DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1091 of 1502

21 - 90

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

• (4) Note pressure with engine at curb idle speed

and rear wheels stopped. Pressure should be zero to 1-1/2 psi maximum. If pressure exceeds this figure,

governor valve or weights are sticking open.

(5) Slowly increase engine rpm and observe speed

ometer and pressure test gauge. Governor pressure should increase in proportion to indicated vehicle

speed (or approximately 1 psi for every 1 mph).

(6) Pressure rise should be smooth and drop back

to 0 to 1-1/2 psi when wheels are braked to a stop and engine returns to curb idle speed.

(7) Compare results of the pressure tests with the

Pressure Test Analysis Charts (Figs. 6 and 7).

Test

Six—42RH/46RH

Transmission

In Overdrive Fourth

Gear

This test checks line pressure at the overdrive

clutch in fourth gear range. Use 300 psi Test

Gauge C-3292 for this test.

(1) Raise vehicle and connect test gauge to over

drive clutch pressure port (Fig. 5). (2) Lower vehicle to enough to allow entry into

drivers seat. Leave vehicle wheels approximately one

foot off shop floor.

(3) Secure test gauge where it can be viewed from

drivers seat.

(4) Verify that overdrive control switch is in ON

position. (5) Start engine and shift into D range.

(6) Increase engine rpm gradually until 3-4 shift

occurs and note gauge pressure. (7) Pressure should be 469-496 kPa (68-72 psi)

with closed throttle and increase to 620-827 kPa (90- 120 psi) at 1/2 to 3/4 throttle. Note that pressure will

increase to 896 kPa (130 psi) or more at full throttle. (8) Refer to pressure test chart (Fig. 7) for pressure

diagnosis.

CONVERTER

STALL

TEST

Stall testing involves determining maximum en

gine rpm obtainable at full throttle with the rear

wheels locked and the transmission in D range. This

test checks the holding ability of the converter over

running clutch and both of the transmission clutches. When stall testing is completed, refer to the Stall

Speed Specifications chart and Stall Speed Diagnosis

guides.

WARNING:

NEVER

ALLOW

ANYONE

TO

STAND

IN

FRONT

OF THE

VEHICLE

DURING

A

STALL

TEST.

ALWAYS

BLOCK

THE

FRONT

WHEELS

AND

APPLY

THE

SERVICE

AND

PARKING

BRAKES

DURING

THE

TEST.

STALL

TEST

PROCEDURE

(1) Connect tachometer to engine.

(2) Check and adjust transmission fluid level.

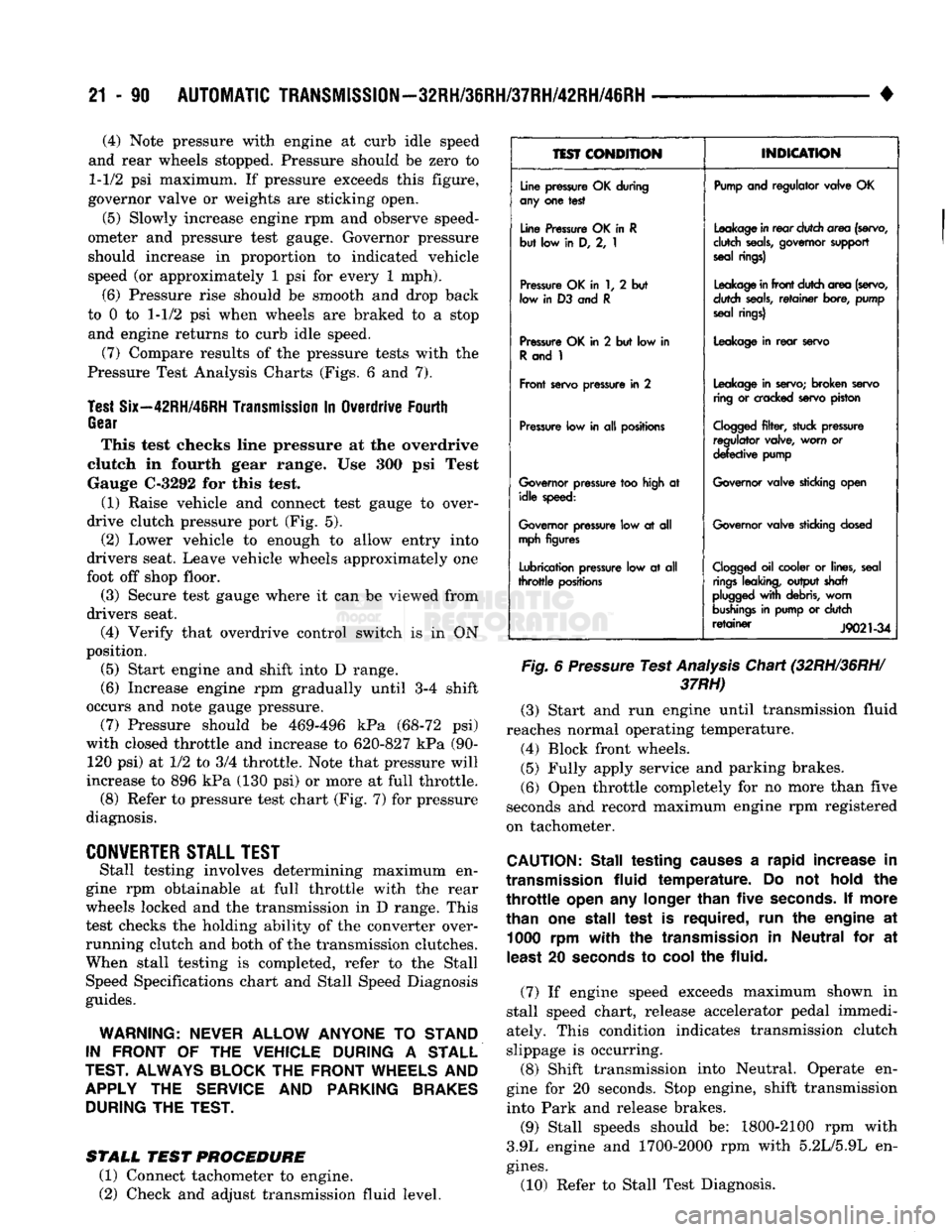

1EST

CONDITION

INDICATION

Line

pressure

OK during

any

one test

Pump

and regulator valve OK

Line

Pressure

OK in R

but low in D, 2, 1

Leakage

in

rear

dutch area

(servo,

dutch

seals,

governor

support

seal

rings)

Pressure

OK in 1, 2 but

low

in D3 and R

Leakage

in

front

dutch area

(servo,

dutch

seals,

retainer

bore,

pump

seal

rings)

Pressure

OK in 2 but low in

R

and 1

Leakage

in

rear

servo

Front

servo

pressure

in 2

Leakage

in

servo;

broken

servo

ring

or

cracked

servo

piston

Pressure

low in all

positions

Cogged

filter,

stuck

pressure

regulator valve, worn or

defective

pump

Governor

pressure

too

high

at idle

speed:

Governor

valve

sticking

open

Governor

pressure

low at all

mph

figures

Governor

valve

sticking

dosed

Lubrication

pressure

low at all

throttle

positions

Clogged

oil cooler or

lines,

seal

rings

leaking,

output shaft

plugged

with

debris,

worn

bushings

in

pump

or dutch

retainer

J9021-34

Fig.

6

Pressure

Test

Analysis

Chart (32RH/36RH/

37RH)

(3) Start and run engine until transmission fluid

reaches normal operating temperature. (4) Block front wheels.

(5) Fully apply service and parking brakes.

(6) Open throttle completely for no more than five

seconds and record maximum engine rpm registered

on tachometer.

CAUTION:

Stall testing

causes

a rapid increase in

transmission

fluid

temperature. Do not

hold

the

throttle

open

any

longer

than

five

seconds.

If more

than one stall test is required, run the engine at 1000 rpm

with

the

transmission

in Neutral for at

least

20

seconds

to

cool

the fluid.

(7) If engine speed exceeds maximum shown in

stall speed chart, release accelerator pedal immedi

ately. This condition indicates transmission clutch

slippage is occurring.

(8) Shift transmission into Neutral. Operate en

gine for 20 seconds. Stop engine, shift transmission

into Park and release brakes.

(9) Stall speeds should be: 1800-2100 rpm with

3.9L engine and 1700-2000 rpm with 5.2L/5.9L en

gines.

(10) Refer to Stall Test Diagnosis.

Page 1092 of 1502

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

21 - 91

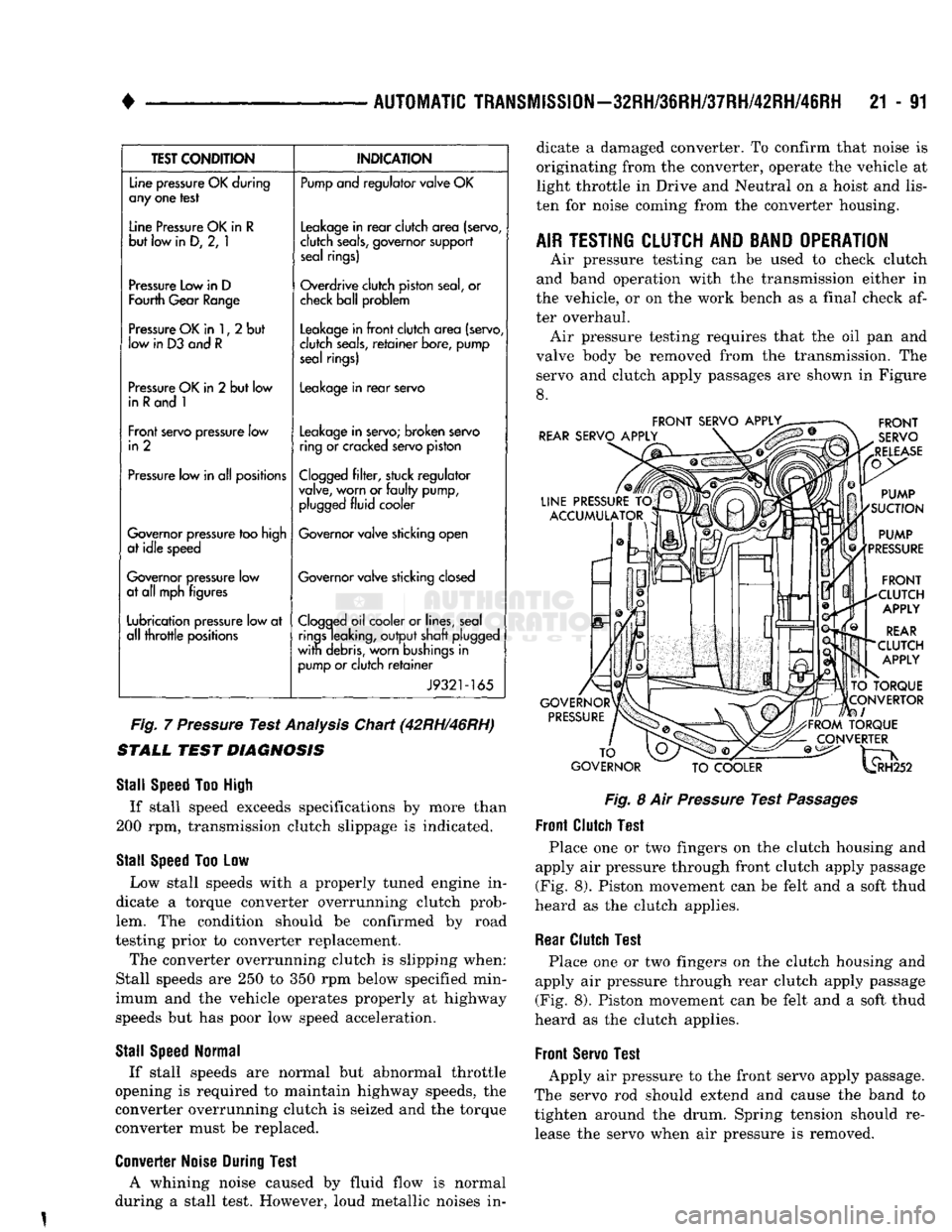

TEST

CONDITION

Line pressure OK during

any one test

Line Pressure OK in

R

but low in D, 2, 1

Pressure Low in D

Fourth Gear Range

Pressure OK in 1, 2 but

low

in

D3

and

R

Pressure OK in 2 but low in

R

and 1

Front servo pressure low

in 2

Pressure low in all positions

Governor pressure too high

at idle speed

Governor pressure low

at all mph figures Lubrication pressure low at

all throttle positions

INDICATION

Pump and regulator valve OK

Leakage in rear clutch area (servo,

clutch seals, governor support seal rings)

Overdrive clutch piston seal, or

check ball problem

Leakage in front clutch area (servo,

clutch seals, retainer bore, pump seal rings)

Leakage in rear servo

Leakage in servo; broken servo

ring or cracked servo piston

Clogged filter, stuck regulator

valve, worn or faulty pump, plugged fluid cooler

Governor valve sticking open

Governor valve sticking closed

Clogged oil cooler or lines, seal rings leaking, output shaft plugged

with debris, worn bushings in pump or clutch retainer

J9321-165

Fig.

7

Pressure

Test

Analysis

Chart (42RH/46RH)

STALL

TEST

DIAGNOSIS

Stall

Speed

Too

High

If stall speed exceeds specifications by more than

200 rpm, transmission clutch slippage is indicated.

Stall

Speed

Too Low Low stall speeds with a properly tuned engine in

dicate a torque converter overrunning clutch prob

lem. The condition should be confirmed by road

testing prior to converter replacement. The converter overrunning clutch is slipping when:

Stall speeds are 250 to 350 rpm below specified min

imum and the vehicle operates properly at highway

speeds but has poor low speed acceleration.

Stall

Speed

Normal

If stall speeds are normal but abnormal throttle

opening is required to maintain highway speeds, the

converter overrunning clutch is seized and the torque

converter must be replaced.

Converter

Noise

During

Test

A whining noise caused by fluid flow is normal

during a stall test. However, loud metallic noises in dicate a damaged converter. To confirm that noise is

originating from the converter, operate the vehicle at

light throttle in Drive and Neutral on a hoist and

lis

ten for noise coming from the converter housing.

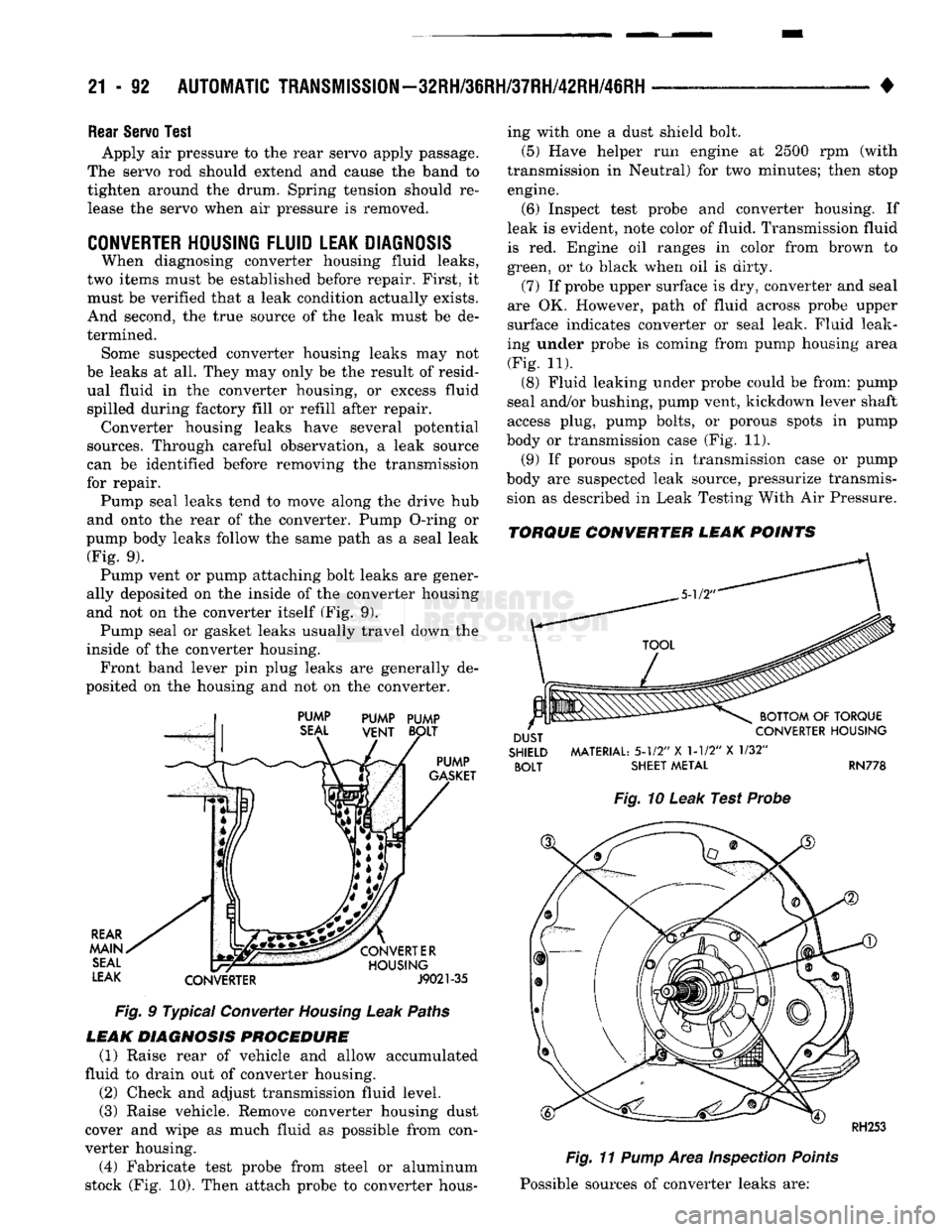

AIR

TESTING

CLUTCH

AND

BAND

OPERATION

Air pressure testing can be used to check clutch

and band operation with the transmission either in

the vehicle, or on the work bench as a final check af

ter overhaul. Air pressure testing requires that the oil pan and

valve body be removed from the transmission. The servo and clutch apply passages are shown in Figure

8.

FRONT

SERVO

APPLY^

REAR

SERVO

APPLY

LINE

PRESSURE

TO

ACCUMULATOR

GOVERNOR

PRESSURE

FRONT

SERVO

RELEASE

PUMP

SUCTION

PUMP

PRESSURE

FRONT

CLUTCH

APPLY

REAR

CLUTCH

APPLY

TO

TORQUE

CONVERTOR

I

FROM

TORQUE

CONVERTER

TO

GOVERNOR

TO

COOLER

^H252

Fig.

8 Air

Pressure

Test

Passages

Front

Clutch

Test

Place one or two fingers on the clutch housing and

apply air pressure through front clutch apply passage (Fig. 8). Piston movement can be felt and a soft thud

heard as the clutch applies.

Rear

Clutch

Test

Place one or two fingers on the clutch housing and

apply air pressure through rear clutch apply passage

(Fig. 8). Piston movement can be felt and a soft thud

heard as the clutch applies.

Front

Servo

Test

Apply air pressure to the front servo apply passage.

The servo rod should extend and cause the band to

tighten around the drum. Spring tension should re lease the servo when air pressure is removed.

Page 1093 of 1502

21

- 12

AUTOMATIC TRANSMISSION—32RH/36RH/37RH/42RH/46RH

•

Rear Servo

Test

Apply air pressure to the rear servo apply passage.

The servo rod should extend and cause the band to

tighten around the drum. Spring tension should re lease the servo when air pressure is removed.

CONVERTER

HOUSING

FLUID

LEAK

DIAGNOSIS

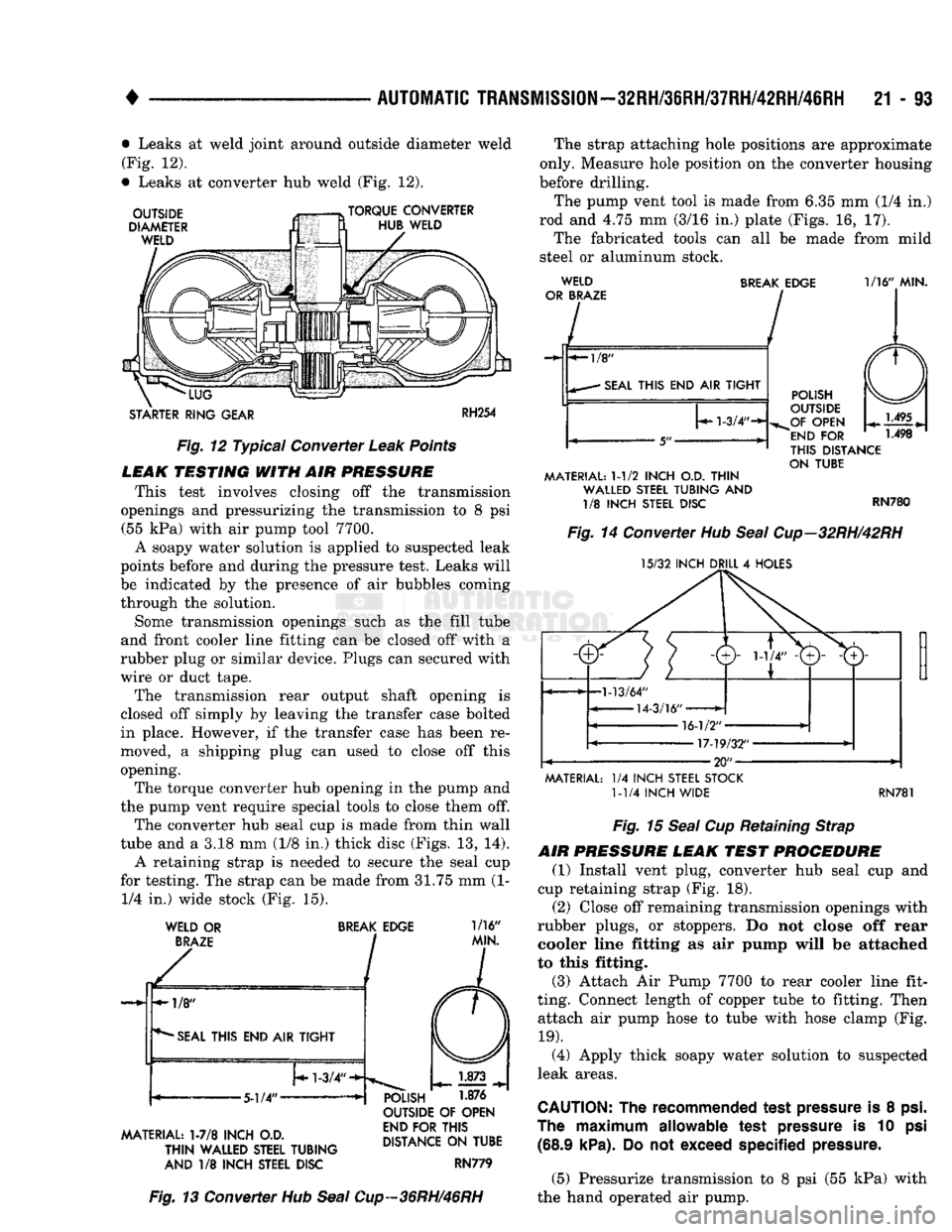

When diagnosing converter housing fluid leaks,

two items must be established before repair. First, it must be verified that a leak condition actually exists.

And second, the true source of the leak must be de

termined. Some suspected converter housing leaks may not

be leaks at all. They may only be the result of resid ual fluid in the converter housing, or excess fluid spilled during factory fill or refill after repair. Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair. Pump seal leaks tend to move along the drive hub

and onto the rear of the converter. Pump O-ring or

pump body leaks follow the same path as a seal leak (Fig. 9). Pump vent or pump attaching bolt leaks are gener

ally deposited on the inside of the converter housing

and not on the converter itself (Fig. 9). Pump seal or gasket leaks usually travel down the

inside of the converter housing. Front band lever pin plug leaks are generally de

posited on the housing and not on the converter.

,j PUMP PUMP PUMP

Fig. 9 Typical Converter Homing Leak Paths

LEAK DIAGNOSIS PROCEDURE (1) Raise rear of vehicle and allow accumulated

fluid to drain out of converter housing.

(2) Check and adjust transmission fluid level.

(3)

Raise vehicle. Remove converter housing dust

cover and wipe as much fluid as possible from con

verter housing.

(4) Fabricate test probe from steel or aluminum

stock (Fig. 10). Then attach probe to converter hous ing with one a dust shield bolt.

(5)

Have helper run engine at 2500 rpm (with

transmission in Neutral) for two minutes; then stop engine. (6) Inspect test probe and converter housing. If

leak is evident, note color of fluid. Transmission fluid

is red. Engine oil ranges in color from brown to

green, or to black when oil is dirty.

(7) If probe upper surface is dry, converter and seal

are OK. However, path of fluid across probe upper

surface indicates converter or seal leak. Fluid leak

ing under probe is coming from pump housing area (Fig. 11).

(8) Fluid leaking under probe could be from: pump

seal and/or bushing, pump vent, kickdown lever shaft

access plug, pump bolts, or porous spots in pump

body or transmission case (Fig. 11).

(9) If porous spots in transmission case or pump

body are suspected leak source, pressurize transmis sion as described in Leak Testing With Air Pressure.

TORQUE CONVERTER LEAK POINTS

SHIELD

MATERIAL:

5-1/2"

X 1-1/2" X 1/32"

BOLT

SHEET

METAL

RN778

Fig.

10 Leak Test Probe

Fig.

11

Pump

Area

Inspection

Points

Possible sources of converter leaks are:

Page 1094 of 1502

•

AUTOMATIC

TRANSMISSION-32RH/3IRH/37RH/42RH/48RH

21 - 13 • Leaks at weld joint around outside diameter weld

(Fig. 12).

• Leaks at converter hub weld (Fig. 12).

OUTSIDE

DIAMETER

WELD

TORQUE CONVERTER

HUB WELD

"LUG

STARTER RING GEAR

RH254

Fig.

12 Typical Converter

Leak

Points

LEAK

TESTING

WITH AIR

PRESSURE

This test involves closing off the transmission

openings and pressurizing the transmission to 8 psi (55 kPa) with air pump tool 7700.

A soapy water solution is applied to suspected leak

points before and during the pressure test. Leaks will

be indicated by the presence of air bubbles coming

through the solution.

Some transmission openings such as the fill tube

and front cooler line fitting can be closed off with a

rubber plug or similar device. Plugs can secured with

wire or duct tape.

The transmission rear output shaft opening is

closed off simply by leaving the transfer case bolted

in place. However, if the transfer case has been re

moved, a shipping plug can used to close off this

opening. The torque converter hub opening in the pump and

the pump vent require special tools to close them off.

The converter hub seal cup is made from thin wall

tube and a 3.18 mm (1/8 in.) thick disc (Figs. 13, 14).

A retaining strap is needed to secure the seal cup

for testing. The strap can be made from 31.75 mm (1- 1/4 in.) wide stock (Fig. 15).

WELD OR

BRAZE

BREAK

EDGE

1/16"

MIN.

MATERIAL: 1-7/8 INCH O.D.

THIN

WALLED STEEL TUBING

AND 1/8 INCH STEEL DISC OUTSIDE OF OPEN

END FOR THIS

DISTANCE ON TUBE

RN779 The strap attaching hole positions are approximate

only. Measure hole position on the converter housing

before drilling.

The pump vent tool is made from 6.35 mm (1/4 in.)

rod and 4.75 mm (3/16 in.) plate (Figs. 16, 17). The fabricated tools can all be made from mild

steel or aluminum stock. WELD

OR BRAZE BREAK EDGE 1/16" MIN.

-«-l/8"

• SEAL THIS END AIR TIGHT

1-3/4"-*-

•

5"-

MATERIAL: 1-1/2 INCH O.D. THIN WALLED STEEL TUBING AND 1/8 INCH STEEL DISC POLISH

OUTSIDE

„OF OPEN

"END

FOR

THIS DISTANCE

ON TUBE

RN780

Fig.

14 Converter Hub

Seal

Cup-32RH/42RH

15/32 INCH DRILL 4 HOLES

MATERIAL: 1/4 INCH STEEL STOCK 1-1/4 INCH WIDE RN781

Fig.

13 Converter Hub

Seal

Cup-36RH/46RH

Fig.

15

Seal

Cup Retaining Strap

AIR

PRESSURE

LEAK

TEST

PROCEDURE

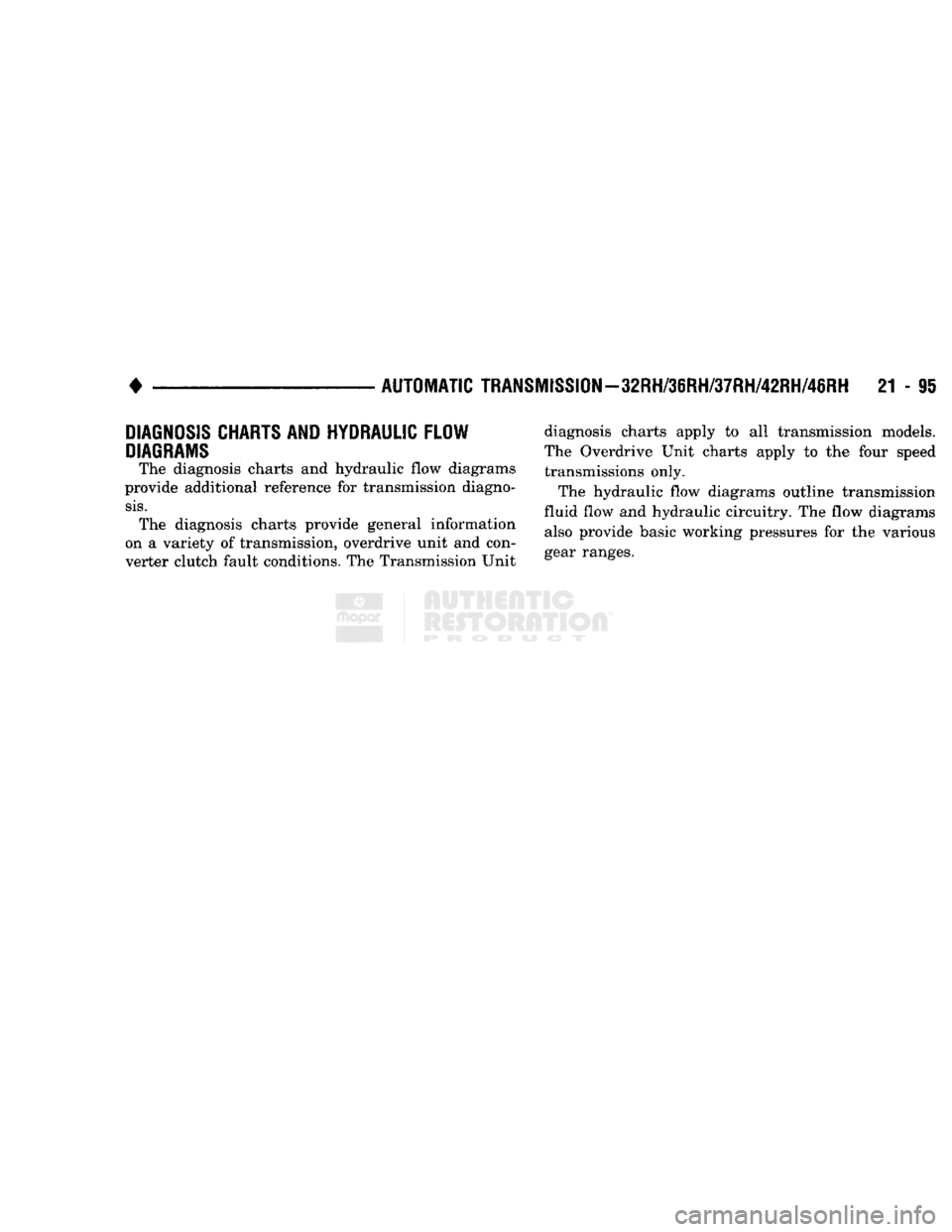

(1) Install vent plug, converter hub seal cup and

cup retaining strap (Fig. 18).

(2) Close off remaining transmission openings with

rubber plugs, or stoppers. Do not close off rear cooler line fitting as air pump will be attached

to this fitting.

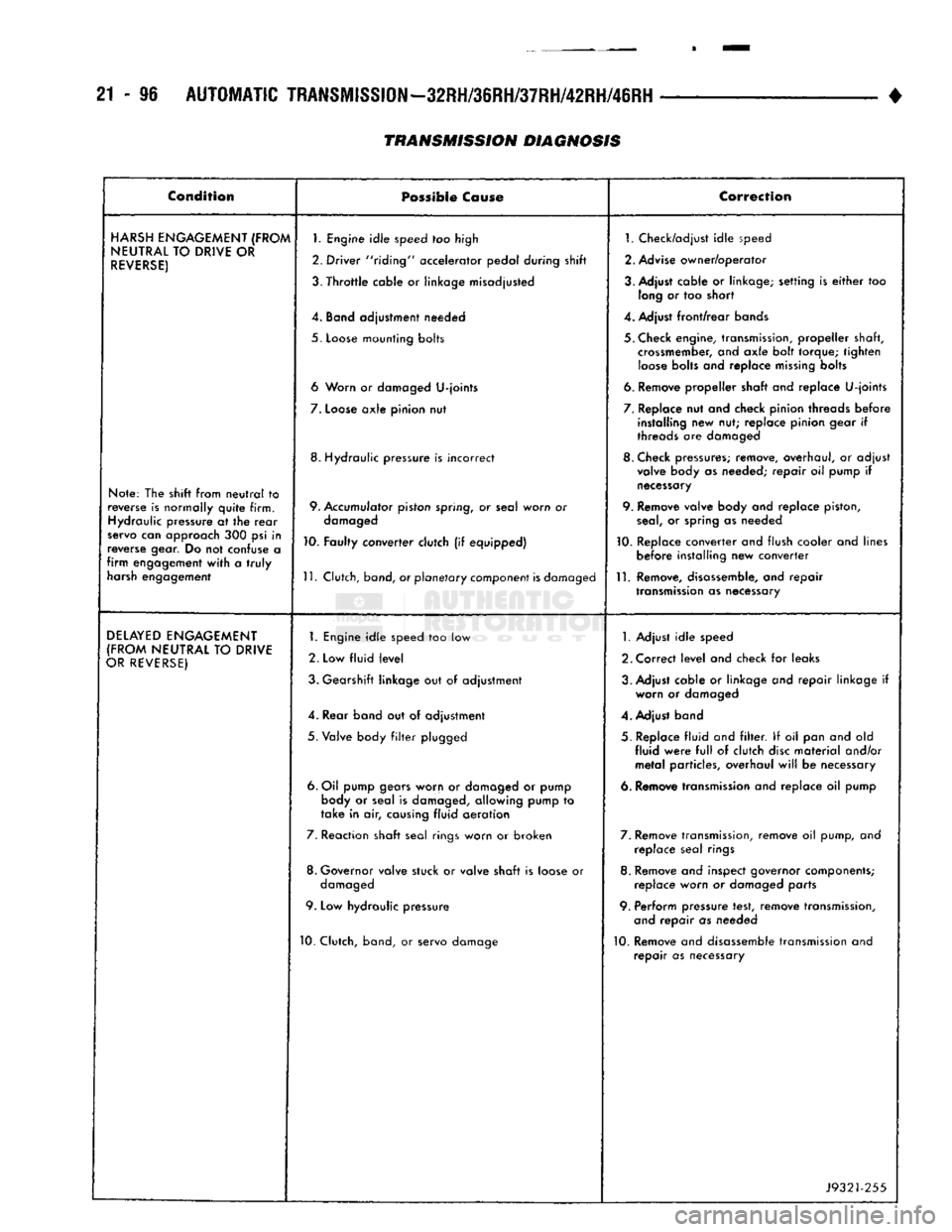

(3) Attach Air Pump 7700 to rear cooler line fit

ting. Connect length of copper tube to fitting. Then attach air pump hose to tube with hose clamp (Fig.

19).

(4) Apply thick soapy water solution to suspected

leak areas.

CAUTION:

The

recommended

test

pressure

is 8

psi.

The

maximum

allowable

test

pressure

is 10 psi

(68.9 kPa).

Do not

exceed

specified

pressure.

(5) Pressurize transmission to 8 psi (55 kPa) with

the hand operated air pump.

Page 1095 of 1502

21

- 14

AUTOMATIC TRANSMISSION—32RH/36RH/37RH/42RH/46RH

•

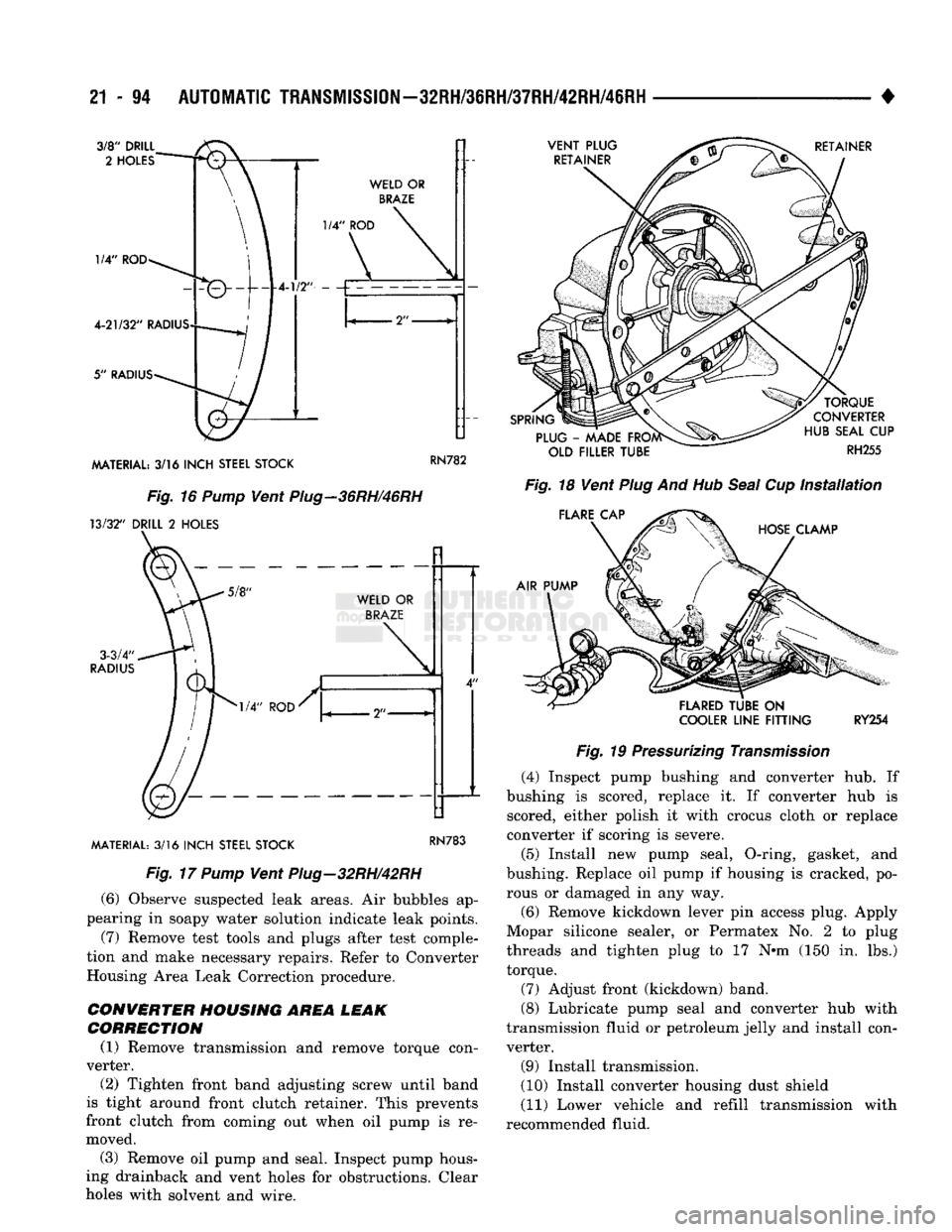

MATERIAL:

3/16

INCH

STEEL

STOCK

Fig. 16 Pump Vent Piug-36RH/46RH

13/32" DRILL

2

HOLES MATERIAL:

3/16

INCH

STEEL

STOCK

KN/aj

Fig. 17 Pump Vent Plug-32RH/42RH

(6) Observe suspected leak areas. Air bubbles ap

pearing in soapy water solution indicate leak points.

(7) Remove test tools and plugs after test comple

tion and make necessary repairs. Refer to Converter Housing Area Leak Correction procedure.

CONVERTER HOUSING AREA LEAK

CORRECTION

(1) Remove transmission and remove torque con

verter.

(2) Tighten front band adjusting screw until band

is tight around front clutch retainer. This prevents

front clutch from coming out when oil pump is re

moved.

(3) Remove oil pump and seal. Inspect pump hous

ing drainback and vent holes for obstructions. Clear

holes with solvent and wire.

COOLER

LINE

FITTING

RY254

Fig. 19 Pressurizing Transmission (4) Inspect pump bushing and converter hub. If

bushing is scored, replace it. If converter hub is scored, either polish it with crocus cloth or replace

converter if scoring is severe.

(5) Install new pump seal, O-ring, gasket, and

bushing. Replace oil pump if housing is cracked, po

rous or damaged in any way.

(6)

Remove kickdown lever pin access plug. Apply

Mopar silicone sealer, or Permatex No. 2 to plug

threads and tighten plug to 17 N*m (150 in. lbs.) torque.

(7) Adjust front (kickdown) band.

(8) Lubricate pump seal and converter hub with

transmission fluid or petroleum jelly and install con

verter.

(9) Install transmission.

(10) Install converter housing dust shield

(11) Lower vehicle and refill transmission with

recommended fluid.

Page 1096 of 1502

•

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

21 - ii

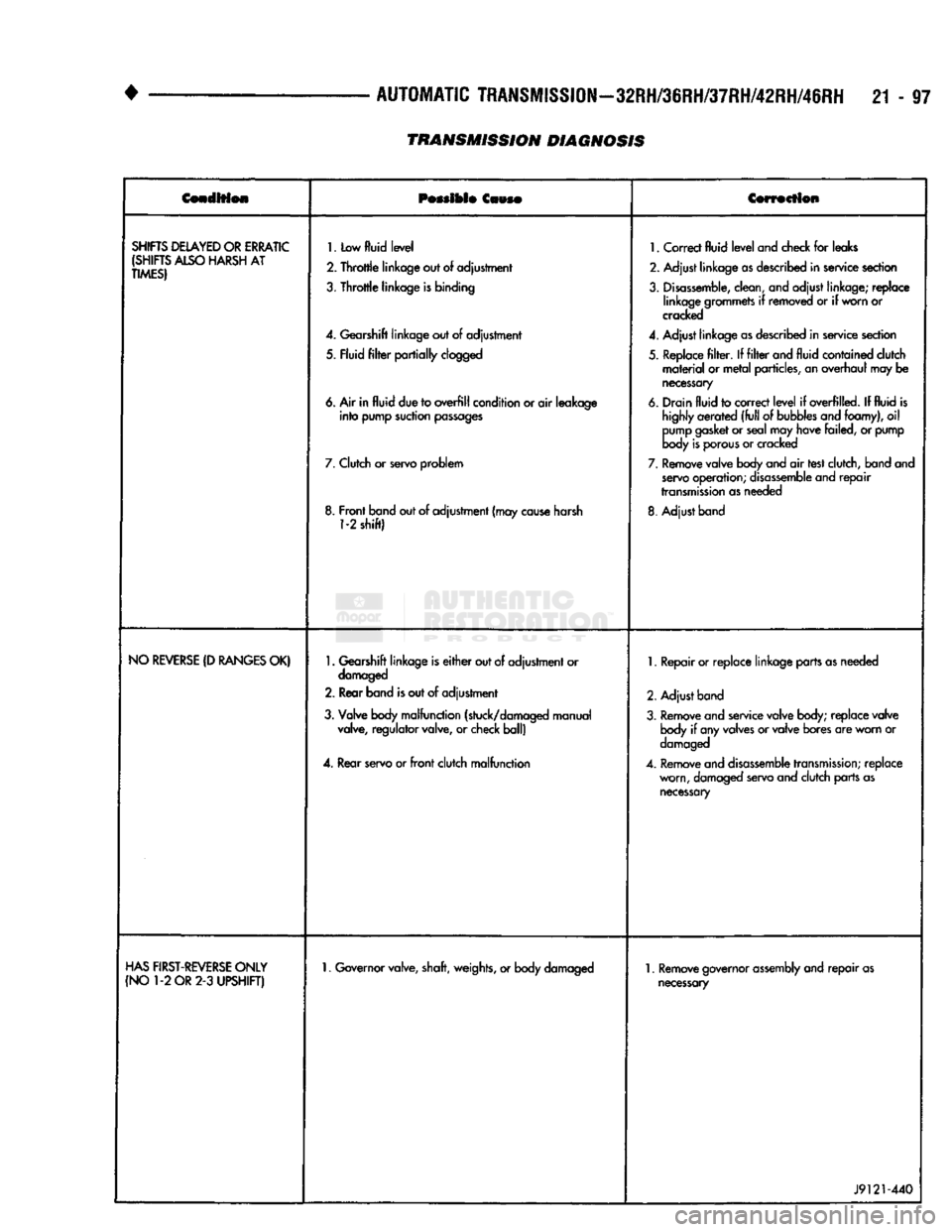

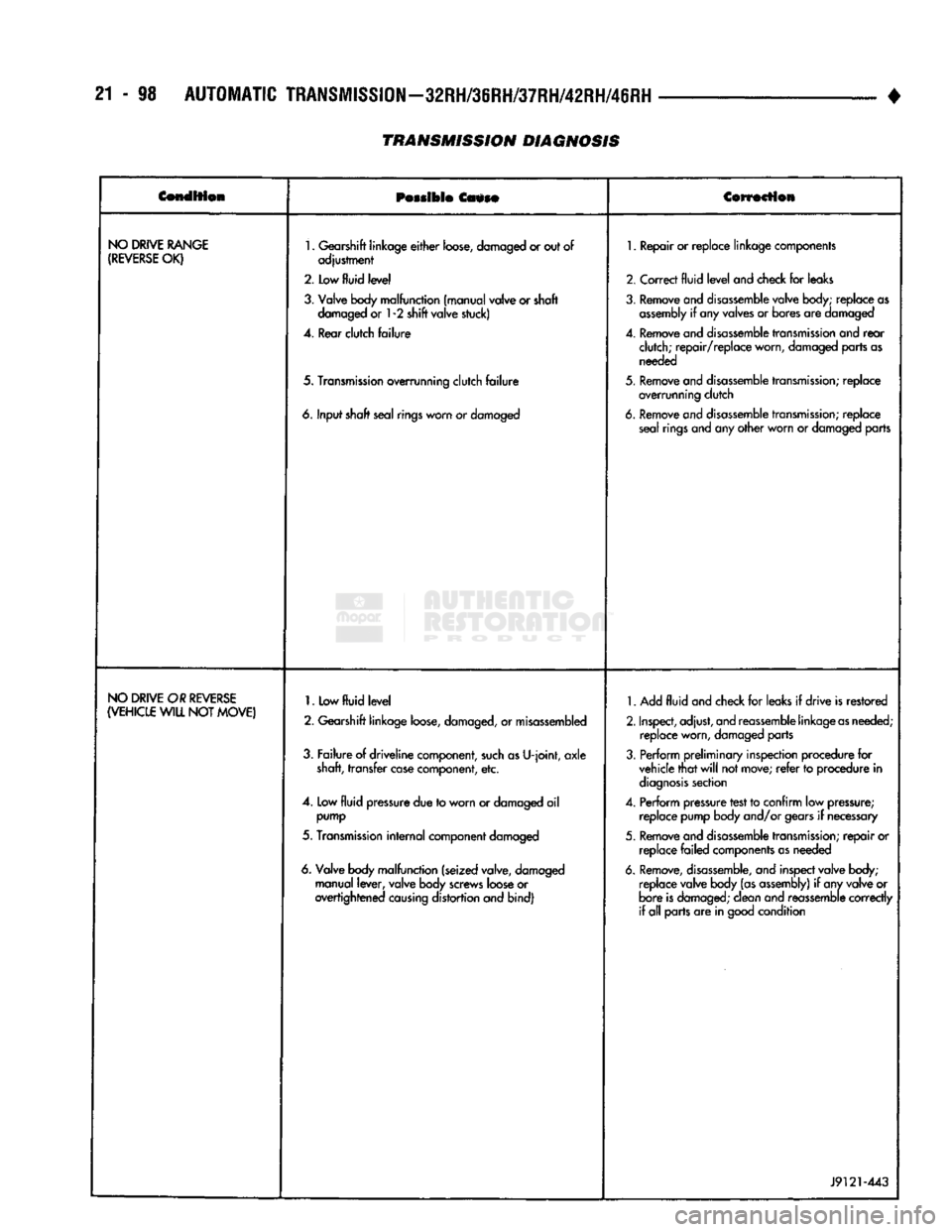

DIAGNOSIS

CHARTS AND HYDRAULIC

FLOW

DIAGRAMS

The diagnosis charts and hydraulic flow diagrams

provide additional reference for transmission diagno

sis.

The diagnosis charts provide general information

on a variety of transmission, overdrive unit and con

verter clutch fault conditions. The Transmission Unit diagnosis charts apply to all transmission models.

The Overdrive Unit charts apply to the four speed

transmissions only.

The hydraulic flow diagrams outline transmission

fluid flow and hydraulic circuitry. The flow diagrams also provide basic working pressures for the various

gear ranges.

Page 1097 of 1502

21 - 96

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

• Condition

Possible

Cause

Correction

HARSH

ENGAGEMENT

(FROM

NEUTRAL

TO

DRIVE

OR

REVERSE)

Note: The shift from

neutral

to

reverse is normally

quite

firm. Hydraulic pressure at the

rear

servo can approach 300 psi in

reverse gear. Do not confuse a

firm

engagement

with

a

truly

harsh engagement

1.

Engine

idle

speed too high

2. Driver "riding" accelerator pedal during shift

3.

Throttle

cable or linkage misadjusted

4. Band adjustment needed

5.

Loose

mounting bolts

6 Worn or damaged

U-joints

7.

Loose

axle

pinion nut

8. Hydraulic pressure is incorrect

9. Accumulator piston spring, or seal worn or damaged

10. Faulty converter clutch (if equipped)

11.

Clutch, band, or

planetary

component

is

damaged 1. Check/adjust

idle

speed

2. Advise owner/operator

3. Adjust cable or linkage; setting is

either

too long or too short

4. Adjust

front/rear

bands

5. Check engine, transmission,

propeller

shaft, crossmember, and

axle

bolt torque;

tighten

loose

bolts and replace

missing

bolts

6. Remove

propeller

shaft and replace

U-joints

7. Replace nut and check pinion threads

before

installing new nut; replace pinion gear if

threads are damaged

8. Check pressures; remove, overhaul, or adjust valve body as needed;

repair

oil pump if

necessary

9. Remove valve body and replace piston,

seal,

or spring as needed

10. Replace converter and flush cooler and lines

before

installing new converter

11.

Remove, disassemble, and

repair

transmission

as necessary

DELAYED

ENGAGEMENT

(FROM

NEUTRAL

TO

DRIVE

OR

REVERSE)

1.

Engine

idle

speed too low

2. Low

fluid

level

3. Gearshift linkage but of adjustment

4. Rear band out of adjustment

5.

Valve body

filter

plugged

6. Oil pump gears worn or damaged or pump body or seal is damaged, allowing pump to

take

in air, causing

fluid

aeration

7. Reaction shaft seal rings worn or broken

8. Governor valve stuck or valve shaft is loose or damaged

9. Low hydraulic pressure

10. Clutch, band, or servo damage

1.

Adjust

idle

speed

2. Correct

level

and check for leaks

3. Adjust cable or linkage and

repair

linkage if worn or damaged

4. Adjust band

5. Replace

fluid

and

filter.

If oil pan and old

fluid

were

full

of clutch

disc

material

and/or

metal

particles, overhaul

will

be necessary

6. Remove transmission and replace oil pump

7. Remove transmission, remove oil pump, and replace seal rings

8. Remove and inspect governor components; replace worn or damaged parts

9. Perform pressure test, remove transmission, and

repair

as needed

10. Remove and disassemble transmission and

repair

as necessary

J9321-255

TRANSMISSION DIAGNOSIS

Page 1098 of 1502

•

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

21 - 97

Cenoltfeie

Possible

Caws®

Cowscilon

SHIFTS

DELAYED

OR

ERRATIC

(SHIFTS

ALSO

HARSH

AT

TIMES)

1.

Low

fluid

level

2.

Throttle

linkage out

of

adjustment

3.

Throttle

linkage

is

binding

4.

Gearshift linkage out

of

adjustment

5. Fluid

filter

partially

clogged

6. Air in

fluid

due to

overfill

condition or

air

leakage

into

pump suction

passages

7.

Clutch

or

servo problem

8. Front band out of adjustment (may

cause

harsh

1-2

shift)

1.

Correct

fluid

level

and check

for

leaks

2. Adjust linkage

as

described in service section

3.

Disassemble,

clean, and adjust linkage; replace linkage grommets

if

removed

or if

worn or

cracked

4.

Adjust linkage

as

described in service section

5. Replace

filter. If filter

and

fluid

contained clutch

material

or

metal

particles, an overhaul may

be

necessary

6. Drain

fluid

to correct

level

if

overfilled.

If

fluid

is

highly

aerated

(full

of

bubbles

and foamy),

oil

pump

gasket

or seal may have failed,

or

pump

body

is

porous

or cracked

7.

Remove valve body and

air

test clutch, band and

servo

operation;

disassemble

and

repair

transmission

as needed

8. Adjust band

NO

REVERSE

(D

RANGES

OK)

1.

Gearshift linkage is

either

out of adjustment or

damaged

2. Rear band

is

out

of

adjustment

3. Valve body malfunction (stuck/damaged manual valve, regulator valve,

or

check ball)

4.

Rear servo or

front

clutch malfunction

1.

Repair or replace linkage parts as needed

2. Adjust band

3. Remove and service valve body; replace valve body

if

any valves or valve bores are worn

or

damaged

4.

Remove and

disassemble

transmission;

replace worn, damaged servo and clutch parts as

necessary

HAS

FIRST-REVERSE

ONLY

(NO

1-2

OR

2-3

UPSHIFT)

1.

Governor valve, shaft, weights, or body damaged

1.

Remove governor

assembly

and

repair

as

necessary

J9121-440

TRANSMISSION DIAGNOSIS

Page 1099 of 1502

21

- 98

AUTOMATIC

TRANSMISSION-32RH/36RH/37RH/42RH/46RH

•

CendSfion

Possible

Cause Correction

NO

DRIVE

RANGE

(REVERSE

OK)

1.

Gearshift linkage

either

loose,

damaged or out of

adjustment

2. Low

fluid

level

3. Valve body malfunction (manual valve or shaft damaged or

1

-2 shift valve stuck)

4. Rear clutch

failure

5.

Transmission

overrunning clutch

failure

6. Input shaft seal

rings

worn or damaged

1.

Repair or replace linkage components

2. Correct

fluid

level

and check for leaks

3. Remove and

disassemble

valve body; replace as

assembly

if

any valves or bores are damaged

4.

Remove and

disassemble

transmission

and

rear

clutch;

repair/replace

worn, damaged parts as needed

5.

Remove and

disassemble

transmission;

replace overrunning clutch

6. Remove and

disassemble

transmission;

replace seal rings and any

other

worn or damaged parts

NO

DRIVE

OR

REVERSE

(VEHICLE

WILL NOT

MOVE)

1.

Low

fluid

level

2. Gearshift linkage

loose,

damaged, or misassembled

3.

Failure

of

driveline

component,

such

as

U-joint,

axle

shaft, transfer

case

component, etc.

4. Low

fluid

pressure due to worn or damaged

oil

pump

5.

Transmission

internal

component damaged

6. Valve body malfunction (seized valve, damaged manual

lever,

valve body screws

loose

or

overtightened

causing

distortion and bind)

1.

Add

fluid

and check for leaks

if

drive

is restored

2.

Inspect,

adjust, and reassemble linkage

as

needed; replace worn, damaged parts

3. Perform

preliminary

inspection procedure for vehicle

that

will

not

move;

refer

to procedure

in

diagnosis

section

4. Perform pressure test to confirm low pressure; replace pump body and/or

gears

if

necessary

5.

Remove and

disassemble

transmission;

repair

or replace

failed

components

as

needed

6.

Remove,

disassemble,

and inspect valve body; replace valve body (as

assembly)

if

any valve or

bore

is

damaged;

clean and reassemble

correctly

if all parts are in good condition

J9121-443

TRANSMISSION DIAGNOSIS

Page 1100 of 1502

•

AUTOMATIC

TRANSMISSION-32RH/36RH/37RH/42RH/46RH

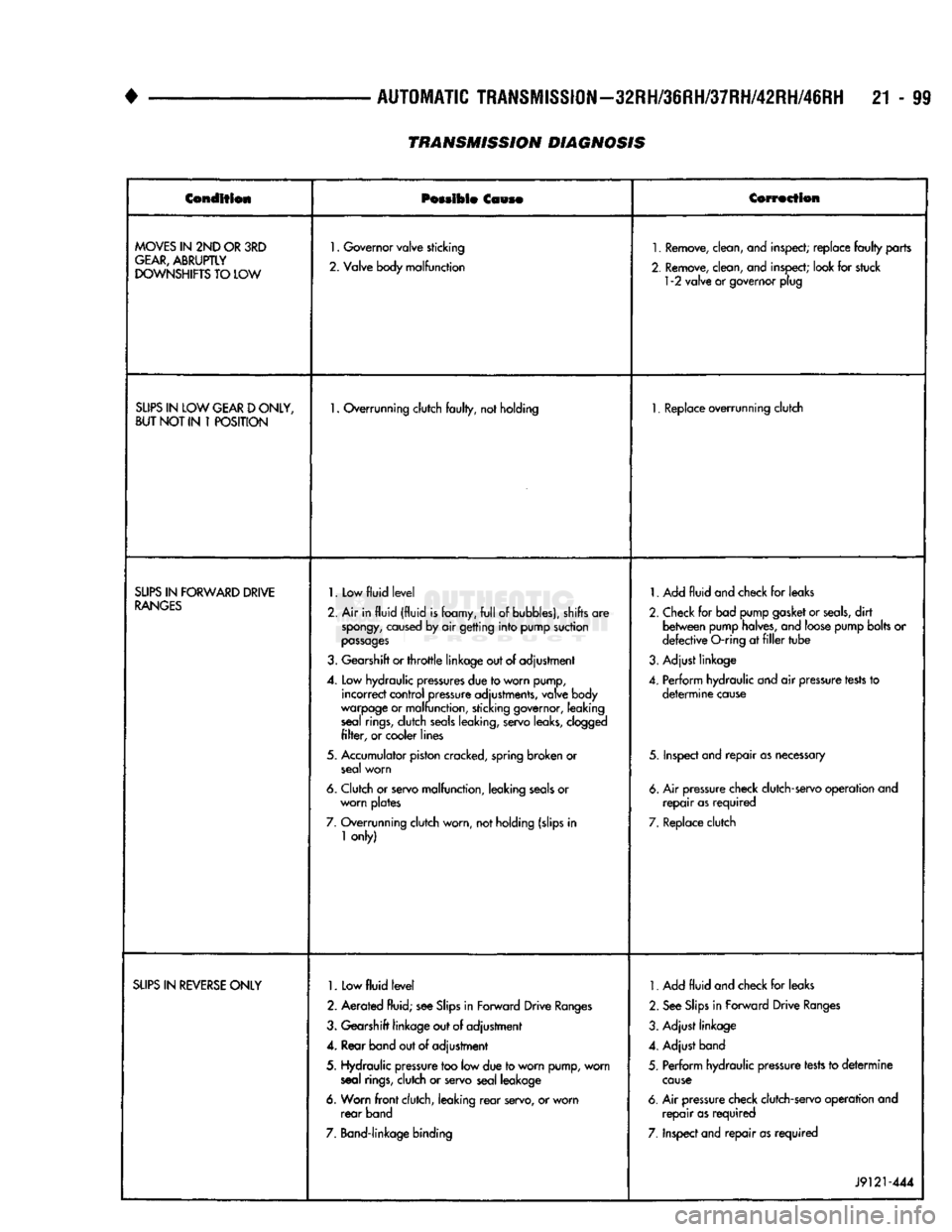

21 - 99 Condition

Possible

Cause

Correction

MOVES

IN 2ND OR 3RD

GEAR,

ABRUPTLY

DOWNSHIFTS

TO LOW

1.

Governor valve sticking

2. Valve body malfunction

1.

Remove, clean, and inspect; replace

faulty

parts

2. Remove, clean, and inspect; look for stuck

1

-2 valve or governor plug

SLIPS

IN LOW

GEAR

D

ONLY,

BUT

NOT IN 1

POSITION

1.

Overrunning clutch

faulty,

not holding

1.

Replace overrunning clutch

SLIPS

IN

FORWARD

DRIVE

RANGES

1.

Low

fluid

level

2. Air in

fluid

(fluid

is

foamy,

full

of bubbles), shifts are

spongy,

caused by air getting

into

pump suction

passages

3. Gearshift or

throttle

linkage out of adjustment

4. Low hydraulic

pressures

due to worn pump, incorrect control pressure adjustments, valve body

warpage or malfunction, sticking governor, leaking seal

rings,

dutch

seals

leaking, servo leaks, clogged

filter,

or cooler lines

5. Accumulator piston cracked, spring broken or seal worn

6. Clutch or servo malfunction, leaking

seals

or worn plates

7. Overrunning clutch worn, not holding (slips in

1

only)

1.

Add

fluid

and check for leaks

2. Check for bad pump gasket or

seals,

dirt

between

pump halves, and loose pump bolts or

defective

O-ring at

filler

tube

3. Adjust linkage

4. Perform hydraulic and air pressure

tests

to

determine

cause

5. Inspect and

repair

as

necessary

6. Air pressure check clutch-servo operation and

repair

as

required

7. Replace clutch

SLIPS

IN

REVERSE

ONLY

1.

Low

fluid

level

2. Aerated fluid; see

Slips

in Forward Drive

Ranges

3. Gearshift linkage out of adjustment

4. Rear band out of adjustment

5. Hydraulic pressure too low due to worn pump, worn seal

rings,

clutch or servo seal leakage

6. Worn

front

clutch, leaking

rear

servo, or worn

rear

band

7. Band-linkage binding

1.

Add

fluid

and check for leaks

2. See

Slips

in Forward Drive

Ranges

3. Adjust linkage

4. Adjust band

5. Perform hydraulic pressure tests to

determine

cause

6. Air pressure check clutch-servo operation and

repair

as

required

7. Inspect and

repair

as

required

J9121-444

TRANSMISSION DIAGNOSIS