DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 961 of 1502

Page 962 of 1502

•

STEERING STEERING

19-1

CONTENTS

page

GENERAL INFORMATION

1

POWER STEERING PUMP

11

POWER STEERING SYSTEM DIAGNOSIS

..... 2

RECIRCULATING

BALL

POWER STEERING GEAR

. 20

page

STEERING COLUMN

3i

STEERING LINKAGE

17

TORQUE SPECIFICATIONS

40

GENERAL

INFORMATION

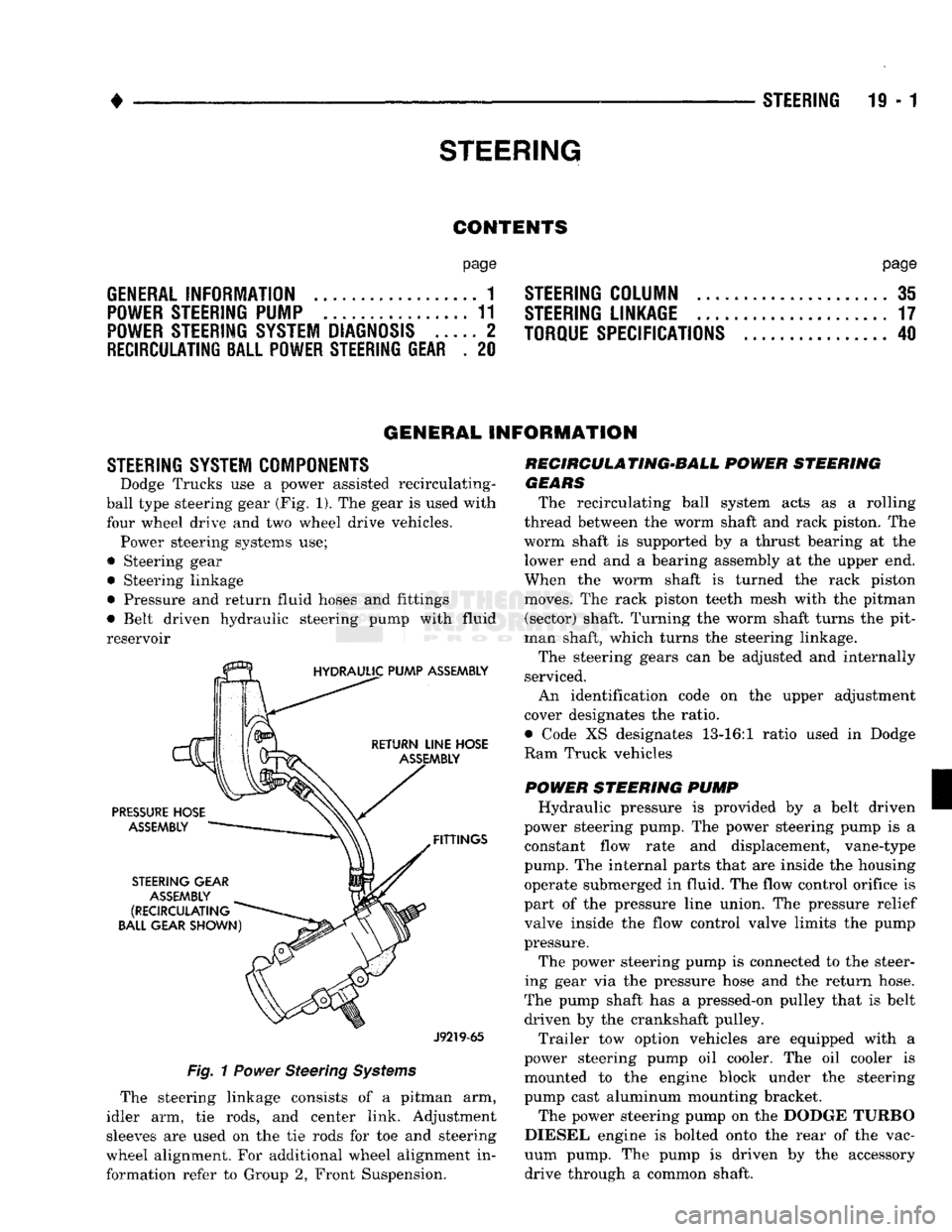

STEERING SYSTEM COMPONENTS

Dodge Trucks

use a

power

assisted recirculating-

ball

type steering gear

(Fig.

1). The

gear

is

used with

four

wheel drive

and two

wheel

drive

vehicles. Power steering systems

use;

•

Steering

gear • Steering linkage

• Pressure

and

return fluid hoses

and

fittings

• Belt driven hydraulic steering pump with

fluid

reservoir

J9219-65

Fig.

1

Power

Steering

Systems

The steering linkage consists

of a

pitman

arm,

idler

arm, tie

rods,

and

center link. Adjustment

sleeves

are

used

on the tie

rods

for toe and

steering

wheel alignment.

For

additional wheel alignment

in

formation refer

to

Group

2,

Front Suspension. RECIRCULA TING-BALL

POWER

STEERING

GEARS

The recirculating ball system acts

as a

rolling

thread between

the

worm shaft

and

rack piston.

The

worm shaft

is

supported

by a

thrust bearing

at the

lower

end

and a

bearing assembly

at

the

upper

end.

When

the

worm shaft

is

turned

the

rack piston

moves.

The

rack piston teeth mesh with

the

pitman (sector) shaft. Turning

the

worm shaft turns

the

pit

man shaft, which turns

the

steering linkage.

The steering gears

can be

adjusted

and

internally

serviced.

An identification code

on the

upper adjustment

cover designates

the

ratio.

• Code

XS

designates 13-16:1 ratio used

in

Dodge

Ram Truck vehicles

POWER

STEERING

PUMP

Hydraulic pressure

is

provided

by a

belt driven

power steering pump.

The

power steering pump

is a

constant flow rate

and

displacement, vane-type

pump.

The

internal parts that

are

inside

the

housing operate submerged

in

fluid.

The

flow control orifice

is

part

of

the

pressure line union.

The

pressure relief

valve inside

the

flow control valve limits

the

pump

pressure.

The power steering pump

is

connected

to

the

steer

ing gear

via the

pressure hose

and the

return hose.

The pump shaft

has

a

pressed-on pulley that

is

belt driven

by the

crankshaft pulley.

Trailer

tow

option vehicles

are

equipped with

a

power steering pump

oil

cooler.

The oil

cooler

is

mounted

to the

engine block under

the

steering

pump cast aluminum mounting bracket.

The power steering pump

on

the

DODGE TURBO

DIESEL engine

is

bolted onto

the

rear

of

the

vac

uum pump.

The

pump

is

driven

by the

accessory drive through

a

common shaft.

Page 963 of 1502

19

- 2

STEERING

• Dodge

Ram

Truck power steering pumps

are

not interchangeable with

pumps installed

in

other vehicles.

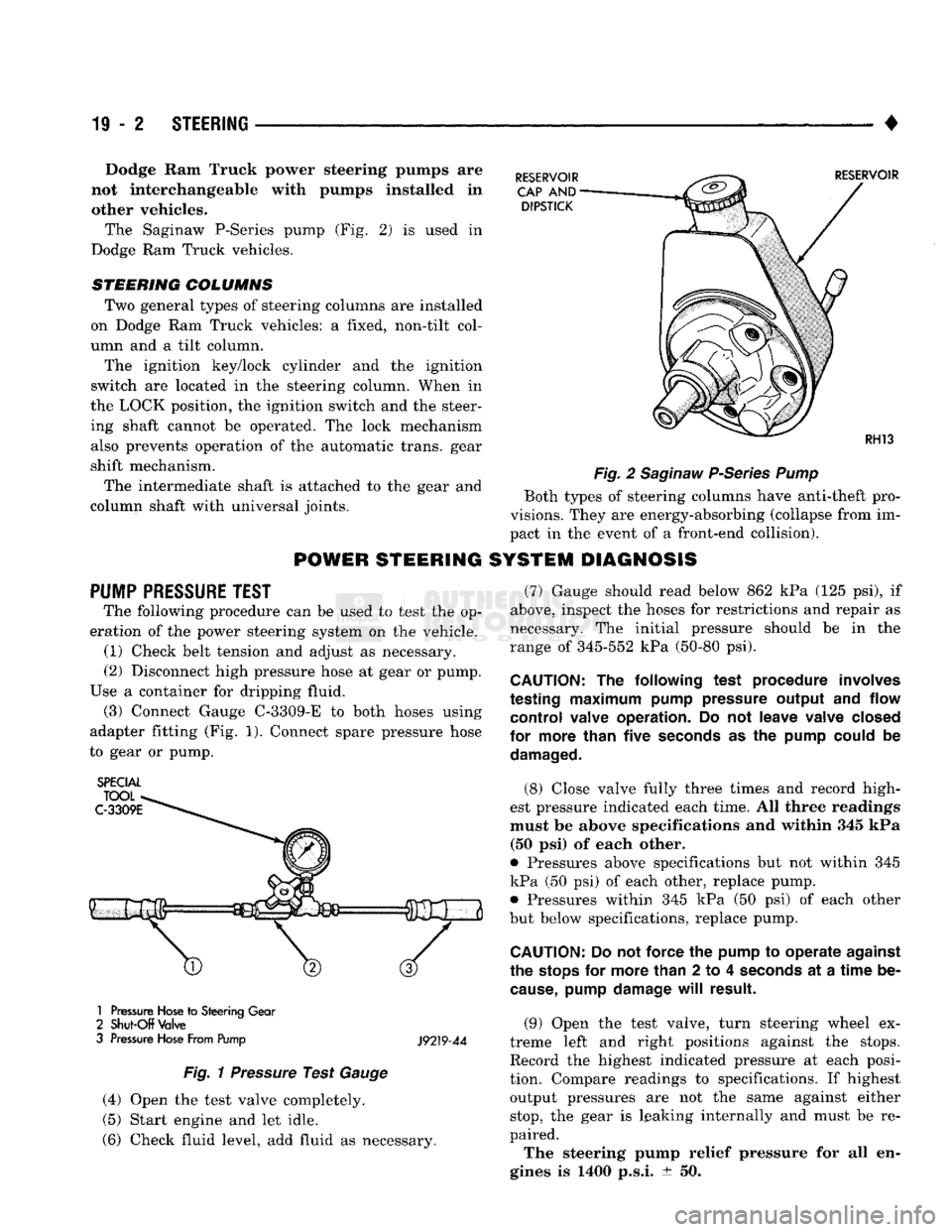

The Saginaw P-Series pump

(Fig. 2) is

used

in

Dodge

Ram

Truck vehicles.

STEERING COLUMNS

Two general types

of

steering columns

are

installed

on Dodge

Ram

Truck vehicles:

a

fixed, non-tilt col

umn

and a

tilt column.

The ignition key/lock cylinder

and the

ignition

switch

are

located

in the

steering column. When

in

the LOCK position,

the

ignition switch

and the

steer ing shaft cannot

be

operated.

The

lock mechanism also prevents operation

of the

automatic trans, gear

shift mechanism.

The intermediate shaft

is

attached

to the

gear

and

column shaft with universal joints.

POWER

STEERING

PUMP

PRESSURE

TEST

The following procedure

can be

used

to

test

the op

eration

of the

power steering system

on the

vehicle. (1) Check belt tension

and

adjust

as

necessary.

(2) Disconnect high pressure hose

at

gear

or

pump.

Use

a

container

for

dripping fluid. (3) Connect Gauge C-3309-E

to

both hoses using

adapter fitting

(Fig. 1).

Connect spare pressure hose

to gear

or

pump.

SPECIAL

1

Pressure

Hose

to

Steering

Gear

2

Shut-Off

Valve

3

Pressure

Hose

From Pump

J9219-44

Fig.

1

Pressure

Test

Gauge

(4) Open

the

test valve completely.

(5) Start engine

and let

idle.

(6) Check fluid level,

add

fluid

as

necessary.

Fig.

2

Saginaw

P-Series

Pump

Both types

of

steering columns have anti-theft pro

visions. They

are

energy-absorbing (collapse from

im

pact

in the

event

of a

front-end collision).

SYSTEM DIAGNOSIS

(7) Gauge should read below

862 kPa (125 psi), if

above, inspect

the

hoses

for

restrictions

and

repair

as

necessary.

The

initial pressure should

be in the

range

of

345-552

kPa

(50-80

psi).

CAUTION:

The

following test procedure involves

testing

maximum

pump pressure output

and

flow control valve operation.

Do not

leave valve closed

for more than five

seconds

as the

pump could

be

damaged.

(8) Close valve fully three times

and

record high

est pressure indicated each time.

All

three readings

must

be

above specifications

and

within

345 kPa

(50

psi) of

each other.

9

Pressures above specifications

but not

within

345

kPa

(50 psi) of

each other, replace pump. • Pressures within

345 kPa (50 psi) of

each other

but below specifications, replace pump.

CAUTION:

Do not

force

the

pump

to

operate against

the

stops

for

more than

2 to 4

seconds

at a

time

be

cause,

pump damage

will

result.

(9) Open

the

test valve, turn steering wheel

ex

treme left

and

right positions against

the

stops.

Record

the

highest indicated pressure

at

each posi

tion. Compare readings

to

specifications.

If

highest output pressures

are not the

same against either

stop,

the

gear

is

leaking internally

and

must

be re

paired.

The steering pump relief pressure

for all en

gines

is 1400

p.s.i.

± 50.

Page 964 of 1502

•

STEERING

19 - 3

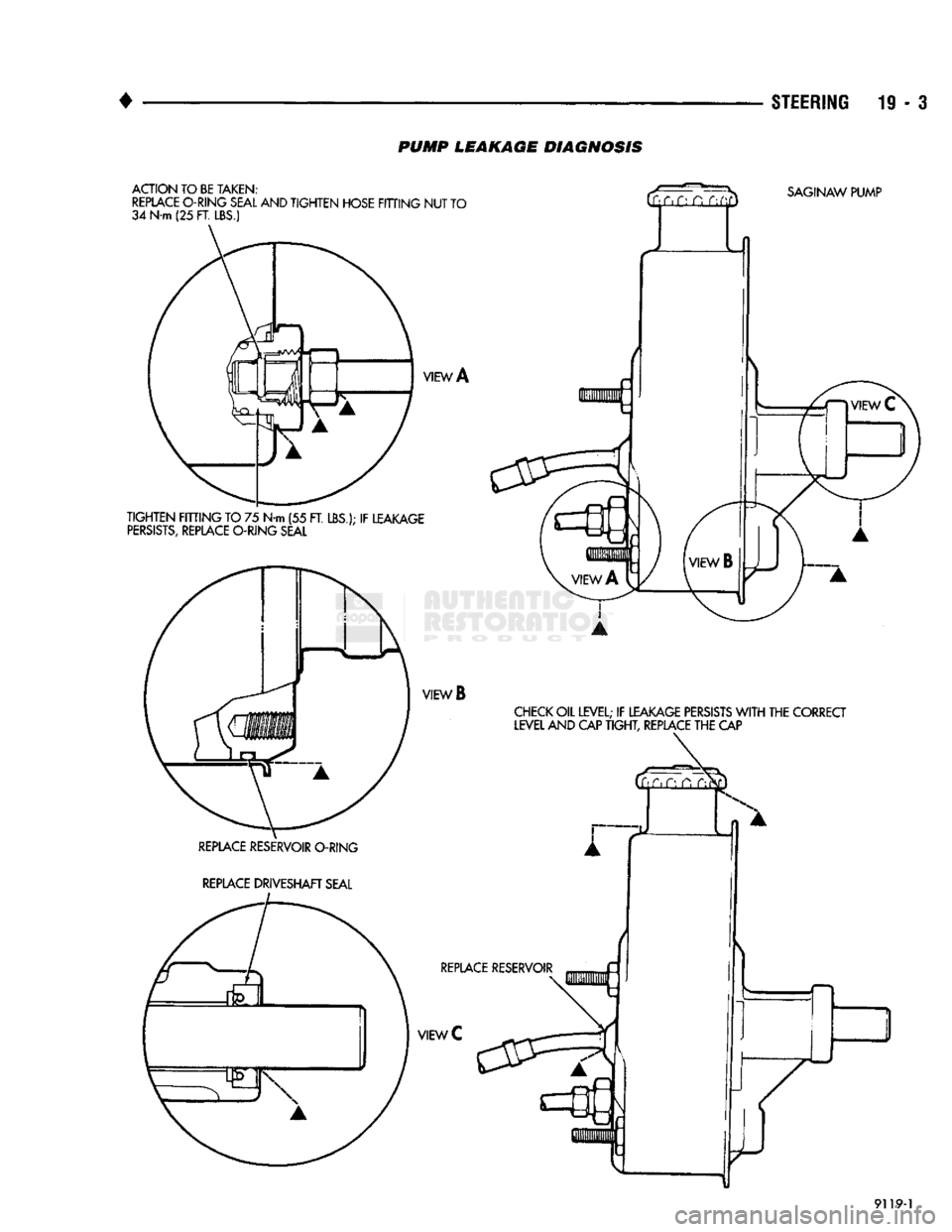

PUMP

LEAKAGE DIAGNOSIS

9119-1

Page 965 of 1502

19

- 4

STEERING

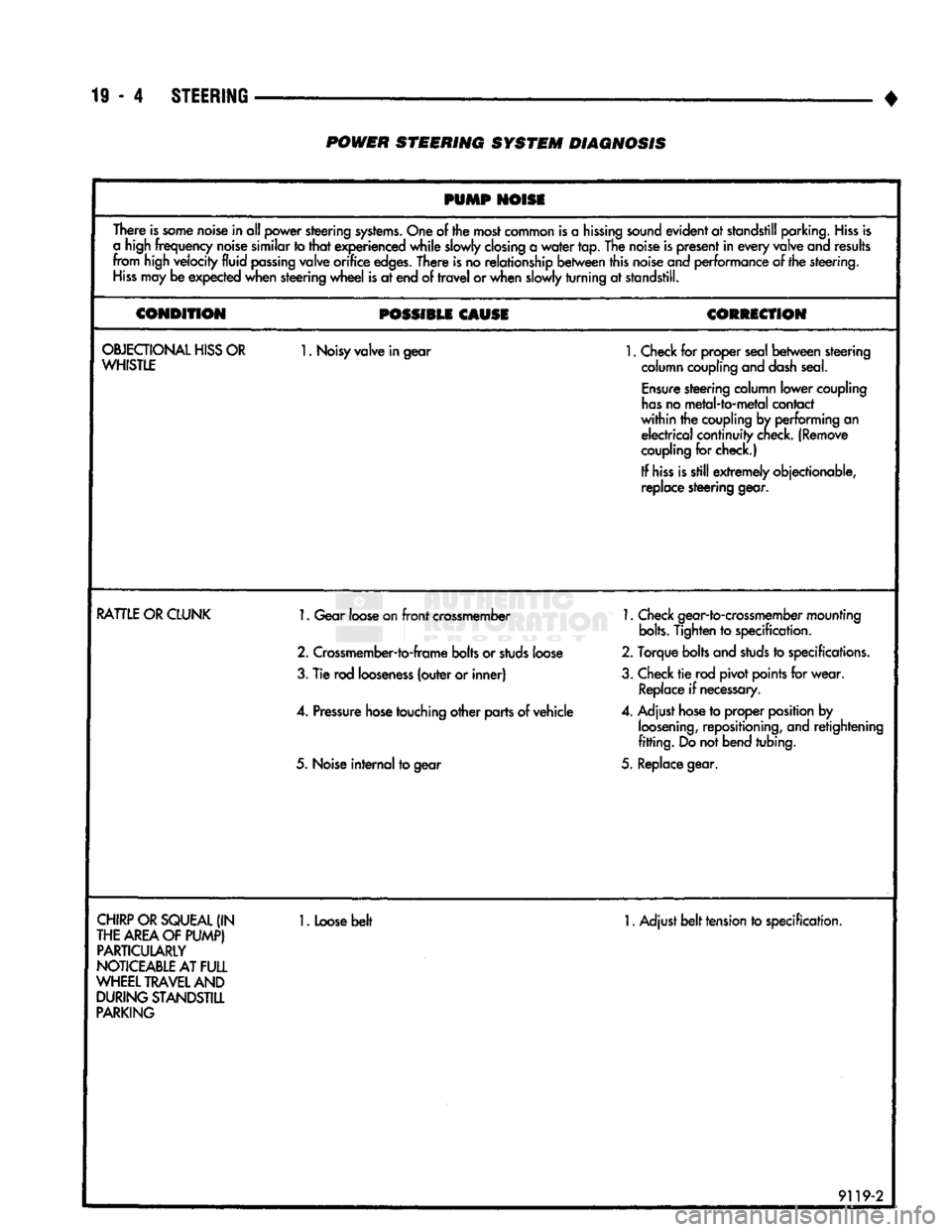

POWER STEERING SYSTEM DIAGNOSIS

PUMP

NOISI

There is some noise in all power steering systems. One of the most common is a hissing sound evident at standstill parking. Hiss is

a high frequency noise similar to that experienced while slowly closing a water tap. The noise is present in every valve and results

from high velocity

fluid

passing valve orifice edges. There is no relationship between this noise and performance of the steering. Hiss may be expected when steering wheel is at end of travel or when slowly turning at standstill.

CONDITION

POSSIBU CAUSI

CORRICriON

OBJECTIONALHISSOR

WHISTLE 1.

Noisy valve in gear

1.

Check for proper seal between steering

column coupling and dash seal.

Ensure steering column lower coupling

has no metal-to-metal contact

within the coupling by performing an electrical continuity check. (Remove

coupling for check.)

If hiss is still extremely objectionable,

replace steering gear.

RATTLE

OR CLUNK

1.

Gear loose on front crossmember

2.

Crossmember-to-frame bolts or studs loose

3.

Tie rod looseness (outer or inner)

4.

Pressure hose touching other parts of vehicle

5.

Noise internal to gear

1.

Check gear-to-crossmember mounting

bolts.

Tighten to specification.

2.

Torque bolts and studs to specifications.

3.

Check tie rod pivot points for wear. Replace if necessary.

4.

Adjust hose to proper position by loosening, repositioning, and retightening

fitting. Do not bend tubing.

5.

Replace gear.

CHIRP OR SQUEAL (IN

THE AREA OF PUMP) PARTICULARLY

NOTICEABLE AT

FULL

WHEEL TRAVEL AND DURING STANDSTILL

PARKING

1.

Loose belt

1.

Adjust belt tension to specification.

9119-2

Page 966 of 1502

•

STEERING

19-5 POWER STEERING SYSTEM DIAGNOSIS

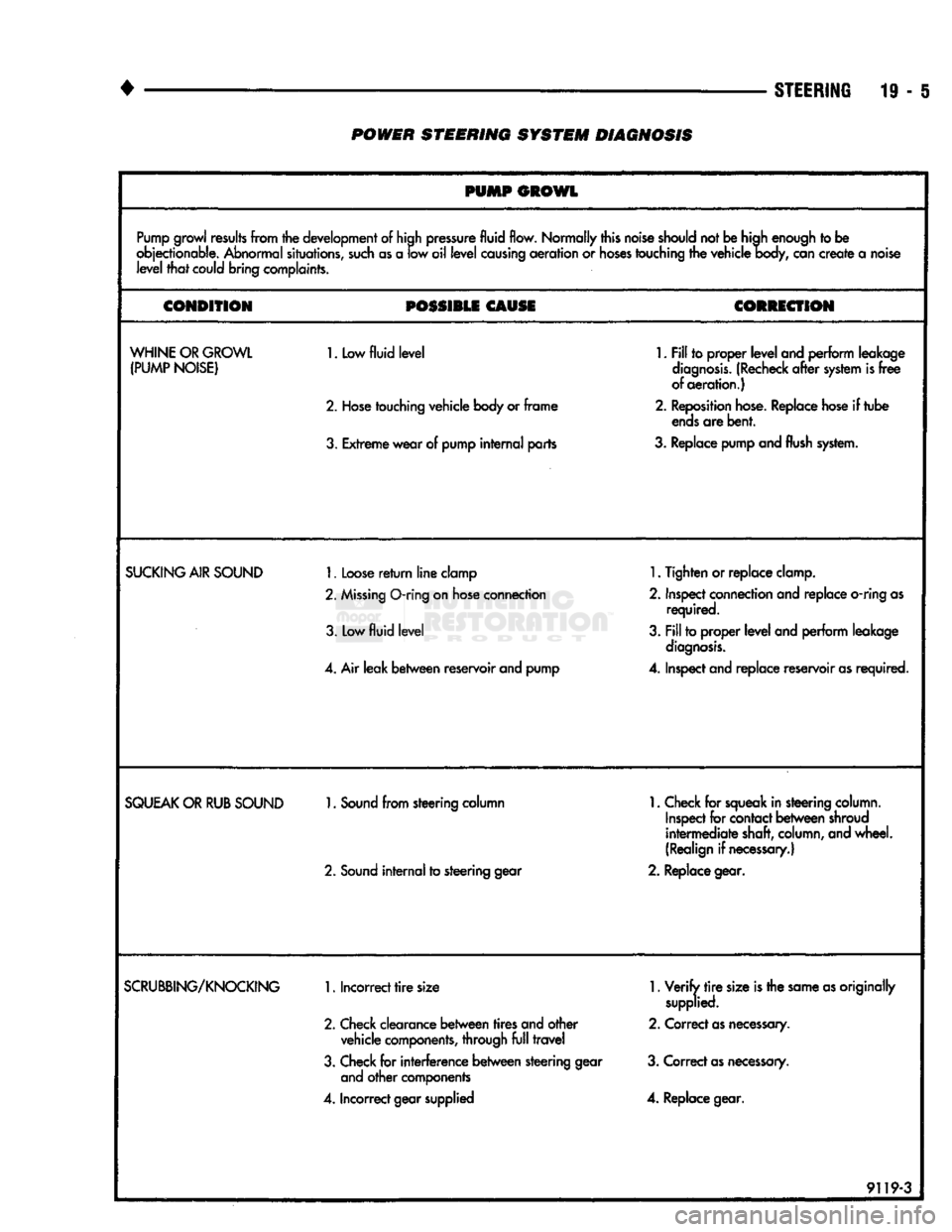

PUMP GROWL

Pump growl results from the development of high pressure fluid flow. Normally this noise should not be high enough to be

objectionable. Abnormal situations, such as a low oil level causing aeration or hoses touching the vehicle body, can create a noise level that could bring complaints.

CONDITION

POSSIBLE

CAUSE

CORRECTION

WHINE OR GROWL (PUMP NOISE)

1. Low

fluid level

2.

Hose touching vehicle body or frame

3.

Extreme wear of pump internal parts

1.

Fill to proper level and perform leakage

diagnosis. (Recheck after system is free

of aeration.)

2.

Reposition hose. Replace hose if tube ends are bent.

3.

Replace pump and

flush

system.

SUCKING

AIR

SOUND

1.

Loose return line clamp

2.

Missing

O-ring

on hose connection

3. Low

fluid level

4.

Air leak between reservoir and pump

1.

Tighten or replace clamp.

2.

Inspect connection and replace

o-ring

as required.

3.

Fill to proper level and perform leakage diagnosis.

4.

Inspect and replace reservoir as required.

SQUEAK

OR

RUB

SOUND

1.

Sound from steering column

2.

Sound internal to steering gear

1.

Check for squeak in steering column.

Inspect for contact between shroud

intermediate shaft, column, and wheel.

(Realign if necessary.)

2.

Replace gear.

SCRUBBING/KNOCKING

1.

Incorrect tire size

2.

Check clearance between tires and other vehicle components, through full travel

3.

Check for interference between steering gear and other components

4.

Incorrect gear supplied

1.

Verify tire size is the same as originally

supplied.

2.

Correct as necessary.

3.

Correct as necessary.

4.

Replace gear.

9119-3

Page 967 of 1502

19

- 6

STEERING

• POWER STEERING SYSTEM DIAGNOSIS

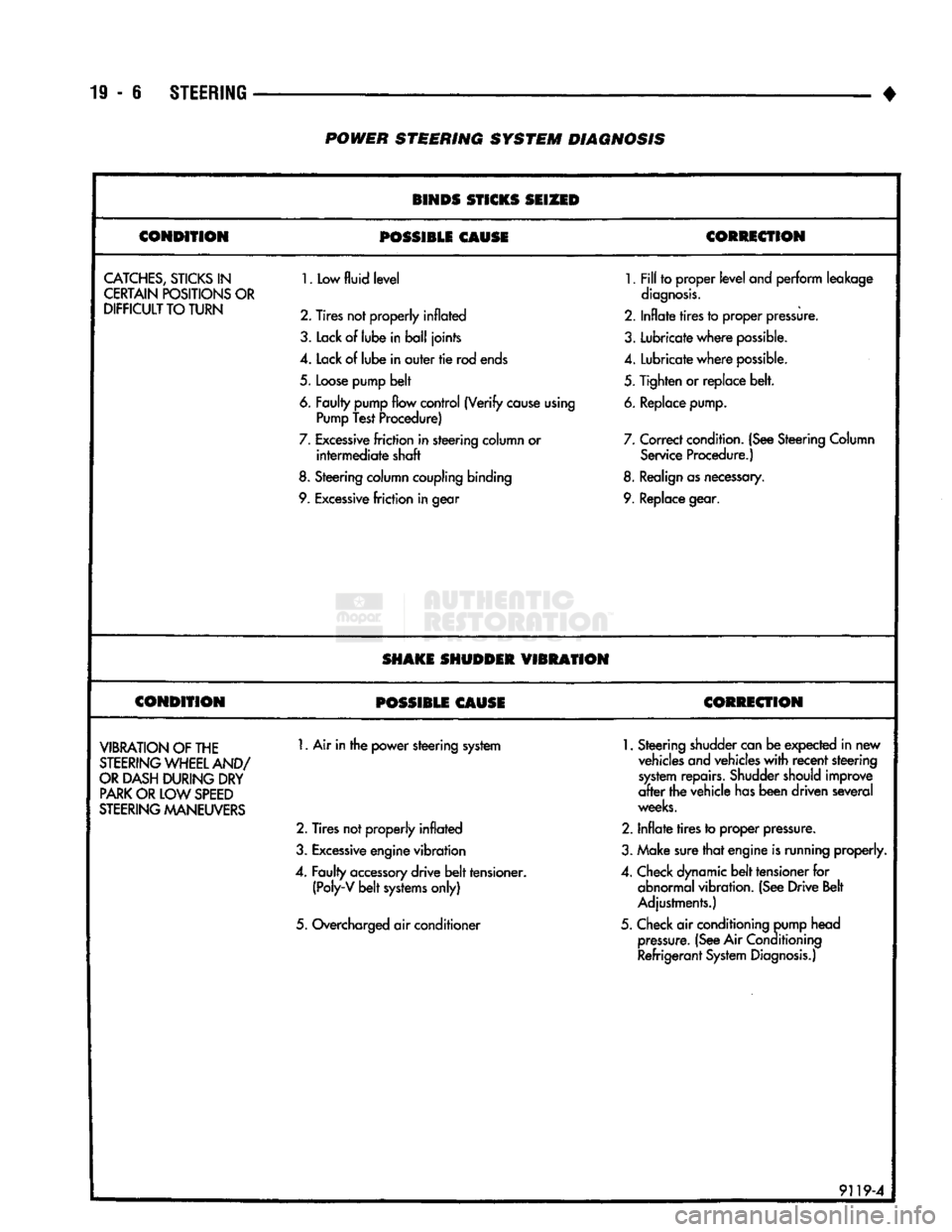

BINDS STICKS SEIZED

CONDITION

POSSIBLE

CAUSE CORRECTION

CATCHES,

STICKS

IN

CERTAIN POSITIONS OR

DIFFICULT

TO TURN

1.

Low

fluid level

2. Tires not properly

inflated

3.

Lack

of

lube

in ball joints

4.

Lack of lube in outer tie rod ends

5.

Loose pump belt

6. Faulty pump flow control (Verify cause using Pump Test Procedure)

7.

Excessive friction in steering column or intermediate shaft

8.

Steering column coupling binding

9. Excessive friction in gear

1.

Fill to proper level

and

perform leakage

diagnosis.

2.

Inflate tires to proper pressure.

3.

Lubricate where possible.

4.

Lubricate where possible.

5.

Tighten or replace belt.

6. Replace pump.

7.

Correct condition. (See Steering Column Service Procedure.)

8. Realign as necessary.

9. Replace gear.

SHAKE SHUDDER

VIBRATION

CONDITION

POSSIBLE CAUSE CORRECTION

VIBRATION

OF THE

STEERING

WHEEL AND/

OR

DASH DURING DRY

PARK

OR LOW

SPEED

STEERING

MANEUVERS

1.

Air in the power steering system

2.

Tires not properly inflated

3.

Excessive engine vibration

4.

Faulty accessory drive belt tensioner. (Poly-V belt systems only)

5.

Overcharged air conditioner

1.

Steering shudder can be expected in new

vehicles and vehicles with recent steering system repairs. Shudder should improve

after the vehicle has been driven several

weeks.

2.

Inflate tires to proper pressure.

3.

Make sure that engine is running properly.

4.

Check dynamic belt tensioner for abnormal vibration. (See Drive Belt

Adjustments.)

5.

Check air conditioning pump head pressure. (See Air

Conditioning

Refrigerant System Diagnosis.)

9119-4

Page 968 of 1502

•

STEERING

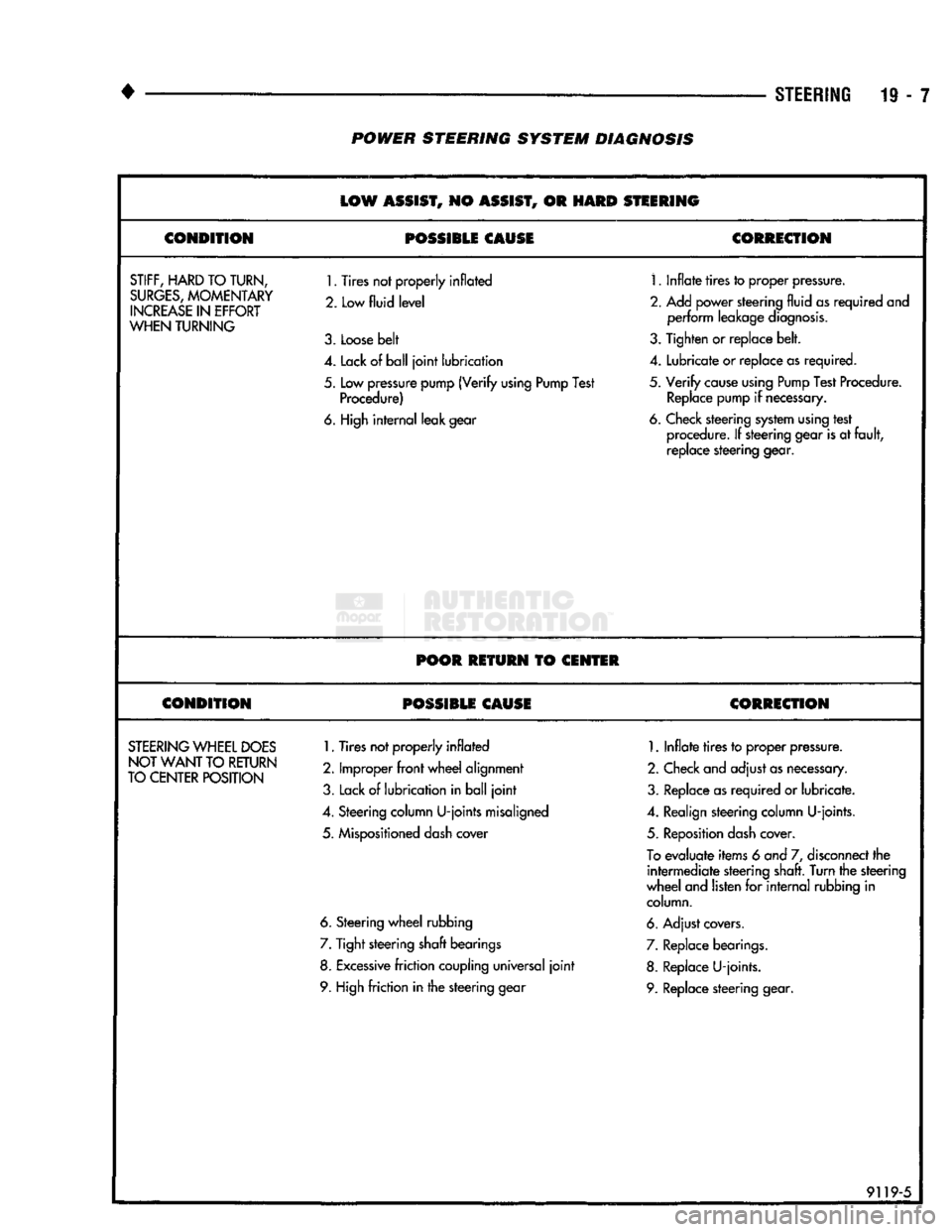

19 - 7 POWER STEERING SYSTEM DIAGNOSIS

LOW

ASSIST,

NO

ASSIST,

OR

HARD

STEERING

CONDITION

POSSIBLE CAUSE

CORRECTION

STIFF,

HARD

TO TURN,

SURGES,

MOMENTARY

INCREASE

IN

EFFORT

WHEN

TURNING

1.

Tires not properly inflated

2. Low

fluid level

3.

Loose belt

1.

Inflate tires to proper pressure.

2.

Add power steering fluid as required and perform leakage diagnosis.

3.

Tighten or replace belt.

4.

Lack of ball joint lubrication

4.

Lubricate or replace as required.

5.

Low pressure pump (Verify using Pump Test Procedure)

5.

Verify cause using Pump Test Procedure.

Replace pump if necessary.

6. High internal leak gear 6. Check steering system using test

procedure. If steering gear is at fault, replace steering gear.

POOR RETURN

TO

CENTER

CONDITION POSSIBLE CAUSE CORRECTION

STEERING

WHEEL

DOES

NOT WANT

TO

RETURN

TO CENTER POSITION

1.

Tires not properly inflated

2.

Improper front wheel alignment

3.

Lack of lubrication in ball joint

1.

Inflate tires to proper pressure.

2.

Check and adjust as necessary.

3.

Replace as required or lubricate.

4.

Steering column U-joints misaligned

4.

Realign steering column U-joints.

5.

Mispositioned dash cover

5.

Reposition dash cover.

To

evaluate items 6 and 7, disconnect the intermediate steering shaft. Turn the steering

wheel and listen for internal rubbing in column.

6. Steering wheel rubbing 6. Adjust covers.

7.

Tight steering shaft bearings

7.

Replace bearings.

8. Excessive friction coupling universal joint 8. Replace U-joints.

9. High friction in the steering gear 9. Replace steering gear.

91195

Page 969 of 1502

19

- 8

STEERING

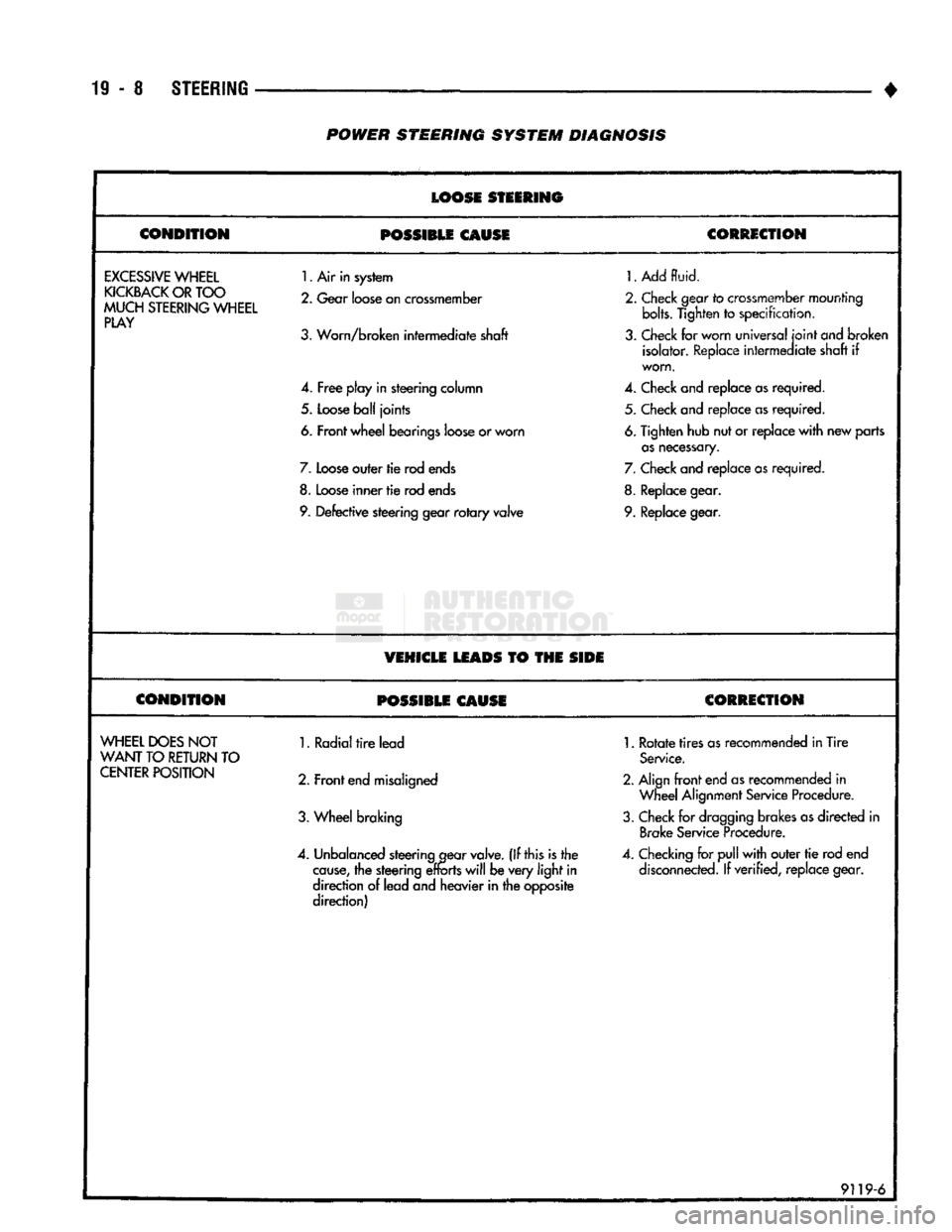

POWER

STEERING

SYSTEM

DIAGNOSIS

LOOSE

STEERING

CONDITION

POSSIBLE

CAUSE

CORRECTION

EXCESSIVE

WHEEL

KICKBACK

OR

TOO

MUCH

STEERING

WHEEL

PLAY

1.

Air in system

2.

Gear

loose

on

crossmember

3.

Worn/broken intermediate shaft

4.

Free

play in steering column

5.

Loose

ball

joints

6. Front wheel bearings

loose

or worn

7.

Loose

outer tie rod

ends

8.

Loose

inner

tie

rod

ends

9.

Defective steering gear

rotary

valve

1.

Add

fluid.

2.

Check

gear

to

crossmember

mounting bolts. Tighten

to

specification,

3.

Check

for worn universal

joint

ond

broken isolator.

Replace

intermediate shaft

if

worn.

4.

Check

and replace

as

required. 5.

Check

and replace

as

required.

6.

Tighten hub nut or replace

with

new parts

as

necessary.

7.

Check

and replace

as

required.

8.

Replace

gear.

9.

Replace

gear.

VEHICLE

LEADS

TO THE

SIDE

CONDITION

POSSIBLE

CAUSE

CORRECTION

WHEEL

DOES

NOT

WANT

TO

RETURN

TO

CENTER

POSITION

1. Radial

tire

lead

2. Front

end

misaligned

3.

Wheel braking

4.

Unbalanced

steering

gear

valve.

(If this is the

cause,

the steering

efforts

will

be very

light

in

direction

of

lead and heavier in the opposite

direction)

1.

Rotate

tires

as

recommended in Tire

Service.

2. Align

front

end

as

recommended

in

Wheel

Alignment

Service

Procedure.

3.

Check

for

dragging

brakes

as

directed

in

Brake

Service

Procedure.

4.

Checking

for

pull

with

outer

tie

rod end

disconnected.

If verified, replace gear.

9119-6

Page 970 of 1502

•

STEERING

19-9 POWER STEERING SYSTEM DIAGNOSIS

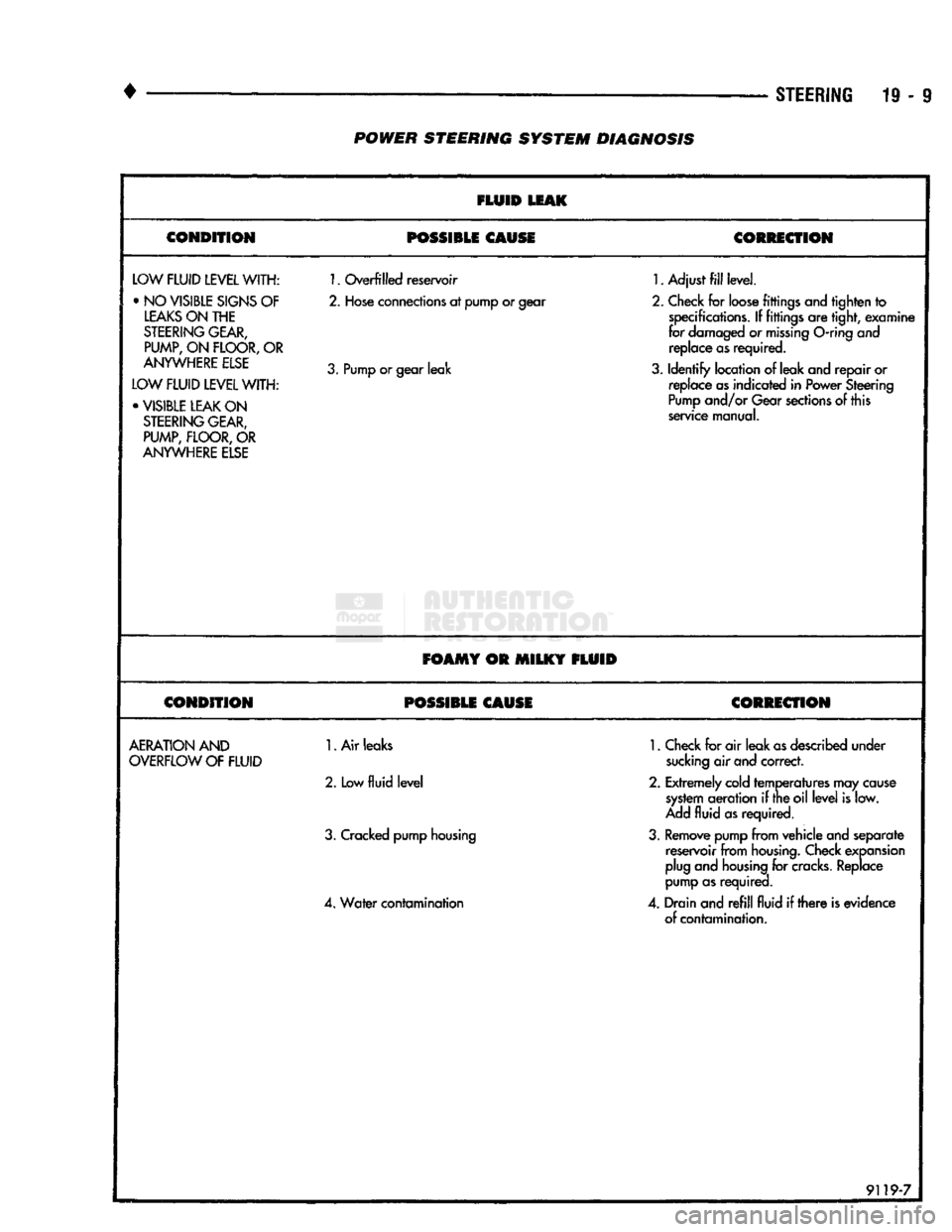

FLUID

LEAK

CONDITION POSSIBLE CAUSE

CORRECTION

LOW

FLUID LEVEL

WITH: •NO

VISIBLE

SIGNS

OF

LEAKS ON THE

STEERING GEAR,

PUMP,

ON

FLOOR,

OR

ANYWHERE ELSE

LOW FLUID LEVEL WITH: • VISIBLE LEAK ON STEERING GEAR, PUMP, FLOOR, OR

ANYWHERE ELSE

1.

Overfilled reservoir

2.

Hose connections at pump or gear

3.

Pump or gear leak

1.

Adjust fill level.

2.

Check for loose fittings and tighten to specifications. If fittings are tight, examine

for damaged or missing

O-ring

and replace as required.

3.

Identify location of leak and repair or replace as indicated in Power Steering

Pump and/or Gear sections of this

service manual.

FOAMY OR MILKY FLUID

CONDITION POSSIBLE CAUSE CORRECTION

AERATION AND

OVERFLOW OF FLUID

1.

Air leaks

2.

Low

fluid level

3.

Cracked pump housing

4.

Water contamination

1.

Check for air leak as described under

sucking air and correct.

2.

Extremely cold temperatures may cause system aeration if the oil level is low.

Add fluid as required.

3.

Remove pump from vehicle and separate reservoir from housing. Check expansion

plug and housing for

cracks.

Replace

pump as required.

4.

Drain and refill fluid if there is evidence of contamination.

9119-7