DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1101 of 1502

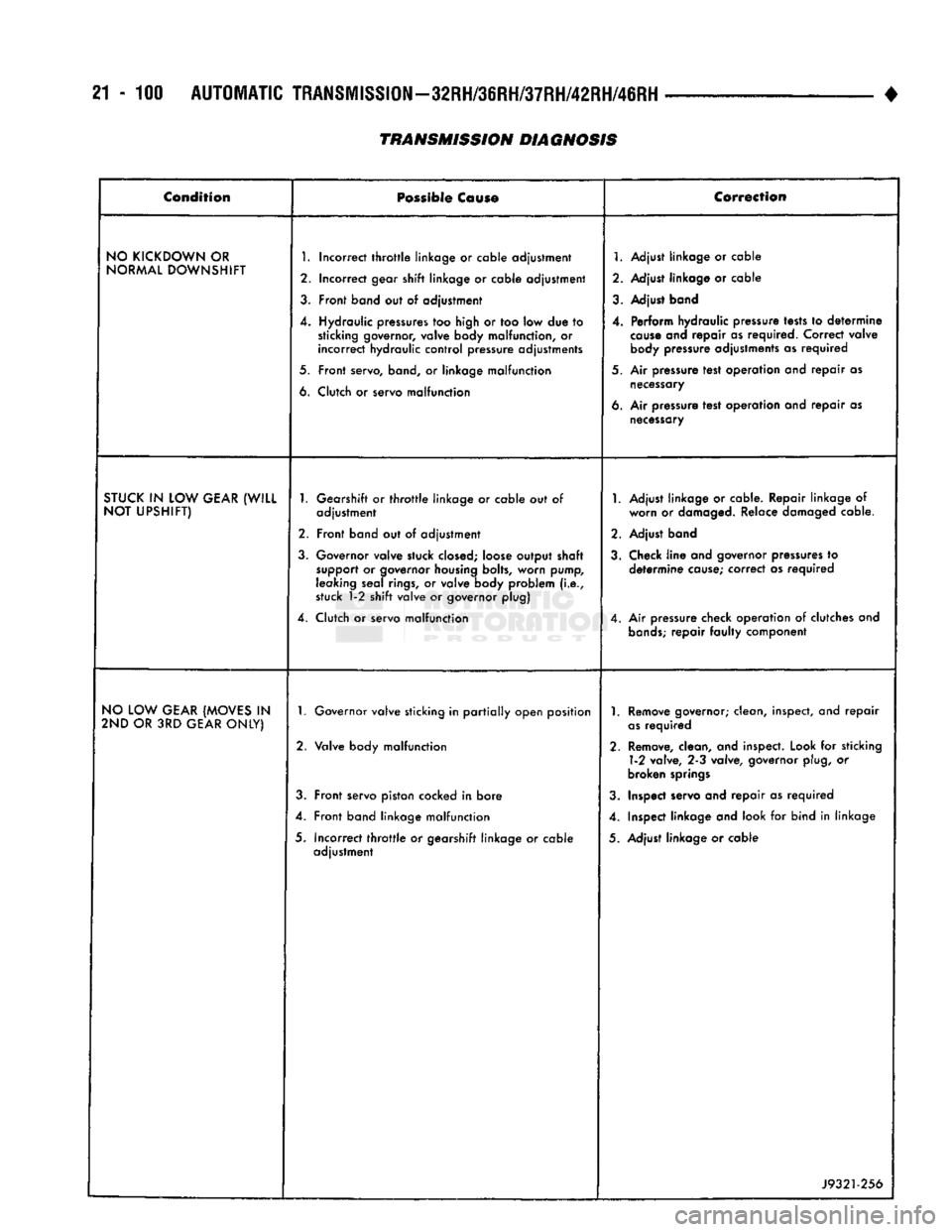

21-100

AUTOMATIC

TRANSMISSION-32RH/36RH/37RH/42RH/46RH

• Condition

Possibie

Cause Correction

NO KICKDOWN

OR

NORMAL DOWNSHIFT

1.

Incorrect

throttle

linkage

or

cable adjustment

2.

Incorrect gear

shift

linkage

or

cable adjustment

3.

Front band

out of

adjustment

4

Hydraulic

pressures

too high

or

too low due

to

sticking governor, valve body malfunction,

or

incorrect

hydraulic

control

pressure adjustments

5.

Front

servo,

band,

or

linkage malfunction

6.

Clutch

or

servo malfunction

1.

Adjust linkage

or

cable

2.

Adjust linkage

or

cable

3.

Adjust band

4.

Perform hydraulic

pressure

tests

to

determine

cause

and repair

as

required. Correct valve

body

pressure

adjustments as required

5.

Air

pressure

test

operation and repair as

necessary

6.

Air

pressure

test

operation and repair as

necessary

STUCK

IN

LOW GEAR

(WILL

NOT UPSHIFT)

1.

Gearshift

or throttle

linkage

or

cable out

of

adjustment

2.

Front band

out of

adjustment

3.

Governor valve stuck

closed;

loose

output

shaft support

or

governor

housing

bolts, worn pump,

leaking seal rings,

or

valve body problem (i.e.,

stuck 1-2

shift

valve

or

governor plug)

4.

Clutch

or

servo malfunction

1.

Adjust linkage

or

cable. Repair linkage

of

worn

or

damaged.

Relace

damaged

cable.

2.

Adjust band

3.

Check

line

and governor

pressures

to

determine

cause;

correct

as required

4.

Air

pressure

check operation

of

clutches and

bands;

repair

faulty

component

NO LOW GEAR (MOVES

IN

2ND OR 3RD GEAR ONLY)

1.

Governor valve sticking

in

partially

open position

2.

Valve body malfunction

3.

Front servo piston cocked

in

bore

4.

Front band linkage malfunction

5.

Incorrect

throttle or

gearshift linkage

or

cable adjustment

1.

Remove

governor; clean, inspect, and repair

as

required

2.

Remove,

clean, and inspect. Look

for

sticking 1-2 vafve, 2-3 valve, governor plug,

or

broken springs

3.

Inspect servo and repair as required

4.

Inspect linkage and look

for

bind

in

linkage

5.

Adjust linkage

or

cable

J9321-256

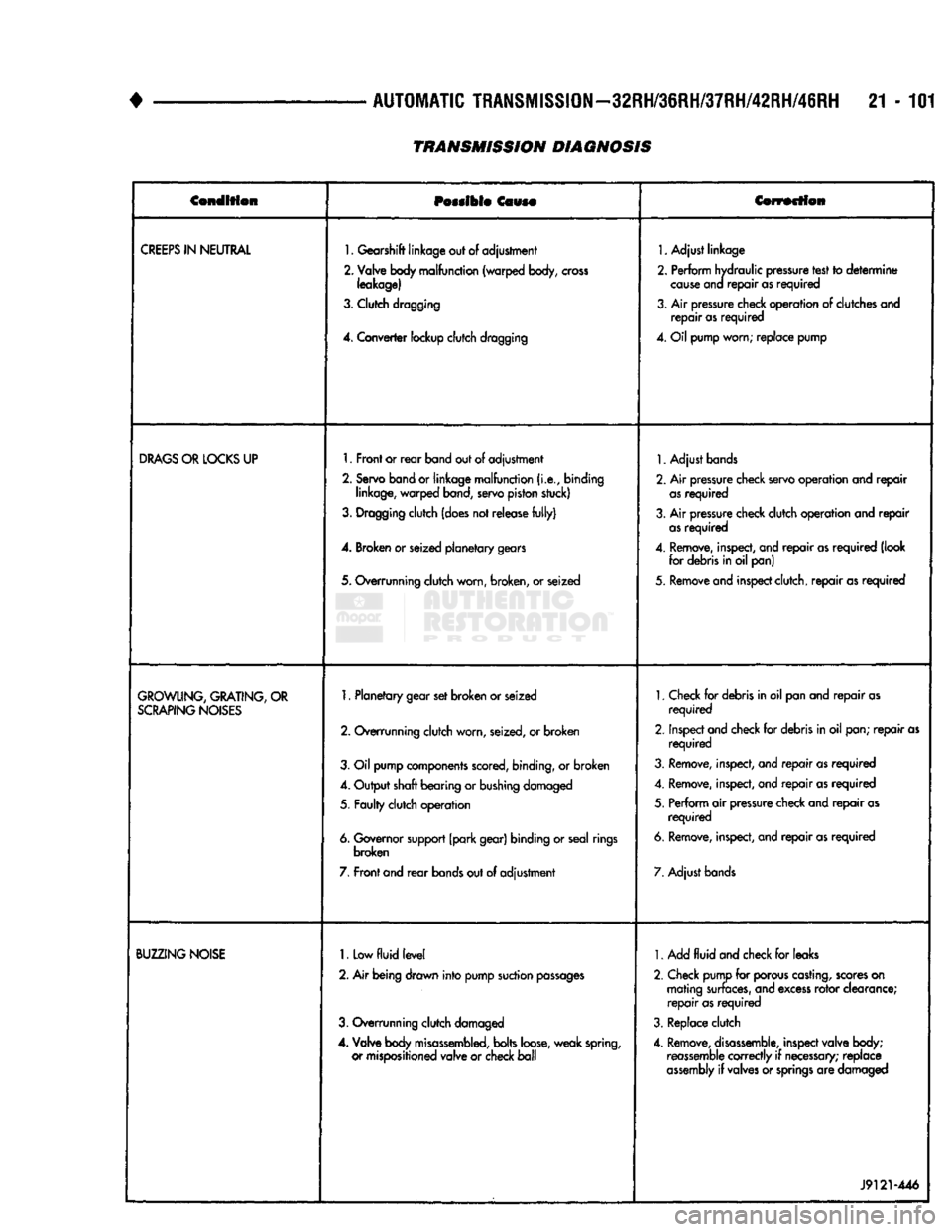

TRANSMISSION DIAGNOSIS

Page 1102 of 1502

+

AUTOMATIC TRANSMISSION—32RH/36RH/37RH/42RH/46RH 21 - 101

TRANSMISSION DIAGNOSIS

Condition

Possible

Cause Correction

CREEPS

IN

NEUTRAL

1. Gearshift linkage out of adjustment

2. Valve body malfunction (warped body,

cross

leakage)

3. Clutch dragging

4.

Converter lockup clutch dragging 1. Adjust linkage

2. Perform hydraulic pressure test to

determine

cause

ana

repair

as

required

3. Air pressure check operation of clutches and

repair

as

required

4. Oil pump worn; replace pump

DRAGS

OR

LOCKS

UP 1. Front or

rear

band out of adjustment

2. Servo band or linkage malfunction

(i.e.,

binding linkage, warped band, servo piston stuck)

3. Dragging clutch (does not release

fully)

4. Broken or seized planetary gears

5. Overrunning clutch worn, broken, or seized 1. Adjust bands

2. Air pressure check servo operation and

repair

as

required

3. Air pressure check clutch operation and

repair

as

required

4. Remove, inspect, and

repair

as

required

(look for debris in oil pan)

5. Remove and inspect clutch,

repair

as

required

GROWLING,

GRATING,

OR

SCRAPING

NOISES

1. Planetary gear set broken or seized

2. Overrunning clutch worn, seized, or broken

3. Oil pump components scored, binding, or broken

4. Output shaft bearing or bushing damaged

5. Faulty clutch operation

6. Governor support (park gear) binding or seal rings broken

7. Front and

rear

bands out of adjustment 1. Check for debris in oil pan and

repair

as

required

2. Inspect and check for debris in oil pan;

repair

as

required

3. Remove, inspect, and

repair

as

required

4. Remove, inspect, and

repair

as

required

5. Perform air pressure check and

repair

as

required

6. Remove, inspect, and

repair

as

required

7. Adjust bands

BUZZING

NOISE

1.

Low

fluid

level

2. Air being drawn into pump suction

passages

3. Overrunning clutch damaged

4.

Valve body

misassembled,

bolts loose, weak spring, or mispositioned valve or check

ball

1. Add

fluid

and check for leaks

2. Check pump for porous casting, scores on mating surfaces, and excess rotor clearance;

repair

as

required

3. Replace clutch

4. Remove,

disassemble,

inspect valve body; reassemble correctly if

necessary;

replace

assembly

if valves or

springs

are damaged

J9121-446

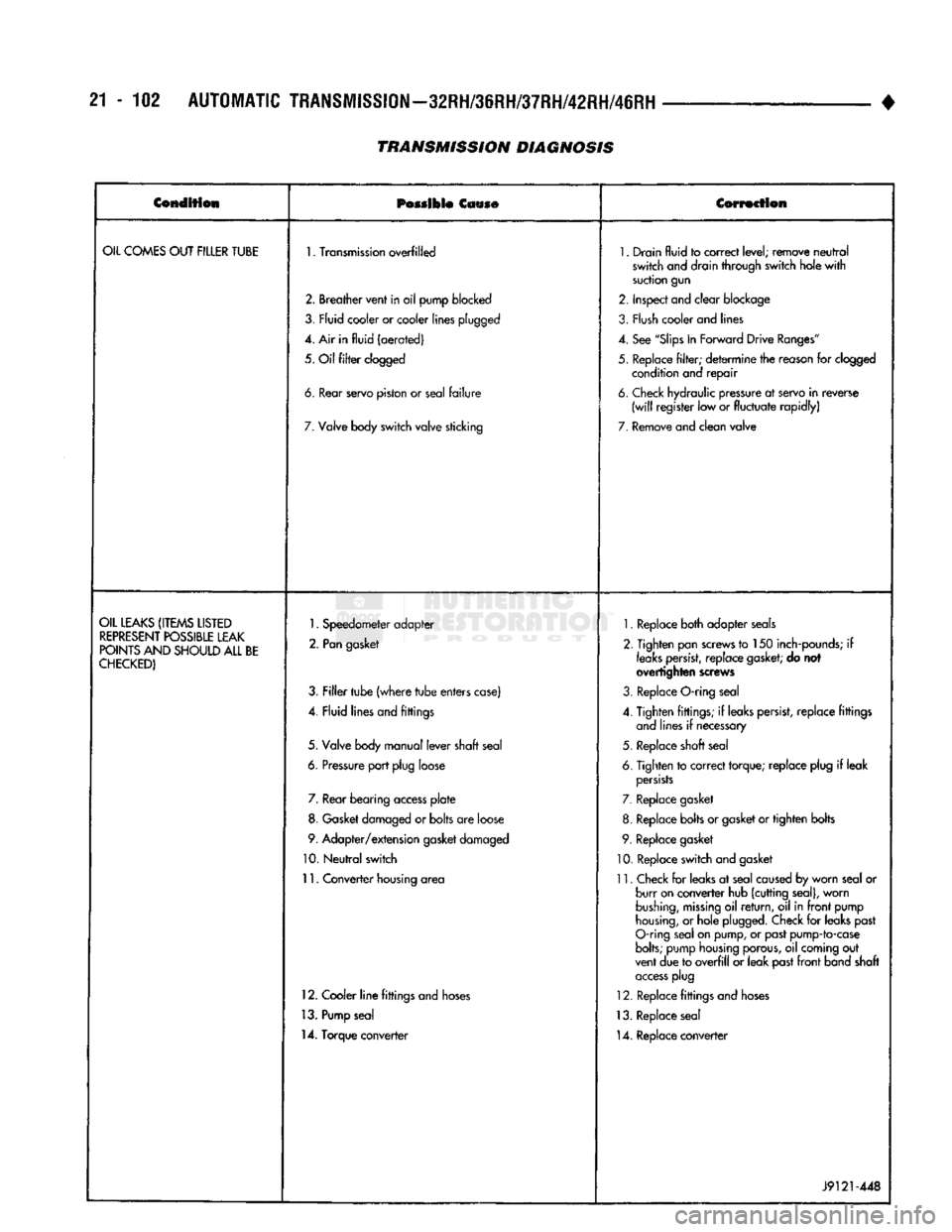

Page 1103 of 1502

21-102

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

TRANSMISSION

DIAGNOSIS

•

Condition

Possible

Cause Correction

OIL

COMES

OUT

FILLER

TUBE

1.

Transmission

overfilled

1.

Drain

fluid

to

correct

level;

remove

neutral

switch

and drain

through

switch

hole

with

suction

gun

2.

Breather

vent

in

oil

pump

blocked

2.

Inspect

and

clear

blockage

3,

Fly id

cooler

or cooler

lines

plugged

3.

Flush

cooler and lines

4. Air in

fluid

(aerated)

4.

See

"Slips

In

Forward

Drive

Ranges"

5.

Oil

filter

clogged

5.

Replace

filter;

determine

the reason for clogged

condition and

repair

6.

tear

servo

piston

or

seal

failure

6.

Check hydraulic pressure at servo

in

reverse

(will

register

low or

fluctuate

rapidly)

7.

Valve body

switch

valve

sticking

7.

Remove

and

clean

valve

OIL

LEAKS

(ITEMS

LISTED

REPRESENT

POSSIBLE

LEAK

POINTS

AND

SHOULD

ALL

BE

CHECKED)

1.

Speedometer

adapter

2.

Pan

gasket

3.

Filler

tube

(where

tube

enters

case)

4.

Fluid

lines

and

fittings

5.

Valve body

manual

lever

shaft

seal

6.

Pressure

port

plug

loose 7. Rear

bearing

access

plate

8. Gasket damaged or

bolts

are loose

9.

Adapter/extension

gasket damaged

10.

Neutral

switch

11.

Converter

housing area

12. Cooler

line

fittings and hoses

13. Pump seal

14. Torque converter

1.

Replace both adapter seals

2. Tighten pan screws to 150 inch-pounds; if

leaks

persist,

replace

gasket;

do not

overtighten screws

3. Replace O-ring seal

4. Tighten fittings; if leaks persist, replace fittings and lines if necessary

5. Replace shaft seal

6. Tighten to correct torque; replace plug if leak

persists

7. Replace gasket

8. Replace bolts or gasket or tighten bolts

9. Replace gasket

10. Replace switch and gasket

11. Check for leaks at seal caused by worn seal or burr on converter hub (cutting seal), worn

bushing,

missing

oil

return,

oil in

front

pump

housing,

or hole plugged. Check for leaks past

O-ring seal on pump, or past pump-to-case

bolts;

pump housing porous, oil coming out

vent due to

overfill

or leak past

front

band shaft

access

plug

12. Replace fittings and hoses

13. Replace seal 14. Replace converter

J9121-448

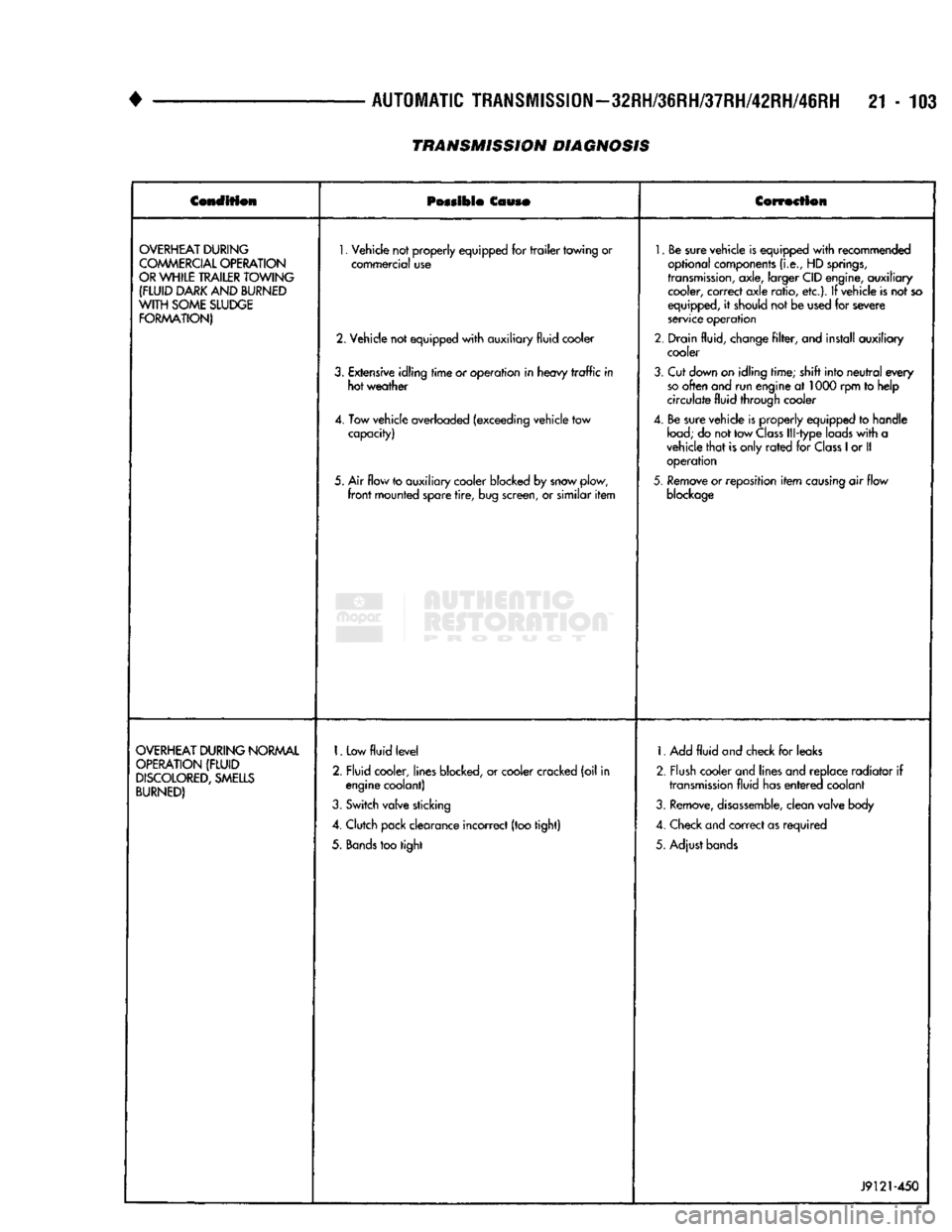

Page 1104 of 1502

•

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

21-103

TRANSMISSION DIAGNOSIS

Condition

Possible

Couso

Correction

OVERHEAT

DURING

COMMERCIAL

OPERATION

OR

WHILE

TRAILER

TOWING

(FLUID

DARK

AND

BURNED

WITH

SOME

SLUDGE

FORMATION)

1.

Vehicle not properly equipped for

trailer

towing or

commercial use

2. Vehicle not equipped

with

auxiliary fluid cooler

3.

Extensive idling

time

or operation in heavy

traffic

in hot weather

4. Tow vehicle overloaded (exceeding vehicle tow capacity)

5. Air flow to auxiliary cooler blocked by snow plow,

front

mounted spare

tire,

bug screen, or similar

item

1.

Be sure vehicle is equipped

with

recommended

optional components

(i.e.,

HD

springs,

transmission,

axle, larger CID engine, auxiliary cooler, correct axle ratio, etc.). If vehicle is not so

equipped, it should not be used for severe

service operation

2. Drain fluid, change

filter,

and install auxiliary cooler

3.

Cut down on idling time; shift into

neutral

every

so

often and run engine at 1000 rpm to help

circulate fluid through cooler

4. Be sure vehicle is properly equipped to handle

load;

do not tow

Class

Ill-type loads

with

a

vehicle

that

is only

rated

for

Class

1

or II operation

5.

Remove or reposition

item

causing

air flow

blockage

OVERHEAT

DURING

NORMAL

OPERATION

(FLUID

DISCOLORED,

SMELLS

BURNED)

1.

Low

fluid

level

2. Fluid cooler, lines blocked, or cooler cracked (oil in engine coolant)

3.

Switch valve sticking

4. Clutch pack clearance incorrect (too tight)

5.

Bands

too tight 1. Add

fluid

and check for leaks

2. Flush cooler and lines and replace radiator if

transmission

fluid has

entered

coolant

3.

Remove,

disassemble,

clean valve body

4. Check and correct as required

5. Adjust bands

J9121-450

Page 1105 of 1502

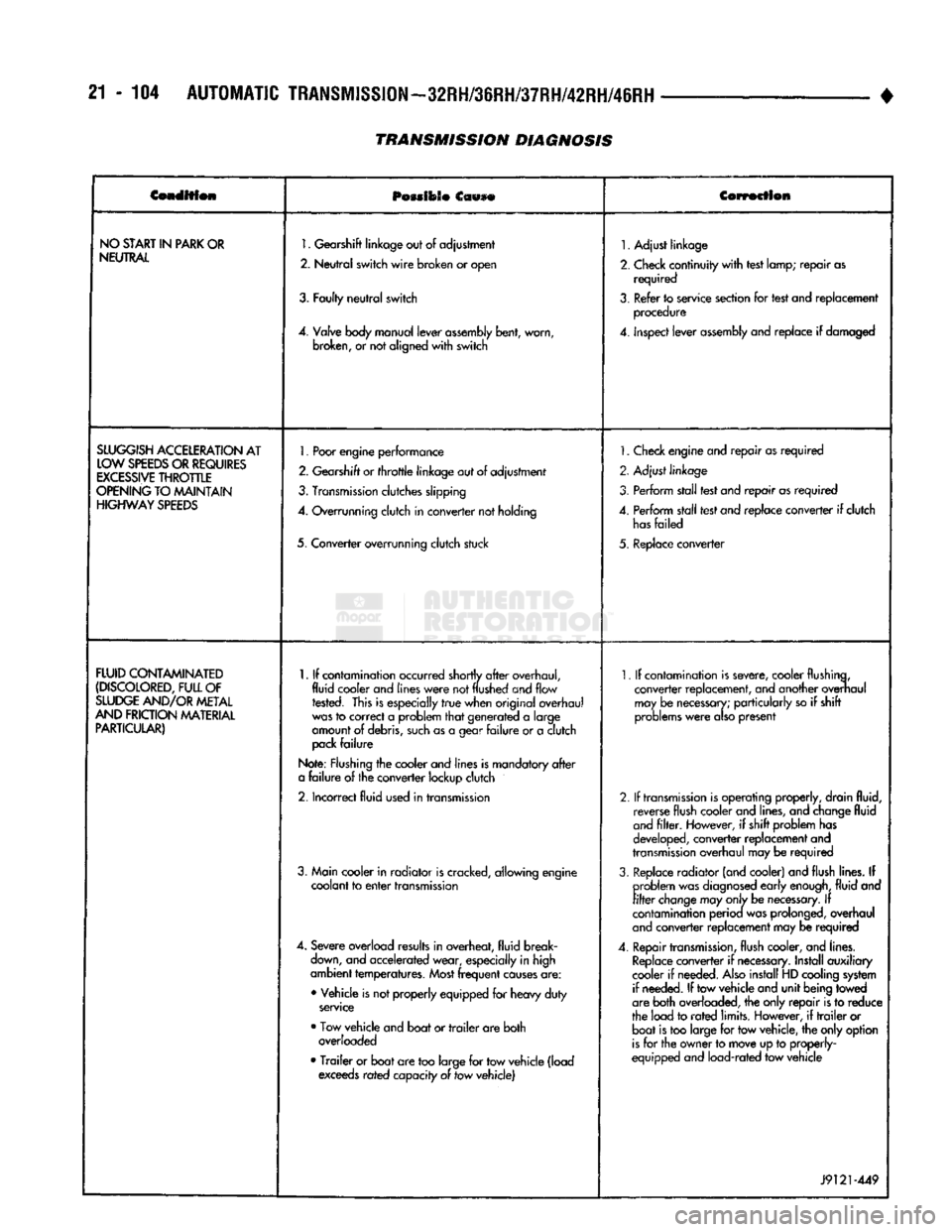

21 - 104

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

•

Condition

POMIOSO

Ccwse

Correction

NO

START

IN

PARK

OR

NEUTRAL

1.

Gearshift

linkage

out

of

adjustment

2.

Neutral

switch

wire

broken

or

open

3.

Faulty

neutral

switch

4.

Valve

body

manual

lever

assembly

bent,

worn,

broken,

or not

aligned

with

switch

1.

Adjust linkage

2.

Check continuity

with

test lamp; repair as required

3.

Refer to service section for test and replacement procedure

4.

inspect lever

assembly

and replace if damaged

SLUGGISH

ACCELERATION

AT

LOW

SPEEDS

OR

REQUIRES

EXCESSIVE

THROTTLE

OPENING

TO MAINTAIN

HIGHWAY

SPEEDS

1.

Poor

engine

performance

2.

Gearshift

or

throttle

linkage

out of adjustment

3.

Transmission

clutches slipping

4.

Overrunning clutch in converter not holding

5. Converter overrunning clutch stuck

1.

Check engine and repair as required

2. Adjust linkage

3. Perform stall test and repair as required

4.

Perform stall test and replace converter if clutch

has

failed

5. Replace converter

FLUID

CONTAMINATED

(DISCOLORED,

FULL

OF

SLUDGE

AND/OR

METAL

AND

FRICTION

MATERIAL

PARTICULAR)

1.

If contamination occurred shortly

after

overhaul,

fluid cooler and

lines

were

not

flushed

and flow rested. This is especially

true

when original overhaul

was

to correct a problem

that

generated a large

amount of debris,

such

as a gear

failure

or a clutch

pack

failure

Note: Flushing the cooler and lines is mandatory

after

a

failure

of the converter lockup clutch

2.

Incorrect fluid used in transmission

3. Main cooler in radiator is cracked, allowing engine coolant to

enter

transmission

4.

Severe overload results in overheat, fluid break

down,

and accelerated wear, especially in high

ambient temperatures.

Most

frequent

causes

are:

• Vehicle is not properly equipped for heavy duty

service

• Tow vehicle and boat or

trailer

are both overloaded

•

Trailer

or boat are too large for tow vehicle (load exceeds rated capacity of tow vehicle)

1.

If contamination is severe, cooler flushing,

converter replacement, and another overhaul may be

necessary;

particularly so if shift

problems

were

also

present

2.

If

transmission

is operating properly, drain fluid, reverse flush cooler and lines, and change fluid

and

filter.

However, if shift problem has

developed, converter replacement and

transmission

overhaul may be required

3.

Replace radiator (and cooler) and flush lines. If problem was

diagnosed

early

enough,

fluid and

filter

change

may

only

be

necessary.

If

contamination perioa was prolonged, overhaul

and

converter replacement may be required

4.

Repair

transmission,

flush cooler, and lines.

Replace

converter if

necessary.

Install auxiliary

cooler if needed.

Also

install HD cooling system if needed. If tow vehicle and unit being towed

are both overloaded, the only repair is to reduce

the load to

rated

limits. However, if

trailer

or boat is too large for tow vehicle, the only option

is

for the owner to move up to properly-

equipped and load-rated tow vehicle

J9121-449

TRANSMISSION DIAGNOSIS

Page 1106 of 1502

•

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

21-105 Condition

Possible

Co

use

Correction

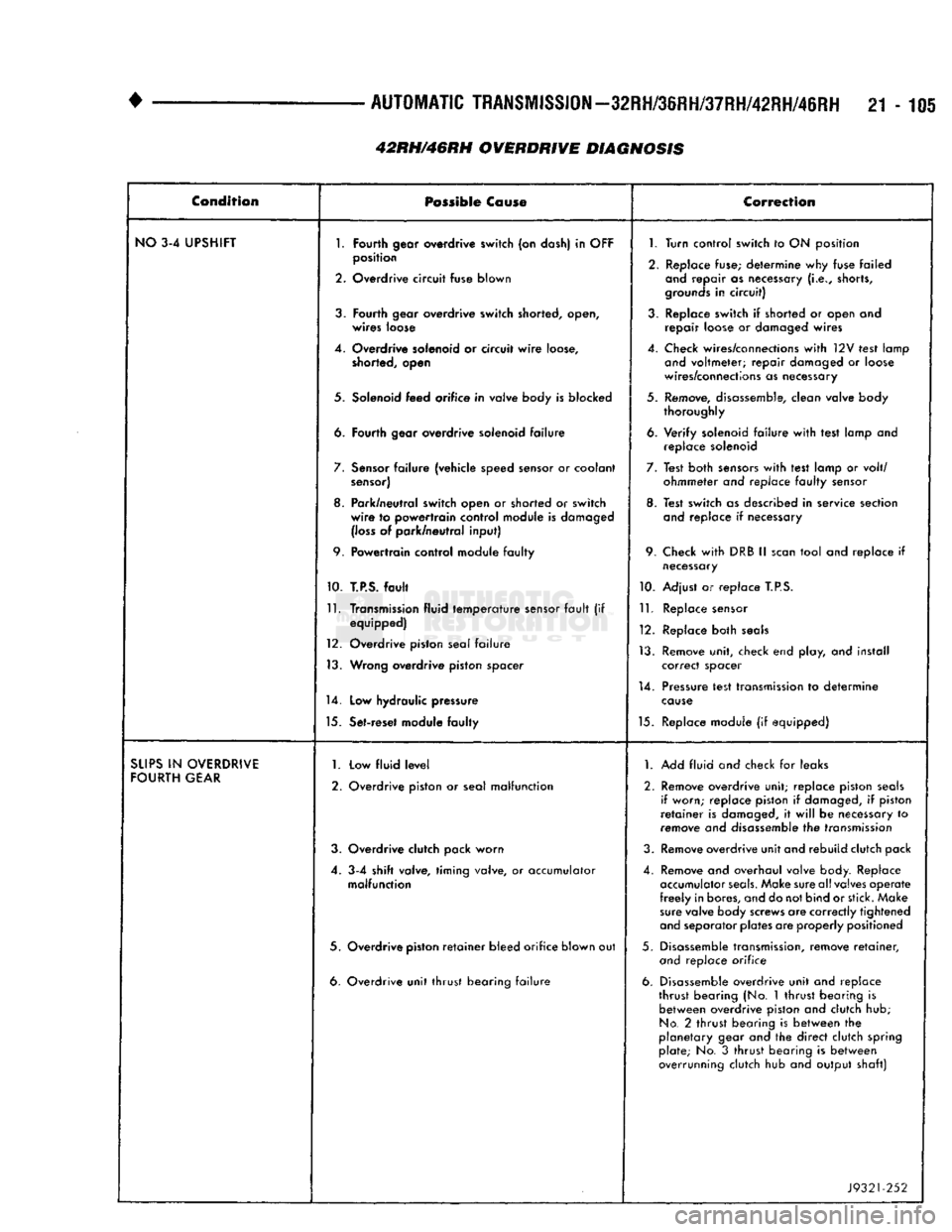

NO

3-4 UPSHIFT

1.

Fourth

gear overdrive

switch

(on dash) in

OFF

1.

Turn control

switch

to ON position

2.

position

Overdrive

circuit

fuse

blown

2. Replace fuse; determine why fuse failed

and

repair as necessary

(i.e.,

shorts,

grounds

in

circuit)

3.

Fourth

gear

overdrive

switch

shorted, open,

wires

loose 3. Replace switch if shorted or open and

repair loose or damaged wires

4. Overdrive solenoid or circuit

wire

loose,

shorted, open 4. Check wires/connections

with

12V test lamp

and

voltmeter; repair damaged or loose

wires/connections as necessary

5. Solenoid

feed

orifice

in valve body is

blocked

5. Remove, disassemble, clean valve body

thoroughly

6.

Fourth

gear

overdrive

solenoid

failure

6. Verify solenoid

failure

with

test lamp and

replace solenoid

7.

Sensor

failure

(vehicle speed sensor or coolant

sensor)

7. Test both

sensors

with

test lamp or volt/

ohmmeter and replace

faulty

sensor

8. Park/neutral switch open or

shorted

or

switch

wire

to

powertrain

control

module is damaged

(loss

of park/neutral

input)

8. Test switch as described in service section

and

replace if necessary

9.

Powertrain

control module

faulty

9. Check

with

DRB II

scan

tool and replace if

necessary

10.

T.P.S.

fault

10. Adjust or replace

T.P.S.

11.

Transmission fluid

temperature

sensor

fault

(if equipped)

12. Overdrive piston seal

failure

13. Wrong

overdrive

piston

spacer

11.

Replace sensor

12. Replace both

seals

13. Remove unit, check end play, and install correct spacer

14.

Low

hydraulic pressure 14. Pressure test transmission to determine

cause

15. Set-reset module

faulty

15. Replace module (if equipped)

SUPS

IN

OVERDRIVE

FOURTH

GEAR

1.

2. Low

fluid

level

Overdrive piston or seal

malfunction

1.

Add fluid and check for leaks

2. Remove overdrive unit; replace piston

seals

if worn; replace piston if damaged, if piston

retainer

is damaged, it

will

be necessary to

remove and disassemble the transmission

3. Overdrive clutch pack

worn

3. Remove overdrive unit and rebuild clutch pack

4. 3-4

shift

valve,

timing

valve, or accumulator

malfunction

4. Remove and overhaul valve body. Replace

accumulator

seals.

Make sure all valves operate

freely

in bores, and do not bind or stick. Make

sure

valve body screws are correctly tightened

and

separator plates are properly positioned

5. Overdrive

piston

retainer

bleed

orifice

blown out 5. Disassemble transmission, remove

retainer,

and

replace orifice

6. Overdrive

unit

thrust

bearing

failure

6. Disassemble overdrive unit and replace

thrust bearing (No. 1 thrust bearing is between overdrive piston and clutch hub;

No.

2 thrust bearing is between the

planetary gear and the direct clutch spring plate; No. 3

thrust

bearing is between

overrunning clutch hub and output shaft)

J9321-252

42RH/46RH OVERDRIVE DIAGNOSIS

Page 1107 of 1502

21-106

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

42RH/46RH OVERDRIVE DIAGNOSIS •

Condition

Possible

Cause

Correction

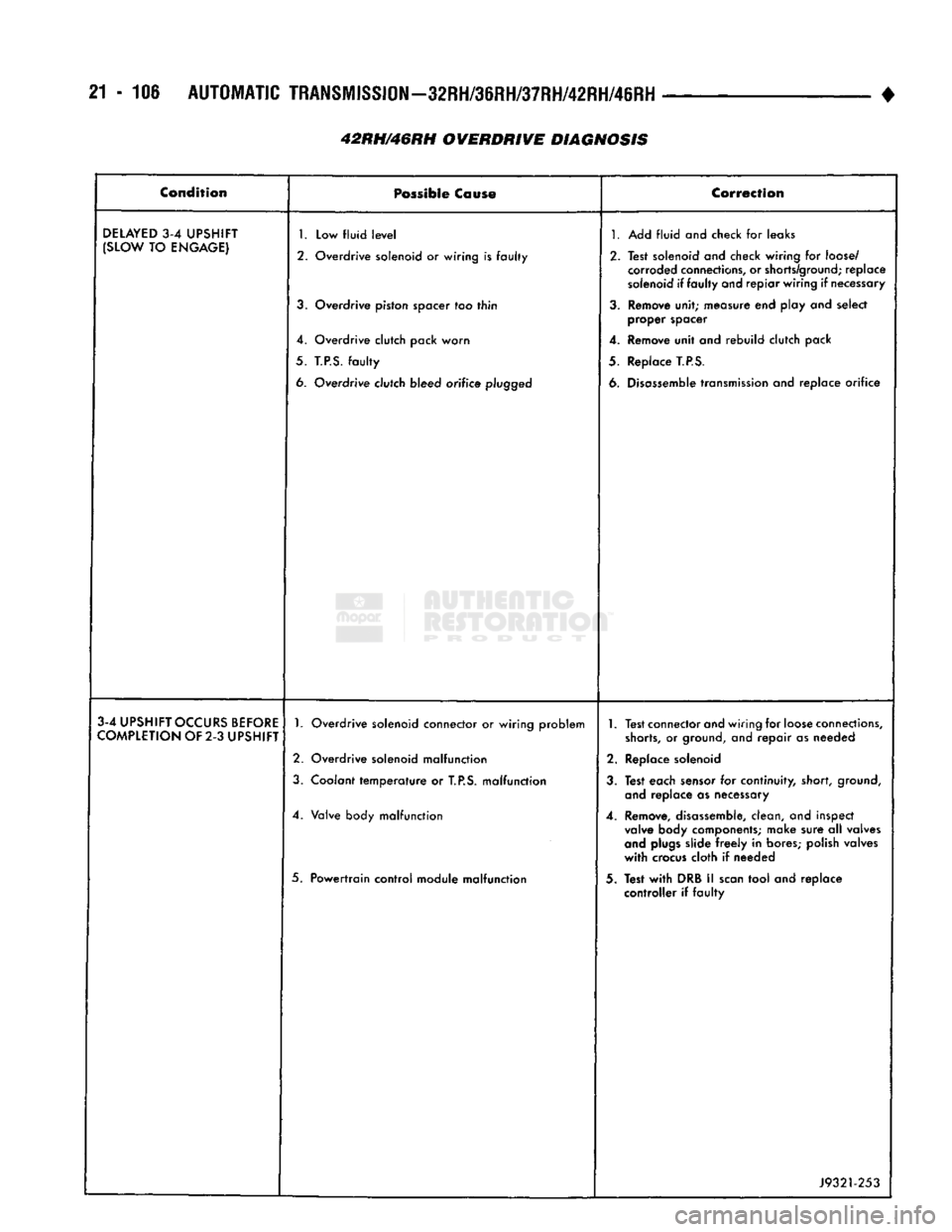

DELAYED

3-4

UPSHIFT

(SLOW

TO

ENGAGE)

1.

Low fluid

level

2. Overdrive solenoid or wiring is faulty

3.

Overdrive piston spacer too thin

4. Overdrive clutch pack worn

5.

T.P.S.

faulty

6. Overdrive clutch bleed orifice

plugged

1.

Add fluid and check for leaks

2. Test solenoid and check wiring for

loose/

corroded

connections,

or

shorts/ground;

replace

solenoid

if faulty and repiar wiring if

necessary

3.

Remove unit; measure end play and select proper spacer

4. Remove unit and rebuild clutch pack

5. Replace

T.P.S.

6.

Disassemble

transmission

and replace orifice

3-4

UPSHIFT

OCCURS

BEFORE

COMPLETION

OF 2-3

UPSHIFT

1.

Overdrive solenoid connector or wiring problem

2. Overdrive solenoid malfunction

3.

Coolant temperature or

T.P.S.

malfunction

4. Valve body malfunction

5. Powertrain control module malfunction

1.

Test connector and wiring for

loose

connections,

shorts,

or

ground,

and repair as needed

2. Replace solenoid

3.

Test each

sensor

for continuity, short,

ground,

and

replace as necessary

4. Remove,

disassemble,

clean, and inspect

valve

body components; make sure all valves

and

plugs

slide

freely

in bores; polish valves

with

crocus

cloth if needed

3. Test

with

DRB II

scan

tool and replace controller if faulty

J9321-253

Page 1108 of 1502

+

AUTOMATIC

TRANSMISSION-32RH/36RH/37RH/42RH/46RH

21-107

42RH/46RH

OVERDRIVE

DIAGNOSIS

Condition

Possible

Cause

Correction

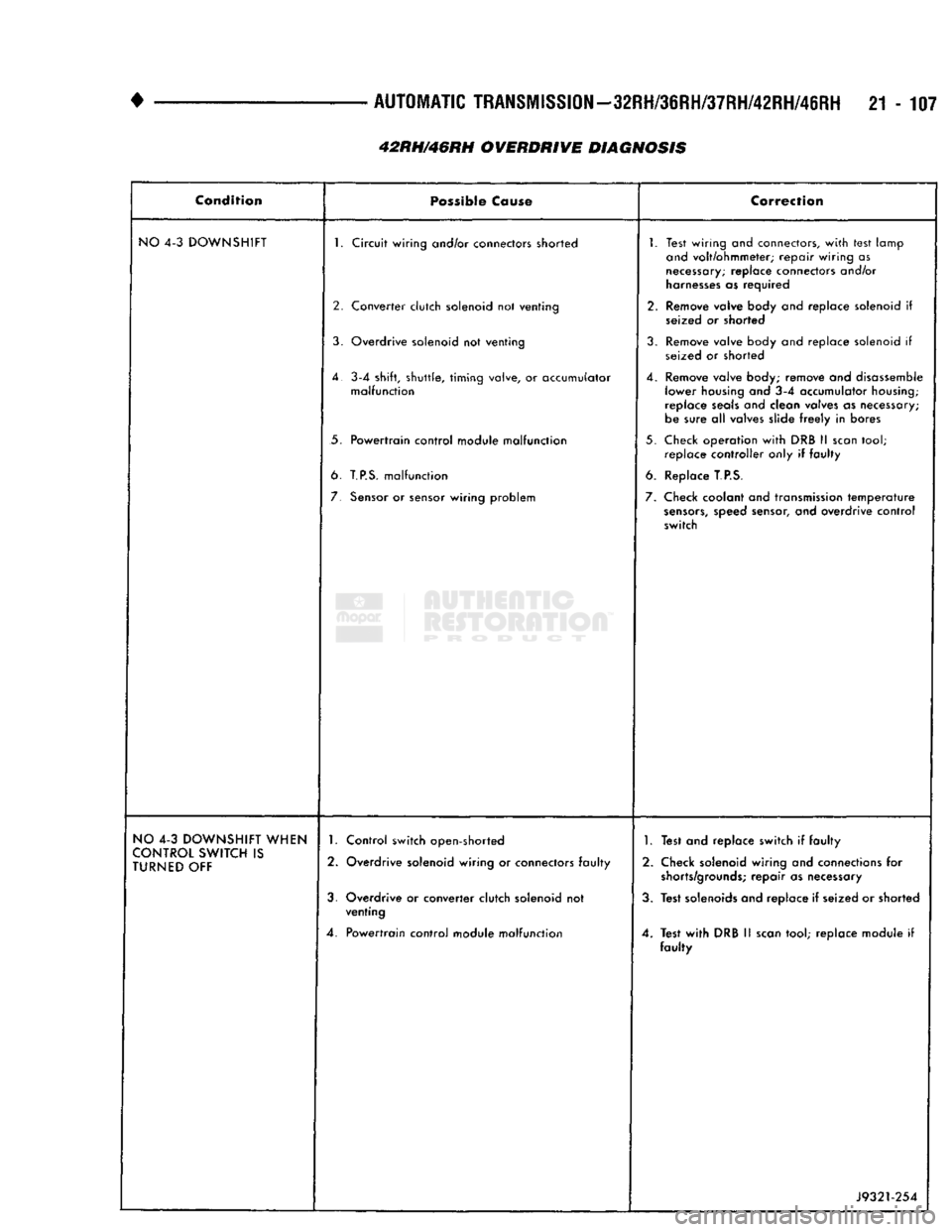

NO

4-3 DOWNSHIFT 1. Circuit wiring and/or connectors shorted

2. Converter clutch solenoid not venting

3. Overdrive solenoid not venting

4.

3-4 shift, shuttle, timing

valve,

or accumulator malfunction

5. Powertrain control module malfunction

6.

T.P.S.

malfunction

7.

Sensor

or sensor wiring problem 1. Test wiring and connectors,

with

test lamp

and

volt/ohmmeter; repair wiring as

necessary;

replace connectors and/or

harnesses

as required

2. Remove valve body and replace solenoid if seized or shorted

3. Remove valve body and replace solenoid if seized or shorted

4. Remove valve body; remove and disassemble lower housing and 3-4 accumulator

housing;

replace

seals

and clean valves as necessary;

be sure all valves slide

freely

in bores

5. Check operation

with

DRB II

scan

tool; replace controller only if faulty

6. Replace

T.P.S.

7. Check coolant and transmission

temperature

sensors,

speed sensor, and overdrive control

switch

NO

4-3 DOWNSHIFT WHEN

CONTROL

SWITCH

IS

TURNED

OFF 1. Control switch open-shorted

2. Overdrive solenoid wiring or connectors faulty

3. Overdrive or converter clutch solenoid not venting

4. Powertrain control module malfunction

1.

Test and replace switch if faulty

2. Check solenoid wiring and connections for

shorts/grounds;

repair as necessary

3. Test solenoids and replace if seized or shorted

4. Test

with

DRB II

scan

tool; replace module if faulty

J9321-254

Page 1109 of 1502

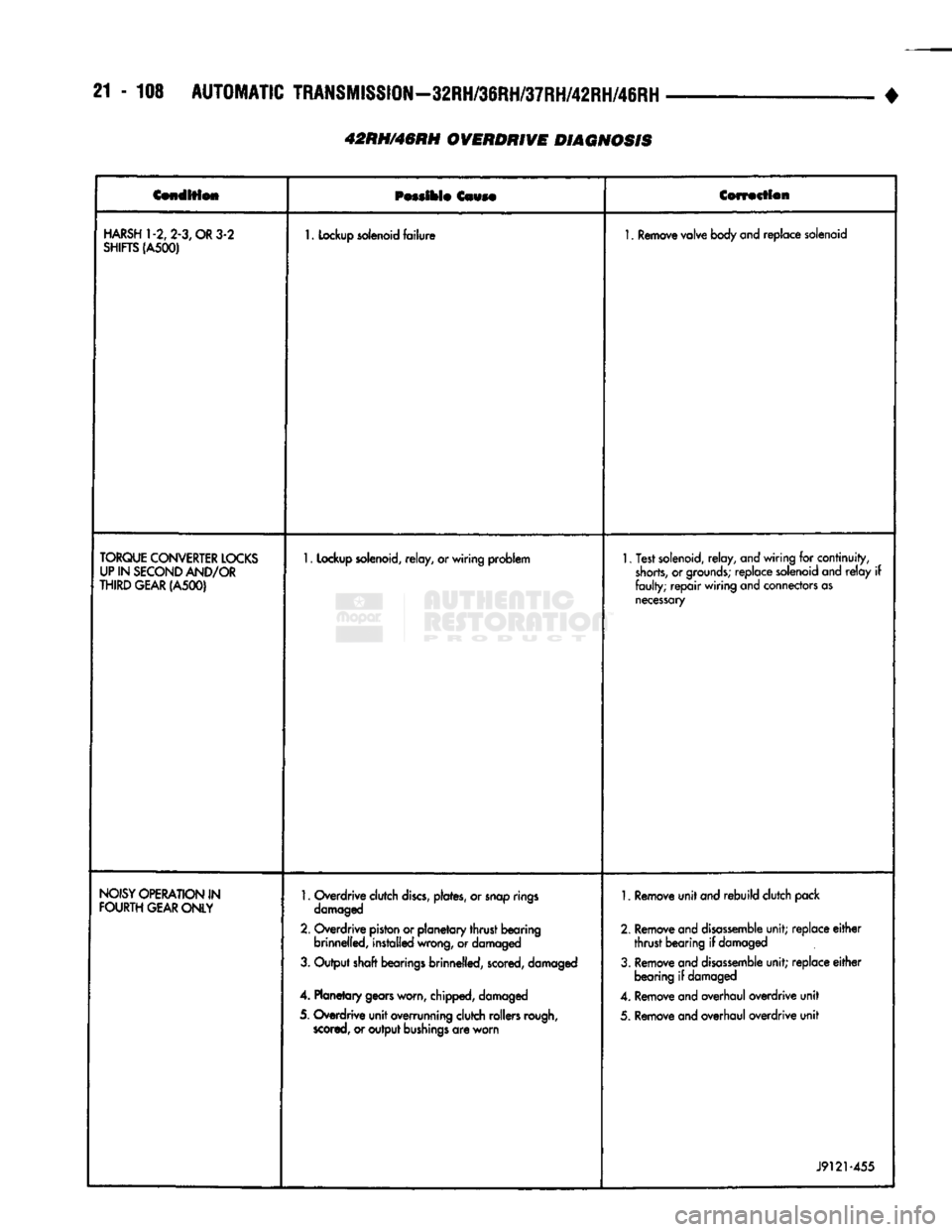

21 - 108

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

•

42RH/46RH OVERDRIVE DIAGNOSIS

Condition

Possible

Cause

Correction

HARSH

1-2, 2-3, OR 3-2

SHIFTS

(A500)

1.

Lockup

solenoid

failure

1.

Remove

valve

body

and

replace

solenoid

TORQUE

CONVERTER

LOCKS

UP

IN

SECOND

AND/OR

THIRD

GEAR

(A500)

1.

Lockup

solenoid,

relay, or wiring problem

1.

Test

solenoid,

relay, and wiring for continuity,

shorts,

or

grounds;

replace

solenoid

and

relay

if

faulty;

repair

wiring and

connectors

as

necessary

NOISY

OPERATION

IN

FOURTH

GEAR

ONLY

1.

Overdrive

clutch

discs,

plates,

or

snap

rings

damaged

2. Overdrive

piston

or planetary thrust bearing brinnelled,

installed

wrong,

or

damaged

3.

Output shaft

bearings

brinnelled,

scored,

damaged

4. Planetary

gears

worn,

chipped,

damaged

5. Overdrive unit

overrunning

clutch rollers

rough,

scored,

or output

bushings

are worn

1.

Remove

unit

and

rebuild

clutch

pack

2.

Remove

and

disassemble

unit; replace

either

thrust bearing if

damaged

3.

Remove

and

disassemble

unit; replace

either

bearing

if

damaged

4.

Remove

and

overhaul overdrive unit

5.

Remove

and

overhaul overdrive unit

J9121 455

Page 1110 of 1502

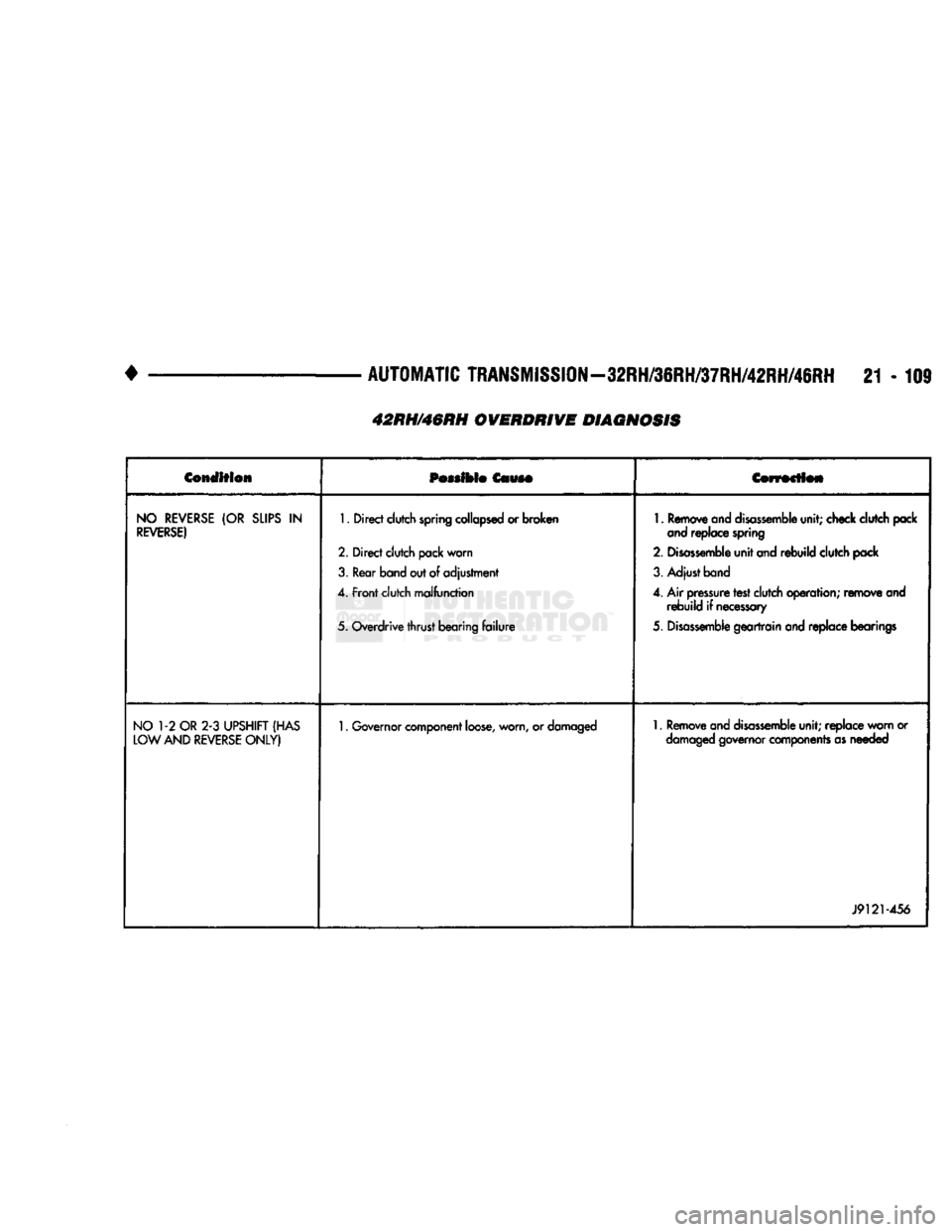

+

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

21 - 109

Condition

Possible Cause

Correction

NO

REVERSE

(OR

SLIPS

IN

REVERSE)

1.

Direct

clutch

spring

collapsed

or

broken

2.

Direct

clutch

pack

worn

3.

Rear

band

out of

adjustment

4.

Front

clutch

malfunction

5.

Overdrive

thrust

bearing

failure

1.

Remove

and disassemble

unit;

check

clutch

pack

and

replace

spring

2. Disassemble

unit

and

rebuild

clutch

pack

3.

Adjust

band

4. Air

pressure

test

clutch

operation;

remove

and

rebuild

if

necessary

5. Disassemble

geartrain

and

replace

bearings

NO

1-2

OR

2-3

UPSHIFT (HAS

LOW

AND REVERSE

ONLY)

1.

Governor

component

loose,

worn,

or

damaged

1.

Remove

and disassemble

unit;

replace

worn

or

damaged

governor

components

as

needed

J9121-456

42RH/46RH OVERDRIVE DIAGNOSIS