torque DODGE RAM SRT-10 2006 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1735 of 5267

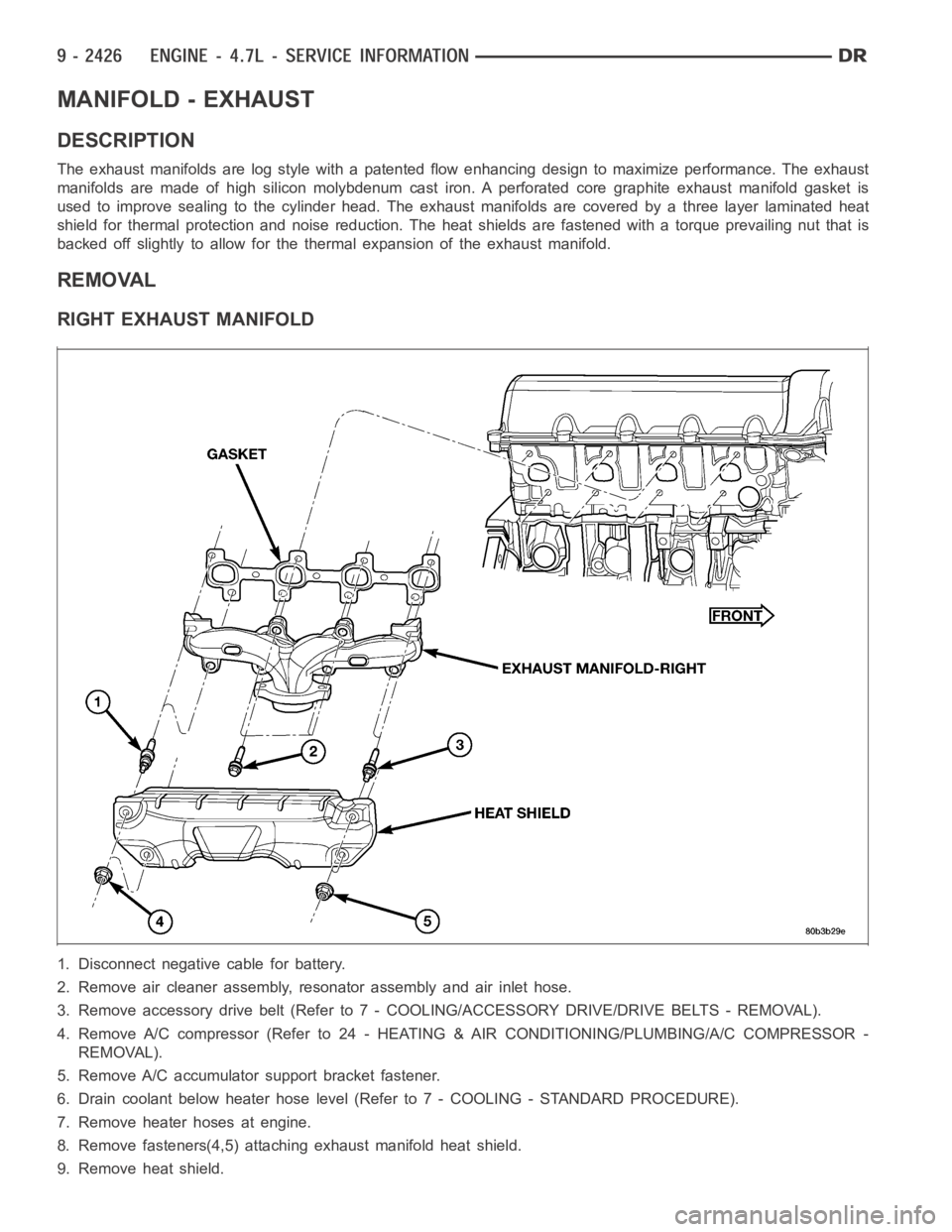

MANIFOLD - EXHAUST

DESCRIPTION

The exhaust manifolds are log style with a patented flow enhancing design to maximize performance. The exhaust

manifolds are made of high silicon molybdenum cast iron. A perforated coregraphite exhaust manifold gasket is

used to improve sealing to the cylinder head. The exhaust manifolds are covered by a three layer laminated heat

shield for thermal protection and noise reduction. The heat shields are fastened with a torque prevailing nut that is

backed off slightly to allow for the thermal expansion of the exhaust manifold.

REMOVAL

RIGHT EXHAUST MANIFOLD

1. Disconnect negative cable for battery.

2. Remove air cleaner assembly, resonator assembly and air inlet hose.

3. Remove accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

4. Remove A/C compressor (Refer to 24 -HEATING & AIR CONDITIONING/PLUMBING/A/C COMPRESSOR -

REMOVAL).

5. Remove A/C accumulator support bracket fastener.

6. Drain coolant below heater hose level (Refer to 7 - COOLING - STANDARD PROCEDURE).

7. Remove heater hoses at engine.

8. Remove fasteners(4,5) attaching exhaust manifold heat shield.

9. Remove heat shield.

Page 1743 of 5267

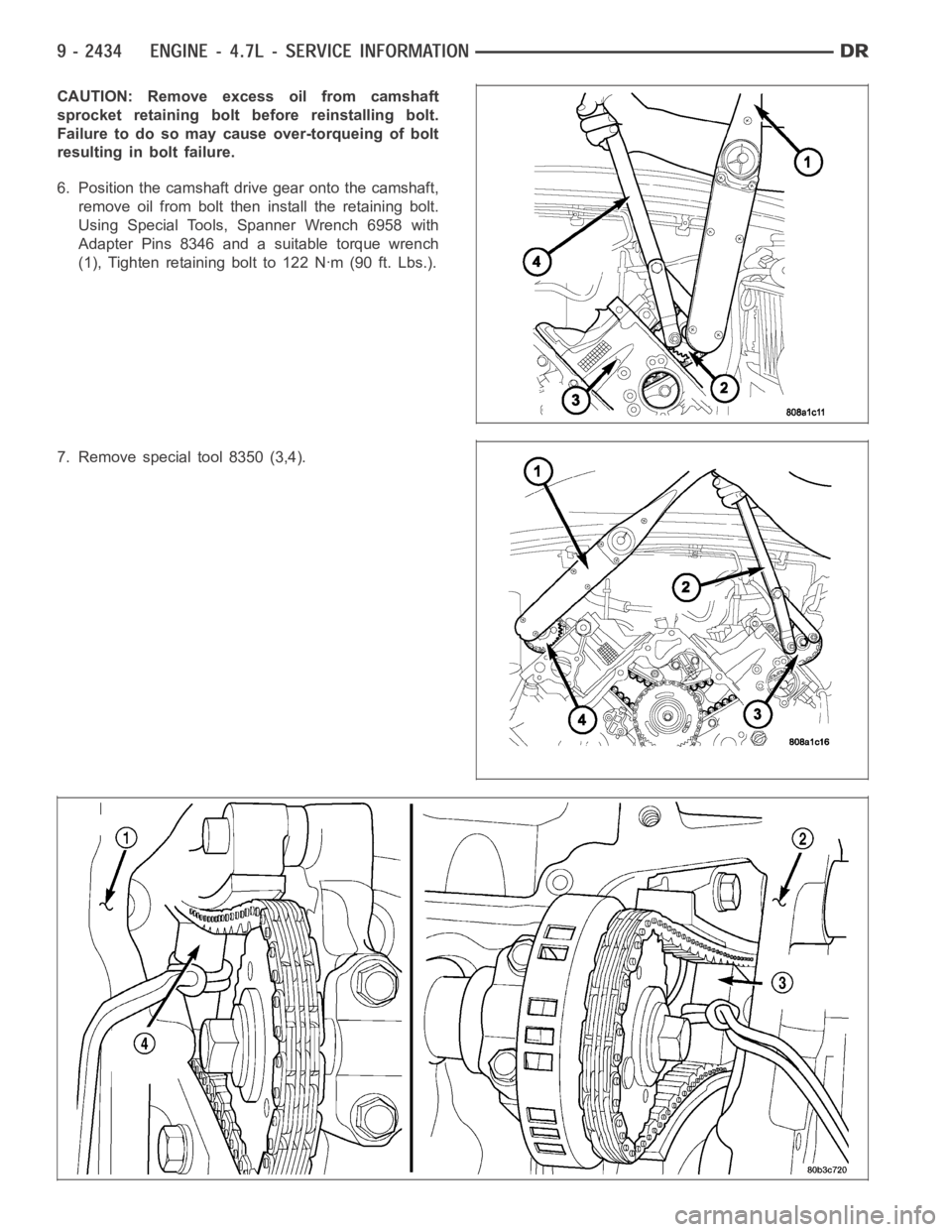

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt.

Failure to do so may cause over-torqueing of bolt

resulting in bolt failure.

6. Position the camshaft drive gear onto the camshaft,

remove oil from bolt then install the retaining bolt.

Using Special Tools, Spanner Wrench 6958 with

Adapter Pins 8346 and a suitable torque wrench

(1), Tighten retaining bolt to 122 Nꞏm (90 ft. Lbs.).

7. Remove special tool 8350 (3,4).

Page 1751 of 5267

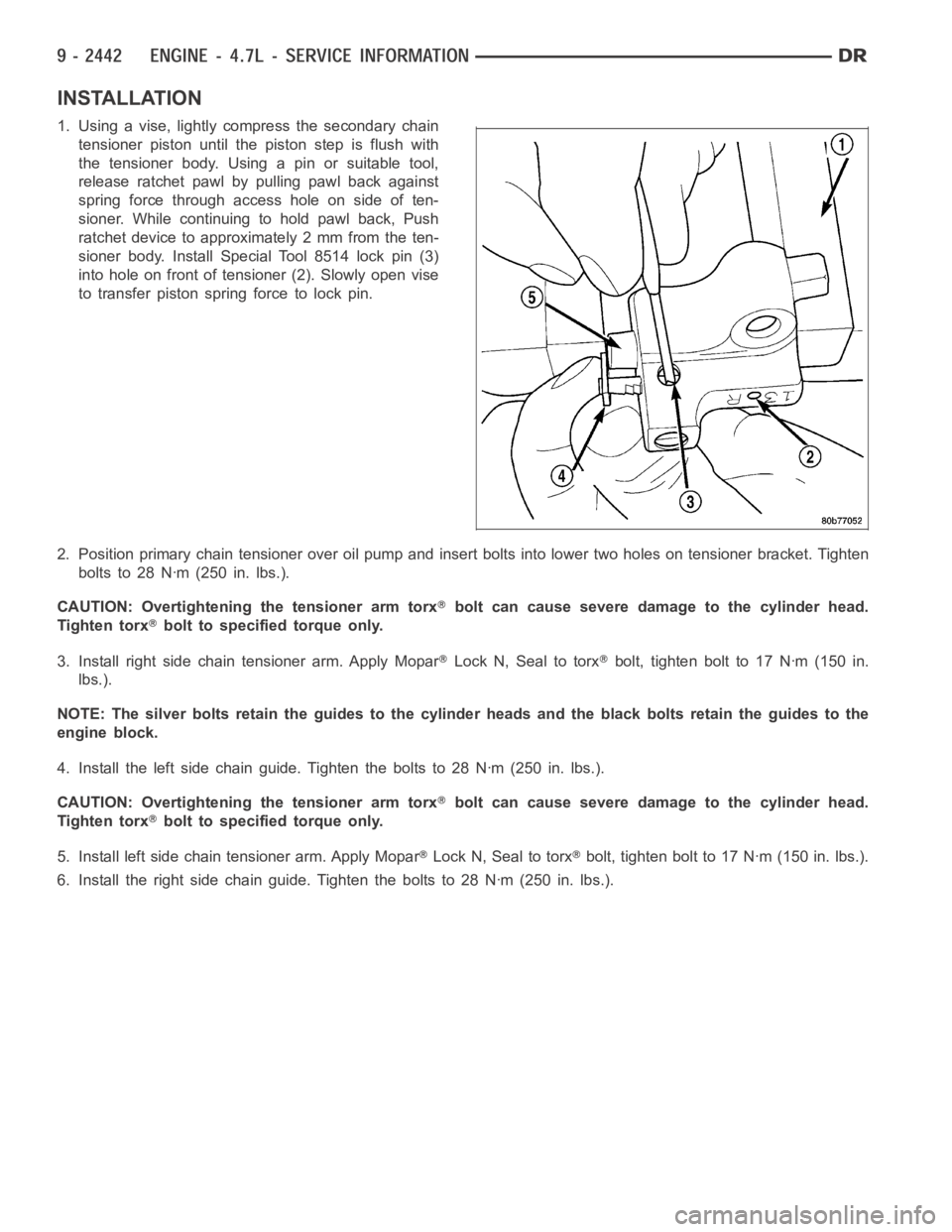

INSTALLATION

1. Using a vise, lightly compress the secondary chain

tensioner piston until the piston step is flush with

the tensioner body. Using a pin or suitable tool,

release ratchet pawl by pulling pawl back against

spring force through access hole on side of ten-

sioner. While continuing to hold pawl back, Push

ratchet device to approximately 2 mm from the ten-

sioner body. Install Special Tool 8514 lock pin (3)

into hole on front of tensioner (2). Slowly open vise

to transfer piston spring force to lock pin.

2. Position primary chain tensioner over oil pump and insert bolts into lower two holes on tensioner bracket. Tighten

bolts to 28 Nꞏm (250 in. lbs.).

CAUTION: Overtightening the tensioner arm torx

bolt can cause severe damage to the cylinder head.

Tighten torx

bolt to specified torque only.

3. Install right side chain tensioner arm. Apply Mopar

Lock N, Seal to torxbolt, tighten bolt to 17 Nꞏm (150 in.

lbs.).

NOTE: The silver bolts retain the guides to the cylinder heads and the blackbolts retain the guides to the

engine block.

4. Install the left side chain guide. Tighten the bolts to 28 Nꞏm (250 in. lbs.).

CAUTION: Overtightening the tensioner arm torx

bolt can cause severe damage to the cylinder head.

Tighten torx

bolt to specified torque only.

5. Install left side chain tensioner arm. Apply Mopar

Lock N, Seal to torxbolt, tighten bolt to 17 Nꞏm (150 in. lbs.).

6. Install the right side chain guide. Tighten the bolts to 28 Nꞏm (250 in. lbs.).

Page 1752 of 5267

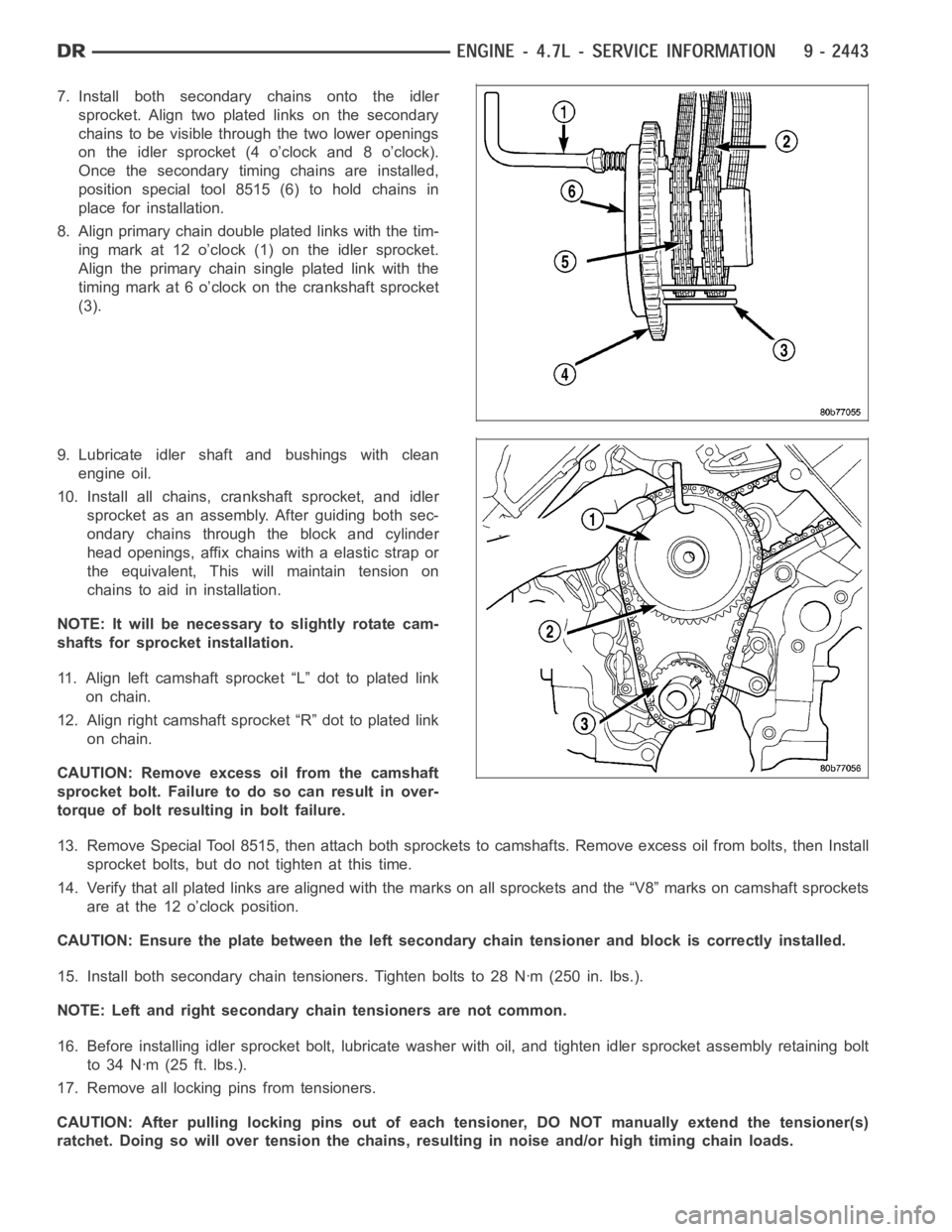

7. Install both secondary chains onto the idler

sprocket. Align two plated links on the secondary

chains to be visible through the two lower openings

on the idler sprocket (4 o’clock and 8 o’clock).

Once the secondary timing chains are installed,

position special tool 8515 (6) to hold chains in

place for installation.

8. Align primary chain double plated links with the tim-

ingmarkat12o’clock(1)ontheidlersprocket.

Align the primary chain single plated link with the

timing mark at 6 o’clock on the crankshaft sprocket

(3).

9. Lubricate idler shaft and bushings with clean

engine oil.

10. Install all chains, crankshaft sprocket, and idler

sprocket as an assembly. After guiding both sec-

ondary chains through the block and cylinder

head openings, affix chains with a elastic strap or

the equivalent, This will maintain tension on

chains to aid in installation.

NOTE: It will be necessary to slightly rotate cam-

shafts for sprocket installation.

11. Align left camshaft sprocket “L” dot to plated link

on chain.

12. Align right camshaft sprocket “R” dot to plated link

on chain.

CAUTION: Remove excess oil from the camshaft

sprocket bolt. Failure to do so can result in over-

torque of bolt resulting in bolt failure.

13. Remove Special Tool 8515, then attach both sprockets to camshafts. Remove excess oil from bolts, then Install

sprocket bolts, but do not tighten at this time.

14. Verify that all plated links are aligned with the marks on all sprocketsand the “V8” marks on camshaft sprockets

are at the 12 o’clock position.

CAUTION: Ensure the plate between the left secondary chain tensioner and block is correctly installed.

15. Install both secondary chain tensioners. Tighten bolts to 28 Nꞏm (250 in. lbs.).

NOTE: Left and right secondary chain tensioners are not common.

16. Before installing idler sprocketbolt, lubricate washer with oil, andtighten idler sprocket assembly retaining bolt

to 34 Nꞏm (25 ft. lbs.).

17. Remove all locking pins from tensioners.

CAUTION: After pulling locking pins out of each tensioner, DO NOT manuallyextend the tensioner(s)

ratchet. Doing so will over tension thechains, resulting in noise and/or high timing chain loads.

Page 1756 of 5267

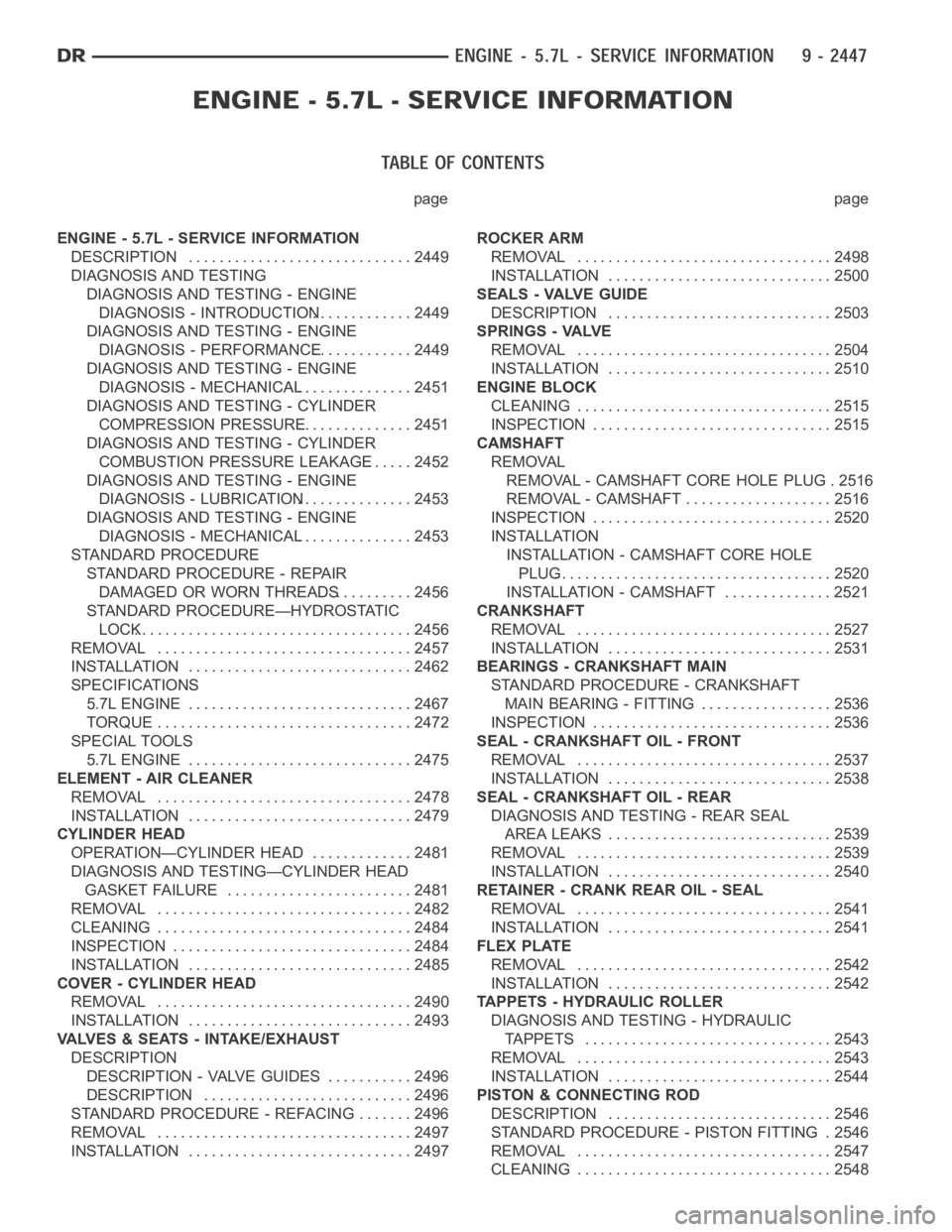

page page

ENGINE - 5.7L - SERVICE INFORMATION

DESCRIPTION ............................. 2449

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION............. 2449

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............. 2449

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL............... 2451

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE............... 2451

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE...... 2452

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - LUBRICATION............... 2453

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL............... 2453

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS.......... 2456

STANDARD PROCEDURE—HYDROSTATIC

LOCK.................................... 2456

REMOVAL ................................. 2457

INSTALLATION ............................. 2462

SPECIFICATIONS

5.7L ENGINE ............................. 2467

TORQUE ................................. 2472

SPECIAL TOOLS

5.7L ENGINE ............................. 2475

ELEMENT - AIR CLEANER

REMOVAL ................................. 2478

INSTALLATION ............................. 2479

CYLINDER HEAD

OPERATION—CYLINDER HEAD ............. 2481

DIAGNOSIS AND TESTING—CYLINDER HEAD

GASKET FAILURE........................ 2481

REMOVAL ................................. 2482

CLEANING ................................. 2484

INSPECTION ............................... 2484

INSTALLATION ............................. 2485

COVER - CYLINDER HEAD

REMOVAL ................................. 2490

INSTALLATION ............................. 2493

VALVES & SEATS - INTAKE/EXHAUST

DESCRIPTION

DESCRIPTION - VALVE GUIDES ........... 2496

DESCRIPTION ........................... 2496

STANDARD PROCEDURE - REFACING ....... 2496

REMOVAL ................................. 2497

INSTALLATION ............................. 2497ROCKER ARM

REMOVAL ................................. 2498

INSTALLATION ............................. 2500

SEALS - VALVE GUIDE

DESCRIPTION ............................. 2503

SPRINGS - VALVE

REMOVAL ................................. 2504

INSTALLATION ............................. 2510

ENGINE BLOCK

CLEANING ................................. 2515

INSPECTION............................... 2515

CAMSHAFT

REMOVAL

REMOVAL - CAMSHAFT CORE HOLE PLUG . 2516

REMOVAL - CAMSHAFT ................... 2516

INSPECTION............................... 2520

INSTALLATION

INSTALLATION - CAMSHAFT CORE HOLE

PLUG.................................... 2520

INSTALLATION - CAMSHAFT .............. 2521

CRANKSHAFT

REMOVAL ................................. 2527

INSTALLATION ............................. 2531

BEARINGS - CRANKSHAFT MAIN

STANDARD PROCEDURE - CRANKSHAFT

MAIN BEARING - FITTING ................. 2536

INSPECTION............................... 2536

SEAL - CRANKSHAFT OIL - FRONT

REMOVAL ................................. 2537

INSTALLATION ............................. 2538

SEAL - CRANKSHAFT OIL - REAR

DIAGNOSIS AND TESTING - REAR SEAL

AREA LEAKS . ............................ 2539

REMOVAL ................................. 2539

INSTALLATION ............................. 2540

RETAINER - CRANK REAR OIL - SEAL

REMOVAL ................................. 2541

INSTALLATION ............................. 2541

FLEX PLATE

REMOVAL ................................. 2542

INSTALLATION ............................. 2542

TAPPETS - HYDRAULIC ROLLER

DIAGNOSIS AND TESTING - HYDRAULIC

TAPPETS ................................ 2543

REMOVAL ................................. 2543

INSTALLATION ............................. 2544

PISTON & CONNECTING ROD

DESCRIPTION ............................. 2546

STANDARD PROCEDURE - PISTON FITTING . 2546

REMOVAL ................................. 2547

CLEANING ................................. 2548

Page 1760 of 5267

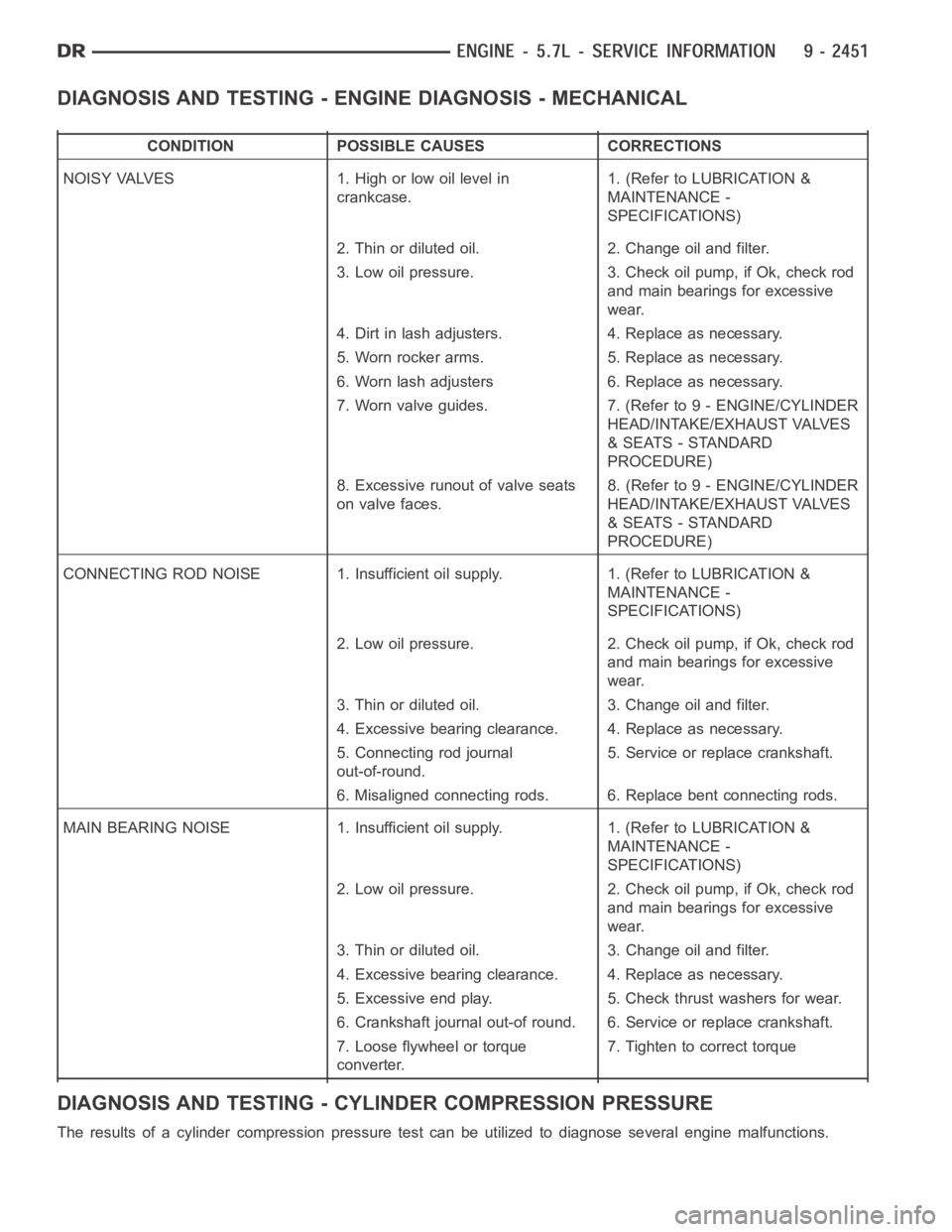

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in

crankcase.1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

4. Dirt in lash adjusters. 4. Replace as necessary.

5. Worn rocker arms. 5. Replace as necessary.

6. Worn lash adjusters 6. Replace as necessary.

7. Worn valve guides. 7. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE)

8. Excessive runout of valve seats

on valve faces.8. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE)

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION&

MAINTENANCE -

SPECIFICATIONS)

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal

out-of-round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check thrust washers for wear.

6. Crankshaft journal out-of round. 6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.7. Tighten to correct torque

DIAGNOSIS AND TESTING - CYLINDER COMPRESSION PRESSURE

The results of a cylinder compressionpressure test can be utilized to diagnose several engine malfunctions.

Page 1764 of 5267

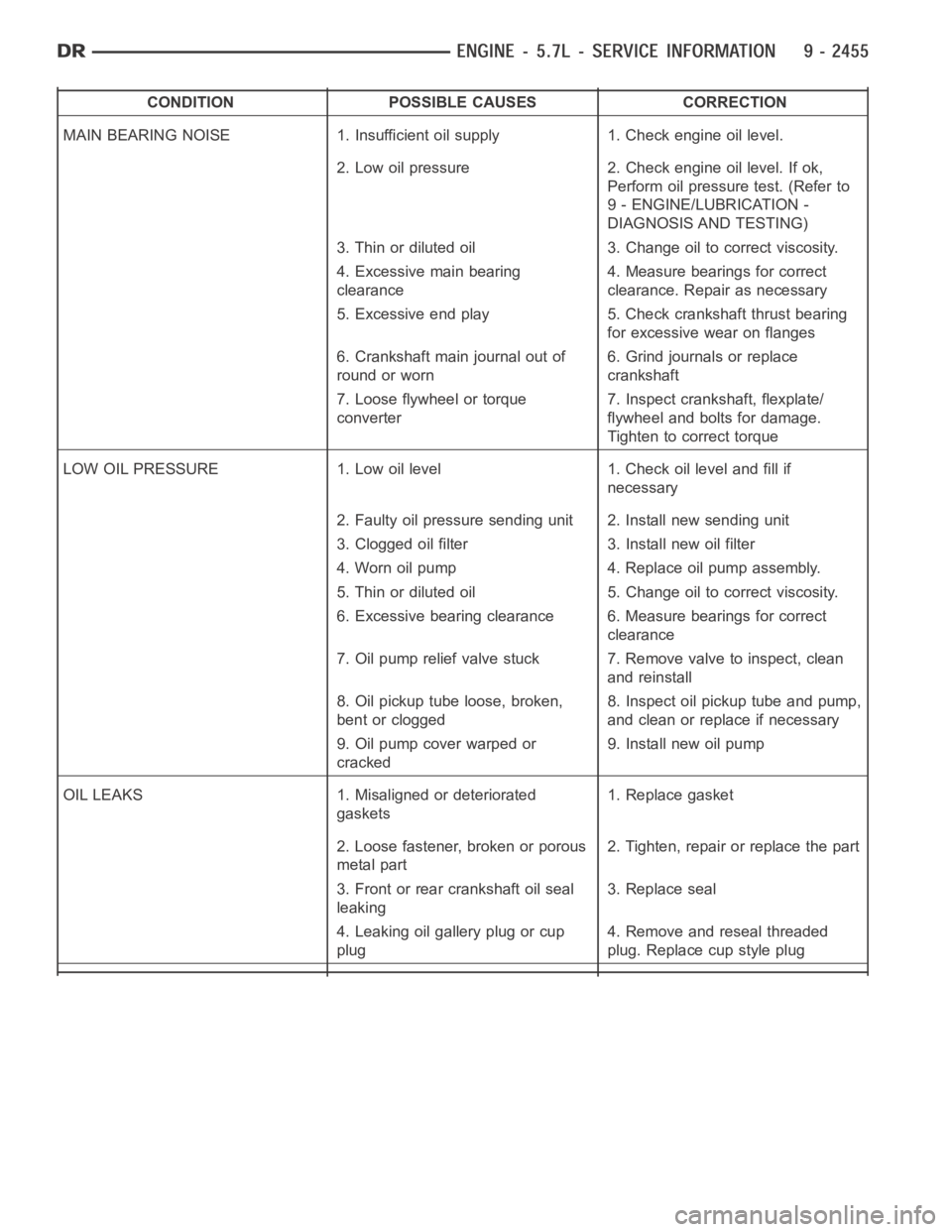

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply 1. Check engine oil level.

2. Low oil pressure 2. Check engine oil level. If ok,

Perform oil pressure test. (Refer to

9 - ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING)

3. Thin or diluted oil 3. Change oil to correct viscosity.

4. Excessive main bearing

clearance4. Measure bearings for correct

clearance. Repair as necessary

5. Excessive end play 5. Check crankshaft thrust bearing

for excessive wear on flanges

6. Crankshaft main journal out of

round or worn6. Grind journals or replace

crankshaft

7. Loose flywheel or torque

converter7. Inspect crankshaft, flexplate/

flywheel and bolts for damage.

Tighten to correct torque

LOW OIL PRESSURE 1. Low oil level 1. Check oil level and fill if

necessary

2. Faulty oil pressure sending unit 2. Install new sending unit

3. Clogged oil filter 3. Install new oil filter

4. Worn oil pump 4. Replace oil pump assembly.

5. Thin or diluted oil 5. Change oil to correct viscosity.

6. Excessive bearing clearance 6. Measure bearings for correct

clearance

7. Oil pump relief valve stuck 7. Remove valve to inspect, clean

and reinstall

8. Oil pickup tube loose, broken,

bent or clogged8. Inspect oil pickup tube and pump,

and clean or replace if necessary

9. Oil pump cover warped or

cracked9. Install new oil pump

OIL LEAKS 1. Misaligned or deteriorated

gaskets1. Replace gasket

2. Loose fastener, broken or porous

metal part2. Tighten, repair or replace the part

3. Front or rear crankshaft oil seal

leaking3. Replace seal

4. Leaking oil gallery plug or cup

plug4. Remove and reseal threaded

plug. Replace cup style plug

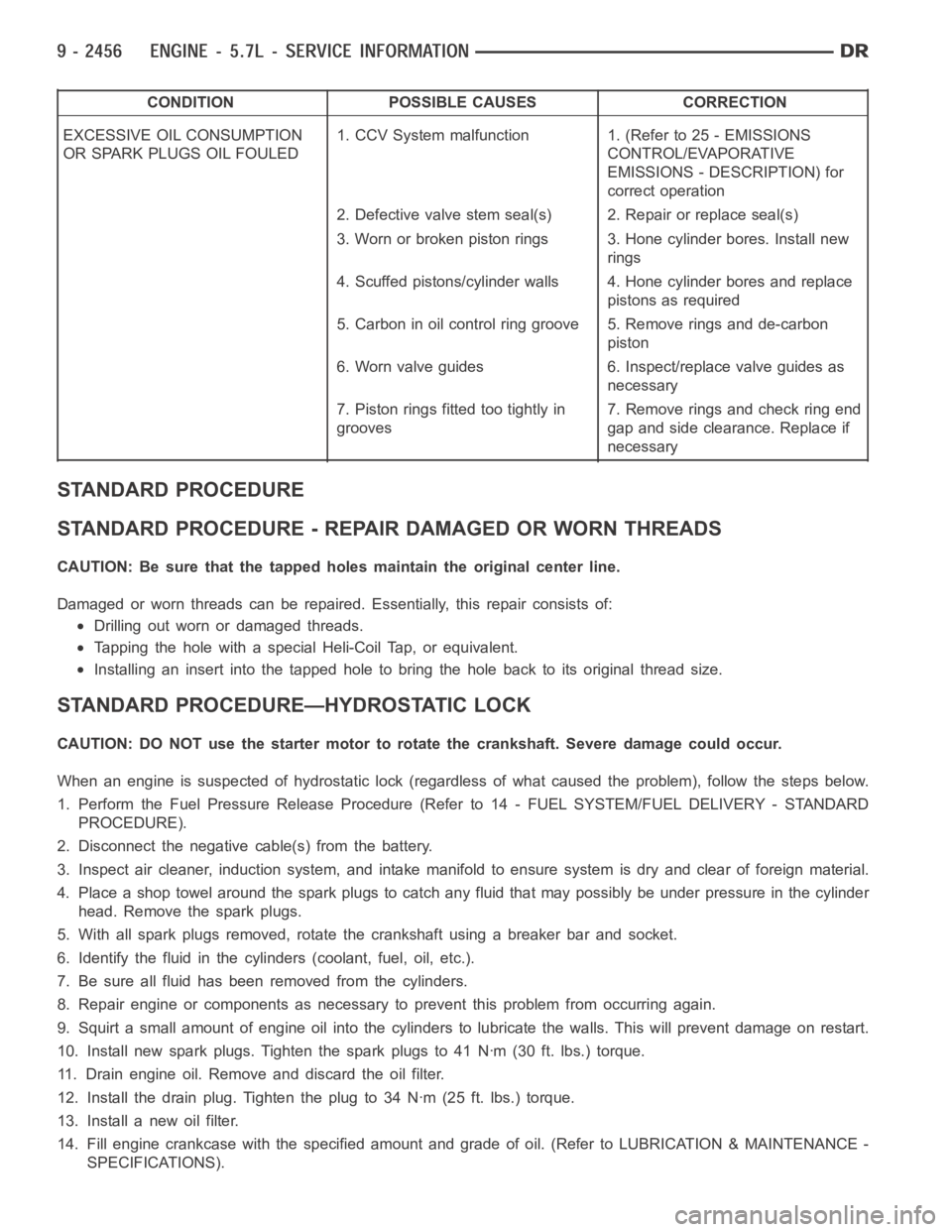

Page 1765 of 5267

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE OIL CONSUMPTION

OR SPARK PLUGS OIL FOULED1. CCV System malfunction 1. (Refer to 25 - EMISSIONS

CONTROL/EVAPORATIVE

EMISSIONS - DESCRIPTION) for

correct operation

2. Defective valve stem seal(s) 2. Repair or replace seal(s)

3. Worn or broken piston rings 3. Hone cylinder bores. Install new

rings

4. Scuffed pistons/cylinder walls 4. Hone cylinder bores and replace

pistons as required

5. Carbon in oil control ring groove 5. Remove rings and de-carbon

piston

6. Worn valve guides 6. Inspect/replace valve guides as

necessary

7. Piston rings fitted too tightly in

grooves7. Remove rings and check ring end

gap and side clearance. Replace if

necessary

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain the original center line.

Damaged or worn threads can be repaired. Essentially, this repair consistsof:

Drilling out worn or damaged threads.

Tapping the hole with a special Heli-Coil Tap, or equivalent.

Installing an insert into the tapped hole to bring the hole back to its original thread size.

STANDARD PROCEDURE—HYDROSTATIC LOCK

CAUTION: DO NOT use the starter motor to rotate the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock (regardless of what causedthe problem), follow the steps below.

1. Perform the Fuel Pressure Release Procedure (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE).

2. Disconnect the negative cable(s) from the battery.

3. Inspect air cleaner, induction system, and intake manifold to ensure system is dry and clear of foreign material.

4. Place a shop towel around the spark plugs to catch any fluid that may possibly be under pressure in the cylinder

head. Remove the spark plugs.

5. With all spark plugs removed, rotate the crankshaft using a breaker bar and socket.

6. Identify the fluid in the cylinders (coolant, fuel, oil, etc.).

7. Be sure all fluid has been removed from the cylinders.

8. Repair engine or components as necessary to prevent this problem from occurring again.

9. Squirt a small amount of engine oil into the cylinders to lubricate the walls. This will prevent damage on restart.

10. Install new spark plugs. Tighten the spark plugs to 41 Nꞏm (30 ft. lbs.) torque.

11. Drain engine oil. Remove and discard the oil filter.

12. Install the drain plug. Tighten the plug to 34 Nꞏm (25 ft. lbs.) torque.

13. Install a new oil filter.

14. Fill engine crankcase with the specified amount and grade of oil. (Refer to LUBRICATION & MAINTENANCE -

SPECIFICATIONS).

Page 1772 of 5267

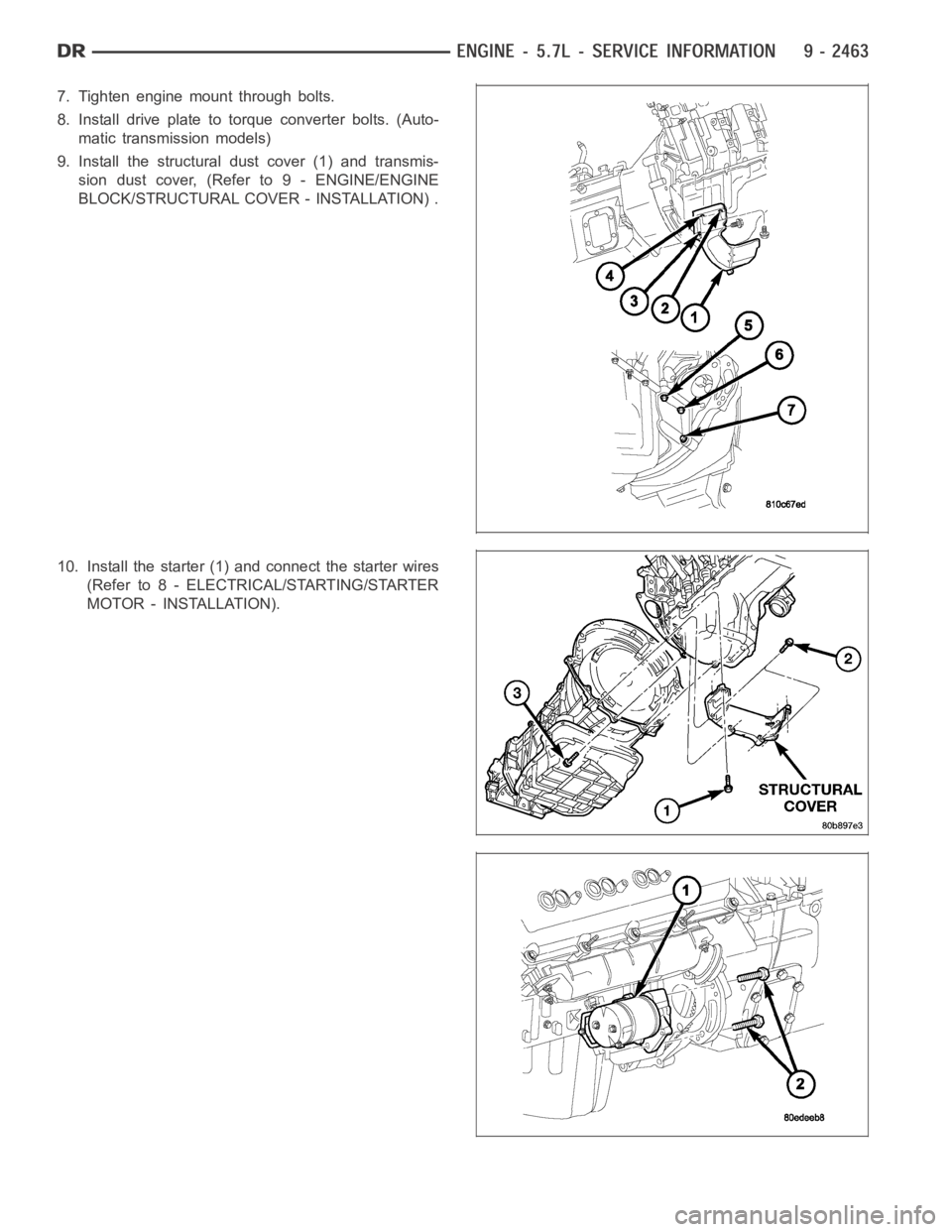

7. Tighten engine mount through bolts.

8. Install drive plate to torque converter bolts. (Auto-

matic transmission models)

9. Install the structural dust cover (1) and transmis-

sion dust cover, (Refer to 9 - ENGINE/ENGINE

BLOCK/STRUCTURAL COVER - INSTALLATION) .

10. Install the starter (1) and connect the starter wires

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION).

Page 1781 of 5267

SPECIFICATION SPECIFICATION

At Curb Idle Speed (MIN)* 25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110 psi)

* CAUTION: If pressure is zero at curb idle, DO NOT run engine

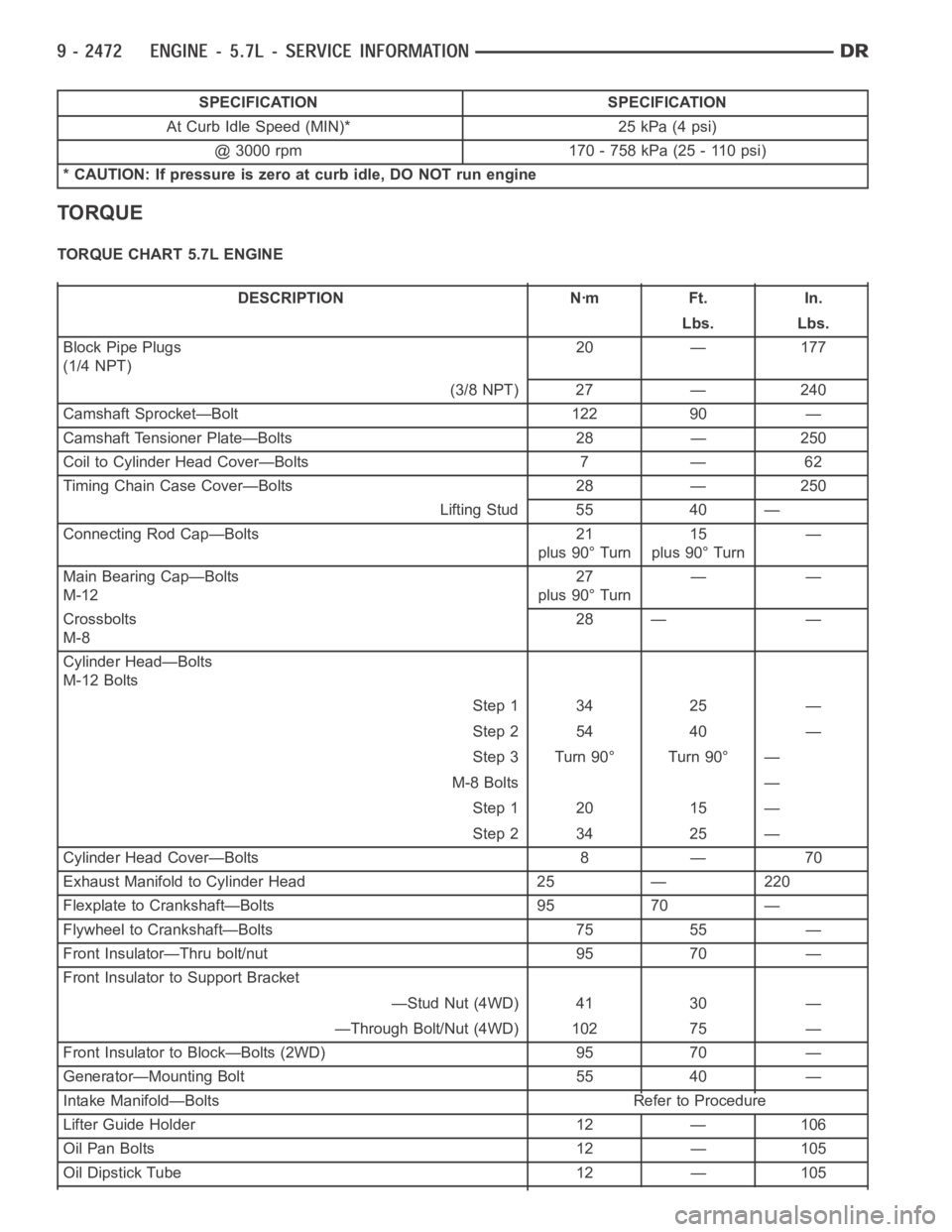

TORQUE

TORQUE CHART 5.7L ENGINE

DESCRIPTION Nꞏm Ft. In.

Lbs. Lbs.

Block Pipe Plugs

(1/4 NPT)20 — 177

(3/8 NPT) 27 — 240

Camshaft Sprocket—Bolt 122 90 —

Camshaft Tensioner Plate—Bolts 28 — 250

Coil to Cylinder Head Cover—Bolts 7 — 62

Timing Chain Case Cover—Bolts 28 — 250

Lifting Stud 55 40 —

Connecting Rod Cap—Bolts 21

plus 90° Turn15

plus 90° Turn—

Main Bearing Cap—Bolts

M-1227

plus 90° Turn——

Crossbolts

M-828 — —

Cylinder Head—Bolts

M-12 Bolts

Step 1 34 25 —

Step 2 54 40 —

Step 3 Turn 90° Turn 90° —

M-8 Bolts —

Step 1 20 15 —

Step 2 34 25 —

Cylinder Head Cover—Bolts 8 — 70

Exhaust Manifold to Cylinder Head 25 — 220

Flexplate to Crankshaft—Bolts 95 70 —

Flywheel to Crankshaft—Bolts 75 55 —

Front Insulator—Thru bolt/nut 95 70 —

Front Insulator to Support Bracket

—Stud Nut (4WD) 41 30 —

—Through Bolt/Nut (4WD) 102 75 —

Front Insulator to Block—Bolts (2WD) 95 70 —

Generator—Mounting Bolt 55 40 —

Intake Manifold—Bolts Refer to Procedure

Lifter Guide Holder 12 — 106

Oil Pan Bolts 12 — 105

Oil Dipstick Tube 12 — 105