torque DODGE RAM SRT-10 2006 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1540 of 5267

2. Position the new cylinder head gasket on the locat-

ing dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

3. Position the cylinder head onto the cylinder block.

Make sure the cylinder head seats fully over the

locating dowels.

NOTE: The four M8 cylinder head mounting bolts

(1) require sealant to be added to them before

installing. Failure to do so may cause leaks.

4. Lubricate the cylinder head bolt threads with clean

engine oil and install the eight M10 bolts.

5. Coat the four M8 cylinder head bolts withMopar

Lock and Seal Adhesivethen install the bolts.

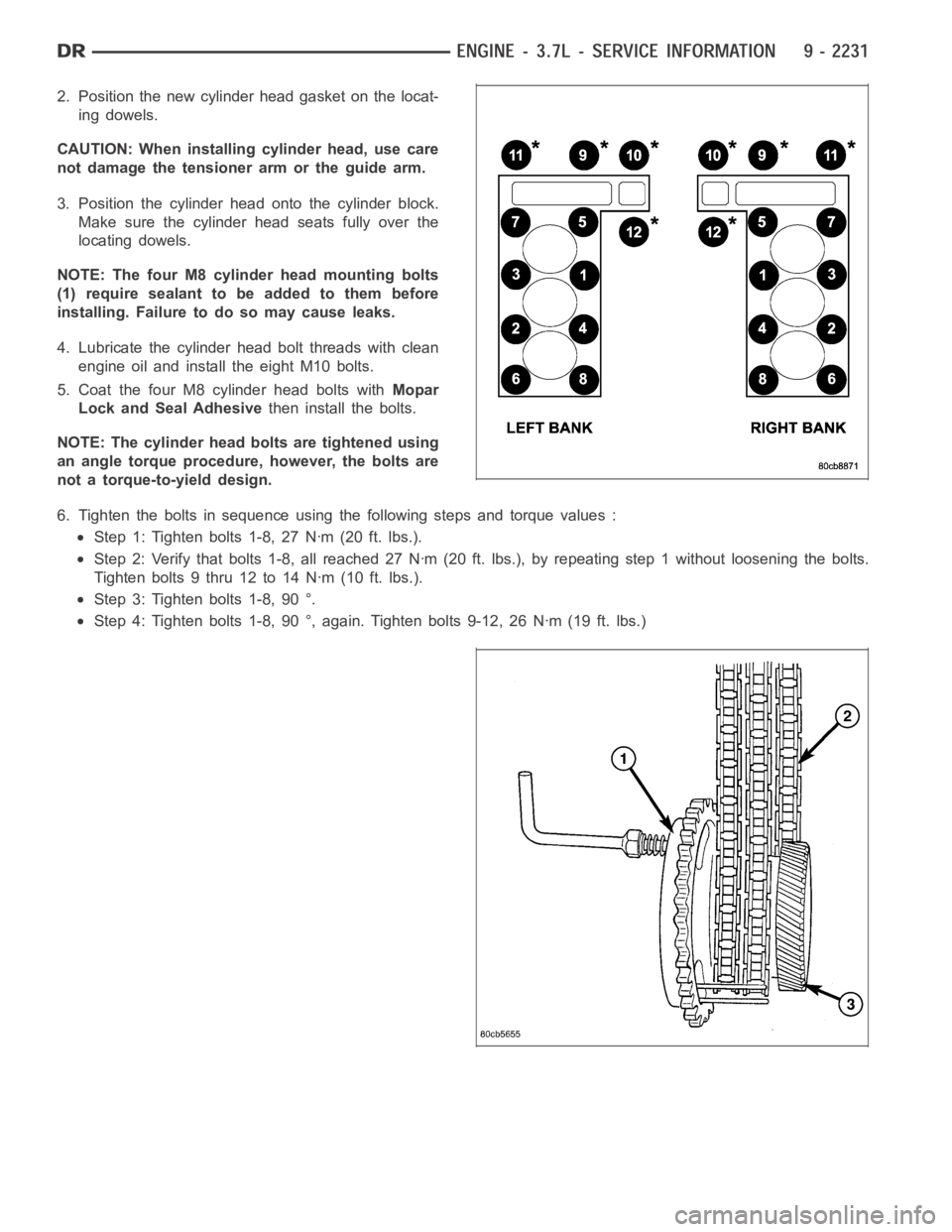

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.

6. Tighten the bolts in sequence using the following steps and torque values:

Step 1: Tighten bolts 1-8, 27 Nꞏm (20 ft. lbs.).

Step 2: Verify that bolts 1-8, all reached 27 Nꞏm (20 ft. lbs.), by repeatingstep 1 without loosening the bolts.

Tightenbolts9thru12to14Nꞏm(10ft.lbs.).

Step 3: Tighten bolts 1-8, 90 °.

Step 4: Tighten bolts 1-8, 90 °, again. Tighten bolts 9-12, 26 Nꞏm (19 ft. lbs.)

Page 1541 of 5267

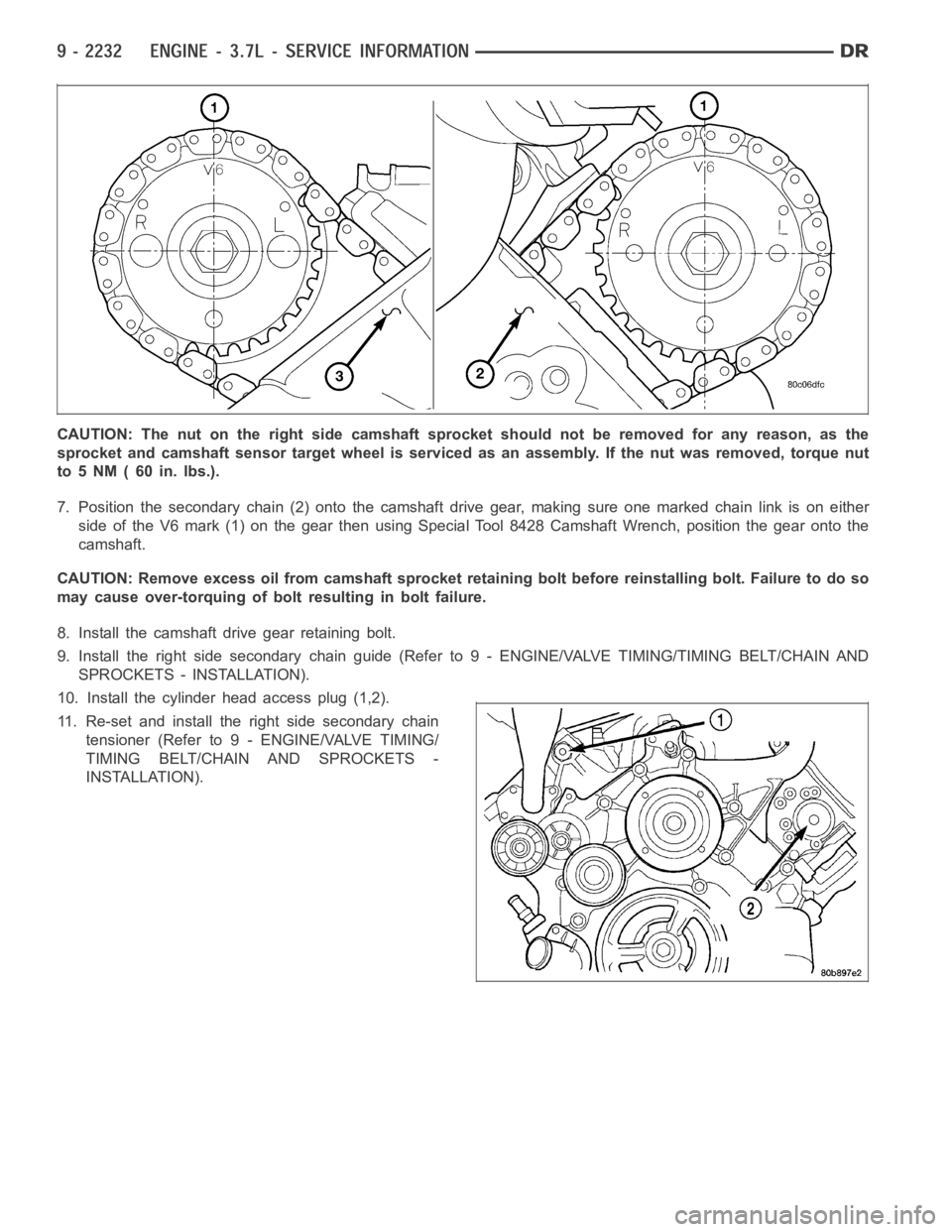

CAUTION: The nut on the right side camshaft sprocket should not be removed for any reason, as the

sprocket and camshaft sensor target wheel is serviced as an assembly. If the nut was removed, torque nut

to 5 NM ( 60 in. lbs.).

7. Position the secondary chain (2) onto the camshaft drive gear, making sure one marked chain link is on either

side of the V6 mark (1) on the gear then using Special Tool 8428 Camshaft Wrench, position the gear onto the

camshaft.

CAUTION: Remove excess oil from camshaft sprocket retaining bolt before reinstalling bolt. Failure to do so

may cause over-torquing of bolt resulting in bolt failure.

8. Install the camshaft drive gear retaining bolt.

9. Install the right side secondary chain guide (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

10. Install the cylinder head access plug (1,2).

11. Re-set and install the right side secondary chain

tensioner (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

Page 1546 of 5267

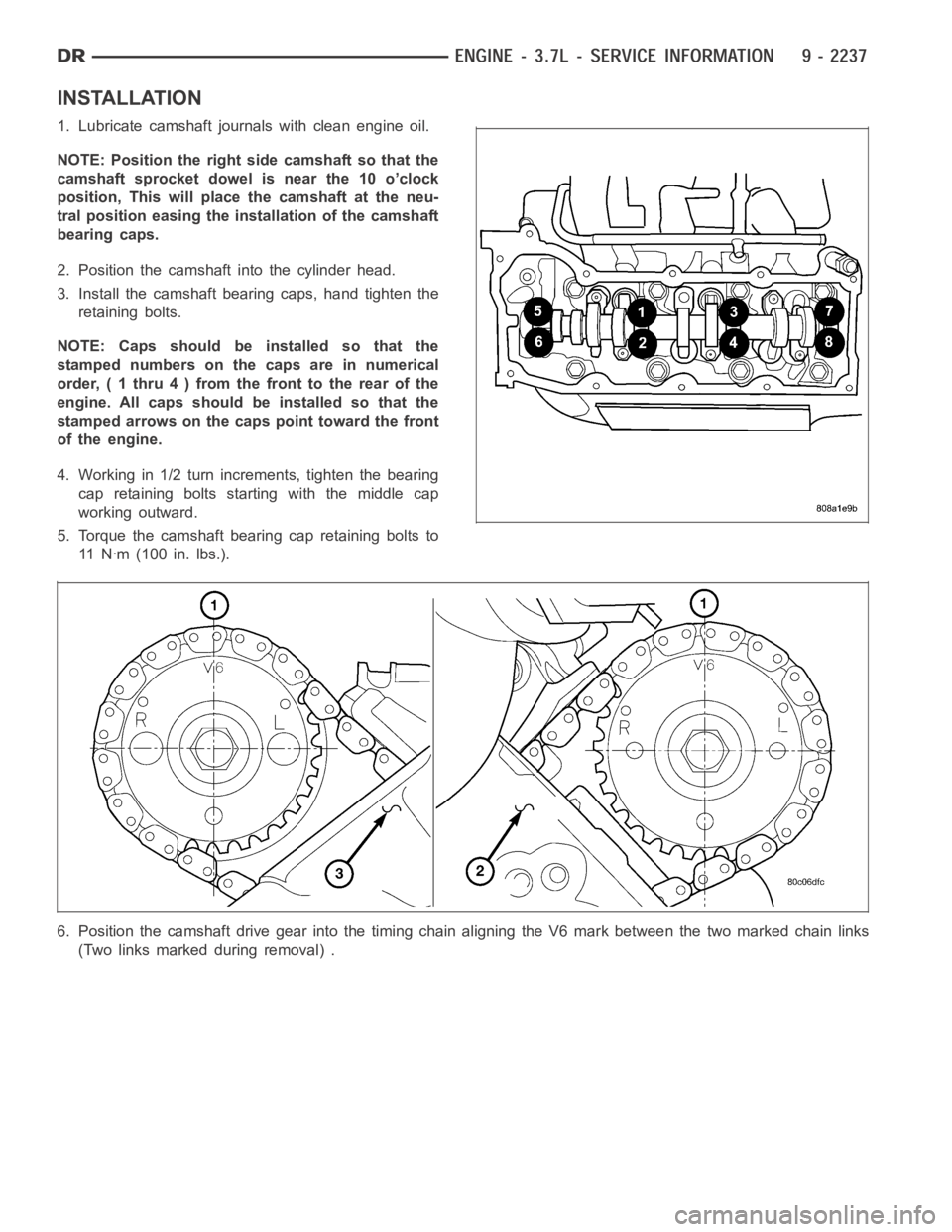

INSTALLATION

1. Lubricate camshaft journals with clean engine oil.

NOTE: Position the right side camshaft so that the

camshaft sprocket dowel is near the 10 o’clock

position, This will place the camshaft at the neu-

tral position easing the installation of the camshaft

bearing caps.

2. Position the camshaft into the cylinder head.

3. Install the camshaft bearing caps, hand tighten the

retaining bolts.

NOTE: Caps should be installed so that the

stamped numbers on the caps are in numerical

order, ( 1 thru 4 ) from the front to the rear of the

engine. All caps should be installed so that the

stamped arrows on the caps point toward the front

of the engine.

4. Working in 1/2 turn increments, tighten the bearing

cap retaining bolts starting with the middle cap

working outward.

5. Torque the camshaft bearing cap retaining bolts to

11 N ꞏm ( 1 0 0 i n . l b s . ) .

6. Position the camshaft drive gear into the timing chain aligning the V6 mark between the two marked chain links

(Two links marked during removal) .

Page 1547 of 5267

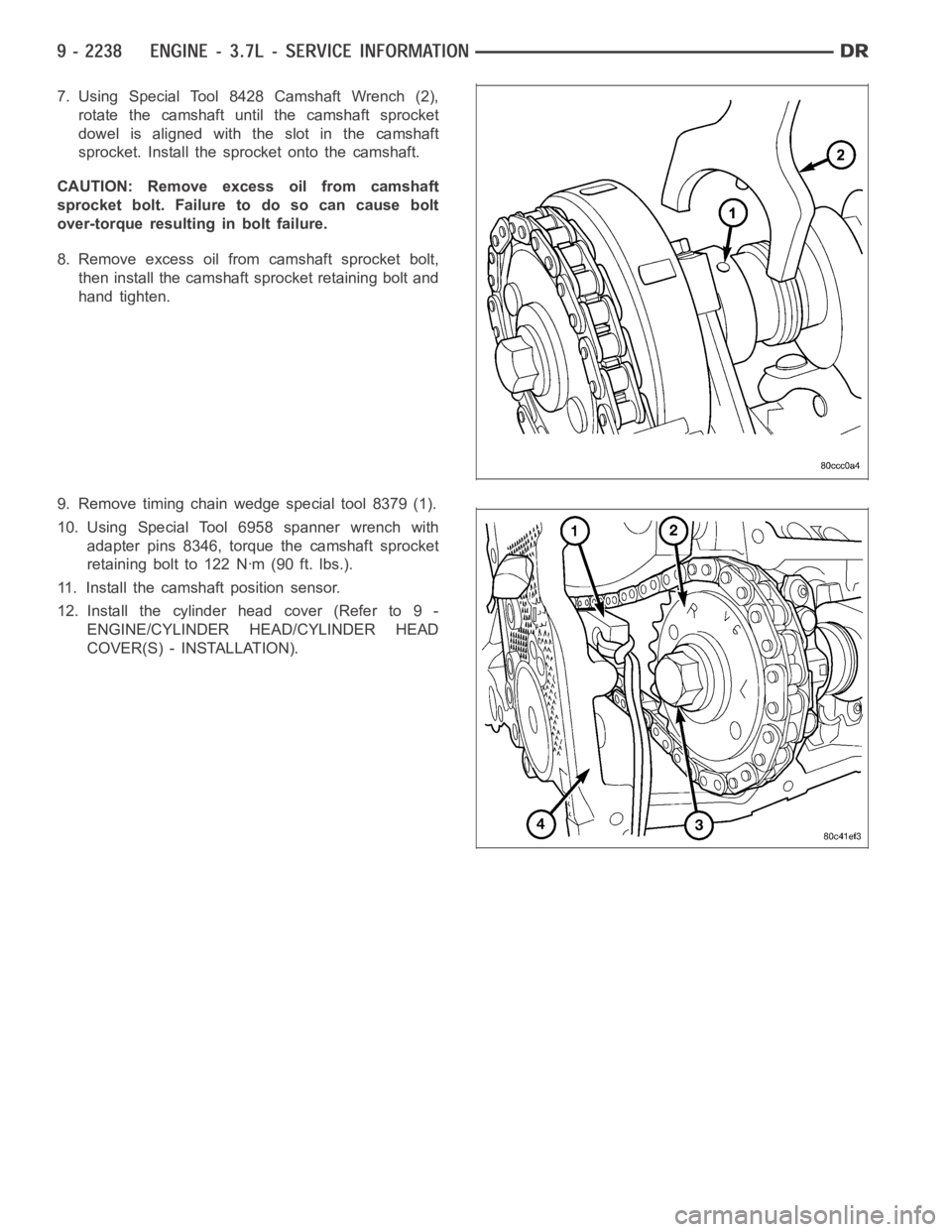

7. Using Special Tool 8428 Camshaft Wrench (2),

rotate the camshaft until the camshaft sprocket

dowel is aligned with the slot in the camshaft

sprocket. Install the sprocket onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket bolt. Failure to do so can cause bolt

over-torque resulting in bolt failure.

8. Remove excess oil from camshaft sprocket bolt,

then install the camshaft sprocket retaining bolt and

hand tighten.

9. Remove timing chain wedge special tool 8379 (1).

10. Using Special Tool 6958 spanner wrench with

adapter pins 8346, torque the camshaft sprocket

retaining bolt to 122 Nꞏm (90 ft. lbs.).

11. Install the camshaft position sensor.

12. Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

Page 1553 of 5267

BLOCK-ENGINE

DESCRIPTION

The cylinder block is made of cast iron.The block is a closed deck design with the left bank forward. To provide

high rigidity and improved NVH an enhanced compacted graphite bedplate isbolted to the block. The block design

allows coolant flow between the cylinders bores, and an internal coolant bypass to a single poppet inlet thermostat

is included in the cast aluminum front cover.

STANDARD PROCEDURE - CYLINDER BORE HONING

Before honing, stuff plenty of clean shop towels under

the bores and over the crankshaft to keep abrasive

materials from entering the crankshaft area.

1. Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best

tool for this job. In addition to deglazing, it will

reduce taper and out-of-round, as well as removing

light scuffing, scoring and scratches. Usually, a few

strokes will clean up a bore and maintain the

required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

2. Deglazing of the cylinder walls may be done if the

cylinder bore is straight and round. Use a cylinder

surfacing hone, Honing Tool C-3501, equipped with

280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be

sufficient to provide a satisfactory surface. Using

honing oil C-3501-3880, or a light honing oil, avail-

able from major oil distributors.

CAUTION: DO NOT use engine or transmission oil, mineral spirits, or kerosene.

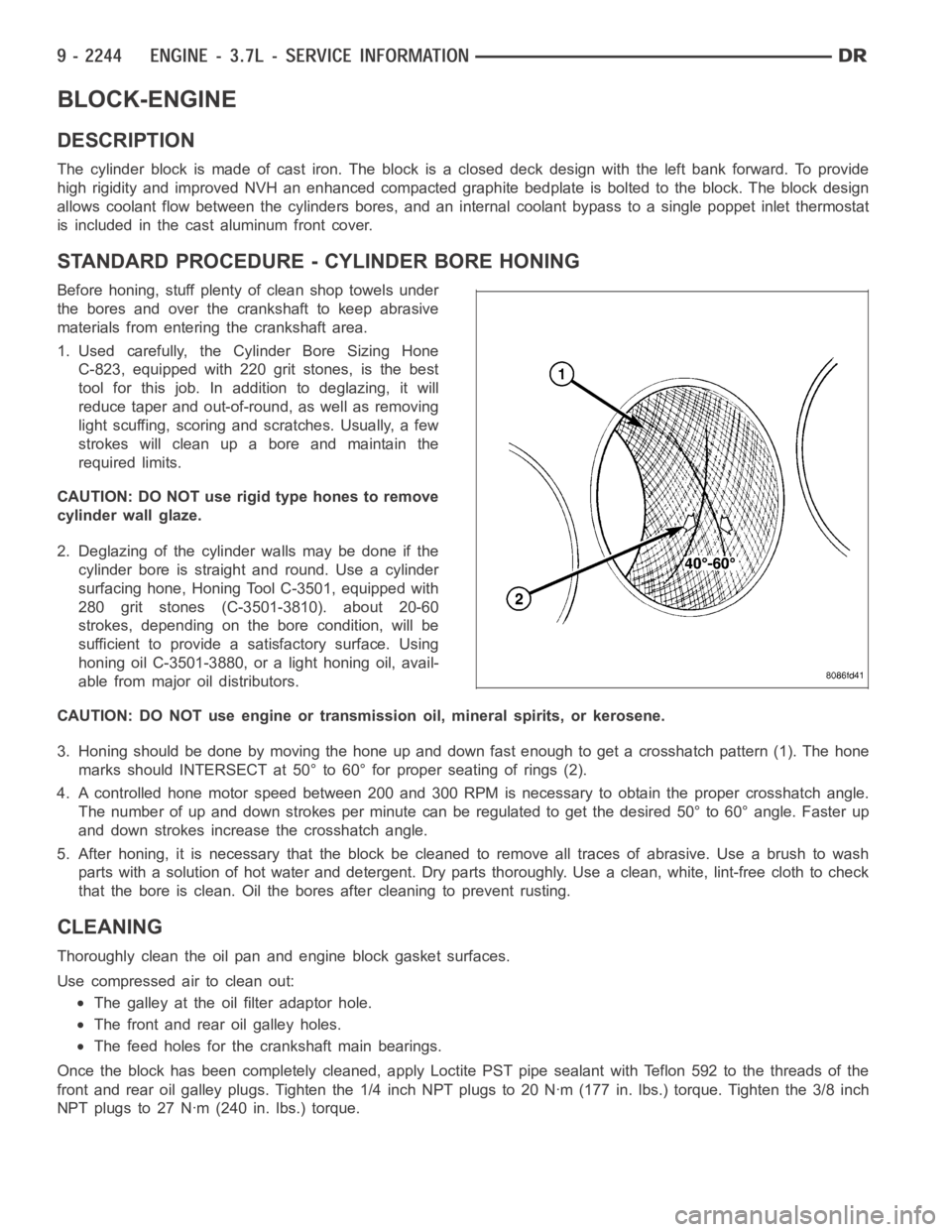

3. Honing should be done by moving the hone up and down fast enough to get a crosshatch pattern (1). The hone

marks should INTERSECT at 50° to 60° for proper seating of rings (2).

4. A controlled hone motor speed between 200 and 300 RPM is necessary to obtain the proper crosshatch angle.

The number of up and down strokes per minute can be regulated to get the desired 50° to 60° angle. Faster up

and down strokes increase the crosshatch angle.

5. After honing, it is necessary that the block be cleaned to remove all traces of abrasive. Use a brush to wash

parts with a solution of hot water and detergent. Dry parts thoroughly. Usea clean, white, lint-free cloth to check

that the bore is clean. Oil the bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gasket surfaces.

Use compressed air to clean out:

The galley at the oil filter adaptor hole.

The front and rear oil galley holes.

The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply Loctite PST pipe sealantwith Teflon 592 to the threads of the

front and rear oil galley plugs. Tighten the 1/4 inch NPT plugs to 20 Nꞏm (177in. lbs.) torque. Tighten the 3/8 inch

NPT plugs to 27 Nꞏm (240 in. lbs.) torque.

Page 1557 of 5267

INSPECTION

NOTE: Thoroughly inspect the connecting rod bearing bores and main bearing bores for scoring, blueing or

severe scratches. Further disassembly may be required.

If connecting rod bearing bores show damage, the cylinder heads must be removed to service the piston and rod

assemblies. If the bedplate or the cylinder block main bearing bores show damage the engine must be replaced.

1. If required, remove the main bearing halves from the cylinder block and bedplate.

2. Thoroughly clean the bedplate to cylinder block sealing surfaces and main bearing bores. Remove all oil and

sealant residue.

3. Inspect the bedplate main bearing bores for cracks, scoring or severe blueing. If either condition exists the

engine must be replaced.

4. Inspect the crankshaft thrust washers for scoring, scratches, wear or blueing. If either condition exist replace the

thrust washers.

5. Inspect the oil pan gasket/windage tray for splits, tears or cracks in the gasket sealing surfaces. Replace gasket

as necessary.

INSTALLATION

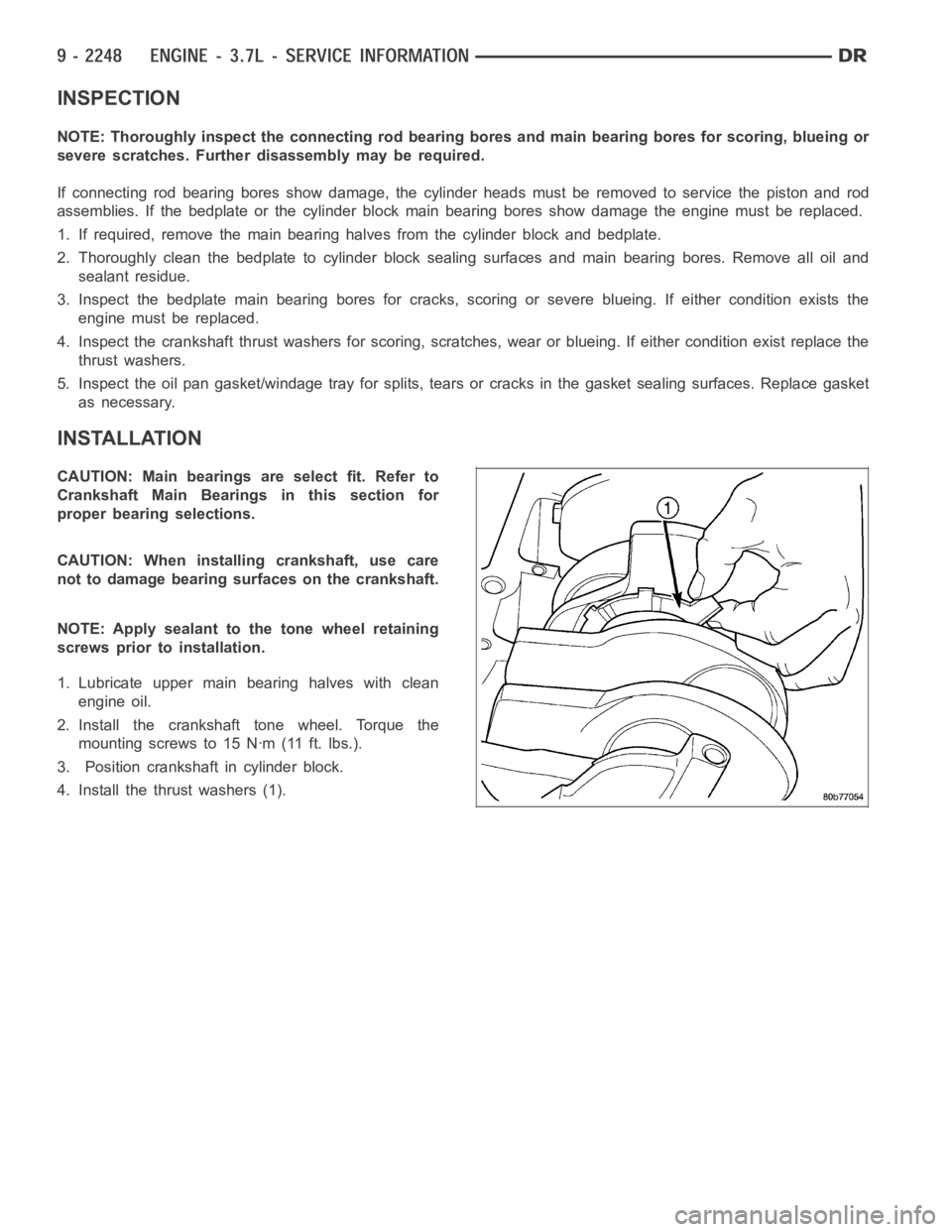

CAUTION: Main bearings are select fit. Refer to

Crankshaft Main Bearings in this section for

proper bearing selections.

CAUTION: When installing crankshaft, use care

not to damage bearing surfaces on the crankshaft.

NOTE: Apply sealant to the tone wheel retaining

screws prior to installation.

1. Lubricate upper main bearing halves with clean

engine oil.

2. Install the crankshaft tone wheel. Torque the

mountingscrewsto15Nꞏm(11ft.lbs.).

3. Position crankshaft in cylinder block.

4. Install the thrust washers (1).

Page 1558 of 5267

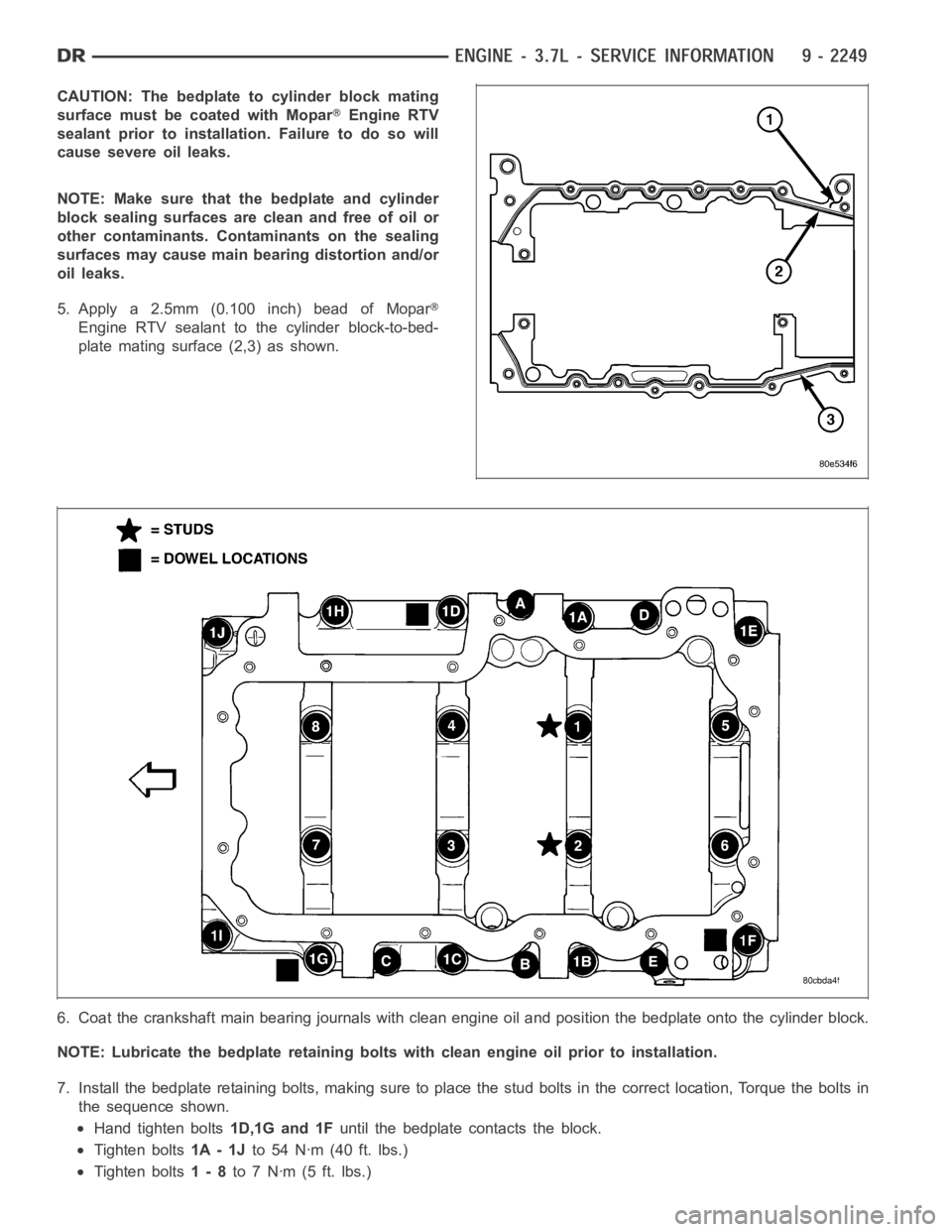

CAUTION: The bedplate to cylinder block mating

surface must be coated with Mopar

Engine RTV

sealant prior to installation. Failure to do so will

cause severe oil leaks.

NOTE: Make sure that the bedplate and cylinder

block sealing surfaces are clean and free of oil or

other contaminants. Contaminants on the sealing

surfaces may cause main bearing distortion and/or

oil leaks.

5. Apply a 2.5mm (0.100 inch) bead of Mopar

Engine RTV sealant to the cylinder block-to-bed-

plate mating surface (2,3) as shown.

6. Coat the crankshaft main bearing journals with clean engine oil and position the bedplate onto the cylinder block.

NOTE: Lubricate the bedplate retaining bolts with clean engine oil prior to installation.

7. Install the bedplate retaining bolts, making sure to place the stud bolts in the correct location, Torque the bolts in

the sequence shown.

Hand tighten bolts1D,1G and 1Funtil the bedplate contacts the block.

Tighten bolts1A - 1Jto 54 Nꞏm (40 ft. lbs.)

Tighten bolts1-8to 7 Nꞏm (5 ft. lbs.)

Page 1564 of 5267

SEAL-CRANKSHAFT OIL-REAR

DIAGNOSIS AND TESTING - REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, oil galley pipe plugs, oil filter

runoff, and main bearing cap to cylinder block mating surfaces. See Engine, for proper repair procedures of

these items.

4. If no leaks are detected, pressurized the crankcase as outlined in the section, Inspection (Engine oil Leaks in

general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled. (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING), under the Oil Leak row, for components inspections on possible

causes and corrections.

7. After the oil leak root cause and appropriate corrective action have been identified, (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR - REMOVAL).

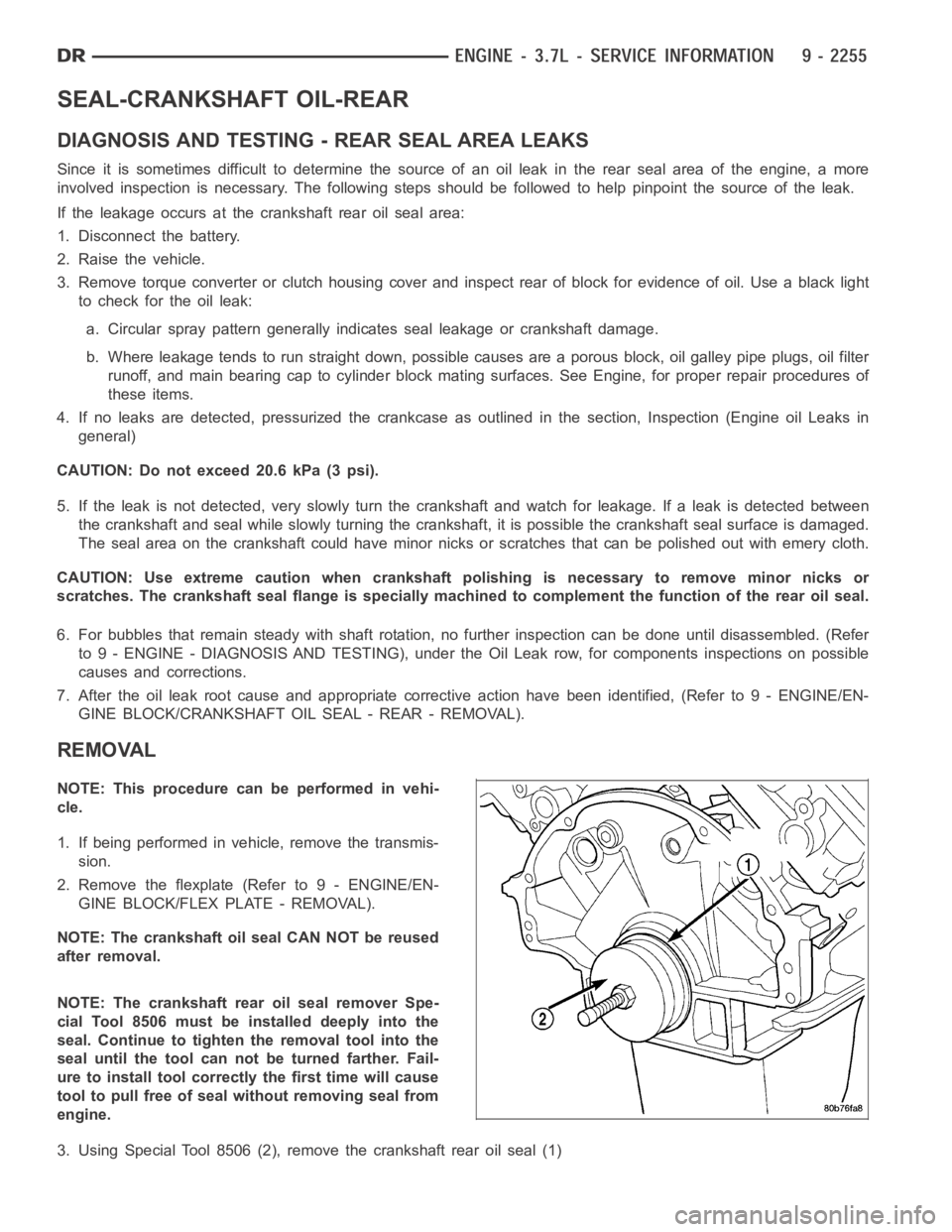

REMOVAL

NOTE: This procedure can be performed in vehi-

cle.

1. If being performed in vehicle, remove the transmis-

sion.

2. Remove the flexplate (Refer to 9 - ENGINE/EN-

GINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Spe-

cial Tool 8506 must be installed deeply into the

seal. Continue to tighten the removal tool into the

seal until the tool can not be turned farther. Fail-

ure to install tool correctly the first time will cause

tool to pull free of seal without removing seal from

engine.

3. Using Special Tool 8506 (2), remove the crankshaft rear oil seal (1)

Page 1569 of 5267

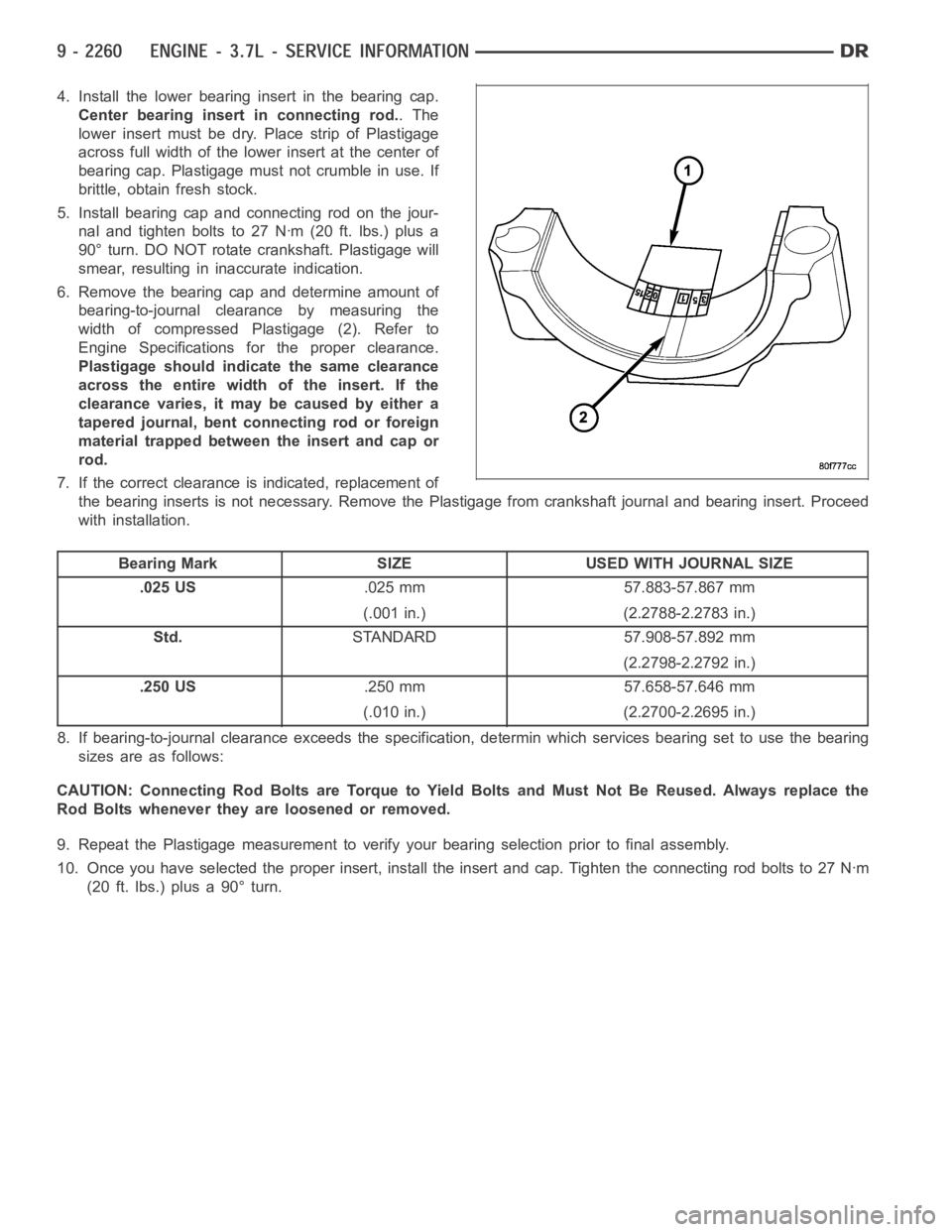

4. Install the lower bearing insert in the bearing cap.

Center bearing insert in connecting rod..The

lower insert must be dry. Place strip of Plastigage

across full width of the lower insert at the center of

bearing cap. Plastigage must not crumble in use. If

brittle, obtain fresh stock.

5. Install bearing cap and connecting rod on the jour-

nal and tighten bolts to 27 Nꞏm (20 ft. lbs.) plus a

90° turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

6. Remove the bearing cap and determine amount of

bearing-to-journal clearance by measuring the

width of compressed Plastigage (2). Refer to

Engine Specifications for the proper clearance.

Plastigage should indicate the same clearance

across the entire width of the insert. If the

clearancevaries,itmaybecausedbyeithera

tapered journal, bent connecting rod or foreign

material trapped between the insert and cap or

rod.

7. If the correct clearance is indicated, replacement of

the bearing inserts is not necessary. Remove the Plastigage from crankshaft journal and bearing insert. Proceed

with installation.

Bearing Mark SIZE USED WITH JOURNAL SIZE

.025 US.025 mm 57.883-57.867 mm

(.001 in.) (2.2788-2.2783 in.)

Std.STANDARD 57.908-57.892 mm

(2.2798-2.2792 in.)

.250 US.250 mm 57.658-57.646 mm

(.010 in.) (2.2700-2.2695 in.)

8. If bearing-to-journal clearance exceeds the specification, determinwhich services bearing set to use the bearing

sizes are as follows:

CAUTION: Connecting Rod Bolts are Torque to Yield Bolts and Must Not Be Reused. Always replace the

Rod Bolts whenever they are loosened or removed.

9. Repeat the Plastigage measurement to verify your bearing selection prior to final assembly.

10. Once you have selected the proper insert, install the insert and cap. Tighten the connecting rod bolts to 27 Nꞏm

(20 ft. lbs.) plus a 90° turn.

Page 1572 of 5267

INSTALLATION

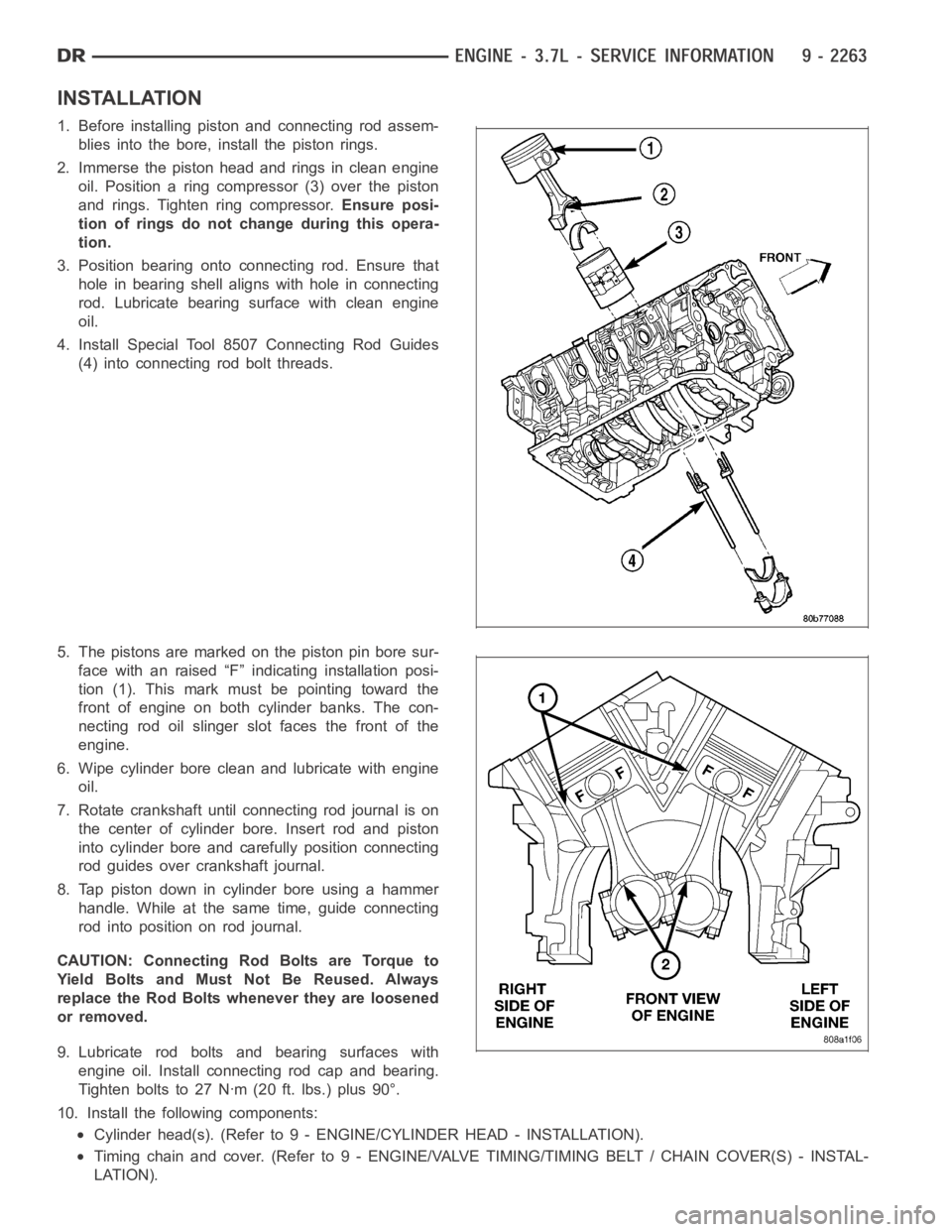

1. Before installing piston and connecting rod assem-

blies into the bore, install the piston rings.

2. Immerse the piston head and rings in clean engine

oil. Position a ring compressor (3) over the piston

and rings. Tighten ring compressor.Ensure posi-

tion of rings do not change during this opera-

tion.

3. Position bearing onto connecting rod. Ensure that

hole in bearing shell aligns with hole in connecting

rod. Lubricate bearing surface with clean engine

oil.

4. Install Special Tool 8507 Connecting Rod Guides

(4) into connecting rod bolt threads.

5. The pistons are marked on the piston pin bore sur-

face with an raised “F” indicating installation posi-

tion (1). This mark must be pointing toward the

front of engine on both cylinder banks. The con-

necting rod oil slinger slot faces the front of the

engine.

6. Wipe cylinder bore clean and lubricate with engine

oil.

7. Rotate crankshaft until connecting rod journal is on

the center of cylinder bore. Insert rod and piston

into cylinder bore and carefully position connecting

rod guides over crankshaft journal.

8. Tap piston down in cylinder bore using a hammer

handle. While at the same time, guide connecting

rodintopositiononrodjournal.

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

9. Lubricate rod bolts and bearing surfaces with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 27 Nꞏm (20 ft. lbs.) plus 90°.

10. Install the following components:

Cylinder head(s). (Refer to 9 - ENGINE/CYLINDER HEAD - INSTALLATION).

Timing chain and cover. (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) - INSTAL-

LATION).