DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1051 of 1502

21

- 50

G360

MANUAL

TRANSMISSION

•

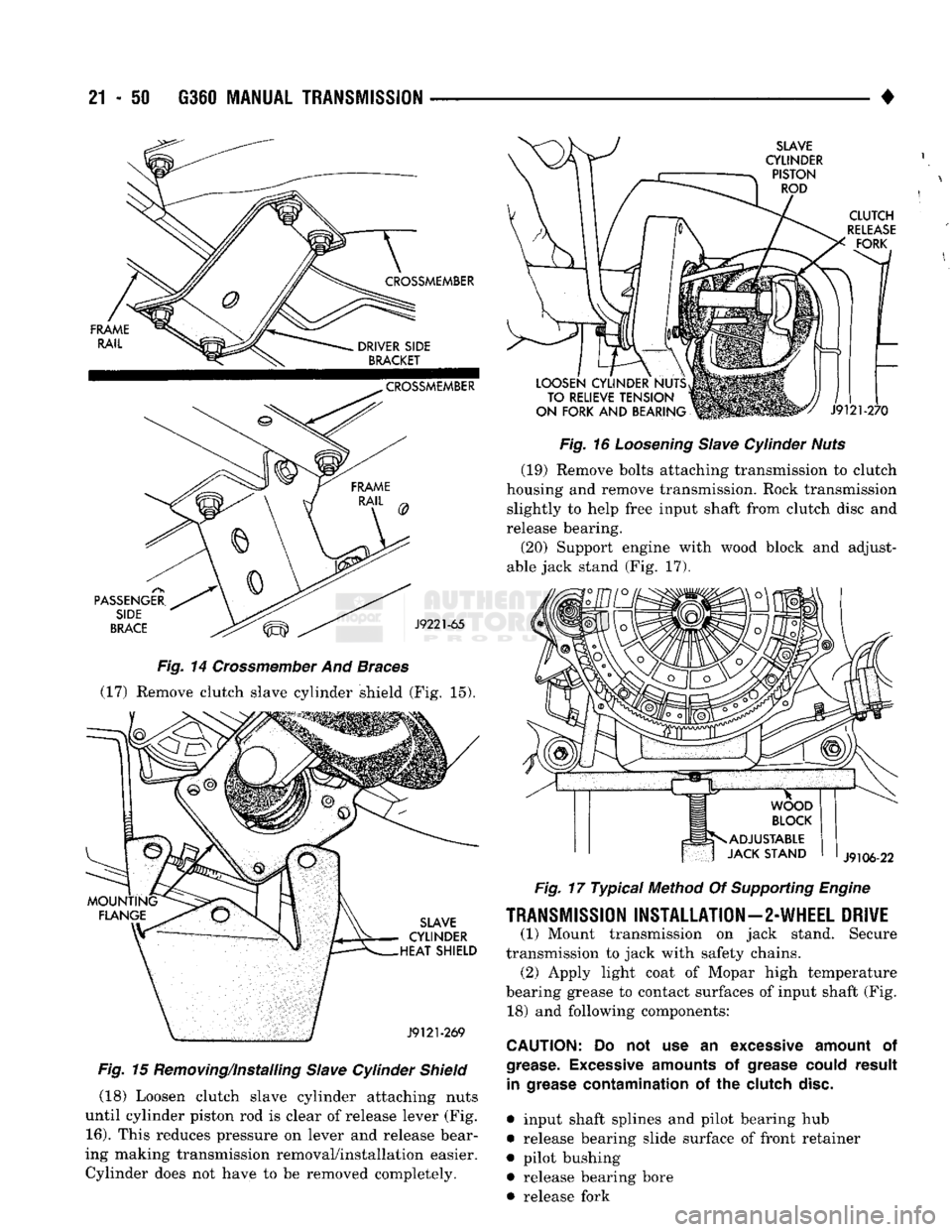

FRAME RAIL

CROSSMEMBER

DRIVER SIDE

BRACKET

PASSENGER.

SIDE

BRACE

CROSSMEMBER

J9221-65

Fig.

14

Crossmember

And

Braces

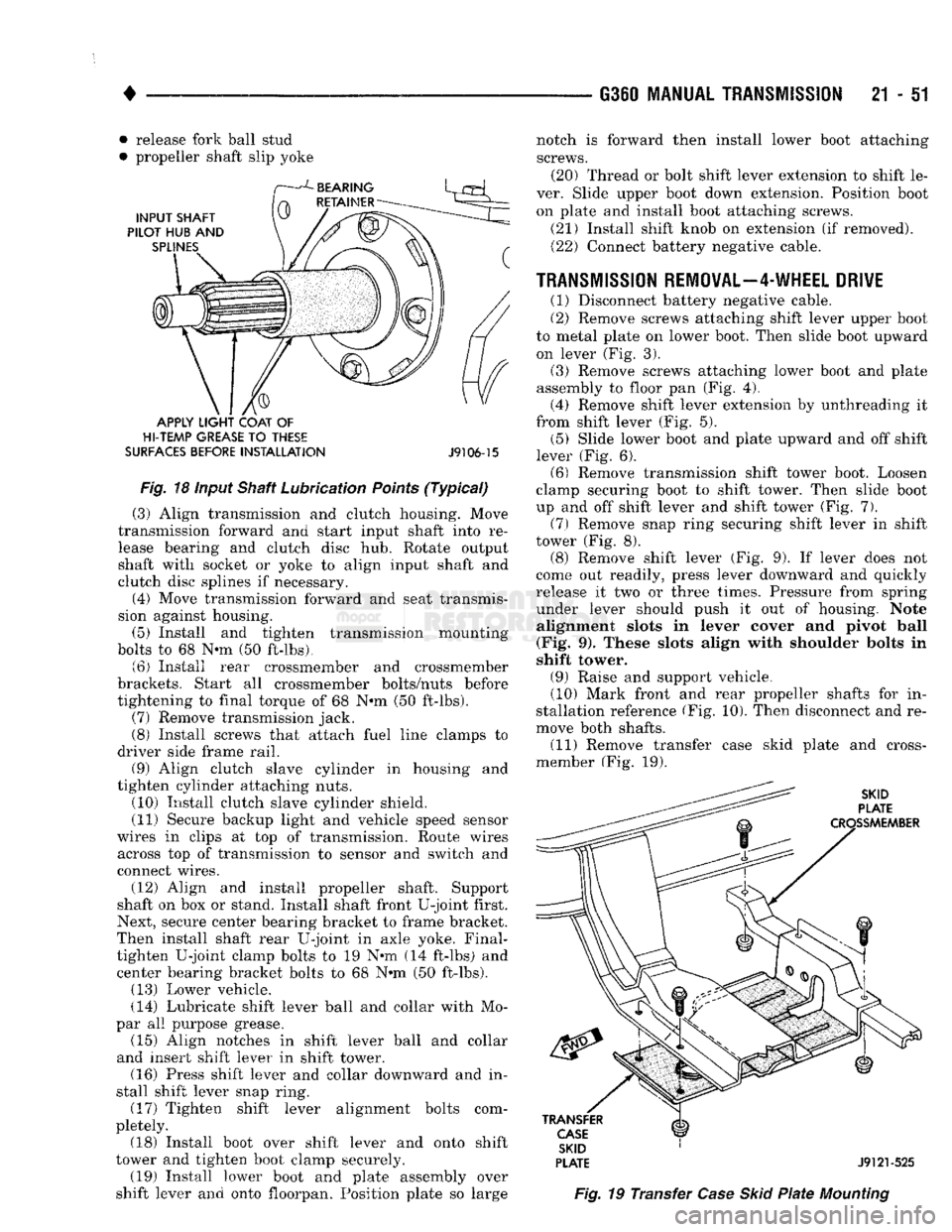

(17) Remove clutch slave cylinder shield (Fig. 15).

SLAVE

CYLINDER

HEAT SHIELD

J9121-269

Fig.

15 Removing/Installing

Slave

Cylinder

Shield

(18) Loosen clutch slave cylinder attaching nuts

until cylinder piston rod is clear of release lever (Fig.

16).

This reduces pressure on lever and release bear

ing making transmission removal/installation easier. Cylinder does not have to be removed completely.

SLAVE

CYLINDER PISTON ROD

CLUTCH

RELEASE

FORK

LOOSEN CYLINDER NUTS TO RELIEVE TENSION

ON FORK AND BEARING

J9121-270

Fig.

16

Loosening

Slave

Cylinder

Nuts

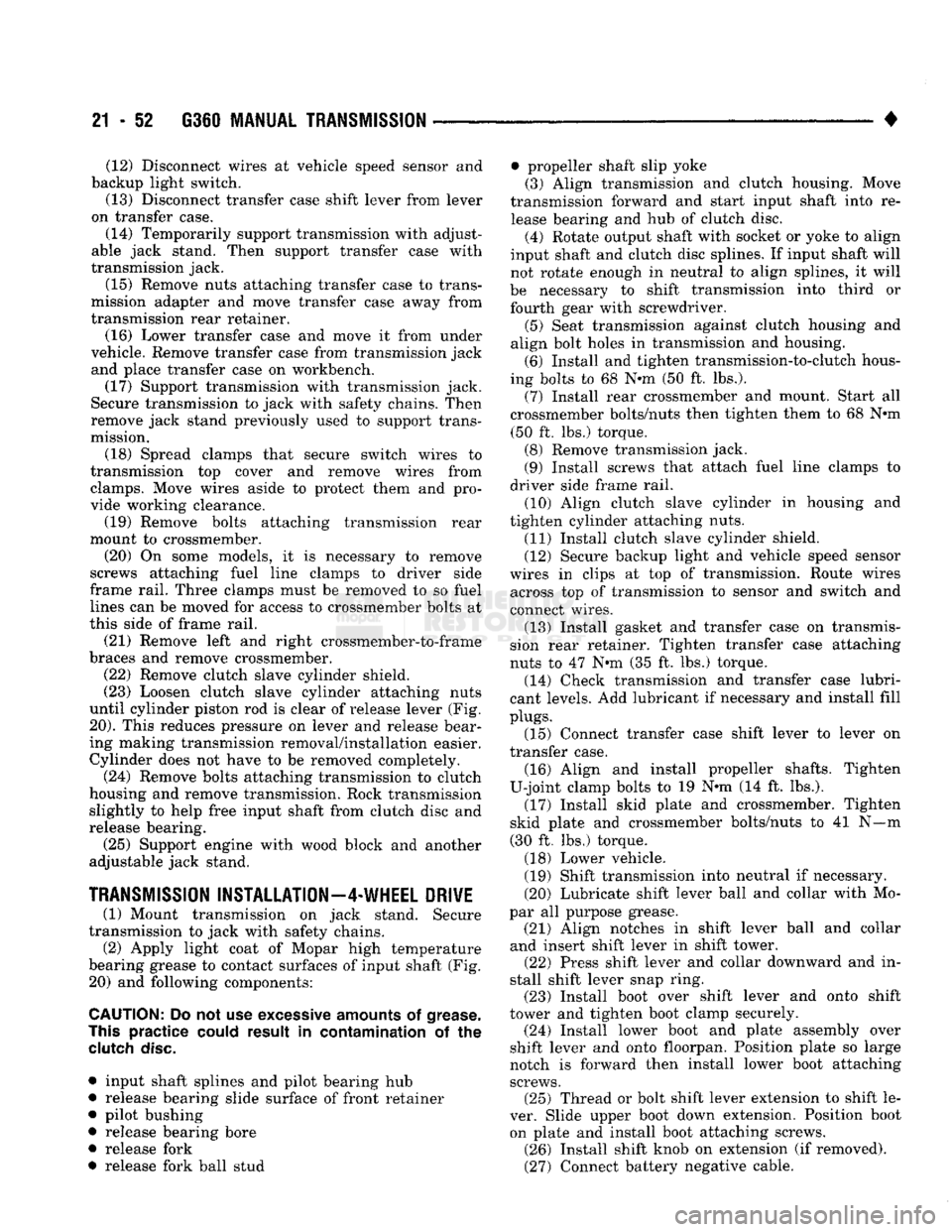

(19) Remove bolts attaching transmission to clutch

housing and remove transmission. Rock transmission slightly to help free input shaft from clutch disc and

release bearing.

(20) Support engine with wood block and adjust

able jack stand (Fig. 17).

J9106-22

Fig.

17 Typical Method Of

Supporting

Engine

TRANSMISSION

INSTALLATION—2-WHEEL

DRIVE

(1) Mount transmission on jack stand. Secure

transmission to jack with safety chains. (2) Apply light coat of Mopar high temperature

bearing grease to contact surfaces of input shaft (Fig. 18) and following components:

CAUTION:

Do not use an

excessive

amount

of

grease. Excessive

amounts

of

grease

could

result

in

grease

contamination

of the

clutch

disc.

• input shaft splines and pilot bearing hub

• release bearing slide surface of front retainer

• pilot bushing • release bearing bore

• release fork

Page 1052 of 1502

•

• release fork ball stud

• propeller shaft slip yoke

APPLY

LIGHT

COAT

OF

HI-TEMP

GREASE

TO

THESE

SURFACES

BEFORE

INSTALLATION

J9106-15

Fig.

18 input Shaft Lubrication

Points

(Typical)

(3) Align transmission and clutch housing. Move

transmission forward and start input shaft into re lease bearing and clutch disc hub. Rotate output

shaft with socket or yoke to align input shaft and

clutch disc splines if necessary.

(4) Move transmission forward and seat transmis

sion against housing. (5) Install and tighten transmission mounting

bolts to 68 N-m (50 ft-lbs). (6) Install rear crossmember and crossmember

brackets. Start all crossmember bolts/nuts before

tightening to final torque of 68 N»m (50 ft-lbs). (7) Remove transmission jack.

(8) Install screws that attach fuel line clamps to

driver side frame rail. (9) Align clutch slave cylinder in housing and

tighten cylinder attaching nuts. (10) Install clutch slave cylinder shield.

(11) Secure backup light and vehicle speed sensor

wires in clips at top of transmission. Route wires across top of transmission to sensor and switch and

connect wires.

(12) Align and install propeller shaft. Support

shaft on box or stand. Install shaft front U-joint first.

Next, secure center bearing bracket to frame bracket.

Then install shaft rear U-joint in axle yoke. Final- tighten U-joint clamp bolts to 19 N@m (14 ft-lbs) and center bearing bracket bolts to 68 N»m (50 ft-lbs). (13) Lower vehicle.

(14) Lubricate shift lever ball and collar with Mo

par all purpose grease. (15) Align notches in shift lever ball and collar

and insert shift lever in shift tower. (16) Press shift lever and collar downward and in

stall shift lever snap ring. (17) Tighten shift lever alignment bolts com

pletely. (18) Install boot over shift lever and onto shift

tower and tighten boot clamp securely. (19) Install lower boot and plate assembly over

shift lever and onto floorpan. Position plate so large G360

MANUAL TRANSMISSION

21 - 51

SKID

PLATE

J9121-525

Fig.

19 Transfer

Case

Skid

Plate

Mounting

notch is forward then install lower boot attaching

screws. (20) Thread or bolt shift lever extension to shift le

ver. Slide upper boot down extension. Position boot on plate and install boot attaching screws.

(21) Install shift knob on extension (if removed). (22) Connect battery negative cable.

TRANSMISSION REMOVAL—4-WHEEL DRIVE

(1) Disconnect battery negative cable.

(2) Remove screws attaching shift lever upper boot

to metal plate on lower boot. Then slide boot upward on lever (Fig. 3).

(3) Remove screws attaching lower boot and plate

assembly to floor pan (Fig. 4). (4) Remove shift lever extension by unthreading it

from shift lever (Fig. 5). (5) Slide lower boot and plate upward and off shift

lever (Fig. 6). (6) Remove transmission shift tower boot. Loosen

clamp securing boot to shift tower. Then slide boot

up and off shift lever and shift tower (Fig. 7).

(7)

Remove snap ring securing shift lever in shift

tower (Fig. 8). (8) Remove shift lever (Fig. 9). If lever does not

come out readily, press lever downward and quickly

release it two or three times. Pressure from spring under lever should push it out of housing. Note alignment slots in lever cover and pivot ball

(Fig. 9). These slots align with shoulder bolts in

shift tower.

(9) Raise and support vehicle.

(10) Mark front and rear propeller shafts for in

stallation reference (Fig. 10). Then disconnect and re

move both shafts. (11) Remove transfer case skid plate and cross-

member (Fig. 19).

Page 1053 of 1502

21 - 52 G360

MANUAL

TRANSMISSION

• (12) Disconnect wires at vehicle speed sensor and

backup light switch.

(13) Disconnect transfer case shift lever from lever

on transfer case.

(14) Temporarily support transmission with adjust

able jack stand. Then support transfer case with

transmission jack.

(15) Remove nuts attaching transfer case to trans

mission adapter and move transfer case away from

transmission rear retainer.

(16) Lower transfer case and move it from under

vehicle. Remove transfer case from transmission jack and place transfer case on workbench.

(17) Support transmission with transmission jack.

Secure transmission to jack with safety chains. Then

remove jack stand previously used to support trans

mission.

(18) Spread clamps that secure switch wires to

transmission top cover and remove wires from clamps. Move wires aside to protect them and pro

vide working clearance.

(19) Remove bolts attaching transmission rear

mount to crossmember.

(20) On some models, it is necessary to remove

screws attaching fuel line clamps to driver side

frame rail. Three clamps must be removed to so fuel lines can be moved for access to crossmember bolts at

this side of frame rail.

(21) Remove left and right crossmember-to-frame

braces and remove crossmember.

(22) Remove clutch slave cylinder shield.

(23) Loosen clutch slave cylinder attaching nuts

until cylinder piston rod is clear of release lever (Fig.

20).

This reduces pressure on lever and release bear

ing making transmission removal/installation easier. Cylinder does not have to be removed completely.

(24) Remove bolts attaching transmission to clutch

housing and remove transmission. Rock transmission slightly to help free input shaft from clutch disc and

release bearing.

(25) Support engine with wood block and another

adjustable jack stand.

TRANSMISSION

INSTALLATION—4-WHEEL

DRIVE

(1) Mount transmission on jack stand. Secure

transmission to jack with safety chains.

(2) Apply light coat of Mopar high temperature

bearing grease to contact surfaces of input shaft (Fig. 20) and following components:

CAUTION:

Do not use

excessive

amounts

of

grease.

This

practice

could

result in contamination of the

clutch

disc.

• input shaft splines and pilot bearing hub

• release bearing slide surface of front retainer

• pilot bushing

• release bearing bore

• release fork

• release fork ball stud • propeller shaft slip yoke

(3) Align transmission and clutch housing. Move

transmission forward and start input shaft into re lease bearing and hub of clutch disc. (4) Rotate output shaft with socket or yoke to align

input shaft and clutch disc splines. If input shaft will

not rotate enough in neutral to align splines, it will

be necessary to shift transmission into third or fourth gear with screwdriver. (5) Seat transmission against clutch housing and

align bolt holes in transmission and housing. (6) Install and tighten transmission-to-clutch hous

ing bolts to 68 N-m (50 ft. lbs.). (7) Install rear crossmember and mount. Start all

crossmember bolts/nuts then tighten them to 68 N*m (50 ft. lbs.) torque. (8) Remove transmission jack.

(9) Install screws that attach fuel line clamps to

driver side frame rail. (10) Align clutch slave cylinder in housing and

tighten cylinder attaching nuts. (11) Install clutch slave cylinder shield.

(12) Secure backup light and vehicle speed sensor

wires in clips at top of transmission. Route wires across top of transmission to sensor and switch and

connect wires.

(13) Install gasket and transfer case on transmis

sion rear retainer. Tighten transfer case attaching

nuts to 47 N-m (35 ft. lbs.) torque. (14) Check transmission and transfer case lubri

cant levels. Add lubricant if necessary and install fill

plugs.

(15) Connect transfer case shift lever to lever on

transfer case.

(16) Align and install propeller shafts. Tighten

U-joint clamp bolts to 19 N-m (14 ft. lbs.). (17) Install skid plate and crossmember. Tighten

skid plate and crossmember bolts/nuts to 41 N—m

(30 ft. lbs.) torque.

(18) Lower vehicle.

(19) Shift transmission into neutral if necessary.

(20) Lubricate shift lever ball and collar with Mo

par all purpose grease. (21) Align notches in shift lever ball and collar

and insert shift lever in shift tower. (22) Press shift lever and collar downward and in

stall shift lever snap ring. (23) Install boot over shift lever and onto shift

tower and tighten boot clamp securely. (24) Install lower boot and plate assembly over

shift lever and onto floorpan. Position plate so large

notch is forward then install lower boot attaching screws. (25) Thread or bolt shift lever extension to shift le

ver. Slide upper boot down extension. Position boot on plate and install boot attaching screws. (26) Install shift knob on extension (if removed).

(27) Connect battery negative cable.

Page 1054 of 1502

•

G360

TRANSMISSION OVERHAUL

21 - 53

G360

TRANSMISSION

OVERHAUL

INDEX

page

Transmission

Assembly

and

Adjustment

.......

63

Transmission

Cleaning

and

Inspection

59

TRANSMISSION

DISASSEMBLY

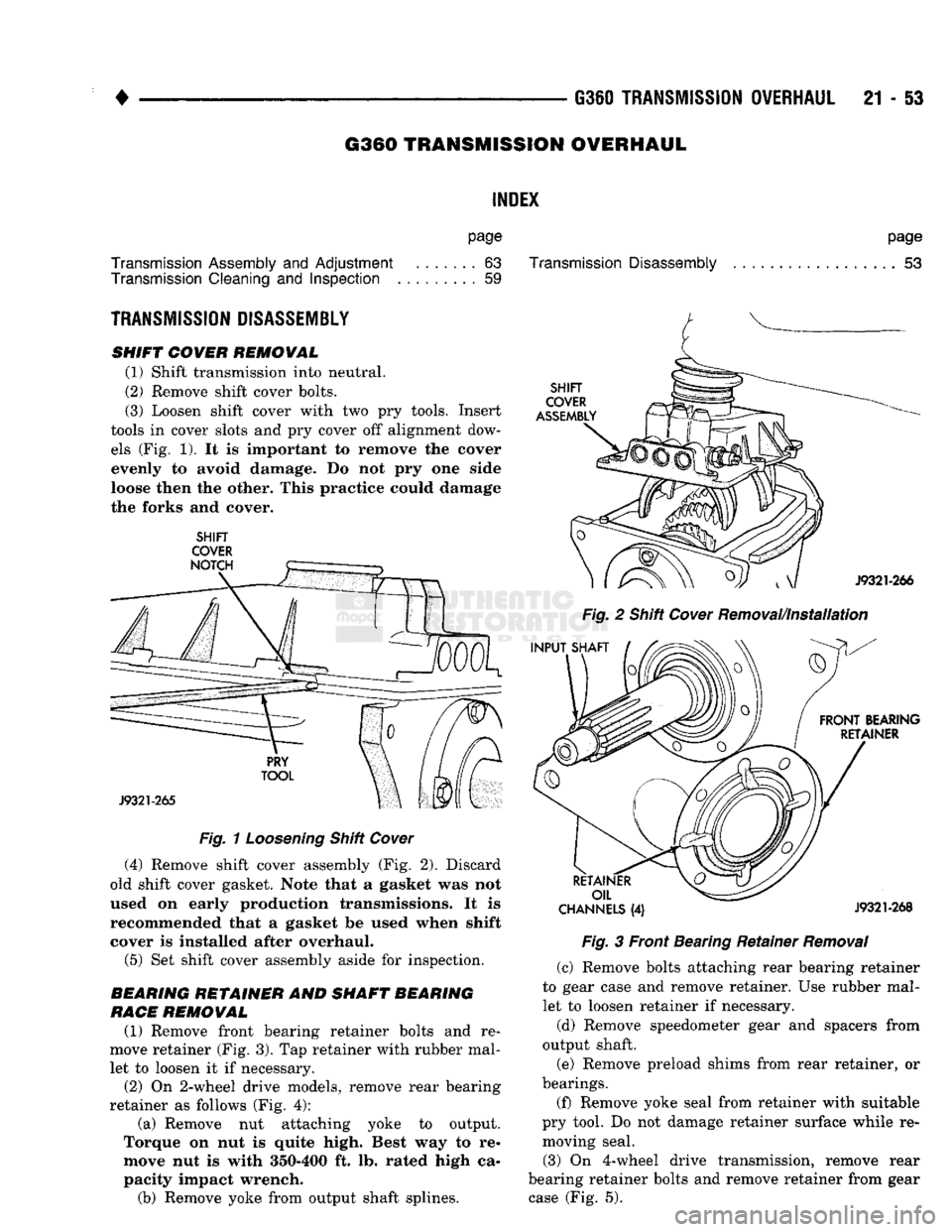

SHIFT COVER REMOVAL (1) Shift transmission into neutral.

(2) Remove shift cover bolts.

(3) Loosen shift cover with

two pry

tools. Insert

tools

in

cover slots

and pry

cover

off

alignment dow els

(Fig. 1). It is

important

to

remove

the

cover evenly

to

avoid damage.

Do not pry one

side

loose then

the

other. This practice could damage the forks

and

cover.

SHIFT

COVER

Fig.

1

Loosening

Shift

Cover

(4) Remove shift cover assembly

(Fig. 2).

Discard

old shift cover gasket. Note that

a

gasket

was not

used

on

early production transmissions.

It is

recommended that

a

gasket

be

used when shift

cover

is

installed after overhaul. (5)

Set

shift cover assembly aside

for

inspection.

REARING

RETAINER

AND

SHAFT BEARING

RACE

REMOVAL (1) Remove front bearing retainer bolts

and re

move retainer

(Fig. 3). Tap

retainer with rubber mal let

to

loosen

it if

necessary.

(2)

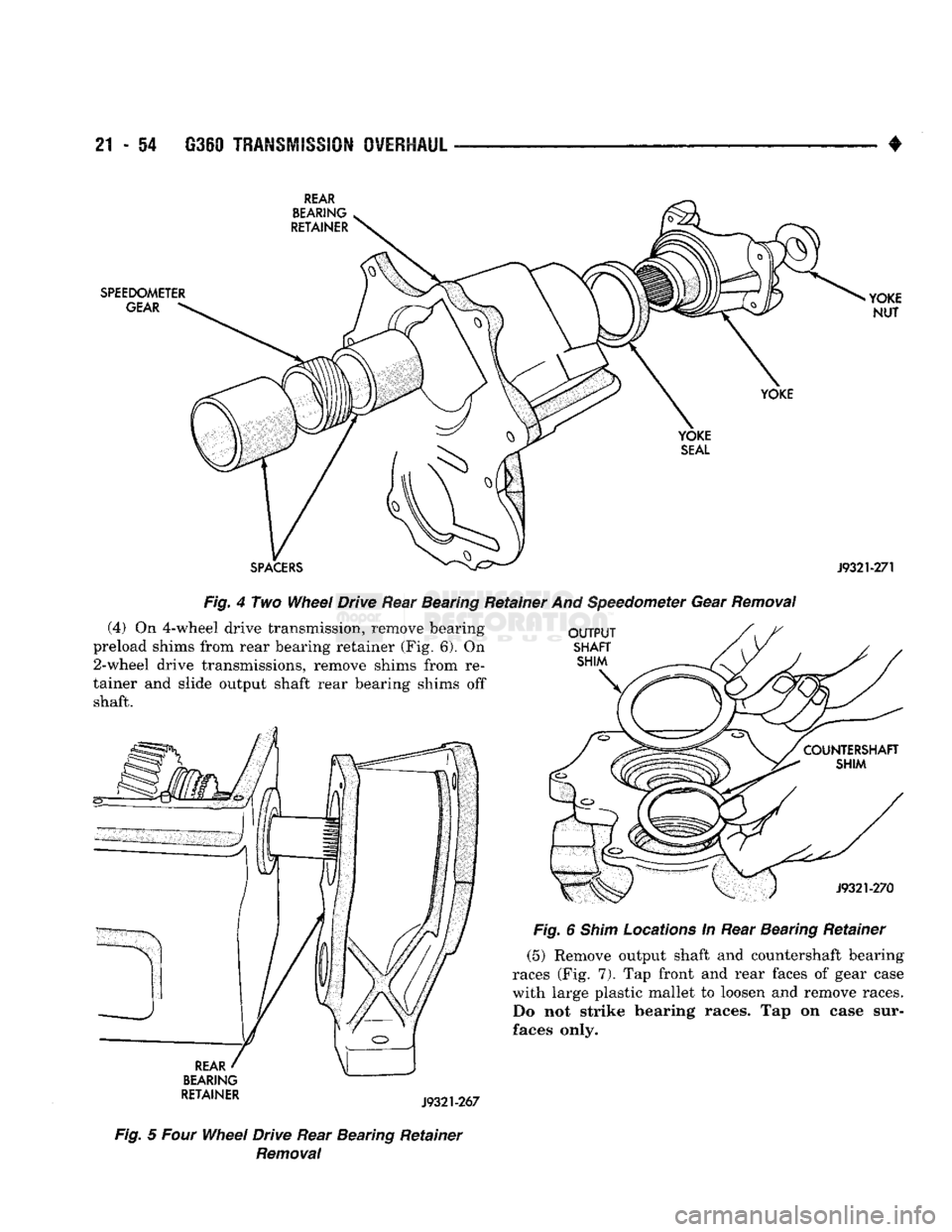

On

2-wheel drive models, remove rear bearing

retainer

as

follows

(Fig. 4):

(a) Remove

nut

attaching yoke

to

output.

Torque

on nut is

quite high. Best

way to re

move

nut is

with 350-400

ft. lb.

rated high

ca

pacity impact wrench.

(b) Remove yoke from output shaft splines.

page

Transmission

Disassembly

53

Fig.

2

Shift

Cover

Removal/Installation

CHANNELS

(4)

J9321-268

Fig.

3

Front Bearing Retainer

Removal

(c) Remove bolts attaching rear bearing retainer

to gear case

and

remove retainer.

Use

rubber mal let

to

loosen retainer

if

necessary.

(d) Remove speedometer gear

and

spacers from

output shaft.

(e) Remove preload shims from rear retainer,

or

bearings.

(f) Remove yoke seal from retainer with suitable

pry tool.

Do not

damage retainer surface while

re

moving seal.

(3)

On

4-wheel drive transmission, remove rear

bearing retainer bolts

and

remove retainer from gear case

(Fig. 5).

Page 1055 of 1502

21

- 54

G350

TRANSMISSION

OVERHAUL

4-

REAR

BEARING

RETAINER

SPEEDOMETER

GEAR

>YOKE

NUT

YOKE

SPACERS

YOKE

SEAL

J9321-271

Fig.

4 Two Wheel Drive Rear Bearing Retainer And Speedometer Gear

Removal

(4)

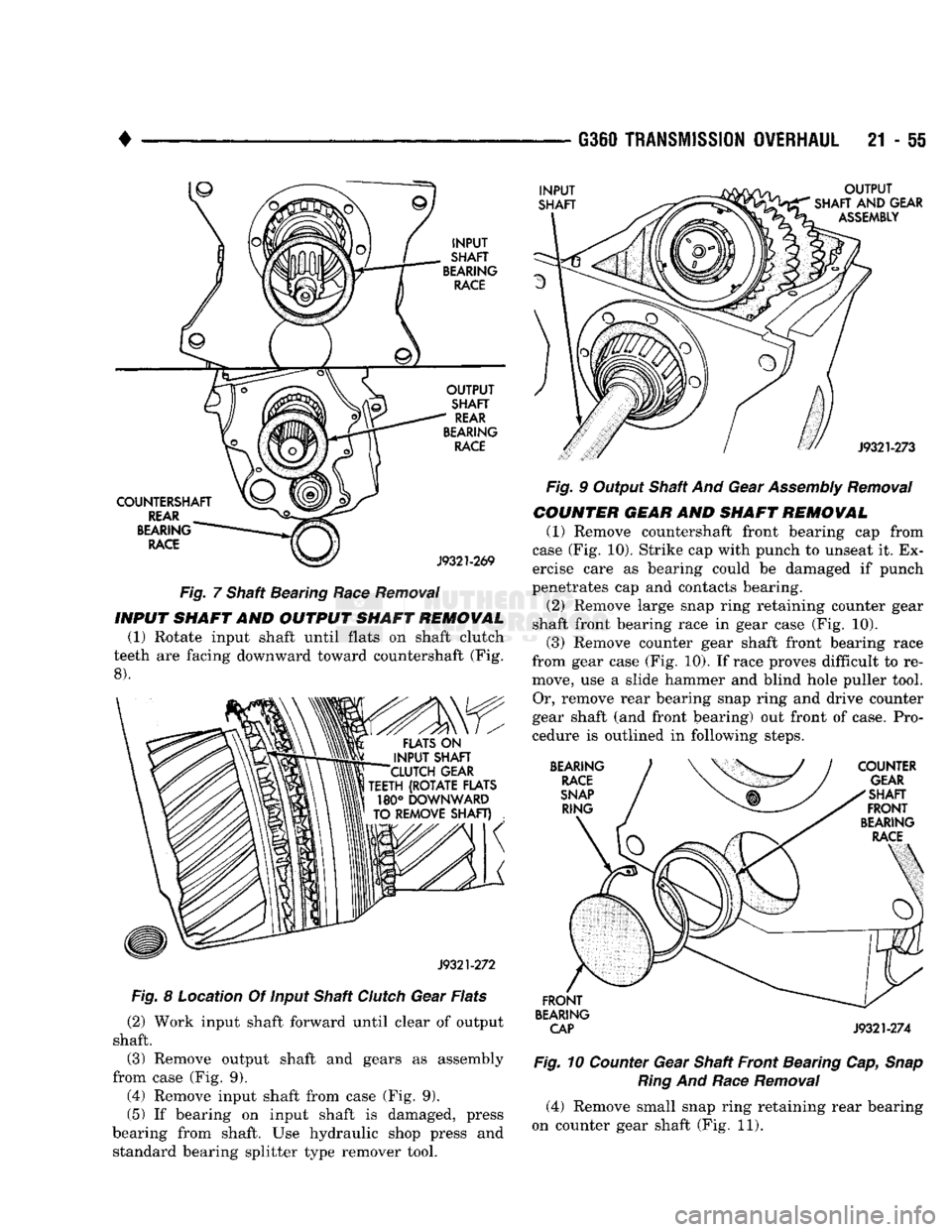

On 4-wheel drive transmission, remove bearing

OUTPUT

preload shims from rear bearing retainer (Fig. 6). On

SHAFT

2-wheel

drive transmissions, remove shims from re-

SHIM

tainer and slide output shaft rear bearing shims off \, shaft.

REAR

BEARING

RETAINER

J9321-270

Fig.

6

Shim

Locations In Rear Bearing Retainer

(5)

Remove output shaft and countershaft bearing

races (Fig. 7). Tap front and rear faces of gear case

with large plastic mallet to loosen and remove races. Do not strike bearing races. Tap on case sur

faces only.

J9321-267

Fig.

5

Four

Wheel Drive Rear Bearing Retainer

Removal

Page 1056 of 1502

•

G360

TRANSMISSION

OVERHAUL

21 - ii

Fig. 7 Shaft Bearing Race Removal

INPUT

SHAFT

AND OUTPUT

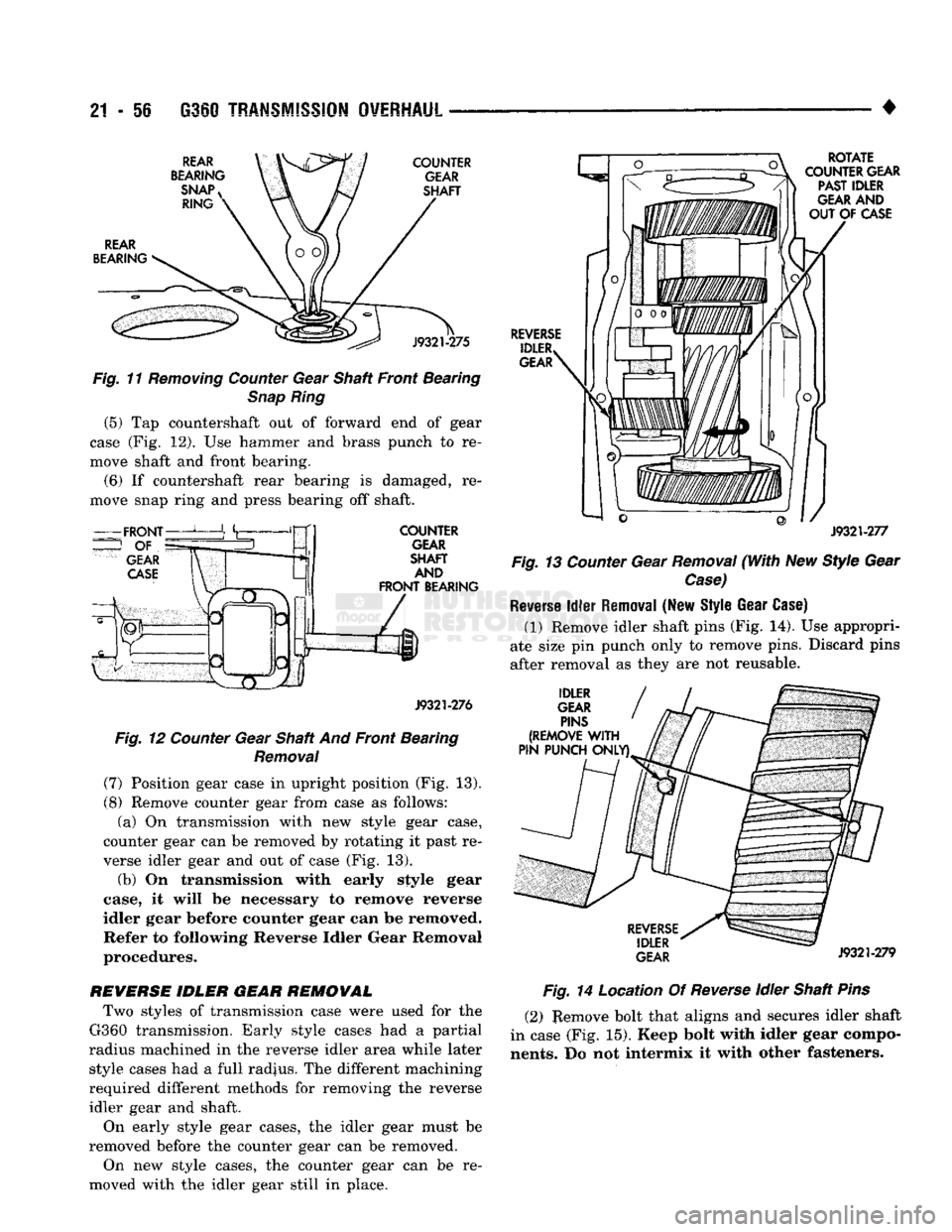

SHAFT REMOWAL

(1)

Rotate input shaft until flats on shaft clutch

teeth are facing downward toward countershaft (Fig.

8).

Fig. 8 Location Of Input Shaft Clutch Gear Flats

(2)

Work input shaft forward until clear of output

shaft.

(3)

Remove output shaft and gears as assembly

from case (Fig. 9).

(4)

Remove input shaft from case (Fig. 9).

(5)

If bearing on input shaft is damaged, press

bearing from shaft. Use hydraulic shop press and standard bearing splitter type remover tool. Fig. 9 Output Shaft And Gear Assembly Removal

COUNTER GEAR

AND

SHAFT REMOWAL

(1)

Remove countershaft front bearing cap from

case (Fig. 10). Strike cap with punch to unseat it. Ex

ercise care as bearing could be damaged if punch

penetrates cap and contacts bearing.

(2)

Remove large snap ring retaining counter gear

shaft front bearing race in gear case (Fig. 10).

(3)

Remove counter gear shaft front bearing race

from gear case (Fig. 10). If race proves difficult to re move, use a slide hammer and blind hole puller tool. Or, remove rear bearing snap ring and drive counter

gear shaft (and front bearing) out front of case. Pro

cedure is outlined in following steps.

BEARING

CAP

J9321-274

Fig. 10 Counter Gear Shaft Front Bearing Cap, Snap Ring And Race Removal

(4)

Remove small snap ring retaining rear bearing

on counter gear shaft (Fig. 11).

Page 1057 of 1502

21

-

56

G360

TRANSMISSION OVERHAUL

^ ^ ^ ^ •

REAR

BEARING

SNAP

RING COUNTER

GEAR

SHAFT

REAR

BEARING

J9321-275

Fig.

11

Removing

Counter

Gear Shaft Front Bearing

Snap

Ring

(5) Tap countershaft out of forward end of gear

case (Fig. 12). Use hammer and brass punch to re

move shaft and front bearing.

(6)

If countershaft rear bearing is damaged, re

move snap ring and press bearing off shaft.

COUNTER

GEAR

SHAFT

AND

FRONT

BEARING

J9321-276

Fig.

12

Counter

Gear Shaft And Front Bearing

Removal

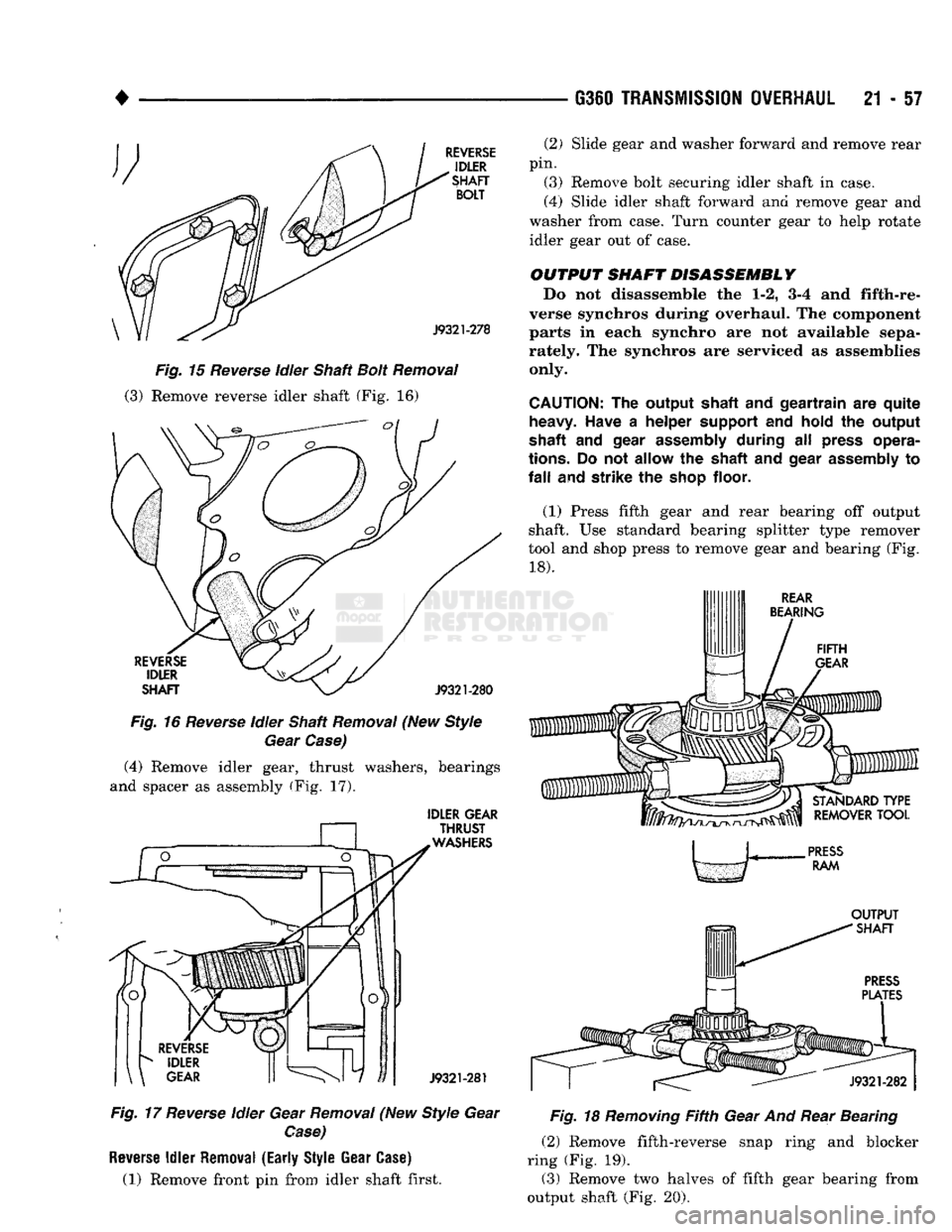

(7) Position gear case in upright position (Fig. 13).

(8) Remove counter gear from case as follows: (a) On transmission with new style gear case,

counter gear can be removed by rotating it past re

verse idler gear and out of case (Fig. 13).

(b) On transmission with early style gear

case, it will be necessary to remove reverse

idler gear before counter gear can be removed. Refer to following Reverse Idler Gear Removal

procedures.

REVERSE IDLER GEAR REMOVAL Two styles of transmission case were used for the

G360 transmission. Early style cases had a partial

radius machined in the reverse idler area while later style cases had a full radius. The different machining

required different methods for removing the reverse idler gear and shaft.

On early style gear cases, the idler gear must be

removed before the counter gear can be removed.

On new style cases, the counter gear can be re

moved with the idler gear still in place.

REVERSE

IDLER

GEAR

ROTATE

COUNTER

GEAR

PAST

IDLER

GEAR

AND

OUT OF

CASE

J9321-277

Fig.

13

Counter

Gear

Removal

(With

New Style Gear

Case)

Reverse

Idler

Removal (New Style Gear Case)

(1) Remove idler shaft pins (Fig. 14). Use appropri

ate size pin punch only to remove pins. Discard pins

after removal as they are not reusable.

IDLER

GEAR

PINS

(REMOVE

WITH

PIN

PUNCH

ONLY)

REVERSE IDLER

GEAR

J9321-279

Fig.

14 Location Of

Reverse

Idler Shaft

Pins

(2) Remove bolt that aligns and secures idler shaft

in case (Fig. 15). Keep bolt with idler gear compo

nents.

Do not intermix it with other fasteners.

Page 1058 of 1502

G350 TRANSMISSION OVERHAUL

21 - 57

REVERSE

IDLER

SHAFT

BOLT

J9321-278

Fig.

15

Reverse

idler

Shaft

-Bolt

Removal

(3) Remove reverse idler shaft (Fig. 16)

REVERSE

IDLER

SHAFT

J9321-280

Fig.

16

Reverse

Idler Shaft

Removal

(New Style

Gear

Case)

(4) Remove idler gear, thrust washers, bearings

and spacer as assembly (Fig. 17).

IDLER

GEAR

THRUST

WASHERS

J9321-281

Fig.

17

Reverse

Idler Gear

Removal

(New Style Gear

Case)

Reverse

Idler

Removal (Early Style Gear

Case)

(1) Remove front pin from idler shaft first. (2) Slide gear and washer forward and remove rear

pin.

(3) Remove bolt securing idler shaft in case.

(4) Slide idler shaft forward and remove gear and

washer from case. Turn counter gear to help rotate idler gear out of case.

OUTPUT

SHAFT DISASSEMBLY

Do not disassemble the 1-2, 3-4 and fifth-re

verse synchros during overhaul. The component

parts in each synchro are not available sepa

rately. The synchros are serviced as assemblies only.

CAUTION:

The

output shaft

and

geartrain

are

quite heavy. Have

a

helper support

and

hold

the

output

shaft

and

gear assembly during

all

press opera

tions.

Do not

allow

the

shaft

and

gear assembly

to

fall

and

strike

the

shop floor.

(1) Press fifth gear and rear bearing off output

shaft. Use standard bearing splitter type remover

tool and shop press to remove gear and bearing (Fig.

18).

REAR

BEARING

STANDARD

TYPE

REMOVER

TOOL

PRESS

RAM

OUTPUT

SHAFT

Fig.

18

Removing

Fifth

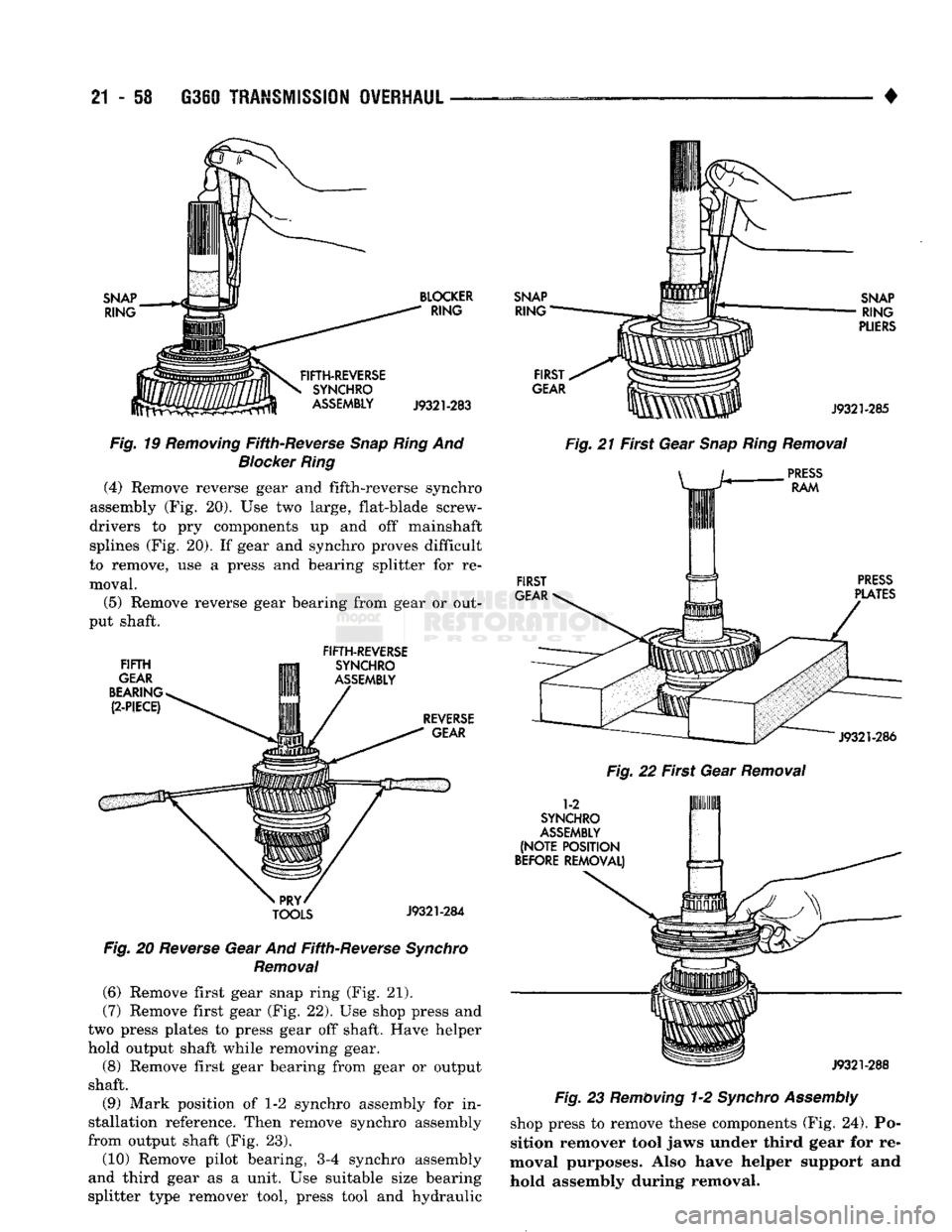

Gear And Rear Bearing (2) Remove fifth-reverse snap ring and blocker

ring (Fig. 19). (3) Remove two halves of fifth gear bearing from

output shaft (Fig. 20).

Page 1059 of 1502

21

- 58

G360

TRANSMISSION

OVERHAUL

•

SNAP

RING

BLOCKER

RING

FIFTH-REVERSE

SYNCHRO

ASSEMBLY

J9321-283

Fig.

19

Removing

Fifth-Reverse

Snap Ring

And

Blocker Ring

(4) Remove reverse gear and fifth-reverse synchro

assembly (Fig. 20). Use two large, flat-blade screw

drivers to pry components up and off mainshaft splines (Fig. 20). If gear and synchro proves difficult

to remove, use a press and bearing splitter for re

moval.

(5) Remove reverse gear bearing from gear or out

put shaft.

FIFTH

GEAR

BEARING

(2-PIECE) FIFTH-REVERSE

SYNCHRO

ASSEMBLY

REVERSE

GEAR

PRY>

TOOLS

J9321-284

Fig.

20

Reverse

Gear And Fifth-Reverse

Synchro

Removal

(6) Remove first gear snap ring (Fig. 21).

(7) Remove first gear (Fig. 22). Use shop press and

two press plates to press gear off shaft. Have helper

hold output shaft while removing gear.

(8) Remove first gear bearing from gear or output

shaft. (9) Mark position of 1-2 synchro assembly for in

stallation reference. Then remove synchro assembly

from output shaft (Fig. 23).

(10) Remove pilot bearing, 3-4 synchro assembly

and third gear as a unit. Use suitable size bearing

splitter type remover tool, press tool and hydraulic

SNAP

RING

FIRST

GEAR

SNAP

RING

PLIERS

J9321-285

Fig.

21 First Gear

Snap Ring

Removal

PRESS

RAM

FIRST

GEAR

PRESS

PLATES

J9321-286

Fig.

22 First Gear

Removal

1-2

SYNCHRO

ASSEMBLY

(NOTE POSITION

BEFORE

REMOVAL)

J9321-288

Fig.

23

Removing

1-2

Synchro Assembly

shop press to remove these components (Fig. 24). Po

sition remover tool jaws under third gear for re

moval purposes. Also have helper support and

hold assembly during removal.

Page 1060 of 1502

•

Fig.

24 Pilot Bearing, 3-4

Synchro

And Third Gear

Removal

THRUST

WASHER

J9321-290

Fig.

25

Second

Gear

Snap

Ring

Removal

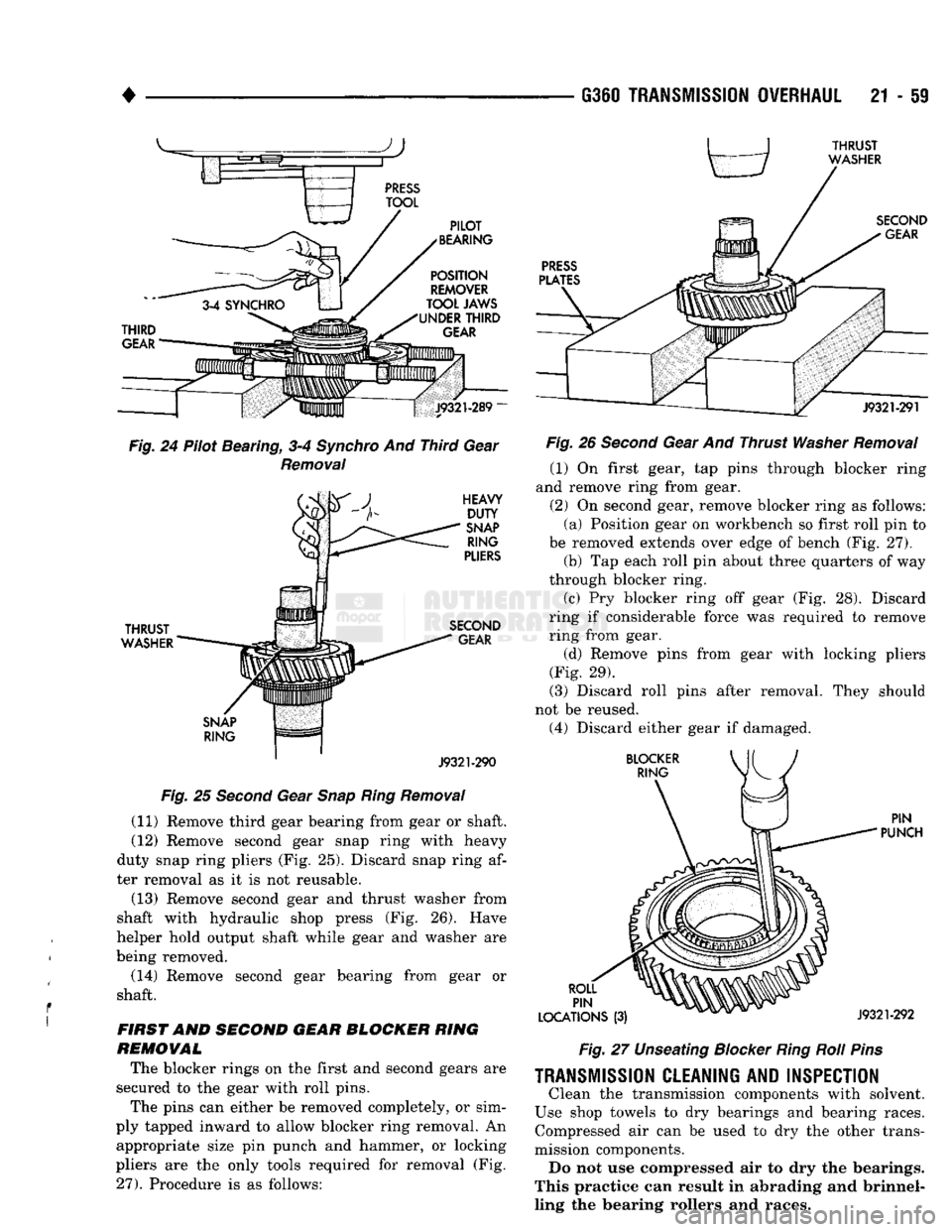

(11) Remove third gear bearing from gear or shaft.

(12) Remove second gear snap ring with heavy

duty snap ring pliers (Fig. 25). Discard snap ring af

ter removal as it is not reusable. (13) Remove second gear and thrust washer from

shaft with hydraulic shop press (Fig. 26). Have

helper hold output shaft while gear and washer are

being removed.

(14) Remove second gear bearing from gear or

shaft.

FIRST

AND SECOND GEAR BLOCKER RING

REMOVAL The blocker rings on the first and second gears are

secured to the gear with roll pins. The pins can either be removed completely, or sim

ply tapped inward to allow blocker ring removal. An appropriate size pin punch and hammer, or locking

pliers are the only tools required for removal (Fig.

27).

Procedure is as follows:

G360

TRANSMISSION

OVERHAUL

21 - 59

Fig.

26

Second

Gear And Thrust

Washer

Removal

(1) On first gear, tap pins through blocker ring

and remove ring from gear.

(2) On second gear, remove blocker ring as follows: (a) Position gear on workbench so first roll pin to

be removed extends over edge of bench (Fig. 27). (b) Tap each roll pin about three quarters of way

through blocker ring. (c) Pry blocker ring off gear (Fig. 28). Discard

ring if considerable force was required to remove

ring from gear.

(d) Remove pins from gear with locking pliers

(Fig. 29).

(3) Discard roll pins after removal. They should

not be reused. (4) Discard either gear if damaged.

Fig.

27 Unseating

Blocker

Ring

Roll

Pins

TRANSMISSION

CLEANING

AND

INSPECTION

Clean the transmission components with solvent.

Use shop towels to dry bearings and bearing races. Compressed air can be used to dry the other trans

mission components. Do not use compressed air to dry the bearings.

This practice can result in abrading and brinnel-

ling the bearing rollers and races.