pinion Flange Loose. 9. Replace nut and check pinion threads

before installing new nut. Replace pinion

gear if threads are damaged.

10. Clutch, band or planetary

component damaged.10. Remove, disassemble and repair

transmission as necessary.

11. Converter Clutch Faulty. 11. Replace converter and flush cooler and

line before installing new converter.

Page 3805 of 5267

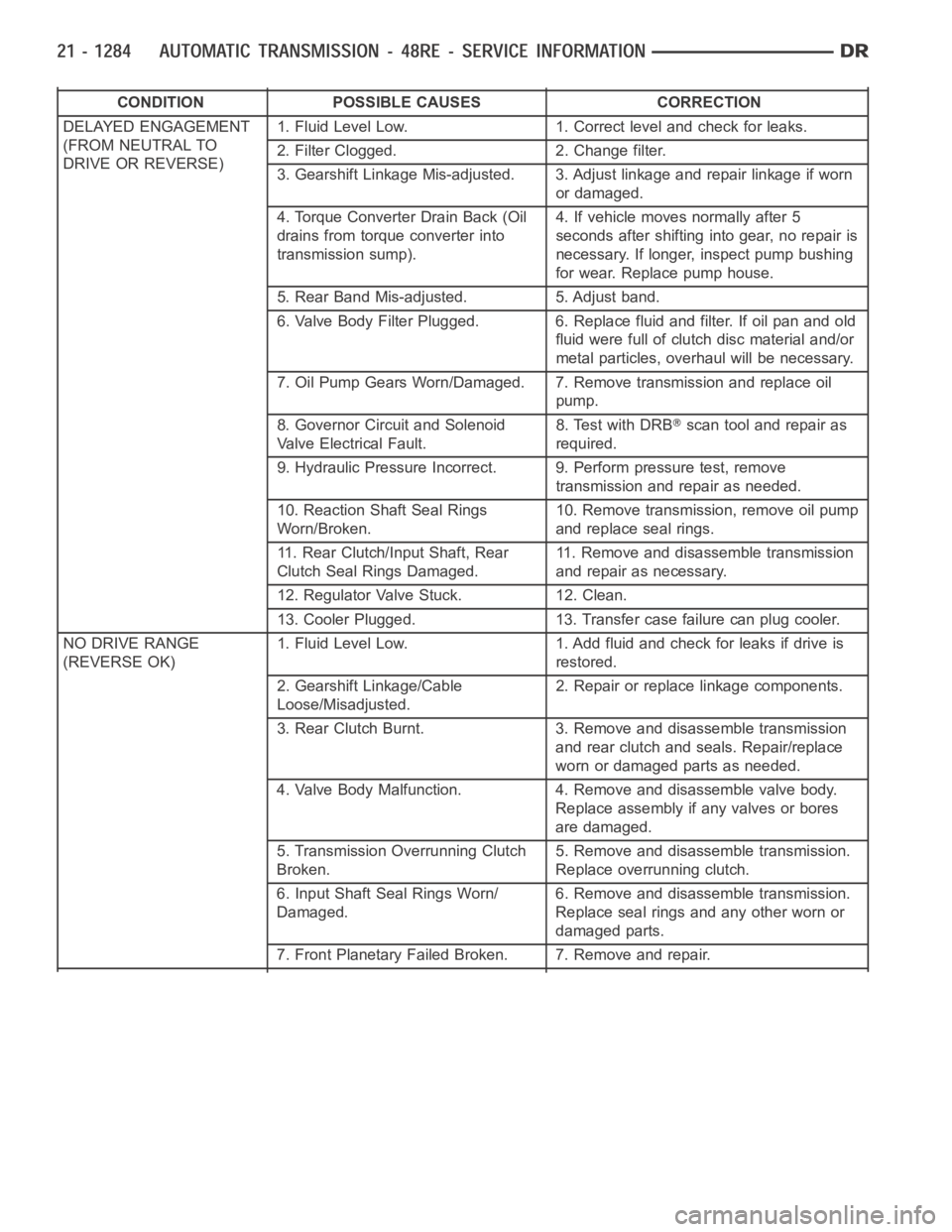

CONDITION POSSIBLE CAUSES CORRECTION

DELAYED ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Mis-adjusted. 3. Adjust linkage and repair linkage ifworn

or damaged.

4. Torque Converter Drain Back (Oil

drains from torque converter into

transmission sump).4. If vehicle moves normally after 5

seconds after shifting into gear, no repair is

necessary. If longer, inspect pump bushing

for wear. Replace pump house.

5. Rear Band Mis-adjusted. 5. Adjust band.

6. Valve Body Filter Plugged. 6. Replace fluid and filter. If oil pan and old

fluid were full of clutch disc material and/or

metal particles, overhaul will be necessary.

7. Oil Pump Gears Worn/Damaged. 7. Remove transmission and replace oil

pump.

8. Governor Circuit and Solenoid

Valve Electrical Fault.8. Test with DRB

scan tool and repair as

required.

9. Hydraulic Pressure Incorrect. 9. Perform pressure test, remove

transmission and repair as needed.

10. Reaction Shaft Seal Rings

Worn/Broken.10. Remove transmission, remove oil pump

and replace seal rings.

11. Rear Clutch/Input Shaft, Rear

Clutch Seal Rings Damaged.11. Remove and disassemble transmission

and repair as necessary.

12. Regulator Valve Stuck. 12. Clean.

13. Cooler Plugged. 13. Transfer case failure can plug cooler.

NO DRIVE RANGE

(REVERSE OK)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.2. Repair or replace linkage components.

3. Rear Clutch Burnt. 3. Removeand disassemble transmission

and rear clutch and seals. Repair/replace

worn or damaged parts as needed.

4. Valve Body Malfunction. 4. Remove and disassemble valve body.

Replace assembly if any valves or bores

are damaged.

5. Transmission Overrunning Clutch

Broken.5. Remove and disassemble transmission.

Replace overrunning clutch.

6. Input Shaft Seal Rings Worn/

Damaged.6. Remove and disassemble transmission.

Replace seal rings and any other worn or

damaged parts.

7. Front Planetary Failed Broken. 7. Remove and repair.