DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1641 of 2321

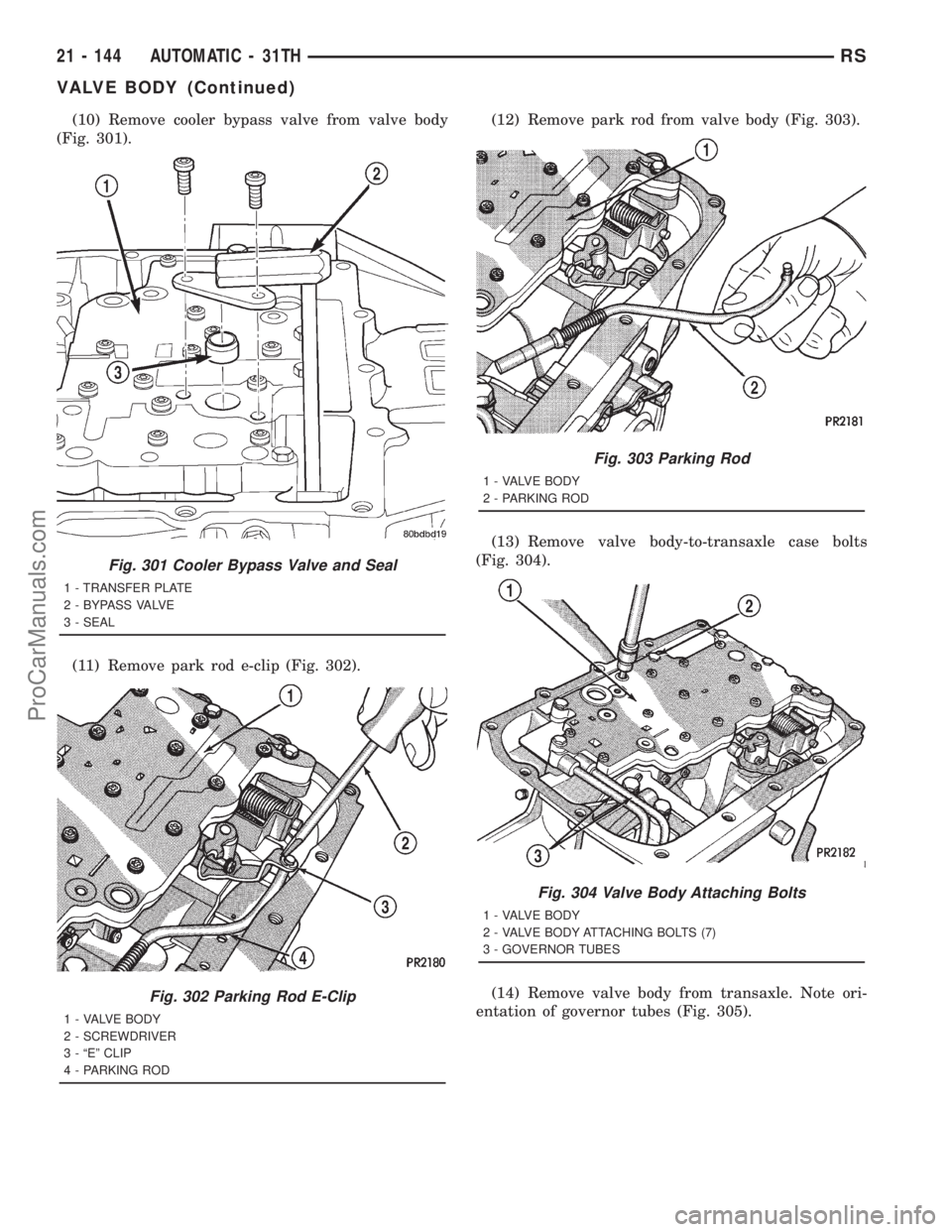

(10) Remove cooler bypass valve from valve body

(Fig. 301).

(11) Remove park rod e-clip (Fig. 302).(12) Remove park rod from valve body (Fig. 303).

(13) Remove valve body-to-transaxle case bolts

(Fig. 304).

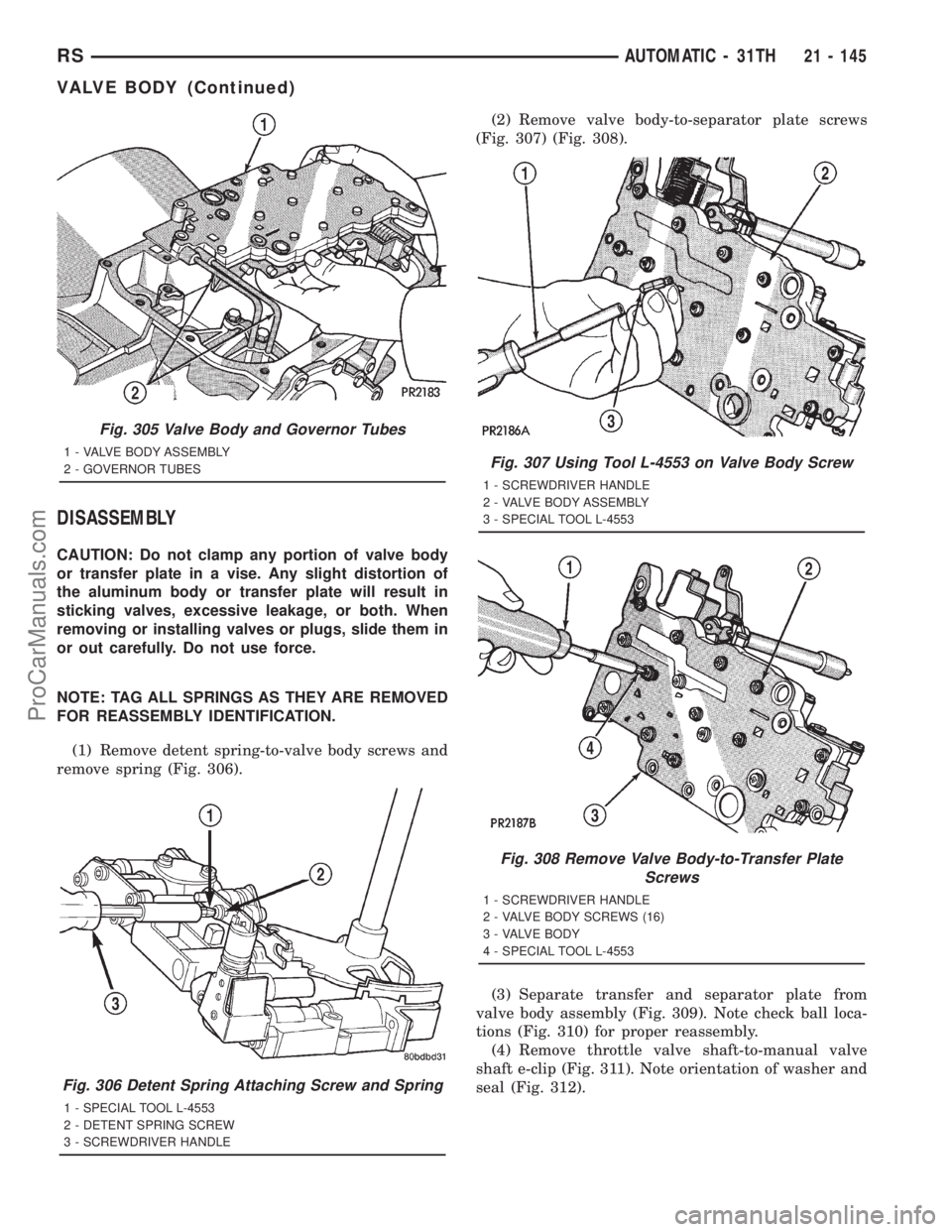

(14) Remove valve body from transaxle. Note ori-

entation of governor tubes (Fig. 305).

Fig. 301 Cooler Bypass Valve and Seal

1 - TRANSFER PLATE

2 - BYPASS VALVE

3 - SEAL

Fig. 302 Parking Rod E-Clip

1 - VALVE BODY

2 - SCREWDRIVER

3 - ªEº CLIP

4 - PARKING ROD

Fig. 303 Parking Rod

1 - VALVE BODY

2 - PARKING ROD

Fig. 304 Valve Body Attaching Bolts

1 - VALVE BODY

2 - VALVE BODY ATTACHING BOLTS (7)

3 - GOVERNOR TUBES

21 - 144 AUTOMATIC - 31THRS

VALVE BODY (Continued)

ProCarManuals.com

Page 1642 of 2321

DISASSEMBLY

CAUTION: Do not clamp any portion of valve body

or transfer plate in a vise. Any slight distortion of

the aluminum body or transfer plate will result in

sticking valves, excessive leakage, or both. When

removing or installing valves or plugs, slide them in

or out carefully. Do not use force.

NOTE: TAG ALL SPRINGS AS THEY ARE REMOVED

FOR REASSEMBLY IDENTIFICATION.

(1) Remove detent spring-to-valve body screws and

remove spring (Fig. 306).(2) Remove valve body-to-separator plate screws

(Fig. 307) (Fig. 308).

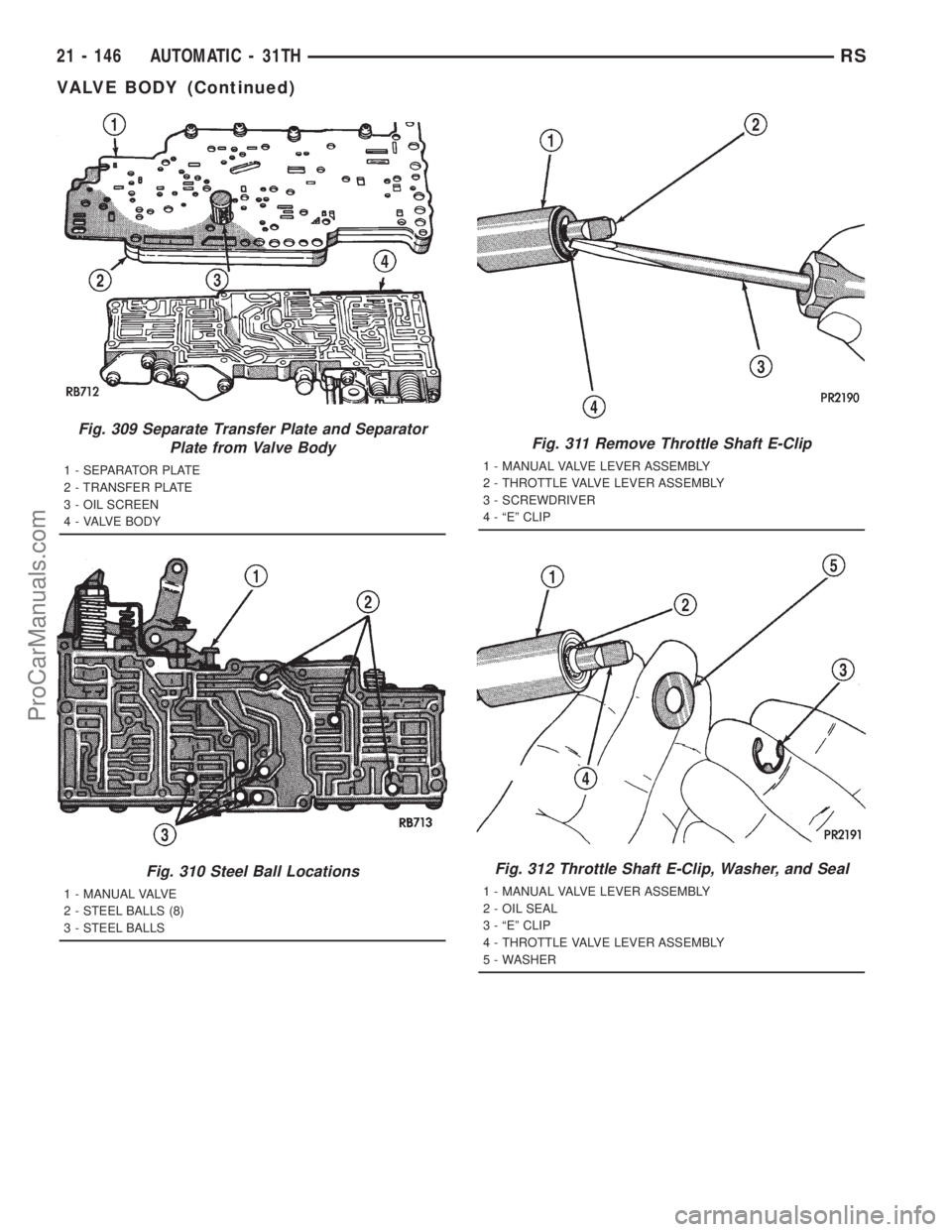

(3) Separate transfer and separator plate from

valve body assembly (Fig. 309). Note check ball loca-

tions (Fig. 310) for proper reassembly.

(4) Remove throttle valve shaft-to-manual valve

shaft e-clip (Fig. 311). Note orientation of washer and

seal (Fig. 312).

Fig. 305 Valve Body and Governor Tubes

1 - VALVE BODY ASSEMBLY

2 - GOVERNOR TUBES

Fig. 306 Detent Spring Attaching Screw and Spring

1 - SPECIAL TOOL L-4553

2 - DETENT SPRING SCREW

3 - SCREWDRIVER HANDLE

Fig. 307 Using Tool L-4553 on Valve Body Screw

1 - SCREWDRIVER HANDLE

2 - VALVE BODY ASSEMBLY

3 - SPECIAL TOOL L-4553

Fig. 308 Remove Valve Body-to-Transfer Plate

Screws

1 - SCREWDRIVER HANDLE

2 - VALVE BODY SCREWS (16)

3 - VALVE BODY

4 - SPECIAL TOOL L-4553

RSAUTOMATIC - 31TH21 - 145

VALVE BODY (Continued)

ProCarManuals.com

Page 1643 of 2321

Fig. 309 Separate Transfer Plate and Separator

Plate from Valve Body

1 - SEPARATOR PLATE

2 - TRANSFER PLATE

3 - OIL SCREEN

4 - VALVE BODY

Fig. 310 Steel Ball Locations

1 - MANUAL VALVE

2 - STEEL BALLS (8)

3 - STEEL BALLS

Fig. 311 Remove Throttle Shaft E-Clip

1 - MANUAL VALVE LEVER ASSEMBLY

2 - THROTTLE VALVE LEVER ASSEMBLY

3 - SCREWDRIVER

4 - ªEº CLIP

Fig. 312 Throttle Shaft E-Clip, Washer, and Seal

1 - MANUAL VALVE LEVER ASSEMBLY

2 - OIL SEAL

3 - ªEº CLIP

4 - THROTTLE VALVE LEVER ASSEMBLY

5 - WASHER

21 - 146 AUTOMATIC - 31THRS

VALVE BODY (Continued)

ProCarManuals.com

Page 1644 of 2321

(5) Remove manual valve shaft/lever from throttle

valve shaft (Fig. 313).

(6) Remove throttle valve lever/shaft (Fig. 314).(7) Remove manual valve from valve body (Fig.

315).

(8) Remove pressure regulator spring retainer/ad-

justing screw bracket (Fig. 316).

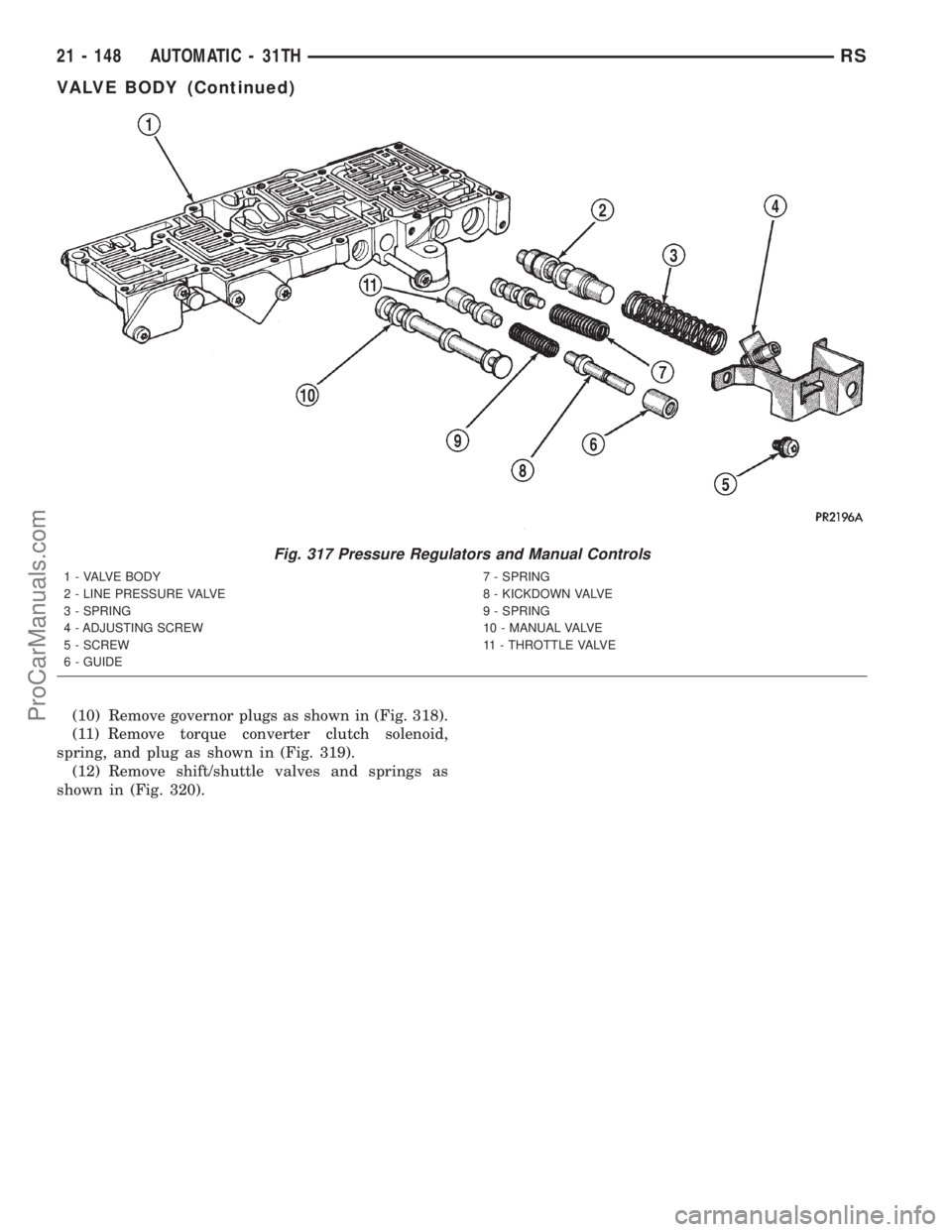

(9) Remove springs and valves as shown in (Fig.

317).

Fig. 313 Manual Valve Lever

1 - THROTTLE VALVE LEVER ASSEMBLY

2 - MANUAL VALVE LEVER ASSEMBLY

3 - VALVE BODY

Fig. 314 Throttle Valve Lever Assembly

1 - THROTTLE VALVE LEVER ASSEMBLY

2 - MANUAL VALVE

3 - VALVE BODY

Fig. 315 Manual Valve

1 - MANUAL VALVE

2 - VALVE BODY

Fig. 316 Pressure Regulator and Adjusting Screw

Bracket

1 - SCREWDRIVER HANDLE

2 - PRESSURE REGULATOR SPRING RETAINER AND

ADJUSTING SCREW BRACKET

3 - VALVE BODY

4 - SCREWS

RSAUTOMATIC - 31TH21 - 147

VALVE BODY (Continued)

ProCarManuals.com

Page 1645 of 2321

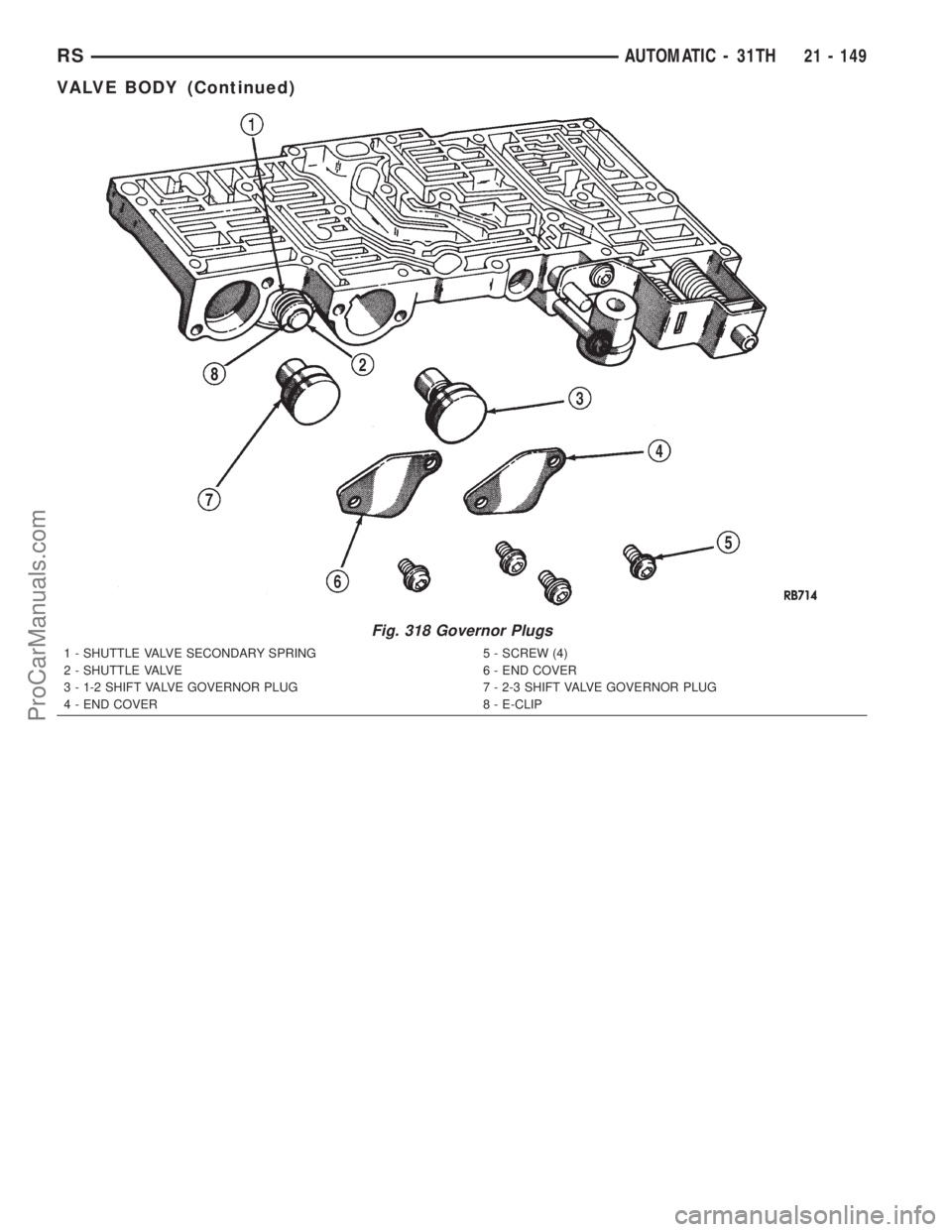

(10) Remove governor plugs as shown in (Fig. 318).

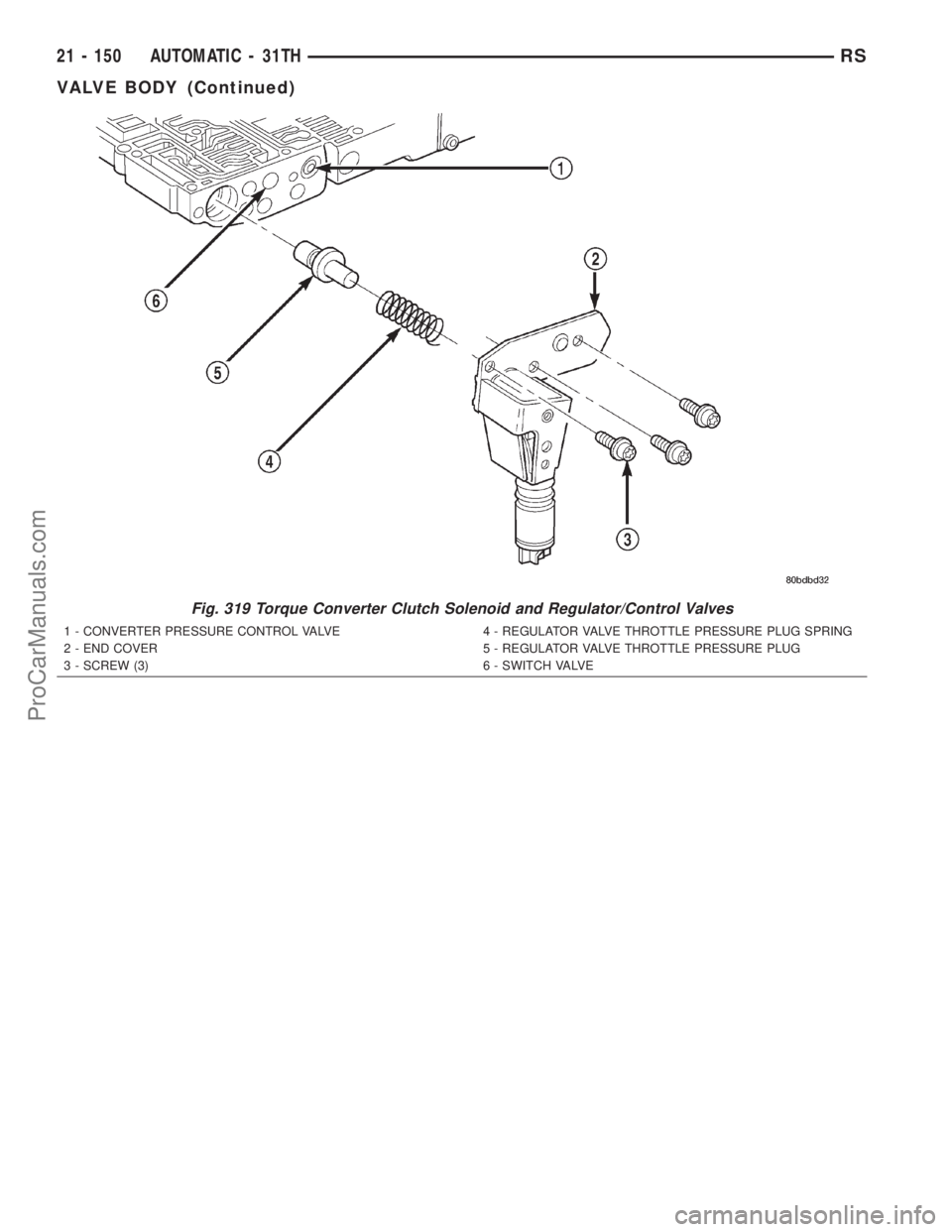

(11) Remove torque converter clutch solenoid,

spring, and plug as shown in (Fig. 319).

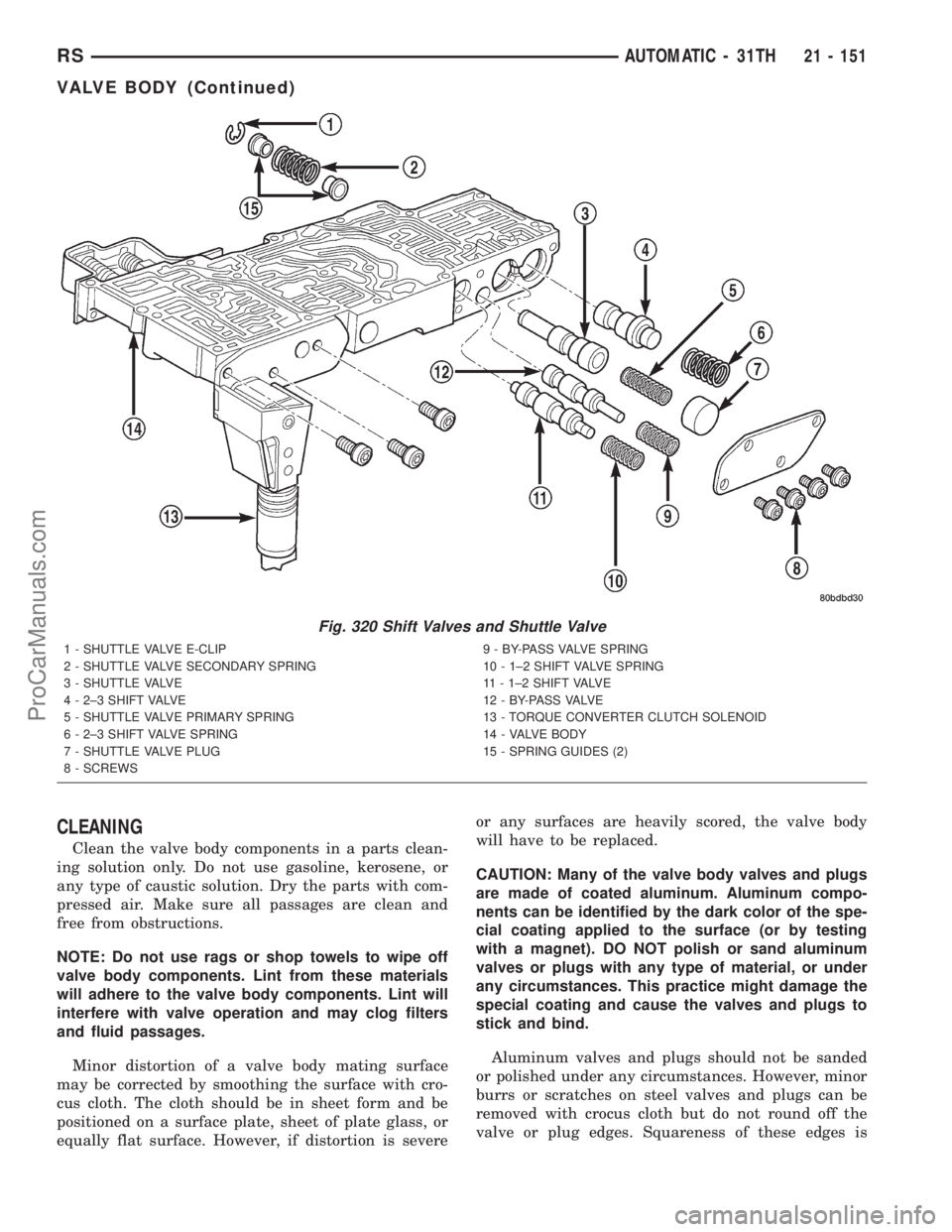

(12) Remove shift/shuttle valves and springs as

shown in (Fig. 320).

Fig. 317 Pressure Regulators and Manual Controls

1 - VALVE BODY

2 - LINE PRESSURE VALVE

3 - SPRING

4 - ADJUSTING SCREW

5 - SCREW

6 - GUIDE7 - SPRING

8 - KICKDOWN VALVE

9 - SPRING

10 - MANUAL VALVE

11 - THROTTLE VALVE

21 - 148 AUTOMATIC - 31THRS

VALVE BODY (Continued)

ProCarManuals.com

Page 1646 of 2321

Fig. 318 Governor Plugs

1 - SHUTTLE VALVE SECONDARY SPRING

2 - SHUTTLE VALVE

3 - 1-2 SHIFT VALVE GOVERNOR PLUG

4 - END COVER5 - SCREW (4)

6 - END COVER

7 - 2-3 SHIFT VALVE GOVERNOR PLUG

8 - E-CLIP

RSAUTOMATIC - 31TH21 - 149

VALVE BODY (Continued)

ProCarManuals.com

Page 1647 of 2321

Fig. 319 Torque Converter Clutch Solenoid and Regulator/Control Valves

1 - CONVERTER PRESSURE CONTROL VALVE

2 - END COVER

3 - SCREW (3)4 - REGULATOR VALVE THROTTLE PRESSURE PLUG SPRING

5 - REGULATOR VALVE THROTTLE PRESSURE PLUG

6 - SWITCH VALVE

21 - 150 AUTOMATIC - 31THRS

VALVE BODY (Continued)

ProCarManuals.com

Page 1648 of 2321

CLEANING

Clean the valve body components in a parts clean-

ing solution only. Do not use gasoline, kerosene, or

any type of caustic solution. Dry the parts with com-

pressed air. Make sure all passages are clean and

free from obstructions.

NOTE: Do not use rags or shop towels to wipe off

valve body components. Lint from these materials

will adhere to the valve body components. Lint will

interfere with valve operation and may clog filters

and fluid passages.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with cro-

cus cloth. The cloth should be in sheet form and be

positioned on a surface plate, sheet of plate glass, or

equally flat surface. However, if distortion is severeor any surfaces are heavily scored, the valve body

will have to be replaced.

CAUTION: Many of the valve body valves and plugs

are made of coated aluminum. Aluminum compo-

nents can be identified by the dark color of the spe-

cial coating applied to the surface (or by testing

with a magnet). DO NOT polish or sand aluminum

valves or plugs with any type of material, or under

any circumstances. This practice might damage the

special coating and cause the valves and plugs to

stick and bind.

Aluminum valves and plugs should not be sanded

or polished under any circumstances. However, minor

burrs or scratches on steel valves and plugs can be

removed with crocus cloth but do not round off the

valve or plug edges. Squareness of these edges is

Fig. 320 Shift Valves and Shuttle Valve

1 - SHUTTLE VALVE E-CLIP

2 - SHUTTLE VALVE SECONDARY SPRING

3 - SHUTTLE VALVE

4 - 2±3 SHIFT VALVE

5 - SHUTTLE VALVE PRIMARY SPRING

6 - 2±3 SHIFT VALVE SPRING

7 - SHUTTLE VALVE PLUG

8 - SCREWS9 - BY-PASS VALVE SPRING

10 - 1±2 SHIFT VALVE SPRING

11 - 1±2 SHIFT VALVE

1 2 - B Y- PA S S VA LV E

13 - TORQUE CONVERTER CLUTCH SOLENOID

14 - VALVE BODY

15 - SPRING GUIDES (2)

RSAUTOMATIC - 31TH21 - 151

VALVE BODY (Continued)

ProCarManuals.com

Page 1649 of 2321

vitally important. These edges prevent foreign matter

from lodging between the valves, plugs and bore.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Also inspect the coating on the alu-

minum valves and plugs. If the coating is damaged

or worn through, the valve (or valve body) should be

replaced.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores. Valve

body bores do not change dimensionally with use. If

the valve body functioned correctly when new, it will

continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

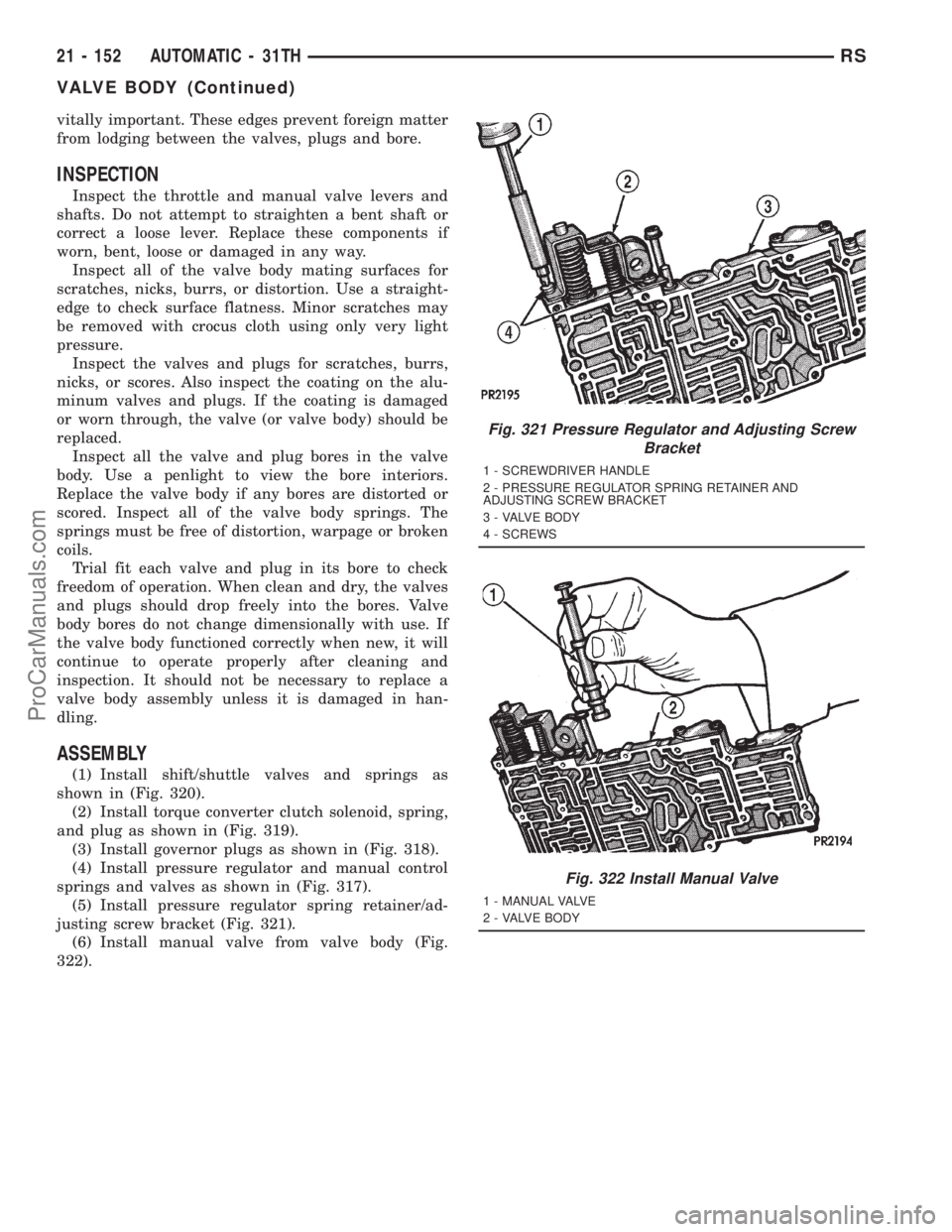

ASSEMBLY

(1) Install shift/shuttle valves and springs as

shown in (Fig. 320).

(2) Install torque converter clutch solenoid, spring,

and plug as shown in (Fig. 319).

(3) Install governor plugs as shown in (Fig. 318).

(4) Install pressure regulator and manual control

springs and valves as shown in (Fig. 317).

(5) Install pressure regulator spring retainer/ad-

justing screw bracket (Fig. 321).

(6) Install manual valve from valve body (Fig.

322).

Fig. 321 Pressure Regulator and Adjusting Screw

Bracket

1 - SCREWDRIVER HANDLE

2 - PRESSURE REGULATOR SPRING RETAINER AND

ADJUSTING SCREW BRACKET

3 - VALVE BODY

4 - SCREWS

Fig. 322 Install Manual Valve

1 - MANUAL VALVE

2 - VALVE BODY

21 - 152 AUTOMATIC - 31THRS

VALVE BODY (Continued)

ProCarManuals.com

Page 1650 of 2321

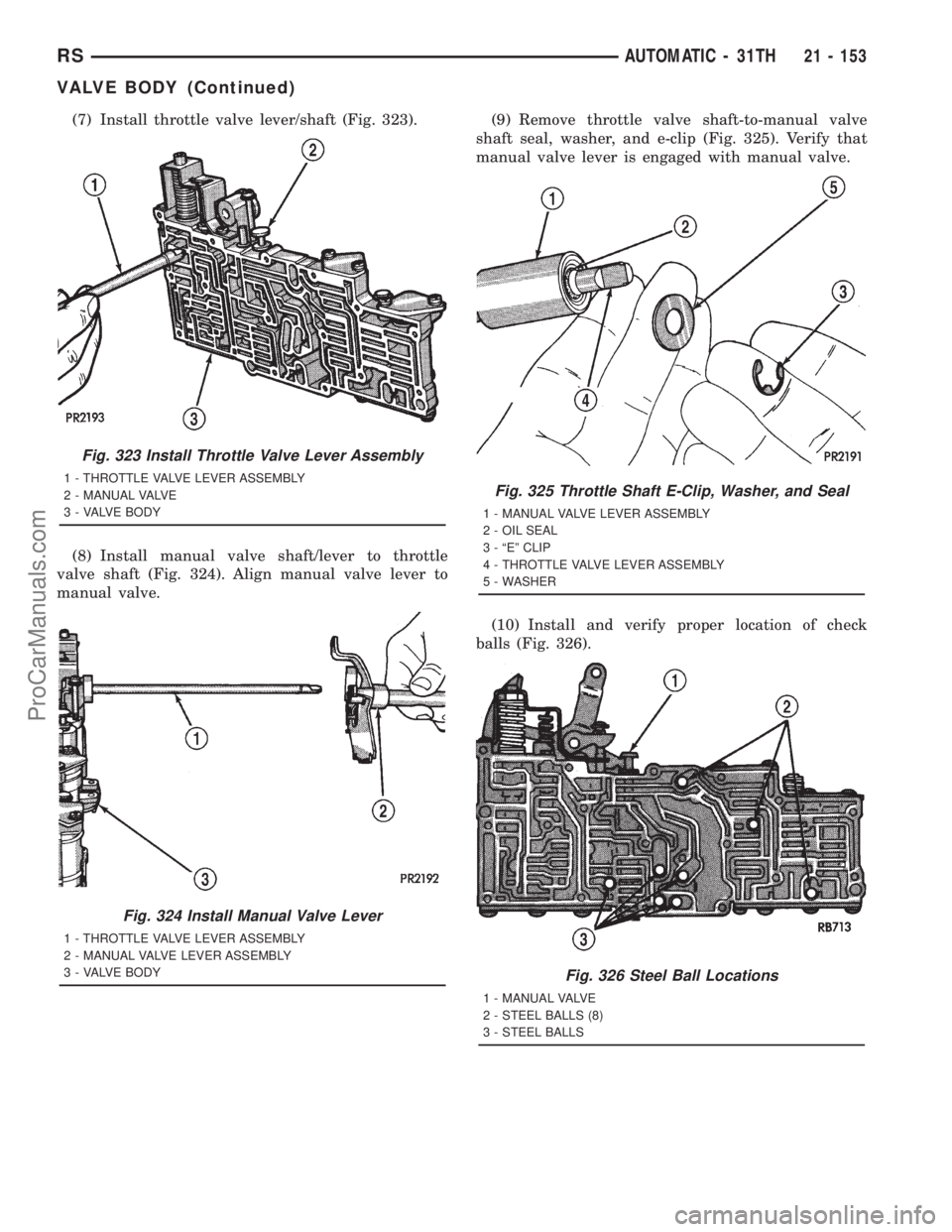

(7) Install throttle valve lever/shaft (Fig. 323).

(8) Install manual valve shaft/lever to throttle

valve shaft (Fig. 324). Align manual valve lever to

manual valve.(9) Remove throttle valve shaft-to-manual valve

shaft seal, washer, and e-clip (Fig. 325). Verify that

manual valve lever is engaged with manual valve.

(10) Install and verify proper location of check

balls (Fig. 326).

Fig. 323 Install Throttle Valve Lever Assembly

1 - THROTTLE VALVE LEVER ASSEMBLY

2 - MANUAL VALVE

3 - VALVE BODY

Fig. 324 Install Manual Valve Lever

1 - THROTTLE VALVE LEVER ASSEMBLY

2 - MANUAL VALVE LEVER ASSEMBLY

3 - VALVE BODY

Fig. 325 Throttle Shaft E-Clip, Washer, and Seal

1 - MANUAL VALVE LEVER ASSEMBLY

2 - OIL SEAL

3 - ªEº CLIP

4 - THROTTLE VALVE LEVER ASSEMBLY

5 - WASHER

Fig. 326 Steel Ball Locations

1 - MANUAL VALVE

2 - STEEL BALLS (8)

3 - STEEL BALLS

RSAUTOMATIC - 31TH21 - 153

VALVE BODY (Continued)

ProCarManuals.com