DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1001 of 1502

19-40

STEERING

•

TORQUE

SPECIFICATIONS

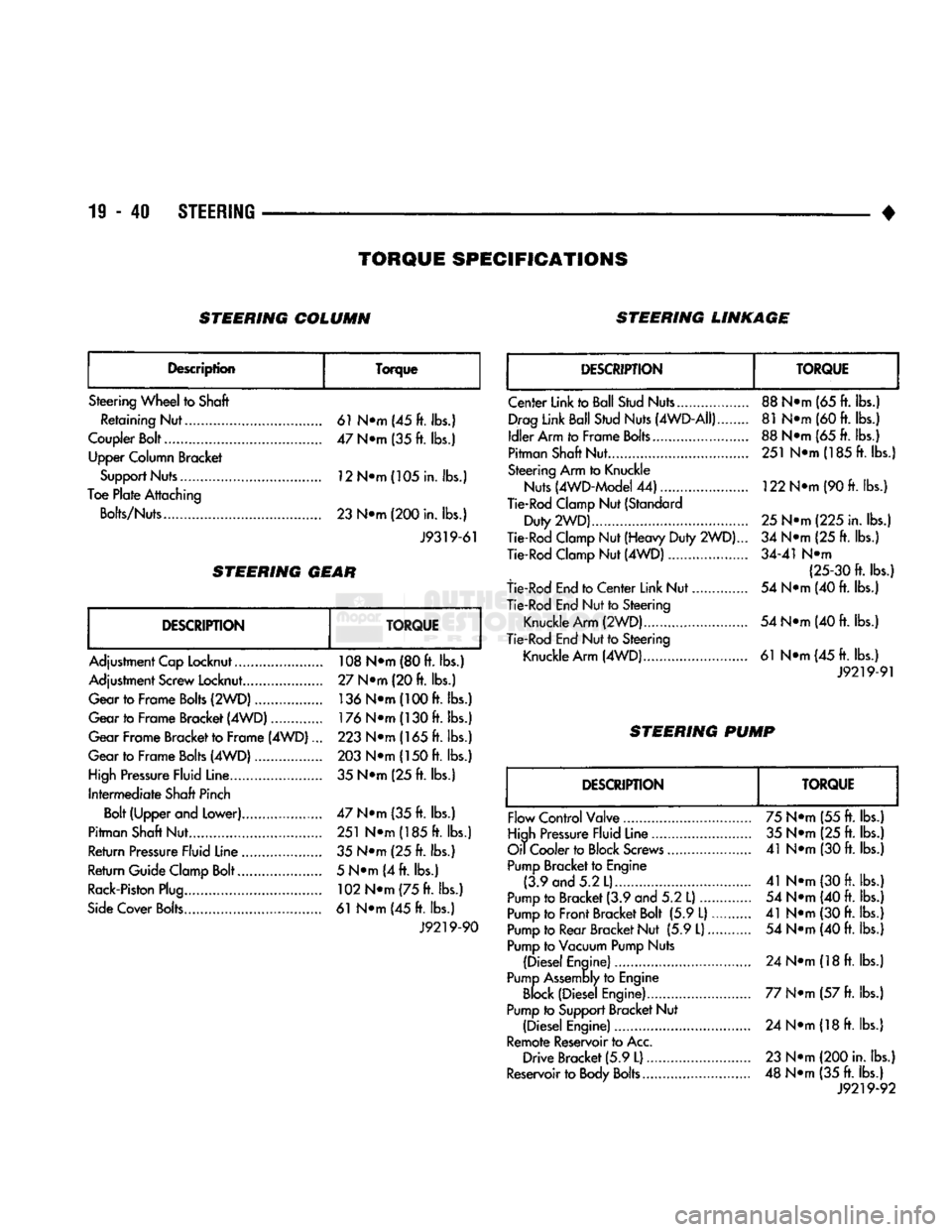

STEERING COLUMN STEERING LINKAGE

Description Torque

Steering Wheel to Shaft Retaining Nut 61 N»m (45 ft. lbs.)

Coupler Bolt 47 N»m (35 ft. lbs.) Upper Column Bracket

Support Nuts 12N*m(105in. lbs.)

Toe Plate Attaching

Bolts/Nuts 23 N«m (200 in. lbs.)

J9319-61

STEERING

GEAR

DESCRIPTION

TORQUE

Adjustment Cap Locknut 108 N»m (80 ft. lbs.)

Adjustment Screw Locknut.... 27 N®m (20 ft. lbs.)

Gear to Frame Bolts (2WD) 136

N®m

(100 ft. lbs.)

Gear to Frame Bracket (4WD) 176

N®m

(130 ft. lbs.)

Gear Frame Bracket to Frame (4WD)... 223 N*m (165 ft. lbs.)

Gear to Frame Bolts (4WD) 203 N*m (150 ft. lbs.)

High Pressure Fluid Line. 35 N*m (25 ft. lbs.)

Intermediate Shaft Pinch Bolt (Upper and Lower) 47 N»m (35 ft. lbs.)

Pitman Shaft Nut 251 N»m (185 ft. lbs.)

Return Pressure Fluid Line 35 N*m (25 ft. lbs.)

Return Guide Clamp Bolt 5 N*m (4 ft. lbs.)

Rack-Piston Plug 102

N®m

(75 ft. lbs.)

Side Cover Bolts 61 N*m (45 ft. lbs.) J9219-90

DESCRIPTION

TORQUE

Center Link to Ball Stud Nuts..., Drag Link Ball Stud Nuts (4WD-AII)

Idler Arm to Frame Bolts...

Pitman Shaft Nut

Steering Arm to Knuckle Nuts (4WD-Model 44)

Tie-Rod Clamp Nut (Standard

Duty 2WD)....

Tie-Rod Clamp Nut (Heavy Duty

2WD).

Tie-Rod Clamp Nut (4WD)

tie-Rod End to Center Link Nut.

Tie-Rod End Nut to Steering

Knuckle

Arm

(2WD)..

Tie-Rod End Nut to Steering Knuckle Arm (4WD) 88 N®m (65 ft. lbs.)

81 N®m (60 ft. lbs.)

88 N*m (65

ft.

lbs.) 251 NTn(185ft. lbs.)

122 N*m (90

ft.

lbs.)

25

N^m (225 in. lbs.)

34 N«m (25

ft.

lbs.)

34-41 N«m (25-30 ft. lbs.)

54 N«m (40

ft.

lbs.)

54 N*m (40

ft.

lbs.)

61 N«m(45ft. lbs.)

J9219-91

STEERING PUMP

DESCRIPTION

TORQUE

Flow Control Valve

High Pressure Fluid Line

Oil Cooler to Block Screws

Pump Bracket to Engine (3.9 and 5.2 L)..

Pump to Bracket (3.9 and 5.2

L)....

Pump to Front Bracket Bolt (5.9 L).

Pump to Rear Bracket Nut (5.9

L)

Pump to Vacuum Pump Nuts

(Diesel Engine)

Pump Assembly to Engine Block (Diesel Engine)

Pump to Support Bracket Nut (Diesel Engine)

Remote Reservoir to Acc, Drive Bracket (5.9

L)

Reservoir to Body Bolts 75 N®m (55

ft.

lbs.)

35 N«*m (25 ft. lbs.)

41 N*m (30

ft.

lbs.)

41 N*m (30

ft.

lbs.) 54 N®m (40

ft.

lbs.)

41 N*m (30

ft.

lbs.) 54 N*m (40

ft.

lbs.)

24 N®m

(18

ft.

lbs.)

77 N*m (57

ft.

lbs.) 24 NTH (18

ft.

lbs.)

23 N*m (200 in. lbs.)

48 N«m (35

ft.

lbs.) J9219-92

Page 1002 of 1502

•

TRANSMISSION

AND

TRANSFER

CASE

21 - 1

CONTENTS

page

AUTOMATIC

TRANSMISSI0N-32RH/36RH/

37RH/42RH/46RH

73

G360

MANUAL

TRANSMISSION

46

6360

TRANSMISSION

OVERHAUL

..........

53

NP2Q5

TRANSFER

CASE

................

342

page

NP241

TRANSFER

CASE

350

NV4500 MANUAL

TRANSMISSION

1

NV4500

TRANSMISSION

OVERHAUL

.........

6

TRANSMISSION/TRANSFER

CASE

SPECIFICATIONS

.....................

364

NV4300

MANUAL TRANSMISSION

INDEX

page

Gear Ratios

1

General

Information

1

Recommended

Lubricant—Capacity—Fill

Level

... 1

Shift

Pattern

1

Transmission Diagnosis

2

page

Transmission

Identification

1

Transmission

Installation—2-Wheel

Drive

4

Transmission

Installation—4-Wheel

Drive

........

5

Transmission

Removal—2-Wheel

Drive

3

Transmission

Removal—4-Wheel

Drive

4

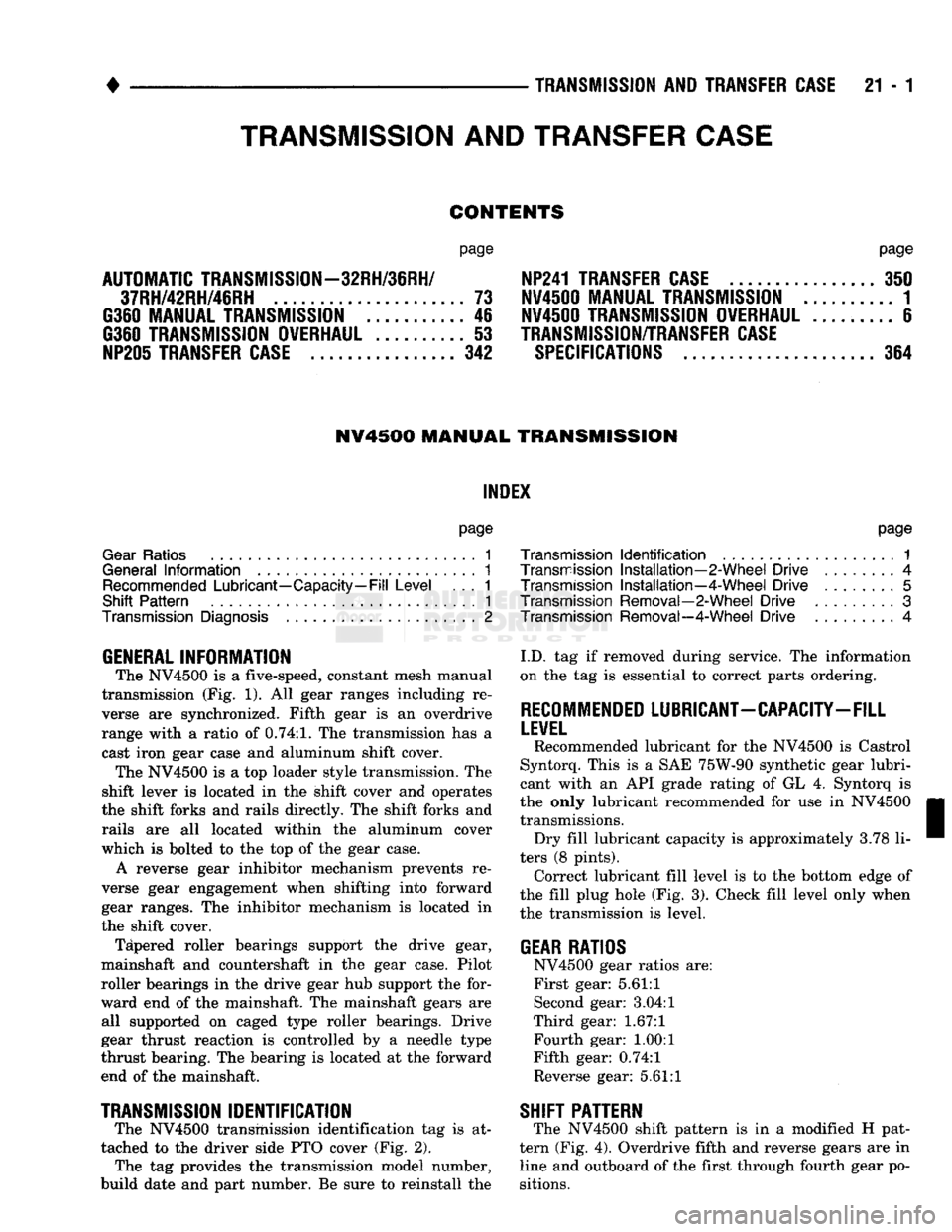

GENERAL

INFORMATION The NV4500

is a

five-speed, constant mesh manual

transmission (Fig.

1). All

gear ranges including

re

verse

are

synchronized. Fifth gear

is an

overdrive

range with

a

ratio

of

0.74:1.

The transmission has

a

cast iron gear case and aluminum shift cover. The NV4500

is a

top loader style transmission. The

shift lever

is

located

in the

shift cover and operates

the shift forks and rails directly. The shift forks and

rails

are all

located within

the

aluminum cover

which

is

bolted

to

the top

of

the gear case.

A reverse gear inhibitor mechanism prevents

re

verse gear engagement when shifting into forward

gear ranges. The inhibitor mechanism

is

located

in

the shift cover.

Tapered roller bearings support

the

drive gear,

mainshaft

and

countershaft

in the

gear case. Pilot

roller bearings

in

the drive gear hub support the for

ward end

of

the mainshaft. The mainshaft gears

are

all supported

on

caged type roller bearings. Drive

gear thrust reaction

is

controlled

by a

needle type

thrust bearing. The bearing

is

located

at

the forward

end

of

the mainshaft.

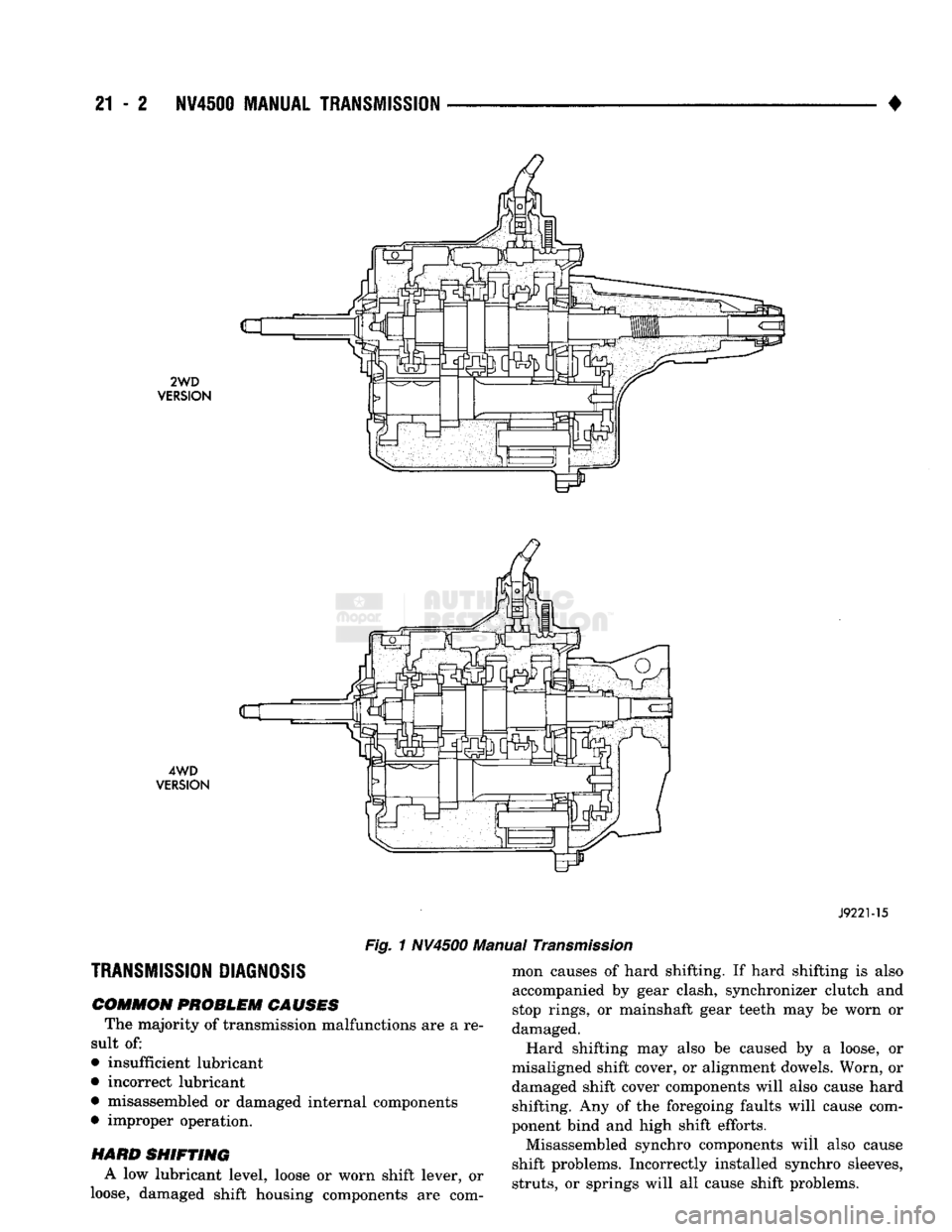

TRANSMISSION

IDENTIFICATION The NV4500 transmission identification

tag is at

tached

to

the driver side PTO cover (Fig.

2).

The

tag

provides

the

transmission model number,

build date and part number.

Be

sure

to

reinstall

the

I.D.

tag if

removed during service. The information

on the tag

is

essential

to

correct parts ordering.

RECOMMENDED

LUBRICANT-CAPACITY-FILL

LEVEL

Recommended lubricant

for

the NV4500

is

Castrol

Syntorq. This

is a

SAE 75W-90 synthetic gear lubri

cant with

an

API grade rating

of

GL

4.

Syntorq

is

the only lubricant recommended

for

use

in

NV4500 transmissions. Dry fill lubricant capacity

is

approximately 3.78

li

ters

(8

pints). Correct lubricant fill level

is to

the bottom edge

of

the fill plug hole (Fig. 3). Check fill level only when

the transmission

is

level.

GEAR

RATIOS

NV4500 gear ratios are:

First gear:

5.61:1

Second gear: 3.04:1

Third gear:

1.67:1

Fourth gear:

1.00:1

Fifth gear: 0.74:1

Reverse gear:

5.61:1

SHIFT

PATTERN

The NV4500 shift pattern

is in a

modified

H

pat

tern (Fig. 4). Overdrive fifth and reverse gears are

in

line and outboard of the first through fourth gear po

sitions.

TRANSMISSION

AND

TRANSFER

CASE

Page 1003 of 1502

21

- 2

NV4500

MANUAL TRANSMISSION

•

2WD

VERSION

4WD

VERSION

J9221-15

Fig.

1 NV4500 Manual

Transmission

TRANSMISSION DIAGNOSIS

COMMON

PROBLEM CAUSES

The majority of transmission malfunctions are a re

sult of:

• insufficient lubricant

• incorrect lubricant

• misassembled or damaged internal components

• improper operation. mon causes of hard shifting. If hard shifting is also

accompanied by gear clash, synchronizer clutch and

stop rings, or mainshaft gear teeth may be worn or

damaged.

Hard shifting may also be caused by a loose, or

misaligned shift cover, or alignment dowels. Worn, or

damaged shift cover components will also cause hard shifting. Any of the foregoing faults will cause com

ponent bind and high shift efforts.

Misassembled synchro components will also cause

shift problems. Incorrectly installed synchro sleeves,

struts,

or springs will all cause shift problems.

HARD

SHIFTING

A low lubricant level, loose or worn shift lever, or

loose, damaged shift housing components are com

Page 1004 of 1502

•

NV4500 MANUAL

TRANSMISSION

21 - 3

PTO

COVER

J9221-14

Fig. 2 NV4500 identification Tag Location

DRAIN

PLUG

J9221-80

Fig. 3 NV4500 Drain And Fill Plug Locations

o

0 ©

0 0©

J9221-13

Fig. 4 NV4500 Shitt Pattern

NOISY OPERATION Transmission noise is most often a result of worn

or damaged components. Chipped, broken gear or

synchronizer teeth and brinnelled, spalled bearings

all cause noise.

Abnormal wear and damage to internal compo

nents is frequently the end result of insufficient lu

bricant, non-recommended lubricants, or improper operation.

SLIPS

OUT OF

GEAR

Transmission disengagement may be caused by

misaligned or damaged shift components, or worn

teeth on the mainshaft gears or synchro components. Incorrect assembly will also contribute to gear disengagement.

LOW LUBRICANT LEWEL

Insufficient transmission lubricant is usually the

result of leaks, or inaccurate fluid level check or re

fill method.

Leaks will be evident by the presence of gear oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill condi

tion.

If air powered lubrication equipment is used to fill

a transmission, be sure the equipment is properly

calibrated. Equipment out of calibration can lead to

an underfill condition.

CLUTCH

PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash and noise.

A damaged pilot bearing will cause noise. If bear

ing damage is severe, drive gear misalignment and

hard shifting can also occur.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear clash.

Damaged or worn clutch hydraulic components, or

leaks in the fluid lines or cylinders will cause hard shifting and gear clash. Failure of one of the clutch

hydraulic cylinders can result in incomplete clutch release or engagement.

Verify that clutch components are all in good con

dition before removing the transmission for repair.

TRANSMISSION

REMOVAL—2-WHEEL DRIVE

(1) Disconnect battery negative cable. (2) Shift transmission into Neutral.

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on lever. (4) Loosen nut that secures shift lever on transmis

sion stub lever. Then remove shift lever from stub le

ver. (5) Raise and support vehicle.

(6) Mark propeller shaft and axle yokes for align

ment reference. Use paint, scriber, or chalk to mark

yokes.

(7) Remove U-joint clamp strap screws and remove

clamps. (8) Remove propeller shaft.

(9) Disconnect and remove exhaust system Y-pipe.

(10) Disconnect wires at speed sensor and backup

light switch. (11) Support engine with adjustable safety stand

and wood block.

Page 1005 of 1502

21

- 4

NV4500 MANUAL TRANSMISSION

(12) If transmission is to be disassembled for re

pair, remove drain plug and drain lubricant from transmission.

(13) move bolts/nuts attaching transmission to rear

mount.

(14) Support transmission with a transmission

jack. Secure transmission to jack with safety chains.

(15) Remove rear crossmember,

(16) Remove bolts attaching clutch slave cylinder

to clutch housing. Then move cylinder aside for

working clearance.

(17) Remove transmission harness wires from clips

on transmission shift cover. (18) Remove bolts attaching transmission to clutch

housing. (19) Slide transmission and jack rearward until

drive gear clears clutch housing. (20) Lower transmission jack and remove trans

mission from under vehicle. (21) If transmission will be overhauled, clean

transmission exterior with solvent or with steam gun.

TRANSMISSION

INSTALLATION—2-WHEEL DRIVE

(1) Apply light coat of Mopar high temperature

bearing grease to contact surfaces of following com

ponents: • drive gear splines and pilot bearing hub

• release bearing slide surface of front retainer

• pilot bearing • release bearing bore

• release fork

• release fork ball stud

• propeller shaft slip yoke (2) Fill transmission with recommended lubricant.

Correct fill level is bottom edge of fill plug hole. (3) Mount transmission on jack and position trans

mission under vehicle. (4) Raise transmission until drive gear is centered

in release bearing and clutch disc hub. (5) Move transmission forward and start drive gear

in release bearing, clutch disc and pilot bushing. (6) Work transmission forward until seated against

clutch housing. Do not allow transmission to remain

unsupported after drive gear has entered clutch disc. (7) Install and tighten transmission-to-clutch hous

ing bolts to 108 N*m (80 ft. lbs.) torque. (8) Install clutch slave cylinder. (9) Connect speed sensor and backup light switch

wires.

(10) Position transmission harness wires in clips

on shift cover. (11) Install transmission mount on transmission or

rear crossmember. (12) Install rear crossmember.

(13) Remove transmission jack and engine support

fixture. (14) Align and connect propeller shaft. (15) Fill transmission with required lubricant, if

necessary. (16) Lower vehicle.

(17) Install shift lever on transmission stub lever.

(18) Install shift boot and bezel. (19) Connect battery negative cable.

TRANSMISSION REMOVAL—4-WHEEL DRIVE

(1) Disconnect battery negative cable.

(2) Shift transmission into Neutral.

(3) Remove shift lever boot and bezel. (4) Loosen nut attaching shift lever to transmis

sion stub lever and remove shift lever from stub le

ver. (5) Raise- vehicle.

(6) Remove skid plate if equipped.

(7) If transmission will be disassembled for repair,

remove drain plug and drain lubricant from trans

mission. (8) Mark propeller shafts and yokes for assembly

reference. (9) Disconnect propeller shafts and remove propel

ler shafts. (10) Disconnect and remove exhaust system

Y-pipe. Then disconnect and lower remaining ex

haust pipes for clearance as necessary. (11) Support engine with adjustable safety stand.

(12) Disconnect speed sensor wires and disconnect

speedometer cable, if equipped. (13) Disconnect backup light switch wires.

(14) Disconnect transfer case shift linkage at

transfer case range lever. (15) Remove bolts/nuts attaching transmission to

rear support. (16) Remove crossmember bolts/nuts and remove

crossmember. (17) Support transfer case with transmission jack.

Secure transfer case to jack with safety chains. (18) Remove transfer case attaching nuts.

(19) Move transfer case rearward until input gear

clears transmission mainshaft. (20) Lower transfer case assembly and move it

from under vehicle. (21) If transmission is being removed for repair,

remove drain plug and drain lubricant from trans mission.

(22) Support transmission with transmission jack.

Secure transmission to jack with safety chains.

(23) Remove transmission harness from retaining

clips on transmission shift cover. (24) Remove bolts/nuts attaching transmission

mount to rear crossmember.

(25) Remove rear crossmember.

(26) Remove clutch slave cylinder splash shield, if

equipped.

(27) Loosen clutch slave cylinder attaching nuts

until cylinder piston rod is clear of release lever.

This reduces pressure on lever and release bearing

Page 1006 of 1502

1

.

NW4500

MANUAL

TRANSMISSION 21 - 5 making transmission removal/installation easier.

Cylinder does not have to be removed completely. (28) Remove bolts attaching transmission to clutch

housing.

(29) Move transmission rearward until drive pin

ion clears clutch disc and release bearing. (30) Lower transmission and remove it from under

vehicle.

(31) If transmission will be overhauled, thoroughly

clean transmission exterior with solvent or steam

gun.

TRANSMISSION INSTALLATION-4-WHEEL DRIVE (1) Apply light coat of Mopar high temperature

bearing grease to contact surfaces of following com

ponents: • drive gear splines and pilot bearing hub • release bearing slide surface of front retainer

• pilot bearing

• release bearing bore

• release fork

• release fork ball stud

• propeller shaft slip yoke (2) Fill transmission with recommended lubricant.

Correct level is to bottom edge of fill plug hole. (3) Mount transmission on jack and position trans

mission under vehicle. Secure transmission to jack

with safety chains. (4) Raise transmission until drive gear is centered

in release bearing and clutch disc hub. (5) Move transmission forward and start drive gear

in release bearing and clutch disc. (6) Work transmission forward until seated against

clutch housing. Do not allow transmission to remain

unsupported after drive gear has entered clutch disc. (7) Install and tighten transmission-to-clutch hous

ing bolts to 108 N*m (80 ft. lbs.) torque. (8) Connect speed sensor and backup light switch

wires.

(9) Position transmission harness wires in clips on

shift cover. (10) Tighten slave cylinder attaching nuts and in

stall slave cylinder shield, if equipped.

(11) Install transmission mount on transmission or

rear crossmember. (12) Install rear crossmember.

(13) Remove transmission jack and engine support

fixture.

(14) Install transfer case on transmission jack. Se

cure transfer case to jack with safety chains. (15) Install new gasket on transmission adapter, or

coat adapter sealing surface with Mopar Gasket

Maker, or silicone adhesive sealer.

(16) Raise jack and align transfer case input gear

with transmission mainshaft.

(17) Move transfer case forward and seat it on

adapter.

(18) Install and tighten transfer case attaching

nuts to 47 N«m (35 ft. lbs.) torque.

(19) Connect transfer case shift lever to range le

ver on transfer case. (20) Align and connect propeller shafts. Tighten

U-joint clamp strap bolts to 19 N*m (170 in. lbs.)

torque.

(21) Check lubricant levels in transmission and

transfer case. Add lubricant if necessary.

(22) Install transfer case skid plate and crossmem

ber. Tighten attaching bolts/nuts to 41 N»m (30 ft. lbs.) torque.

(23) Install exhaust system components.

(24) Lower vehicle.

(25) Install transmission shift lever, boot and be

zel.

(26) Connect battery negative cable.

Page 1007 of 1502

21

- i NV4500

TRANSMISSION OVERHAUL

NV4500

TRANSMISSION

OVERHAUL

INDEX

page

Shift

Cover Service

....................... 43

Transmission Assembly

and

Adjustment

....... 26

TRANSMISSION DISASSEMBLY

SHIFT

COVER REMOVAL

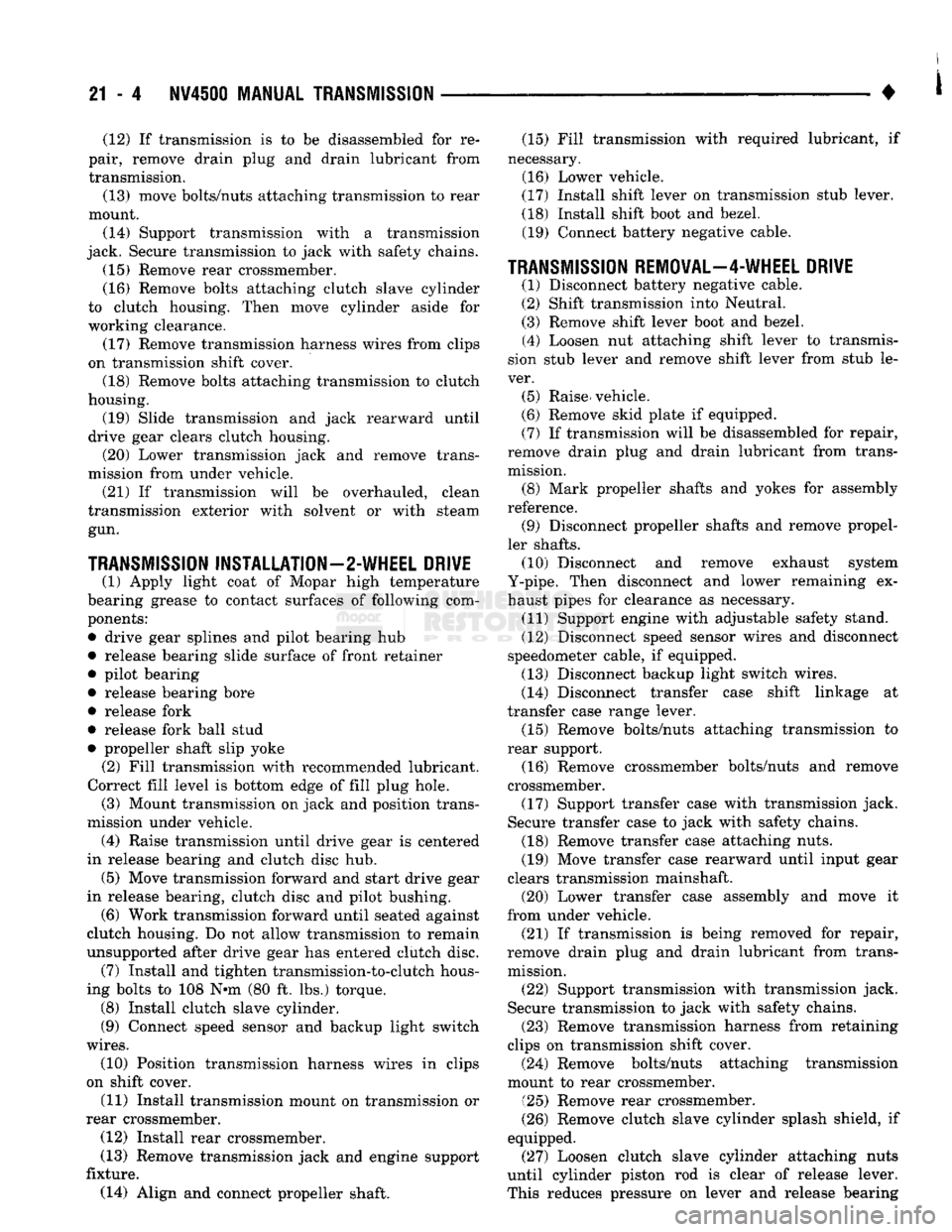

(1) Remove shift cover bolts (Fig. 1).

Fig.

1 Shift

Cower

Bolt

Removal/installation

(2)

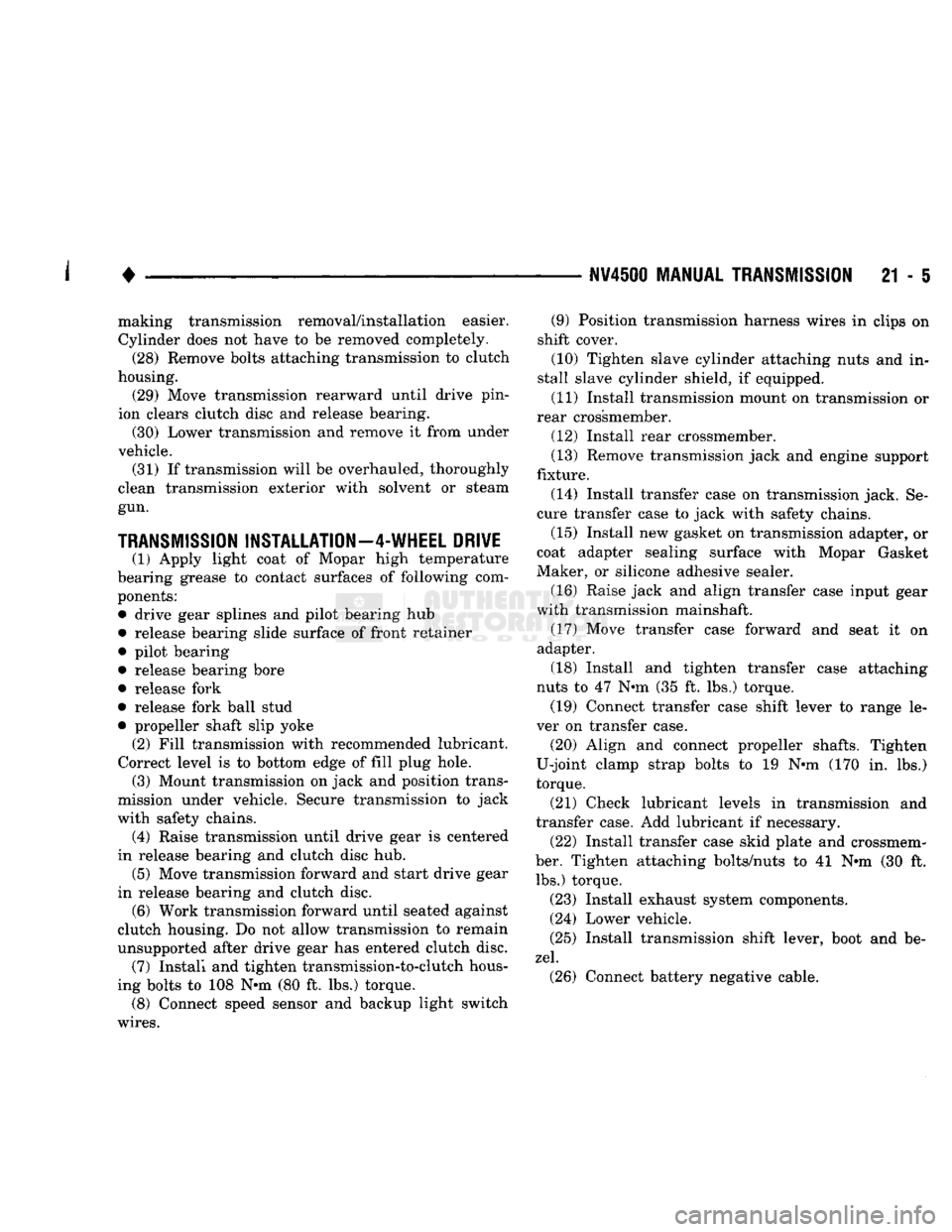

Loosen shift cover with pry tool. To avoid dam

aging cover seal surface, insert pry tool only in slots

provided in cover (Fig. 2).

SHIFT

COVER SLOT

Fig.

2

Loosening

Shift

Cover

(3)

Raise cover enough to disengage it from align

ment dowels in gear case (Fig. 3).

(4)

Raise front of shift cover and lift cover up and

off gear case (Fig. 3).

page

Transmission Cleaning

and

Inspection

......... 21

Transmission Disassembly

6

(5)

Set cover assembly aside for inspection. If cover

components are damaged, refer to shift cover service

information.

SHIFT

COVER

Fig.

3 Shift

Cover

Removal/installation

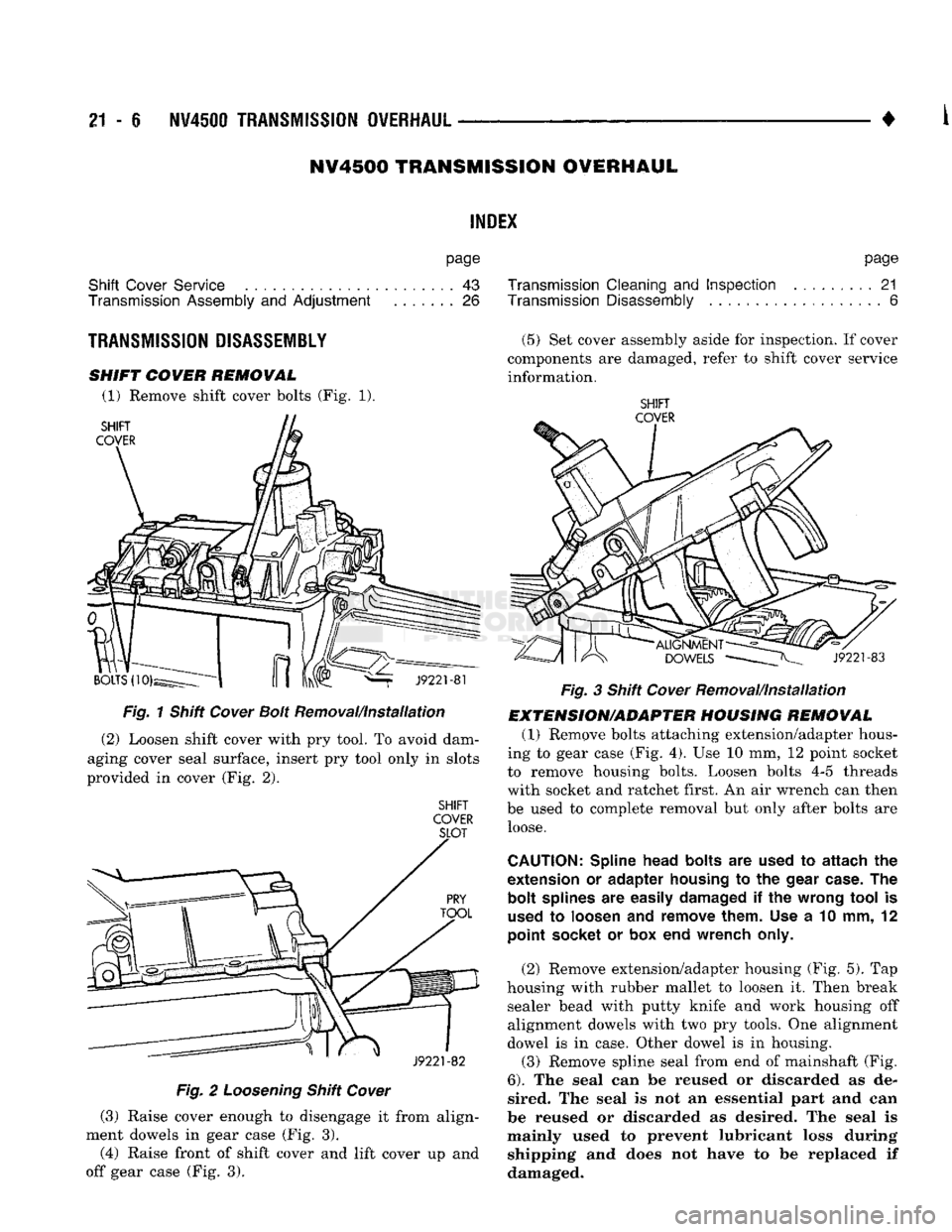

EXTENSION/ADAPTER HOUSING REMOVAL

(1)

Remove bolts attaching extension/adapter hous

ing to gear case (Fig. 4). Use 10 mm, 12 point socket

to remove housing bolts. Loosen bolts 4-5 threads

with socket and ratchet first. An air wrench can then

be used to complete removal but only after bolts are loose.

CAUTION:

Spline head bolts

are

used

to

attach

the

extension

or

adapter housing

to the

gear

case.

The

bolt splines

are

easily damaged

if the

wrong

tool

is

used

to

loosen

and

remove them.

Use a 10 mm, 12

point socket

or box end

wrench only.

(2)

Remove extension/adapter housing (Fig. 5). Tap

housing with rubber mallet to loosen it. Then break sealer bead with putty knife and work housing off

alignment dowels with two pry tools. One alignment

dowel is in case. Other dowel is in housing.

(3)

Remove spline seal from end of mainshaft (Fig.

6).

The seal can be reused or discarded as de

sired. The seal is not an essential part and can

be reused or discarded as desired. The seal is

mainly used to prevent lubricant loss during shipping and does not have to be replaced if damaged.

Page 1008 of 1502

NV4500

TRANSMISSION

OVERHAUL

21 - 7

EXTENSION

HOUSING

SPLINE

HEAD

BOLTS

(8)

J9221-84

Fig. 4 Extension/Adapter

Housing

Bolts

EXTENSION

HOUSING

GEAR

CASE

J9221-85

Fig.

5 Extension/Adapter

Housing

Removal/Installation

MAINSHAFT

RUBBER

SPLINE

SEAL

J9221-86

Fig.

6 Mainshaft

Spline

Seal

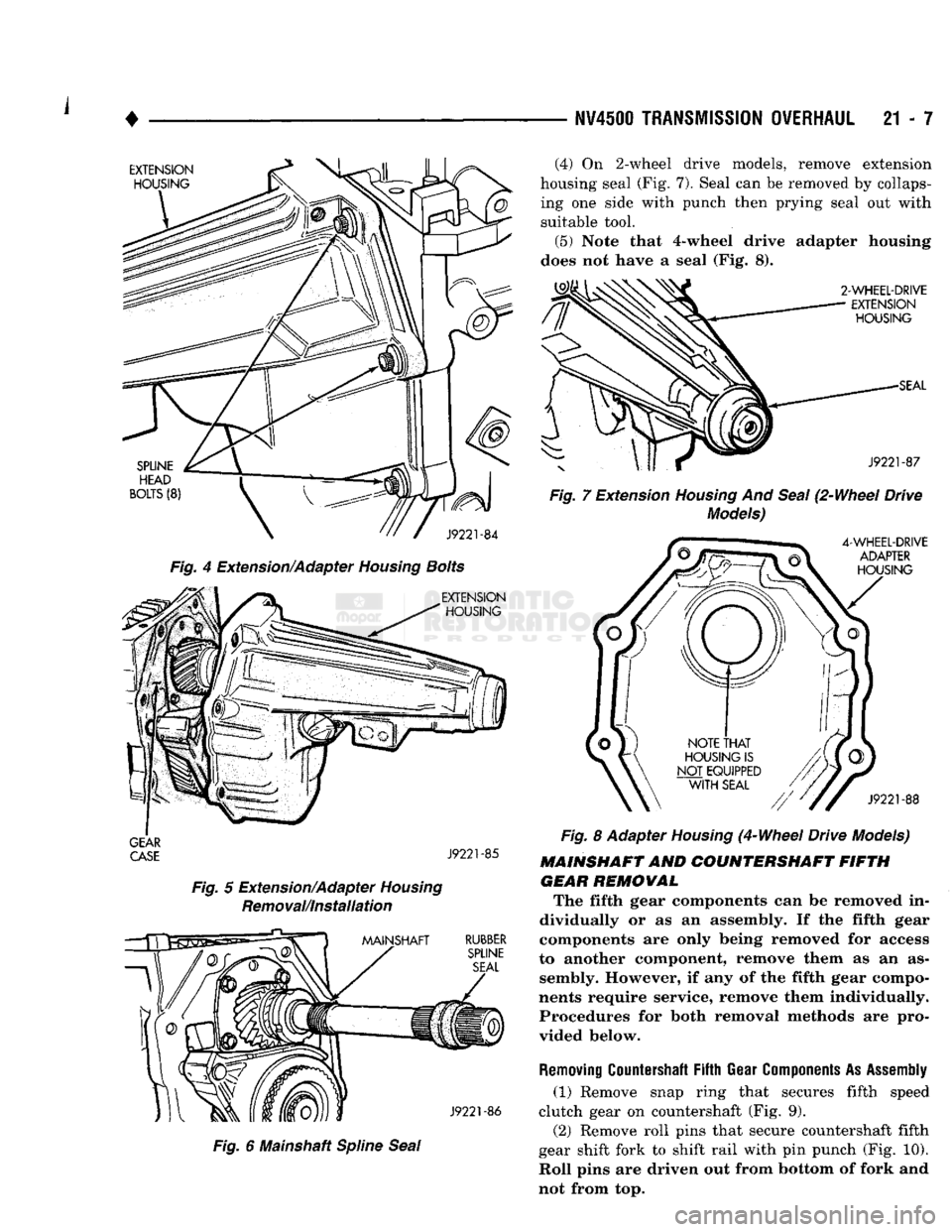

(4)

On 2-wheel drive models, remove extension

housing seal (Fig. 7). Seal can be removed by collaps ing one side with punch then prying seal out with

suitable tool.

(5) Note that 4-wheel drive adapter housing

does not have a seal (Fig. 8).

2-WHEEL-DRIVE

EXTENSION

HOUSING

SEAL

J9221-87

Fig.

7 Extension

Housing

And

Seal

(2-Wheel Drive

Models)

4-WHEEL-DRIVE

ADAPTER

HOUSING

J9221-88

Fig.

8 Adapter

Housing

(4-Wheel Drive Models)

MAINSHAFT AND COUNTERSHAFT FIFTH GEAR REMOWAL The fifth gear components can be removed in

dividually or as an assembly. If the fifth gear

components are only being removed for access

to another component, remove them as an as sembly. However, if any of the fifth gear compo

nents require service, remove them individually. Procedures for both removal methods are pro

vided below.

Removing

Countershaft

Fifth

Gear

Components

As

Assembly

(1) Remove snap ring that secures fifth speed

clutch gear on countershaft (Fig. 9). (2) Remove roll pins that secure countershaft fifth

gear shift fork to shift rail with pin punch (Fig. 10).

Roll pins are driven out from bottom of fork and

not from top.

Page 1009 of 1502

21

- 8

NV4500

TRANSMISSION OVERHAUL

———— ^ ____ - #

CLUTCH

GEAR J9221-89

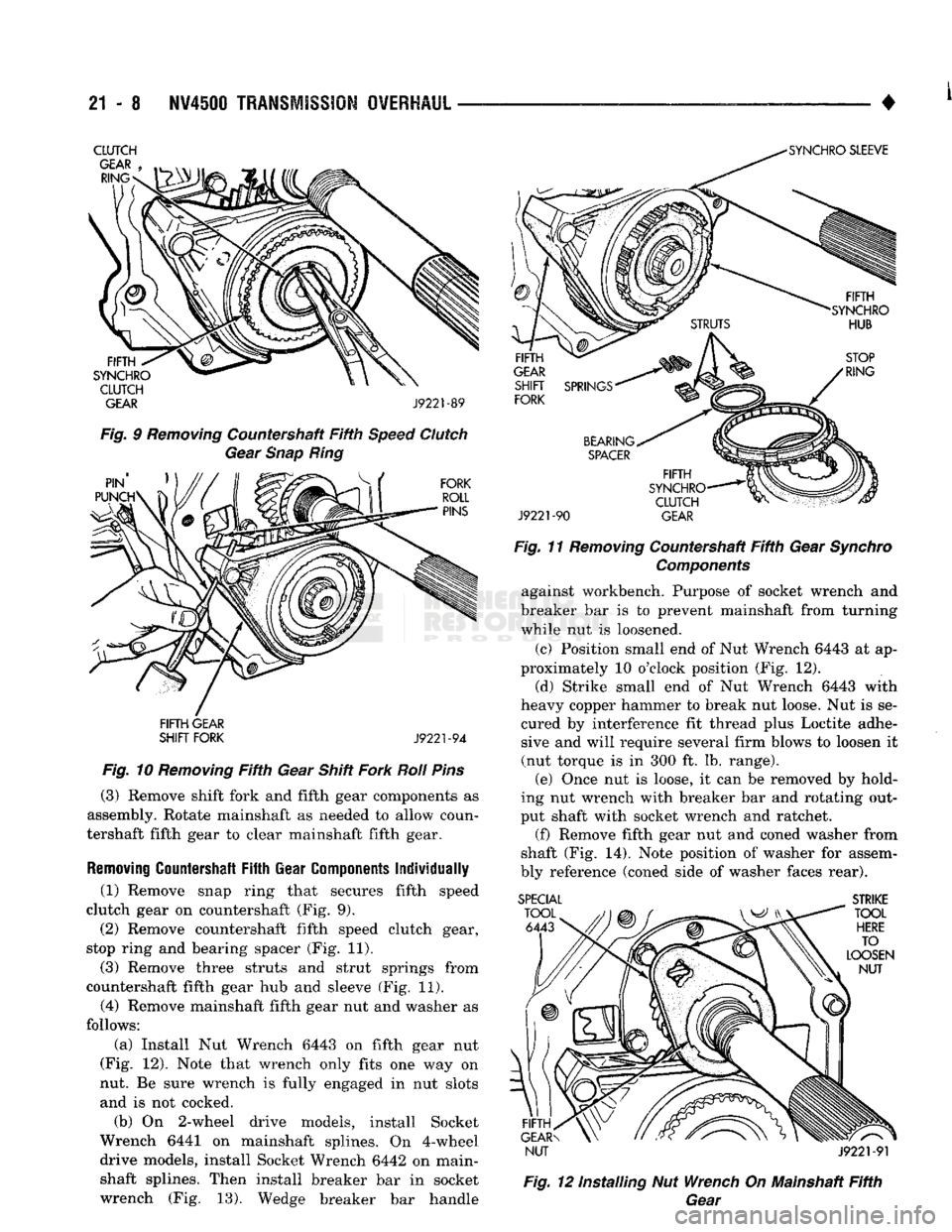

Fig. 9 Removing Countershaft Fifth Speed Clutch Gear Snap Ring

FIFTH GEAR

SHIFT FORK

J9221-94

Fig. 10 Removing Fifth Gear Shift Fork Roil Pins

(3) Remove shift fork and fifth gear components as

assembly. Rotate mainshaft as needed to allow coun

tershaft fifth gear to clear mainshaft fifth gear.

Removing

Countershaft

Fifth

Gear

Components

Individually

(1) Remove snap ring that secures fifth speed

clutch gear on countershaft (Fig. 9). (2) Remove countershaft fifth speed clutch gear,

stop ring and bearing spacer (Fig. 11).

(3) Remove three struts and strut springs from

countershaft fifth gear hub and sleeve (Fig. 11). (4) Remove mainshaft fifth gear nut and washer as

follows:

(a) Install Nut Wrench 6443 on fifth gear nut

(Fig. 12). Note that wrench only fits one way on

nut. Be sure wrench is fully engaged in nut slots and is not cocked.

(b) On 2-wheel drive models, install Socket

Wrench 6441 on mainshaft splines. On 4-wheel drive models, install Socket Wrench 6442 on main-

shaft splines. Then install breaker bar in socket wrench (Fig. 13). Wedge breaker bar handle

J9221-90

GEAR

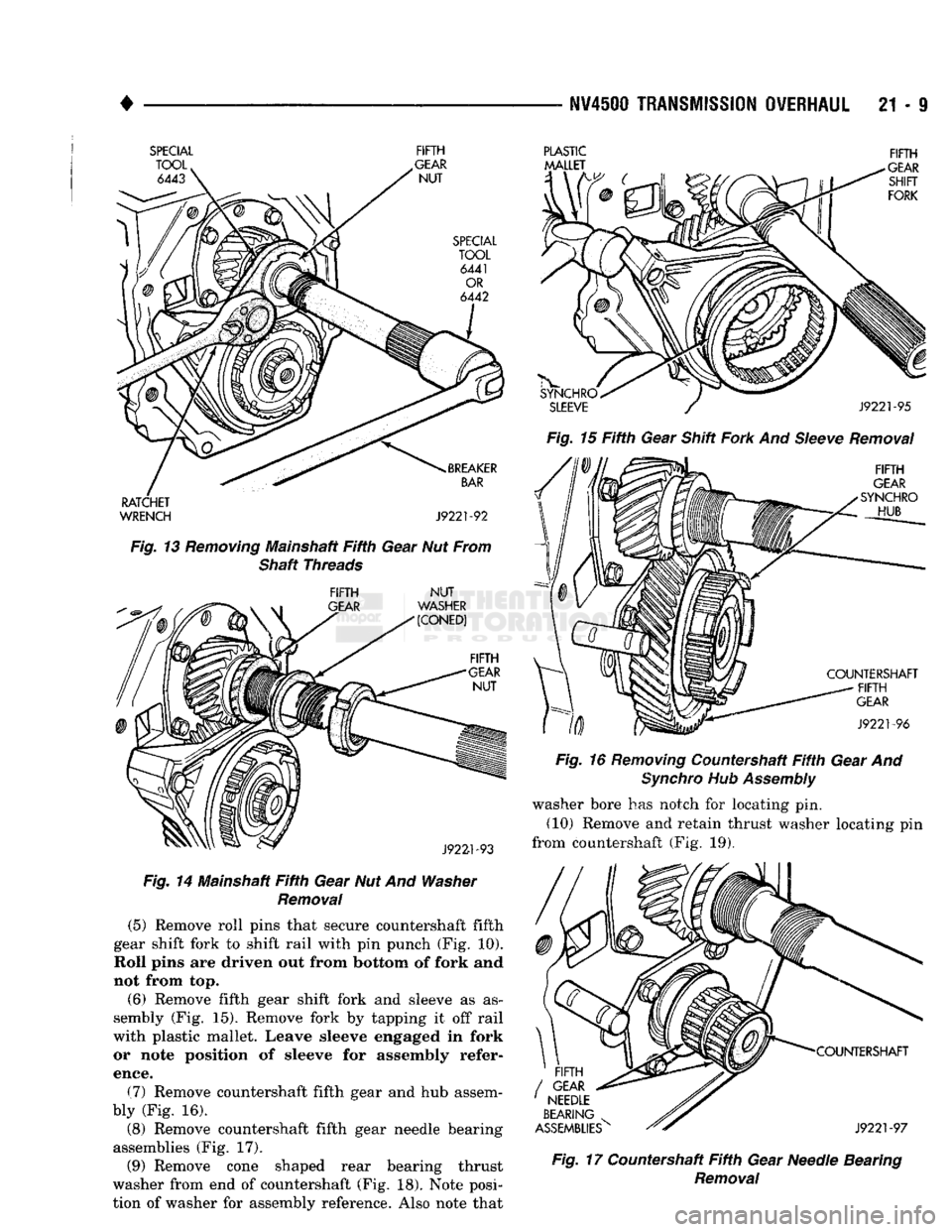

Fig. 11 Removing Countershaft Fifth Gear Synchro Components against workbench. Purpose of socket wrench and

breaker bar is to prevent mainshaft from turning

while nut is loosened.

(c) Position small end of Nut Wrench 6443 at ap

proximately 10 o'clock position (Fig. 12).

(d) Strike small end of Nut Wrench 6443 with

heavy copper hammer to break nut loose. Nut is se

cured by interference fit thread plus Loctite adhe sive and will require several firm blows to loosen it

(nut torque is in 300 ft. lb. range). (e) Once nut is loose, it can be removed by hold

ing nut wrench with breaker bar and rotating out

put shaft with socket wrench and ratchet.

(f)

Remove fifth gear nut and coned washer from

shaft (Fig. 14). Note position of washer for assem

bly reference (coned side of washer faces rear). SPECIAL

STRIKE

NUT J9221-91

Fig. 12 installing Nut Wrench On Mainshaft Fifth Gear

Page 1010 of 1502

NV4500

TRANSMISSION

OVERHAUL

21 - I

SPECIAL FIFTH

RATCHET

WRENCH J9221-92

Fig. 13 Removing Mainshaft Fifth Gear Nut From Shaft Threads

FIFTH

NUT

Fig. 14 Mainshaft Fifth Gear Nut And Washer Removal (5) Remove roll pins that secure countershaft fifth

gear shift fork to shift rail with pin punch (Fig. 10).

Roll pins are driven out from

bottom

of fork and

not from top.

(6) Remove fifth gear shift fork and sleeve as as

sembly (Fig. 15). Remove fork by tapping it off rail

with plastic mallet. Leave sleeve engaged in fork or note position of sleeve for assembly refer

ence.

(7) Remove countershaft fifth gear and hub assem

bly (Fig. 16). (8) Remove countershaft fifth gear needle bearing

assemblies (Fig. 17). (9) Remove cone shaped rear bearing thrust

washer from end of countershaft (Fig. 18). Note posi

tion of washer for assembly reference. Also note that

PLASTIC FIFTH

Fig. 15 Fifth Gear Shift Fork And Sleeve Removal

Fig. 16 Removing Countershaft Fifth Gear And Synchro Hub Assembly washer bore has notch for locating pin.

(10) Remove and retain thrust washer locating pin

from countershaft (Fig. 19). Fig. 17 Countershaft Fifth Gear Needle Bearing

Removal