DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 971 of 1502

19

- 10

STEERING

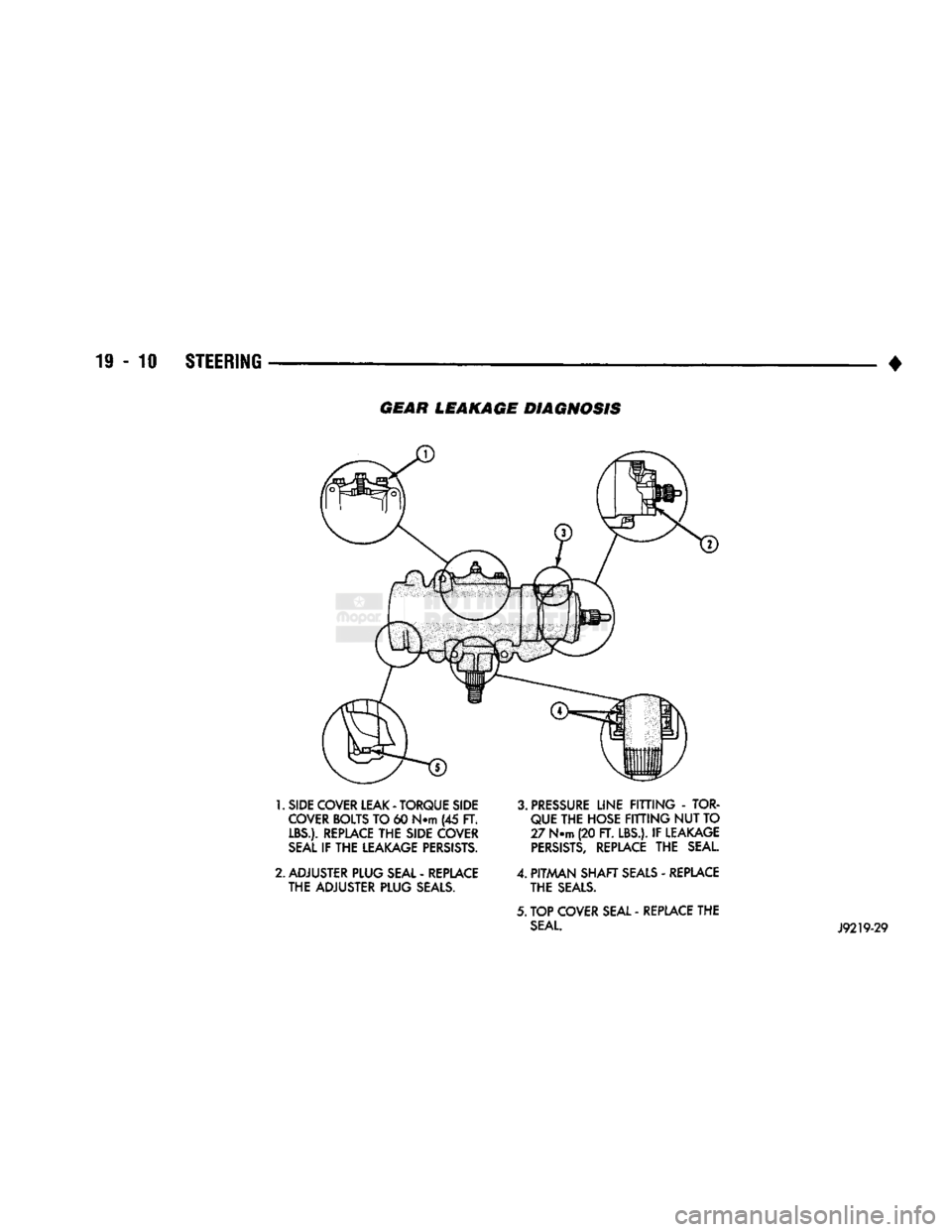

• GEAR LEAKAGE DIAGNOSIS

1.

SIDE COVER LEAK

-

TORQUE SIDE COVER BOLTS

TO 60

NTTI

(45 FT.

LBS.). REPLACE

THE

SIDE COVER

SEAL

IF THE

LEAKAGE PERSISTS.

2.

ADJUSTER PLUG SEAL

-

REPLACE

THE

ADJUSTER PLUG SEALS.

3.

PRESSURE

LINE

FITTING - TOR

QUE THE

HOSE

FITTING NUT TO

27

N.m

(20

FT. LBS.).

IF

LEAKAGE

PERSISTS,

REPLACE

THE

SEAL.

4.

PITMAN

SHAFT

SEALS

-

REPLACE

THE SEALS.

5. TOP

COVER SEAL

-

REPLACE

THE

SEAL. J9219-29

Page 972 of 1502

•

STEERING

19 - 11

POWER STEERING PUMP

INDEX

page

Power

Steering

Hose

11

Power

Steering Pump—Initial Operation

15

Pump

Pulley

15

Pump

Replacement—Diesel Engine

12

SERVICE

INFORMATION

The power steering pump internal components are

not serviced or adjusted. If a malfunction or an inter

nal fluid leak occurs, the complete unit must be re

placed.

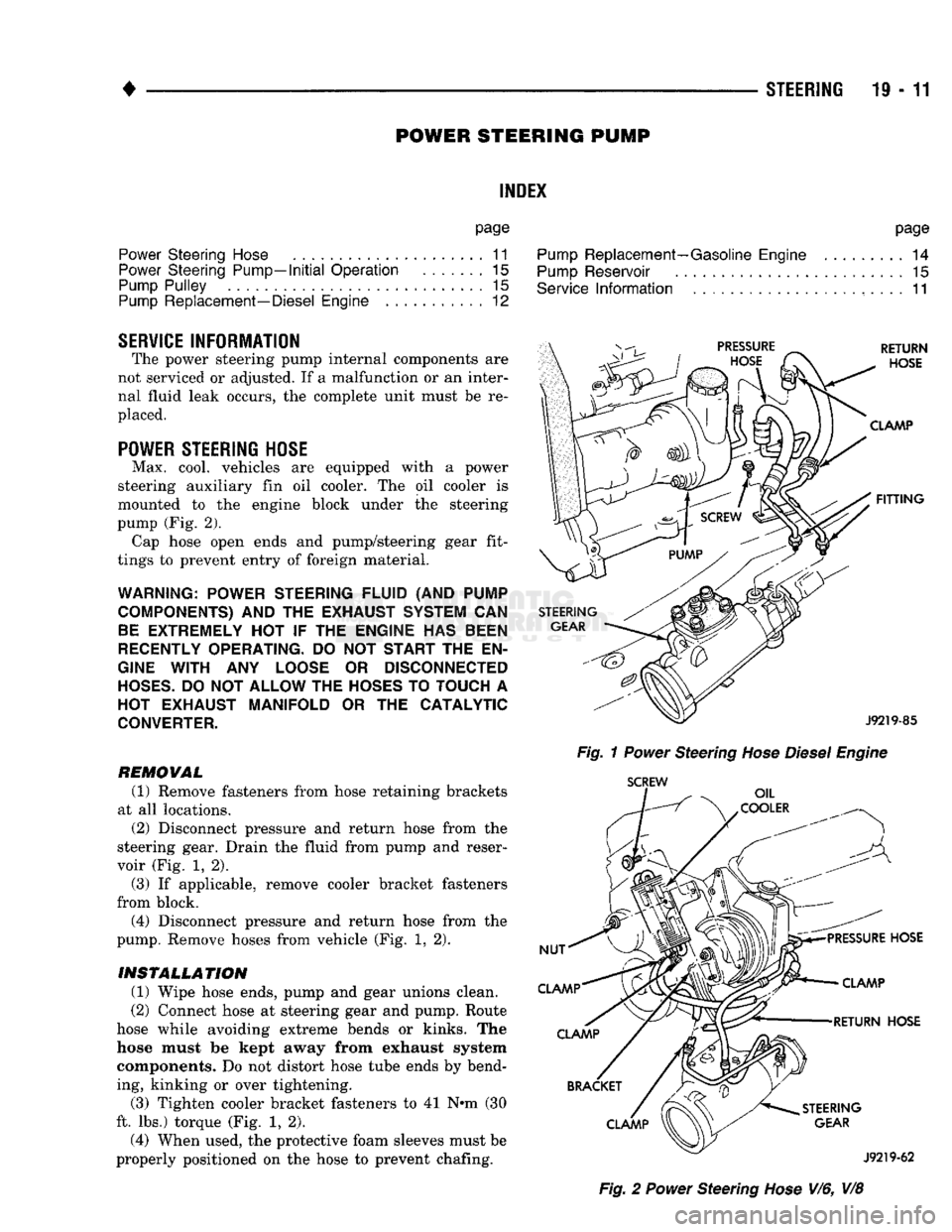

POWER

STEERING HOSE

Max. cool, vehicles are equipped with a power

steering auxiliary fin oil cooler. The oil cooler is

mounted to the engine block under the steering

pump (Fig. 2). Cap hose open ends and pump/steering gear fit

tings to prevent entry of foreign material.

WARNING; POWER STEERING

FLUID

(AND

PUMP

COMPONENTS)

AND THE

EXHAUST SYSTEM

CAN

BE EXTREMELY

HOT IF THE

ENGINE

HAS

BEEN

RECENTLY OPERATING.

DO NOT

START

THE EN

GINE WITH

ANY

LOOSE

OR

DISCONNECTED

HOSES.

DO

NOT

ALLOW

THE

HOSES

TO

TOUCH

A

HOT EXHAUST

MANIFOLD

OR THE

CATALYTIC

CONVERTER.

REMOWAL (1) Remove fasteners from hose retaining brackets

at all locations. (2) Disconnect pressure and return hose from the

steering gear. Drain the fluid from pump and reser

voir (Fig. 1, 2).

(3) If applicable, remove cooler bracket fasteners

from block. (4) Disconnect pressure and return hose from the

pump. Remove hoses from vehicle (Fig. 1, 2).

INSTALLATION

(1) Wipe hose ends, pump and gear unions clean.

(2) Connect hose at steering gear and pump. Route

hose while avoiding extreme bends or kinks. The

hose must be kept away from exhaust system components. Do not distort hose tube ends by bend

ing, kinking or over tightening.

(3) Tighten cooler bracket fasteners to 41 N»m (30

ft. lbs.) torque (Fig. 1, 2). (4) When used, the protective foam sleeves must be

properly positioned on the hose to prevent chafing. page

Pump

Replacement—Gasoline Engine

......... 14

Pump

Reservoir

15

Service

Information

....................... 11

Fig.

1

Power

Steering

Hose Diesel Engine

SCREW

Fig.

2

Power

Steering

Hose

V/6, V/8

Page 973 of 1502

19

- 12

STEERING

• (5) Tighten fittings at pump and gear to 35 Nnn

(25 ft. lbs.) torque.

(6)

Install clamps on return hose on gear and

pump.

(7)

After installation, inspect and test for fluid

leaks.

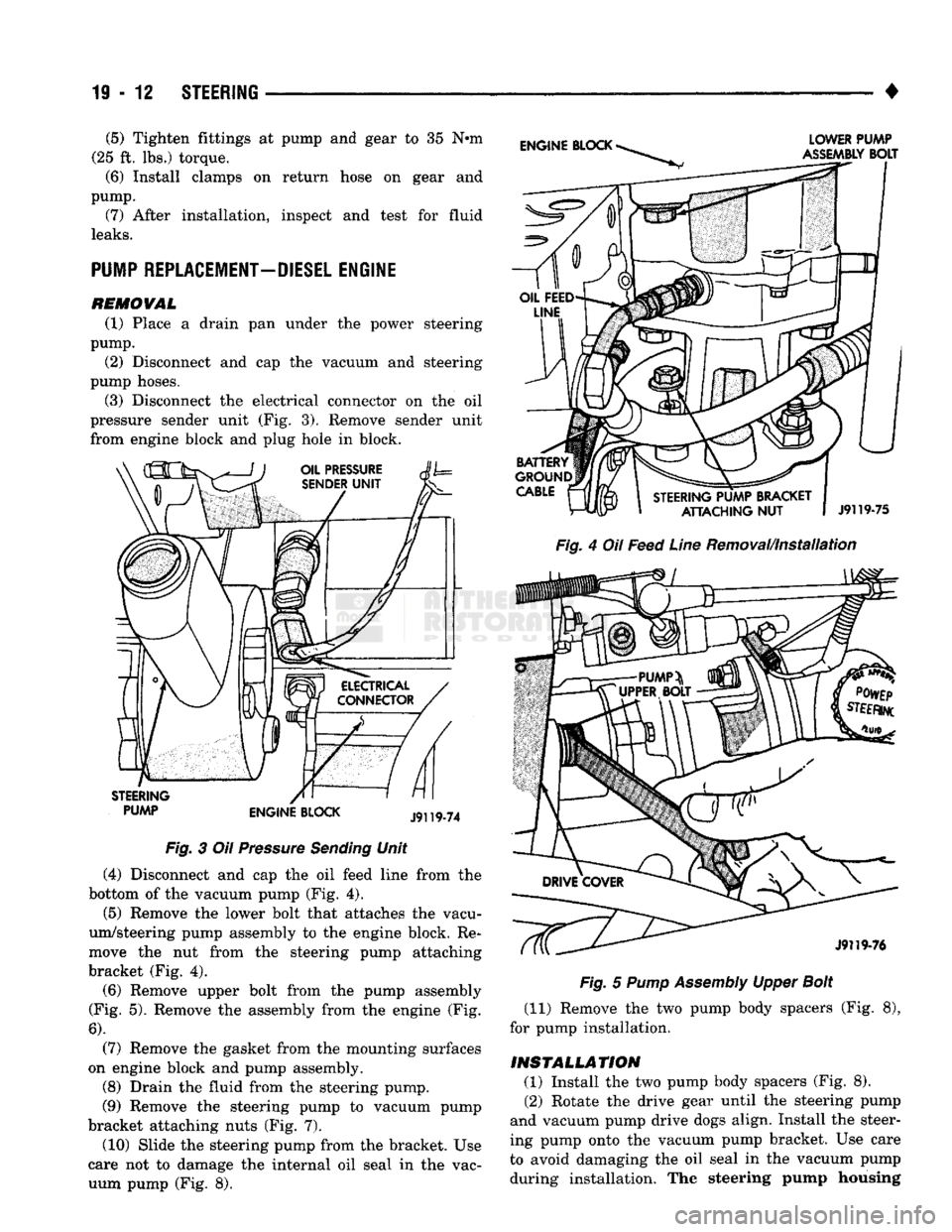

PUMP REPLACEMENT—DIESEL ENGINE

REMOVAL

(1) Place a drain pan under the power steering

pump.

(2) Disconnect and cap the vacuum and steering

pump hoses.

(3) Disconnect the electrical connector on the oil

pressure sender unit (Fig. 3). Remove sender unit

from engine block and plug hole in block.

PUMP ENGINE BLOCK Fig.

3 Oil

Pressure

Sending

Unit

(4) Disconnect and cap the oil feed line from the

bottom of the vacuum pump (Fig. 4). (5) Remove the lower bolt that attaches the vacu

um/steering pump assembly to the engine block. Re

move the nut from the steering pump attaching

bracket (Fig. 4).

(6)

Remove upper bolt from the pump assembly

(Fig. 5). Remove the assembly from the engine (Fig.

6).

(7) Remove the gasket from the mounting surfaces

on engine block and pump assembly.

(8) Drain the fluid from the steering pump.

(9) Remove the steering pump to vacuum pump

bracket attaching nuts (Fig. 7).

(10) Slide the steering pump from the bracket. Use

care not to damage the internal oil seal in the vac uum pump (Fig. 8).

Fig.

4 Oil

Feed

Line

Removal/Installation

Fig.

5

Pump

Assembly

Upper

Bolt

(11) Remove the two pump body spacers (Fig. 8),

for pump installation.

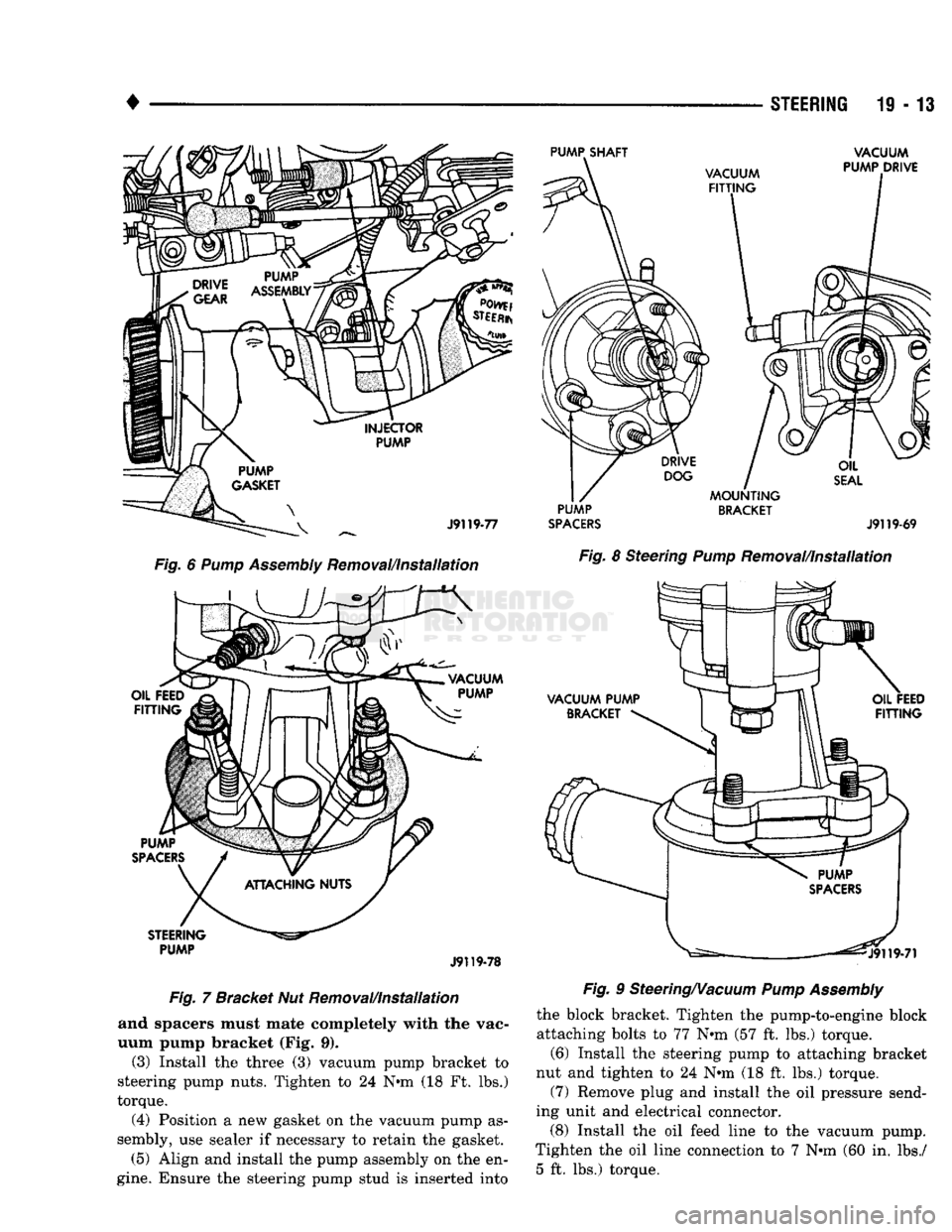

INSTALLATION (1) Install the two pump body spacers (Fig. 8).

(2) Rotate the drive gear until the steering pump

and vacuum pump drive dogs align. Install the steer

ing pump onto the vacuum pump bracket. Use care

to avoid damaging the oil seal in the vacuum pump during installation. The steering pump housing

Page 974 of 1502

•

STEERING

19 - 13

Fig.

6 Pump Assembly Removal/Installation

PUMP

Jf

119-78

Fig. 7 Bracket Nut Removal/Installation

and spacers must mate completely with the vac

uum pump bracket (Fig. 9).

(3) Install the three (3) vacuum pump bracket to

steering pump nuts. Tighten to 24 N«m (18 Ft. lbs.)

torque.

(4) Position a new gasket on the vacuum pump as

sembly, use sealer if necessary to retain the gasket.

(5) Align and install the pump assembly on the en

gine.

Ensure the steering pump stud is inserted into

PUMP

BRACKET

SPACERS

J9119-69

Fig.

8 Steering

Pump

Removal/Installation

Fig.

9 Steering/Vacuum

Pump Assembly

the block bracket. Tighten the pump-to-engine block

attaching bolts to 77 N*m (57 ft. lbs.) torque.

(6) Install the steering pump to attaching bracket

nut and tighten to 24 N*m (18 ft. lbs.) torque.

(7) Remove plug and install the oil pressure send

ing unit and electrical connector. (8) Install the oil feed line to the vacuum pump.

Tighten the oil line connection to 7 N»m (60 in. lbs./ 5 ft. lbs.) torque.

Page 975 of 1502

19

- 14

STEERING

• (9) Install the fluid hoses to the power steering

pump, Tighten the pressure fitting at the pump to 30

N*m (22 ft. lbs.) torque.

(10) Install and clamp the hose on the vacuum

pump. (11) Fill the reservoir with power steering fluid

only. If necessary, refer to Pump Initial Operation

for detailed instructions.

(12) Start and run the engine. Check the operation

of the brakes, if necessary refer to Group 5, Brakes

for additional information.

PUMP REPLACEMENT—GASOLINE ENGINE

REMOVAL

WARNING:

DO NOT

REMOVE

THE

WATER PUMP COOLANT TUBE UNLESS

THE

COOLANT SYSTEM HAS BEEN DEPRESSUR1ZED

AND

DRAINED*

WARNING:

DO NOT

ATTEMPT

TO

REMOVE

THE

PUMP

WITHOUT

REMOVING

THE

BELT FIRST.

THE

AUTOMATIC TENSIONER

IS

UNDER

A

HIGH

SPRING

LOAD.

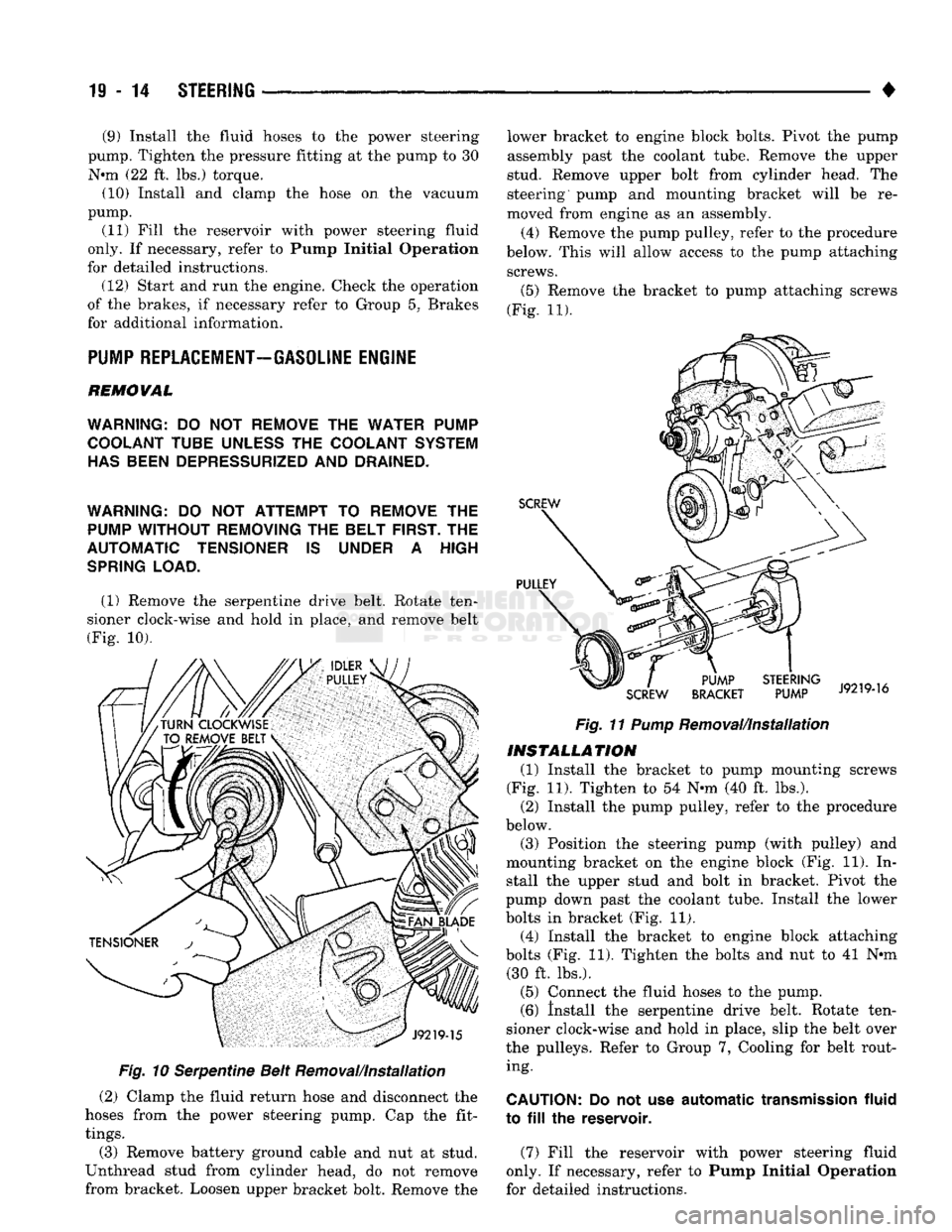

(1) Remove the serpentine drive belt. Rotate ten

sioner clock-wise and hold in place, and remove belt

(Fig. 10).

Fig.

10 Serpentine Belt Removal/Installation

(2) Clamp the fluid return hose and disconnect the

hoses from the power steering pump. Cap the fit

tings.

(3) Remove battery ground cable and nut at stud.

Unthread stud from cylinder head, do not remove

from bracket. Loosen upper bracket bolt. Remove the lower bracket to engine block bolts. Pivot the pump

assembly past the coolant tube. Remove the upper

stud. Remove upper bolt from cylinder head. The

steering pump and mounting bracket will be re

moved from engine as an assembly.

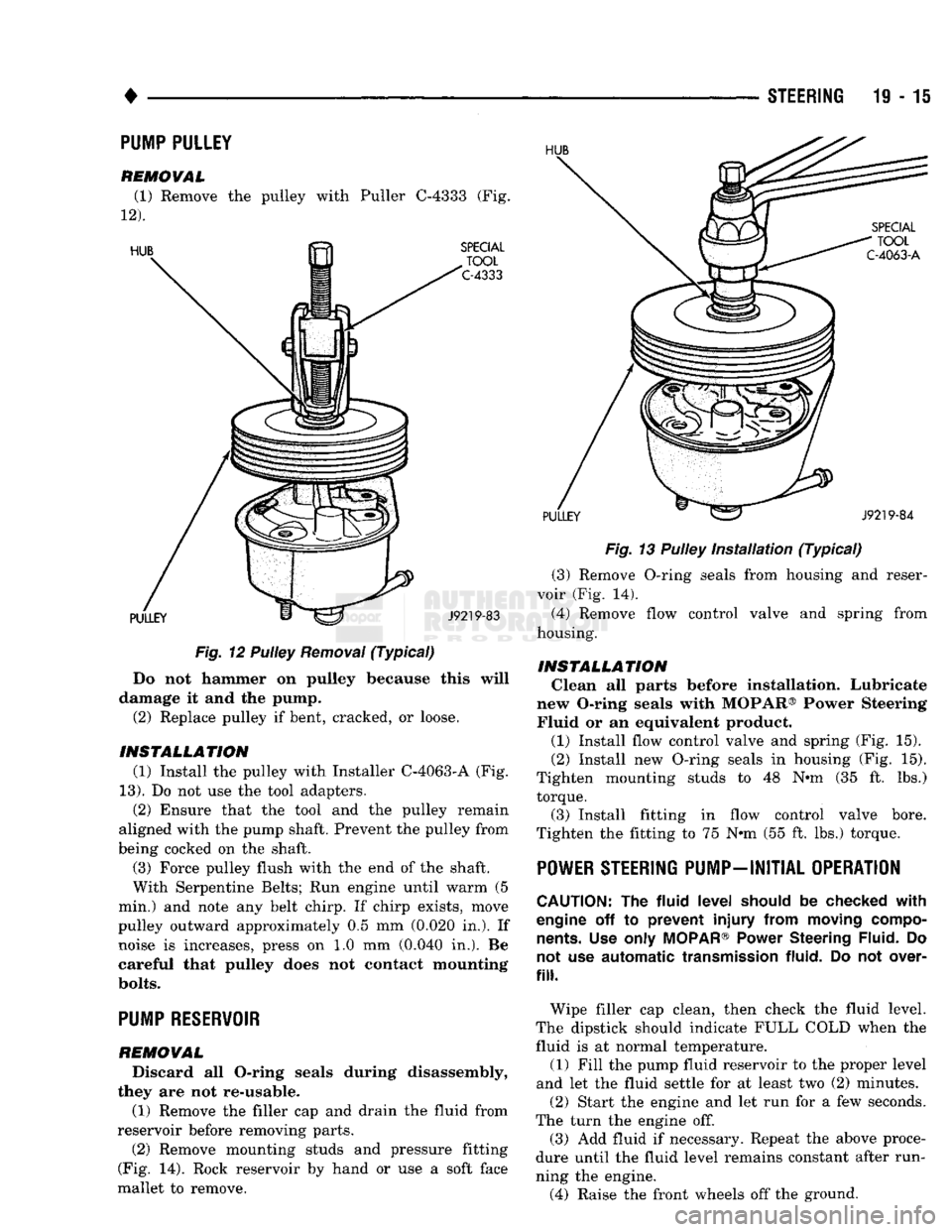

(4) Remove the pump pulley, refer to the procedure

below. This will allow access to the pump attaching screws.

(5)

Remove the bracket to pump attaching screws

(Fig. 11).

Fig.

11

Pump

Removal/Installation

INSTALLATION

(1) Install the bracket to pump mounting screws

(Fig. 11). Tighten to 54 N-m (40 ft. lbs.). (2) Install the pump pulley, refer to the procedure

below.

(3) Position the steering pump (with pulley) and

mounting bracket on the engine block (Fig. 11). In stall the upper stud and bolt in bracket. Pivot the

pump down past the coolant tube. Install the lower

bolts in bracket (Fig. 11). (4) Install the bracket to engine block attaching

bolts (Fig. 11). Tighten the bolts and nut to 41 N*m (30 ft. lbs.).

(5) Connect the fluid hoses to the pump. (6) Install the serpentine drive belt. Rotate ten

sioner clock-wise and hold in place, slip the belt over

the pulleys. Refer to Group 7, Cooling for belt rout ing.

CAUTION:

Do not use

automatic

transmission

fluid

to

fill the

reservoir.

(7) Fill the reservoir with power steering fluid

only. If necessary, refer to Pump Initial Operation

for detailed instructions.

Page 976 of 1502

#

_ ,

Fig.

12 Pulley

Removal

(Typical)

Do not hammer on pulley because this will

damage it and the pump. (2) Replace pulley if bent, cracked, or loose.

INSTALLATION (1) Install the pulley with Installer C-4063-A (Fig.

13).

Do not use the tool adapters. (2) Ensure that the tool and the pulley remain

aligned with the pump shaft. Prevent the pulley from

being cocked on the shaft.

(3) Force pulley flush with the end of the shaft.

With Serpentine Belts; Run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If noise is increases, press on 1.0 mm (0.040 in.). Be

careful that pulley does not contact mounting

bolts.

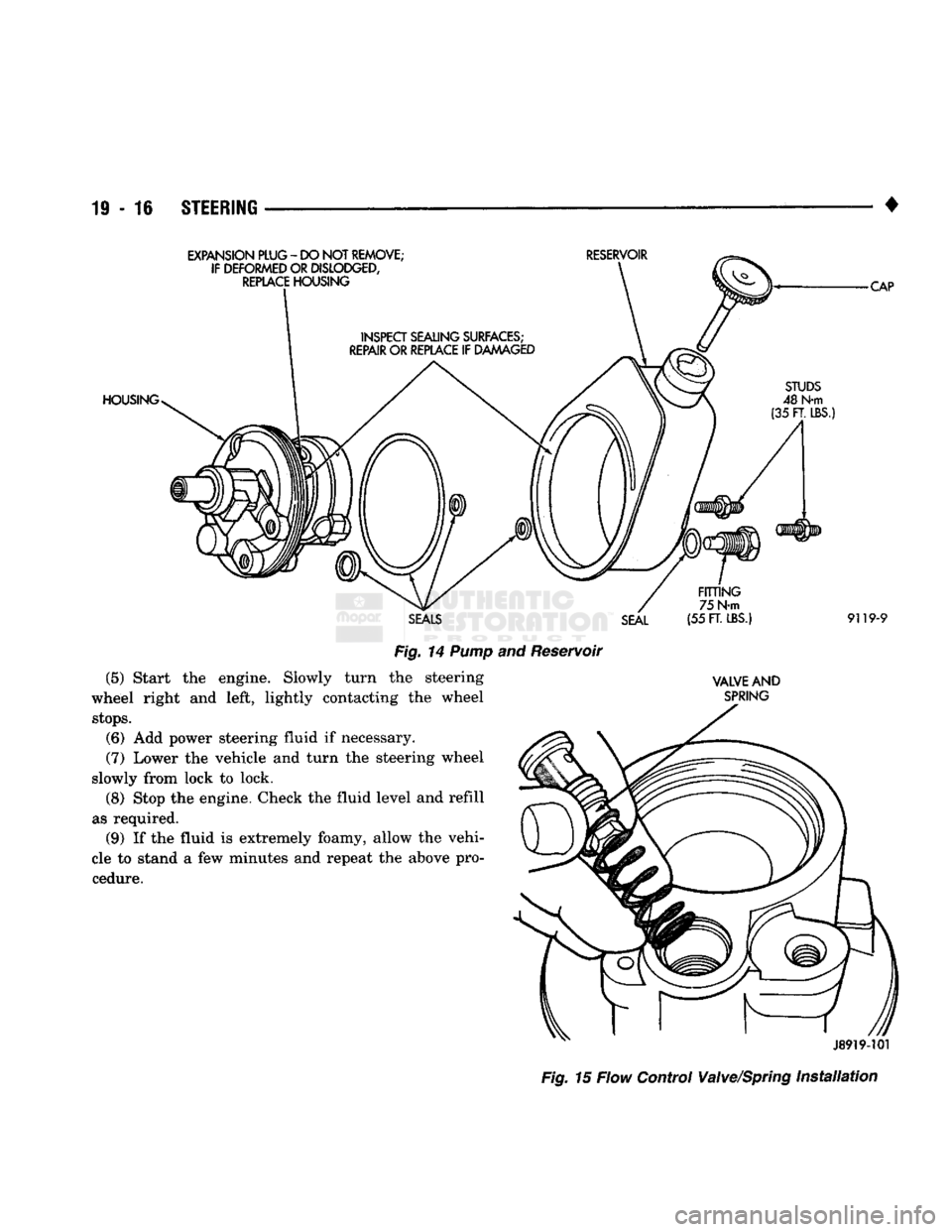

PUMP RESERVOIR

REMOVAL

Discard all O-ring seals during disassembly,

they are not re-usable.

(1) Remove the filler cap and drain the fluid from

reservoir before removing parts. (2) Remove mounting studs and pressure fitting

(Fig. 14). Rock reservoir by hand or use a soft face

mallet to remove. STEERING 19-15

Fig.

13 Pulley

Installation

(Typical)

(3) Remove O-ring seals from housing and reser

voir (Fig. 14). (4) Remove flow control valve and spring from

housing.

INSTALLATION Clean all parts before installation. Lubricate

new O-ring seals with MOPAR® Power Steering Fluid or an equivalent product.

(1) Install flow control valve and spring (Fig. 15).

(2) Install new O-ring seals in housing (Fig. 15).

Tighten mounting studs to 48 N«m (35 ft. lbs.) torque.

(3) Install fitting in flow control valve bore.

Tighten the fitting to 75 N-m (55 ft. lbs.) torque.

POWER STEERING PUMP-INITIAL OPERATION

CAUTION:

The

fluid

level

should

be

checked

with

engine

off to

prevent

injury

from

moving

compo

nents.

Use

only

MOPAR®

Power

Steering

Fluid.

Do

not

use

automatic

transmission

fluid.

Do not

over

fill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicate FULL COLD when the fluid is at normal temperature. (1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes. (2) Start the engine and let run for a few seconds.

The turn the engine off. (3) Add fluid if necessary. Repeat the above proce

dure until the fluid level remains constant after run

ning the engine. (4) Raise the front wheels off the ground.

PUMP PULLEY

REMOVAL

(1) Remove the pulley with Puller C-4333 (Fig.

12).

Page 977 of 1502

19

- 16

STEERING

•

EXPANSION PLUG

-

DO NOT

REMOVE; IF DEFORMED

OR

DISLODGED,

REPLACE

HOUSING

RESERVOIR

HOUSING

CAP

SEAL FITTING

75 N-m

(55

FT.

LBS.)

9119-9

(5)

Start the engine. Slowly turn

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock. (8) Stop the engine. Check the fluid level and refill

as required. (9) If the fluid is extremely foamy, allow the vehi

cle to stand a few minutes and repeat the above pro cedure.

Fig.

14

Pump

and Reservoir

the steering

VALVE

AND

SPRING

J8919-101

Fig.

15 Flow Control Valve/Spring

Installation

Page 978 of 1502

•

STEERING

19 - 17

STEERING

LINKAGE

SERVICE

INFORMATION

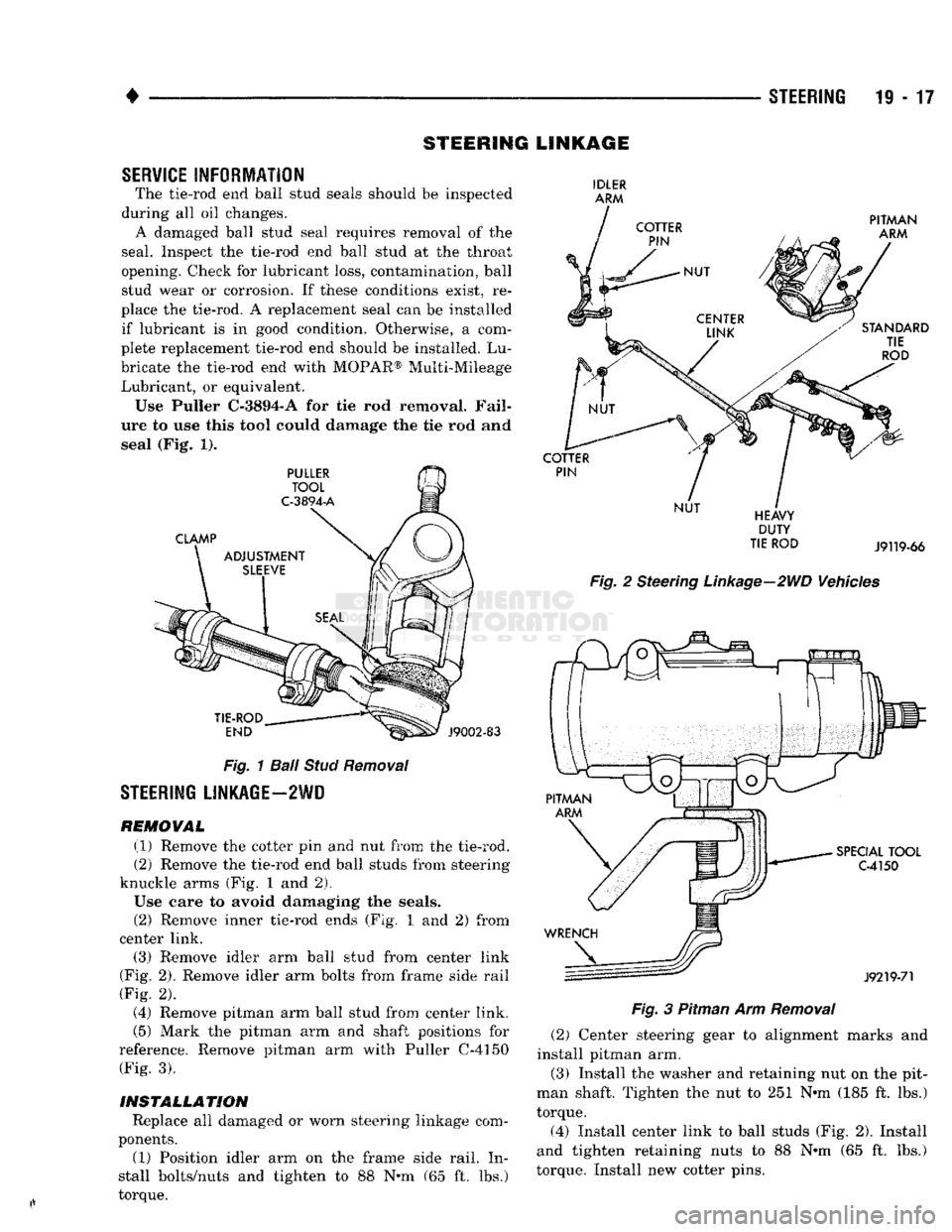

The tie-rod end ball stud seals should be inspected

during all oil changes. A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re

place the tie-rod. A replacement seal can be installed if lubricant is in good condition. Otherwise, a com

plete replacement tie-rod end should be installed. Lu

bricate the tie-rod end with MOPAR® Multi-Mileage Lubricant, or equivalent. Use Puller C-3894-A for tie rod removal. Fail

ure to use this tool could damage the tie rod and seal (Fig. 1).

Fig.

1

Ball

Stud

Removal

STEERING

LINKAGE—2WD

REMOWAL (1) Remove the cotter pin and nut from the tie-rod.

(2) Remove the tie-rod end ball studs from steering

knuckle arms (Fig. 1 and 2),

Use care to avoid damaging the seals. (2) Remove inner tie-rod ends (Fig. 1 and 2) from

center link. (3) Remove idler arm ball stud from center link

(Fig. 2). Remove idler arm bolts from frame side rail

(Fig. 2). (4) Remove pitman arm ball stud from center link.

(5) Mark the pitman arm and shaft positions for

reference. Remove pitman arm with Puller C-4150 (Fig. 3).

INSTALLATION

Replace all damaged or worn steering linkage com

ponents.

(1) Position idler arm on the frame side rail. In

stall bolts/nuts and tighten to 88 N-m (65 ft. lbs.)

torque.

IDLER

ARM

DUTY

TIE

ROD

J9119-66

Fig.

2 Steering

Linkage—2WD

Vehicles

Fig.

3 Pitman Arm

Removal

(2) Center steering gear to alignment marks and

install pitman arm.

(3) Install the washer and retaining nut on the pit

man shaft. Tighten the nut to 251 N-m (185 ft. lbs.)

torque. (4) Install center link to ball studs (Fig. 2). Install

and tighten retaining nuts to 88 N-m (65 ft. lbs.)

torque. Install new cotter pins.

Page 979 of 1502

19

- 18

STEERING

•

CAUTION:

It is

possible

to install the

center

link

re

versed

position.

This

will

result

in

incorrect

geome

try and interferences during vehicle jounce. Viewed

from the

front

of the vehicle, the

center

link

ends

should

turn

upward. Viewed

from

the side of the ve

hicle,

the

ends

should

turn

toward

the

front

of the

vehicle. The

tie-rod

ball

studs

enter

the

center

link

bores

from

the

rear.

(5) Install tie-rod ends into center link (Fig. 2).

Tighten the nuts to 54 N»m (40 ft. lbs.) torque. In stall new cotter pins.

(6) Insert tie-rod ends into steering knuckle arm

(Fig. 2). Tighten the nuts to 54 N-m (40 ft. lbs.)

torque. Install new cotter pins. (7) Remove the supports and lower the vehicle to

the surface. Adjust the wheel toe position (refer to

the Alignment Specifications chart within Group 2,

Front Suspension).

Position the clamp on the sleeve so retaining

bolt is located on the bottom side of the sleeve.

(8) After adjustment, tighten the tie-rod adjust

ment sleeve clamp bolt;

• Standard Duty— 25.4 N-m (225 in. lbs.) torque

• Heavy Duty- 34 N-m (25 ft. lbs.) torque

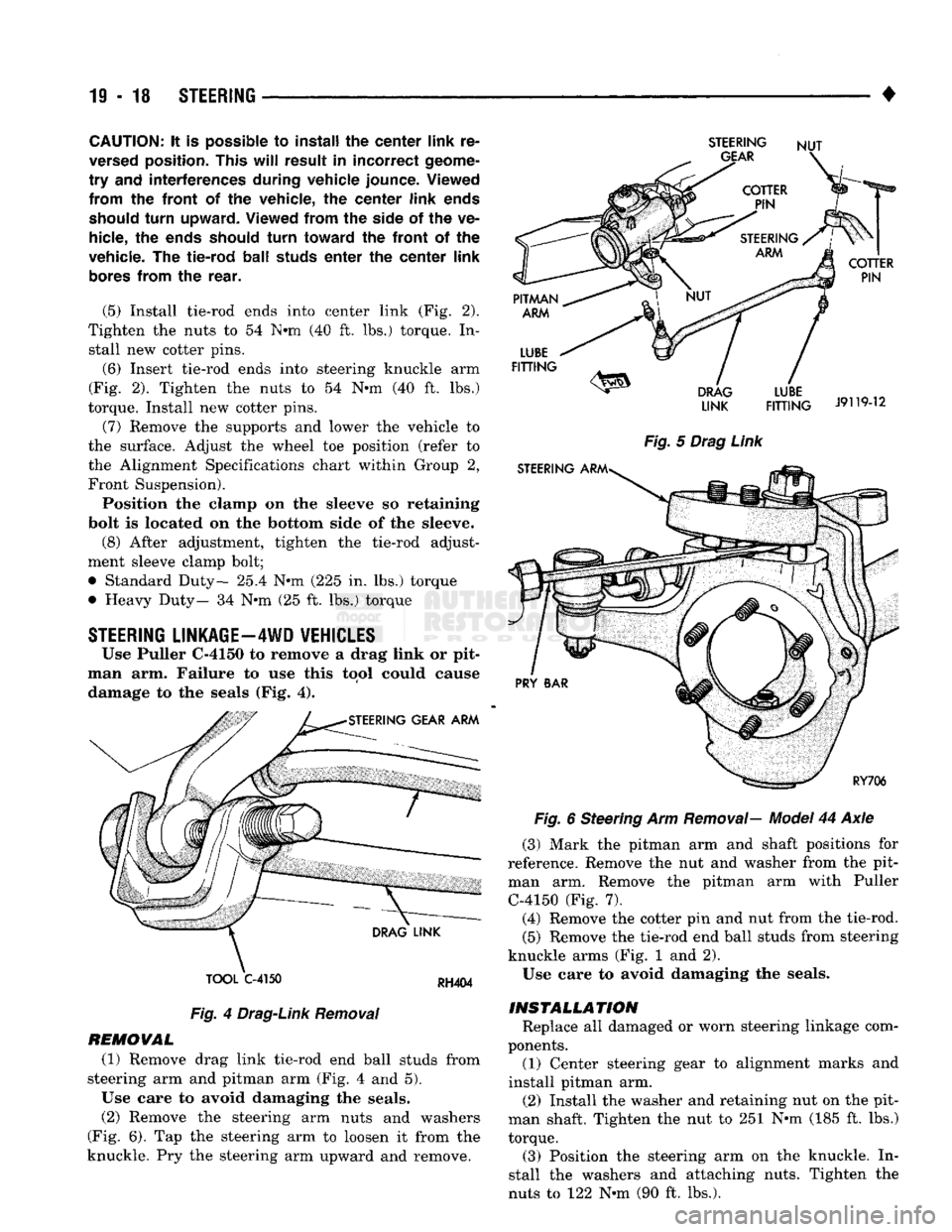

STEERING

LINKAGE—4WD

VEHICLES

Use Puller C-4150 to remove a drag link or pit

man arm. Failure to use this tool could cause damage to the seals (Fig. 4).

TOOL

C-4150

RH404

Fig.

4

Drag-Link

Removal

REMOVAL (1) Remove drag link tie-rod end ball studs from

steering arm and pitman arm (Fig. 4 and 5).

Use care to avoid damaging the seals. (2) Remove the steering arm nuts and washers

(Fig. 6). Tap the steering arm to loosen it from the

knuckle. Pry the steering arm upward and remove.

STEERING

NUT

LINK

FITTING

J9119-12

Fig.

5

Drag

Link

Fig.

6 Steering Arm

Removal—

Model

44 Axle

(3) Mark the pitman arm and shaft positions for

reference. Remove the nut and washer from the pit

man arm. Remove the pitman arm with Puller C-4150 (Fig. 7). (4) Remove the cotter pin and nut from the tie-rod.

(5) Remove the tie-rod end ball studs from steering

knuckle arms (Fig. 1 and 2).

Use care to avoid damaging the seals.

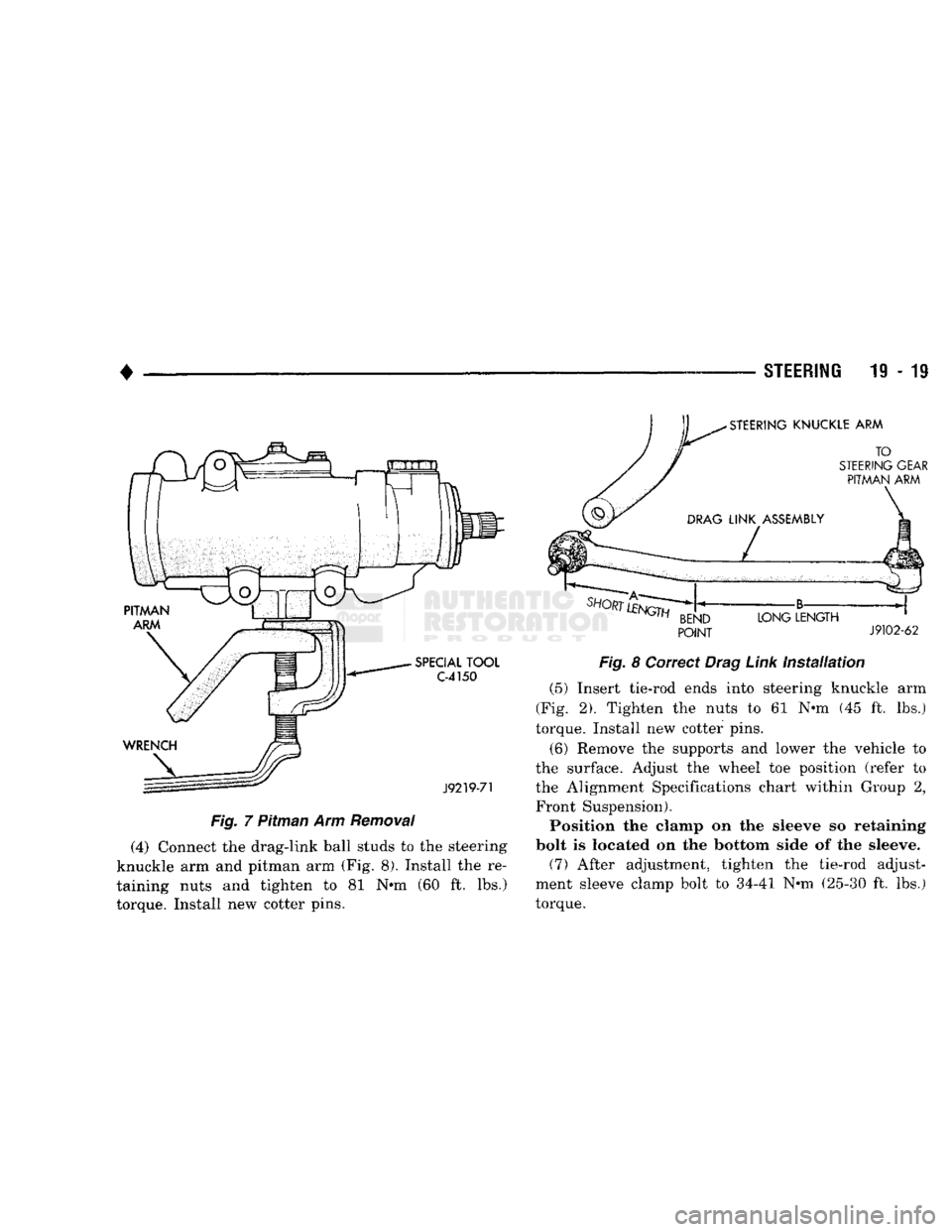

INSTALLATION

Replace all damaged or worn steering linkage com

ponents. (1) Center steering gear to alignment marks and

install pitman arm.

(2) Install the washer and retaining nut on the pit

man shaft. Tighten the nut to 251 N-m (185 ft. lbs.)

torque. (3) Position the steering arm on the knuckle. In

stall the washers and attaching nuts. Tighten the

nuts to 122 N-m (90 ft. lbs.).

Page 980 of 1502

•

STEERING

19 - 19

Fig.

7 Pitman Arm

Removal

(4) Connect the drag-link ball studs to the steering

knuckle arm and pitman arm (Fig. 8). Install the re

taining nuts and tighten to 81 N»m (60 ft. lbs.)

torque. Install new cotter pins.

POINT

J9102-62

Fig.

8 Correct

Drag

Link

installation

(5) Insert tie-rod ends into steering knuckle arm

(Fig. 2). Tighten the nuts to 61 N-m (45 ft. lbs.)

torque. Install new cotter pins.

(6) Remove the supports and lower the vehicle to

the surface. Adjust the wheel toe position (refer to the Alignment Specifications chart within Group 2, Front Suspension). Position the clamp on the sleeve so retaining

bolt is located on the bottom side of the sleeve. (7) After adjustment, tighten the tie-rod adjust

ment sleeve clamp bolt to 34-41 N-m (25-30 ft. lbs.)

torque.