sensor DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 860 of 1502

•

FUEL

SYSTEM

14 - 41

THROTTLE

BODY

FUEL

RAIL

CONNECTING

HOSES

THROTTLE

BODY

MOUNTING

BOLTS

J9214-31

Fig.

18

Throttle

Body

MOUNTING

SCREWS

MAP

SENSOR

RUBBER

FITTING

J9314-87

Fig.

19 Air Control

Passage

FUEL

RAIL

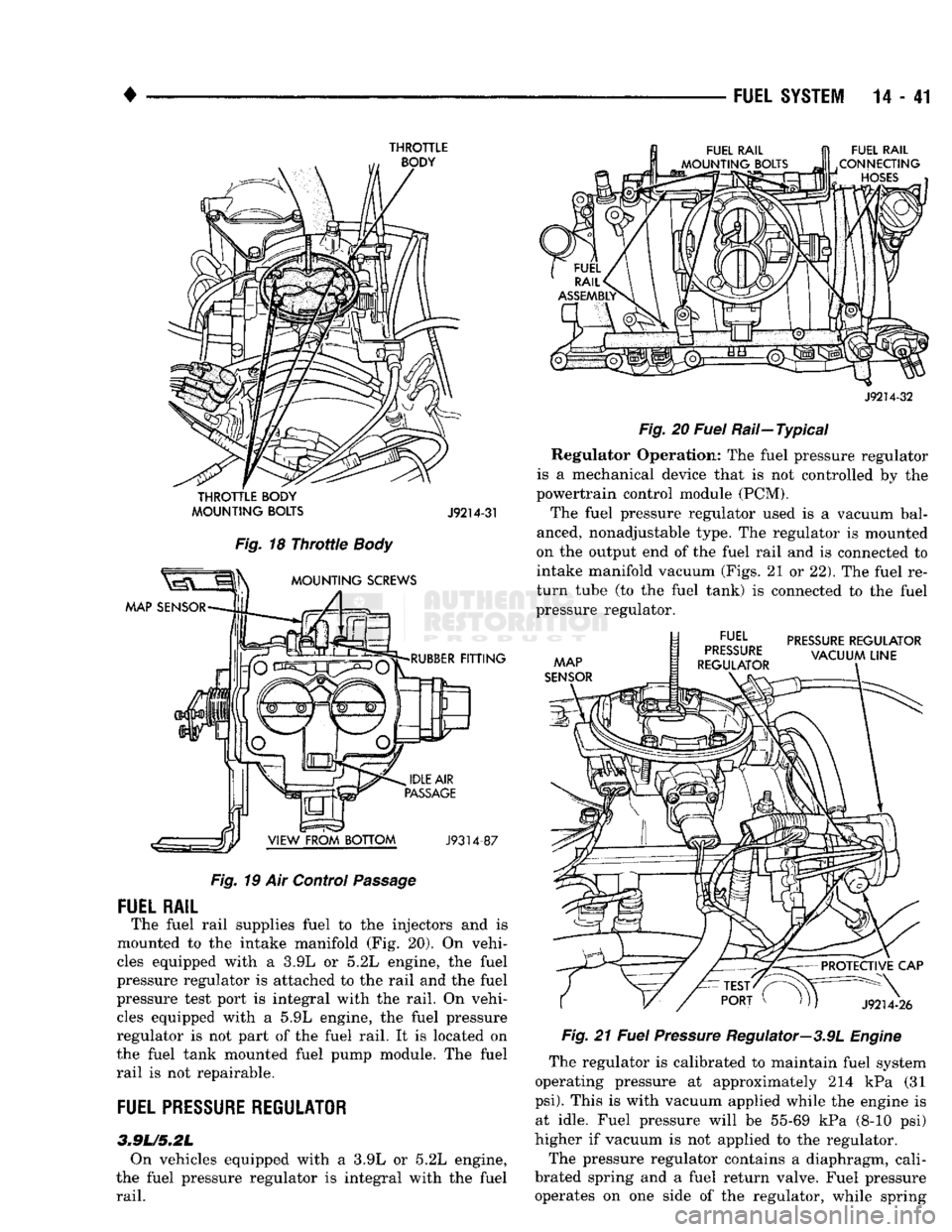

The fuel rail supplies fuel to the injectors and is

mounted to the intake manifold (Fig. 20). On vehi

cles equipped with a 3.9L or 5.2L engine, the fuel

pressure regulator is attached to the rail and the fuel

pressure test port is integral with the rail. On vehi cles equipped with a 5.9L engine, the fuel pressure

regulator is not part of the fuel rail. It is located on

the fuel tank mounted fuel pump module. The fuel

rail is not repairable.

FUEL

PRESSURE

REGULATOR

3.9L/5.2L On vehicles equipped with a 3.9L or 5.2L engine,

the fuel pressure regulator is integral with the fuel

rail.

J9214-32

Fig.

20

Fuel

Rail—Typical Regulator Operation: The fuel pressure regulator

is a mechanical device that is not controlled by the

powertrain control module (PCM).

The fuel pressure regulator used is a vacuum bal

anced, nonadjustable type. The regulator is mounted

on the output end of the fuel rail and is connected to

intake manifold vacuum (Figs. 21 or 22). The fuel re

turn tube (to the fuel tank) is connected to the fuel

pressure regulator.

MAP

SENSOR

docc EL

PRESSURE

REGULATOR

„

VACUUM

LINE

REGULATOR

PROTECTIVE

CAP

J9214-26

Fig.

21

Fuel

Pressure

Regulator—3.9L

Engine

The regulator is calibrated to maintain fuel system

operating pressure at approximately 214 kPa (31

psi).

This is with vacuum applied while the engine is at idle. Fuel pressure will be 55-69 kPa (8-10 psi)

higher if vacuum is not applied to the regulator.

The pressure regulator contains a diaphragm, cali

brated spring and a fuel return valve. Fuel pressure operates on one side of the regulator, while spring

Page 862 of 1502

MULTI-PORT

FUEL

INJECTION

(MPI)—GENERAL DIAGNOSIS—EXCEPT DIESEL

INDEX

page

Camshaft Position Sensor Testing

............

52

Charge

Air

Temperature Sensor Test

52

Coolant Temperature Sensor Test

52

Crankshaft Position Sensor Test

54

Diagnostic Trouble Code (DTC)

60

DRB

II

Scan

Tool

........................

60

Fuel

Injector

Test

57

Fuel Pump Pressure Test

57

Idle

Air

Control

(IAC) Motor Test

55

Manifold Absolute Pressure (MAP) Sensor Test

. 53

page

On-Board

Diagnostics (OBD)

59

Oxygen

(02)

Sensor Heating Element Test

54

Powertrain

Control

Module (PCM) 60-Way Connector

. 47

Relays—Operation/Testing

56

Starter

Motor Relay Test

57

System

Schematics

. 47

Throttle

Position Sensor (TPS) Test

54

Visual Inspection

43

VISUAL

INSPECTION

A visual inspection

for

loose, disconnected,

or

incor

rectly routed wires

and

hoses should

be

made. This should

be

done before attempting

to

diagnose

or

ser

vice

the

fuel injection system.

A

visual check will

help spot these faults

and

save unnecessary test

and

diagnostic time.

A

thorough visual inspection will

in

clude

the

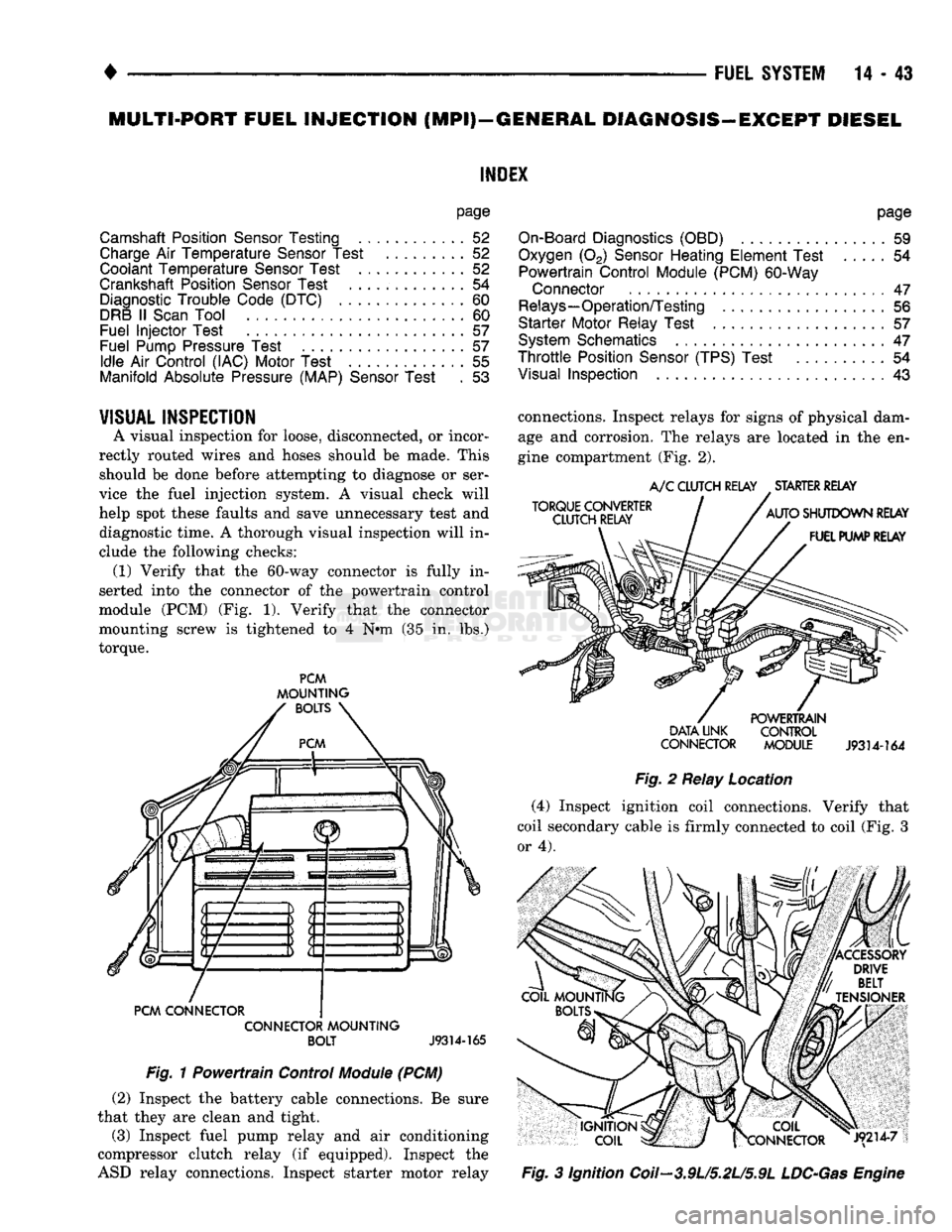

following checks: (1) Verify that

the

60-way connector

is

fully

in

serted into

the

connector

of the

powertrain control

module

(PCM) (Fig. 1).

Verify that

the

connector

mounting screw

is

tightened

to 4 N#m (35 in. lbs.)

torque.

PCM

MOUNTING

BOLTS

PCM CONNECTOR CONNECTOR MOUNTING BOLT

J9314-165

Fig.

1

Powertrain Control

Module

(PCM) (2) Inspect

the

battery cable connections.

Be

sure

that they

are

clean

and

tight.

(3) Inspect fuel pump relay

and air

conditioning

compressor clutch relay

(if

equipped). Inspect

the

ASD relay connections. Inspect starter motor relay connections. Inspect relays

for

signs

of

physical dam

age

and

corrosion.

The

relays

are

located

in the en

gine compartment

(Fig. 2).

TORQUE CONVERTER

CLUTCH RELAY

A/C

CLUTCH RELAY STARTER RELAY

AUTO SHUTDOWN RELAY FUEL PUMP RELAY POWERTRAIN

DATA UNK CONTROL

CONNECTOR MODULE

J9314-164

Fig.

2

Relay Location (4) Inspect ignition coil connections. Verify that

coil secondary cable

is

firmly connected

to

coil (Fig.

3

or 4).

|X COIL

frCONNECTOR J9214-7

Fig.

3

Ignition Coil—3.9U5.2L/5.9L

LDC-Gas

Engine

Page 863 of 1502

14 - 44

FUEL

SYSTEM

•

Fig.

4 ignition Coil—5.9L

HDC-Gas

Engine

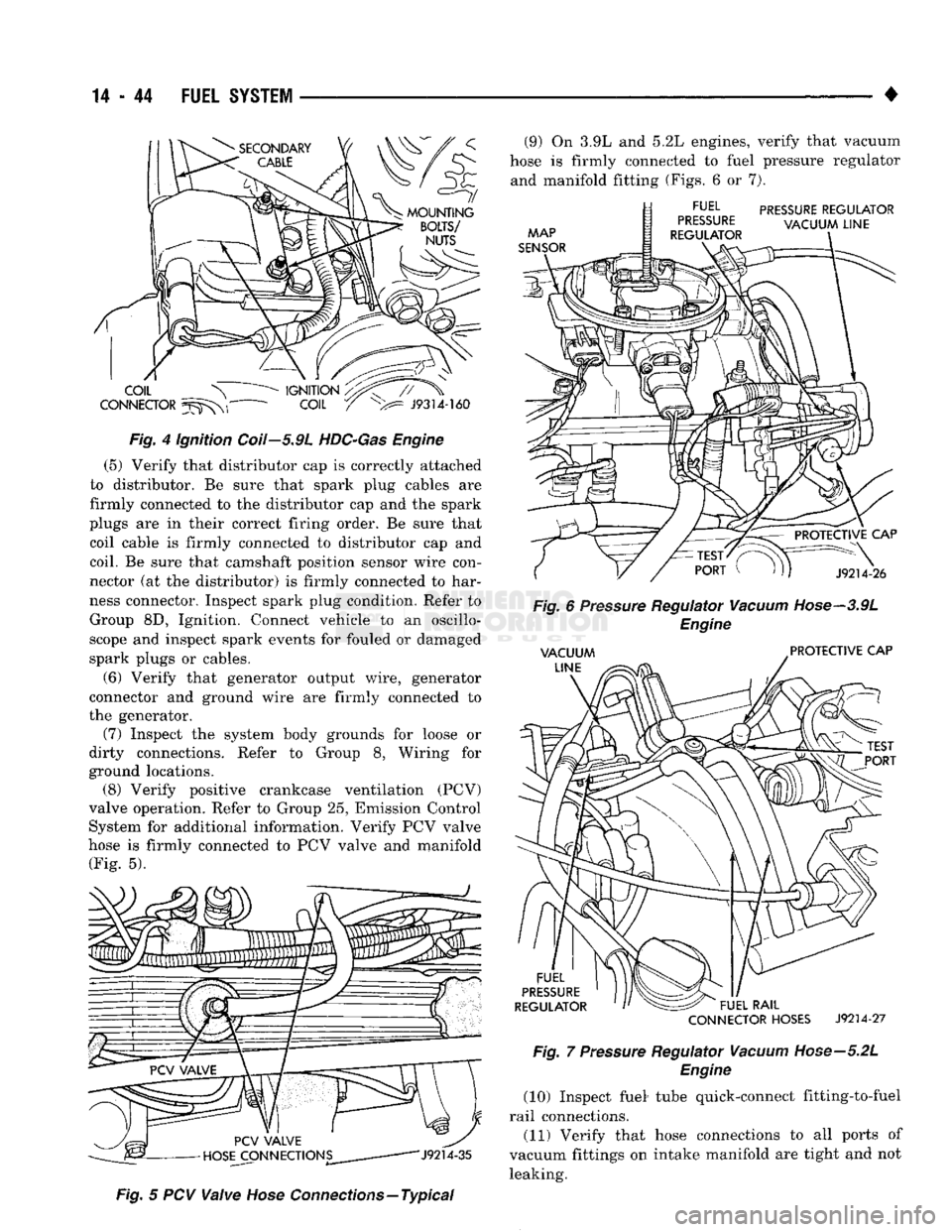

(5) Verify that distributor cap is correctly attached

to distributor. Be sure that spark plug cables are

firmly connected to the distributor cap and the spark

plugs are in their correct firing order. Be sure that coil cable is firmly connected to distributor cap and

coil. Be sure that camshaft position sensor wire con

nector (at the distributor) is firmly connected to har

ness connector. Inspect spark plug condition. Refer to Group 8D, Ignition. Connect vehicle to an oscillo

scope and inspect spark events for fouled or damaged

spark plugs or cables.

(6) Verify that generator output wire, generator

connector and ground wire are firmly connected to

the generator. (7) Inspect the system body grounds for loose or

dirty connections. Refer to Group 8, Wiring for

ground locations. (8) Verify positive crankcase ventilation (PCV)

valve operation. Refer to Group 25, Emission Control System for additional information. Verify PCV valve

hose is firmly connected to PCV valve and manifold (Fig. 5).

Fig.

5 PCV

Valve

Hose

Connections—Typical (9) On 3.9L and 5.2L engines, verify that vacuum

hose is firmly connected to fuel pressure regulator and manifold fitting (Figs. 6 or 7).

CONNECTOR

HOSES

J9214-27

Fig.

7

Pressure

Regulator

Vacuum

Hose—5.2L

Engine

(10) Inspect fuel* tube quick-connect fitting-to-fuel

rail connections. (11) Verify that hose connections to all ports of

vacuum fittings on intake manifold are tight and not leaking.

Page 864 of 1502

•

FUEL

SYSTEM

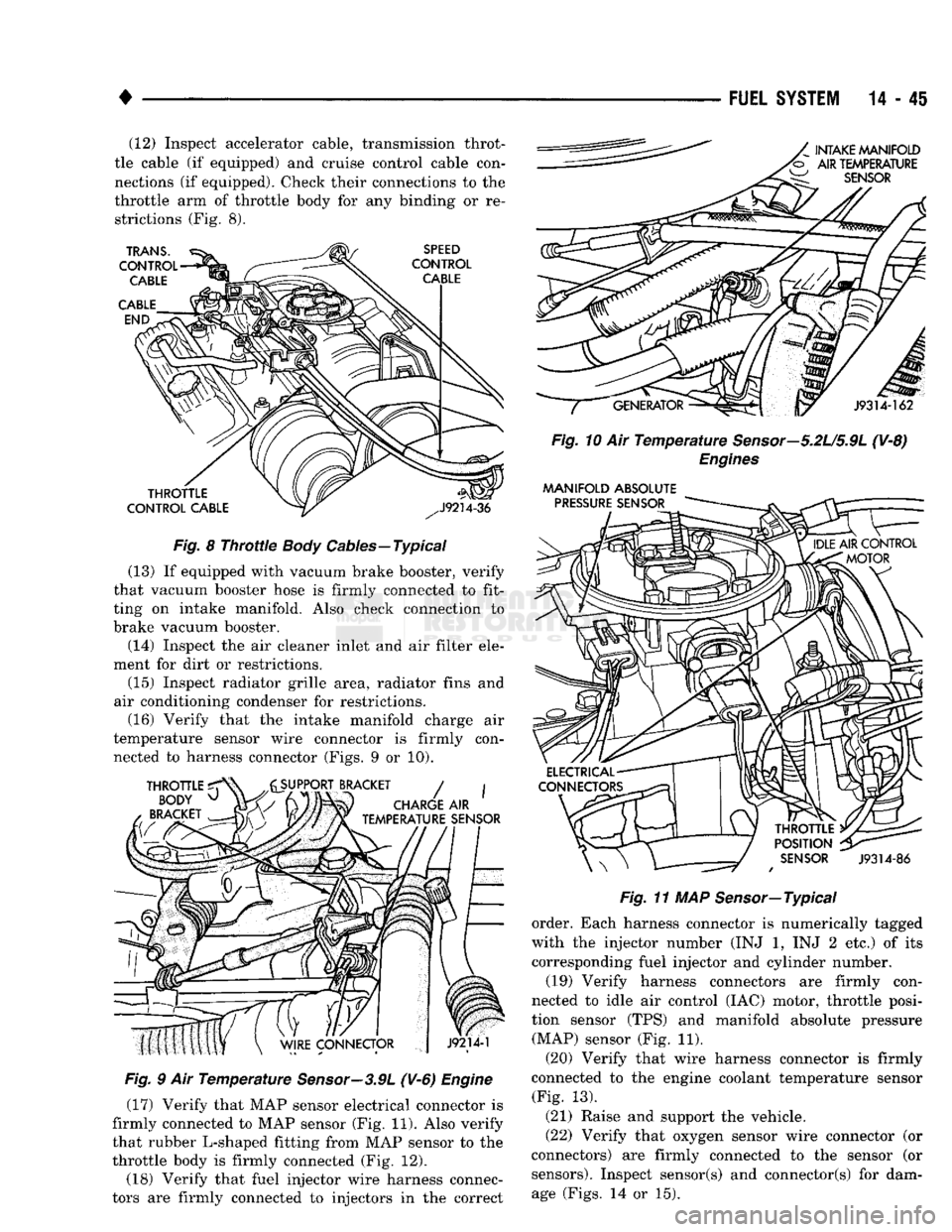

14-45 (12) Inspect accelerator cable, transmission throt

tle cable (if equipped) and cruise control cable con

nections (if equipped). Check their connections to the

throttle arm of throttle body for any binding or re strictions (Fig. 8).

Fig.

8

Throttle

Body

Cables—Typical

(13) If equipped with vacuum brake booster, verify

that vacuum booster hose is firmly connected to fit

ting on intake manifold. Also check connection to

brake vacuum booster.

(14) Inspect the air cleaner inlet and air filter ele

ment for dirt or restrictions.

(15) Inspect radiator grille area, radiator fins and

air conditioning condenser for restrictions. (16) Verify that the intake manifold charge air

temperature sensor wire connector is firmly con nected to harness connector (Figs. 9 or 10).

Fig.

9 Air

Temperature

Sensor—3.9L

(V-6)

Engine

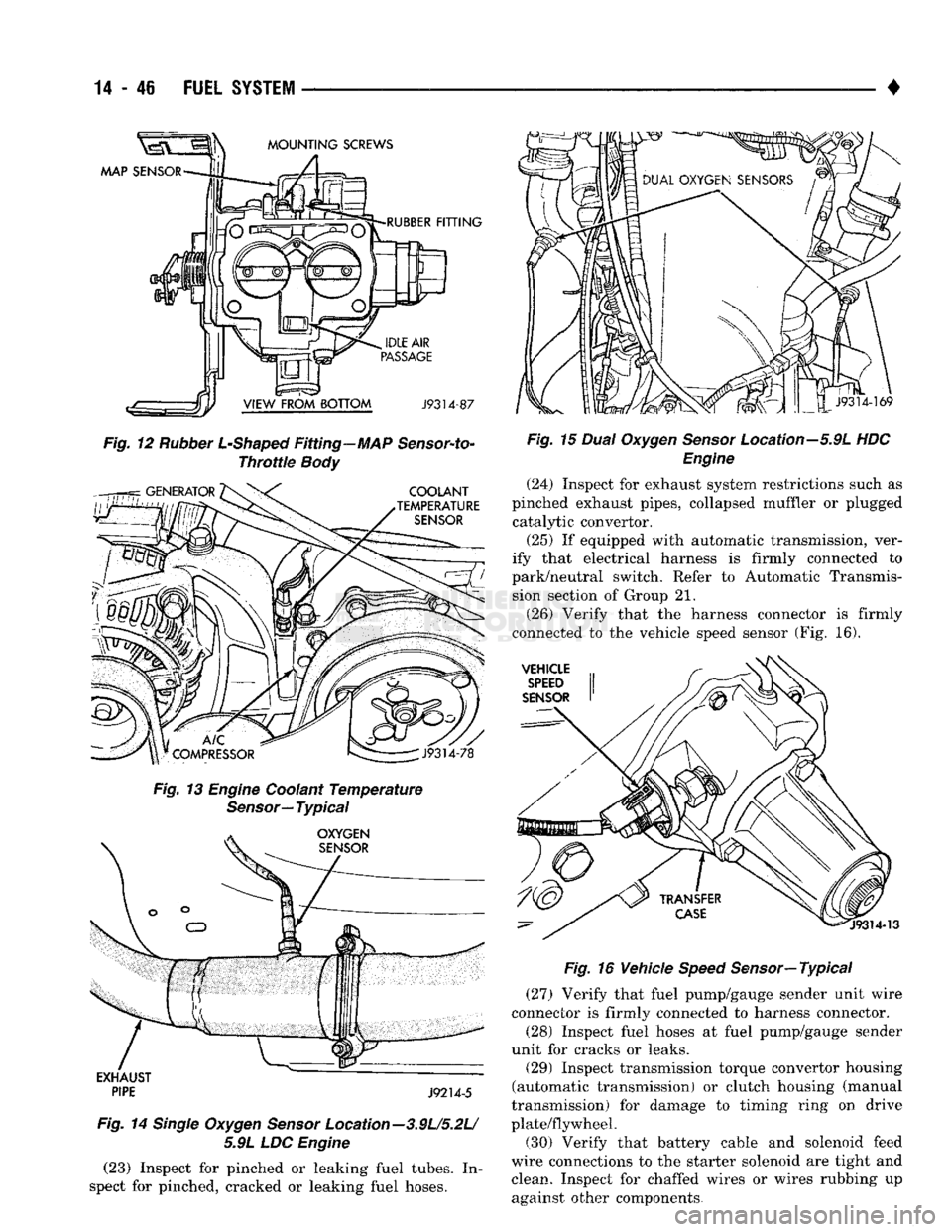

(17) Verify that MAP sensor electrical connector is

firmly connected to MAP sensor (Fig. 11). Also verify

that rubber L-shaped fitting from MAP sensor to the

throttle body is firmly connected (Fig. 12).

(18) Verify that fuel injector wire harness connec

tors are firmly connected to injectors in the correct

Fig.

10 Air

Temperature

Sensor—5.2U5.9L

(V-8)

Engines

MANIFOLD

ABSOLUTE

Fig.

11 MAP Sensor—Typical

order. Each harness connector is numerically tagged

with the injector number (INJ 1, INJ 2 etc.) of its

corresponding fuel injector and cylinder number.

(19) Verify harness connectors are firmly con

nected to idle air control (IAC) motor, throttle posi

tion sensor (TPS) and manifold absolute pressure (MAP) sensor (Fig. 11).

(20) Verify that wire harness connector is firmly

connected to the engine coolant temperature sensor (Fig. 13).

(21) Raise and support the vehicle.

(22) Verify that oxygen sensor wire connector (or

connectors) are firmly connected to the sensor (or sensors). Inspect sensor(s) and connector(s) for damage (Figs. 14 or 15).

Page 865 of 1502

14

- 46

FUEL

SYSTEM

Fig.

12

Rubber

L-Shaped

Fitting—MAP

Sensor-to-

Throttie

Body

Fig.

13

Engine

Coolant

Temperature

Sensor—

Typical

EXHAUST

~~

PIPE

J9214-5

Fig.

14

Single

Oxygen

Sensor

Location-3.9U5.2L/ 5.9L LDC

Engine

(23) Inspect for pinched or leaking fuel tubes. In

spect for pinched, cracked or leaking fuel hoses. •

Fig.

15

Dual

Oxygen

Sensor

Location—5.9L HDC

Engine

(24) Inspect for exhaust system restrictions such as

pinched exhaust pipes, collapsed muffler or plugged catalytic convertor.

(25) If equipped with automatic transmission, ver

ify that electrical harness is firmly connected to

park/neutral switch. Refer to Automatic Transmis sion section of Group 21.

(26) Verify that the harness connector is firmly

connected to the vehicle speed sensor (Fig. 16).

Fig.

16 Vehicle

Speed

Sensor—

Typical

(27) Verify that fuel pump/gauge sender unit wire

connector is firmly connected to harness connector.

(28) Inspect fuel hoses at fuel pump/gauge sender

unit for cracks or leaks.

(29) Inspect transmission torque convertor housing

(automatic transmission) or clutch housing (manual

transmission) for damage to timing ring on drive

plate/flywheel. (30) Verify that battery cable and solenoid feed

wire connections to the starter solenoid are tight and clean. Inspect for chaffed wires or wires rubbing up against other components.

Page 867 of 1502

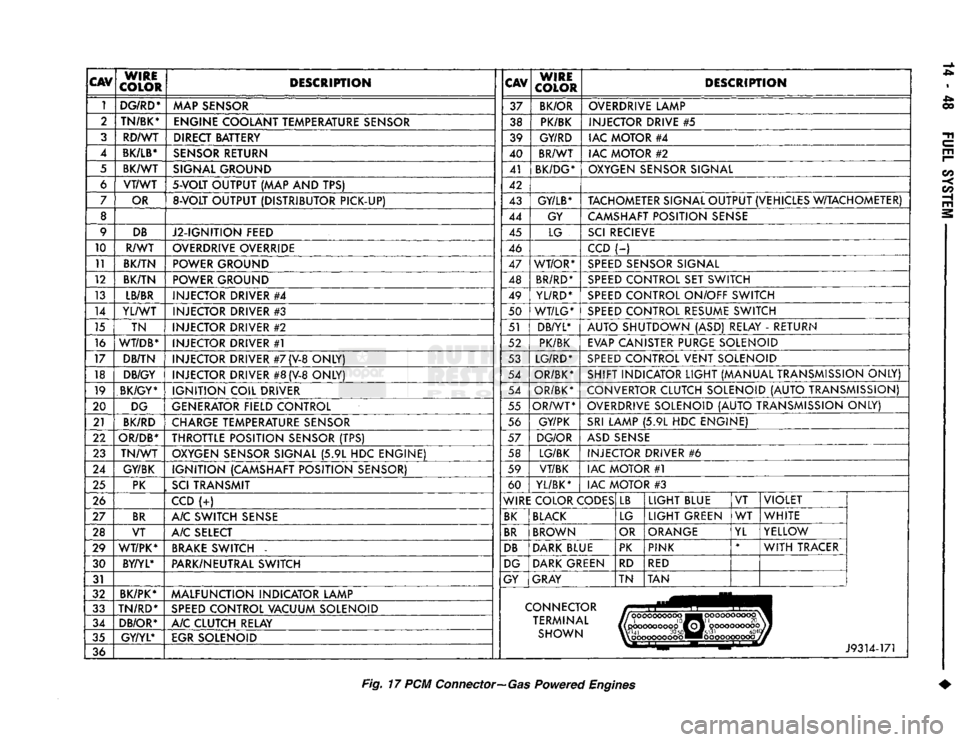

CAV

WIRE

COLOR DESCRIPTION

CAV

WIRE

COLOR DESCRIPTION

1 DG/RD*

MAP SENSOR 37

BK/OR OVERDRIVE LAMP

2 TN/BK*

ENGINE COOLANT TEMPERATURE SENSOR 38 PK/BK INJECTOR DRIVE

#5

3 RD/WT DIRECT BATTERY 39 GY/RD IAC MOTOR

#4

4

BK/LB*

SENSOR RETURN 40 BR/WT

IAC MOTOR

#2

5 BK/WT SIGNAL GROUND 41

BK/DG* OXYGEN SENSOR SIGNAL

6 VT/WT

5-VOLT

OUTPUT

(MAP AND TPS)

42

7 OR

8-VOLT

OUTPUT (DISTRIBUTOR PICK-UP) 43

GY/LB*

TACHOMETER SIGNAL OUTPUT (VEHICLES W/TACHOMETER)

8 44 GY CAMSHAFT POSITION SENSE

9 DB

J2-IGNITION FEED 45

LG SCI RECIEVE

10 R/WT OVERDRIVE OVERRIDE

46 CCD

(-)

11 BK/TN POWER GROUND 47 WT/OR* SPEED SENSOR SIGNAL

12 BK/TN POWER GROUND 48 BR/RD* SPEED CONTROL

SET

SWITCH

13 LB/BR

INJECTOR DRIVER

#4

49

YL/RD* SPEED CONTROL ON/OFF SWITCH

14 YL/WT

INJECTOR DRIVER

#3

50 WT/LG* SPEED CONTROL RESUME SWITCH

15 TN INJECTOR DRIVER

#2

51 DB/YL*

AUTO SHUTDOWN

(ASD)

RELAY

-

RETURN

16

WT/DB*

INJECTOR DRIVER

#1

52 PK/BK

EVAP CANISTER PURGE SOLENOID

17 DB/TN INJECTOR DRIVER

#7

(V-8

ONLY) 53 LG/RD* SPEED CONTROL VENT SOLENOID

18 DB/GY

INJECTOR DRIVER

#8

(V-8

ONLY) 54

OR/BK* SHIFT INDICATOR LIGHT (MANUAL TRANSMISSION ONLY)

19 BK/GY*

IGNITION COIL DRIVER 54

OR/BK* CONVERTOR CLUTCH SOLENOID (AUTO TRANSMISSION)

20 DG

GENERATOR FIELD CONTROL 55

OR/WT OVERDRIVE SOLENOID (AUTO TRANSMISSION ONLY)

21 BK/RD

CHARGE TEMPERATURE SENSOR 56

GY/PK SRI LAMP

(5.9L HDC

ENGINE)

22

OR/DB*

THROTTLE POSITION SENSOR

(TPS)

57

DG/OR ASD SENSE

23 TN/WT

OXYGEN SENSOR SIGNAL

(5.9L HDC

ENGINE) 58 LG/BK

INJECTOR DRIVER

#6

24 GY/BK IGNITION (CAMSHAFT POSITION SENSOR) 59

VT/BK IAC MOTOR

#1

25 PK

,

SCI

TRANSMIT 60

YL/BK* IAC MOTOR

#3

26 CCD

(-:-)

WIRE COLOR CODES LB

LIGHT BLUE

VT VIOLET

27 BR

A/C SWITCH SENSE BK BLACK

LG LIGHT GREEN

WT

WHITE

28 VT A/C SELECT BR BROWN

OR ORANGE

YL YELLOW

29 WT/PK* BRAKE SWITCH

-

DB DARK BLUE PK

PINK *

WITH TRACER

30 BY/YL*

PARK/NEUTRAL SWITCH DG DARK GREEN

RD

RED

31 GY

GRAY TN TAN

32 BK/PK*

MALFUNCTION INDICATOR LAMP

33 TN/RD*

SPEED CONTROL VACUUM SOLENOID CONNECTOR

34 DB/OR* A/C CLUTCH RELAY TERMINAL

|(pcKX>coooop0ffoj'

oooooooooojj

35 GY/YL*

EGR SOLENOID SHOWN W'41

30

50«M#5l31

604

%\

oooooooooo ••ooooooooooj

36 J9314-171

Fig.

17 PCM

Connector—Gas

Powered

Engines

Page 868 of 1502

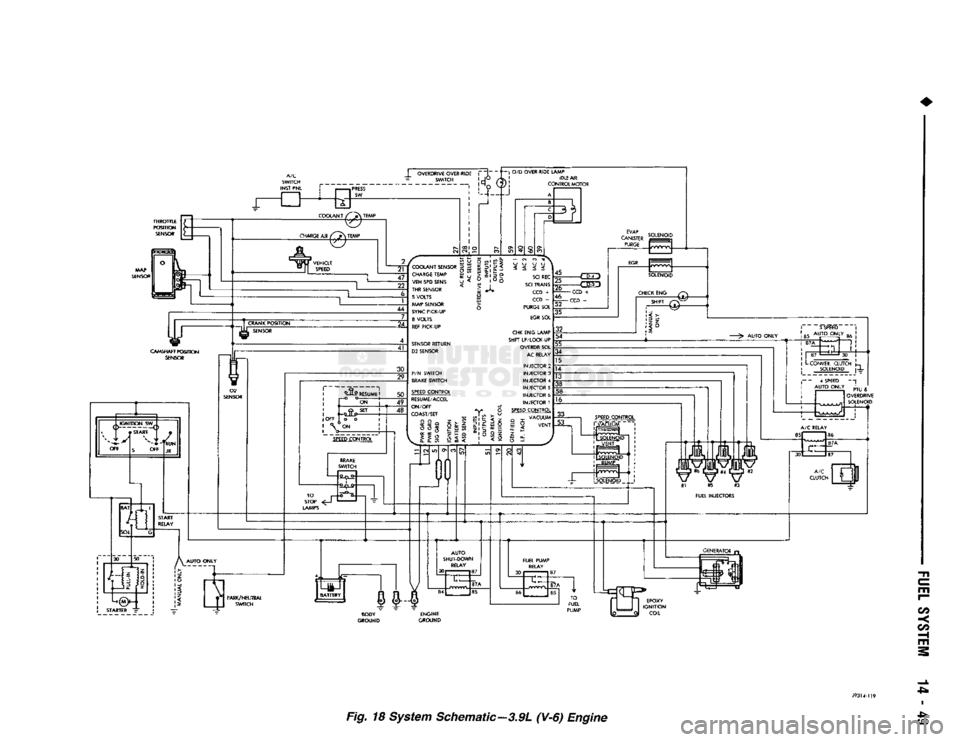

•

THROTTLE

POSITION

SENSOR

CO

Fig. 18 System Schematic—3.9L (V-6) Engine

CO

Page 871 of 1502

14-52

FUEL

SYSTEM

•

CAMSHAFT

POSITION

SENSOR

TESTING

Refer to Group 8D, Ignition Systems for testing.

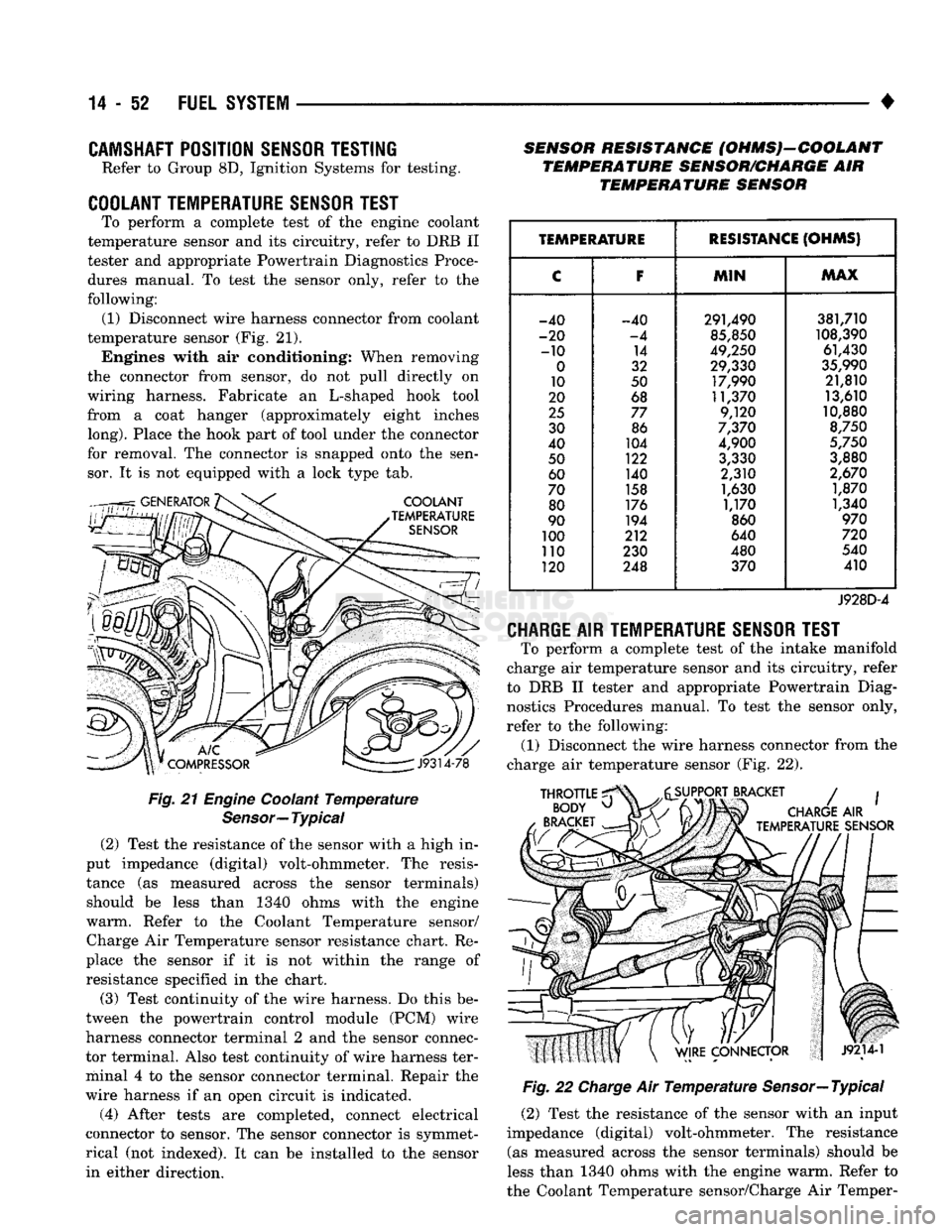

COOLANT

TEMPERATURE

SENSOR

TEST

To perform a complete test of the engine coolant

temperature sensor and its circuitry, refer to DRB II

tester and appropriate Powertrain Diagnostics Proce

dures manual. To test the sensor only, refer to the

following: (1) Disconnect wire harness connector from coolant

temperature sensor (Fig. 21). Engines with air conditioning; When removing

the connector from sensor, do not pull directly on

wiring harness. Fabricate an L-shaped hook tool

from a coat hanger (approximately eight inches

long).

Place the hook part of tool under the connector

for removal. The connector is snapped onto the sen sor. It is not equipped with a lock type tab.

Fig.

21

Engine

Coolant

Temperature

Sensor—

Typical

(2) Test the resistance of the sensor with a high in

put impedance (digital) volt-ohmmeter. The resis

tance (as measured across the sensor terminals) should be less than 1340 ohms with the engine

warm. Refer to the Coolant Temperature sensor/ Charge Air Temperature sensor resistance chart. Re

place the sensor if it is not within the range of resistance specified in the chart.

(3) Test continuity of the wire harness. Do this be

tween the powertrain control module (PCM) wire

harness connector terminal 2 and the sensor connec

tor terminal. Also test continuity of wire harness ter

minal 4 to the sensor connector terminal. Repair the

wire harness if an open circuit is indicated.

(4) After tests are completed, connect electrical

connector to sensor. The sensor connector is symmet

rical (not indexed). It can be installed to the sensor in either direction. SENSOR RESISTANCE (OHMS)-COOLANT

TEMPERATURE SENSOR/CHARGE AIR TEMPERATURE SENSOR

TEMPERATURE

RESISTANCE

(OHMS)

C F

MIN MAX

-40 -40 291,490 381,710

-20 -4 85,850 108,390

-10 14 49,250 61,430

0 32 29,330 35,990

10 50 17,990 21,810

20 68 11,370 13,610

25 77 9,120 10,880

30 86 7,370 8,750

40 104 4,900 5,750

50 122 3,330 3,880

60 140 2,310 2,670

70 158 1,630 1,870

80 176 1,170 1,340

90 194 860 970

100 212 640 720

no 230 480 540

120 248 370 410

J928D-4

CHARGE

AIR

TEMPERATURE SENSOR TEST

To perform a complete test of the intake manifold

charge air temperature sensor and its circuitry, refer

to DRB II tester and appropriate Powertrain Diag nostics Procedures manual. To test the sensor only,

refer to the following: (1) Disconnect the wire harness connector from the

charge air temperature sensor (Fig. 22).

Fig.

22

Charge

Air

Temperature

Sensor—Typical

(2) Test the resistance of the sensor with an input

impedance (digital) volt-ohmmeter. The resistance (as measured across the sensor terminals) should be

less than 1340 ohms with the engine warm. Refer to

the Coolant Temperature sensor/Charge Air Temper-

Page 872 of 1502

•

FUEL

SYSTEM

14-53 ature sensor resistance chart. Replace the sensor if it

is not within the range of resistance specified in the chart. (3) Test the resistance of the wire harness. Do this

between the powertrain control module (PCM) wire

harness connector terminal 21 and the sensor connec tor terminal. Also check between terminal 4 to the sensor connector terminal. Repair the wire harness

as necessary if the resistance is greater than 1 ohm.

MANIFOLD

ABSOLUTE

PRESSURE

(MAP)

SENSOR

TEST

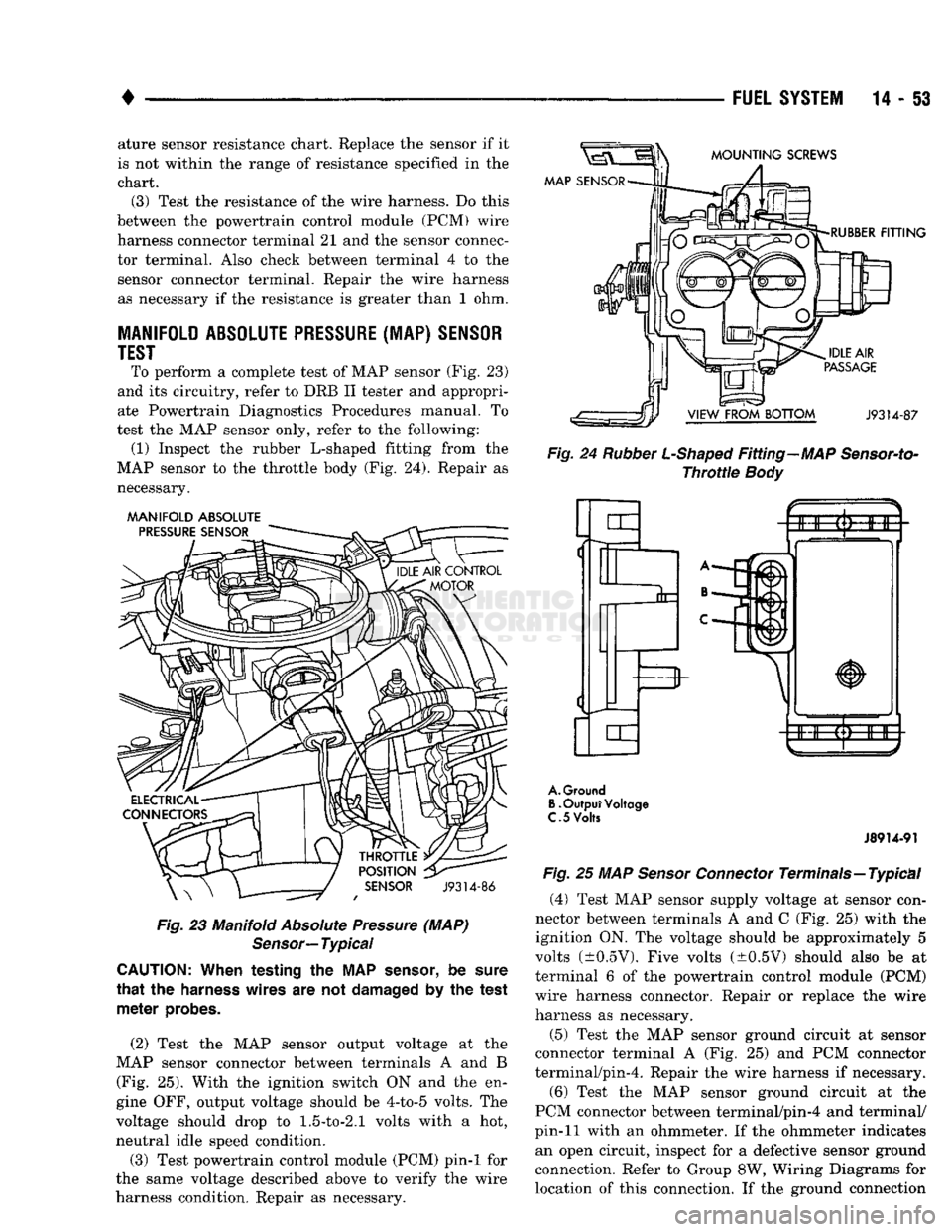

To perform a complete test of MAP sensor (Fig. 23)

and its circuitry, refer to DRB II tester and appropri

ate Powertrain Diagnostics Procedures manual. To

test the MAP sensor only, refer to the following: (1) Inspect the rubber L-shaped fitting from the

MAP sensor to the throttle body (Fig. 24). Repair as necessary.

MANIFOLD

ABSOLUTE

Fig.

23 Manifold

Absolute

Pressure

(MAP)

Sensor—

Typical

CAUTION:

When testing the MAP

sensor,

be

sure

that

the

harness

wires are not

damaged

by the test

meter

probes.

(2) Test the MAP sensor output voltage at the

MAP sensor connector between terminals A and B (Fig. 25). With the ignition switch ON and the en

gine OFF, output voltage should be 4-to-5 volts. The

voltage should drop to

1.5-to-2.1

volts with a hot,

neutral idle speed condition.

(3) Test powertrain control module (PCM) pin-1 for

the same voltage described above to verify the wire

harness condition. Repair as necessary.

Fig.

24

Rubber

L-Shaped

Fitting—MAP

Sensor-to-

Throttle

Body

A.

Ground

B.

Output Voltage

C.

5

Volts

J8914-91

Fig.

25 MAP

Sensor

Connector

Terminals—Typical

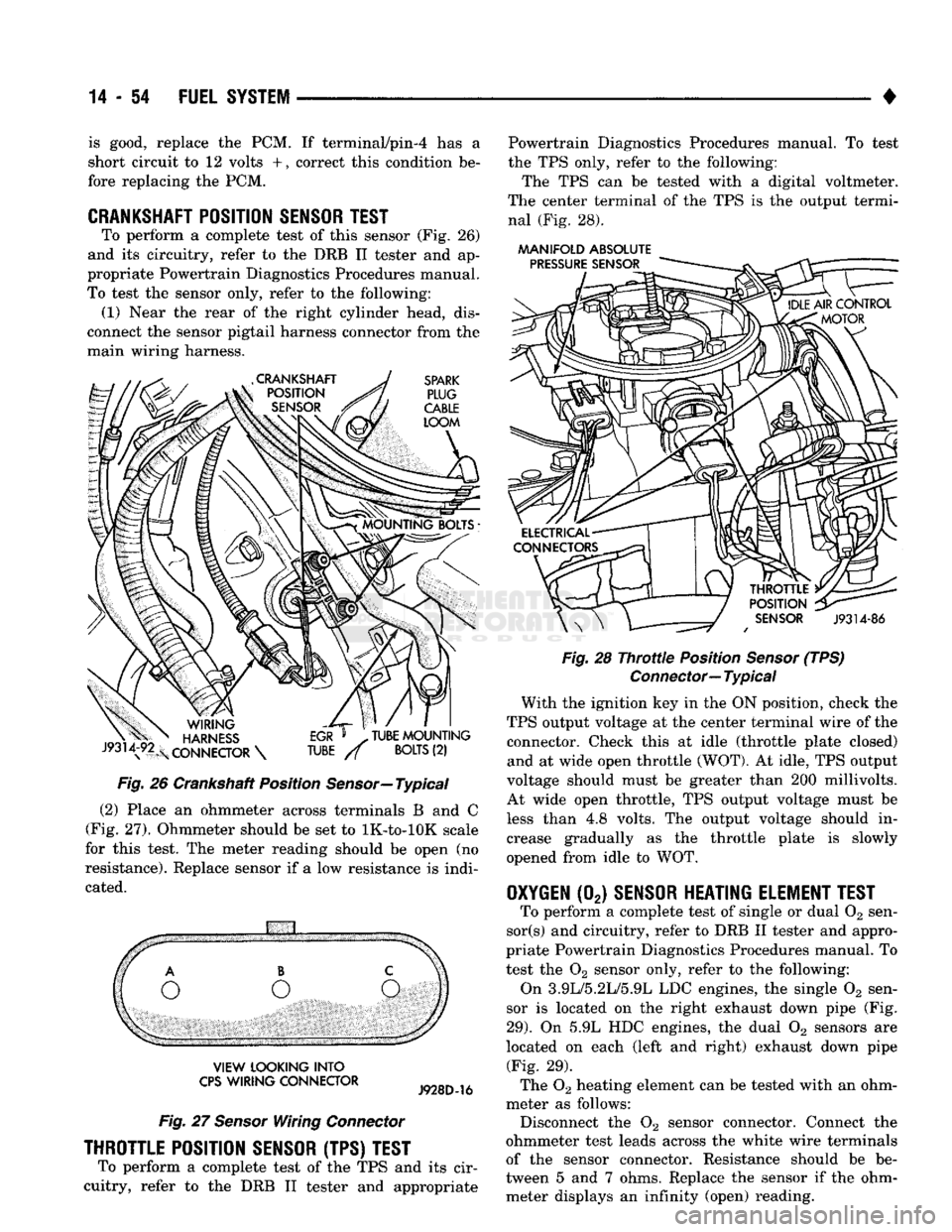

(4)

Test MAP sensor supply voltage at sensor con

nector between terminals A and C (Fig. 25) with the ignition ON. The voltage should be approximately 5

volts (±0.5V). Five volts (±0.5V) should also be at

terminal 6 of the powertrain control module (PCM)

wire harness connector. Repair or replace the wire

harness as necessary.

(5) Test the MAP sensor ground circuit at sensor

connector terminal A (Fig. 25) and PCM connector

terminal/pin-4. Repair the wire harness if necessary.

(6) Test the MAP sensor ground circuit at the

PCM connector between terminal/pin-4 and terminal/

pin-11 with an ohmmeter. If the ohmmeter indicates an open circuit, inspect for a defective sensor ground

connection. Refer to Group 8W, Wiring Diagrams for

location of this connection. If the ground connection

Page 873 of 1502

14-54 FUEL SYSTEM

• is good, replace the PCM. If terminal/pin-4 has a

short circuit to 12 volts +, correct this condition be

fore replacing the PCM.

CRANKSHAFT POSITION SENSOR TEST

To perform a complete test of this sensor (Fig. 26)

and its circuitry, refer to the DRB II tester and ap

propriate Powertrain Diagnostics Procedures manual.

To test the sensor only, refer to the following: (1) Near the rear of the right cylinder head, dis

connect the sensor pigtail harness connector from the

main wiring harness.

Fig.

26 Crankshaft Position

Sensor—

Typical

(2) Place an ohmmeter across terminals B and C

(Fig. 27). Ohmmeter should be set to lK-to-lOK scale

for this test. The meter reading should be open (no

resistance). Replace sensor if a low resistance is indi

cated.

VIEW

LOOKING

INTO

CPS

WIRING

CONNECTOR

Fig.

27

Sensor

Wiring

Connector

THROTTLE POSITION SENSOR (TPS) TEST

To perform a complete test of the TPS and its cir

cuitry, refer to the DRB II tester and appropriate Powertrain Diagnostics Procedures manual. To test

the TPS only, refer to the following:

The TPS can be tested with a digital voltmeter.

The center terminal of the TPS is the output termi nal (Fig. 28).

AAANIFOLD

ABSOLUTE

Fig.

28

Throttle

Position

Sensor

(TPS)

Connector—

Typical

With the ignition key in the ON position, check the

TPS output voltage at the center terminal wire of the connector. Check this at idle (throttle plate closed) and at wide open throttle (WOT). At idle, TPS output

voltage should must be greater than 200 millivolts.

At wide open throttle, TPS output voltage must be

less than 4.8 volts. The output voltage should in

crease gradually as the throttle plate is slowly

opened from idle to WOT.

OXYGEN

(02)

SENSOR HEATING ELEMENT TEST

To perform a complete test of single or dual 02 sen-

sor(s) and circuitry, refer to DRB II tester and appro

priate Powertrain Diagnostics Procedures manual. To

test the 02 sensor only, refer to the following:

On 3.9L/5.2L/5.9L LDC engines, the single 02 sen

sor is located on the right exhaust down pipe (Fig.

29).

On 5.9L HDC engines, the dual 02 sensors are

located on each (left and right) exhaust down pipe (Fig. 29).

The 02 heating element can be tested with an ohm

meter as follows: Disconnect the 02 sensor connector. Connect the

ohmmeter test leads across the white wire terminals

of the sensor connector. Resistance should be be

tween 5 and 7 ohms. Replace the sensor if the ohm meter displays an infinity (open) reading.