torque DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1661 of 5267

4. Lubricate the cylinder head bolt threads with clean engine oil and install the ten M11 bolts.

5. Coat the four M8 cylinder head bolts withMopar

Lock and Seal Adhesivethen install the bolts.

NOTE: The cylinder head bolts are tightened using an angle torque procedure, however, the bolts are not a

torque-to-yield design.

6. Tighten the bolts in sequence using the following steps and torque values:

Step 1: Tighten bolts 1–10, 20 Nꞏm (15 ft. lbs.).

Step 2: Tighten bolts 1–10, 47 Nꞏm (35 ft. lbs.). Tighten bolts 11–14, 25 Nꞏm(18 ft. lbs.).

Step 3: Tighten bolts 1–10, 90 degrees. Tighten bolts 11–14, 30 Nꞏm (22 ft. lbs.).

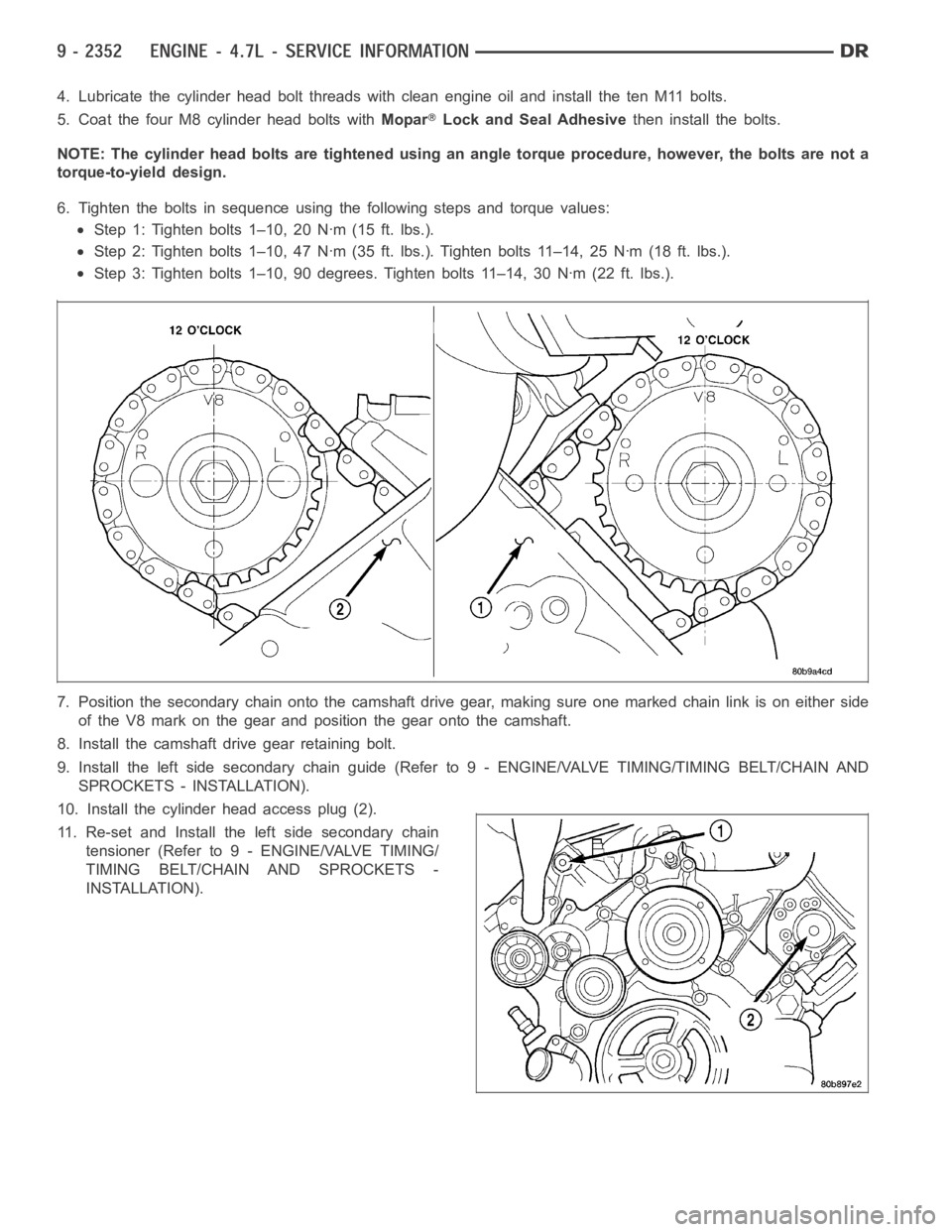

7. Position the secondary chain onto the camshaft drive gear, making sure one marked chain link is on either side

of the V8 mark on the gear and position the gear onto the camshaft.

8. Install the camshaft drive gear retaining bolt.

9. Install the left side secondary chain guide (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

10. Install the cylinder head access plug (2).

11. Re-set and Install the left side secondary chain

tensioner (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

Page 1662 of 5267

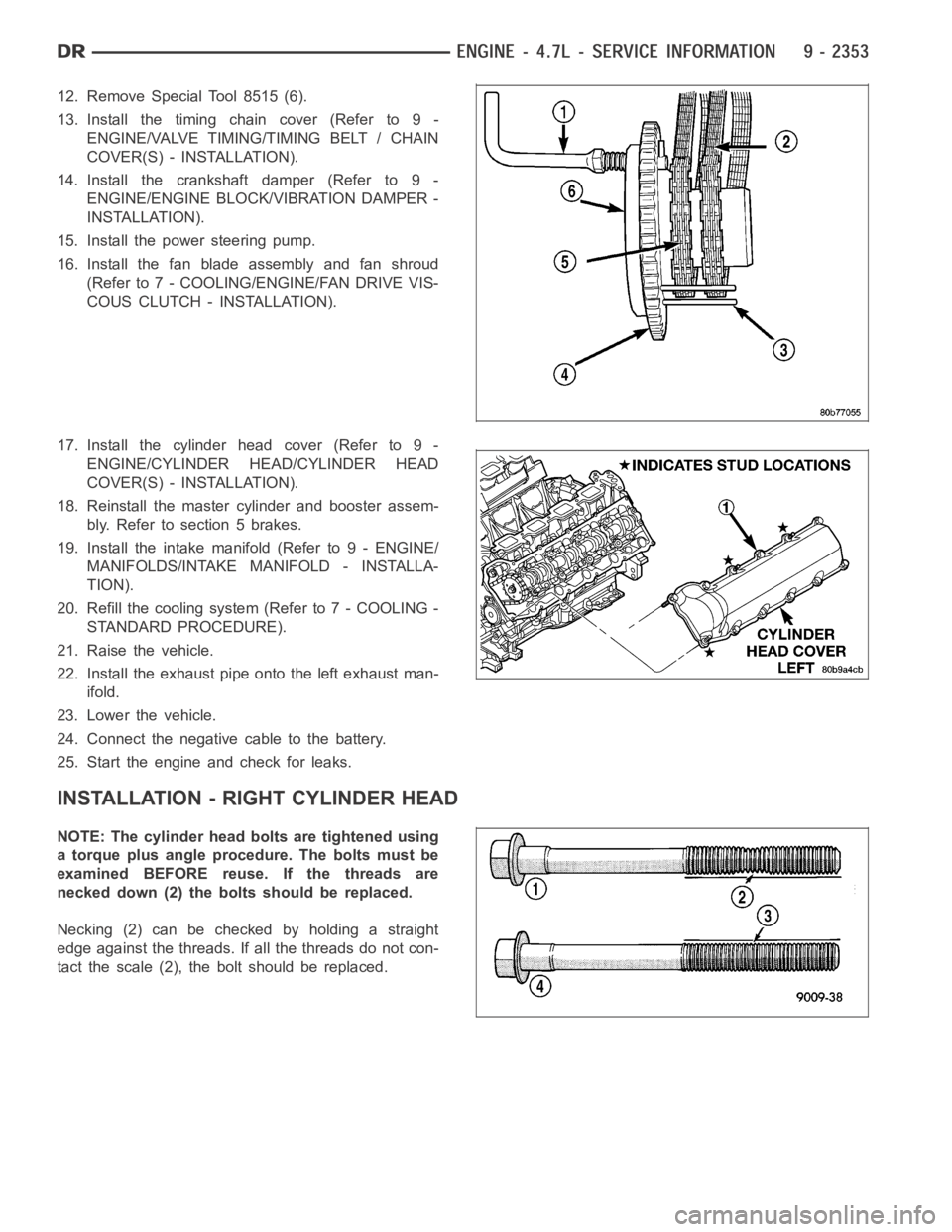

12. Remove Special Tool 8515 (6).

13. Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

14. Install the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

15. Install the power steering pump.

16. Install the fan blade assembly and fan shroud

(Refer to 7 - COOLING/ENGINE/FAN DRIVE VIS-

COUS CLUTCH - INSTALLATION).

17. Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

18. Reinstall the master cylinder and booster assem-

bly.Refertosection5brakes.

19. Install the intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

20. Refill the cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

21. Raise the vehicle.

22. Install the exhaust pipe onto the left exhaust man-

ifold.

23. Lower the vehicle.

24. Connect the negative cable to the battery.

25. Start the engine and check for leaks.

INSTALLATION - RIGHT CYLINDER HEAD

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are

necked down (2) the bolts should be replaced.

Necking(2)canbecheckedbyholdingastraight

edge against the threads. If all the threads do not con-

tactthescale(2),theboltshouldbereplaced.

Page 1663 of 5267

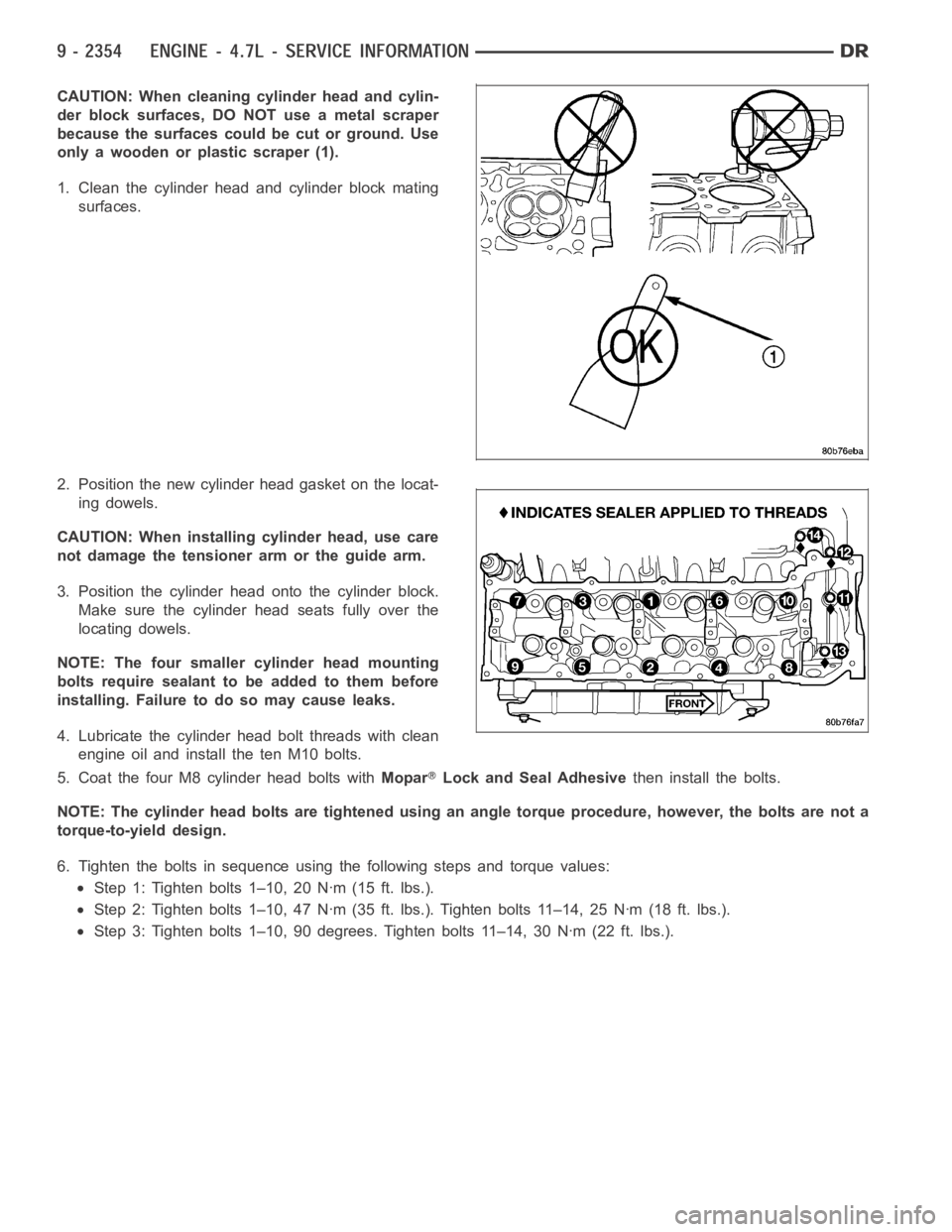

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper (1).

1. Clean the cylinder head and cylinder block mating

surfaces.

2. Position the new cylinder head gasket on the locat-

ing dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

3. Position the cylinder head onto the cylinder block.

Make sure the cylinder head seats fully over the

locating dowels.

NOTE: The four smaller cylinder head mounting

bolts require sealant to be added to them before

installing. Failure to do so may cause leaks.

4. Lubricate the cylinder head bolt threads with clean

engine oil and install the ten M10 bolts.

5. Coat the four M8 cylinder head bolts withMopar

Lock and Seal Adhesivethen install the bolts.

NOTE: The cylinder head bolts are tightened using an angle torque procedure, however, the bolts are not a

torque-to-yield design.

6. Tighten the bolts in sequence using the following steps and torque values:

Step 1: Tighten bolts 1–10, 20 Nꞏm (15 ft. lbs.).

Step 2: Tighten bolts 1–10, 47 Nꞏm (35 ft. lbs.). Tighten bolts 11–14, 25 Nꞏm(18 ft. lbs.).

Step 3: Tighten bolts 1–10, 90 degrees. Tighten bolts 11–14, 30 Nꞏm (22 ft. lbs.).

Page 1668 of 5267

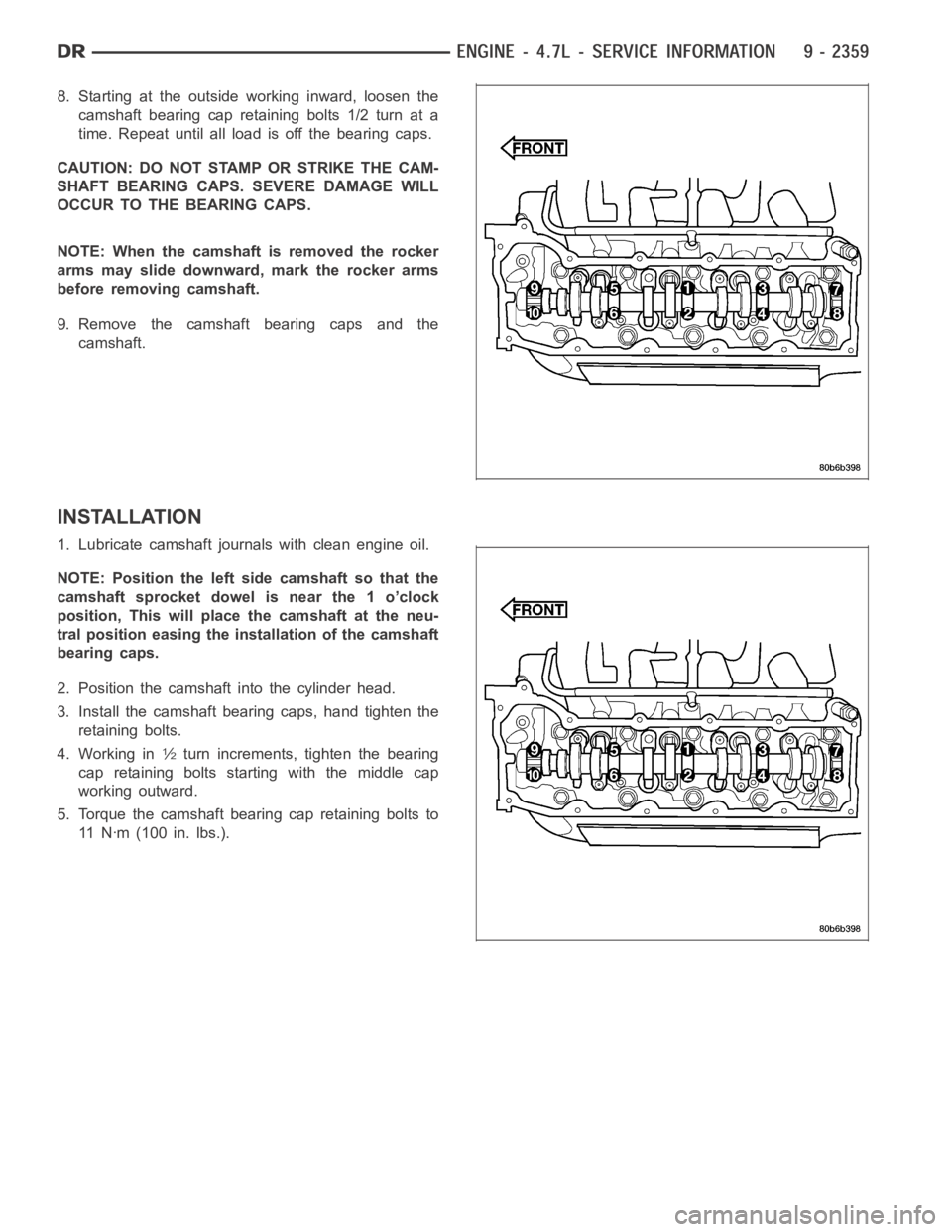

8. Starting at the outside working inward, loosen the

camshaft bearing cap retaining bolts 1/2 turn at a

time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

9. Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

1. Lubricate camshaft journals with clean engine oil.

NOTE: Position the left side camshaft so that the

camshaft sprocket dowel is near the 1 o’clock

position, This will place the camshaft at the neu-

tral position easing the installation of the camshaft

bearing caps.

2. Position the camshaft into the cylinder head.

3. Install the camshaft bearing caps, hand tighten the

retaining bolts.

4. Working in

1⁄2turn increments, tighten the bearing

cap retaining bolts starting with the middle cap

working outward.

5. Torque the camshaft bearing cap retaining bolts to

11 N ꞏm ( 1 0 0 i n . l b s . ) .

Page 1669 of 5267

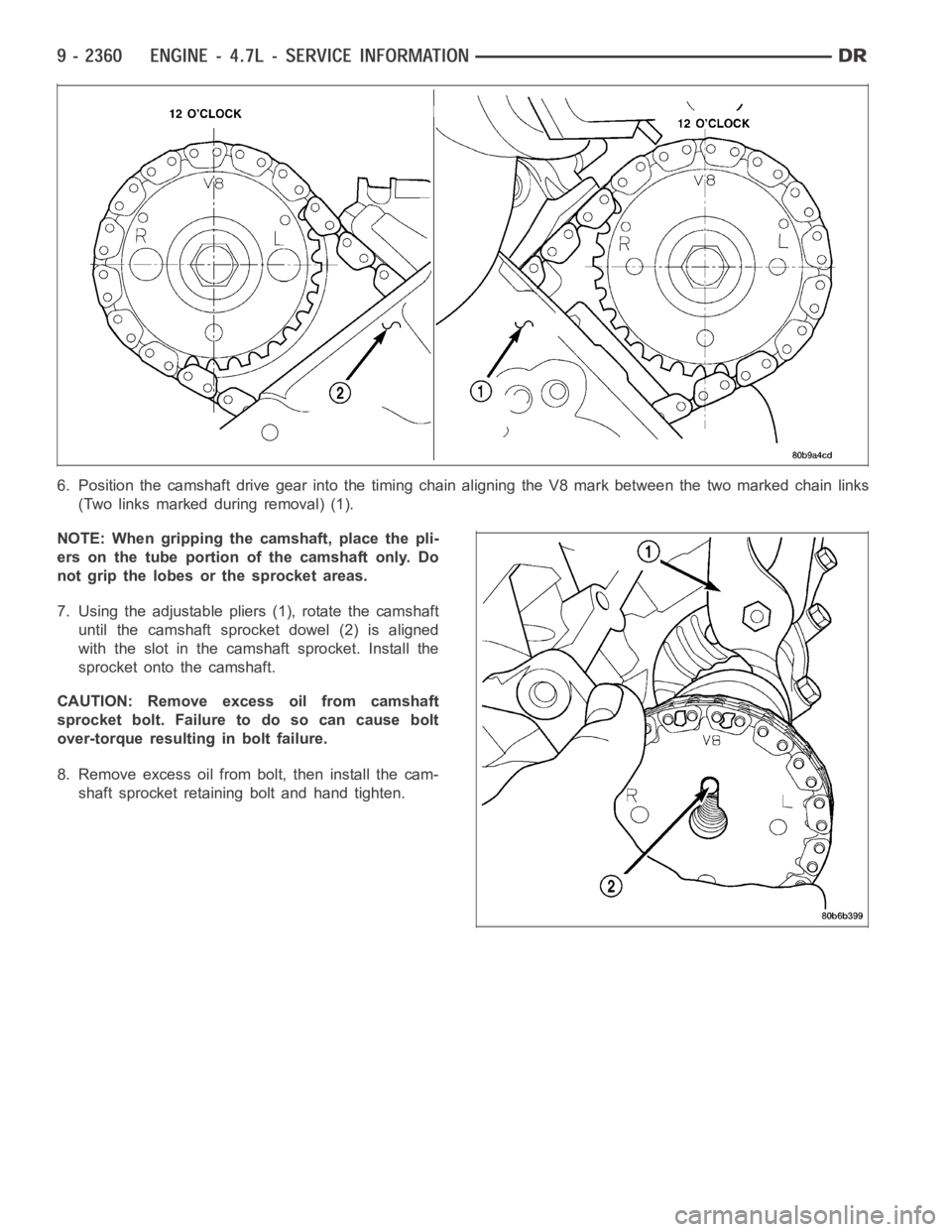

6. Position the camshaft drive gear into the timing chain aligning the V8 mark between the two marked chain links

(Two links marked during removal) (1).

NOTE: When gripping the camshaft, place the pli-

ers on the tube portion of the camshaft only. Do

not grip the lobes or the sprocket areas.

7. Using the adjustable pliers (1), rotate the camshaft

until the camshaft sprocket dowel (2) is aligned

with the slot in the camshaft sprocket. Install the

sprocket onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket bolt. Failure to do so can cause bolt

over-torque resulting in bolt failure.

8. Remove excess oil from bolt, then install the cam-

shaft sprocket retaining bolt and hand tighten.

Page 1670 of 5267

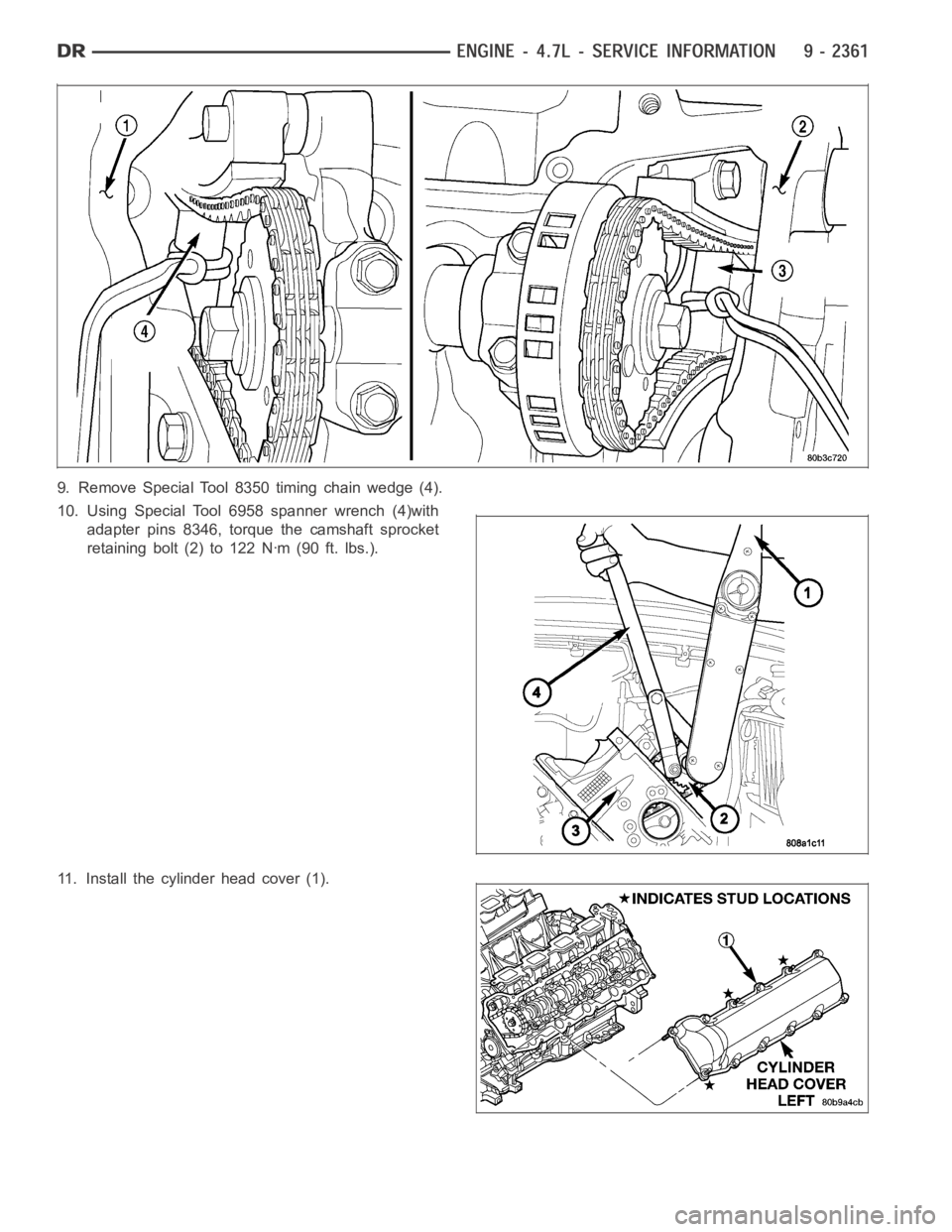

9. Remove Special Tool 8350 timing chain wedge (4).

10. Using Special Tool 6958 spanner wrench (4)with

adapter pins 8346, torque the camshaft sprocket

retaining bolt (2) to 122 Nꞏm (90 ft. lbs.).

11. Install the cylinder head cover (1).

Page 1674 of 5267

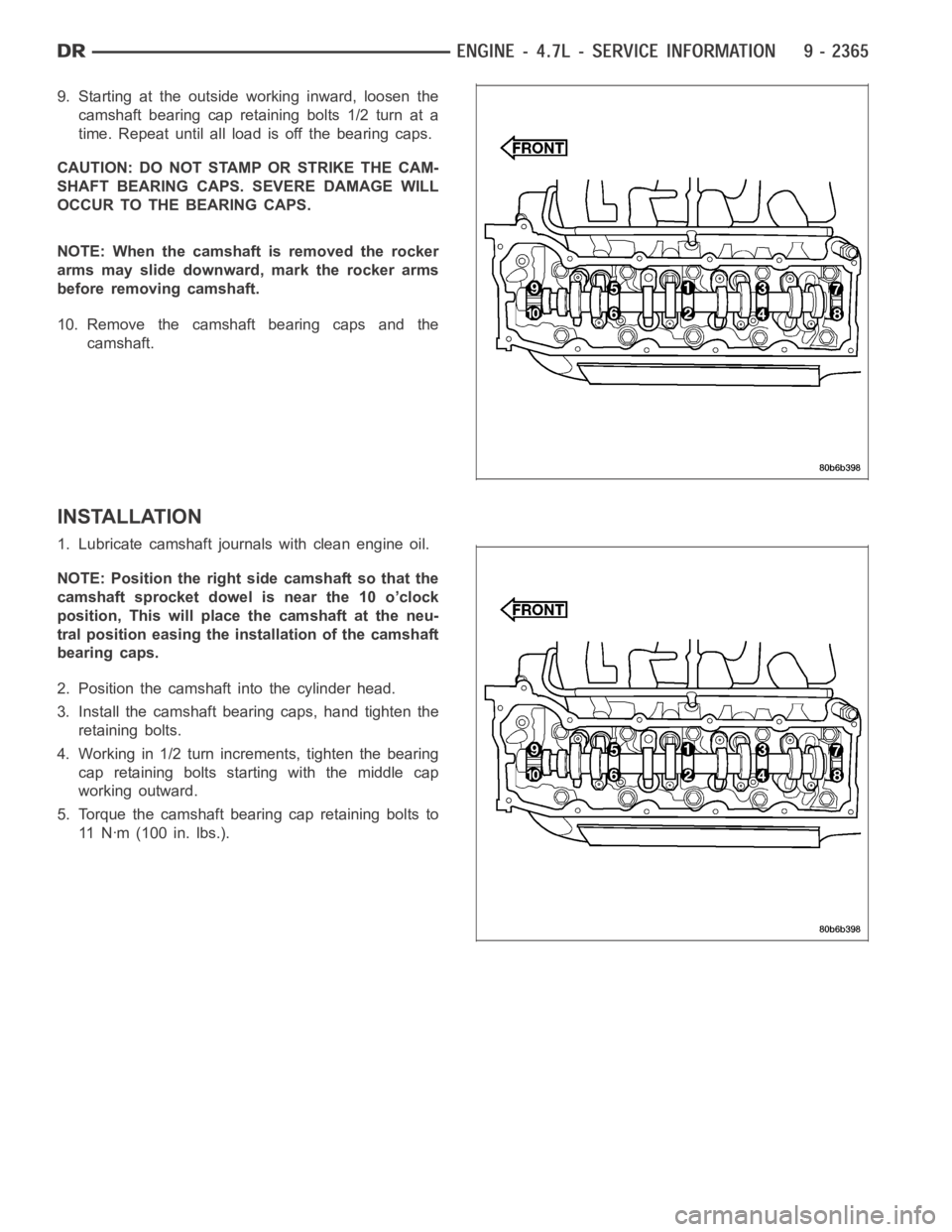

9. Starting at the outside working inward, loosen the

camshaft bearing cap retaining bolts 1/2 turn at a

time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

10. Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

1. Lubricate camshaft journals with clean engine oil.

NOTE: Position the right side camshaft so that the

camshaft sprocket dowel is near the 10 o’clock

position, This will place the camshaft at the neu-

tral position easing the installation of the camshaft

bearing caps.

2. Position the camshaft into the cylinder head.

3. Install the camshaft bearing caps, hand tighten the

retaining bolts.

4. Working in 1/2 turn increments, tighten the bearing

cap retaining bolts starting with the middle cap

working outward.

5. Torque the camshaft bearing cap retaining bolts to

11 N ꞏm ( 1 0 0 i n . l b s . ) .

Page 1675 of 5267

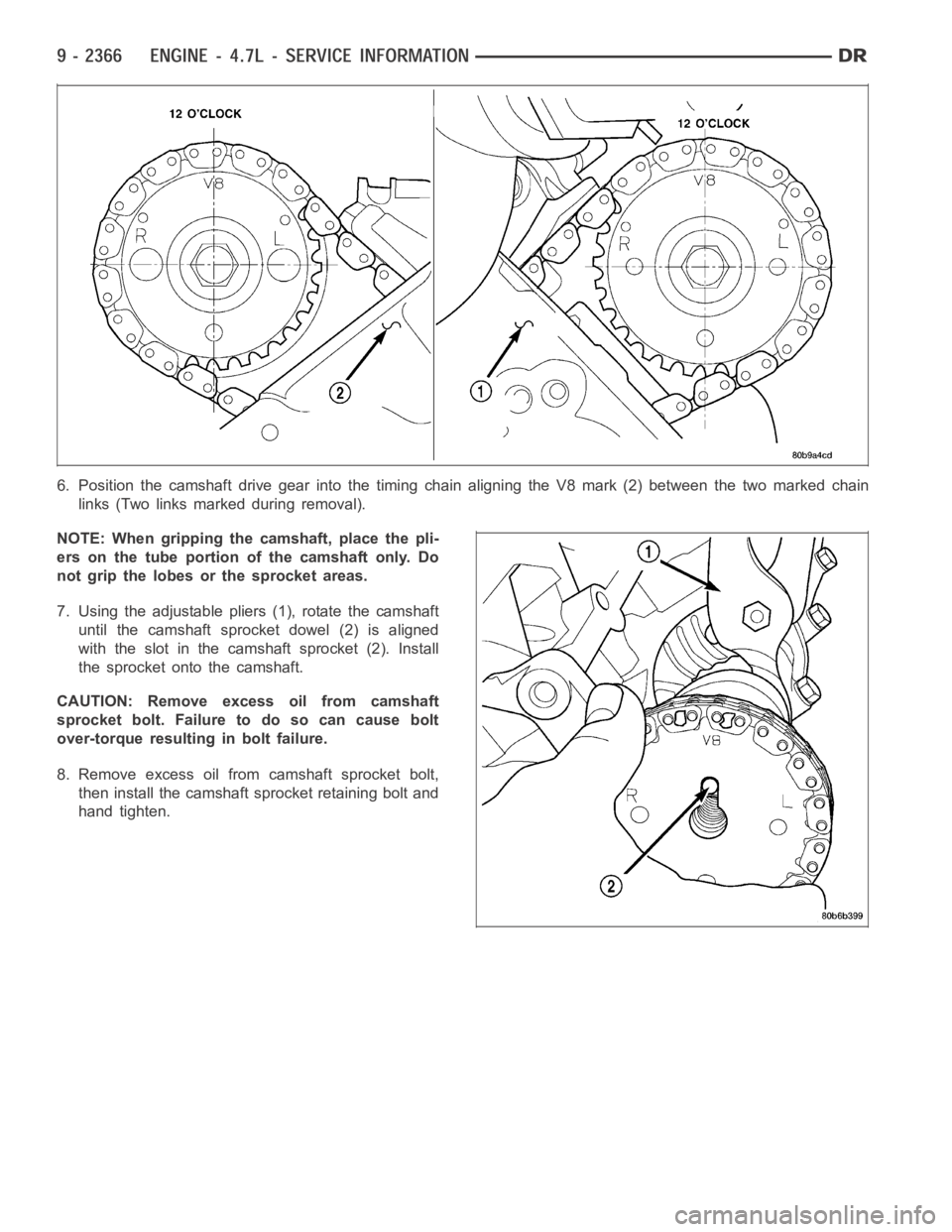

6. Position the camshaft drive gear into the timing chain aligning the V8 mark (2) between the two marked chain

links (Two links marked during removal).

NOTE: When gripping the camshaft, place the pli-

ers on the tube portion of the camshaft only. Do

not grip the lobes or the sprocket areas.

7. Using the adjustable pliers (1), rotate the camshaft

until the camshaft sprocket dowel (2) is aligned

withtheslotinthecamshaftsprocket(2).Install

the sprocket onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket bolt. Failure to do so can cause bolt

over-torque resulting in bolt failure.

8. Remove excess oil from camshaft sprocket bolt,

then install the camshaft sprocket retaining bolt and

hand tighten.

Page 1676 of 5267

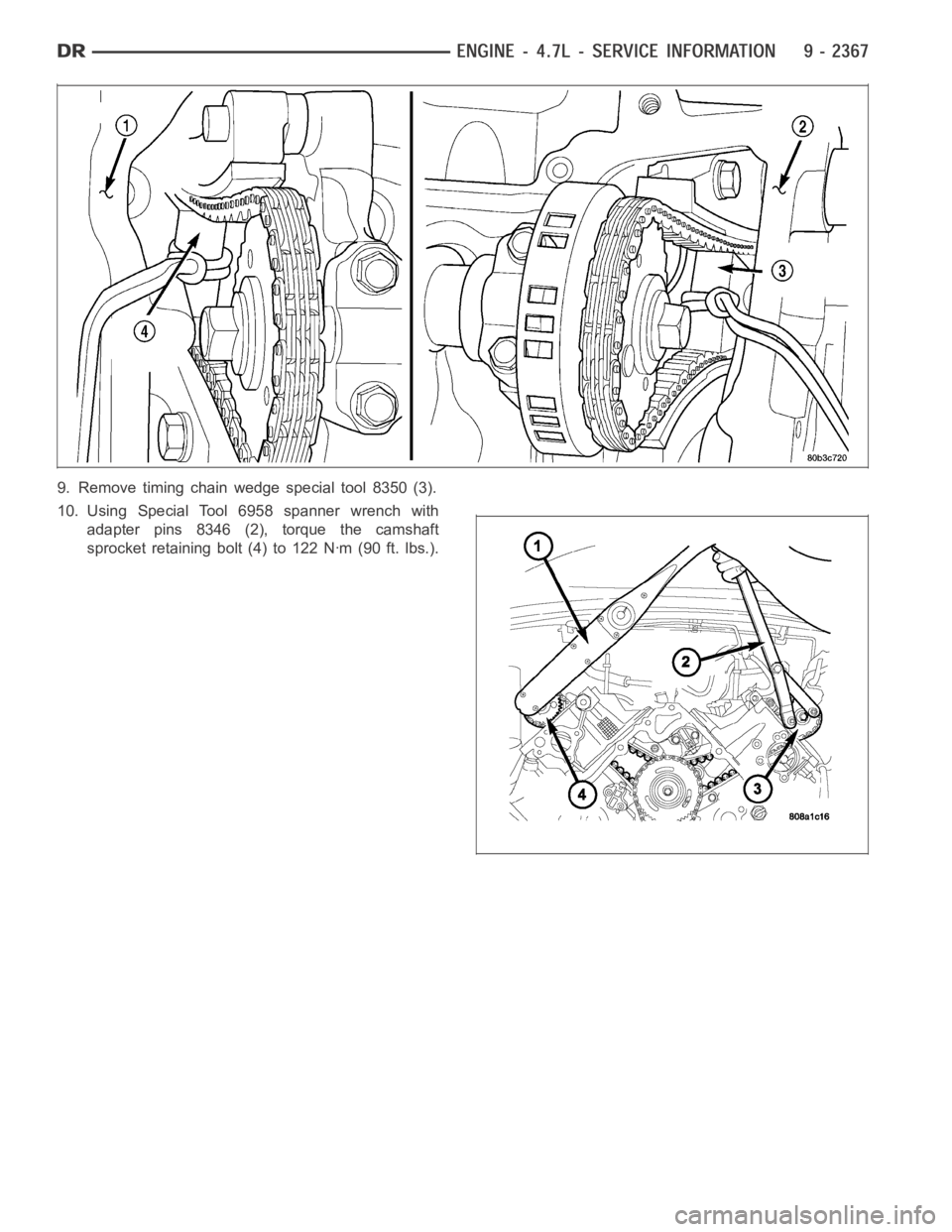

9. Remove timing chain wedge special tool 8350 (3).

10. Using Special Tool 6958 spanner wrench with

adapter pins 8346 (2), torque the camshaft

sprocket retaining bolt (4) to 122 Nꞏm (90 ft. lbs.).

Page 1681 of 5267

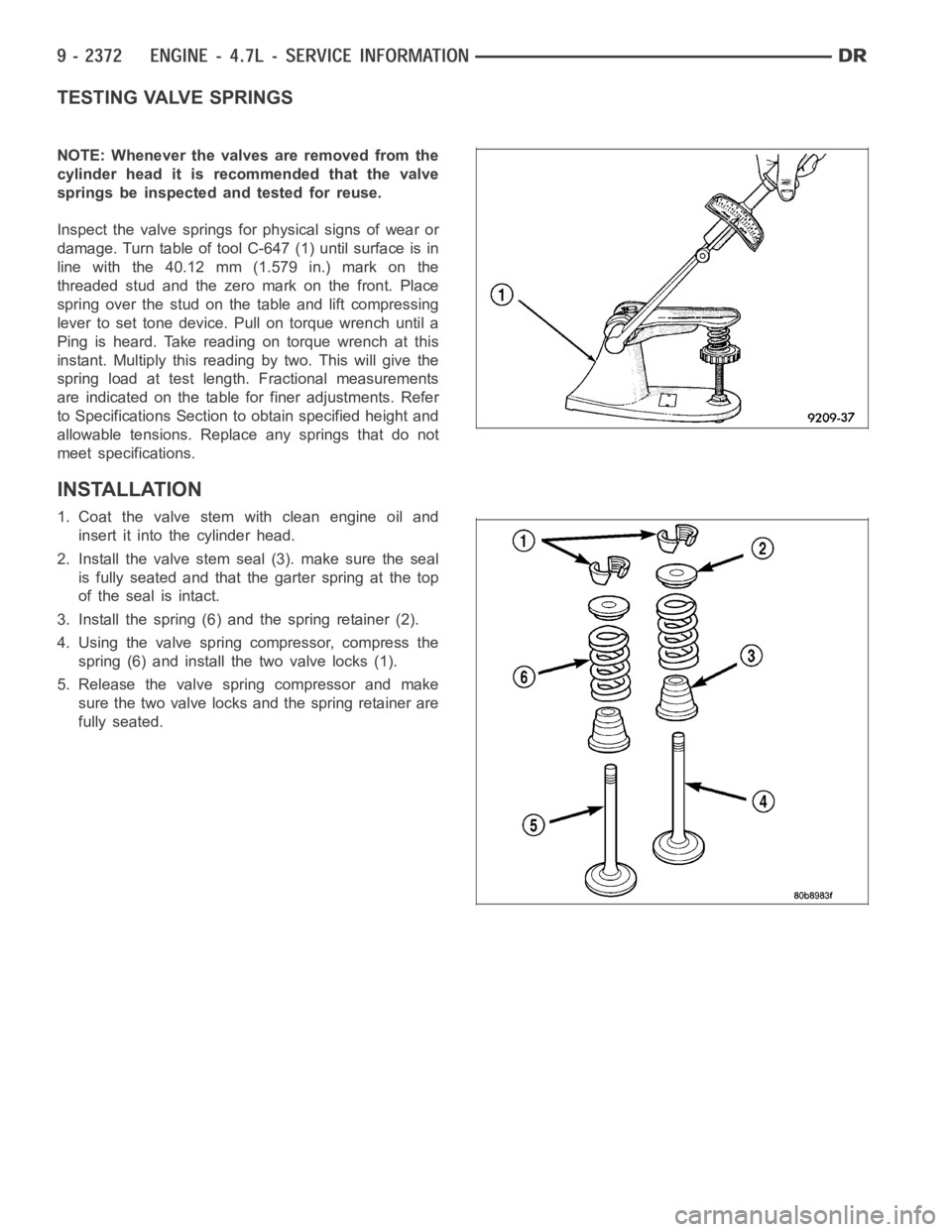

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear or

damage. Turn table of tool C-647 (1) until surface is in

line with the 40.12 mm (1.579 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over the stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until a

Ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give the

spring load at test length. Fractional measurements

are indicated on the table for finer adjustments. Refer

to Specifications Section to obtain specified height and

allowable tensions. Replace any springs that do not

meet specifications.

INSTALLATION

1. Coat the valve stem with clean engine oil and

insert it into the cylinder head.

2. Install the valve stem seal (3). make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

3. Install the spring (6) and the spring retainer (2).

4. Using the valve spring compressor, compress the

spring (6) and install the two valve locks (1).

5. Release the valve spring compressor and make

sure the two valve locks and the spring retainer are

fully seated.