sensor DODGE TRUCK 1993 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 601 of 1502

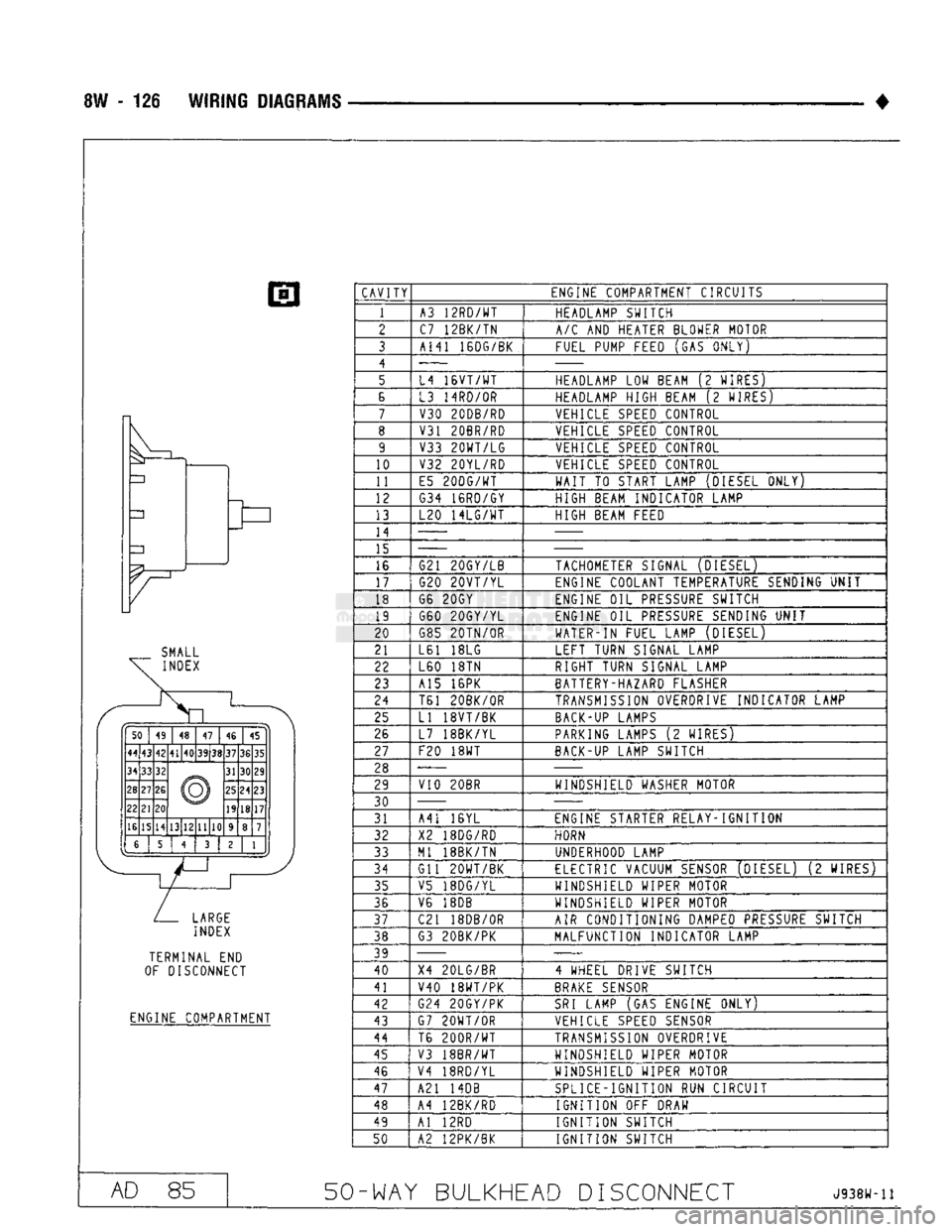

8W - 126

WIRING

DIAGRAMS

SMALL

INDEX

50 49 48

47

46 45

44 43 42 41

40 39

38 37

36 35

34 33 32

© 31

30 29

28 27

26

© 25

24 23

22 21

20 ©

19 18

17

16 15 14 13 12 11 10 9 8 7

6 5 4

3 2

1

LARGE

INDEX TERMINAL END

OF DISCONNECT

ENGINE COMPARTMENT CAVITY

1

10

11

12

13

14 15

16

17

18 19

20

21

22

23

24

25

26

27

28

29

30 31

32 33

34

35

36

37

38

39 40

41

42

43

44

45

46

47

48

50 ENGINE COMPARTMENT CIRCUITS

A3 12RD/WT C7 12BK/TN

A141 16DG/BK

L4

16VT/WT

L3 14RD/0R

V30 20DB/RD

V31 20BR/RD V33

20WT/LG

V32 20YL/RD

E5

20DG/WT

G34 16RD/GY

L20

14LG/WT

G21 20GY/LB G20

20VT/YL

G6 20GY

G60 20GY/YL

G85 20TN/OR

L61 18LG L60 18TN

A15 16PK

T61 20BK/0R

LI 18VT/BK

L7 18BK/YL

F20 18WT

V10 20BR

A41 16YL

X2 18DG/RD

Ml 18BK/TN

Gil

20WT/BK

V5 18DG/YL

V6 18DB

C21 18DB/0R

G3 20BK/PK

X4 20LG/BR V40 18WT/PK

G24 20GY/PK

G7 2GWT/0R T6

200R/WT

V3 18BR/WT

V4 18RD/YL

A21 14DB

A4 12BK/RD Al 12RD

A2 12PK/BK HEADLAMP SWITCH

A/C

AND HEATER BLOWER MOTOR

FUEL PUMP FEED (GAS ONLY)

HEADLAMP LOW BEAM (2 WIRES)

HEADLAMP HIGH BEAM (2 WIRES)

VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL

WAIT

TO START LAMP (DIESEL

QNLYr

HIGH BEAM INDICATOR LAMP

HIGH BEAM FEED

TACHOMETER SIGNAL (DIESEL)

ENGINE COOLANT TEMPERATURE SENDING

UNIT

ENGINE OIL

PRESSURE

SWITCH

ENGINE OIL

PRESSURE

SENDING

UNIT

WATER-IN FUEL LAMP (DIESEL)

LEFT TURN SIGNAL LAMP RIGHT TURN SIGNAL LAMP

BATTERY-HAZARD FLASHER

TRANSMISSION

OVERDRIVE INDICATOR LAMP

BACK-UP LAMPS

PARKING LAMPS (2 WIRES)

BACK-UP LAMP SWITCH

WINDSHIELD WASHER MOTOR

ENGINE STARTER RELAY

-1GNITI

ON HORN

UNDERHOOD LAMP

ELECTRIC

VACUUM

SENSOR

(DIESEL) (2 WIRES)

WINDSHIELD WIPER MOTOR

WINDSHIELD WIPER MOTOR

AIR CONDITIONING DAMPED

PRESSURE

SWITCH

MALFUNCTION INDICATOR LAMP

4 WHEEL DRIVE SWITCH

BRAKE

SENSOR

SRI

LAMP (GAS ENGINE ONLY)

VEHICLE

SPEED SENSOR

TRANSMISSION

OVERDRIVE

WINDSHIELD WIPER MOTOR

WINDSHIELD WIPER MOTOR

SPLICE-IGNITION RUN CIRCUIT

IGNITION

OFF DRAW

IGNITION

SWITCH

IGNITION

SWITCH

AD 85 50-WAY BULKHEAD DISCONNECT

J938W-11

Page 602 of 1502

•

WIRING

DIAGRAMS

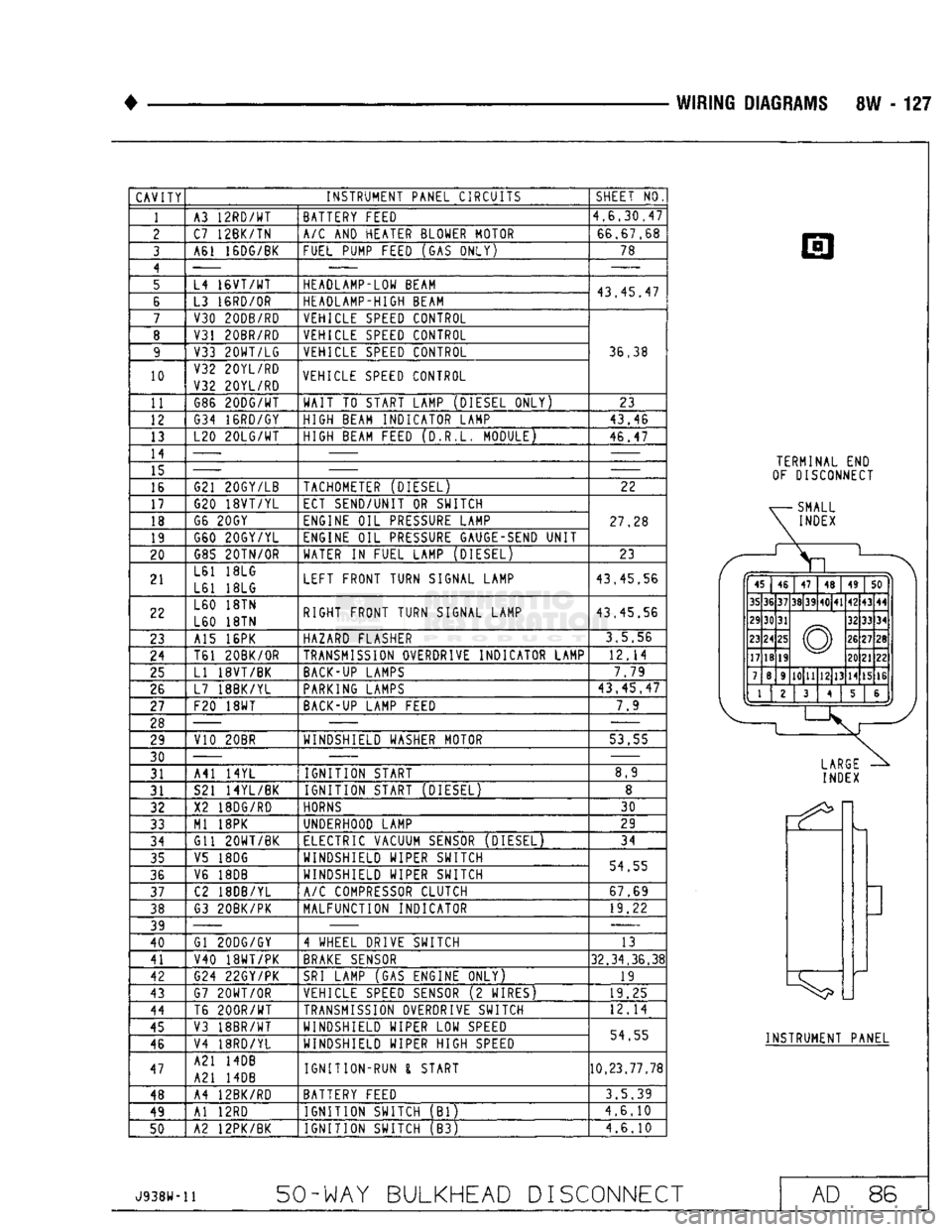

8W - 127

CAVITY

INSTRUMENT PANEL CIRCUITS

1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28 29

30 31

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

A3

12RD/WT

C7 12BK/TN

A61 16DG/BK

L4

16VT/WT

L3

16RD/0R

V30 20DB/RD

V31 20BR/RD

V33

20WT/LG

V32 20YL/RD

V32 20YL/RD G86

20DG/WT

G34 16RD/GY

L20

20LG/WT

G21 20GY/LB

G20

18VT/YL

G6

20GY

G60 20GY/YL G85

20TN/0R

L61

18LG

L61

18LG

L60

18TN

L60

18TN

A15

16PK

T61 20BK/OR

LI

18VT/BK

L7 18BK/YL

F20

18WT

V10 20BR

A41

14YL

S21 14YL/BK

X2

18DG/R0

Ml

18PK

Gil

20WT/BK

V5

18DG

V6

18DB

C2 18DB/YL

G3 20BK/PK

Gl 20DG/GY

V40

18WT/PK

G24 22GY/PK

G7

20WT/0R

T6

200R/WT

V3 18BR/WT

V4 18RD/YL

A21

14DB

A21

14DB

A4 12BK/RD

Al

12RD

A2 12PK/BK BATTERY FEED

A/C

AND

HEATER BLOWER MOTOR

FUEL PUMP FEED

(GAS

ONLY)

HEADLAMP-LOW BEAM

HEADLAMP-HIGH BEAM VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL

WAIT

TO

START LAMP (DIESEL ONLY)

HIGH BEAM INDICATOR LAMP

HIGH BEAM FEED (D.R.L. MODULE)

TACHOMETER (DIESEL)

ECT SEND/UNIT

OR

SWITCH

ENGINE

OIL

PRESSURE

LAMP

ENGINE

OIL

PRESSURE

GAUGE-SEND

UNIT

WATER

IN

FUEL LAMP (DIESEL)

LEFT FRONT TURN SIGNAL LAMP

RIGHT FRONT TURN SIGNAL LAMP

HAZARD FLASHER

TRANSMISSION

OVERDRIVE INDICATOR LAMP

BACK-UP

LAMPS

PARKING

LAMPS

BACK-UP

LAMP FEED

WINDSHIELD WASHER MOTOR

IGNITION START

IGNITION START (DIESEL)

HORNS

UNDERHOOD LAMP

ELECTRIC VACUUM

SENSOR

(DIESEL) WINDSHIELD WIPER SWITCH

WINDSHIELD WIPER SWITCH

A/C

COMPRESSOR CLUTCH

MALFUNCTION INDICATOR

4 WHEEL DRIVE SWITCH

BRAKE

SENSOR

SRI

LAMP

(GAS

ENGINE ONLY)

VEHICLE

SPEED

SENSOR

(2

WIRES)

TRANSMISSION

OVERDRIVE SWITCH

WINDSHIELD WIPER

LOW

SPEED

WINDSHIELD WIPER HIGH

SPEED

IGNITION-RUN

I

START

BATTERY FEED IGNITION SWITCH

(Bl)

IGNITION SWITCH

(B3)

SHEET

NO

4,6.30,47

66,67,68 78

43,45,47

36,38

23

43,46

46,47

22

27,28

23

43.45,56

43,45.56

3,5,56

12,14 7.79

43,45,47

7.9

53.55 8,9

30

29

34

54,55 67,69 19,22

13

32,34,36,38

19

19,25

12,14

54.55

10,23.77,78

3.5.39

4,6.10

4.6.10

TERMINAL

END

OF DISCONNECT

ff

p

45 46

47

48 49

50

35 36 37

38 39

40 41

42

43 44

29 30 31

© 32

33 34

23 24

25

© 26

27 28

17 18

19 ©

20 21 22

7 8 9

10 11

12 13

14 15 16

1

^

1.

2

3

4 5 &

J *j

LARGE

INDEX

INSTRUMENT PANEL

J938W-11

50-WAY BULKHEAD

DISCONNECT

AD

86

Page 605 of 1502

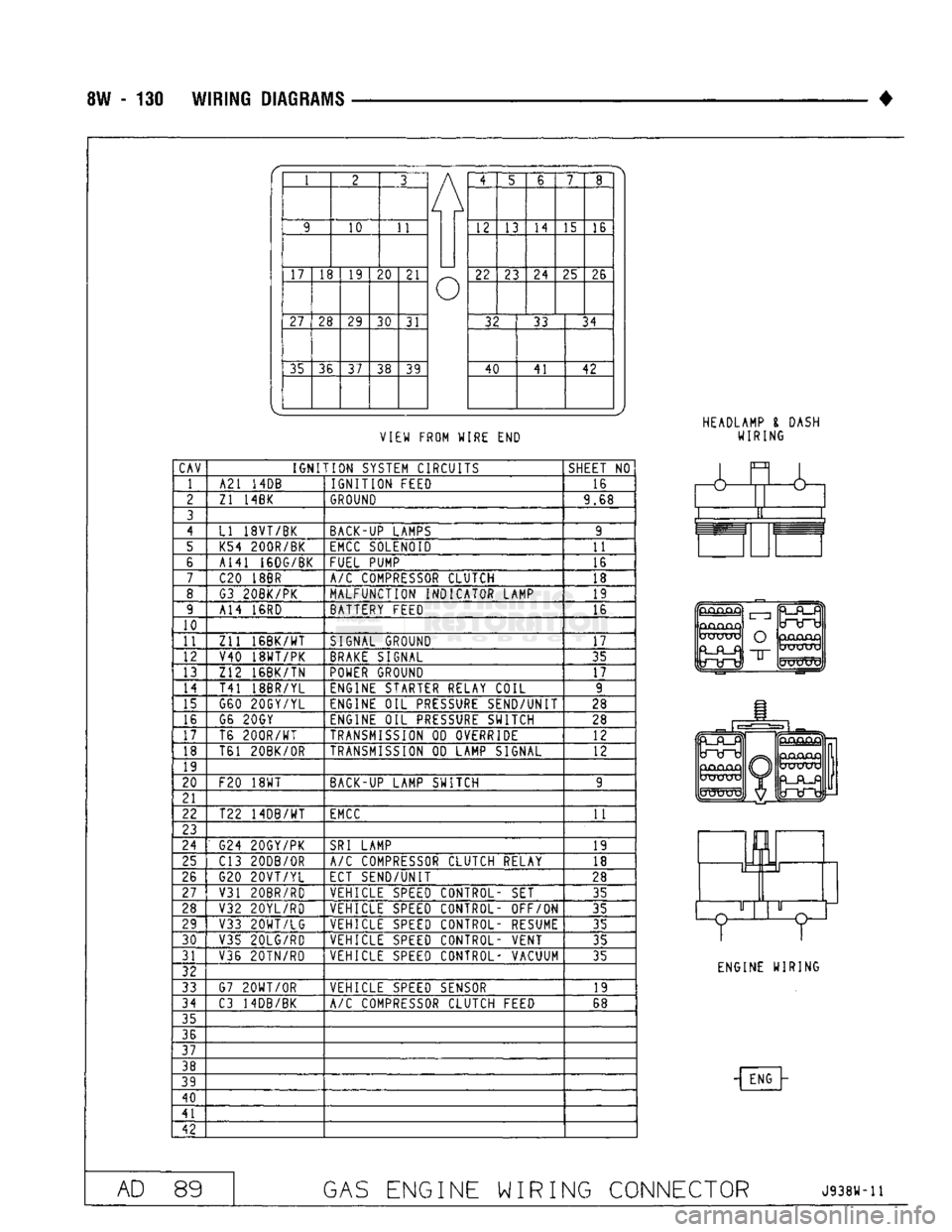

8W - 130

WIRING

DIAGRAMS

•

1 2 3

A 4

5 6

7

8

/

9

10

11

/

12 13

14

15 16

/

17

18

19

20

21

u

22

23

24

25 26

u

27

28 29

30

31

u

32 33

34

u

35 36

37

38 39

u

40

41 42

u

VIEW FROM WIRE

END

HEADLAMP

I

DASH

WIRING

CAV

IGNITION

SYSTEM CIRCUITS

SHEET

NO

1 A21

14DB

IGNITION

FEED 16

2

Zl 14BK

GROUND

9.68

3

4

LI 18VT/BK BACK-UP LAMPS 9

5 K54 200R/BK

EMCC

SOLENOID

11

6 A141 16DG/BK

FUEL PUMP 16

7

C20

18BR

A/C

COMPRESSOR CLUTCH 18

8 G3 20BK/PK MALFUNCTION INDICATOR LAMP 19

9 A14

16RD

BATTERY FEED 16

10

11

Zll

16BK/WT

SIGNAL GROUND

17

12 V40 18WT/PK

BRAKE

SIGNAL 35

13 Z12 16BK/TN

POWER

GROUND

17

14

T41 18BR/YL ENGINE STARTER RELAY COIL 9

15 G60 20GY/YL ENGINE

OIL

PRESSURE

SEND/UNIT 28

16 G6 20GY

ENGINE

OIL

PRESSURE

SWITCH 28

17 T6

200R/WT

TRANSMISSION

OD

OVERRIDE 12

18 T61 20BK/0R

TRANSMISSION

OD

LAMP SIGNAL

12

19

20

F20

18WT

BACK-UP LAMP SWITCH 9

21

22 T22 14DB/WT

EMCC

11

23

24

G24 20GY/PK

SRI

LAMP

19

25 C13 20DB/0R

A/C

COMPRESSOR CLUTCH RELAY

18

26 G20

20VT/YL

ECT SEND/UNIT

28

27

V31 20BR/RD VEHICLE

SPEED

CONTROL-

SET

35

28 V32 20YL/RD VEHICLE

SPEED

CONTROL- OFF/ON

35

29 V33

20WT/LG

VEHICLE

SPEED

CONTROL- RESUME 35

30

V35 20LG/RD VEHICLE

SPEED

CONTROL- VENT

35

31 V36 20TN/RD VEHICLE

SPEED

CONTROL- VACUUM

35

32

33 G7

20WT/0R

VEHICLE

SPEED

SENSOR 19

34

C3 14DB/BK

A/C

COMPRESSOR CLUTCH FEED 68

35

36

37

38

39

40

41

42

&

GjCUQjQ

UXJUXj

O

"IT

mJKXTV

ENGINE WIRING

- ENG

AD

89

GAS

ENGINE WIRING CONNECTOR

J938W-11

Page 617 of 1502

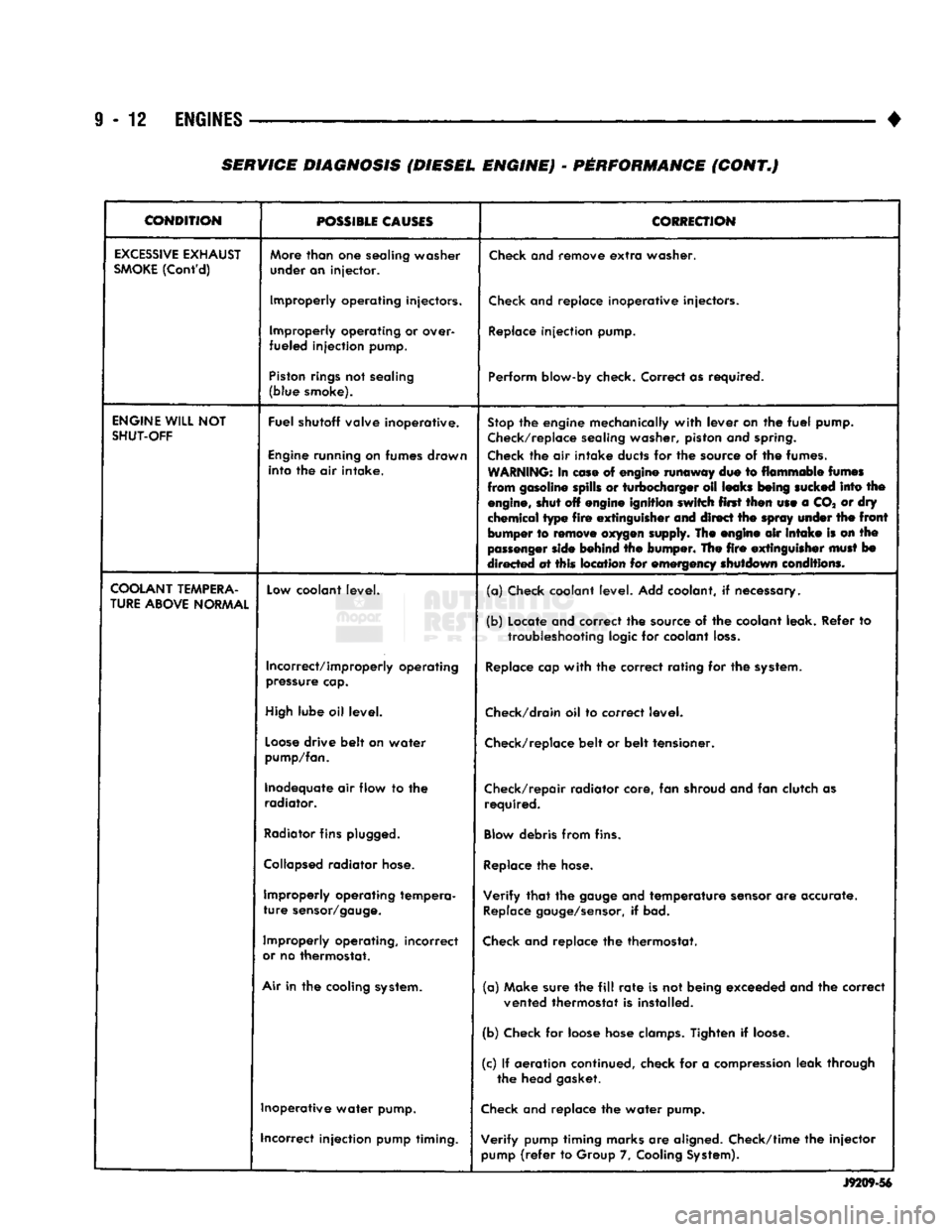

9

- 12

ENGINES

•

CONDITION

POSSIBLE

CAUSES

CORRECTION

EXCESSIVE

EXHAUST

SMOKE

(Cont'd)

More

than

one

sealing washer

under an injector.

Check

and remove

extra

washer.

Improperly operating injectors.

Check

and replace inoperative injectors.

Improperly operating or over-

fueled injection pump.

Replace

injection pump.

Piston

rings

not sealing

(blue smoke). Perform blow-by check. Correct as required.

ENGINE

WILL

NOT

SHUT-OFF

Fuel shutoff valve inoperative.

Engine

running on fumes drawn into the air intake.

Stop

the engine mechanically

with

lever on the

fuel

pump.

Check/replace

sealing washer, piston and

spring.

Check

the air intake ducts for the source of the fumes.

WARNING:

In

ease

of engine runaway due to flammable

fumes

from gasoline spills or turbocharger oil leaks

being

sucked

into the

engine,

shut off engine ignition switch first then use a CO* or dry

chemical type

fire

extinguisher

and direct the

spray

under

the

front

bumper to

remove

oxygen

supply. The engine air

intake

is on the

passenger

side

behind the bumper. The

fire

extinguisher

must

bo

directed at this location for emergency shutdown conditions.

COOLANT

TEMPERA

TURE

ABOVE

NORMAL

Low

coolant level.

(a) Check coolant level. Add coolant, if necessary.

(b) Locate and correct the source of the coolant leak. Refer to

troubleshooting

logic for coolant

loss.

Incorrect/improperly operating

pressure

cap.

Replace

cap

with

the correct rating for the

system.

High

lube oil level.

Check/drain

oil to correct level.

Loose

drive belt on water

pump/fan.

Check/replace

belt or belt tensioner.

Inadequate air flow to the radiator. Check/repair radiator core, fan shroud and fan clutch as

required.

Radiator

fins

plugged.

Blow

debris from fins.

Collapsed

radiator

hose.

Replace

the

hose.

Improperly operating tempera

ture

sensor/gauge.

Verify

that

the

gauge

and temperature

sensor

are accurate.

Replace

gauge/sensor,

if bad.

Improperly operating, incorrect

or

no thermostat.

Check

and replace the thermostat.

Air

in the cooling

system.

(a) Make sure the

fill

rate

is not being exceeded and the correct

vented thermostat is installed.

(b) Check for loose hose

clamps.

Tighten if

loose.

(c) If aeration continued, check for a

compression

leak through the head gasket.

Inoperative water pump.

Check

and replace the water pump.

incorrect injection pump timing. Verify pump timing marks are aligned. Check/time the injector

pump

(refer

to Group 7,

Cooling

System).

J9209-56

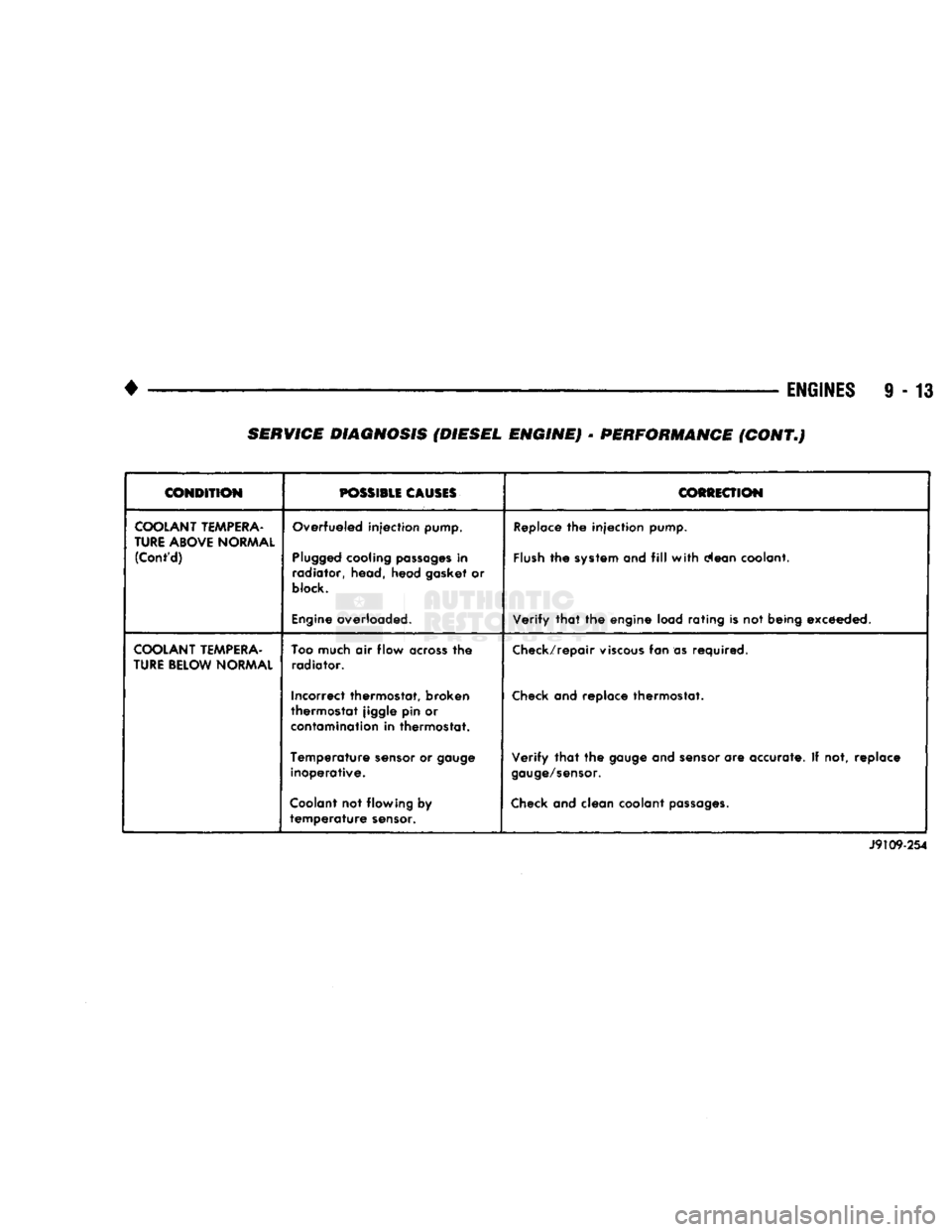

SERVICE DIAGNOSIS (DIESEL ENGINE) - PERFORMANCE (CONT.)

Page 618 of 1502

•

ENGINES

9 - 13

CONDITION

POSSIBLE

CAUSES

COfiiiECTION

COOLANT

TEMPERA

TURE

ABOVE

NORMAL

(Cont'd)

Overfueled injection pump.

Plugged

cooling

passages

in

radiator, head, head gasket or

block.

Engine

overloaded.

Replace

the injection

pump.

Flush

the

system

and

fill

with

clean coolant.

Verify

that

the engine load rating is not being exceeded.

COOLANT

TEMPERA

TURE

BELOW

NORMAL

Too

much air flow

across

the

radiator.

Incorrect thermostat, broken

thermostat jiggle pin or

contamination

in thermostat.

Temperature

sensor

or

gauge

inoperative.

Coolant

not flowing by

temperature

sensor.

Check/repair

viscous

fan as required.

Check

and replace thermostat.

Verify

that

the

gauge

and

sensor

are accurate. If not, replace

gauge/sensor.

Check

and clean coolant

passages.

J9109-254

SERVICE DIAGNOSIS (DIESEL ENGINE) • PERFORMANCE (CONT.)

Page 758 of 1502

5.9L

(DIESEL)

ENGINE

9 - 155

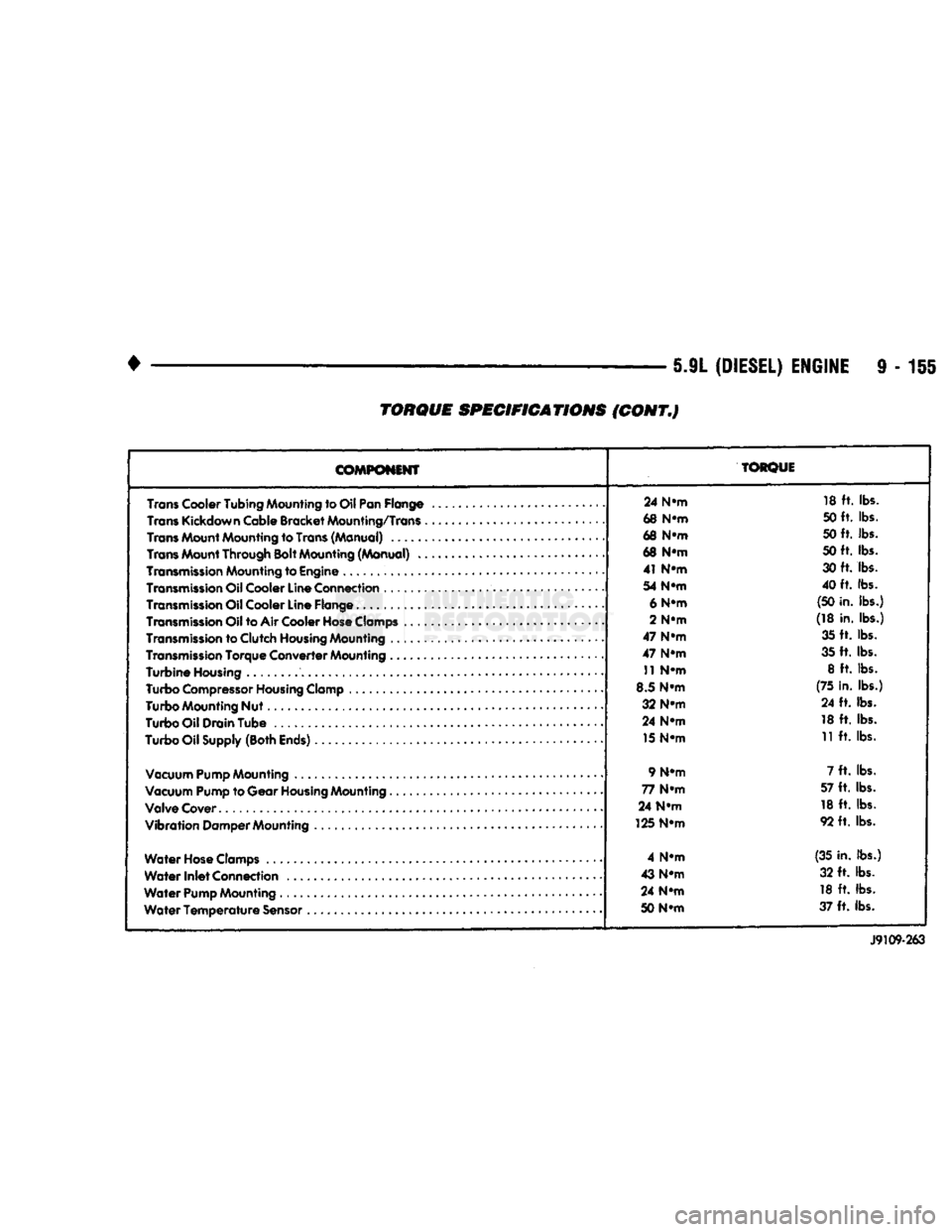

TORQUE SPECIFICATIONS (CONT.)

COMPONENT

TORQUE

24 N-m 18 ft. lbs.

Trans

Kickdown Cable

Bracket

Mounting/Trans

68 N-m 50 ft. lbs.

68 N-m 50 ft. lbs.

68 N-m 50 ft. lbs.

41 N-m 30 ft. lbs.

54 N-m 40 ft. lbs.

Transmission

Oil Cooler

Line

Flange........

......... .. ......

6

N-m

(50

in.

lbs.)

Transmission

Oil to Air Cooler

Hose

Clamps

2

N-m

(18 in. lbs.)

Transmission

to

Clutch

Housing

Mounting

• 47 N-m

35 ft. lbs.

Transmission

Torque

Converter

Mounting

47 N-m 35 ft. lbs.

Turbine

Housing

11

N-m 8 ft. lbs.

Turbo

Compressor

Housing

Clamp

8.5 N-m (75

in.

lbs.)

Turbo

Mounting

Nut 32 N-m 24 ft. lbs.

Turbo

Oil

Drain

Tube

• 24 N-m

18 ft. lbs.

Turbo

Oil

Supply

(Both

Ends)

.

15

N-m

11

ft.

lbs.

Vacuum

Pump

Mounting

9

N-m

7 ft. lbs.

Vacuum Pump to

Gear

Housing

Mounting

77 N-m 57 ft. lbs.

Valve

Cover.

24 N-m

18 ft. lbs.

Vibration

Damper

Mounting

125 N-m

92 ft. lbs.

Water

Hose

Clamps

4 N-m (35

in.

lbs.)

Water

Inlet

Connection

43 N-m

32 ft. lbs.

Water

Pump

Mounting

24 N-m

18 ft. lbs.

Water

Temperature

Sensor

50 N-m 37 ft. lbs.

J9109-263

Page 778 of 1502

EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 19

EXHAUST

MANIFOLD

GASKET

J9111-52

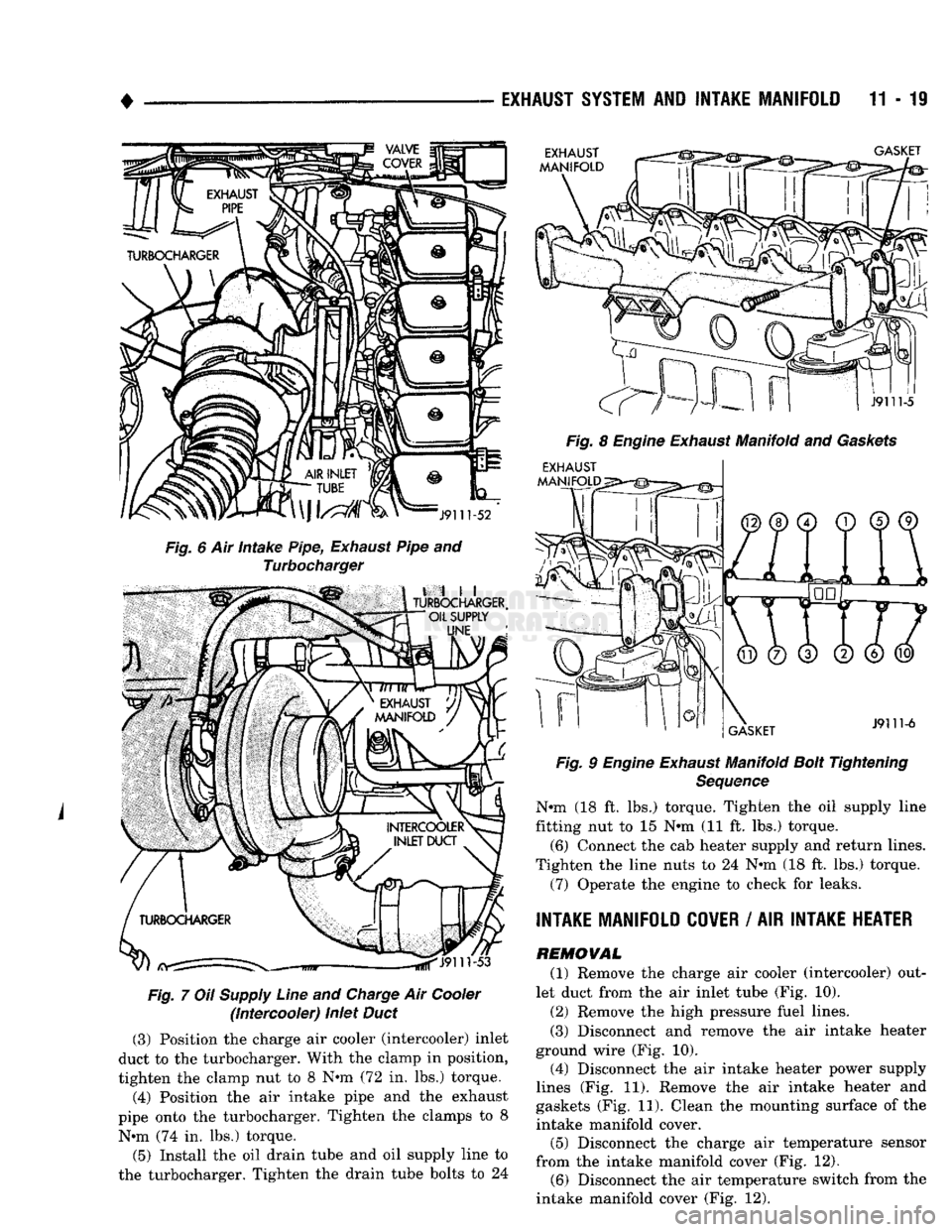

Fig.

6 Air intake Pipe,

Exhaust

Pipe and

Turbocharger

,

till

TURBOCHARGER,

OIL SUPPLY

UNE

^J9111-53

Fig.

7

OH

Supply Line and Charge Air Cooler (intercooler) inlet

Duct

(3) Position the charge air cooler (intercooler) inlet

duct to the turbocharger. With the clamp in position,

tighten the clamp nut to 8 Nun (72 in. lbs.) torque.

(4) Position the air intake pipe and the exhaust

pipe onto the turbocharger. Tighten the clamps to 8 Nun (74 in. lbs.) torque.

(5) Install the oil drain tube and oil supply line to

the turbocharger. Tighten the drain tube bolts to 24

J9111-5

Fig.

8

Engine

Exhaust

Manifold and

Gaskets

EXHAUST

MANIFOLD^^^^

GASKET

J9111-6

Fig.

9

Engine

Exhaust

Manifold

Bolt

Tightening

Sequence

Nun (18 ft. lbs.) torque. Tighten the oil supply line

fitting nut to 15 Nun (11 ft. lbs.) torque. (6) Connect the cab heater supply and return lines.

Tighten the line nuts to 24 Nun (18 ft. lbs.) torque. (7) Operate the engine to check for leaks.

INTAKE MANIFOLD COVER / AIR INTAKE HEATER

REMOVAL (1) Remove the charge air cooler (intercooler) out

let duct from the air inlet tube (Fig. 10). (2) Remove the high pressure fuel lines. (3) Disconnect and remove the air intake heater

ground wire (Fig. 10). (4) Disconnect the air intake heater power supply

lines (Fig. 11). Remove the air intake heater and

gaskets (Fig. 11). Clean the mounting surface of the

intake manifold cover. (5) Disconnect the charge air temperature sensor

from the intake manifold cover (Fig. 12). (6) Disconnect the air temperature switch from the

intake manifold cover (Fig. 12).

Page 779 of 1502

11-20 EXHAUST

SYSTEM

AND

INTAKE MANIFOLD

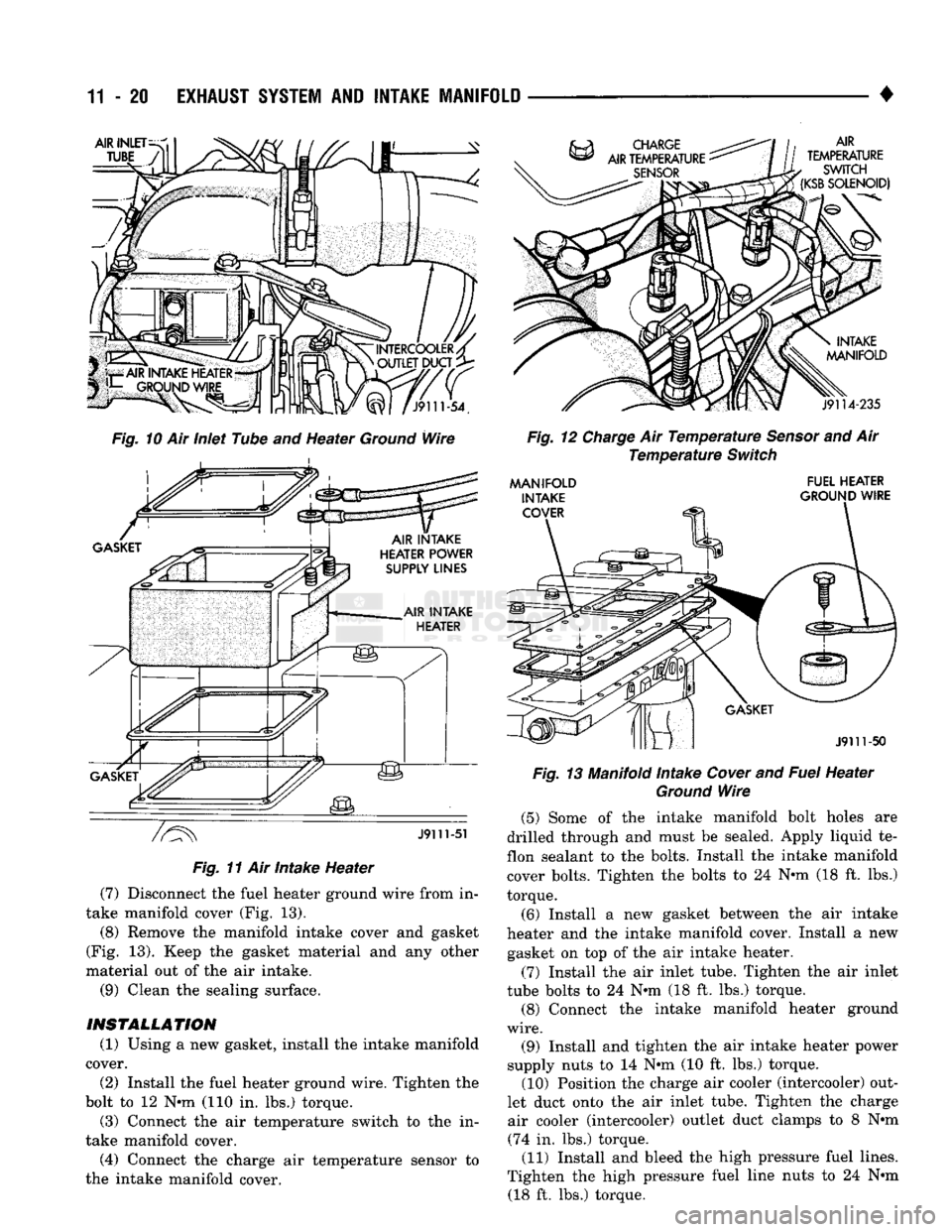

AIR INLET

INTERCOOLER/ OUTLET DUCT

X^l

/J9111-54.

Fig.

10 Air Inlet Tube and Heater

Ground

Wire

J9111-51

Fig.

11 Air Intake Heater (7) Disconnect the fuel heater ground wire from in

take manifold cover (Fig. 13).

(8) Remove the manifold intake cover and gasket

(Fig. 13). Keep the gasket material and any other

material out of the air intake.

(9) Clean the sealing surface.

INSTALLATION

(1) Using a new gasket, install the intake manifold

cover. (2) Install the fuel heater ground wire. Tighten the

bolt to 12 Nun (110 in. lbs.) torque.

(3) Connect the air temperature switch to the in

take manifold cover.

(4) Connect the charge air temperature sensor to

the intake manifold cover.

AIR

TEMPERATURE

SWITCH

(KSB

SOLENOID)

J9114-235

Fig.

12

Charge

Air

Temperature

Sensor

and Air

Temperature

Switch

AAANIFOLD INTAKE COVER FUEL HEATER

GROUND WIRE

J9111-50

Fig.

13 Manifold Intake

Cover

and

Fuel

Heater

Ground

Wire

(5) Some of the intake manifold bolt holes are

drilled through and must be sealed. Apply liquid te

flon sealant to the bolts. Install the intake manifold

cover bolts. Tighten the bolts to 24 Nun (18 ft. lbs.)

torque.

(6) Install a new gasket between the air intake

heater and the intake manifold cover. Install a new gasket on top of the air intake heater.

(7) Install the air inlet tube. Tighten the air inlet

tube bolts to 24 Nun (18 ft. lbs.) torque. (8) Connect the intake manifold heater ground

wire.

(9) Install and tighten the air intake heater power

supply nuts to 14 Nun (10 ft. lbs.) torque. (10) Position the charge air cooler (intercooler) out

let duct onto the air inlet tube. Tighten the charge air cooler (intercooler) outlet duct clamps to 8 Nun (74 in. lbs.) torque. (11) Install and bleed the high pressure fuel lines.

Tighten the high pressure fuel line nuts to 24 Nun (18 ft. lbs.) torque.

Page 848 of 1502

•

FUEL

SYSTEM

14-29

MULTI-PORT

FUEL

INJECTION

(MPI)-COMPONENT DESCRIPTION/SYSTEM

OPERATION-EXCEPT DIESEL

INDEX

page

Air

Conditioning (A/C) Clutch

Relay-Pern

Output

. 35

Air

Conditioning (A/C)

Controls—PCM

Input

.... 31

Auto

Shut

Down

(ASD)

Relay-PCM

Output

. ... 36

Automatic

Shut

Down

(ASD)

Sense-PCM

Input

. 31

Battery

Voltage-PCM

Input

32

Brake

Switch-PCM

Input

32

Camshaft

Position

Sensor—PCM

Input

32

Charge

Air

Temperature

Sensor—PCM

Input

. . . 32

Crankshaft

Position

Sensor-PCM

Input

.......

32

Electric

Exhaust

Gas Recirculation Transducer

(EET)

Solenoid-PCM

Output

...

.......

36

Engine

Coolant Temperature

Sensor—PCM

Input

. 33

EVAP

Canister

Purge

Solenoid—PCM

Output

. . . 37

Fuel

Injectors-PCM Output

37

Fuel

Pressure

Regulator

41

Fuel

Rail

41

General

Information

.......................

29

Generator

Field-PCM

Output

36

Generator

Lamp-PCM

Output

36

Idle

Air

Control

(IAC)

Motor-PCM

Output

......

36

Ignition

Circuit

Sense—PCM

Input

33

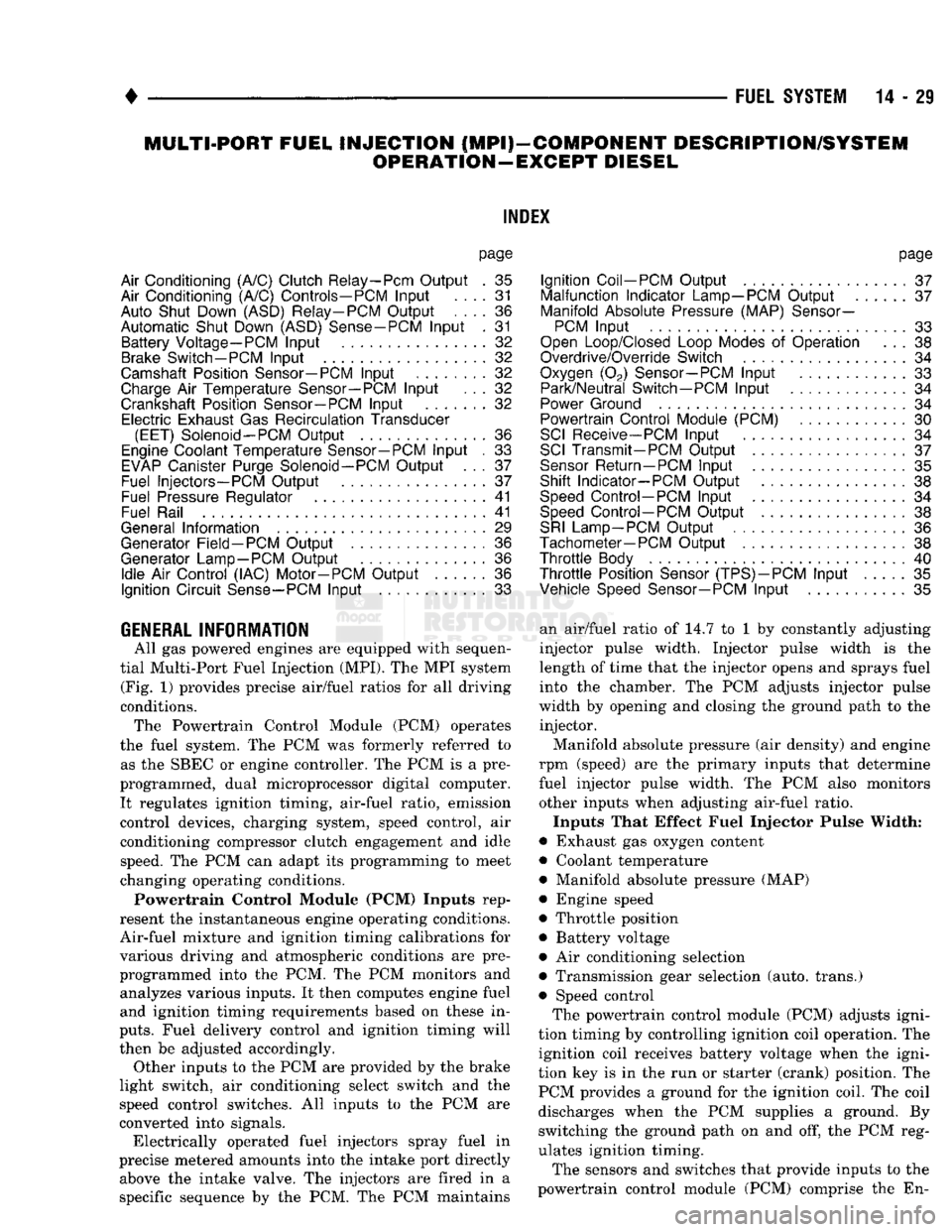

GENERAL

INFORMATION

All

gas

powered engines

are

equipped with sequen

tial Multi-Port Fuel Injection (MPI).

The MPI

system (Fig.

1)

provides precise air/fuel ratios

for all

driving

conditions. The Powertrain Control Module

(PCM)

operates

the fuel system.

The PCM was

formerly referred

to

as

the

SBEC

or

engine controller.

The PCM is a

pre

programmed, dual microprocessor digital computer. It regulates ignition timing, air-fuel ratio, emission

control devices, charging system, speed control,

air

conditioning compressor clutch engagement

and

idle speed.

The PCM can

adapt

its

programming

to

meet

changing operating conditions.

Powertrain Control Module (PCM) Inputs rep

resent

the

instantaneous engine operating conditions.

Air-fuel mixture

and

ignition timing calibrations

for

various driving

and

atmospheric conditions

are

pre

programmed into

the PCM. The PCM

monitors

and

analyzes various inputs.

It

then computes engine fuel

and ignition timing requirements based

on

these

in

puts.

Fuel delivery control

and

ignition timing will

then

be

adjusted accordingly. Other inputs

to the

PCM

are

provided

by the

brake

light switch,

air

conditioning select switch

and the

speed control switches.

All

inputs

to the PCM are

converted into signals. Electrically operated fuel injectors spray fuel

in

precise metered amounts into

the

intake port directly above

the

intake valve.

The

injectors

are

fired

in a

specific sequence

by the PCM. The PCM

maintains

page

Ignition

Coil-PCM

Output

37

Malfunction Indicator

Lamp—PCM

Output

37

Manifold

Absolute

Pressure

(MAP)

Sensor-

PCM

Input

33

Open

Loop/Closed

Loop

Modes

of

Operation

. . . 38

Overdrive/Override

Switch

34

Oxygen

(02)

Sensor—PCM

Input

33

Park/Neutral

Switch—PCM

Input

34

Power

Ground

34

Powertrain Control Module

(PCM)

30

SCI

Receive-PCM

Input

. 34

SCI

Transmit-PCM

Output

37

Sensor

Return

—PCM

Input

35

Shift Indicator-PCM Output

38

Speed

Control-PCM

Input

34

Speed

Control-PCM

Output

38

SRI

Lamp-PCM

Output

36

Tachometer—PCM

Output

38

Throttle

Body

40

Throttle

Position

Sensor

(TPS)-PCM

Input

35

Vehicle

Speed

Sensor-PCM

Input

35

an air/fuel ratio

of 14.7 to 1 by

constantly adjusting

injector pulse width. Injector pulse width

is the

length

of

time that

the

injector opens

and

sprays fuel into

the

chamber.

The PCM

adjusts injector pulse

width

by

opening

and

closing

the

ground path

to the

injector.

Manifold absolute pressure

(air

density)

and

engine

rpm (speed)

are the

primary inputs that determine

fuel injector pulse width.

The PCM

also monitors

other inputs when adjusting air-fuel ratio.

Inputs That Effect Fuel Injector Pulse Width:

• Exhaust

gas

oxygen content

• Coolant temperature

• Manifold absolute pressure (MAP)

• Engine speed

• Throttle position

• Battery voltage •

Air

conditioning selection

• Transmission gear selection (auto, trans.)

• Speed control The powertrain control module (PCM) adjusts igni

tion timing

by

controlling ignition coil operation.

The

ignition coil receives battery voltage when

the

igni

tion

key is in the run or

starter (crank) position.

The

PCM provides

a

ground

for the

ignition coil.

The

coil

discharges when

the PCM

supplies

a

ground.

By

switching

the

ground path

on and off, the PCM

reg

ulates ignition timing.

The sensors

and

switches that provide inputs

to the

powertrain control module

(PCM)

comprise

the En-

Page 849 of 1502

14

- 30

FUEL

SYSTEM

INPUTS

OUTPUTS

POWERTRAIN

CONTROL

MODULE

DRB

II

SCAN

TOOL

SPEED

CONTROL

BRAKE

SWITCH

A/C

LOW

PRESSURE

CUTOFF

SWITCH VEHICLE

SPEED

SENSOR PARK/NEUTRAL

SWITCH TORQUE CONVERTER

CLUTCH SOLENOID

MALFUNCTION

INDICATOR

LAMP

m

HEATED

i

*OXYGEN SENSOR ENGINE

COOLANT

yy

BATTERY

TEMPERATURE

SENSOR

MAP SENSOR

i—r

CHARGE

AIR

TEMPERATURE

SENSOR

AIR CHARGE

TEMPERATURE

SENSOR

DISTRIBUTOR

WITH

CAMSHAFT

r

POSITION

SENSOR

(|

TACHOMETER

A/C

CLUTCH RELAY

AUTO

SHUTDOWN

RELAY OVERDRIVE

SOLENOID

IDLE AIR

CONTROL MOTOR

SPEED

CONTROL

SHIFT

INDICATOR

LAMP

EMISSION

CONTROL SOLENOIDS

IGNITION

COIL

OVERDRIVE

OVERRIDE SWITCH

ASD

SENSE

FUEL

INJECTORS

PARK

THROTTLE

SOLENOID

GENERATOR CRANKSHAFT

POSITION FUEL

PUMP

RELAY

J9314-117

Fig.

1 Multi-Port

Fuel

Injection

Components—Except

Diesel

gine Control System. It is also comprised of the PCM Outputs (engine control devices that the are operated

by the PCM).

SYSTEM DIAGNOSIS

The powertrain control module (PCM) tests many

of its own input and output circuits. If a diagnostic

trouble code (DTC) is found in a major system, this information is stored in the PCM memory. Refer to

On-Board Diagnostics in the Multi-Port Fuel Injec

tion—General Diagnosis—Except Diesel section of

this group for DTC information.

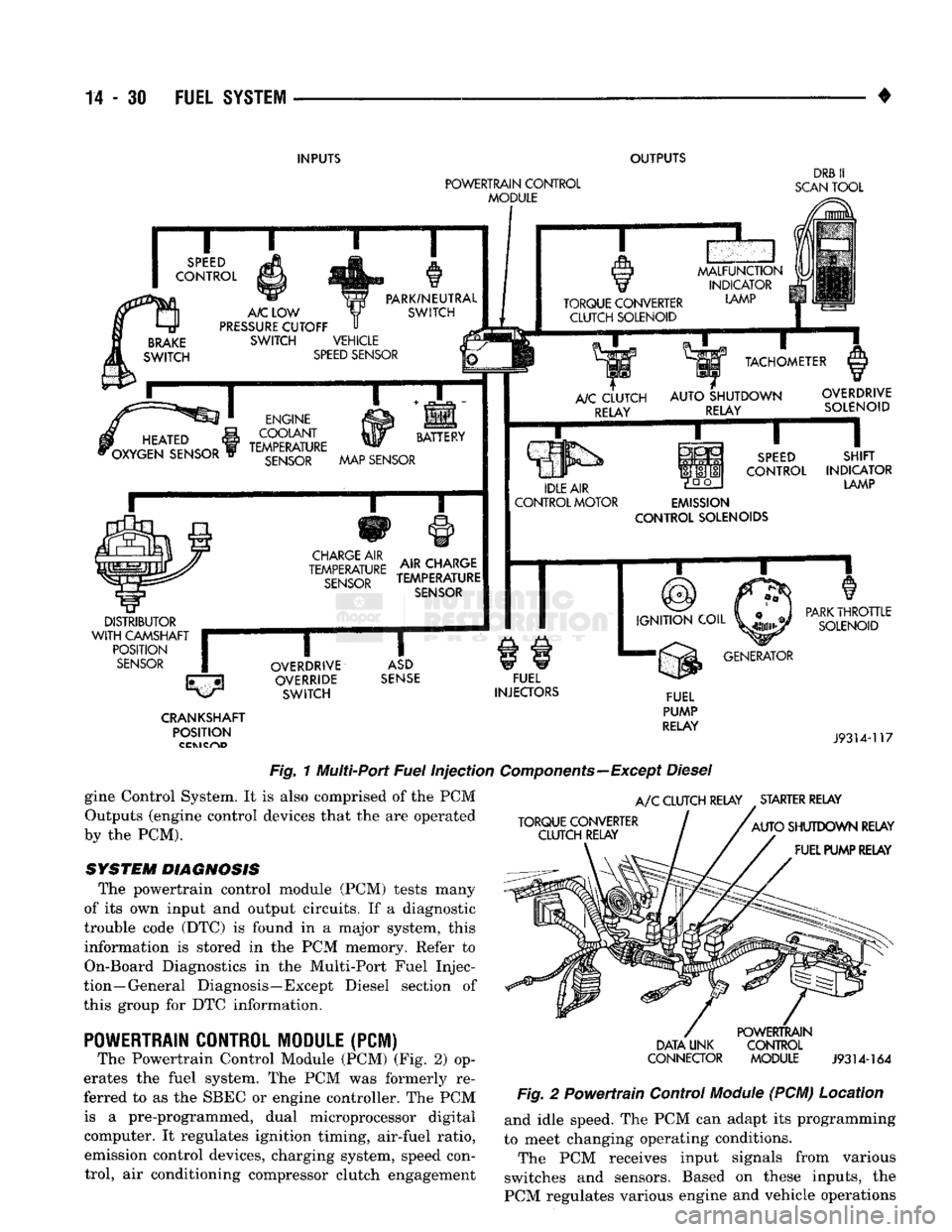

POWERTRAIN

CONTROL MODULE (PCM)

The Powertrain Control Module (PCM) (Fig. 2) op

erates the fuel system. The PCM was formerly re

ferred to as the SBEC or engine controller. The PCM is a pre-programmed, dual microprocessor digital computer. It regulates ignition timing, air-fuel ratio, emission control devices, charging system, speed control, air conditioning compressor clutch engagement

A/C

CLUTCH RELAY STARTER RELAY

TORQUE CONVERTER CLUTCH RELAY

AUTO

SHUTDOWN RELAY

FUEL PUMP RELAY

DATA UNK

CONNECTOR

POWERTRAIN

CONTROL MODULE

J9314-164

Fig.

2 Powertrain Control

Module

(PCM) Location and idle speed. The PCM can adapt its programming

to meet changing operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations