torque DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1582 of 5267

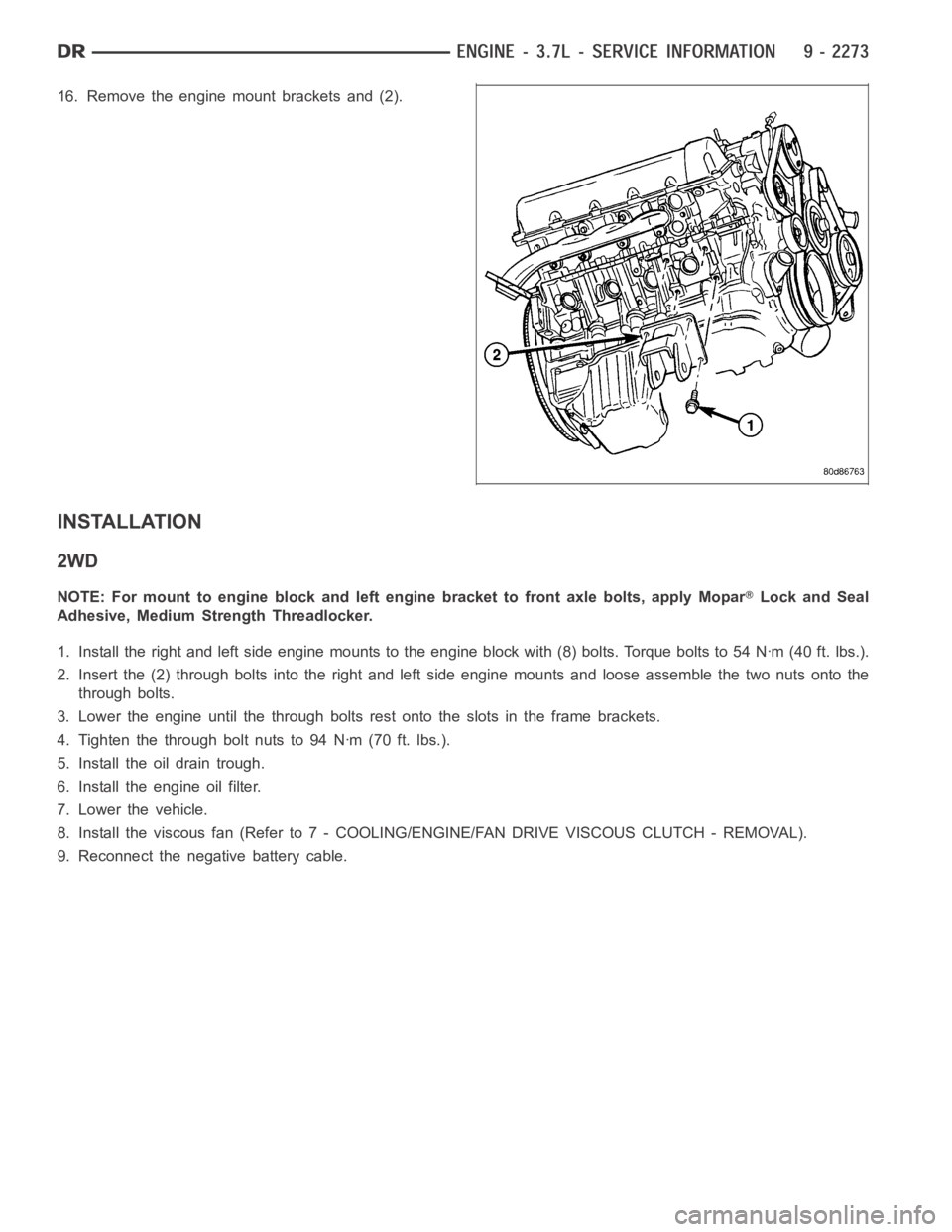

16. Remove the engine mount brackets and (2).

INSTALLATION

2WD

NOTE: For mount to engine block and left engine bracket to front axle bolts,apply MoparLock and Seal

Adhesive, Medium Strength Threadlocker.

1. Install the right and left side engine mounts to the engine block with (8)bolts. Torque bolts to 54 Nꞏm (40 ft. lbs.).

2. Insert the (2) through bolts into the right and left side engine mounts and loose assemble the two nuts onto the

through bolts.

3. Lower the engine until the through bolts rest onto the slots in the frame brackets.

4. Tighten the through bolt nuts to 94 Nꞏm (70 ft. lbs.).

5. Install the oil drain trough.

6. Install the engine oil filter.

7. Lower the vehicle.

8. Install the viscous fan (Refer to 7 - COOLING/ENGINE/FAN DRIVE VISCOUS CLUTCH - REMOVAL).

9. Reconnect the negative battery cable.

Page 1583 of 5267

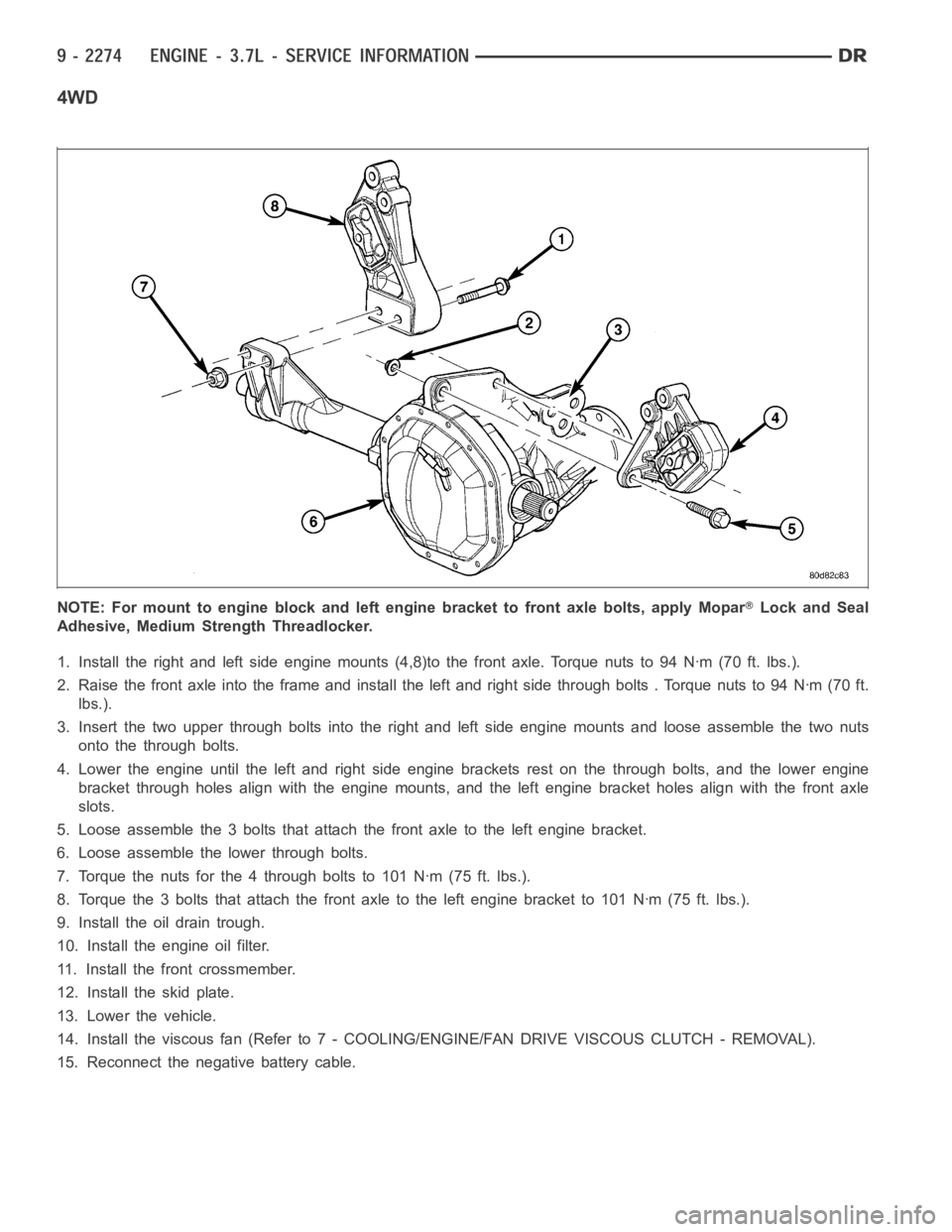

4WD

NOTE: For mount to engine block and left engine bracket to front axle bolts,apply MoparLock and Seal

Adhesive, Medium Strength Threadlocker.

1. Install the right and left side engine mounts (4,8)to the front axle. Torquenutsto94Nꞏm(70ft.lbs.).

2. Raise the front axle into the frame and install the left and right side through bolts . Torque nuts to 94 Nꞏm (70 ft.

lbs.).

3. Insert the two upper through bolts into the right and left side engine mounts and loose assemble the two nuts

onto the through bolts.

4. Lower the engine until the left and right side engine brackets rest on thethrough bolts, and the lower engine

bracket through holes align with the engine mounts, and the left engine bracket holes align with the front axle

slots.

5. Loose assemble the 3 bolts that attach the front axle to the left engine bracket.

6. Loose assemble the lower through bolts.

7. Torque the nuts for the 4 through bolts to 101 Nꞏm (75 ft. lbs.).

8. Torque the 3 bolts that attach the front axle to the left engine bracket to101Nꞏm(75ft.lbs.).

9. Install the oil drain trough.

10. Install the engine oil filter.

11. Install the front crossmember.

12. Install the skid plate.

13. Lower the vehicle.

14. Install the viscous fan (Refer to 7 - COOLING/ENGINE/FAN DRIVE VISCOUSCLUTCH - REMOVAL).

15. Reconnect the negative battery cable.

Page 1584 of 5267

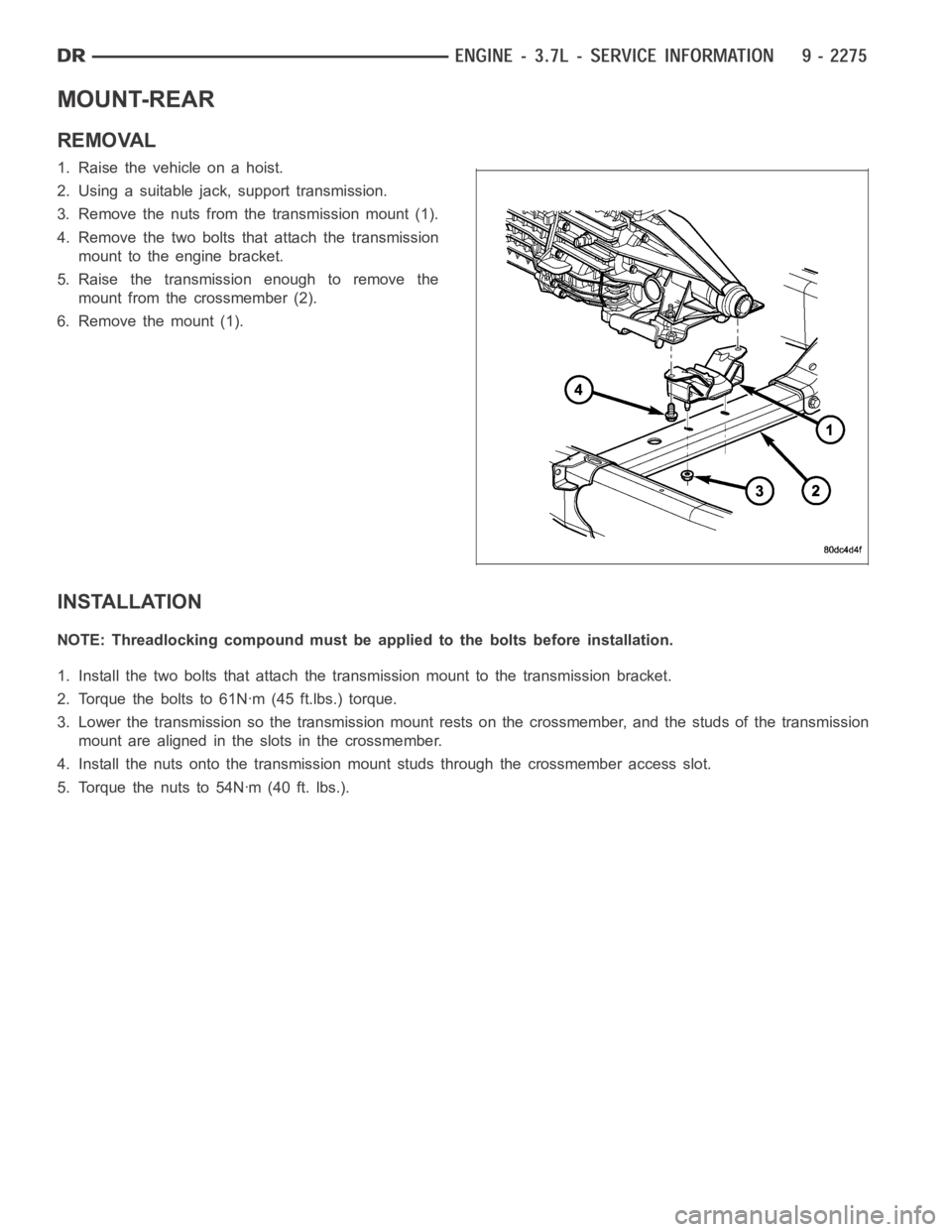

MOUNT-REAR

REMOVAL

1. Raise the vehicle on a hoist.

2. Using a suitable jack, support transmission.

3. Remove the nuts from the transmission mount (1).

4. Remove the two bolts that attach the transmission

mount to the engine bracket.

5. Raise the transmission enough to remove the

mount from the crossmember (2).

6. Remove the mount (1).

INSTALLATION

NOTE: Threadlocking compound must be applied to the bolts before installation.

1. Install the two bolts that attach the transmission mount to the transmission bracket.

2. Torque the bolts to 61Nꞏm (45 ft.lbs.) torque.

3. Lower the transmission so the transmission mount rests on the crossmember, and the studs of the transmission

mount are aligned in the slots in the crossmember.

4. Install the nuts onto the transmission mount studs through the crossmember access slot.

5. Torque the nuts to 54Nꞏm (40 ft. lbs.).

Page 1587 of 5267

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the engine, particularly at thearea of the suspected leak. If an oil leak

source is not readily identifiable, thefollowingstepsshouldbefollowed:

1. Do not clean or degrease the engine at this time because some solvents maycause rubber to swell, temporarily

stopping the leak.

2. Add an oil soluble dye (use as recommended by manufacturer). Start the engine and let idle for approximately 15

minutes. Check the oil dipstick to make sure the dye is thoroughly mixed as indicated with a bright yellow color

under a black light.

3. Using a black light, inspect the entire engine for fluorescent dye, particularly at the suspected area of oil leak. If

the oil leak is found and identified, repair per service manual instructions.

4. If dye is not observed, drive the vehicle at various speeds for approximately 24 km (15 miles), and repeat inspec-

tion.If the oil leak source is not positively identified at this time, proceed with the air leak detection test method.

Air Leak Detection Test Method

1. Disconnect the breather cap to air cleaner hose at the breather cap end. Cap or plug breather cap nipple.

2. Remove the PCV valve from the cylinder head cover. Cap or plug the PCV valvegrommet.

3. Attach an air hose with pressure gauge and regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to more than 20.6 kPa (3 PSI) of test pressure.

4. Gradually apply air pressure from 1 psi to 2.5 psi maximum while applyingsoapy water at the suspected source.

Adjust the regulator to the suitable test pressure that provide the best bubbles which will pinpoint the leak

source. If the oil leak is detected and identified, repair per service manual procedures.

5. If the leakage occurs at the rear oil seal area, refer to the section, Inspection for Rear Seal Area Leak.

6. If no leaks are detected, turn off the air supply and remove the air hose and all plugs and caps. Install the PCV

valve and breather cap hose.

7. Clean the oil off the suspect oil leak area using a suitable solvent. Drive the vehicle at various speeds approx-

imately 24 km (15 miles). Inspect the engine for signs of an oil leak by usinga black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, oil galley pipe plugs, oil filter

runoff, and main bearing cap to cylinder block mating surfaces.

4. If no leaks are detected, pressurize the crankcase as outlined in the, Inspection (Engine oil Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled.

Page 1588 of 5267

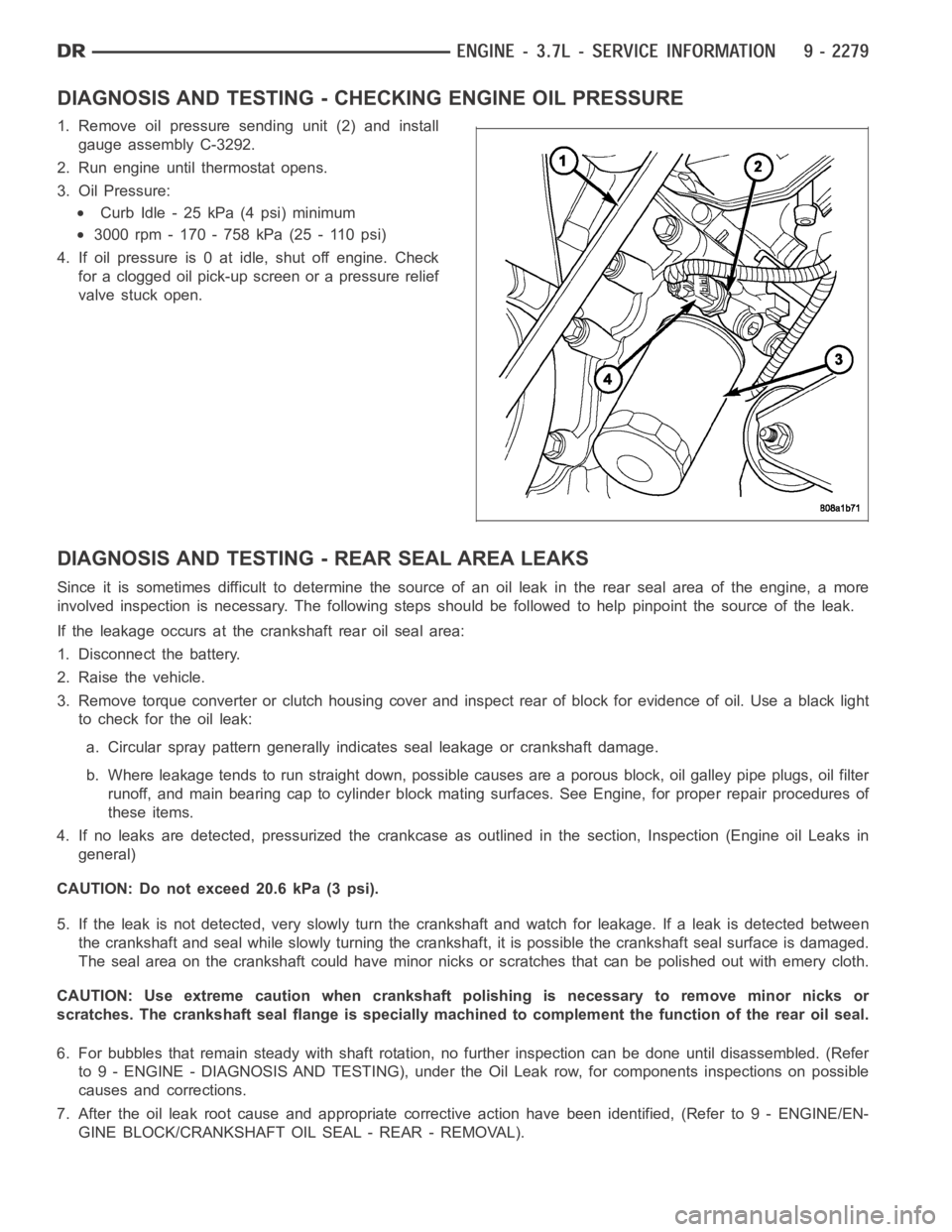

DIAGNOSIS AND TESTING - CHECKING ENGINE OIL PRESSURE

1. Remove oil pressure sending unit (2) and install

gauge assembly C-3292.

2. Run engine until thermostat opens.

3. Oil Pressure:

Curb Idle - 25 kPa (4 psi) minimum

3000 rpm - 170 - 758 kPa (25 - 110 psi)

4. If oil pressure is 0 at idle, shut off engine. Check

for a clogged oil pick-up screen or a pressure relief

valve stuck open.

DIAGNOSIS AND TESTING - REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, oil galley pipe plugs, oil filter

runoff, and main bearing cap to cylinder block mating surfaces. See Engine, for proper repair procedures of

these items.

4. If no leaks are detected, pressurized the crankcase as outlined in the section, Inspection (Engine oil Leaks in

general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled. (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING), under the Oil Leak row, for components inspections on possible

causes and corrections.

7. After the oil leak root cause and appropriate corrective action have been identified, (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR - REMOVAL).

Page 1600 of 5267

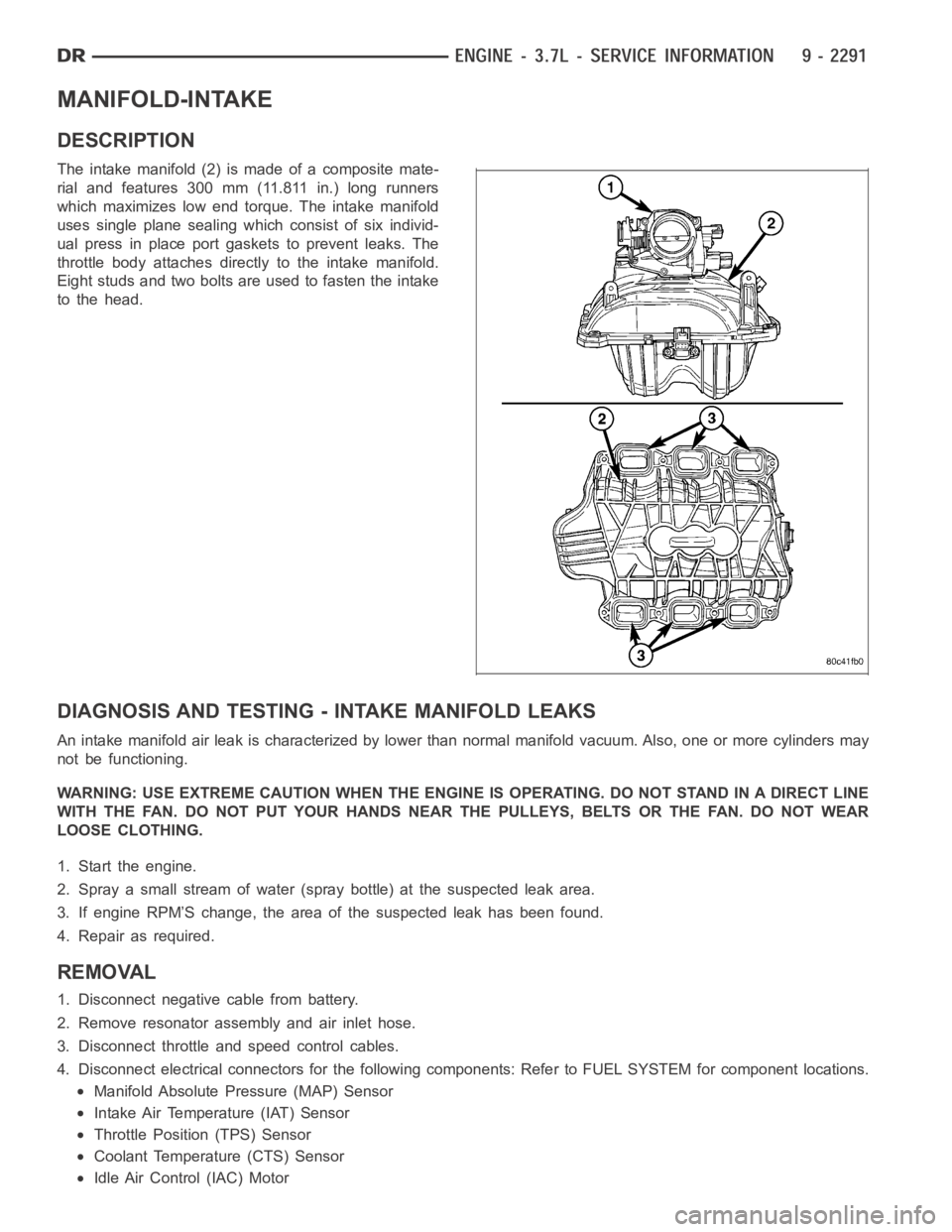

MANIFOLD-INTAKE

DESCRIPTION

The intake manifold (2) is made of a composite mate-

rial and features 300 mm (11.811 in.) long runners

which maximizes low end torque. The intake manifold

uses single plane sealing which consist of six individ-

ual press in place port gaskets to prevent leaks. The

throttle body attaches directly to the intake manifold.

Eight studs and two bolts are used to fasten the intake

to the head.

DIAGNOSIS AND TESTING -INTAKE MANIFOLD LEAKS

An intake manifold air leak is characterized by lower than normal manifoldvacuum. Also, one or more cylinders may

not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE ENGINE IS OPERATING. DO NOT STAND IN ADIRECT LINE

WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR THE FAN. DO NOT WEAR

LOOSE CLOTHING.

1. Start the engine.

2. Spray a small stream of water (spray bottle) at the suspected leak area.

3. If engine RPM’S change, the area of the suspected leak has been found.

4. Repair as required.

REMOVAL

1. Disconnect negative cable from battery.

2. Remove resonator assembly and air inlet hose.

3. Disconnect throttle and speed control cables.

4. Disconnect electrical connectors for the following components: Referto FUEL SYSTEM for component locations.

Manifold Absolute Pressure (MAP) Sensor

Intake Air Temperature (IAT) Sensor

Throttle Position (TPS) Sensor

Coolant Temperature (CTS) Sensor

Idle Air Control (IAC) Motor

Page 1603 of 5267

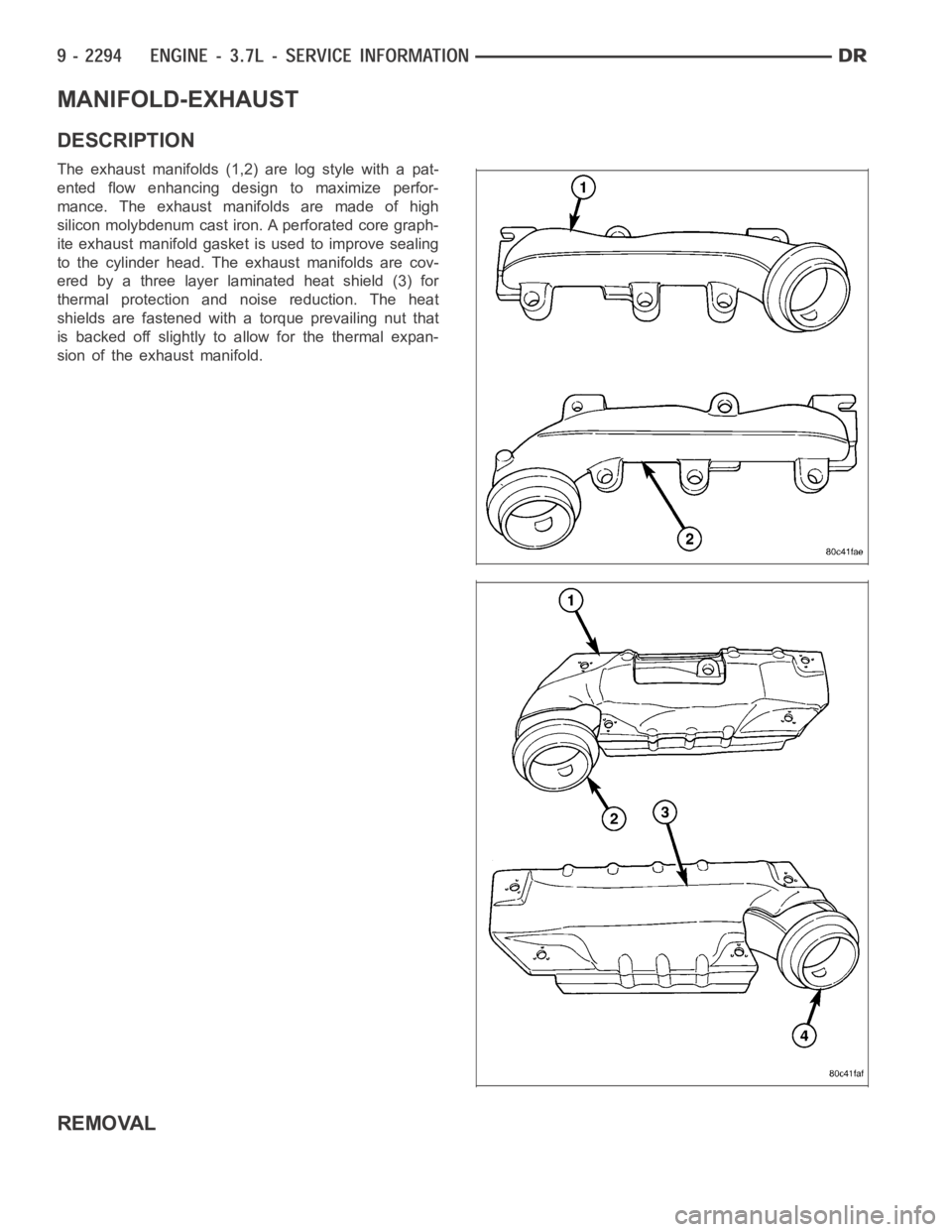

MANIFOLD-EXHAUST

DESCRIPTION

The exhaust manifolds (1,2) are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core graph-

ite exhaust manifold gasket is used to improve sealing

to the cylinder head. The exhaust manifolds are cov-

ered by a three layer laminated heat shield (3) for

thermal protection and noise reduction. The heat

shields are fastened witha torque prevailing nut that

is backed off slightly to allow for the thermal expan-

sion of the exhaust manifold.

REMOVAL

Page 1605 of 5267

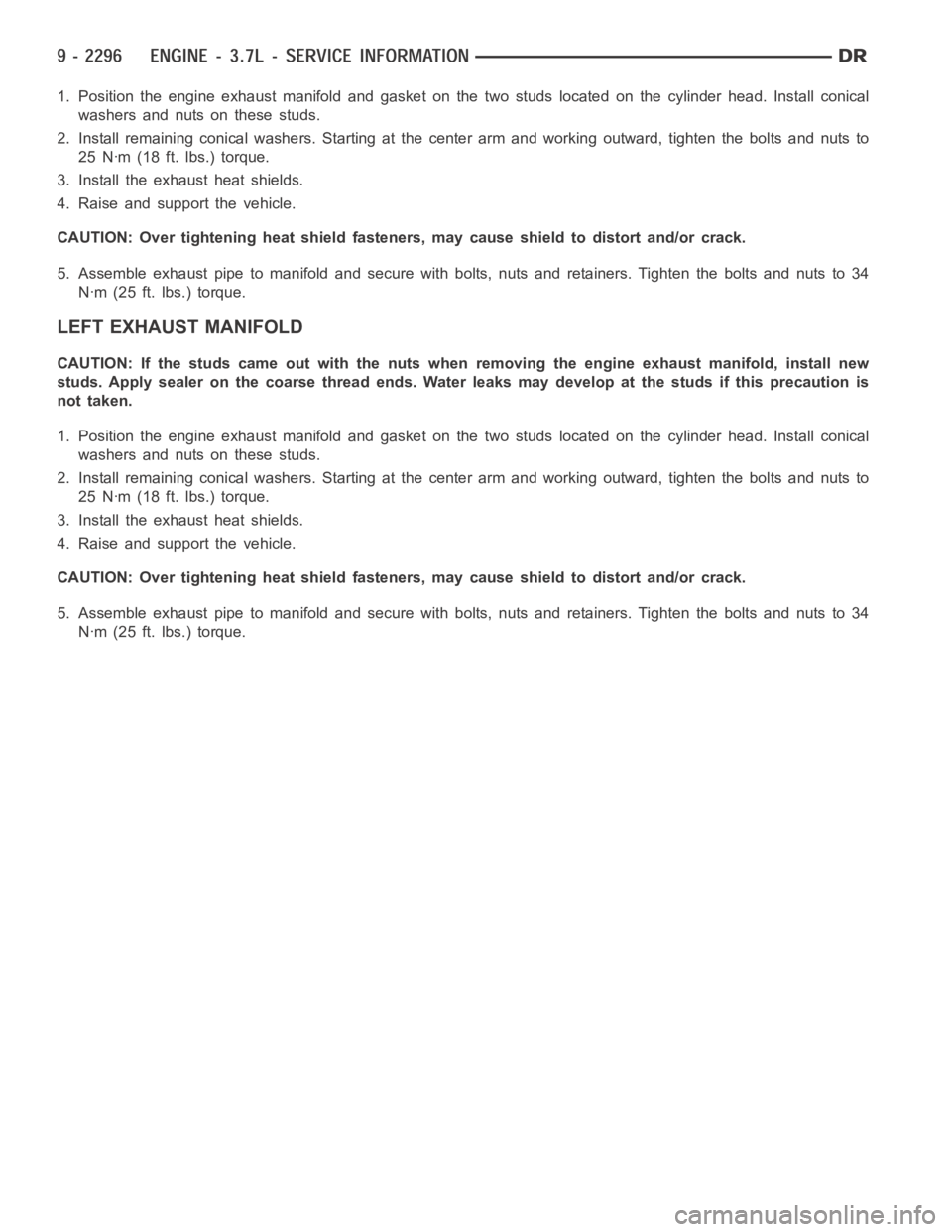

1. Position the engine exhaust manifold and gasket on the two studs locatedon the cylinder head. Install conical

washers and nuts on these studs.

2. Install remaining conical washers. Starting at the center arm and working outward, tighten the bolts and nuts to

25 Nꞏm (18 ft. lbs.) torque.

3. Install the exhaust heat shields.

4. Raise and support the vehicle.

CAUTION: Over tightening heat shield fasteners, may cause shield to distort and/or crack.

5. Assemble exhaust pipe to manifold and secure with bolts, nuts and retainers. Tighten the bolts and nuts to 34

Nꞏm (25 ft. lbs.) torque.

LEFT EXHAUST MANIFOLD

CAUTION: If the studs came out with the nuts when removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends. Water leaks may develop at the studs if this precaution is

not taken.

1. Position the engine exhaust manifold and gasket on the two studs locatedon the cylinder head. Install conical

washers and nuts on these studs.

2. Install remaining conical washers. Starting at the center arm and working outward, tighten the bolts and nuts to

25 Nꞏm (18 ft. lbs.) torque.

3. Install the exhaust heat shields.

4. Raise and support the vehicle.

CAUTION: Over tightening heat shield fasteners, may cause shield to distort and/or crack.

5. Assemble exhaust pipe to manifold and secure with bolts, nuts and retainers. Tighten the bolts and nuts to 34

Nꞏm (25 ft. lbs.) torque.

Page 1610 of 5267

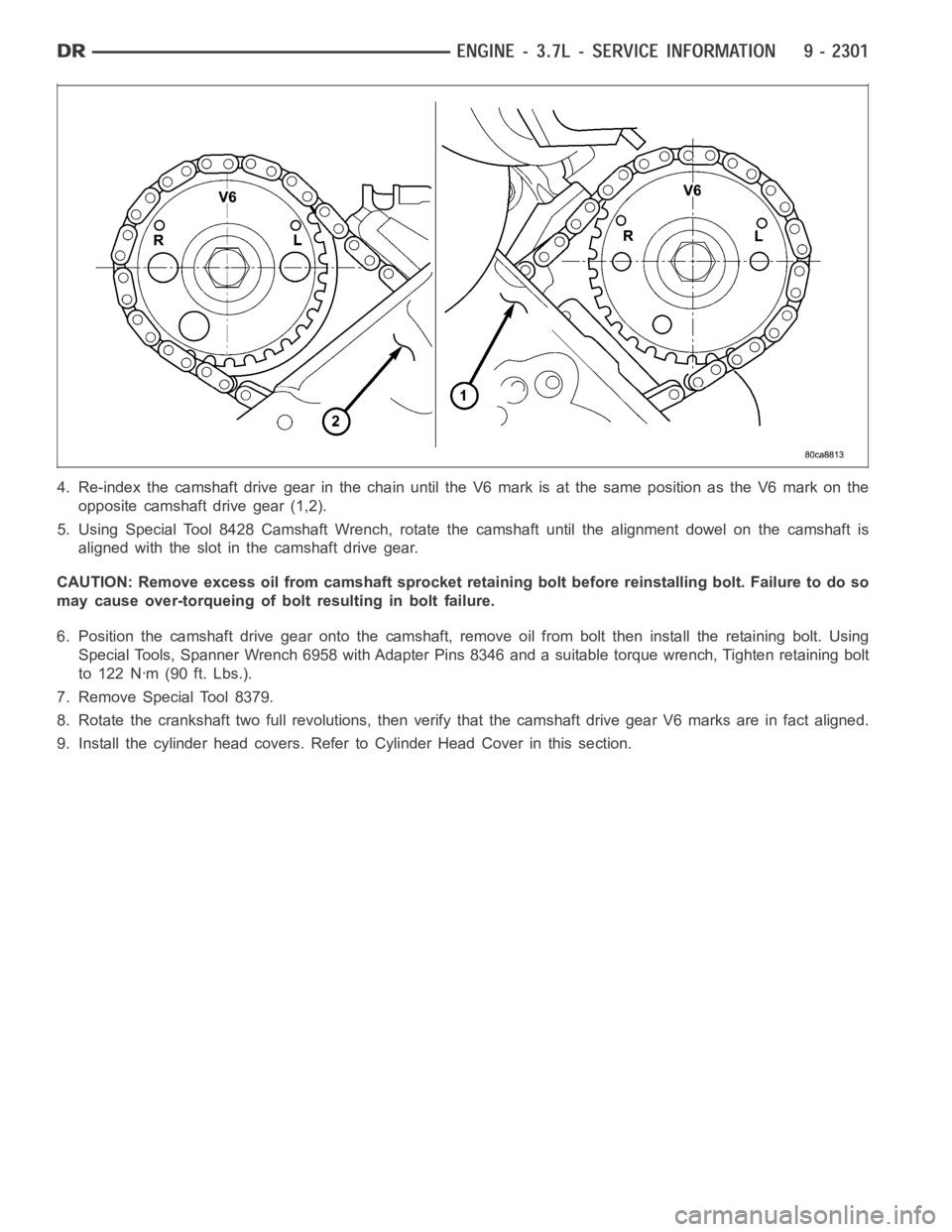

4. Re-index the camshaft drive gear in the chain until the V6 mark is at the same position as the V6 mark on the

opposite camshaft drive gear (1,2).

5. Using Special Tool 8428 Camshaft Wrench, rotate the camshaft until the alignment dowel on the camshaft is

aligned with the slot in the camshaft drive gear.

CAUTION: Remove excess oil from camshaft sprocket retaining bolt before reinstalling bolt. Failure to do so

may cause over-torqueing of bolt resulting in bolt failure.

6. Position the camshaft drive gear onto the camshaft, remove oil from boltthen install the retaining bolt. Using

Special Tools, Spanner Wrench 6958 with Adapter Pins 8346 and a suitable torque wrench, Tighten retaining bolt

to 122 Nꞏm (90 ft. Lbs.).

7. Remove Special Tool 8379.

8. Rotate the crankshaft two full revolutions, then verify that the camshaftdrivegearV6marksareinfactaligned.

9. Install the cylinder head covers. Refer to Cylinder Head Cover in this section.

Page 1612 of 5267

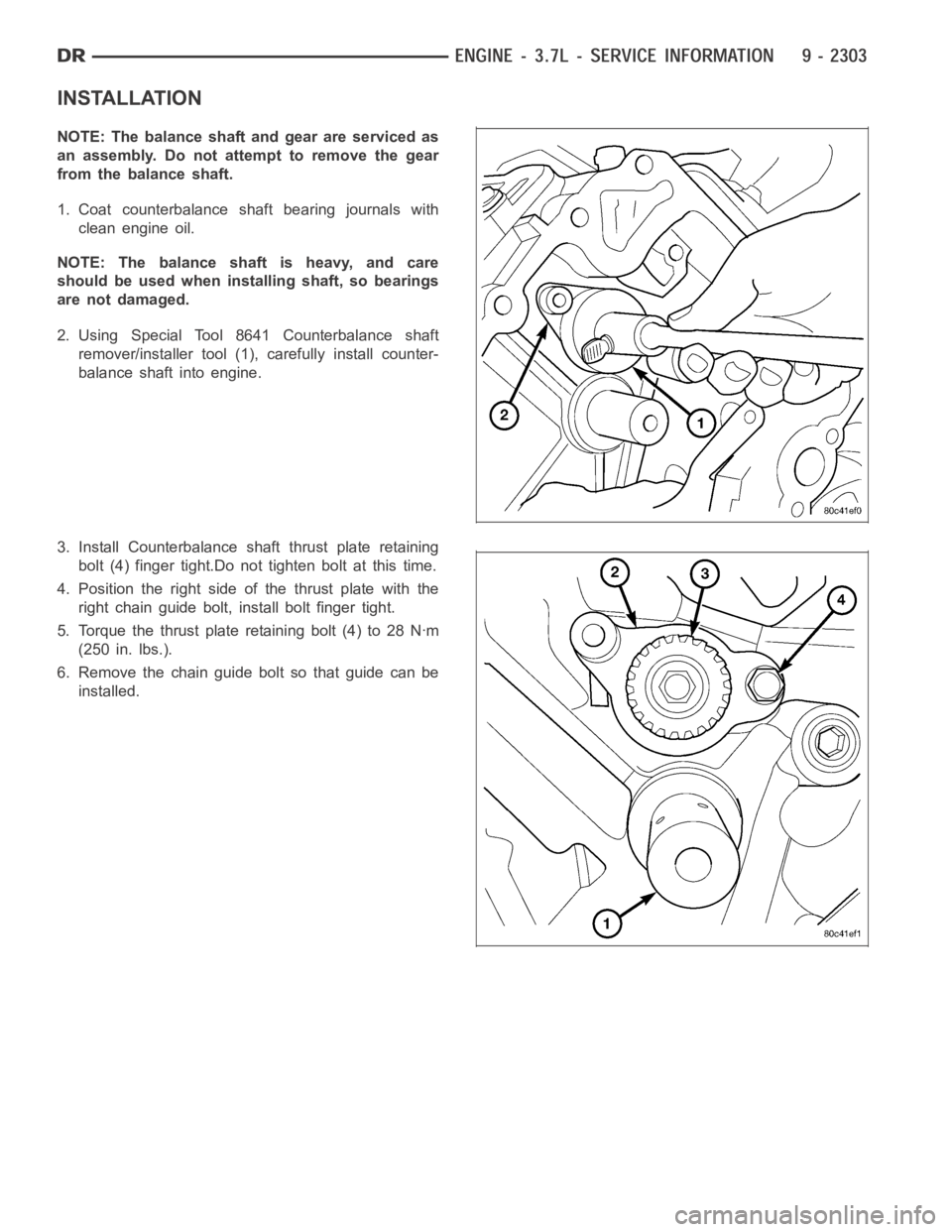

INSTALLATION

NOTE: The balance shaft and gear are serviced as

an assembly. Do not attempt to remove the gear

from the balance shaft.

1. Coat counterbalance shaft bearing journals with

clean engine oil.

NOTE: The balance shaft is heavy, and care

should be used when installing shaft, so bearings

are not damaged.

2. Using Special Tool 8641 Counterbalance shaft

remover/installer tool (1), carefully install counter-

balance shaft into engine.

3. Install Counterbalance shaft thrust plate retaining

bolt (4) finger tight.Do not tighten bolt at this time.

4. Position the right side of the thrust plate with the

right chain guide bolt, install bolt finger tight.

5. Torque the thrust plate retaining bolt (4) to 28 Nꞏm

(250 in. lbs.).

6. Remove the chain guide bolt so that guide can be

installed.