DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 961 of 5267

Theory of Operation

The engine coolant temperature sensor is a negative temperature coefficient thermistor-type sensor whose resis-

tance varies inversely with temperature. At cold temperatures the sensorresistance is high so the voltage is high.

As the coolant temperature increases the resistance decreases and the voltage becomes low.

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts.

Set Condition:

The Engine Coolant Temperature (ECT) Signal circuit voltage at the PCM goes below 0.8 of a volt for more

than 3 seconds.

Possible Causes

(K2) ECT SIGNAL CIRCUIT SHORTED TO GROUND

(K2) ECT SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND CIRCUIT

ECT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ECT SENSOR VOLTAGE BELOW 1.0 OF A VOLT

Ignition on, engine not running.

With a scan tool, read the ECT voltage.

Is the voltage below 1.0 of a volt?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Symptom. (Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)

2.ECT SENSOR

Turn the ignition off.

Disconnect the ECT harness connector.

Ignition on, engine not running.

With a scan tool, read ECT voltage.

Is the voltage above 1.0 volt?

Ye s>>

Replace the ECT Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 962 of 5267

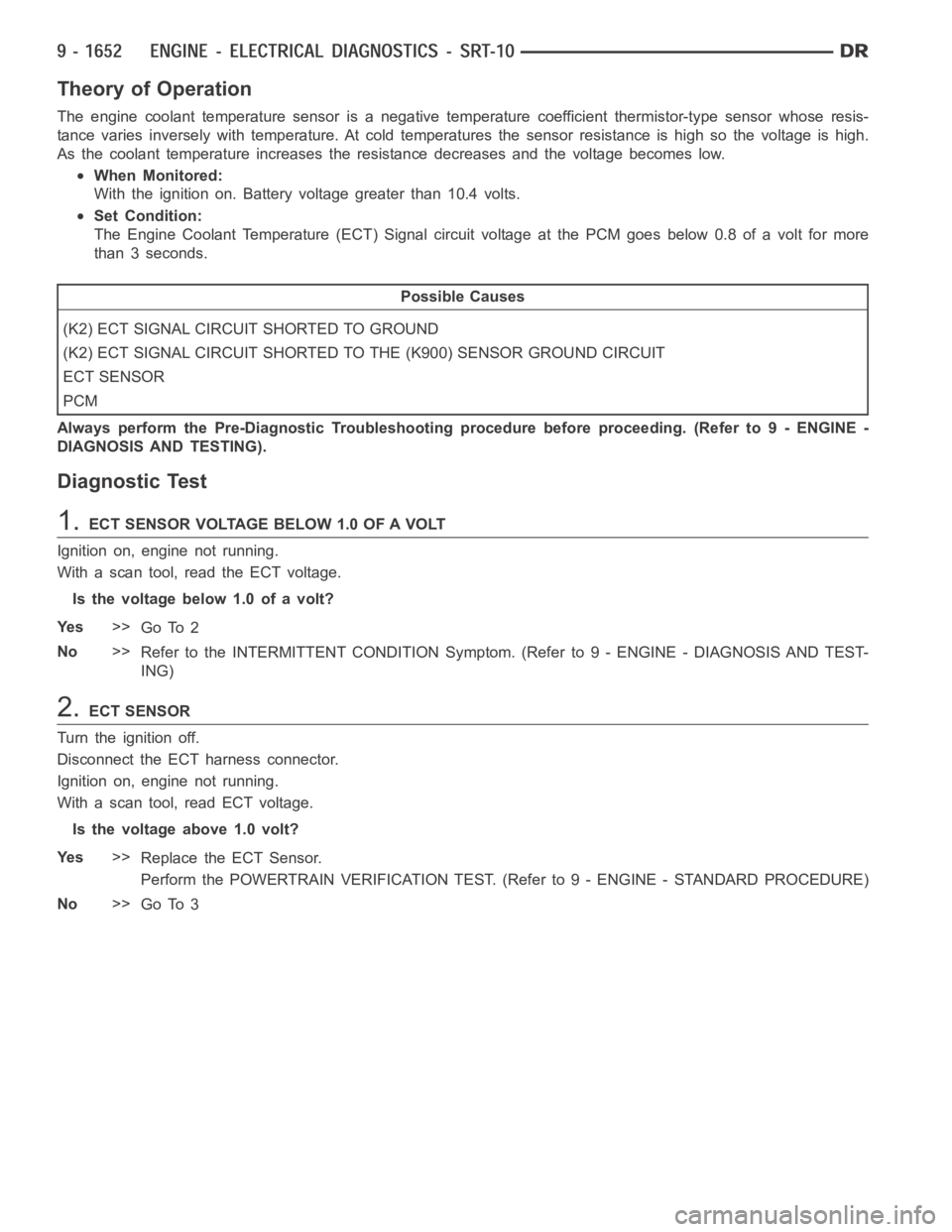

3.(K2) ECT SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND CIRCUIT

Turn the ignition off.

Disconnect the C1 PCM harness connector.

Measure the resistance between the (K900) Sensor ground circuit and

the (K2) ECT Signal circuit in the ECT Sensor harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the short to between the (K900) Sensor ground cir-

cuit and the (K2) ECT Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

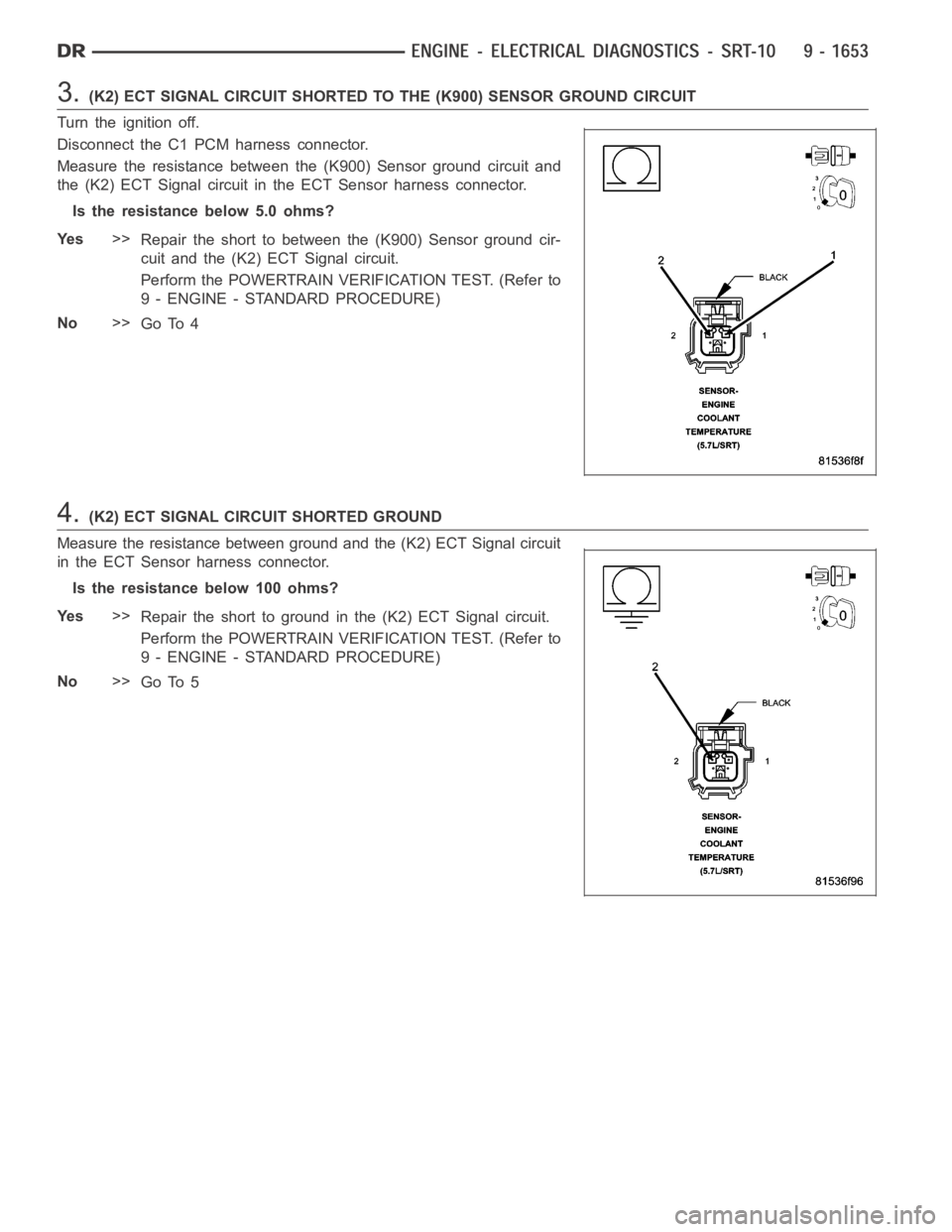

4.(K2) ECT SIGNAL CIRCUIT SHORTED GROUND

Measure the resistance between ground and the (K2) ECT Signal circuit

in the ECT Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K2) ECT Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

Page 963 of 5267

5.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 964 of 5267

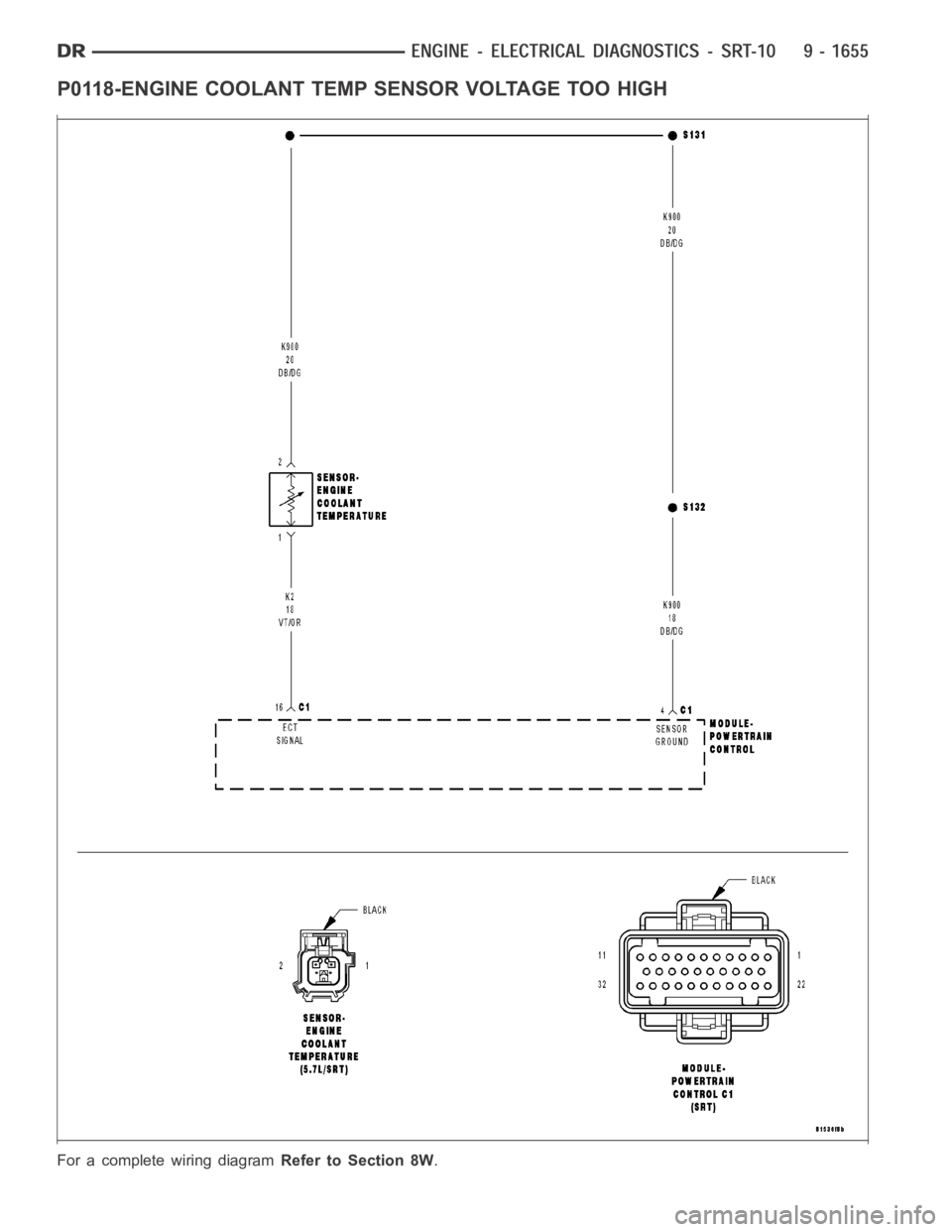

P0118-ENGINE COOLANT TEMP SENSOR VOLTAGE TOO HIGH

For a complete wiring diagramRefer to Section 8W.

Page 965 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts.

Set Condition:

The Engine Coolant Temperature (ECT) sensor circuit voltage at the PCM is greater than 4.94 volts for more

than 3.0 seconds.

Possible Causes

(K2) ECT SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(K2) ECT SIGNAL CIRCUIT OPEN

(K900) SENSOR GROUND CIRCUIT OPEN

ECT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ECT SENSOR VOLTAGE ABOVE 4.94 VOLTS

Ignition on, engine not running.

With a scan tool, read the ECT voltage.

Is the voltage above 4.94 volts?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Symptom. (Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)

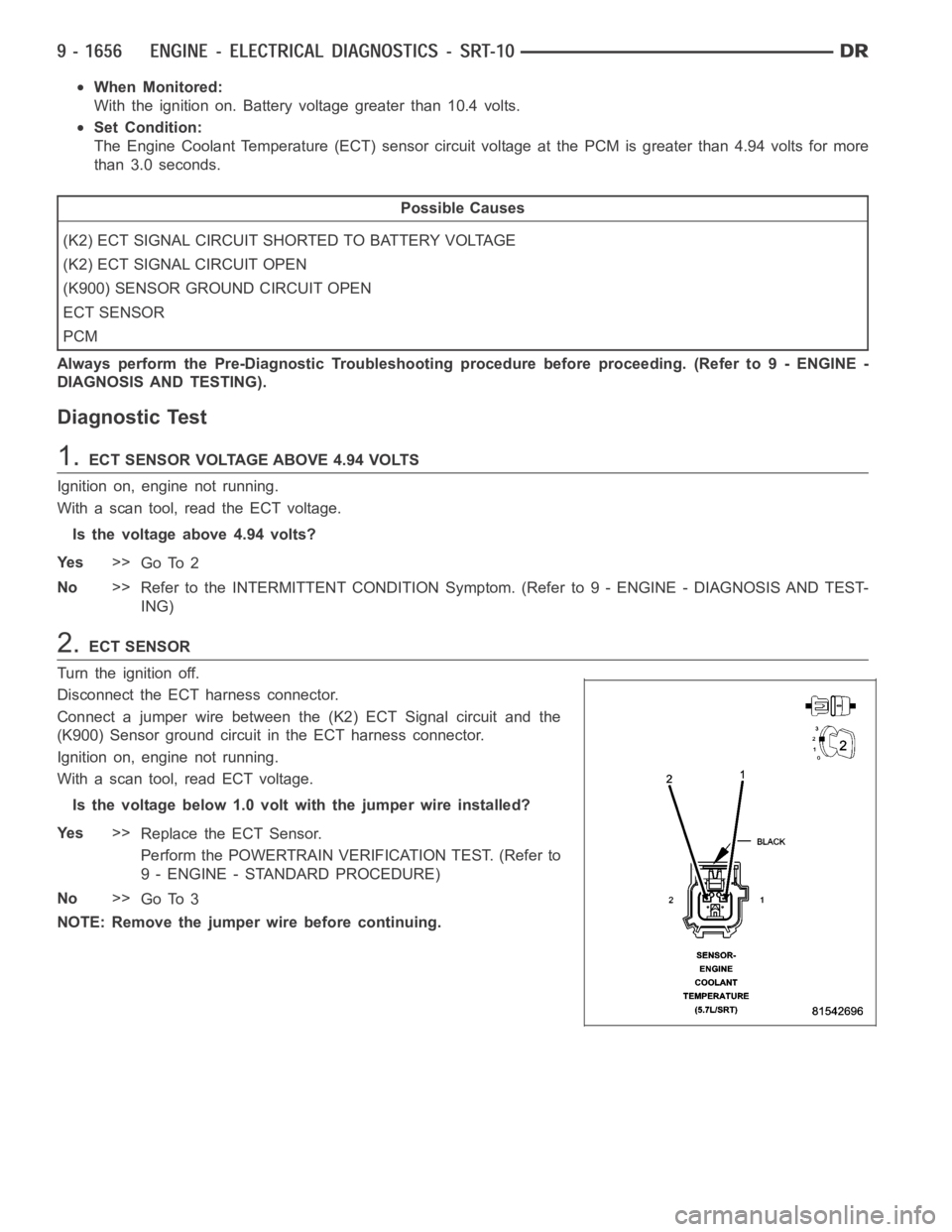

2.ECT SENSOR

Turn the ignition off.

Disconnect the ECT harness connector.

Connect a jumper wire between the (K2) ECT Signal circuit and the

(K900) Sensor ground circuit in the ECT harness connector.

Ignition on, engine not running.

With a scan tool, read ECT voltage.

Is the voltage below 1.0 volt with the jumper wire installed?

Ye s>>

Replace the ECT Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

NOTE: Remove the jumper wire before continuing.

Page 966 of 5267

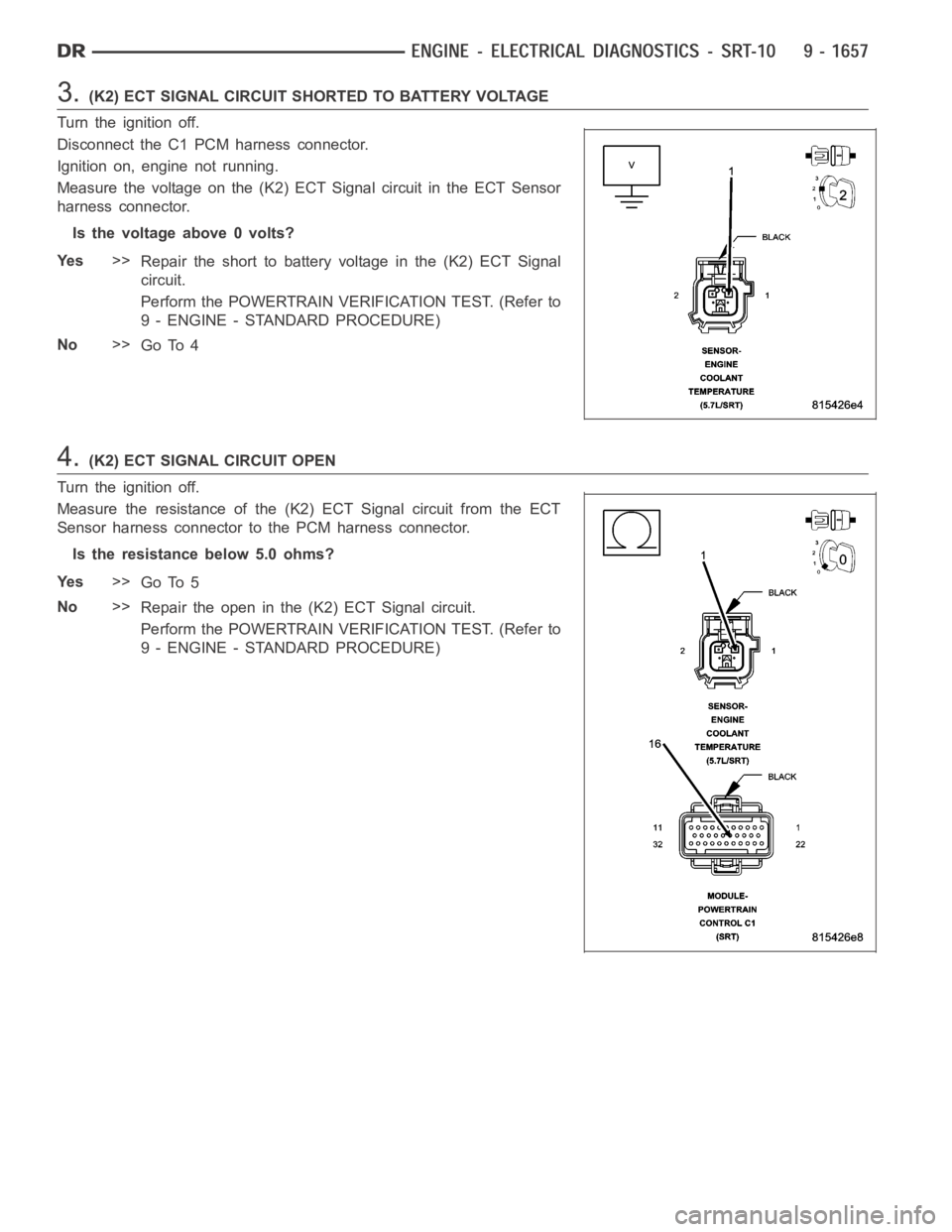

3.(K2) ECT SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the C1 PCM harness connector.

Ignition on, engine not running.

Measure the voltage on the (K2) ECT Signal circuit in the ECT Sensor

harness connector.

Is the voltage above 0 volts?

Ye s>>

Repair the short to battery voltage in the (K2) ECT Signal

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.(K2) ECT SIGNAL CIRCUIT OPEN

Turn the ignition off.

Measure the resistance of the (K2) ECT Signal circuit from the ECT

Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 5

No>>

Repair the open in the (K2) ECT Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 967 of 5267

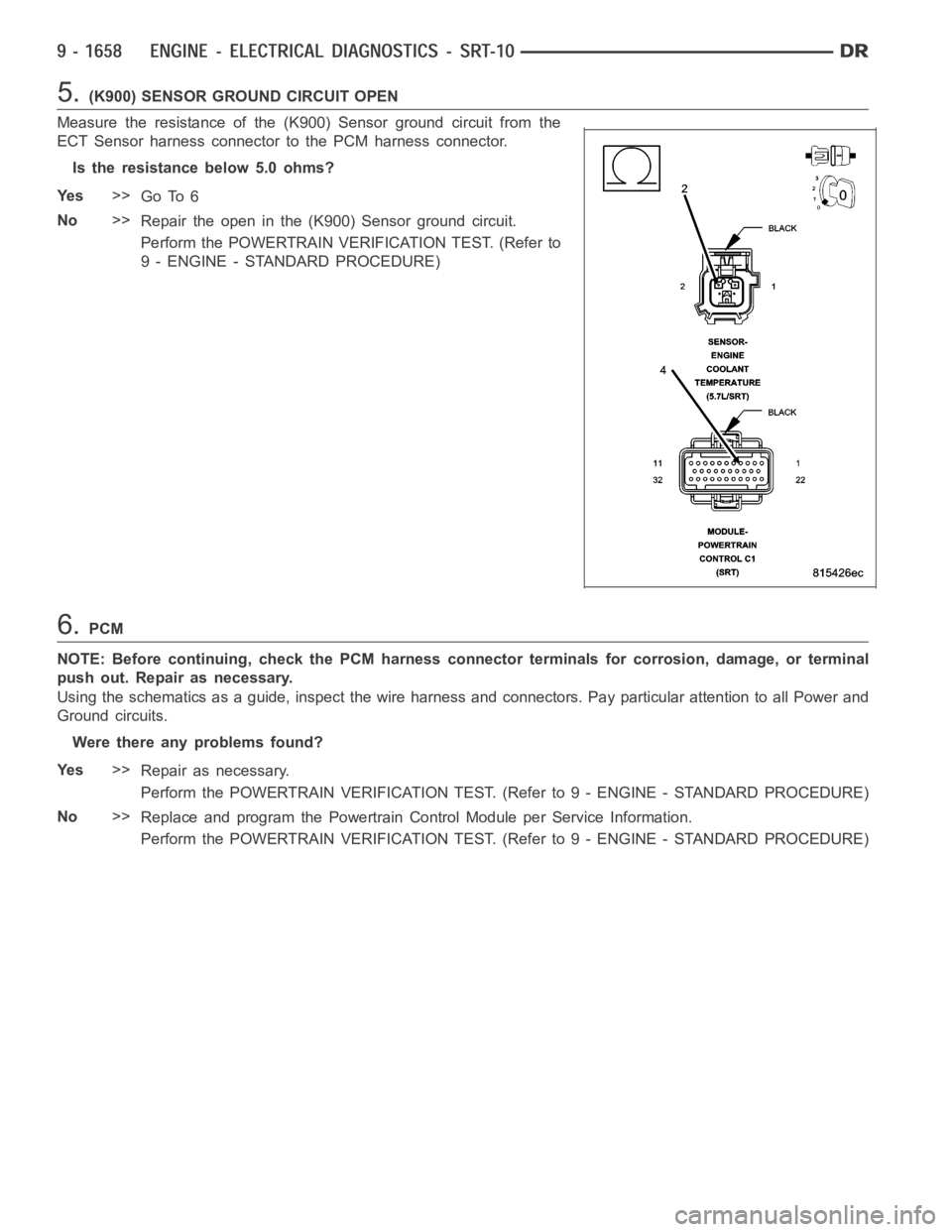

5.(K900) SENSOR GROUND CIRCUIT OPEN

Measure the resistance of the (K900) Sensor ground circuit from the

ECT Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the open in the (K900) Sensor ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

6.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 968 of 5267

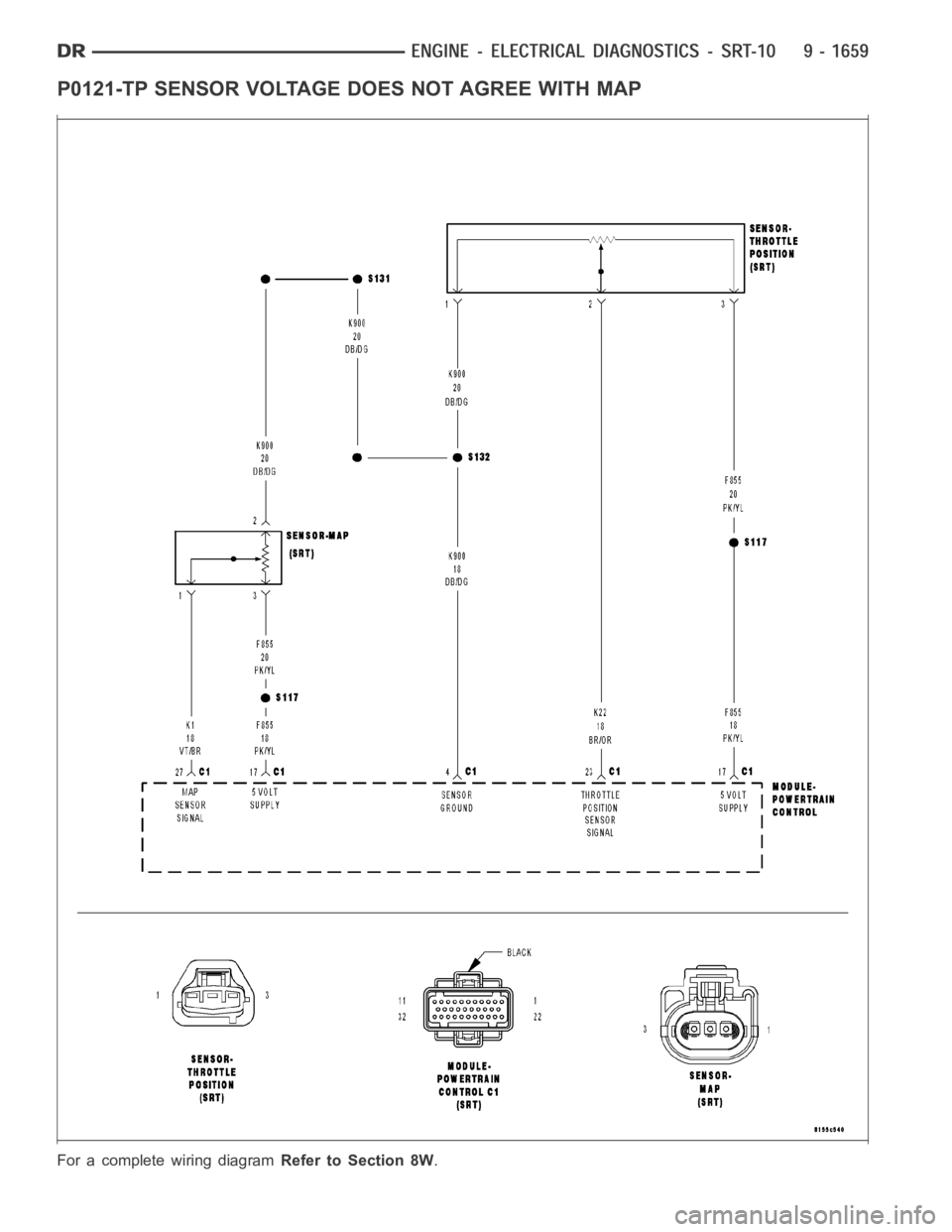

P0121-TP SENSOR VOLTAGE DOES NOT AGREE WITH MAP

For a complete wiring diagramRefer to Section 8W.

Page 969 of 5267

When Monitored:

With the engine running and no MAP Sensor or TP Sensor DTC’s set. Engine speed must be greater than

1600 RPM.

Set Condition:

The PCM performs two separate tests. When the manifold vacuum is high, the TP Sensor should be low.

When the manifold vacuum is low, the TP Sensor signal should be high. If the proper TP Sensor voltage is not

detected when the two conditions are met, a DTC will be set after 4 seconds.

Possible Causes

RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

MAP SENSOR

RESISTANCE IN THE (K1) MAP SENSOR SIGNAL CIRCUIT

(K1) MAP SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

TP SENSOR OPERATION

RESISTANCE IN THE TP SENSOR (F855) 5-VOLT SUPPLY

TP SENSOR (F855) 5-VOLT SUPPLY SHORTED TO GROUND

THROTTLE POSITION SENSOR

RESISTANCE IN THE (K22) TP SENSOR NO.1 SIGNAL CIRCUIT

RESISTANCE BETWEEN GROUND AND THE (K22) TP SENSOR NO.1 SIGNAL CIRCUIT

RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.GOOD TRIP EQUAL TO ZERO

NOTE: Diagnose any TP Sensor or MAP component DTCs first before continuing.

NOTE: If the P0500 - No Vehicle Speed Signal is set along with this DTC, referto the P0500 diagnostics

before continuing.

NOTE: The throttle plate and linkage should be free of binding and carbon build up.

NOTE: Make sure the throttle plate is at the idle position.

Ignition on, engine not running.

NOTE: Repair any vacuum leaks that are present before continuing.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 970 of 5267

2.MAP SENSOR OPERATION

Start the engine.

With the scan tool, monitor the MAP Sensor voltage.

Snap the throttle.

Does the scan tool display MAP voltage from below 2.0 volts at idle to above 3.5 volts at WOT?

Ye s>>

Go To 3

No>>

Go To 10

3.TP SENSOR OPERATION

Ignition on, engine not running.

With the scan tool, monitor the TP Sensor voltage while slowly depressing the throttle pedal from the idle position

to the wide open throttle position.

Does voltage start at approximately 0.8 of a volt and go above 3.5 volts witha smooth transition?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

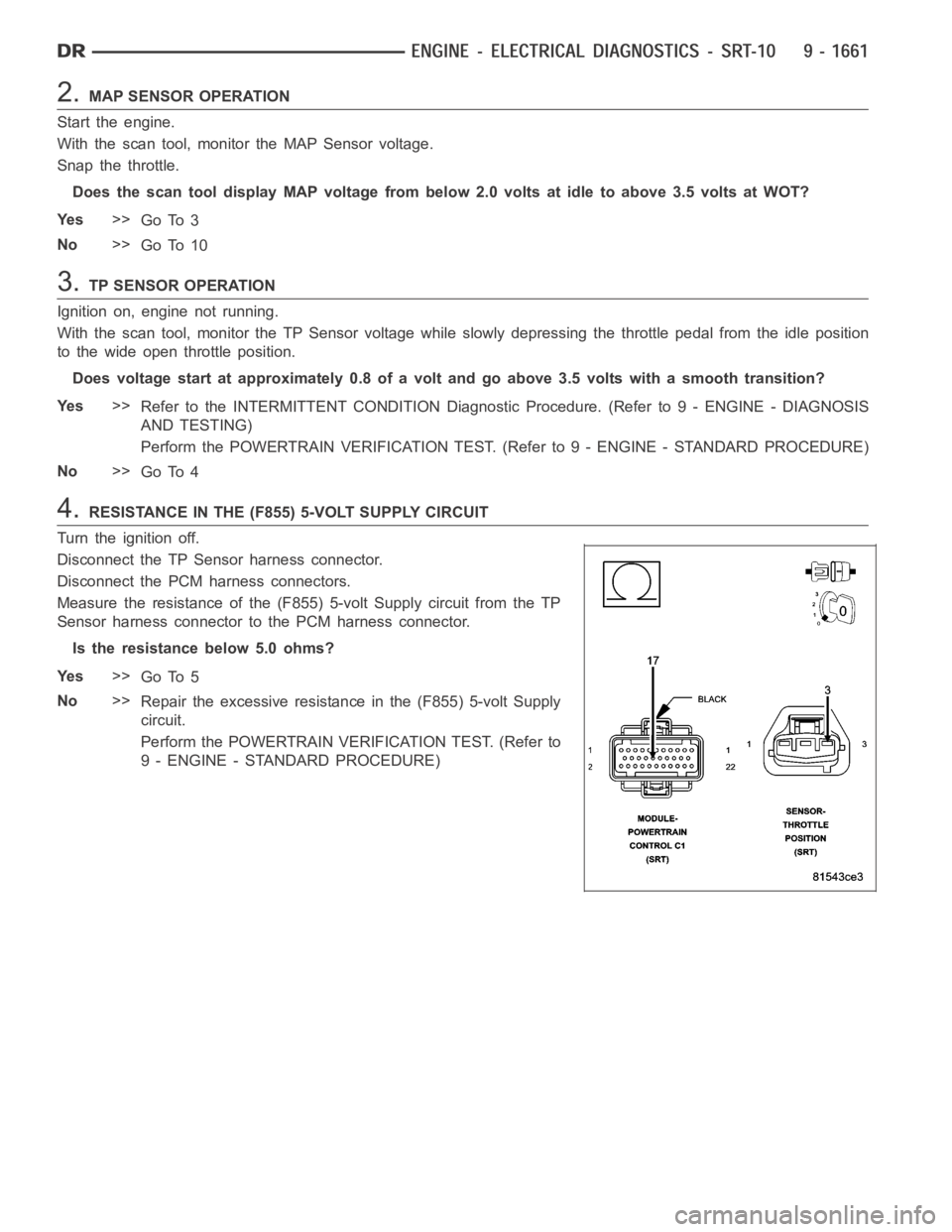

4.RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the TP Sensor harness connector.

Disconnect the PCM harness connectors.

Measure the resistance of the (F855) 5-volt Supply circuit from the TP

Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 5

No>>

Repair the excessive resistance in the (F855) 5-volt Supply

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)