DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 991 of 1502

11-30 STEERING

Fig.

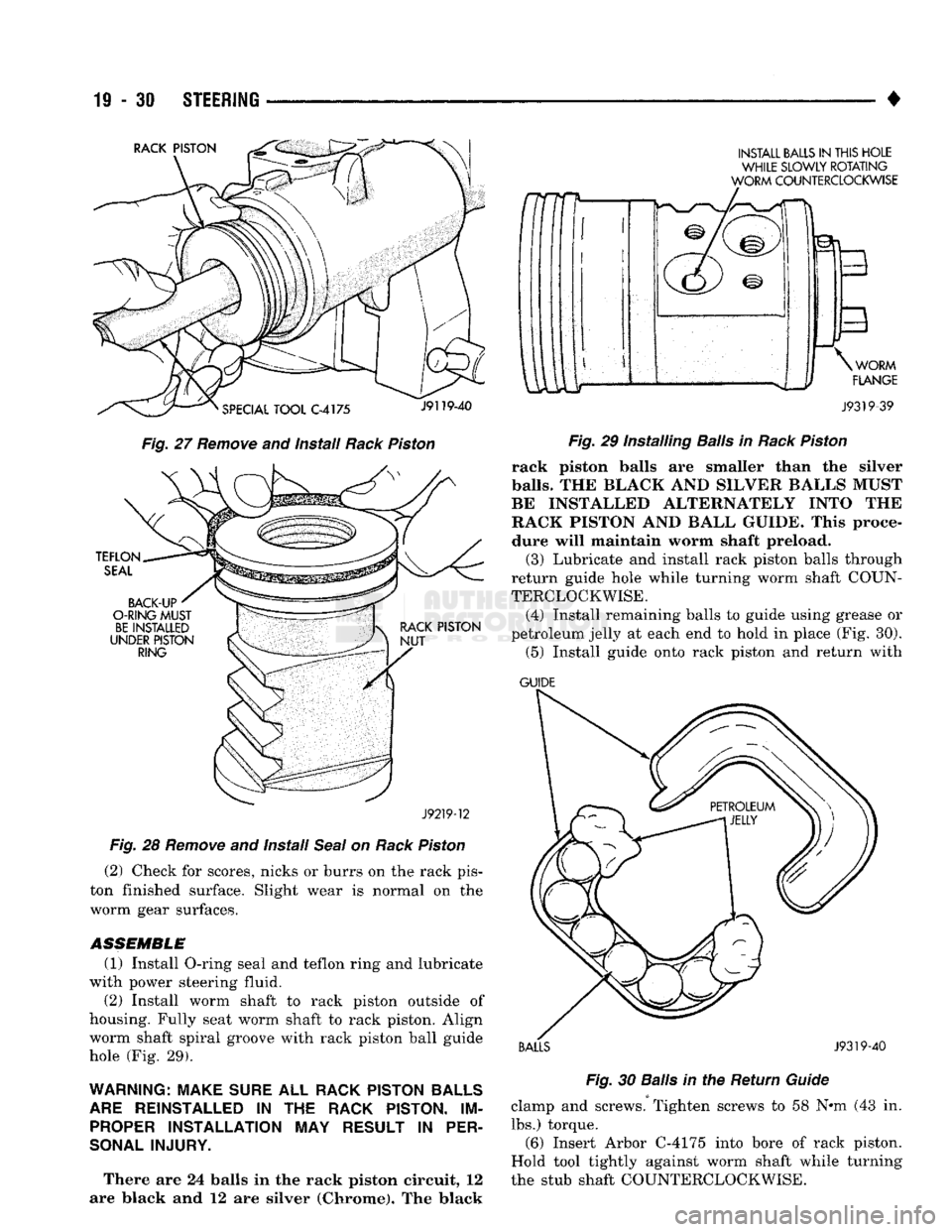

27 Remove and install Rack Piston

J92T9-12

Fig. 28 Remove and Install Seal on Rack Piston (2) Check for scores, nicks or burrs on the rack pis

ton finished surface. Slight wear is normal on the

worm gear surfaces.

ASSEMBLE

(1) Install O-ring seal and teflon ring and lubricate

with power steering fluid. (2) Install worm shaft to rack piston outside of

housing. Fully seat worm shaft to rack piston. Align worm shaft spiral groove with rack piston ball guide

hole (Fig. 29).

WARNING: MAKE SURE ALL RACK PISTON BALLS ARE REINSTALLED IN THE RACK PISTON. IM PROPER INSTALLATION MAY RESULT IN PER

SONAL INJURY.

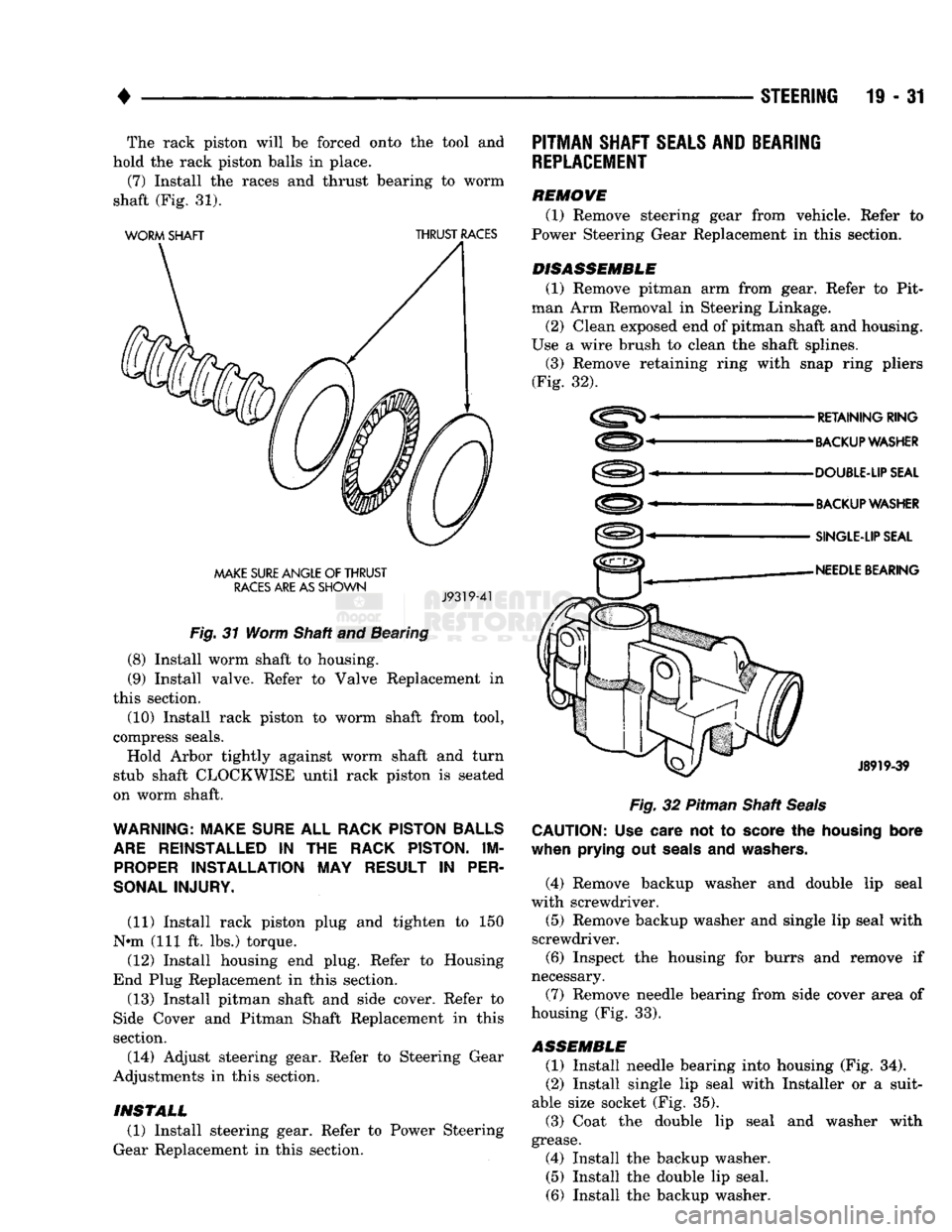

There are 24 balls in the rack piston circuit, 12

are Mack and 12 are silver (Chrome). The black w

INSTALL BALLS IN THIS HOLE WHILE SLOWLY ROTATING

WORM COUNTERCLOCKWISE

J9319-39

Fig.

29 Installing

Balls

in

Rack

Piston

rack piston balls are smaller than the silver

balls.

THE BLACK AND SILVEE BALLS MUST

BE INSTALLED ALT1ENATELY INTO THE

RACK PISTON AND BALL GUIDE. This proce

dure will maintain worm shaft preload. (3) Lubricate and install rack piston balls through

return guide hole while turning worm shaft COUN

TERCLOCKWISE.

(4) Install remaining balls to guide using grease or

petroleum jelly at each end to hold in place (Fig. 30). (5) Install guide onto rack piston and return with

GUIDE

BALLS J9319-40 Fig.

30

Balls

in the Return

Guide

clamp and screws. Tighten screws to 58 N#m (43 in. lbs.) torque. (6) Insert Arbor C-4175 into bore of rack piston.

Hold tool tightly against worm shaft while turning

the stub shaft COUNTERCLOCKWISE.

Page 992 of 1502

•

STEERING

19 - 31 The rack piston will be forced onto the tool and

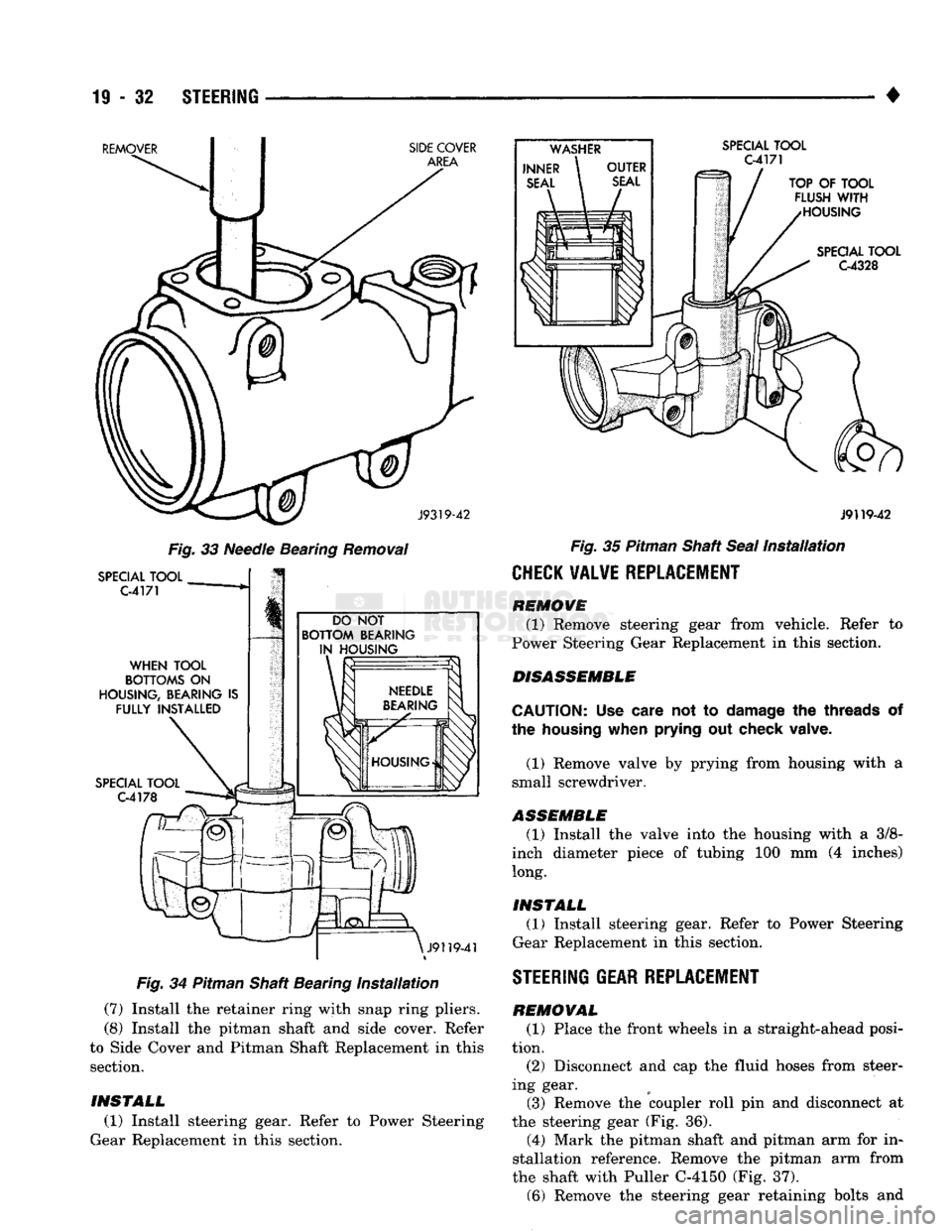

hold the rack piston balls in place. (7) Install the races and thrust bearing to worm

shaft (Fig. 31).

WORM

SHAFT

THRUST

RACES

MAKE

SURE

ANGLE

OF

THRUST

RACES

ARE AS

SHOWN

J9319-41

Fig.

31 Worm Shaft and Bearing

(8) Install worm shaft to housing. (9) Install valve. Refer to Valve Replacement in

this section.

(10) Install rack piston to worm shaft from tool,

compress seals. Hold Arbor tightly against worm shaft and turn

stub shaft CLOCKWISE until rack piston is seated

on worm shaft.

WARNING: MAKE

SURE

ALL

RACK PISTON BALLS

ARE

REINSTALLED

IN THE

RACK PISTON.

IM

PROPER

INSTALLATION

MAY

RESULT

IN

PER

SONAL INJURY.

(11) Install rack piston plug and tighten to 150

N»m (111 ft. lbs.) torque. (12) Install housing end plug. Refer to Housing

End Plug Replacement in this section. (13) Install pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

(14) Adjust steering gear. Refer to Steering Gear

Adjustments in this section.

PITMAN

SHAFT

SEALS AND

BEARING

REPLACEMENT

REMOVE (1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

(1) Remove pitman arm from gear. Refer to Pit

man Arm Removal in Steering Linkage.

(2) Clean exposed end of pitman shaft and housing.

Use a wire brush to clean the shaft splines. (3) Remove retaining ring with snap ring pliers

(Fig. 32).

RETAINING

RING

BACKUP WASHER

DOUBLE-UP SEAL

BACKUP WASHER

SINGLE-LIP SEAL

NEEDLE

BEARING

J8919-39

Fig.

32 Pitman Shaft

Seals

CAUTION:

Use

care

not to

score

the

housing

bore

when

prying

out

seals

and

washers.

(4) Remove backup washer and double lip seal

with screwdriver.

(5) Remove backup washer and single lip seal with

screwdriver. (6) Inspect the housing for burrs and remove if

necessary.

(7) Remove needle bearing from side cover area of

housing (Fig. 33).

ASSEMBLE

(1) Install needle bearing into housing (Fig. 34).

(2) Install single lip seal with Installer or a suit

able size socket (Fig. 35).

(3) Coat the double lip seal and washer with

grease. (4) Install the backup washer. (5) Install the double lip seal.

(6) Install the backup washer.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

Page 993 of 1502

19

- 32

STEERING

REMOVER SIDE COVER

AREA

SPECIAL

TOOL

C-4171

J9319-42

Fig.

33

Needle Bearing Removal

SPECIAL

TOOL

C-4171

WHEN

TOOL

BOTTOMS

ON

HOUSING,

BEARING

IS

FULLY INSTALLED

SPECIAL

TOOL

C-4178

DO

NOT

BOTTOM BEARING IN HOUSING

\

J9119-4

Fig.

34

Pitman Shaft Bearing

Installation

(7) Install

the

retainer ring with snap ring pliers.

(8) Install

the

pitman shaft

and

side cover. Refer

to Side Cover

and

Pitman Shaft Replacement

in

this section.

TOP

OF

TOOL

FLUSH

WITH

HOUSING

SPECIAL

TOOL

C4328

J9119-42

Fig.

35

Pitman Shaft Seal

Installation

CHECK VALVE REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer

to

Power Steering Gear Replacement

in

this section.

DISASSEMBLE

CAUTION:

Use

care

not to

damage

the

threads

of

the

housing

when

prying

out

check valve.

(1) Remove valve

by

prying from housing with

a

small screwdriver.

ASSEMBLE (1) Install

the

valve into

the

housing with

a 3/8-

inch diameter piece

of

tubing

100 mm (4

inches) long.

INSTALL (1) Install steering gear. Refer

to

Power Steering

Gear Replacement

in

this section.

STEERING GEAR REPLACEMENT

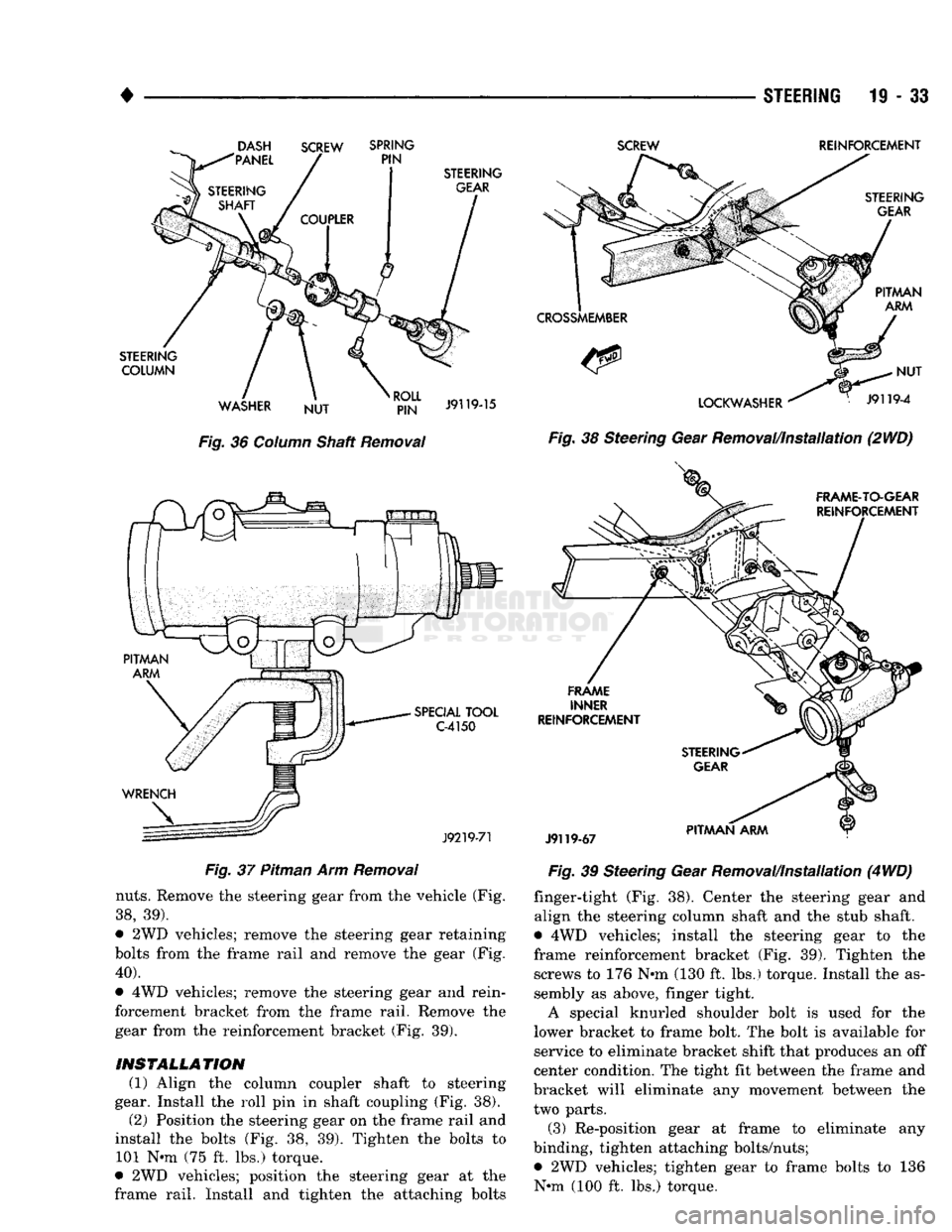

REMOVAL (1) Place

the

front wheels

in a

straight-ahead posi

tion. (2) Disconnect

and cap the

fluid hoses from steer

ing gear. (3) Remove

the

coupler roll

pin and

disconnect

at

the steering gear

(Fig. 36).

(4) Mark

the

pitman shaft

and

pitman

arm for in

stallation reference. Remove

the

pitman

arm

from

the shaft with Puller C-4150

(Fig. 37).

(6) Remove

the

steering gear retaining bolts

and

INSTALL

(1) Install steering gear. Refer

to

Power Steering

Gear Replacement

in

this section.

Page 994 of 1502

•

STEERING 11-33

Fig.

36

Column

Shaft

Removal

Fig.

37 Pitman Arm

Removal

nuts.

Remove the steering gear from the vehicle (Fig.

38,

39).

9

2WD vehicles; remove the steering gear retaining

bolts from the frame rail and remove the gear (Fig.

40).

• 4WD vehicles; remove the steering gear and rein

forcement bracket from the frame rail. Remove the

gear from the reinforcement bracket (Fig. 39).

INSTALLATION (1) Align the column coupler shaft to steering

gear. Install the roll pin in shaft coupling (Fig. 38).

(2) Position the steering gear on the frame rail and

install the bolts (Fig. 38, 39). Tighten the bolts to 101 N-m (75 ft. lbs.) torque.

• 2WD vehicles; position the steering gear at the

frame rail. Install and tighten the attaching bolts

SCREW

REINFORCEMENT

Fig.

38 Steering Gear Removal/Installation (2WD)

Fig.

39 Steering Gear Removal/Installation (4

WD)

finger-tight (Fig. 38). Center the steering gear and

align the steering column shaft and the stub shaft.

• 4WD vehicles; install the steering gear to the

frame reinforcement bracket (Fig. 39). Tighten the screws to 176 N»m (130 ft. lbs.) torque. Install the assembly as above, finger tight.

A special knurled shoulder bolt is used for the

lower bracket to frame bolt. The bolt is available for service to eliminate bracket shift that produces an off

center condition. The tight fit between the frame and

bracket will eliminate any movement between the two parts.

(3) Re-position gear at frame to eliminate any

binding, tighten attaching bolts/nuts;

• 2WD vehicles; tighten gear to frame bolts to 136 N-m (100 ft. lbs.) torque.

Page 995 of 1502

19

- 34

STEERING

• •

4WD vehicles; tighten gear frame reinforcement

bracket to frame bolts/nuts to 223 N-m (165 ft. lbs.)

torque.

(4) Align and install the pitman arm.

(5) Install the washer and retaining nut on the pit

man shaft. Tighten the nut to 251 N-m (185 ft. lbs.)

torque.

(6) Connect fluid hoses to steering gear, tighten to

28 N-m (21 ft. lbs.). Add fluid, refer to Power Steer

ing Pump Initial Operation.

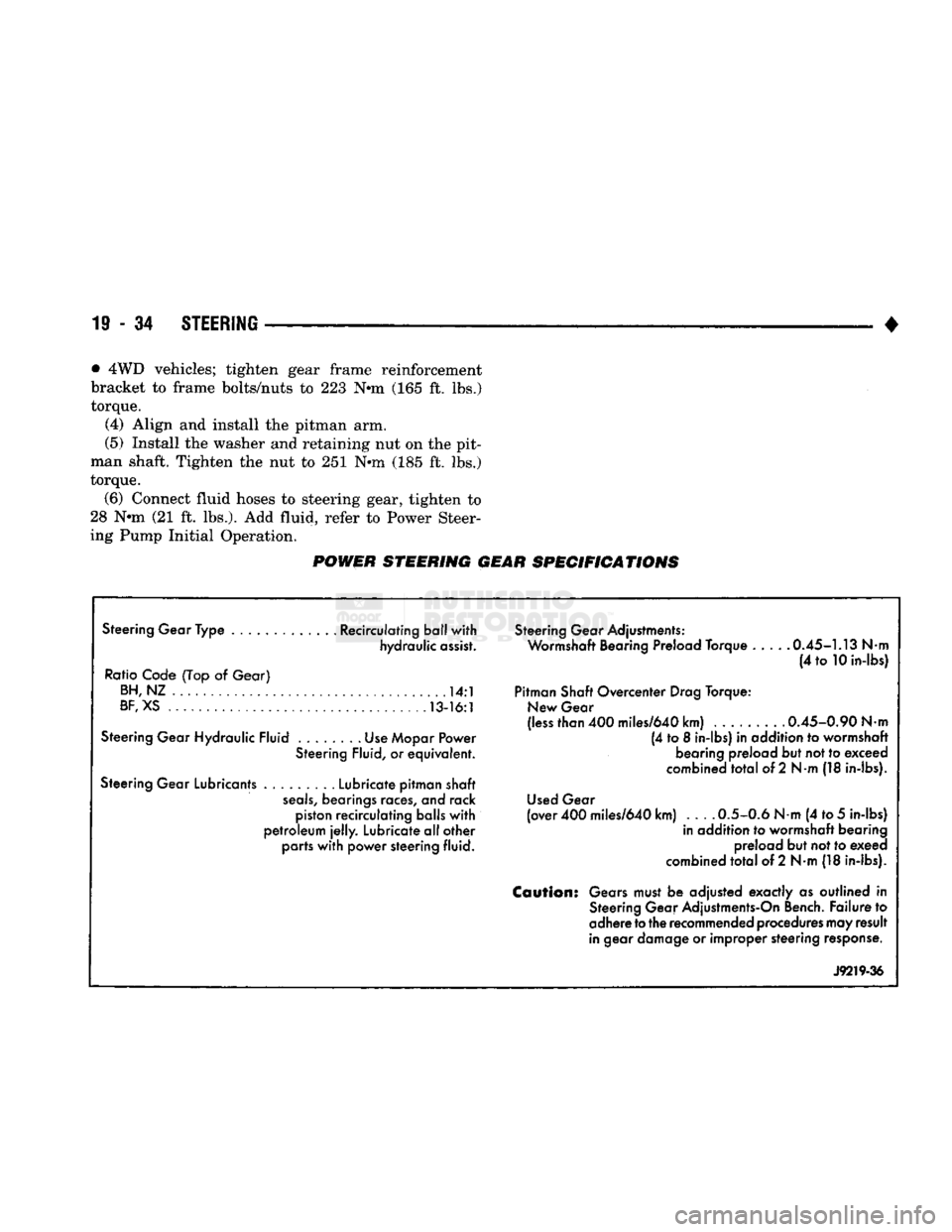

POWER STEERING GEAR SPECIFICATIONS

Steering Gear Type ............. Recirculating ball with hydraulic assist.

Ratio Code (Top

of

Gear) BH,NZ

14:1

BF,

XS 13-16:1

Steering Gear Hydraulic Fluid Use Mopar Power Steering Fluid,

or

equivalent.

Steering Gear Lubricants Lubricate pitman shaft

seals,

bearings races,

and

rack piston recirculating balls with

petroleum

jelly.

Lubricate all other parts with power steering fluid. Steering Gear Adjustments:

Wormshaft Bearing Preload Torque 0.45-1.13

Nm

(4

to

10 in-lbs)

Pitman Shaft Overcenter Drag Torque: New Gear

(less than 400 miles/640 km) ......... 0.45-0.90

Nm

(4

to 8

in-lbs)

in

addition

to

wormshaft bearing preload but not to exceed

combined total

of

2

Nm

(18 in-lbs).

Used Gear

(over 400 miles/640 km) 0.5-0.6

Nm

(4 to

5

in-lbs) in addition

to

wormshaft bearing preload but not to exeed

combined total

of

2 N-m (18 in-lbs).

Caution:

Gears must

be

adjusted exactly

as

outlined

in

Steering Gear Adjustments-On Bench. Failure

to

adhere

to

the recommended procedures may result

in gear damage

or

improper steering response.

J9219-36

Page 996 of 1502

•

STEERING 19 - 3i STEERING COLUMN

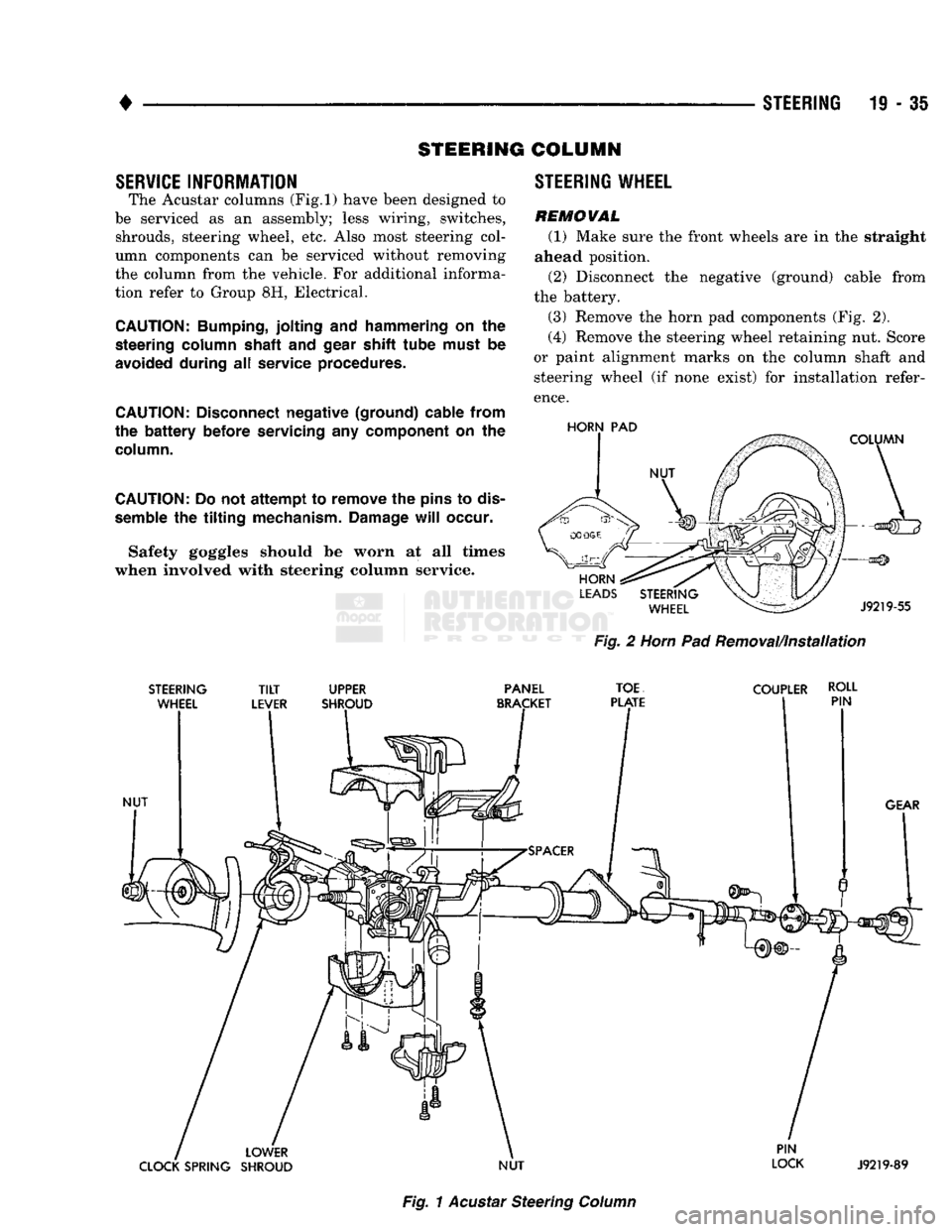

SERVICE INFORMATION The Acustar columns

(Fig.l)

have been designed to

be serviced as an assembly; less wiring, switches, shrouds, steering wheel, etc. Also most steering col

umn components can be serviced without removing

the column from the vehicle. For additional informa

tion refer to Group 8H, Electrical.

CAUTION:

Bumping,

jolting

and

hammering

on the

steering

column

shaft

and

gear shift

tube

must

be

avoided during

all

service procedures.

CAUTION:

Disconnect negative (ground) cable from

the

battery

before servicing

any

component

on the

column.

CAUTION:

Do not

attempt

to remove the

pins

to

dis

semble

the

tilting

mechanism. Damage

will

occur.

Safety goggles should be worn at all times

when involved with steering column service. STEERING WHEEL

REMOWAL

(1) Make sure the front wheels are in the straight

ahead position.

(2) Disconnect the negative (ground) cable from

the battery.

(3) Remove the horn pad components (Fig. 2).

(4) Remove the steering wheel retaining nut. Score

or paint alignment marks on the column shaft and steering wheel (if none exist) for installation refer

ence.

HORN

PAD

Fig.

2

Horn

Pad Removal/installation

STEERING

TILT

UPPER PANEL

TOE

COUPLER ROLL

Fig.

1

Acustar

Steering

Column

Page 997 of 1502

19-36 STEERING

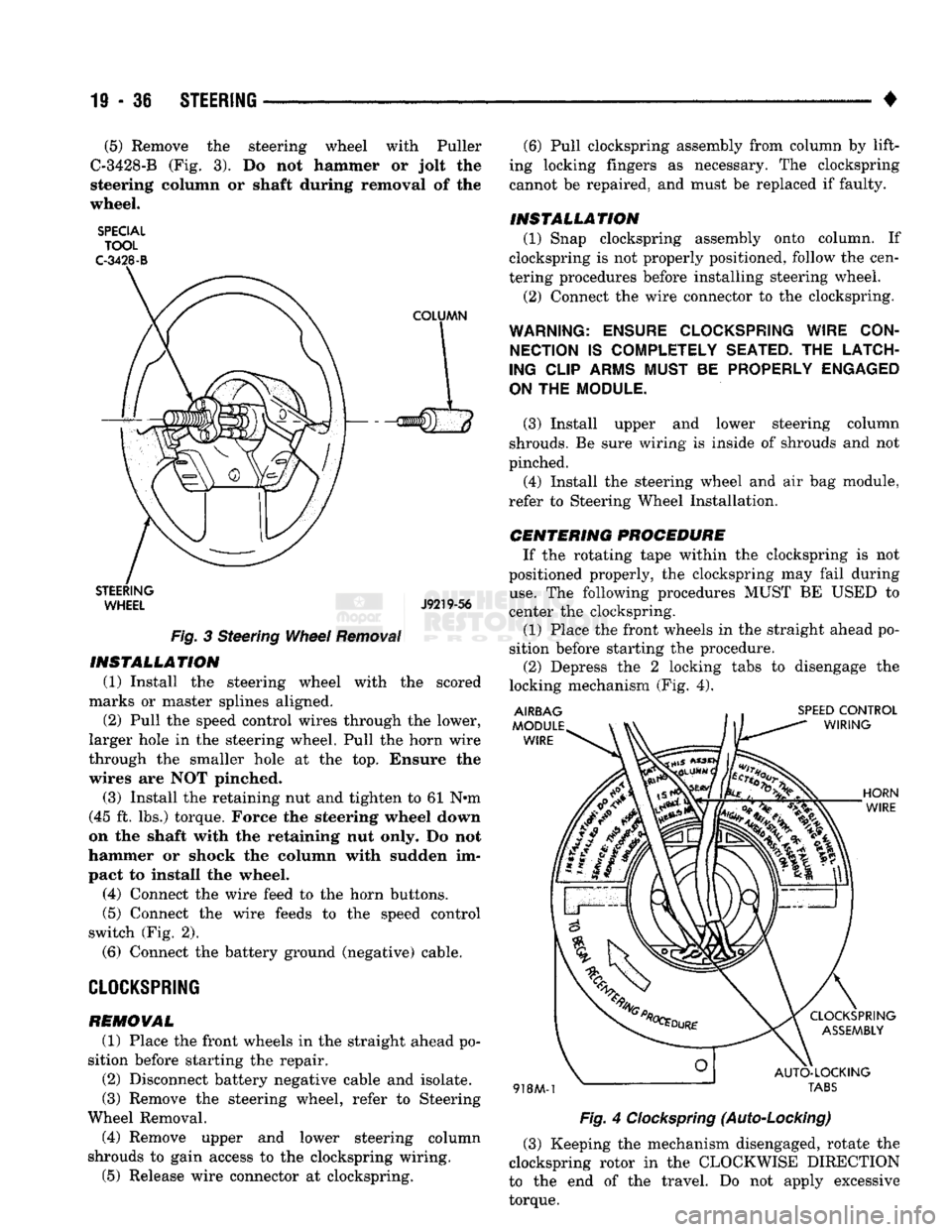

• (5) Remove the steering wheel with Puller

C-3428-B (Fig. 3). Do not hammer or jolt the

steering column or shaft during removal of the

wheel.

SPECIAL TOOL

C-3428-B

STEERING WHEEL J9219-56

Fig.

3 Steering

Wheel

Removal

INSTALLATION

(1) Install the steering wheel with the scored

marks or master splines aligned. (2) Pull the speed control wires through the lower,

larger hole in the steering wheel. Pull the horn wire

through the smaller hole at the top. Ensure the

wires are NOT pinched.

(3) Install the retaining nut and tighten to 61 N«m

(45 ft. lbs.) torque. Force the steering wheel down

on the shaft with the retaining nut only. Do not

hammer or shock the column with sudden im

pact to install the wheel.

(4) Connect the wire feed to the horn buttons.

(5) Connect the wire feeds to the speed control

switch (Fig. 2).

(6) Connect the battery ground (negative) cable.

CLOCKSPRING

REMOVAL

(1) Place the front wheels in the straight ahead po

sition before starting the repair.

(2) Disconnect battery negative cable and isolate.

(3) Remove the steering wheel, refer to Steering

Wheel Removal. (4) Remove upper and lower steering column

shrouds to gain access to the clockspring wiring.

(5) Release wire connector at clockspring. (6) Pull clockspring assembly from column by lift

ing locking fingers as necessary. The clockspring

cannot be repaired, and must be replaced if faulty.

INSTALLATION

(1) Snap clockspring assembly onto column. If

clockspring is not properly positioned, follow the cen

tering procedures before installing steering wheel.

(2) Connect the wire connector to the clockspring.

WARNING: ENSURE CLOCKSPRING WIRE CON NECTION

IS

COMPLETELY SEATED.

THE

LATCH

ING CLIP ARMS MUST

BE

PROPERLY ENGAGED

ON

THE

MODULE.

(3) Install upper and lower steering column

shrouds. Be sure wiring is inside of shrouds and not

pinched. (4) Install the steering wheel and air bag module,

refer to Steering Wheel Installation.

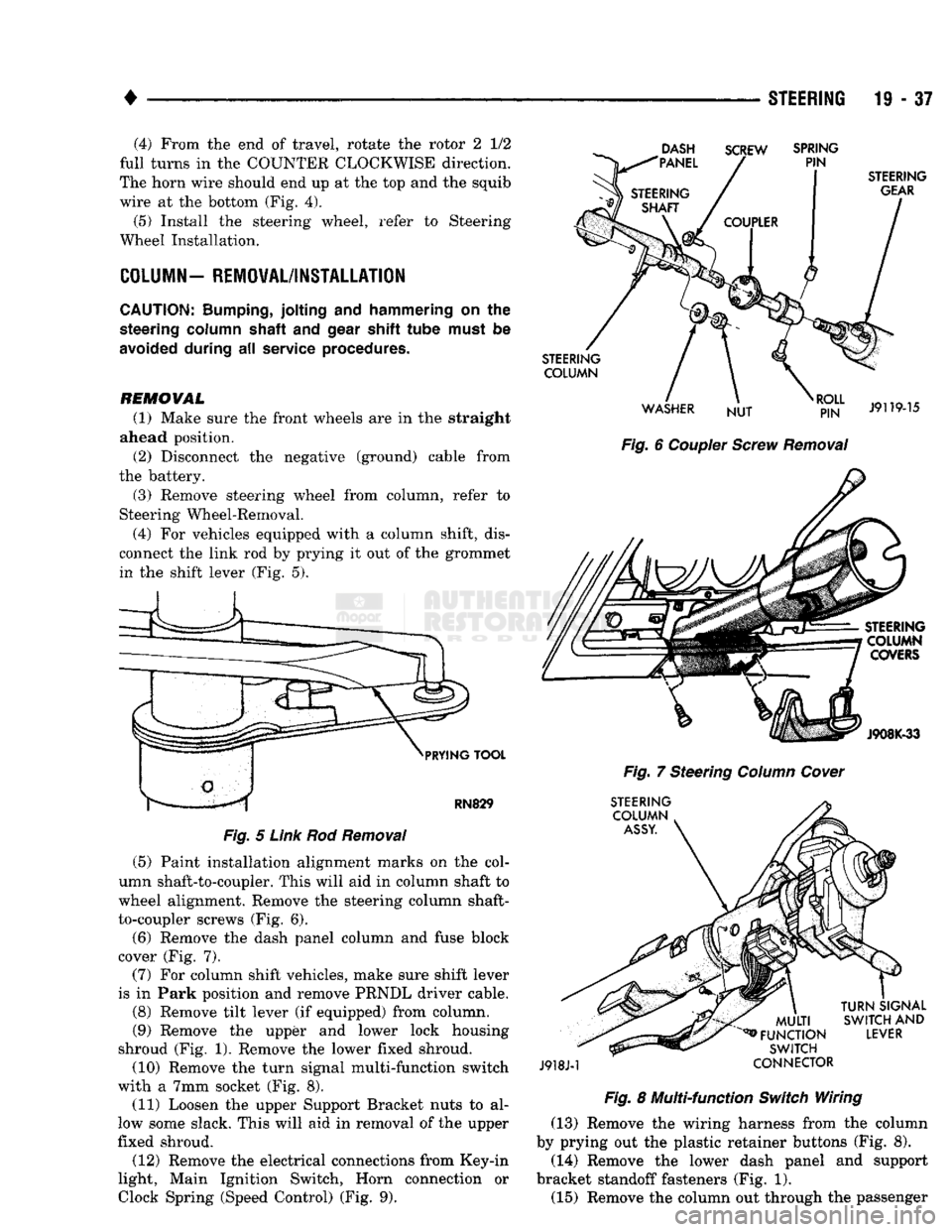

CENTERING

PROCEDURE

If the rotating tape within the clockspring is not

positioned properly, the clockspring may fail during

use.

The following procedures MUST BE USED to

center the clockspring.

(1) Place the front wheels in the straight ahead po

sition before starting the procedure. (2) Depress the 2 locking tabs to disengage the

locking mechanism (Fig. 4).

Fig.

4

Clockspring

(Auto-Locking)

(3) Keeping the mechanism disengaged, rotate the

clockspring rotor in the CLOCKWISE DIRECTION

to the end of the travel. Do not apply excessive

torque.

Page 998 of 1502

•

STEERING

19 • 37 (4) From the end of travel, rotate the rotor 2 1/2

full turns in the COUNTER CLOCKWISE direction.

The horn wire should end up at the top and the squib

wire at the bottom (Fig. 4).

(5) Install the steering wheel, refer to Steering

Wheel Installation.

COLUMN—

REMOVAL/INSTALLATION

CAUTION:

Bumping,

jolting

and

hammering

on the

steering

column

shaft

and

gear

shift

tube

must

be

avoided

during

all

service

procedures.

REMOVAL (1) Make sure the front wheels are in the straight

ahead position.

(2) Disconnect the negative (ground) cable from

the battery.

(3) Remove steering wheel from column, refer to

Steering Wheel-Removal.

(4) For vehicles equipped with a column shift, dis

connect the link rod by prying it out of the grommet in the shift lever (Fig. 5).

DASH

"PANEL SCREW

SPRING

PIN

PRYING

TOOL

RN829

Fig.

5

Link

Rod

Removal

(5) Paint installation alignment marks on the col

umn shaft-to-coupler. This will aid in column shaft to

wheel alignment. Remove the steering column shaft-

to-coupler screws (Fig. 6).

(6) Remove the dash panel column and fuse block

cover (Fig. 7).

(7) For column shift vehicles, make sure shift lever

is in Park position and remove PRNDL driver cable.

(8) Remove tilt lever (if equipped) from column.

(9) Remove the upper and lower lock housing

shroud (Fig. 1). Remove the lower fixed shroud.

(10) Remove the turn signal multi-function switch

with a 7mm socket (Fig. 8). (11) Loosen the upper Support Bracket nuts to al

low some slack. This will aid in removal of the upper

fixed shroud.

(12) Remove the electrical connections from Key-in

light, Main Ignition Switch, Horn connection or

Clock

Spring (Speed

Control)

(Fig. 9).

STEERING

GEAR

STEERING COLUMN

WASHER NUT

RJ?N"

J9119-15

Fig.

6

Coupler

Screw

Removal

STEERING COLUMN COVERS

J908K-33

Fig.

7 Steering

Column

Cover

STEERING COLUMN

ASSY.

J918J-1

MULTI

^FUNCTION

SWITCH

CONNECTOR

TURN

SIGNAL

SWITCH

AND

LEVER

Fig.

8 Multi-function

Switch

Wiring (13) Remove the wiring harness from the column

by prying out the plastic retainer buttons (Fig. 8).

(14) Remove the lower dash panel and support

bracket standoff fasteners (Fig. 1). (15) Remove the column out through the passenger

Page 999 of 1502

19

- 38

STEERING

KEY-IN SWITCH

&

MULTI FUNCTION

SWITCH CONTROL J918J-2

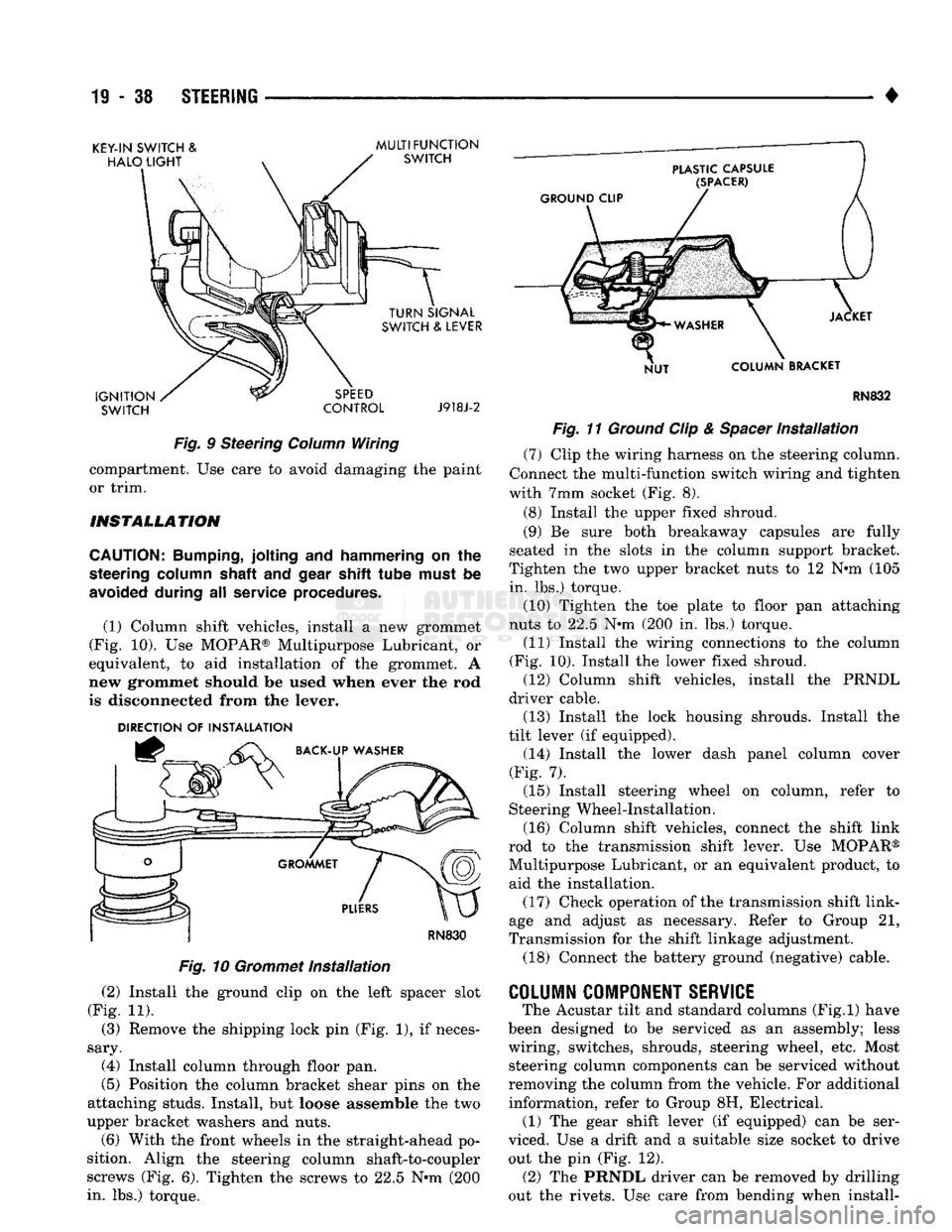

Fig.

9 Steering

Column

Wiring compartment. Use care to avoid damaging the paint

or trim.

INSTALLATION

CAUTION:

Bumping,

jolting and hammering on the

steering

column

shaft

and

gear

shift tube

must

be

avoided

during all service

procedures.

(1) Column shift vehicles, install a new grommet

(Fig. 10). Use MOPAR® Multipurpose Lubricant, or

equivalent, to aid installation of the grommet. A

new grommet should be used when ever the rod

is disconnected from the lever.

DIRECTION

OF

INSTALLATION

RN830

Fig.

10

Grommet

Installation

(2) Install the ground clip on the left spacer slot

(Fig. 11). (3) Remove the shipping lock pin (Fig. 1), if neces

sary. (4) Install column through floor pan.

(5) Position the column bracket shear pins on the

attaching studs. Install, but loose assemble the two

upper bracket washers and nuts. (6) With the front wheels in the straight-ahead po

sition. Align the steering column shaft-to-coupler

screws (Fig. 6). Tighten the screws to 22.5 N*m (200

in. lbs.) torque. RN832

Fig.

11

Ground

Clip &

Spacer

Installation

(7) Clip the wiring harness on the steering column.

Connect the multi-function switch wiring and tighten

with 7mm socket (Fig. 8).

(8) Install the upper fixed shroud.

(9) Be sure both breakaway capsules are fully

seated in the slots in the column support bracket.

Tighten the two upper bracket nuts to 12 N-m (105

in. lbs.) torque.

(10) Tighten the toe plate to floor pan attaching

nuts to 22.5 N-m (200 in. lbs.) torque.

(11) Install the wiring connections to the column

(Fig. 10). Install the lower fixed shroud. (12) Column shift vehicles, install the PRNDL

driver cable. (13) Install the lock housing shrouds. Install the

tilt lever (if equipped). (14) Install the lower dash panel column cover

(Fig. 7).

(15) Install steering wheel on column, refer to

Steering Wheel-Installation.

(16) Column shift vehicles, connect the shift link

rod to the transmission shift lever. Use MOPAR®

Multipurpose Lubricant, or an equivalent product, to

aid the installation. (17) Check operation of the transmission shift link

age and adjust as necessary. Refer to Group 21,

Transmission for the shift linkage adjustment.

(18) Connect the battery ground (negative) cable.

COLUMN

COMPONENT

SERVICE

The Acustar tilt and standard columns (Fig.l) have

been designed to be serviced as an assembly; less

wiring, switches, shrouds, steering wheel, etc. Most steering column components can be serviced without

removing the column from the vehicle. For additional

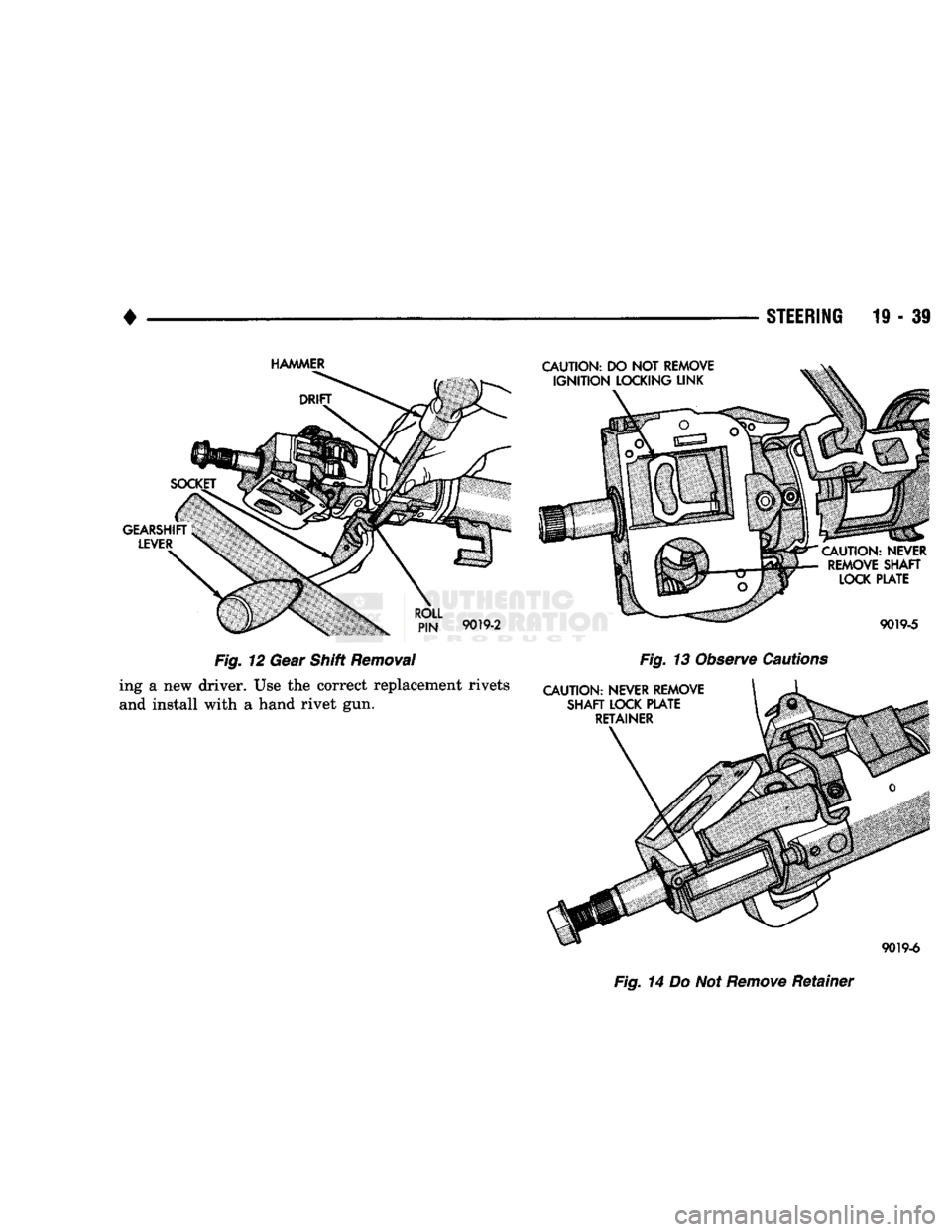

information, refer to Group 8H, Electrical. (1) The gear shift lever (if equipped) can be ser

viced. Use a drift and a suitable size socket to drive out the pin (Fig. 12). (2) The PRNDL driver can be removed by drilling

out the rivets. Use care from bending when install-

Page 1000 of 1502

•

STEERING

19-39

Fig. 14 Do Not

Remove

Retainer