sensor DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 874 of 1502

•

FUEL

SYSTEM

14 - 55

Fig.

30

Dual

Oxygen

Sensors—5.9L

HDC

Engine

IDLE

AIR

CONTROL

(IAC)

MOTOR

TEST

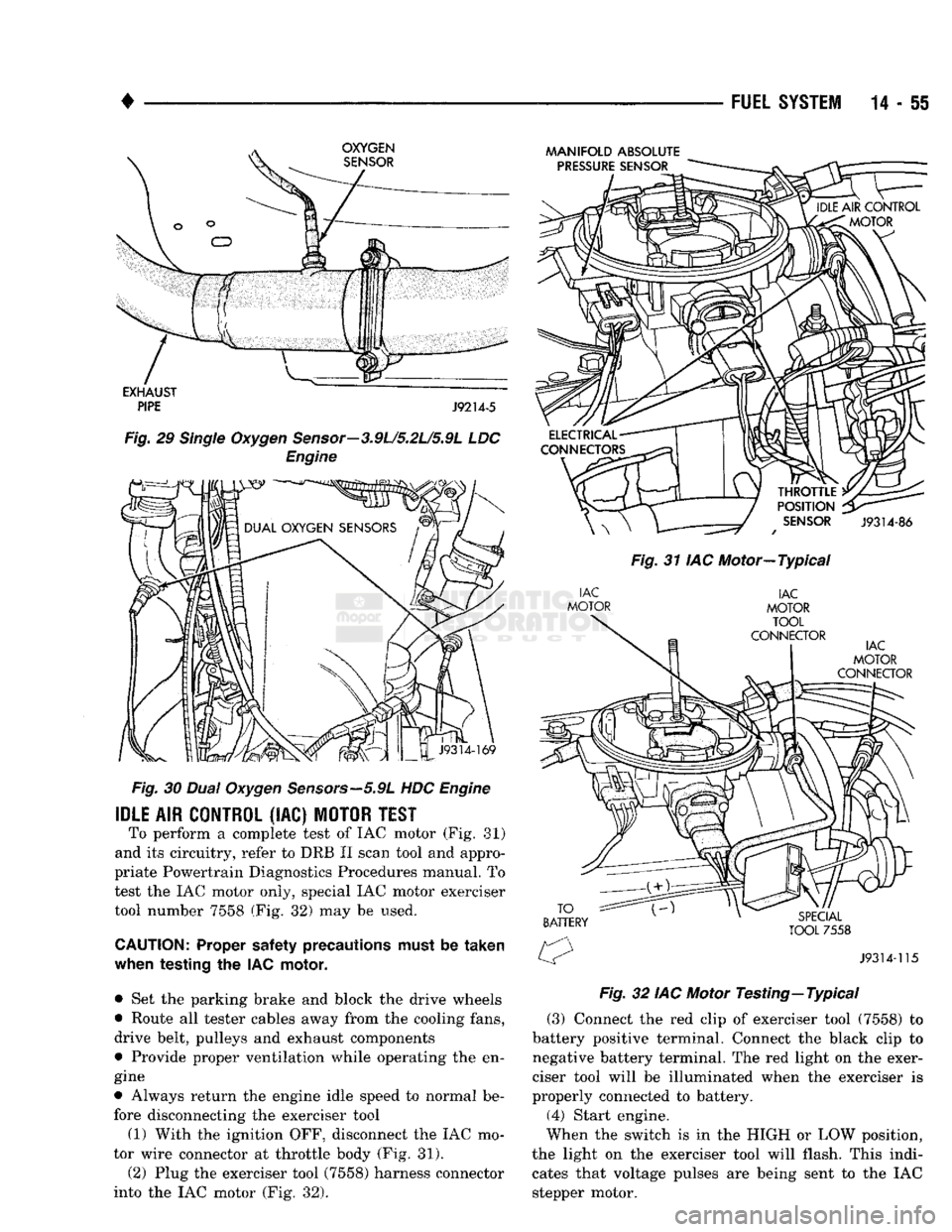

To perform a complete test of IAC motor (Fig. 81)

and its circuitry, refer to DRB II scan tool and appro

priate Powertrain Diagnostics Procedures manual. To

test the IAC motor only, special IAC motor exerciser tool number 7558 (Fig. 32) may be used.

CAUTION:

Proper safety precautions must be

taken

when

testing

the IAC

motor,

• Set the parking brake and block the drive wheels

• Route all tester cables away from the cooling fans,

drive belt, pulleys and exhaust components

• Provide proper ventilation while operating the en

gine

• Always return the engine idle speed to normal be

fore disconnecting the exerciser tool

(1) With the ignition OFF, disconnect the IAC mo

tor wire connector at throttle body (Fig. 31).

(2) Plug the exerciser tool (7558) harness connector

into the IAC motor (Fig. 32).

MANIFOLD

ABSOLUTE

Fig.

31 IAC Motor—Typical

Fig.

32 IAC Motor

Testing—

Typical

(3) Connect the red clip of exerciser tool (7558) to

battery positive terminal. Connect the black clip to

negative battery terminal. The red light on the exer

ciser tool will be illuminated when the exerciser is

properly connected to battery. (4) Start engine.

When the switch is in the HIGH or LOW position,

the light on the exerciser tool will flash. This indi cates that voltage pulses are being sent to the IAC

stepper motor.

Page 878 of 1502

•

FUEL SYSTEM

14 - 59

fill

DHADn

HIAf5MflCTipQ

/f|Rn

The powertrain control module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a monitored circuit often enough to indicate an actual

problem, a diagnostic trouble code (DTC) is stored.

The DTC will be stored in the PCM memory for eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can cels the DTC after 51 engine starts.

Certain criteria must be met for a diagnostic trou

ble code (DTC) to be entered into PCM memory. The criteria may be a specific range of engine rpm, en

gine temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met. Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does not occur within the specified rpm range.

A DTC indicates that the powertrain control mod

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.

There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored Circuits in this section.

MONITORED

CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit - The PCM can deter

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit is open or shorted.

Output Device Current Flow - The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to

(

+

)

voltage.

Oxygen Sensor - The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A diagnostic trouble code (DTC) may not be displayed for these

conditions.

Fuel Pressure: Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

line.

However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored in the PCM.

Secondary Ignition Circuit: The PCM cannot de

tect an inoperative ignition coil, fouled or worn spark

plugs,

ignition cross firing, or open circuited spark

plug cables.

Engine Timing: The PCM cannot detect an incor

rectly indexed timing chain, camshaft sprocket or crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression: The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System: The PCM cannot detect

a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions: The PCM cannot de

termine if the fuel injector is clogged, or the wrong injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

Excessive Oil Consumption: Although the PCM

monitors exhaust stream oxygen content through ox

ygen sensor (closed loop), it cannot determine exces sive oil consumption.

Throttle Body Air Flow: The PCM cannot detect

a clogged or restricted air cleaner inlet or air filter

element.

Evaporative System: The PCM will not detect a

restricted, plugged or loaded EVAP canister. Vacuum Assist: Leaks or restrictions in the vac

uum circuits of vacuum assisted engine control sys

tem devices are not monitored by the PCM. However, a vacuum leak at the MAP sensor will be monitored

and a diagnostic trouble code (DTC) will be gener

ated by the PCM.

Powertrain Control Module (PCM) System

Ground: The PCM cannot determine a poor system

ground. However, a DTC may be generated as a re

sult of this condition.

Powertrain Control Module (PCM) Connector

Engagement: The PCM cannot determine spread or

damaged connector pins. However, a DTC may be generated as a result of this condition.

Page 879 of 1502

14 - SO

FUEL

SYSTEM

•

HIGH

AND LOW

LIMITS

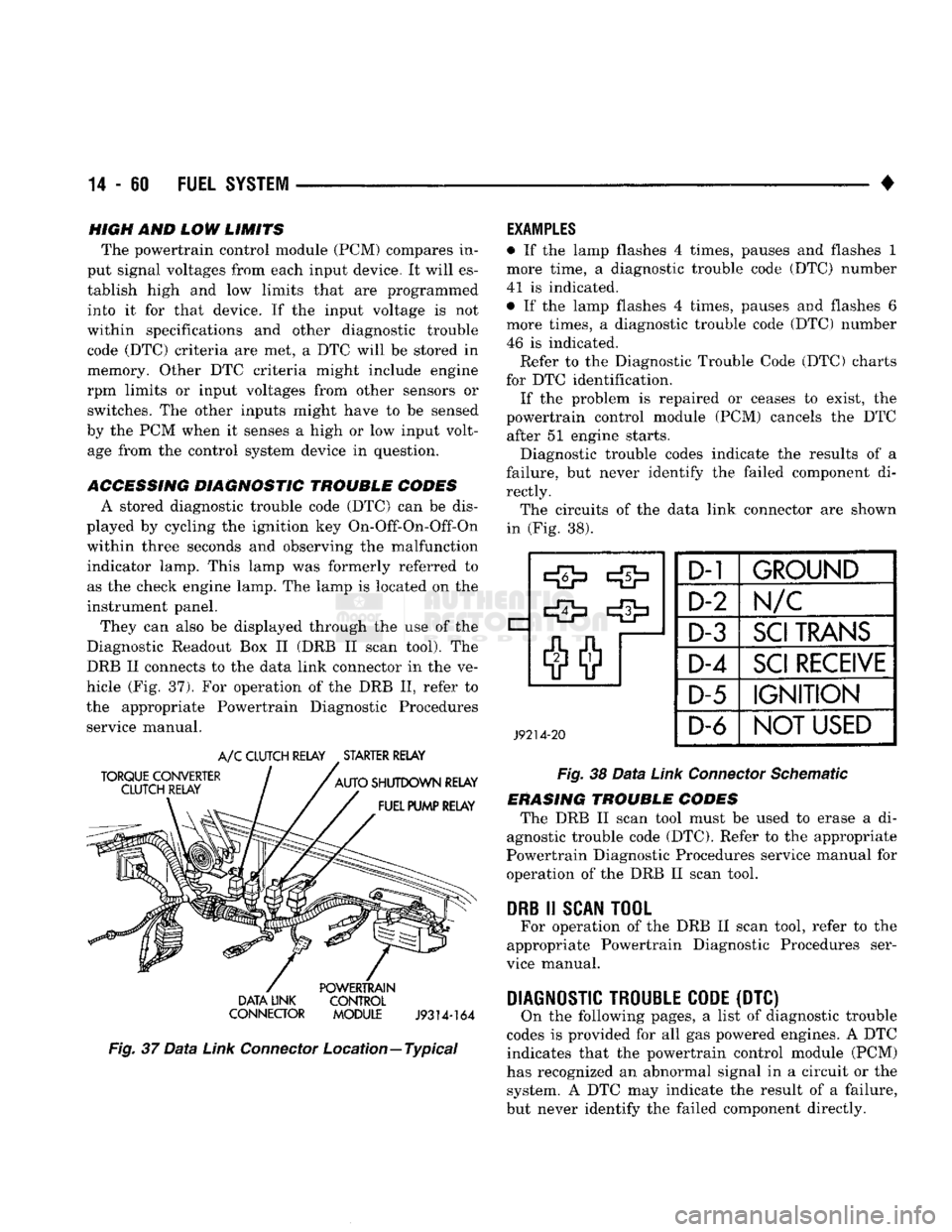

The powertrain control module (PCM) compares in

put signal voltages from each input device. It will es

tablish high and low limits that are programmed into it for that device. If the input voltage is not

within specifications and other diagnostic trouble code (DTC) criteria are met, a DTC will be stored in

memory. Other DTC criteria might include engine

rpm limits or input voltages from other sensors or switches. The other inputs might have to be sensed

by the PCM when it senses a high or low input volt age from the control system device in question.

ACCESSING DIAGNOSTIC TROUBLE CODES A stored diagnostic trouble code (DTC) can be dis

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the malfunction indicator lamp. This lamp was formerly referred to

as the check engine lamp. The lamp is located on the

instrument panel.

They can also be displayed through the use of the

Diagnostic Readout Box II (DRB II scan tool). The

DRB II connects to the data link connector in the ve

hicle (Fig. 37). For operation of the DRB II, refer to

the appropriate Powertrain Diagnostic Procedures service manual.

TORQUE CONVERTER

CLUTCH RELAY

A/C

CLUTCH RELAY

.

STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY POWERTRAIN

DATA LINK CONTROL

CONNECTOR MODULE

J9314-164

Fig.

37

Data

Link

Connector

Location—Typical

EXAMPLES

• If the lamp flashes 4 times, pauses and flashes 1

more time, a diagnostic trouble code (DTC) number

41 is indicated.

• If the lamp flashes 4 times, pauses and flashes 6

more times, a diagnostic trouble code (DTC) number

46 is indicated. Refer to the Diagnostic Trouble Code (DTC) charts

for DTC identification. If the problem is repaired or ceases to exist, the

powertrain control module (PCM) cancels the DTC after 51 engine starts.

Diagnostic trouble codes indicate the results of a

failure, but never identify the failed component di

rectly. The circuits of the data link connector are shown

in (Fig. 38).

J9214-20

D-1

GROUND

D-2 Im/c

D-3

SCI

TRANS

D-4

SCI

RECEIVE

D-5

IGNITION

D-6

NOT

USED

Fig.

38

Data

Link

Connector

Schematic

ERASING TROUBLE CODES The DRB II scan tool must be used to erase a di

agnostic trouble code (DTC). Refer to the appropriate

Powertrain Diagnostic Procedures service manual for operation of the DRB II scan tool.

DRB

II

SCAN

TOOL

For operation of the DRB II scan tool, refer to the

appropriate Powertrain Diagnostic Procedures ser

vice manual.

DIAGNOSTIC TROUBLE CODE

(DTC) On the following pages, a list of diagnostic trouble

codes is provided for all gas powered engines. A DTC indicates that the powertrain control module (PCM)

has recognized an abnormal signal in a circuit or the system. A DTC may indicate the result of a failure,

but never identify the failed component directly.

Page 880 of 1502

•

FUEL

SYSTEM

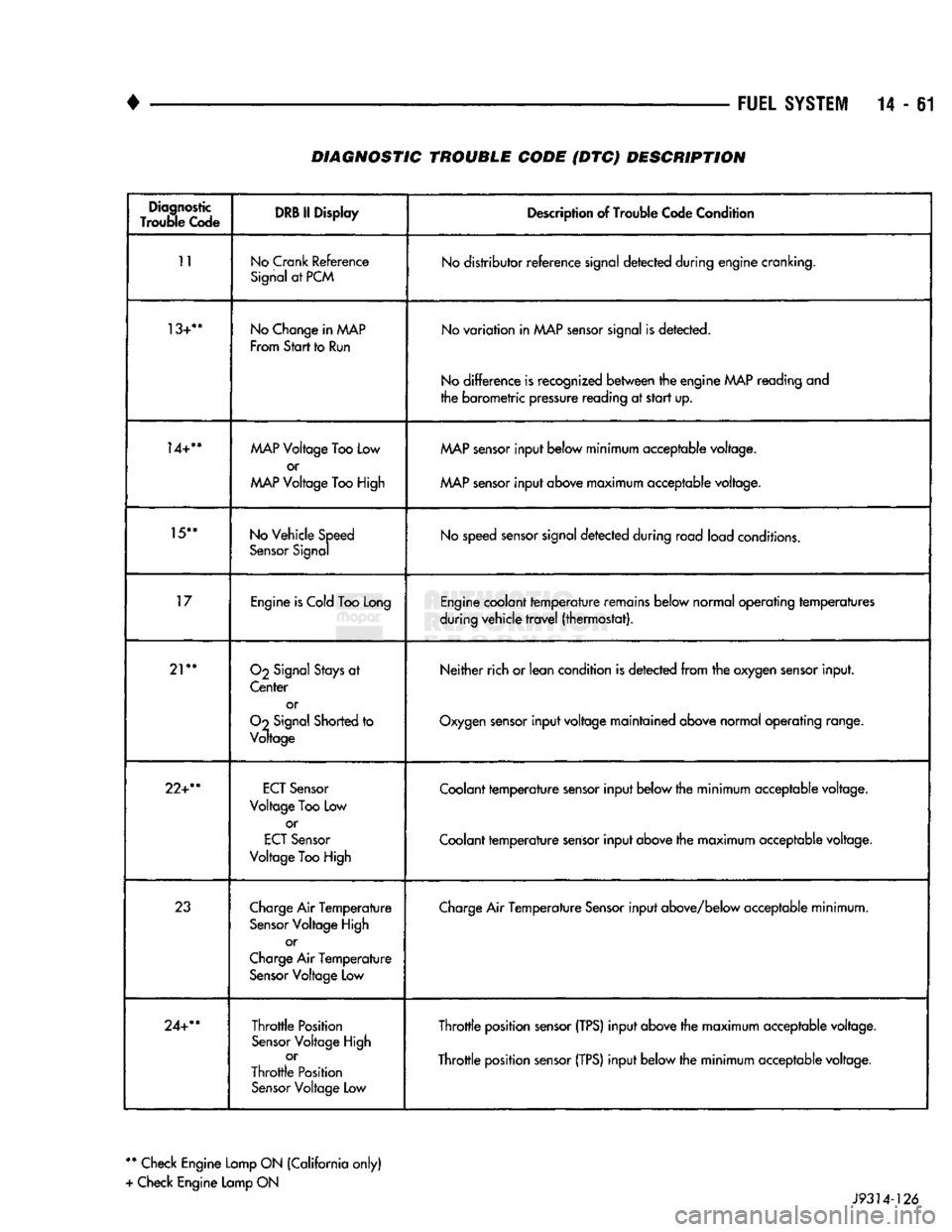

14-61 DIAGNOSTIC TROUBLE CODE {DTC) DESCRIPTION

Diagnostic

Trouble

Code DRB II

Display

Description of Trouble Code Condition

11

No

Crank

Reference

Signal at PCM No distributor reference signal detected during engine cranking.

13+**

No Change in

AAAP

From

Start

to Run No variation in MAP sensor signal is detected.

No difference is recognized between the engine

MAP

reading and

the barometric pressure reading at start up.

14+**

MAP

Voltage Too Low

or

MAP

Voltage Too High

MAP

sensor input below minimum acceptable voltage.

MAP sensor input above maximum acceptable voltage.

15**

No Vehicle Speed

Sensor Signal No speed sensor signal detected during road load conditions.

17

Engine is Cold Too Long Engine coolant temperature remains below normal operating temperatures

during vehicle travel (thermostat).

21**

O2

Signal Stays at

Center or

Oo

Signal Shorted to

Voltage Neither rich or lean condition

is

detected from the oxygen sensor input.

Oxygen sensor input voltage maintained above normal operating range.

22+**

ECT

Sensor

Voltage

Too

Low or

ECT

Sensor

Voltage

Too

High Coolant temperature sensor input below the minimum acceptable voltage.

Coolant temperature sensor input above the maximum acceptable voltage.

23

Charge Air Temperature

Sensor Voltage High or

Charge Air Temperature Sensor Voltage Low Charge Air Temperature Sensor input above/below acceptable minimum.

24+**

Throttle Position

Sensor Voltage High or

Throttle Position Sensor Voltage

Low

Throttle position sensor

(TPS)

input above the maximum acceptable voltage.

Throttle position sensor

(TPS)

input below the minimum acceptable voltage.

**

Check Engine Lamp ON (California only)

+ Check Engine Lamp ON J9314-126

Page 882 of 1502

•

FUEL

SYSTEM

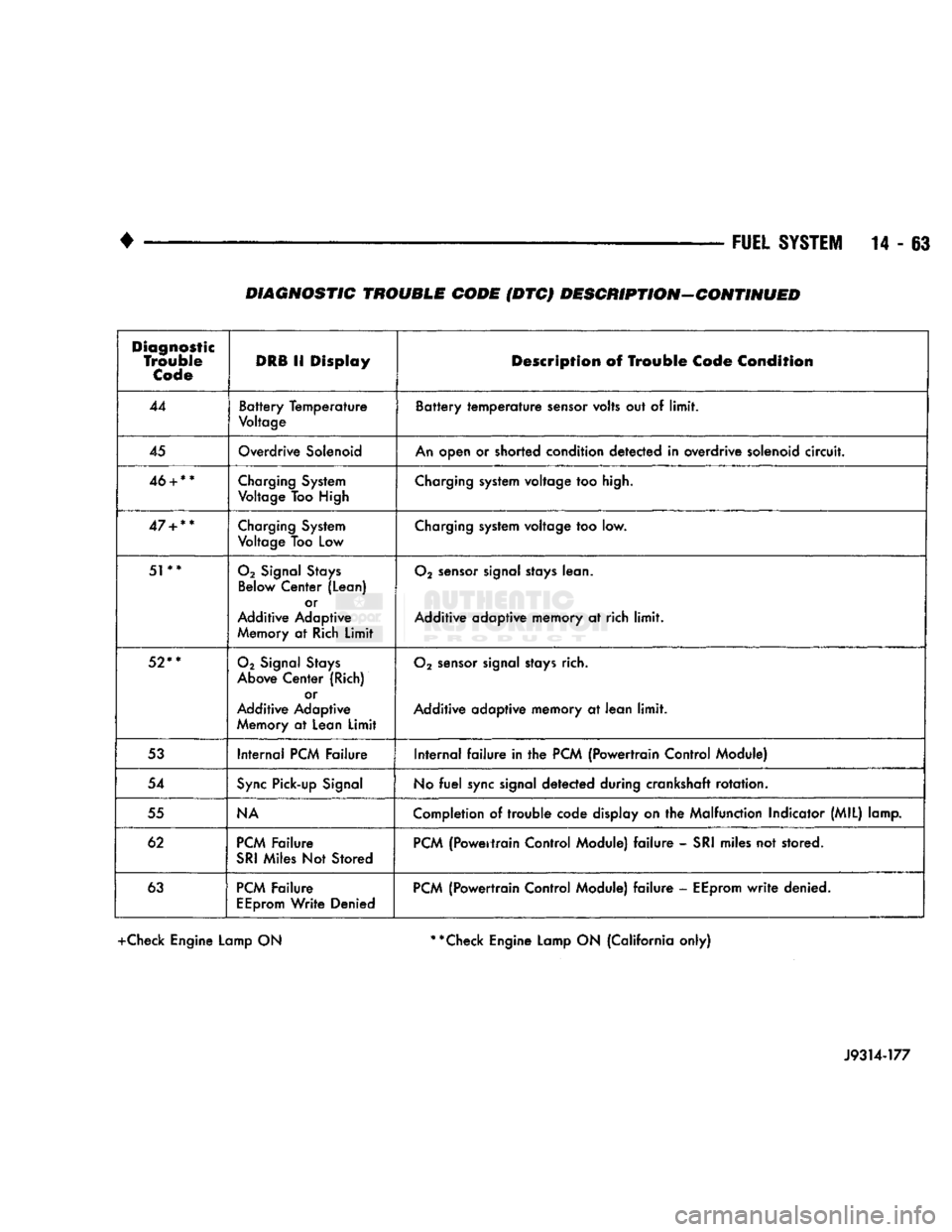

14 - 63 DIAGNOSTIC TROUBLE CODE (DTC) DESCRIPTION-CONTINUED

Diagnostic

Trouble

Code

DRB

11

Display

Description

of

Trouble

Code

Condition

44

Battery Temperature

Voltage

Battery temperature

sensor

volts

out of

limit.

45

Overdrive

Solenoid

An

open

or

shorted condition detected

in

overdrive solenoid

circuit.

46

+

**

Charging

System

Voltage

Too High

Charging

system voltage

too

high.

47

+

**

Charging

System

Voltage

Too

Low

Charging

system voltage

too low.

51**

02

Signal

Stays

Below

Center (Lean) or

Additive Adaptive

Memory

at

Rich

Limit

02

sensor

signal

stays

lean.

Additive adaptive memory

at rich

limit.

52**

02

Signal

Stays

Above

Center (Rich) or

Additive Adaptive

Memory

at

Lean

Limit

02

sensor

signal

stays

rich.

Additive adaptive memory

at

lean

limit.

53

Internal

PCM

Failure Internal

failure in the

PCM

{Powertrain Control Module)

54

Sync

Pick-up

Signal

No

fuel

sync

signal detected during crankshaft rotation.

55

NA

Completion

of trouble

code display

on the

Malfunction Indicator (MIL) lamp.

62

PCM

Failure

SRI

Miles

Not

Stored

PCM

(Powertrain Control Module)

failure -

SRI

miles

not

stored.

63

PCM

Failure

EEprom

Write Denied

PCM

(Powertrain Control Module)

failure -

EEprom

write

denied.

+Check Engine Lamp ON **Check Engine Lamp ON (California only)

J9314-177

Page 883 of 1502

MULTI-PORT

FUEL

INJECTION

(MPI)-COMPONENT

REMOVAL/INSTALLATION

—EXCEPT DIESEL

INDEX

page

Accelerator Pedal

and Throttle

Cable

. 64

Air Conditioning (A/C) Clutch Relay

64

Air

Filter/Filter

Housing

64

Automatic Shut Down (ASD) Relay

. 64

Brake

Switch

64

Camshaft

Position

Sensor

..................

64

Charge

Air

Temperature

Sensor

64

Crankshaft Position

Sensor

64

Engine

Coolant Temperature

Sensor

65

EVAP

Canister Purge Solenoid

65

Fuel

Filter

65

Fuel Filter/Fuel Pressure Regulator—5.9L Engine

. 65

Fuel Injector(S)

67

Fuel Pressure Regulator

67

Fuel Pump Module

68

Fuel Pump Relay

68

ACCELERATOR

PEDAL

AND THROTTLE

CABLE

Refer

to

the

Accelerator Pedal

and

Throttle Cable

section

of

this group

for

removal/installation proce

dures.

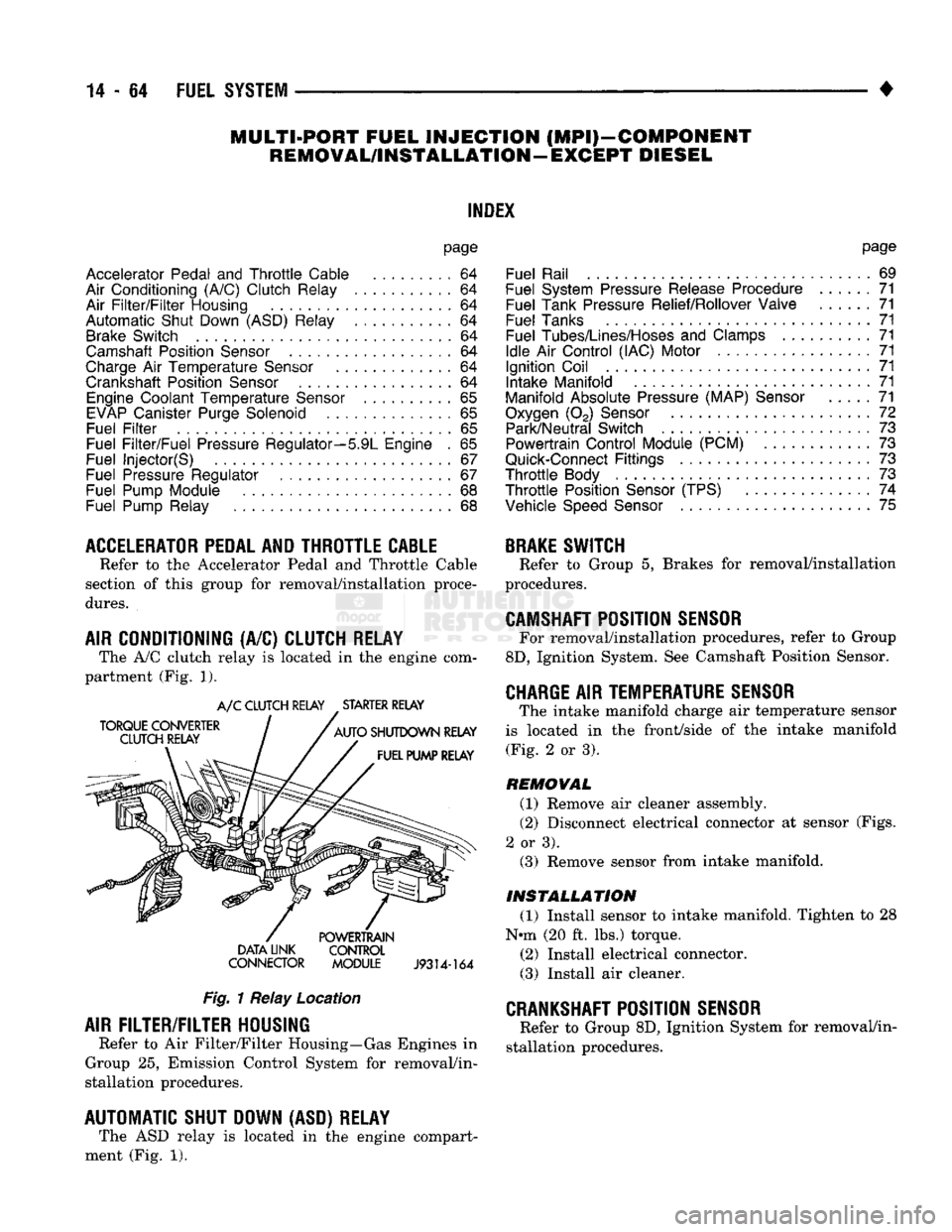

AIR

CONDITIONING (A/C) CLUTCH RELAY The A/C clutch relay

is

located

in

the

engine com

partment (Fig.

1).

A/C CLUTCH RELAY STARTER RELAY

DATA LINK CONTROL

CONNECTOR MODULE

J9314-164

Fig.

1 Relay Location

AIR

FILTER/FILTER

HOUSING

Refer

to

Air Filter/Filter Housing—Gas Engines

in

Group

25,

Emission Control System

for

removal/in

stallation procedures.

AUTOMATIC SHUT DOWN (ASD) RELAY The ASD relay

is

located

in

the

engine compart

ment (Fig.

1).

page

Fuel Rail

69

Fuel System Pressure Release Procedure

......

71

Fuel Tank Pressure Relief/Rollover Valve

71

Fuel Tanks

71

Fuel

Tubes/Lines/Hoses

and

Clamps

71

Idle

Air

Control (IAC) Motor

71

Ignition Coil

71

Intake Manifold

71

Manifold Absolute Pressure (MAP)

Sensor

71

Oxygen

(02)

Sensor

72

Park/Neutral Switch

. 73

Powertrain Control Module (PCM)

73

Quick-Connect

Fittings

73

Throttle

Body

73

Throttle

Position

Sensor

(TPS)

......

74

Vehicle

Speed

Sensor

75

BRAKE

SWITCH

Refer

to

Group

5,

Brakes

for

removal/installation

procedures.

CAMSHAFT

POSITION

SENSOR

For removal/installation procedures, refer

to

Group

8D,

Ignition System. See Camshaft Position Sensor.

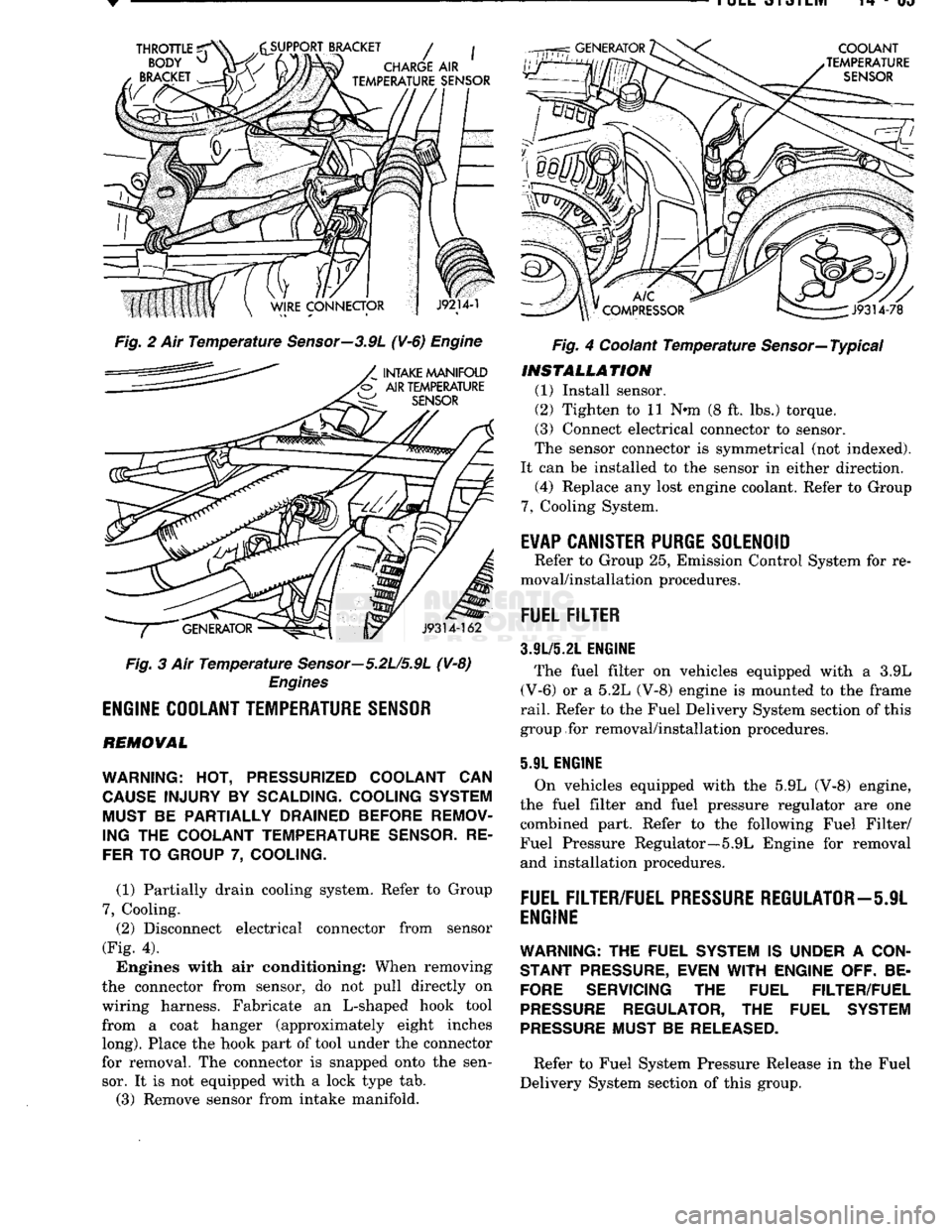

CHARGE

AIR

TEMPERATURE SENSOR

The intake manifold charge

air

temperature sensor

is located

in the

front/side

of

the

intake manifold (Fig.

2

or

3).

REMOVAL

(1) Remove

air

cleaner assembly.

(2) Disconnect electrical connector

at

sensor (Figs.

2

or

3). (3) Remove sensor from intake manifold.

INSTALLATION

(1) Install sensor

to

intake manifold. Tighten

to 28

Nnn (20

ft.

lbs.) torque.

(2) Install electrical connector.

(3) Install

air

cleaner.

CRANKSHAFT

POSITION

SENSOR

Refer

to

Group 8D, Ignition System

for

removal/in

stallation procedures.

Page 884 of 1502

Fig. 2 Ait Temperature Sensor—3.9L (¥-6) Engine

Fig. 3 Air Temperature Sensor—5.2U5.9L (V-8)

Engines

ENGINE

COOLANT

TEMPERATURE

SENSOR

REMOVAL

WARNING:

HOT,

PRESSURIZED COOLANT

CAN

CAUSE

INJURY

BY

SCALDING- COOLING SYSTEM MUST

BE

PARTIALLY DRAINED BEFORE REMOV

ING

THE

COOLANT TEMPERATURE

SENSOR.

RE

FER

TO

GROUP

7,

COOLING.

(1) Partially drain cooling system. Refer to Group

7,

Cooling. (2) Disconnect electrical connector from sensor

(Fig. 4).

Engines with air conditioning: When removing

the connector from sensor, do not pull directly on

wiring harness. Fabricate an L-shaped hook tool from a coat hanger (approximately eight inches

long).

Place the hook part of tool under the connector

for removal. The connector is snapped onto the sen sor. It is not equipped with a lock type tab.

(3) Remove sensor from intake manifold. Fig. 4 Coolant Temperature Sensor—Typical

INSTALLATION

(1) Install sensor.

(2) Tighten to 11 Nnn (8 ft. lbs.) torque.

(3) Connect electrical connector to sensor.

The sensor connector is symmetrical (not indexed).

It can be installed to the sensor in either direction. (4) Replace any lost engine coolant. Refer to Group

7,

Cooling System.

E¥AP

CANISTER

PURGE

SOLENOID

Refer to Group 25, Emission Control System for re

moval/installation procedures.

FUEL

FILTER

3.9L/5.21.

ENGINE

The fuel filter on vehicles equipped with a 3.9L

(V-6) or a 5.2L (V-8) engine is mounted to the frame

rail.

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

5.91 ENGINE

On vehicles equipped with the 5.9L (V-8) engine,

the fuel filter and fuel pressure regulator are one combined part. Refer to the following Fuel Filter/

Fuel Pressure Regulator—5.9L Engine for removal and installation procedures.

FUEL

FILTER/FUEL

PRESSURE

REGULATOR—5JL

ENGINE

WARNING:

THE FUEL SYSTEM IS UNDER A

CON

STANT

PRESSURE,

EVEN

WITH

ENGINE OFF. BE

FORE

SERVICING THE FUEL FILTER/FUEL

PRESSURE

REGULATOR, THE FUEL SYSTEM

PRESSURE

MUST BE

RELEASED.

Refer to Fuel System Pressure Release in the Fuel

Delivery System section of this group.

Page 888 of 1502

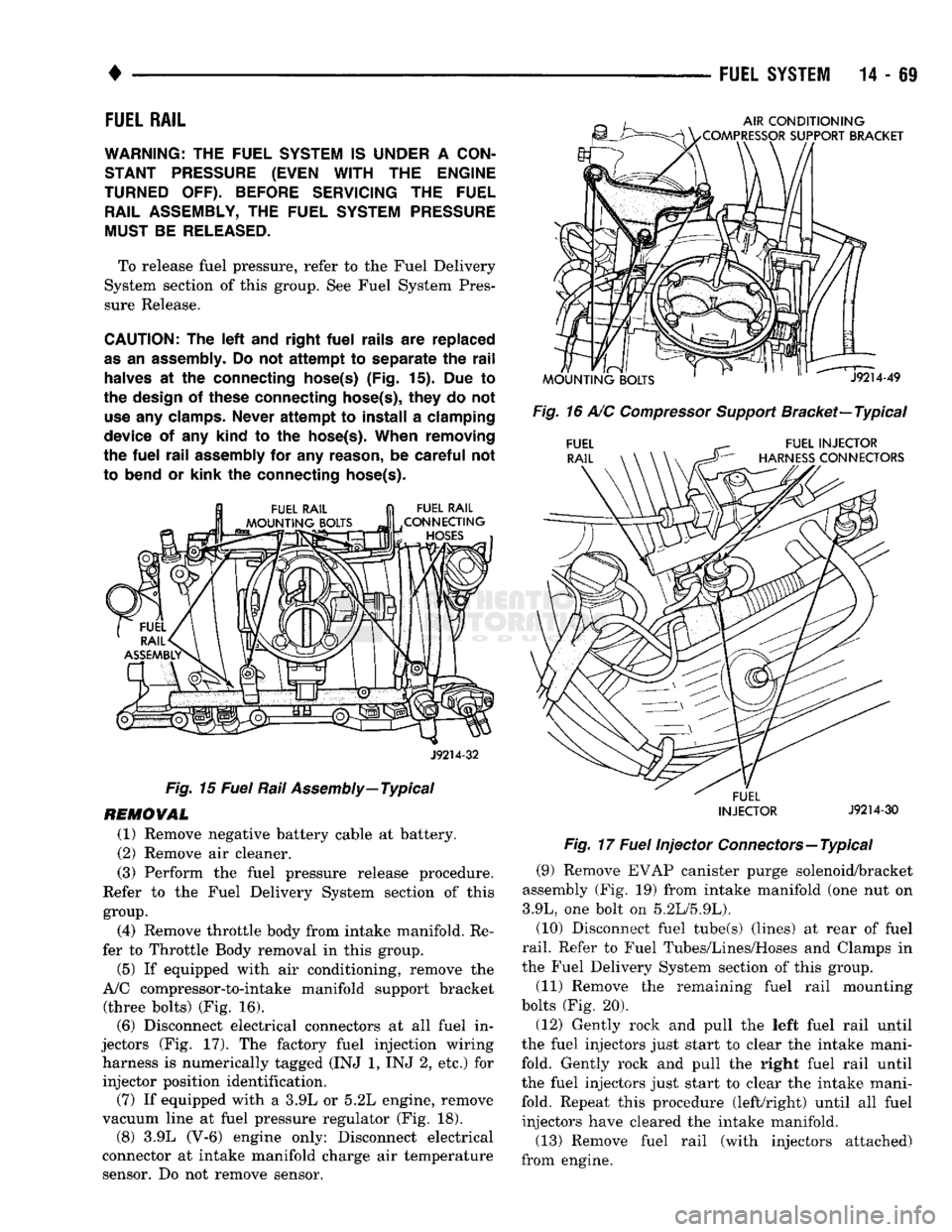

FUEL

RAIL

WARNING:

THE

FUEL SYSTEM

IS

UNDER

A

CON STANT PRESSURE (EVEN

WITH

THE

ENGINE

TURNED

OFF).

BEFORE SERVICING

THE

FUEL RAIL ASSEMBLY,

THE

FUEL SYSTEM PRESSURE

MUST

BE

RELEASED.

To release fuel pressure, refer to the Fuel Delivery

System section of this group. See Fuel System Pres

sure Release.

CAUTION:

The left and

right

fuel

rails

are

replaced

as

an

assembly.

Do not

attempt

to

separate

the

rail

halves

at the

connecting hose(s)

(Fig. 15). Due to

the design

of

these connecting hose(s),

they

do not

use

any

clamps. Never

attempt

to

install

a

clamping

device

of any

kind

to the

hose(s).

When

removing

the

fuel

rail

assembly

for any

reason,

be

careful

not

to bend

or

kink

the

connecting hose(s). FUEL RAIL

CONNECTING

HOSES

AIR

CONDITIONING

/COMPRESSOR

SUPPORT BRACKET

MOUNTING

BOLTS

' "

J9214-49

Fig.

16 A/C

Compressor

Support

Bracket—

Typical

FUEL RAIL FUEL INJECTOR

HARNESS

CONNECTORS

J9214-32

Fig.

15

Fuel

Rail

Assembly—

Typical

REMOVAL

(1) Remove negative battery cable at battery.

(2) Remove air cleaner.

(3) Perform the fuel pressure release procedure.

Refer to the Fuel Delivery System section of this group.

(4) Remove throttle body from intake manifold. Re

fer to Throttle Body removal in this group.

(5) If equipped with air conditioning, remove the

A/C compressor-to-intake manifold support bracket (three bolts) (Fig. 16). (6) Disconnect electrical connectors at all fuel in

jectors (Fig. 17). The factory fuel injection wiring harness is numerically tagged (INJ 1, INJ 2, etc.) for injector position identification. (7) If equipped with a 3.9L or 5.2L engine, remove

vacuum line at fuel pressure regulator (Fig. 18). (8) 3.9L (V-6) engine only: Disconnect electrical

connector at intake manifold charge air temperature sensor. Do not remove sensor. '

FUEL

INJECTOR

J9214-30

Fig.

17

Fuel

Injector Connectors—Typical

(9) Remove EVAP canister purge solenoid/bracket

assembly (Fig. 19) from intake manifold (one nut on

3.9L, one bolt on 5.2L/5.9L).

(10) Disconnect fuel tube(s) (lines) at rear of fuel

rail.

Refer to Fuel Tubes/Lines/Hoses and Clamps in

the Fuel Delivery System section of this group.

(11) Remove the remaining fuel rail mounting

bolts (Fig. 20).

(12) Gently rock and pull the left fuel rail until

the fuel injectors just start to clear the intake mani

fold. Gently rock and pull the right fuel rail until

the fuel injectors just start to clear the intake mani fold. Repeat this procedure (left/right) until all fuel injectors have cleared the intake manifold.

(13) Remove fuel rail (with injectors attached)

from engine.

Page 889 of 1502

14

- 70

FUEL

SYSTEM

•

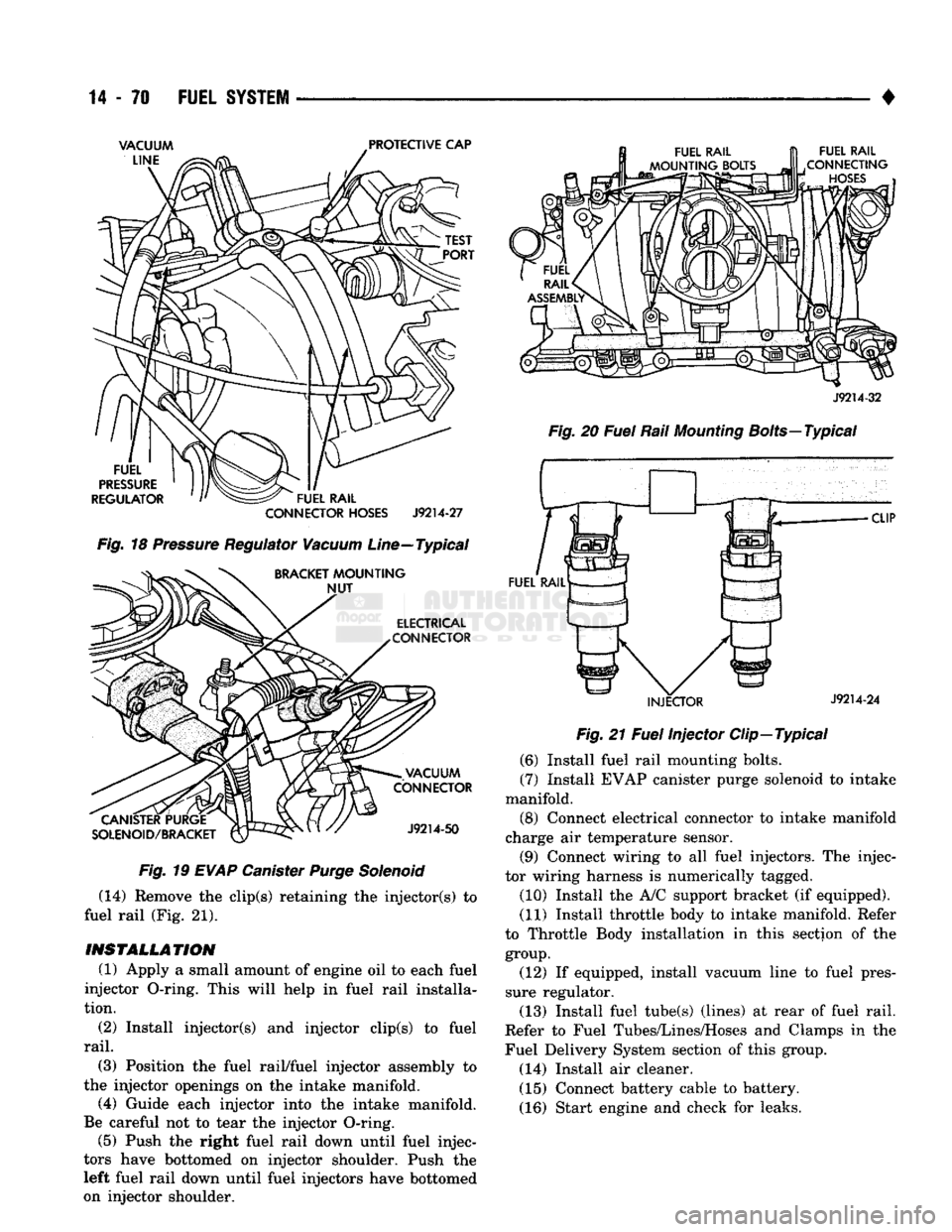

CANISTER PURGE

SOLENOID/BRACKET VACUUM

CONNECTOR

J9214-50

Fig.

19

EVAP

Canister

Purge

Solenoid

(14) Remove the clip(s) retaining the injector(s) to

fuel rail (Fig. 21).

INSTALLATION

(1) Apply a small amount of engine oil to each fuel

injector O-ring. This will help in fuel rail installa

tion.

(2) Install injector(s) and injector clip(s) to fuel

rail.

(3) Position the fuel rail/fuel injector assembly to

the injector openings on the intake manifold.

(4) Guide each injector into the intake manifold.

Be careful not to tear the injector O-ring. (5) Push the right fuel rail down until fuel injec

tors have bottomed on injector shoulder. Push the

left fuel rail down until fuel injectors have bottomed

on injector shoulder.

INJECTOR

J9214-24

Fig.

21

Fuel

Injector Clip—Typical

(6) Install fuel rail mounting bolts.

(7) Install EVAP canister purge solenoid to intake

manifold. (8) Connect electrical connector to intake manifold

charge air temperature sensor.

(9) Connect wiring to all fuel injectors. The injec

tor wiring harness is numerically tagged.

(10) Install the A/C support bracket (if equipped).

(11) Install throttle body to intake manifold. Refer

to Throttle Body installation in this section of the

group.

(12) If equipped, install vacuum line to fuel pres

sure regulator.

(13) Install fuel tube(s) (lines) at rear of fuel rail.

Refer to Fuel Tubes/Lines/Hoses and Clamps in the

Fuel Delivery System section of this group.

(14) Install air cleaner. (15) Connect battery cable to battery.

(16) Start engine and check for leaks.

Page 890 of 1502

•

FUEL SYSTEM

14-71

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING:

THE

FUEL

SYSTEM

IS

UNDER

A

CON

STANT

PRESSURE

(EVEN

WITH

THE

ENGINE

TURNED

OFF).

BEFORE

SERVICING

THE

FUEL

PUMP,

FUEL

LINES

(TUBES),

FUEL

FILTER,

OR

FUEL

INJECTOR(S),

THE

FUEL

SYSTEM

PRESSURE

MUST

BE

RELEASED.

To release fuel pressure, refer to the Fuel Delivery

System section of this group. See Fuel System Pres

sure Release Procedure.

FUEL TANKS

Refer to the Fuel Tank section of this group for re

moval/installation procedures.

FUEL TANK

PRESSURE

RELIEF/ROLLOVER VALVE

Refer to the Fuel Tank section of this group for re

moval/installation procedures.

FUEL

TUBES/LINES/HOSES

AND CLAMPS

Refer to Fuel Tubes/Lines/Hoses and Clamps in the

Fuel Delivery System section of this group for remov al/installation procedures. Also refer to Quick-Connect Fittings in the Fuel

Delivery System section of this group for removal/in

stallation procedures.

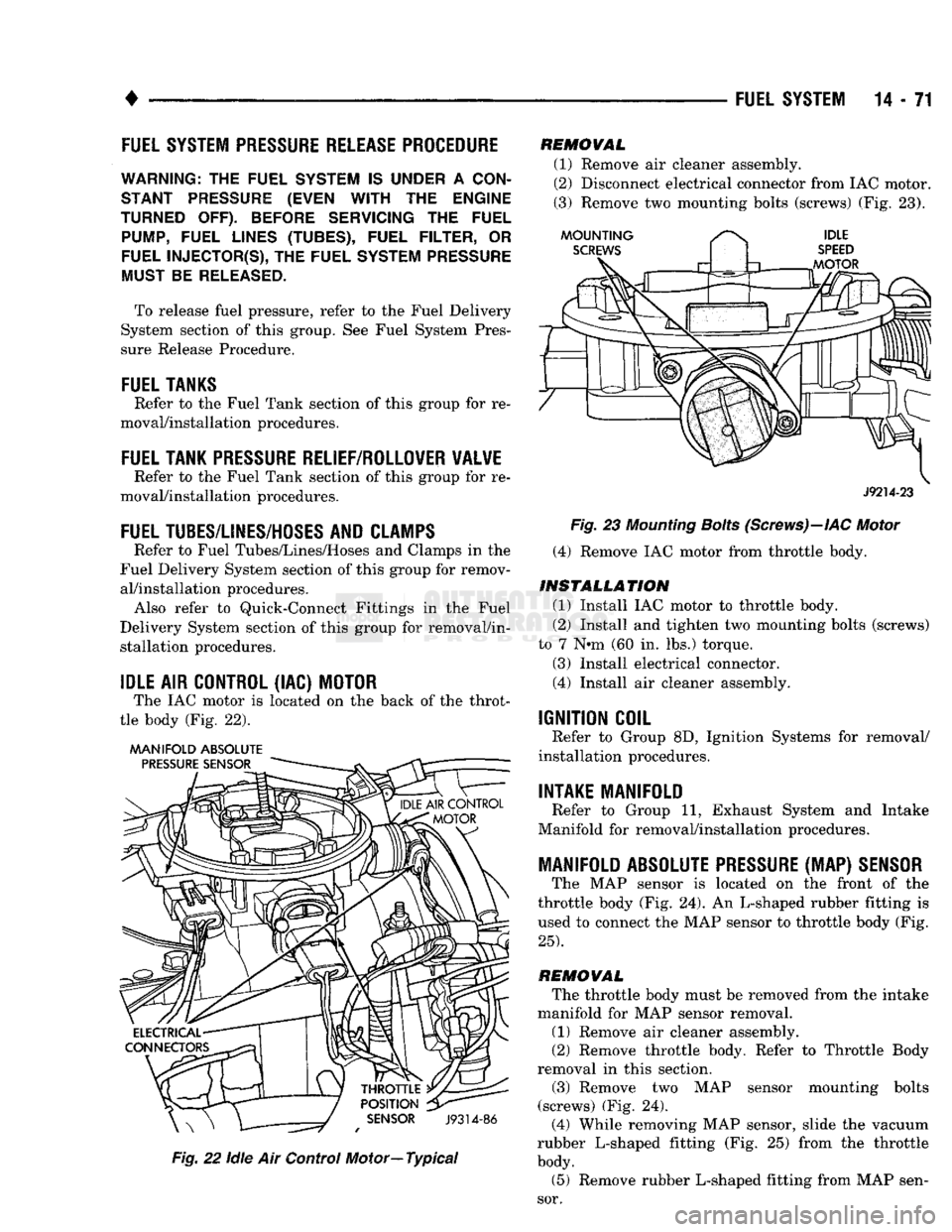

IDLE

AIR

CONTROL

(IAC)

MOTOR

The IAC motor is located on the back of the throt

tle body (Fig. 22).

MANIFOLD ABSOLUTE

Fig.

22

idle

Air Control Motor—Typical

REMOVAL

(1) Remove air cleaner assembly.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws) (Fig. 23).

J9214-23

Fig.

23

Mounting

Bolts

(Screws)—IAC

Motor

(4) Remove IAC motor from throttle body.

INSTALLATION

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N»m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air cleaner assembly.

IGNITION COIL

Refer to Group 8D, Ignition Systems for removal/

installation procedures.

INTAKE MANIFOLD

Refer to Group 11, Exhaust System and Intake

Manifold for removal/installation procedures.

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

The MAP sensor is located on the front of the

throttle body (Fig. 24). An L-shaped rubber fitting is

used to connect the MAP sensor to throttle body (Fig.

25).

REMOVAL

The throttle body must be removed from the intake

manifold for MAP sensor removal.

(1) Remove air cleaner assembly.

(2) Remove throttle body. Refer to Throttle Body

removal in this section.

(3) Remove two MAP sensor mounting bolts

(screws) (Fig. 24). (4) While removing MAP sensor, slide the vacuum

rubber L-shaped fitting (Fig. 25) from the throttle

body.

(5) Remove rubber L-shaped fitting from MAP sen

sor.