DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4601 of 5267

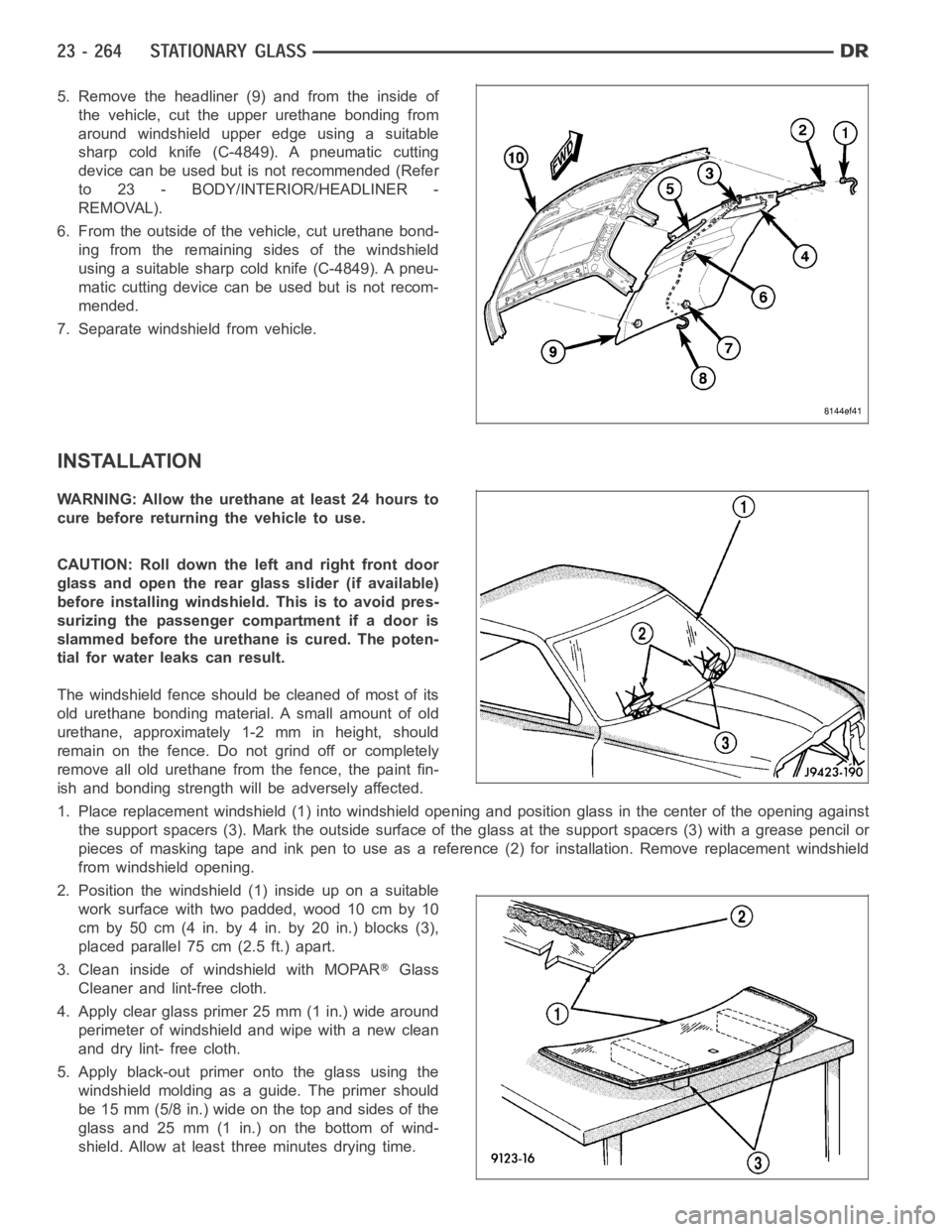

5. Remove the headliner (9) and from the inside of

the vehicle, cut the upper urethane bonding from

around windshield upper edge using a suitable

sharp cold knife (C-4849). A pneumatic cutting

device can be used but is not recommended (Refer

to 23 - BODY/INTERIOR/HEADLINER -

REMOVAL).

6. From the outside of the vehicle, cut urethane bond-

ing from the remaining sides of the windshield

using a suitable sharp cold knife (C-4849). A pneu-

matic cutting device can be used but is not recom-

mended.

7. Separate windshield from vehicle.

INSTALLATION

WARNING: Allow the urethane at least 24 hours to

cure before returning the vehicle to use.

CAUTION: Roll down the left and right front door

glass and open the rear glass slider (if available)

before installing windshield. This is to avoid pres-

surizing the passenger compartment if a door is

slammed before the urethane is cured. The poten-

tial for water leaks can result.

The windshield fence should be cleaned of most of its

old urethane bonding material. A small amount of old

urethane, approximately 1-2 mm in height, should

remain on the fence. Do not grind off or completely

remove all old urethane from the fence, the paint fin-

ish and bonding strength will be adversely affected.

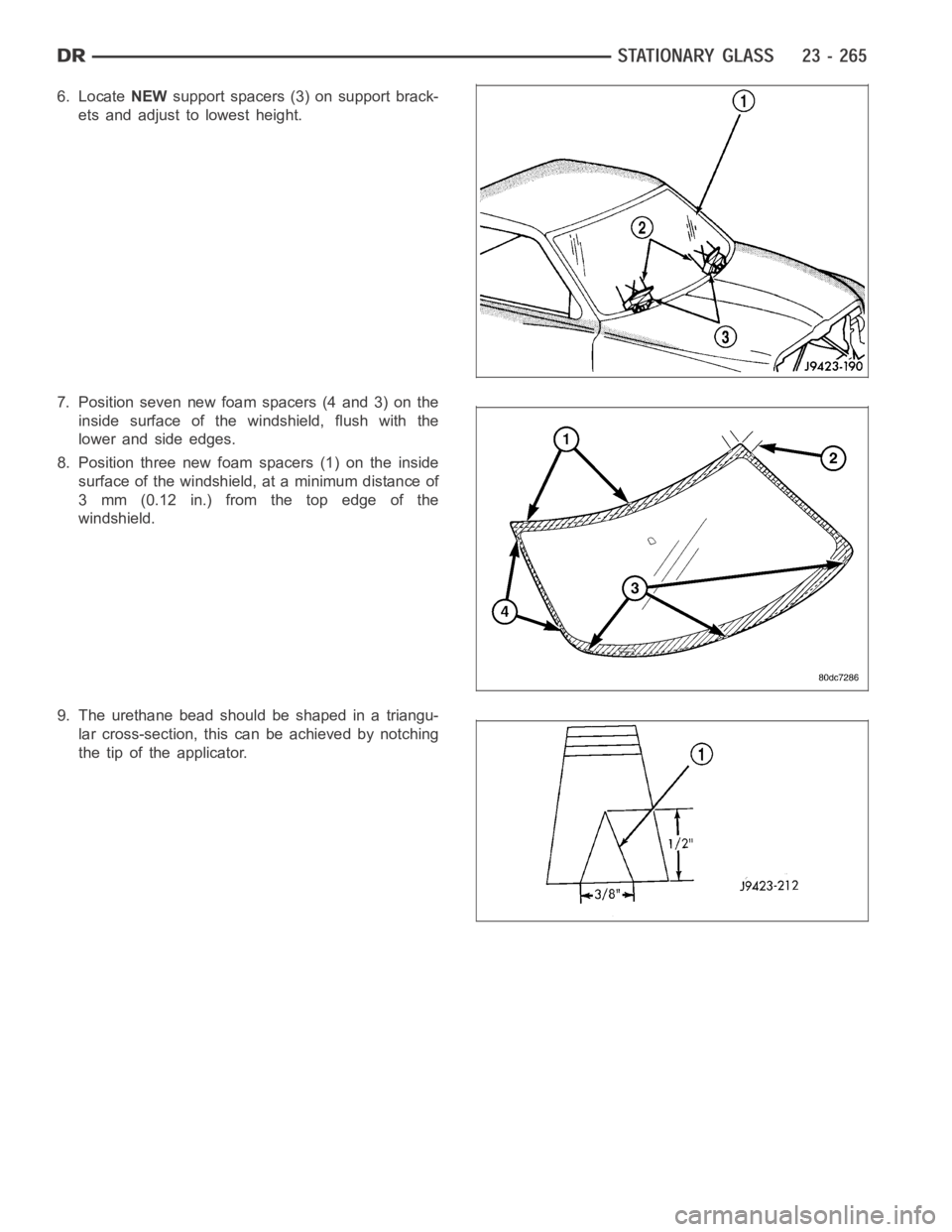

1. Place replacement windshield (1) into windshield opening and positionglass in the center of the opening against

the support spacers (3). Mark the outside surface of the glass at the support spacers (3) with a grease pencil or

pieces of masking tape and ink pen to use as a reference (2) for installation. Remove replacement windshield

from windshield opening.

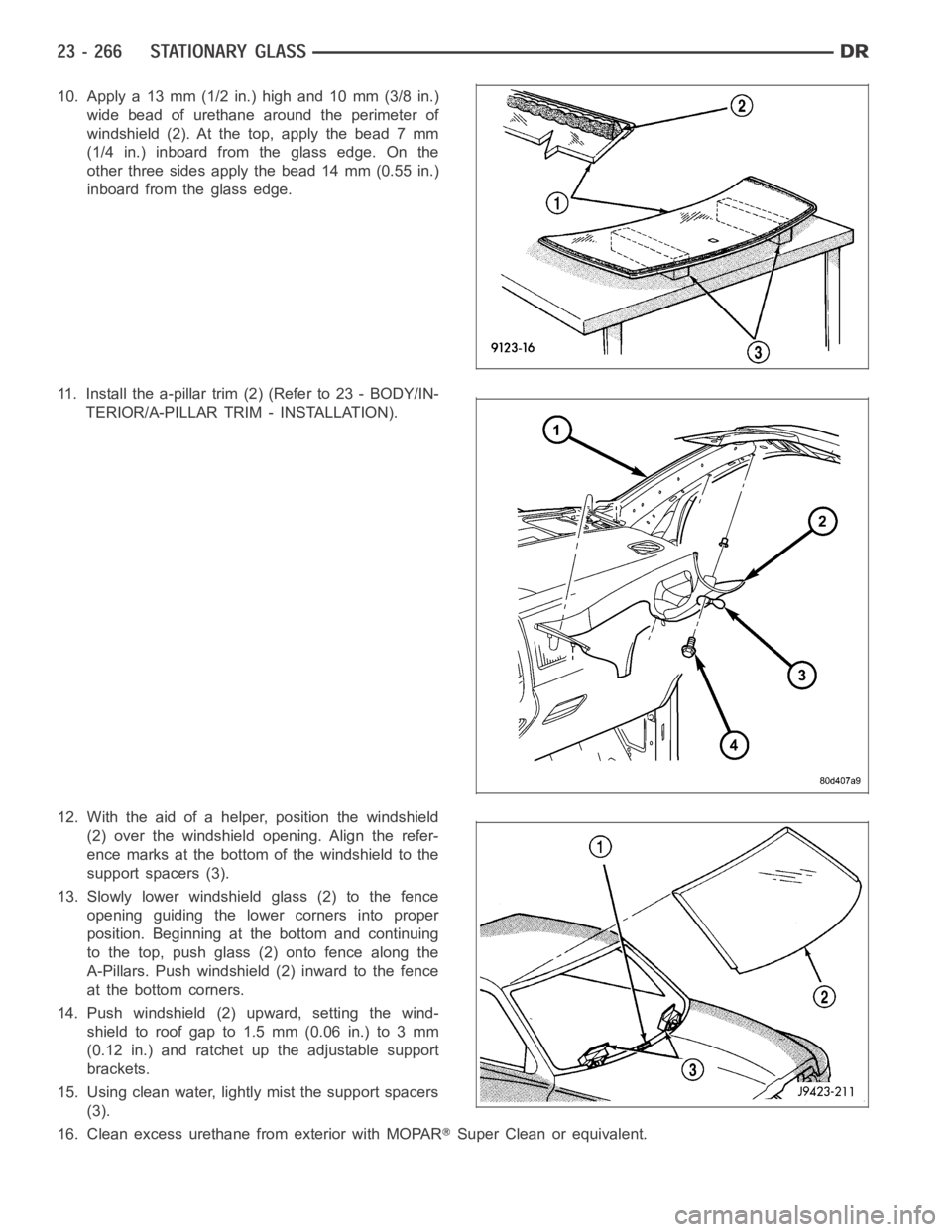

2. Position the windshield (1) inside up on a suitable

work surface with two padded, wood 10 cm by 10

cm by 50 cm (4 in. by 4 in. by 20 in.) blocks (3),

placed parallel 75 cm (2.5 ft.) apart.

3. Clean inside of windshield with MOPAR

Glass

Cleaner and lint-free cloth.

4. Apply clear glass primer 25 mm (1 in.) wide around

perimeter of windshield and wipe with a new clean

and dry lint- free cloth.

5. Apply black-out primer onto the glass using the

windshield molding as a guide. The primer should

be 15 mm (5/8 in.) wide on the top and sides of the

glass and 25 mm (1 in.) on the bottom of wind-

shield. Allow at least three minutes drying time.

Page 4602 of 5267

6. LocateNEWsupport spacers (3) on support brack-

ets and adjust to lowest height.

7. Position seven new foam spacers (4 and 3) on the

inside surface of the windshield, flush with the

lower and side edges.

8. Position three new foam spacers (1) on the inside

surface of the windshield, at a minimum distance of

3 mm (0.12 in.) from the top edge of the

windshield.

9. The urethane bead should be shaped in a triangu-

lar cross-section, this canbeachievedbynotching

the tip of the applicator.

Page 4603 of 5267

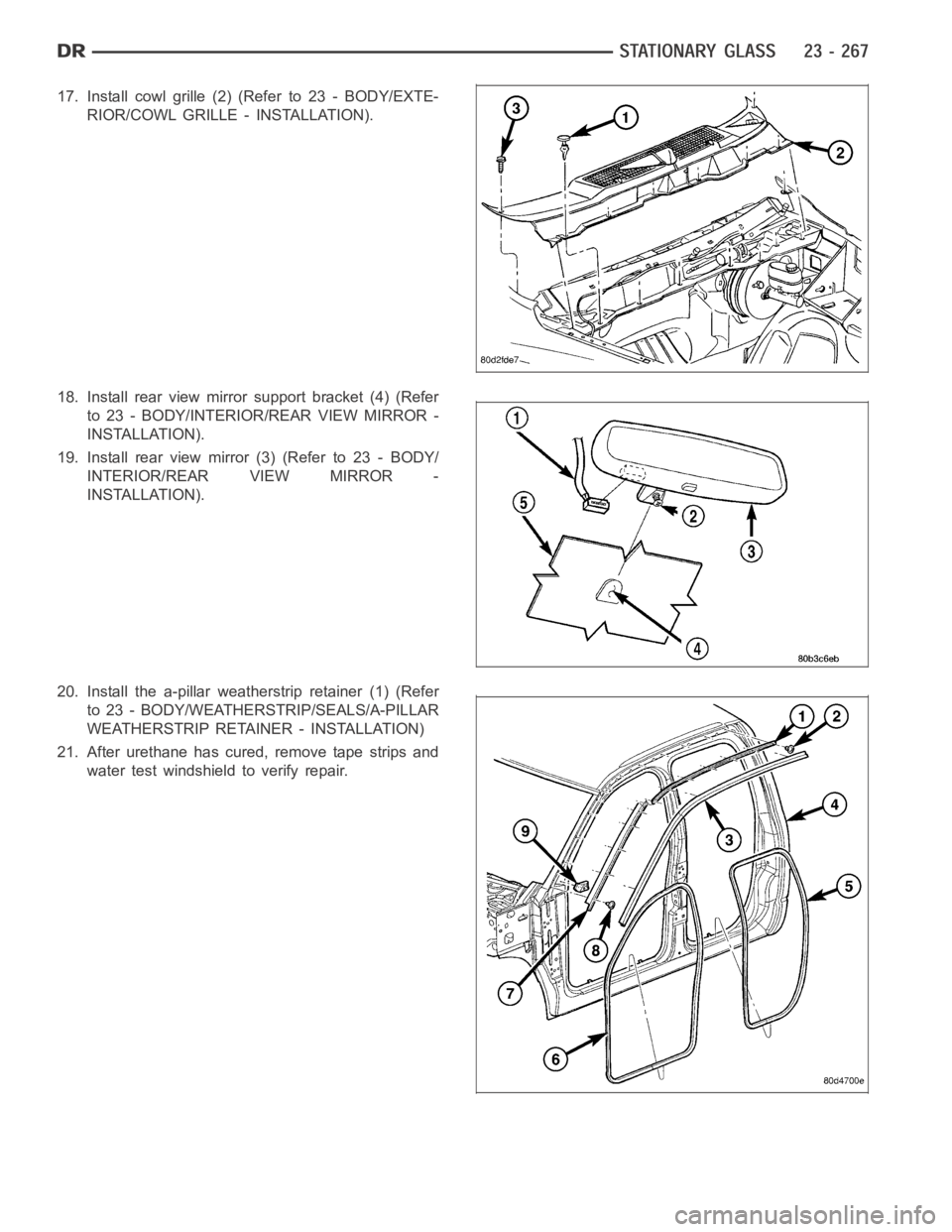

10. Apply a 13 mm (1/2 in.) high and 10 mm (3/8 in.)

wide bead of urethane around the perimeter of

windshield(2).Atthetop,applythebead7mm

(1/4 in.) inboard from the glass edge. On the

other three sides apply the bead 14 mm (0.55 in.)

inboard from the glass edge.

11. Install the a-pillar trim (2) (Refer to 23 - BODY/IN-

TERIOR/A-PILLAR TRIM - INSTALLATION).

12. With the aid of a helper, position the windshield

(2) over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers (3).

13. Slowly lower windshield glass (2) to the fence

opening guiding the lower corners into proper

position. Beginning at the bottom and continuing

to the top, push glass (2) onto fence along the

A-Pillars. Push windshield (2) inward to the fence

at the bottom corners.

14. Push windshield (2) upward, setting the wind-

shieldtoroofgapto1.5mm(0.06in.)to3mm

(0.12 in.) and ratchet up the adjustable support

brackets.

15. Using clean water, lightly mist the support spacers

(3).

16. Clean excess urethane from exterior with MOPAR

Super Clean or equivalent.

Page 4604 of 5267

17. Install cowl grille (2) (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - INSTALLATION).

18. Install rear view mirror support bracket (4) (Refer

to 23 - BODY/INTERIOR/REAR VIEW MIRROR -

INSTALLATION).

19. Install rear view mirror (3) (Refer to 23 - BODY/

INTERIOR/REAR VIEW MIRROR -

INSTALLATION).

20. Install the a-pillar weatherstrip retainer (1) (Refer

to 23 - BODY/WEATHERSTRIP/SEALS/A-PILLAR

WEATHERSTRIP RETAINER - INSTALLATION)

21. After urethane has cured, remove tape strips and

water test windshield to verify repair.

Page 4605 of 5267

BACKLITE VENT GLASS - REGULATOR

REMOVAL

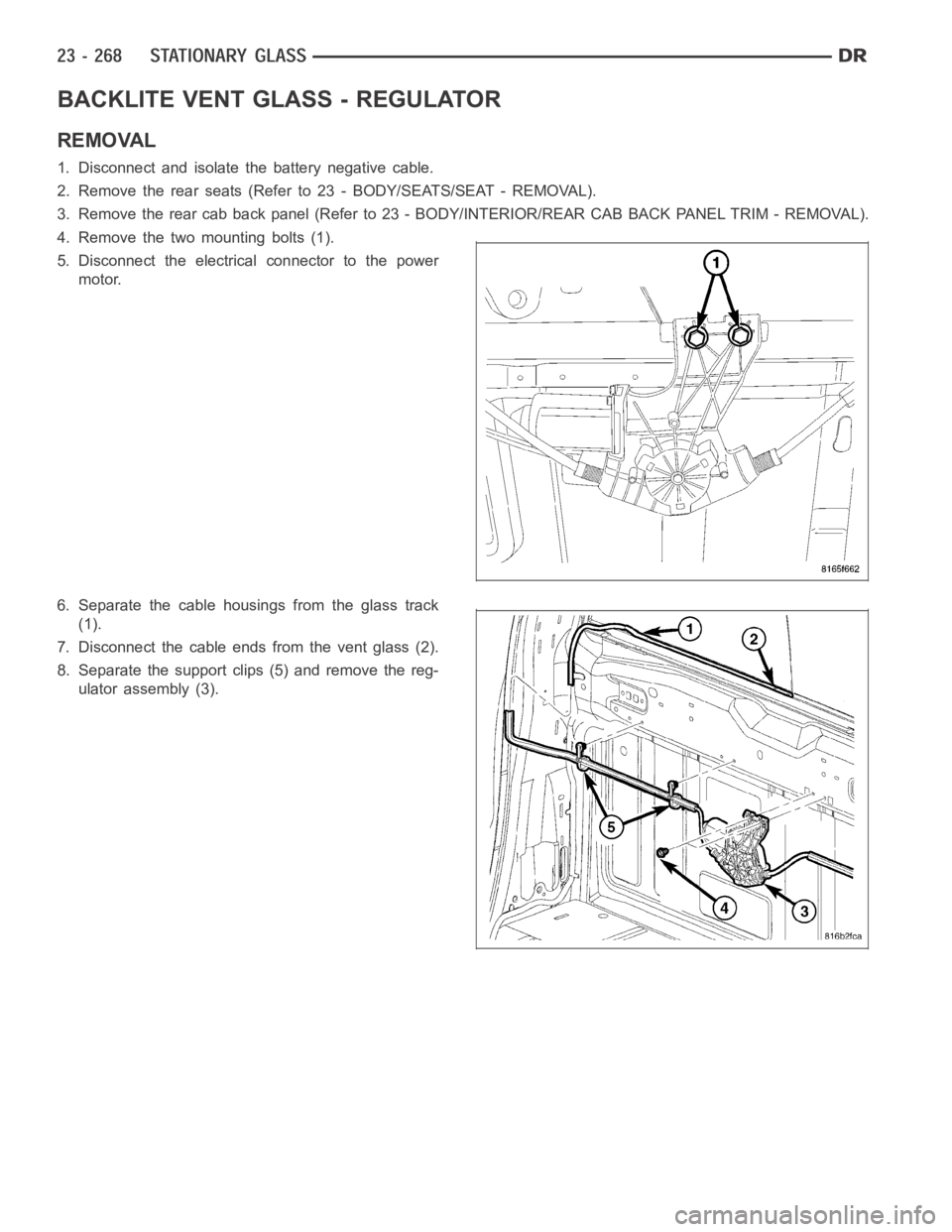

1. Disconnect and isolate the battery negative cable.

2. Remove the rear seats (Refer to 23 - BODY/SEATS/SEAT - REMOVAL).

3. Remove the rear cab back panel (Refer to 23 - BODY/INTERIOR/REAR CAB BACKPANEL TRIM - REMOVAL).

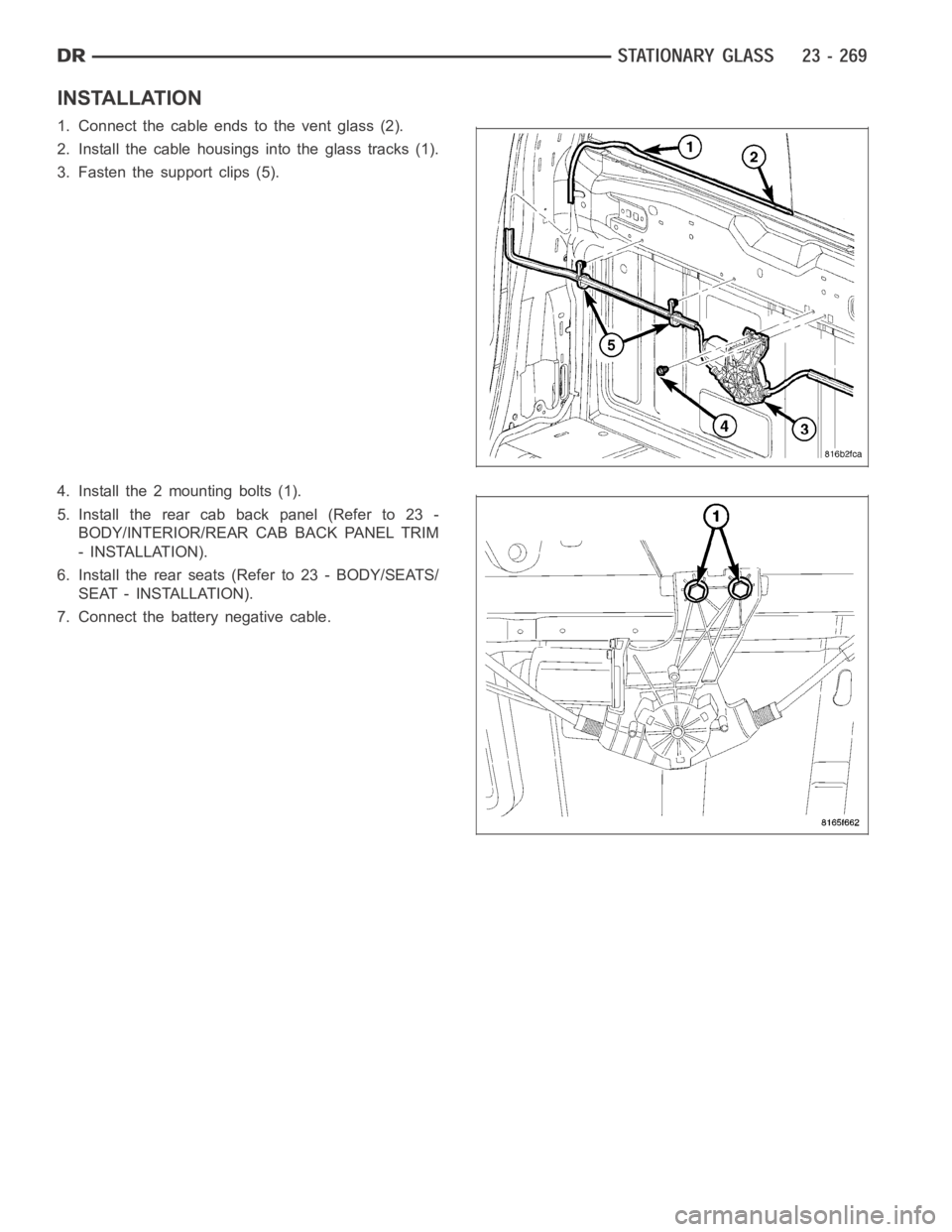

4. Remove the two mounting bolts (1).

5. Disconnect the electrical connector to the power

motor.

6. Separate the cable housings from the glass track

(1).

7. Disconnect the cable ends from the vent glass (2).

8. Separate the support clips (5) and remove the reg-

ulator assembly (3).

Page 4606 of 5267

INSTALLATION

1. Connect the cable ends to the vent glass (2).

2. Install the cable housings into the glass tracks (1).

3. Fasten the support clips (5).

4. Install the 2 mounting bolts (1).

5. Install the rear cab back panel (Refer to 23 -

BODY/INTERIOR/REAR CAB BACK PANEL TRIM

- INSTALLATION).

6. Install the rear seats (Refer to 23 - BODY/SEATS/

SEAT - INSTALLATION).

7. Connect the battery negative cable.

Page 4607 of 5267

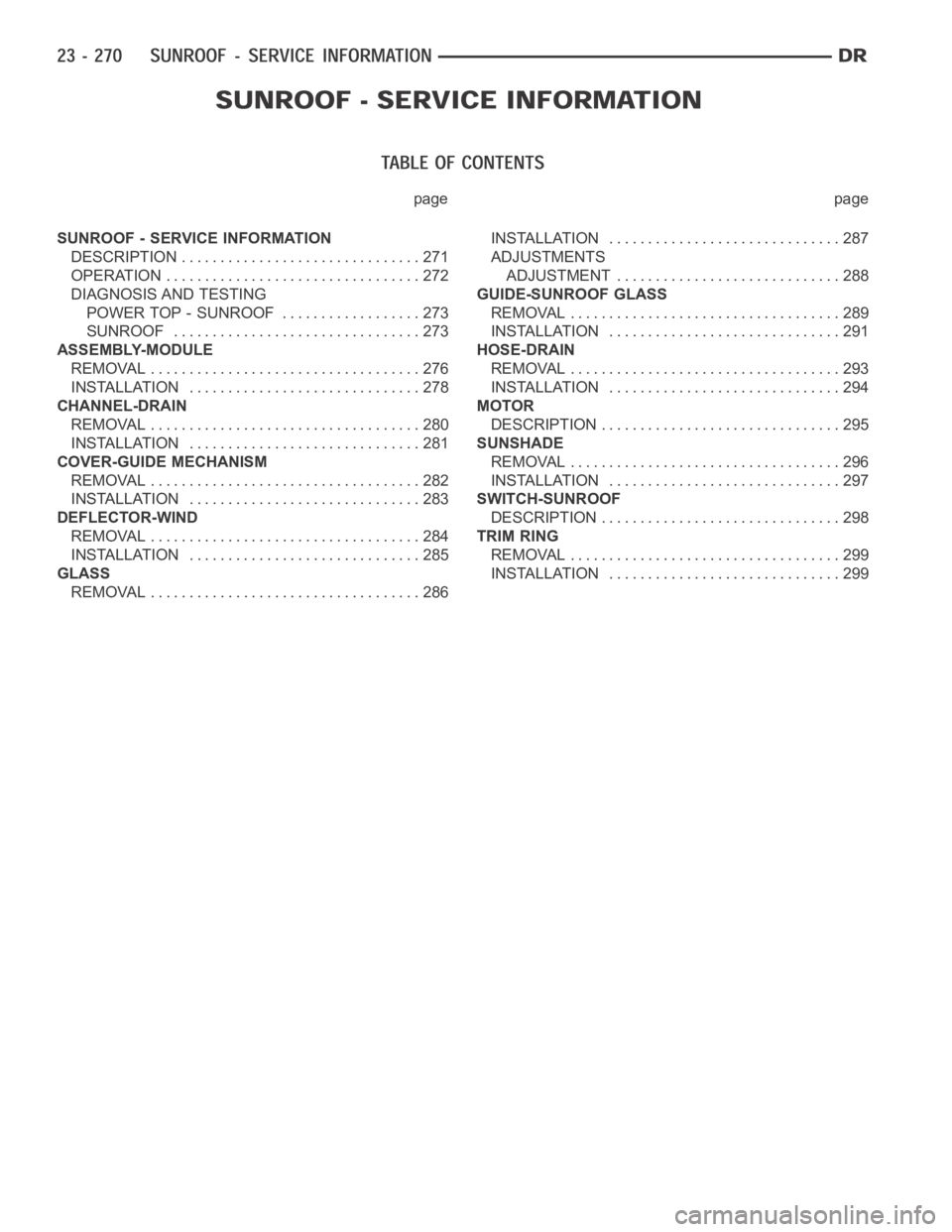

page page

SUNROOF - SERVICE INFORMATION

DESCRIPTION ............................... 271

OPERATION ................................. 272

DIAGNOSIS AND TESTING

POWER TOP - SUNROOF .................. 273

SUNROOF ................................ 273

ASSEMBLY-MODULE

REMOVAL ................................... 276

INSTALLATION .............................. 278

CHANNEL-DRAIN

REMOVAL ................................... 280

INSTALLATION .............................. 281

COVER-GUIDE MECHANISM

REMOVAL ................................... 282

INSTALLATION .............................. 283

DEFLECTOR-WIND

REMOVAL ................................... 284

INSTALLATION .............................. 285

GLASS

REMOVAL ................................... 286INSTALLATION .............................. 287

ADJUSTMENTS

ADJUSTMENT ............................. 288

GUIDE-SUNROOF GLASS

REMOVAL ................................... 289

INSTALLATION .............................. 291

HOSE-DRAIN

REMOVAL ................................... 293

INSTALLATION .............................. 294

MOTOR

DESCRIPTION ............................... 295

SUNSHADE

REMOVAL ................................... 296

INSTALLATION .............................. 297

SWITCH-SUNROOF

DESCRIPTION ............................... 298

TRIM RING

REMOVAL ................................... 299

INSTALLATION .............................. 299

Page 4608 of 5267

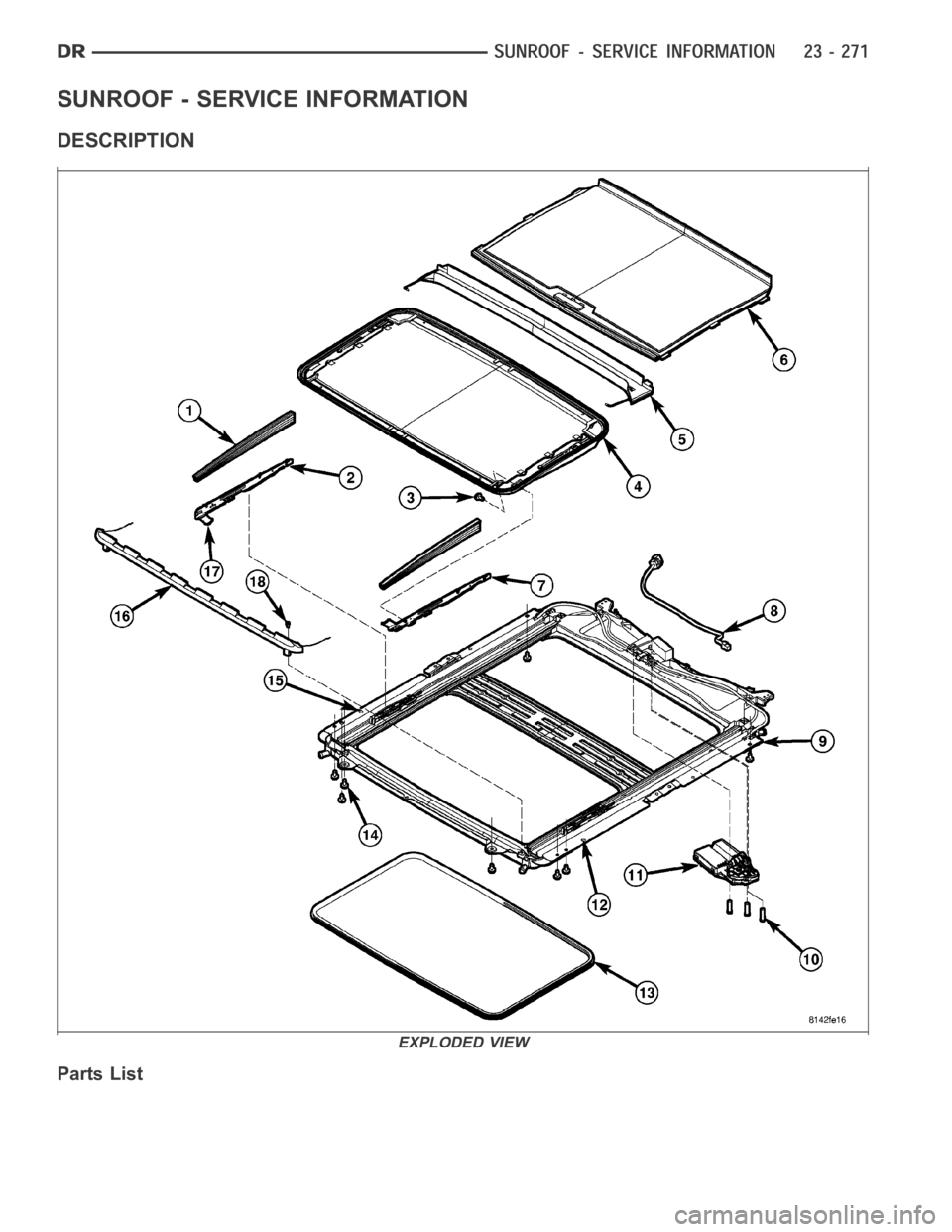

SUNROOF - SERVICE INFORMATION

DESCRIPTION

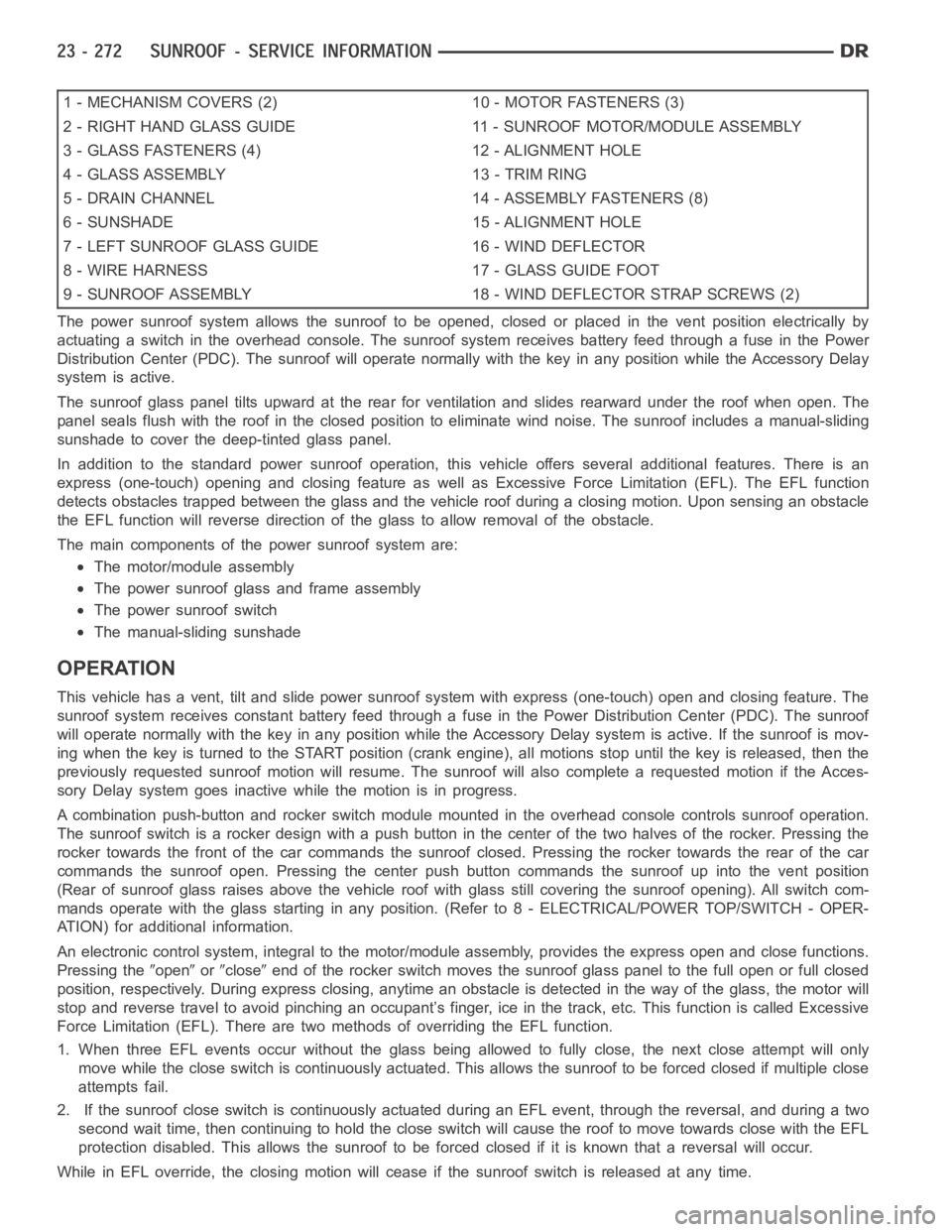

Parts List

EXPLODED VIEW

Page 4609 of 5267

1 - MECHANISM COVERS (2) 10 - MOTOR FASTENERS (3)

2 - RIGHT HAND GLASS GUIDE 11 - SUNROOF MOTOR/MODULE ASSEMBLY

3 - GLASS FASTENERS (4) 12 - ALIGNMENT HOLE

4 - GLASS ASSEMBLY 13 - TRIM RING

5 - DRAIN CHANNEL 14 - ASSEMBLY FASTENERS (8)

6 - SUNSHADE 15 - ALIGNMENT HOLE

7 - LEFT SUNROOF GLASS GUIDE 16 - WIND DEFLECTOR

8 - WIRE HARNESS 17 - GLASS GUIDE FOOT

9 - SUNROOF ASSEMBLY 18 - WIND DEFLECTOR STRAP SCREWS (2)

The power sunroof system allows the sunroof to be opened, closed or placed in the vent position electrically by

actuating a switch in the overhead console. The sunroof system receives battery feed through a fuse in the Power

Distribution Center (PDC). The sunroof will operate normally with the keyin any position while the Accessory Delay

system is active.

The sunroof glass panel tilts upward at the rear for ventilation and slidesrearward under the roof when open. The

panel seals flush with the roof in the closed position to eliminate wind noise. The sunroof includes a manual-sliding

sunshade to cover the deep-tinted glass panel.

In addition to the standard power sunroof operation, this vehicle offers several additional features. There is an

express (one-touch) opening and closing feature as well as Excessive Force Limitation (EFL). The EFL function

detects obstacles trapped between the glass and the vehicle roof during a closing motion. Upon sensing an obstacle

the EFL function will reverse direction of the glass to allow removal of theobstacle.

The main components of thepower sunroof system are:

The motor/module assembly

The power sunroof glass and frame assembly

The power sunroof switch

The manual-sliding sunshade

OPERATION

This vehicle has a vent, tilt and slide power sunroof system with express (one-touch) open and closing feature. The

sunroof system receives constant battery feed through a fuse in the Power Distribution Center (PDC). The sunroof

will operate normally with the key in any position while the Accessory Delay system is active. If the sunroof is mov-

ing when the key is turned to the START position (crank engine), all motionsstop until the key is released, then the

previously requested sunroof motion will resume. The sunroof will also complete a requested motion if the Acces-

sory Delay system goes inactivewhile the motion is in progress.

A combination push-button and rocker switch module mounted in the overhead console controls sunroof operation.

The sunroof switch is a rocker design with a push button in the center of the two halves of the rocker. Pressing the

rocker towards the front of the car commands the sunroof closed. Pressing the rocker towards the rear of the car

commands the sunroof open. Pressing the center push button commands the sunroof up into the vent position

(Rear of sunroof glass raises above the vehicle roof with glass still covering the sunroof opening). All switch com-

mands operate with the glass startingin any position. (Refer to 8 - ELECTRICAL/POWER TOP/SWITCH - OPER-

ATION) for additional information.

An electronic control system, integralto the motor/module assembly, provides the express open and close functions.

Pressing the

openorcloseend of the rocker switch moves the sunroof glass panel to the full open or fullclosed

position, respectively. During express closing, anytime an obstacle is detected in the way of the glass, the motor will

stop and reverse travel to avoid pinching an occupant’s finger, ice in the track, etc. This function is called Excessive

Force Limitation (EFL). There are two methods of overriding the EFL function.

1. When three EFL events occur without the glass being allowed to fully close, the next close attempt will only

move while the close switch is continuously actuated. This allows the sunrooftobeforcedclosedifmultipleclose

attempts fail.

2. If the sunroof close switch is continuously actuated during an EFL event, through the reversal, and during a two

second wait time, then continuing to hold the close switch will cause the roof to move towards close with the EFL

protection disabled. This allows the sunroof to be forced closed if it is known that a reversal will occur.

While in EFL override, the closing motion will cease if the sunroof switch is released at any time.

Page 4610 of 5267

The motor/module is programmed to learn the speed required to drive the panel based on position and recalibrates

itself as needed. If the sunroof becomes uncalibrated, it will only respond to the vent switch. If the vent switch is

pressed, the glass will move toward vent; if the switch is released, all motion stops. In the event that the sunroof

system becomes uncalibrated performthe sunroof position calibration procedure, (Refer to 8 - ELECTRICAL/

POWER TOP/MOTOR - STANDARD PROCEDURE -SUNROOF POSITION CALIBRATION).

DIAGNOSIS AND TESTING

POWER TOP - SUNROOF

Any diagnosis of the power sunroof system should begin with the use of a scantool and the proper Diagnostic

Procedures Information. The scan tool can provide confirmation that the Controller Area Network (CAN) Data Bus is

functional, that all of the electronic modules are sending and receiving the proper messages on the CAN Data Bus,

and that the power sunroof motor is being sent the proper hard wired output by the sunroof switch.

For complete circuit diagrams, refer to the appropriate wiring information. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures, details of wire harness routing and retention, connector pin-out

information and location views for the various wire harness connectors, splices and grounds.

Refer to the appropriate diagnostic information.

SUNROOF

Refer to SUNROOF DIAGNOSIS CHART for possible causes. Before beginning sunroof diagnostics verify that all

other power accessories are in proper operating condition. If not, a common electrical problem may exist. Refer to

Wiring Diagrams, in this publication for circuit, splice and component descriptions. Check the condition of the circuit

protection (20 amp circuit breaker in the Junction Block). Inspect all wiring connector pins for proper engagement

and continuity. Check for battery voltage at the power sunroof controller, refer to Wiring Diagrams, for circuit infor-

mation. If battery voltage of more than 10 volts is detected at the controller, proceed with the following tests (the

controller will not operate at less than 10 volts).

Before beginning diagnosis for wind noise or water leaks, verify that the problem was not caused by releasing the

control switch before the sunroof was fully closed. The sunroof module hasa water-management system. If how-

ever, the sunroof glass is in a partial closed position, high pressure water may be forced beyond the water man-

agement system boundariesand onto the headlining.

Every time the sunroof module loses power it must be initialized. This is done by connecting power to the sunroof

and moving the sunroof toward the closed position. When initialization occurs a slight “kick” in the sunroof module

will be seen and heard. This is the indication that the sunroof module is initialized

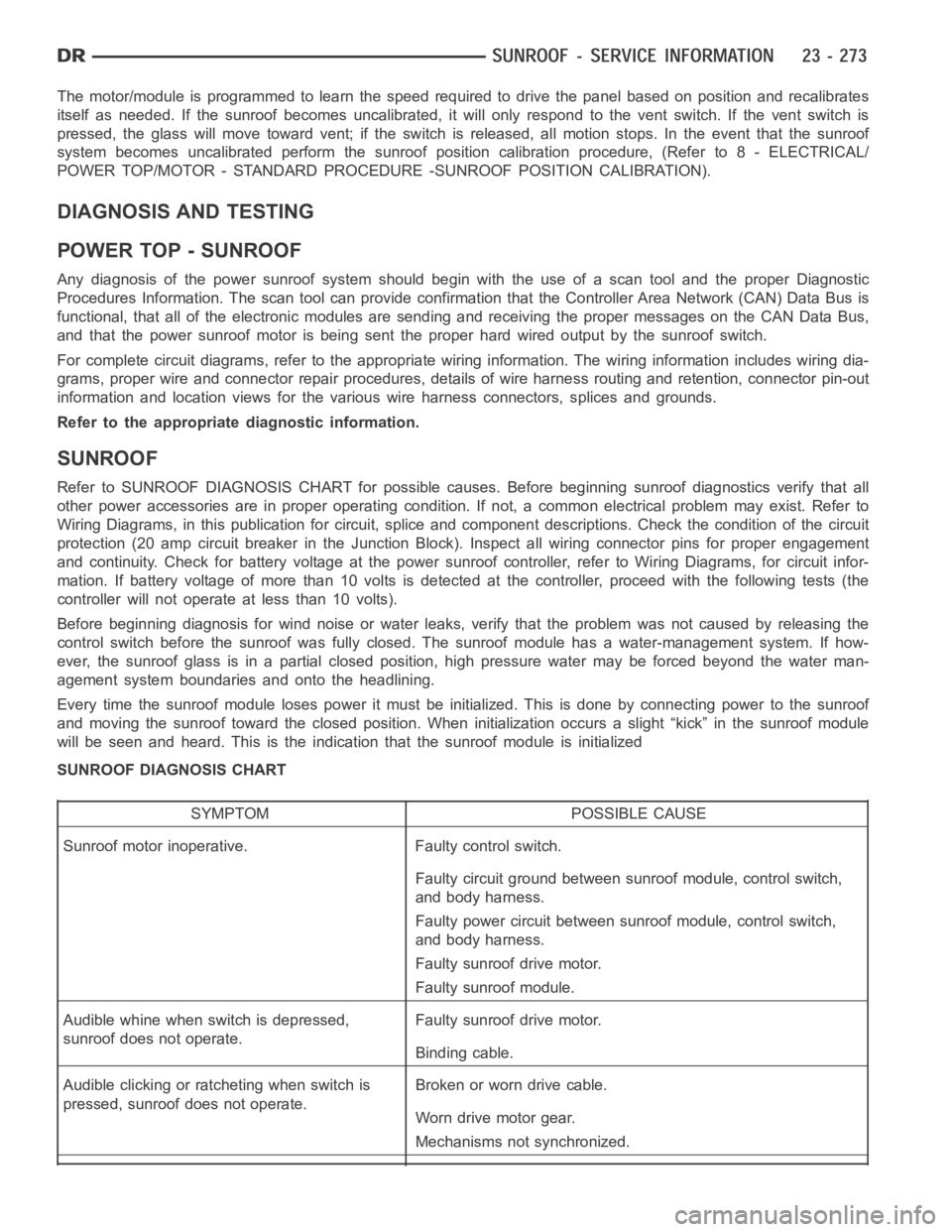

SUNROOF DIAGNOSIS CHART

SYMPTOM POSSIBLE CAUSE

Sunroof motor inoperative. Faulty control switch.

Faulty circuit ground between sunroof module, control switch,

and body harness.

Faulty power circuit between sunroof module, control switch,

and body harness.

Faulty sunroof drive motor.

Faulty sunroof module.

Audible whine when switch is depressed,

sunroof does not operate.Faulty sunroof drive motor.

Binding cable.

Audible clicking or ratcheting when switch is

pressed, sunroof does not operate.Broken or worn drive cable.

Worn drive motor gear.

Mechanisms not synchronized.