DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1311 of 1502

21

- 310

TRANSMISSION 0VERHAUL-46RH

• plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves and plugs should drop freely into the bores.

Valve body bores do not change dimensionally with

use.

If the valve body functioned correctly when new,

it will continue to operate properly after cleaning

and inspection. It should not be necessary to replace

a valve body assembly unless it is damaged in han

dling.

VALWE

BODY BEASSEMBLY

CAUTION; Do not

force valves

or

plugs

into place

during reassembly.

If the

valve body bores, valves

and

plugs

are

free

of

distortion

or

burrs,

the

valve

body

components should

all

slide into place easily.

In addition,

do not

overtighten

the

transfer

plate

and

valve body screws during reassembly. Over

tightening

can

distort

the

housings

resulting

in

valve sticking,

cross

leakage

and

unsatisfactory

op

eration. Tighten valve body screws

to

recom mended torque only.

Lower Housing Assembly (Fig.

116)

(1) Lubricate valves, springs, and the housing

valve and plug bores with Mopar ATF Plus, or

Dexron II® transmission fluid. (2) Install 3-4 timing valve spring and valve in

lower housing. (3) Install 3-4 shuttle valve in lower housing.

Press valve inward and install E-clip on end of valve

to secure it in housing.

(4) Install 3-4 shuttle valve spring and throttle

plug in housing. (5) Install timing valve end plate. Tighten end

plate screws to 4 N»m (35 in. lbs.) torque.

(6) Install 3-4 shift valve and spring.

(7) Install converter clutch valve, spring and plug.

(8) Install converter clutch timing valve and

spring.

3-4 Accumulator

Assembly

(Fig.

117) (1) Lubricate accumulator piston, seals and hous

ing piston bore with ATF Plus, or Dexron II®. (2) Install new seal rings on accumulator piston.

(3) Install piston and spring in housing.

(4) Install end plate on housing.

Transfer Plate Assembly

(1) Install rear clutch check ball in transfer plate

(Fig. 110). (2) Install filter screen in upper housing separator

plate (Fig. 109). (3) Align and position upper housing separator

plate on transfer plate (Fig. 109).

(4) Install brace plate (Fig. 108). Tighten brace at

taching screws to 4 Nnn (35 in. lbs.) torque. (5) Install remaining separator plate attaching

screws. Tighten screws to 4 N*m (35 in. lbs.) torque.

Page 1312 of 1502

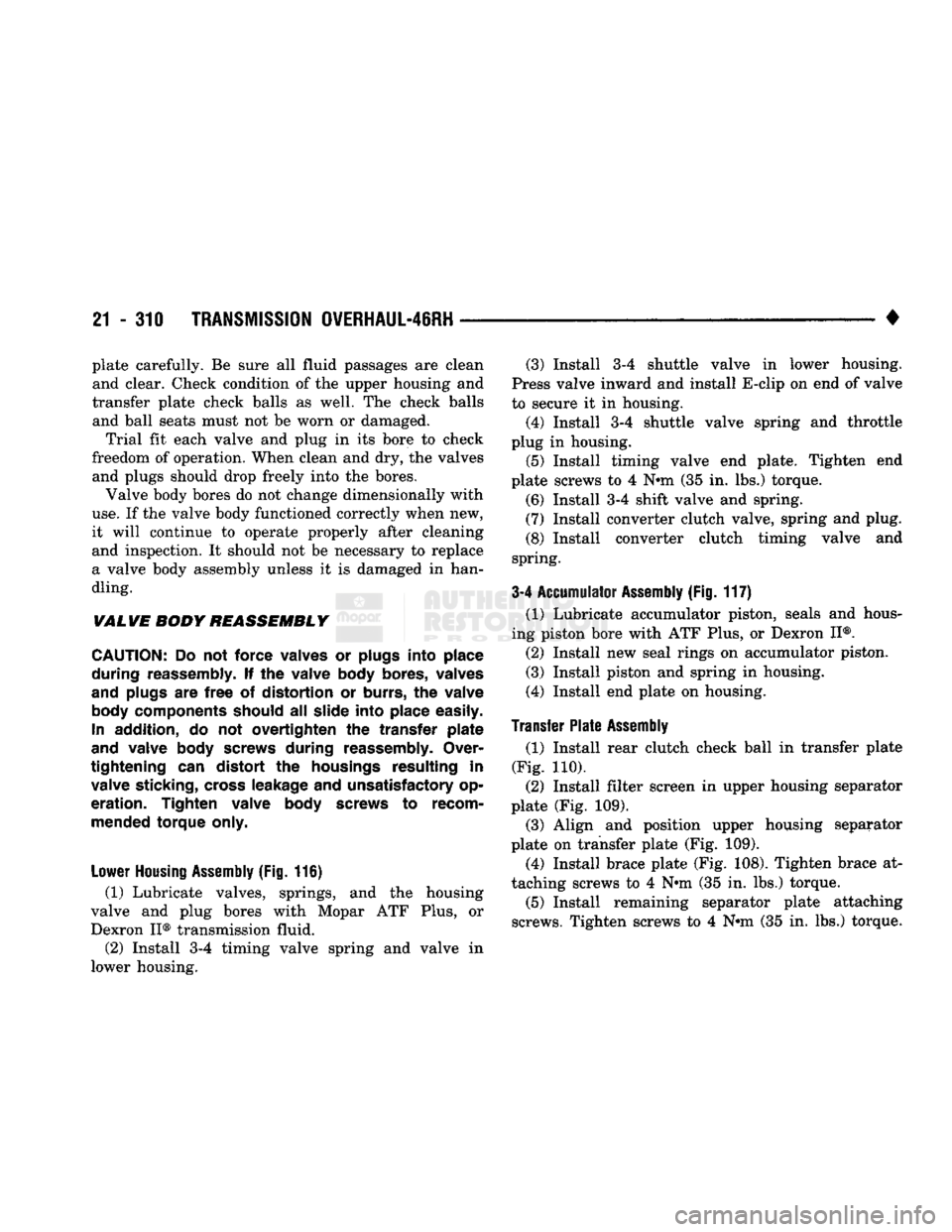

SHIFT

VALVE

END PLATE

2-3

SHIFT

VALVE AND

SPRING

SHUTTLE VALVE

SECONDARY

SPRING,

GUIDES,

E-CLIP

1-2

SHIFT

CONTROL VALVE AND SPRING

REGULATOR VALVE

END PLATE SHUTTLE VALVE

COVER

SLEEVE

REGULATOR

VALVE

THROTTLE

PRESSURE

PLUG

RETAINER VALVE

SPRING

2-3

SHIFT

VALVE GOVERNOR PLUG

LINE

PRESSURE

ADJUSTING*

SCREW

ADJUSTING

SCREW

BRACKET

SHUTTLE VALVE

PLUG

(ALUM.)

GOVERNOR VALVE END PLATE

AAANUAL LEVER DETENT BALL

AND SPRING

J9221-21 E

w

00

o

z

m

30

Fig. 118 Upper Housing Components—46RH

Valve

Body (Alum.

Indicates

Aluminum

Part)

Page 1313 of 1502

21

- 312 TRANSMISSION OWERHAUL-46RH

•

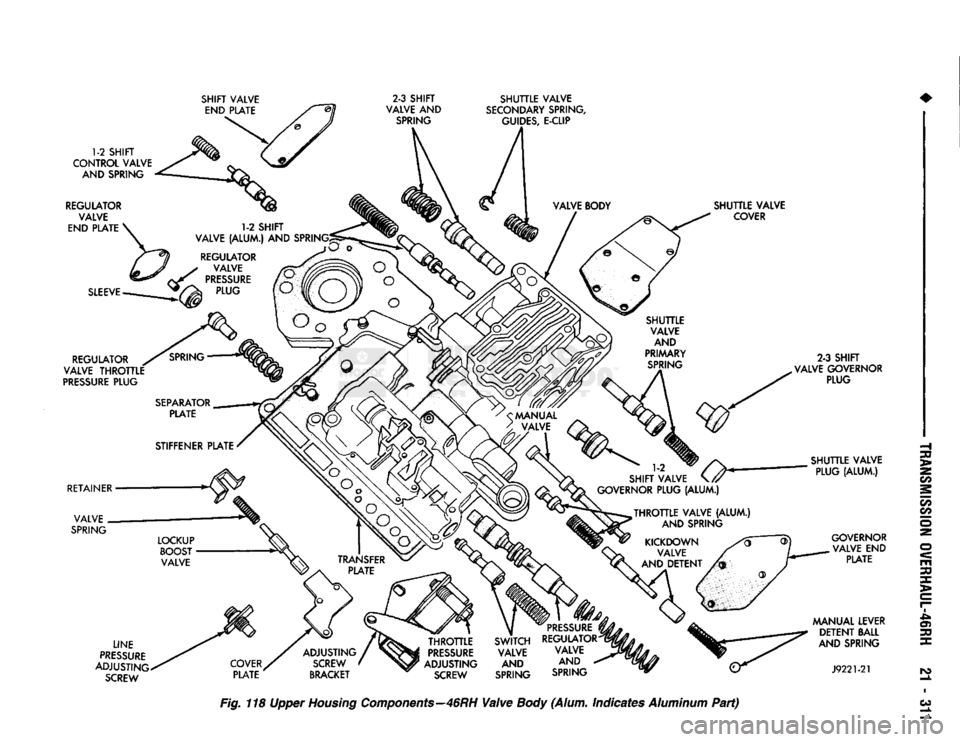

Assembling

Upper

And

Lower

Housings

(1) Position upper housing so internal passages

and check ball seats are facing upward. Then install

check balls in housing (Fig. 111). Seven check balls are used. The single large check ball is approxi

mately 8.7 mm (11/32 in.) diameter. The remaining 6

check balls are approximately 6.3 mm (1/4 in.) in di ameter.

(2) Position transfer plate assembly on upper hous

ing (Fig. 119).

(3) Position lower housing separator plate on

transfer plate (Fig. 119).

TRANSFER

UPPER PLATE HOUSING

J932M59

Fig. 119 Lower Housing Separator Plate Installation—46RH

(4) Install lower housing on assembled transfer

plate and upper housing (Fig. 120).

(5)

Install and start valve body screws by hand.

Then tighten screws evenly to 4 N*m (35 in. lbs.)

torque. Start at center and work out to sides when

tightening screws. Fig. 120 Assembling Valve Body Upper And Lower

Housings—46RH

Upper

Housing

Valve

And

Plug

Installation

(Figs.

114,111,

118)

(1) Lubricate valves, plugs, springs with Mopar

ATF Plus transmission fluid.

(2) Assemble regulator

valve

line pressure plug,

sleeve, throttle plug and spring. Insert assembly in

upper housing and install cover plate. Tighten cover

plate screws to 4 N»m (35 in. lbs.) torque.

(3) Install 1-2 and 2-3 shift valves and springs.

(4) Install 1-2 shift control valve and spring.

(5) Install shift valve cover plate. (6) Install shuttle valve as follows: (a) Insert plastic guides in shuttle valve second

ary spring and install spring on end of valve.

(b) Hold shuttle valve in place.

(c) Compress secondary spring and install E-clip

in groove at end of shuttle valve. (d) Verify that spring and E-clip are properly

seated before proceeding. (7) Install shuttle valve cover plate. Tighten cover

plate screws to 4 N®m (35 in. lbs.) torque.

(8) Install 1-2 and 2-3 valve governor plugs in

valve body. (9) Install shuttle valve primary spring and throt

tle plug. (10) Align and install governor plug cover. Tighten

cover screws to 4 N#m (35 in. lbs.) torque.

(11) Install manual valve.

(12) Install throttle valve and spring.

(13) Install kickdown valve, and detent. (14) Install regulator valve.

(15) Install switch valve.

Boost

Valve

Tube

Installation

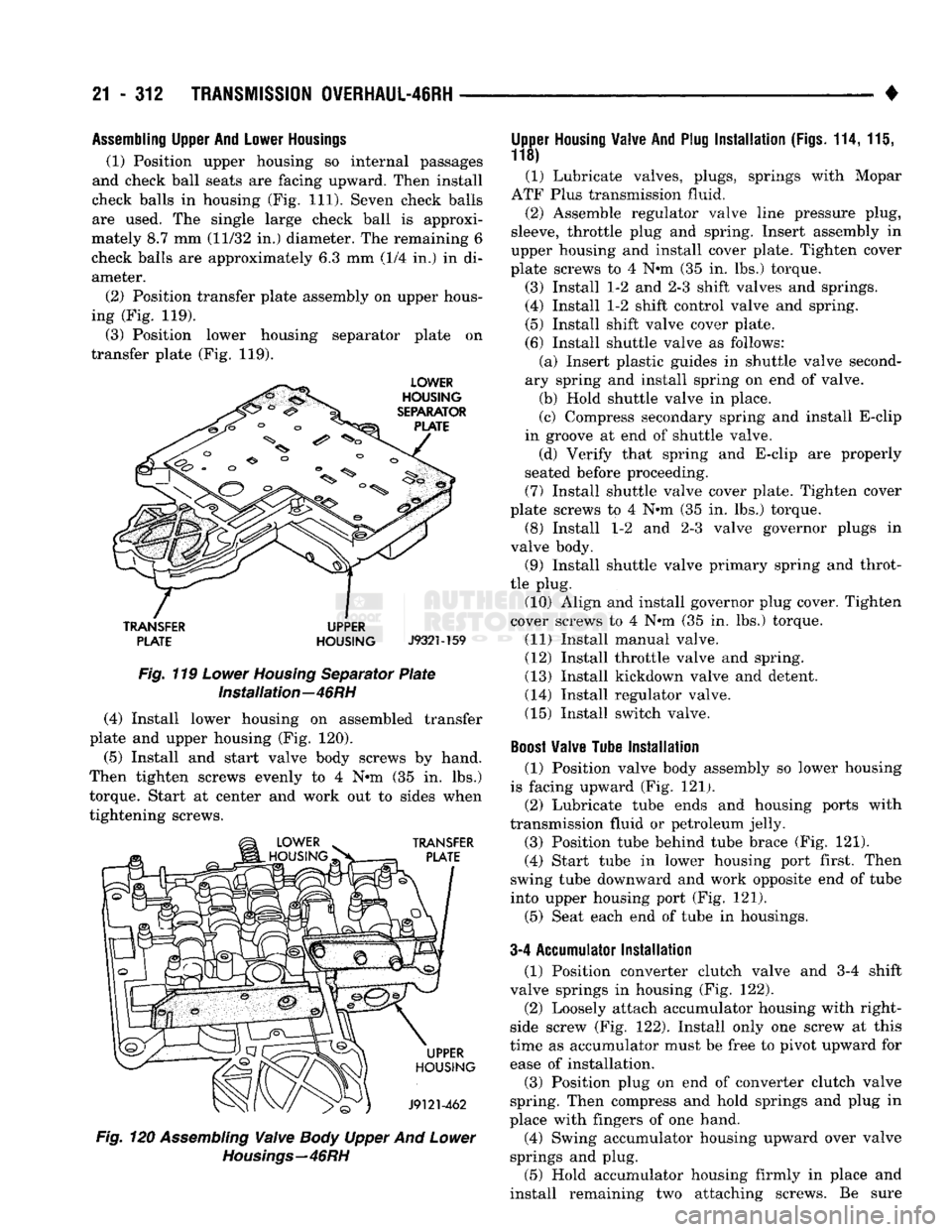

(1) Position valve body assembly so lower housing

is facing upward (Fig. 121). (2) Lubricate tube ends and housing ports with

transmission fluid or petroleum jelly.

(3) Position tube behind tube brace (Fig. 121).

(4) Start tube in lower housing port first. Then

swing tube downward and work opposite end of tube

into upper housing port (Fig. 121).

(5) Seat each end of tube in housings.

3-4 Accumulator

Installation

(1) Position converter clutch valve and 3-4 shift

valve springs in housing (Fig. 122). (2) Loosely attach accumulator housing with right-

side screw (Fig. 122). Install only one screw at this

time as accumulator must be free to pivot upward for ease of installation.

(3) Position plug on end of converter clutch valve

spring. Then compress and hold springs and plug in

place with fingers of one hand.

(4) Swing accumulator housing upward over valve

springs and plug.

(5) Hold accumulator housing firmly in place and

install remaining two attaching screws. Be sure

Page 1314 of 1502

•

TRANSMISSION

OVERHAUL-46RH

21 - 313

TUBE

BRACE

UPPER

LOWER

HOUSING PORT

J932M62

Fig.

121

Boost

Valve

Tube Installation—46RH

springs and clutch valve plug are properly seated (Fig. 123).

RIGHT-SIDE

SCREW

3-4 ACCUMULATOR

Fig.

122 Installing Converter

Clutch

And 3-4 Shift

Valve

Springs—46RH

CLUTCH ACCUMULATOR

VALVE PLUG

BOSS

J9321-161

Fig.

123 Seating 3-4

Accumulator

On

Lower

Housing—46RH

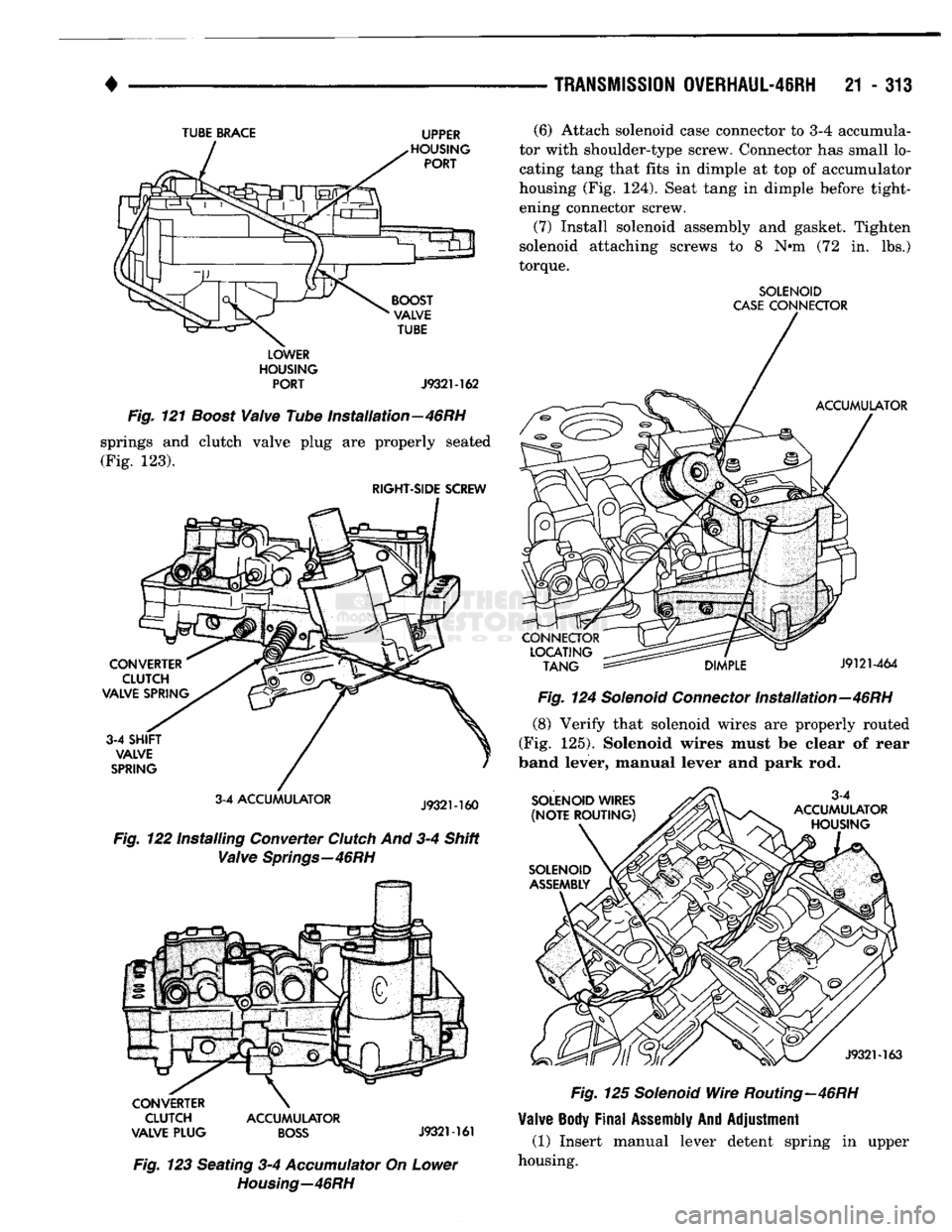

(6) Attach solenoid case connector to 3-4 accumula

tor with shoulder-type screw. Connector has small lo

cating tang that fits in dimple at top of accumulator

housing (Fig. 124). Seat tang in dimple before tight ening connector screw.

(7) Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N*m (72 in. lbs.)

torque.

SOLENOID

CASE

CONNECTOR

Fig.

124

Solenoid

Connector

Installation—46RH

(8) Verify that solenoid wires are properly routed

(Fig. 125). Solenoid wires must be clear of rear

band lever, manual lever and park rod.

Fig.

125

Solenoid

Wire

Routing—46RH

Valve

Body

Final

Assembly

And

Adjustment

(1) Insert manual lever detent spring in upper

housing.

Page 1315 of 1502

21

- 314

TRANSMISSION

OVERHAUL-46RH

—

•

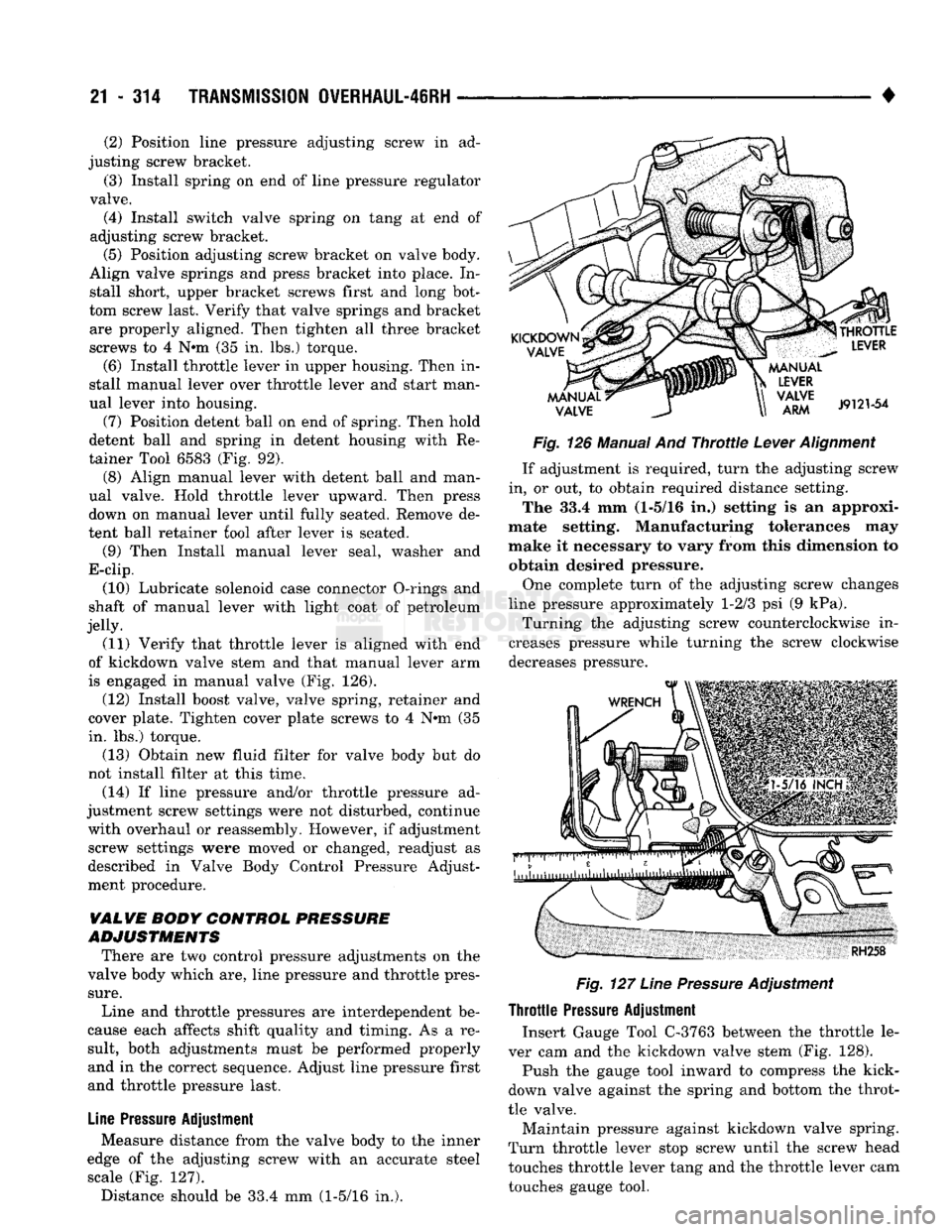

Fig.

126 Manual And

Throttle

Lever

Alignment

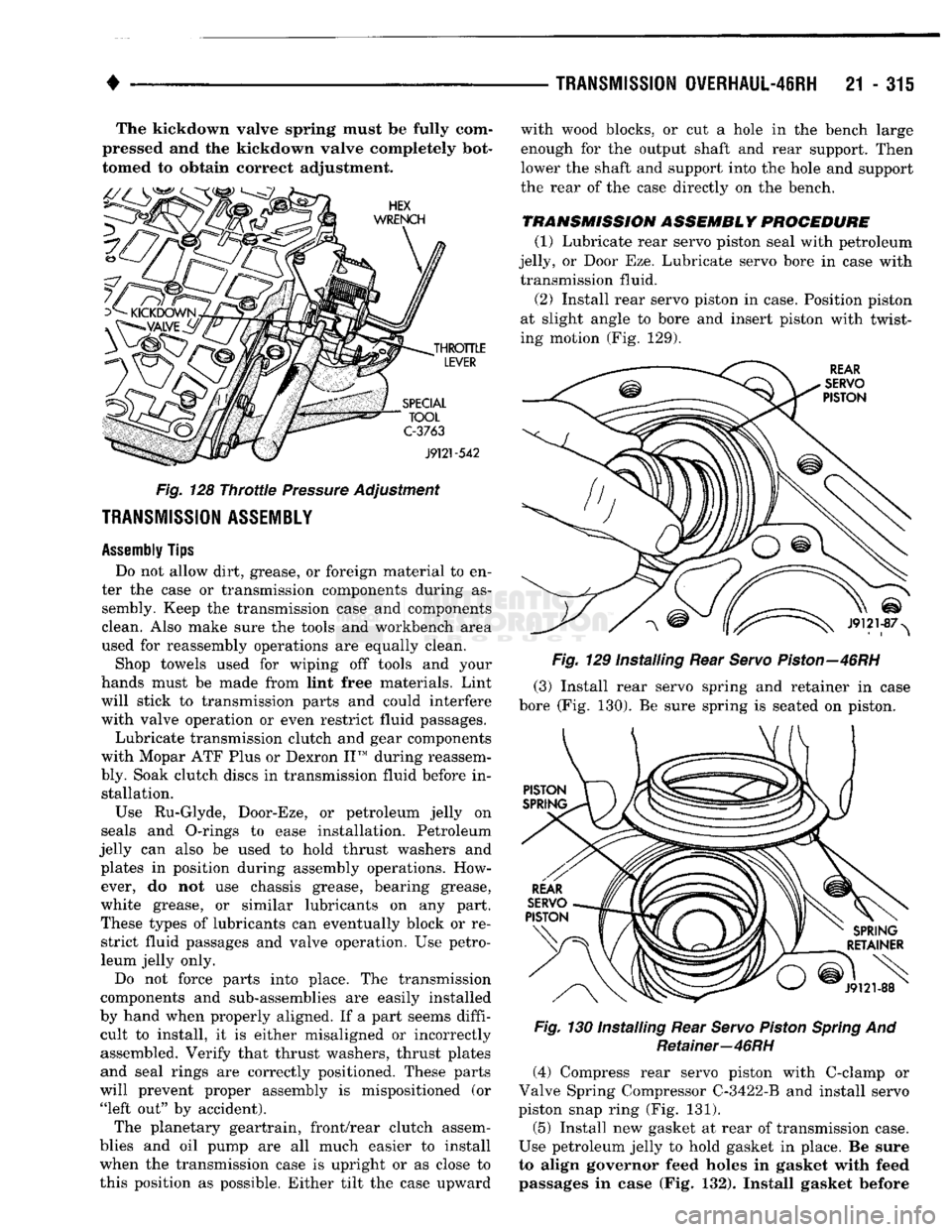

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting. The 33.4 mm (1-5/16 in.) setting is an approxi

mate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa). Turning the adjusting screw counterclockwise in

creases pressure while turning the screw clockwise

decreases pressure.

Fig.

127

Line

Pressure

Adjustment

Throttle

Pressure

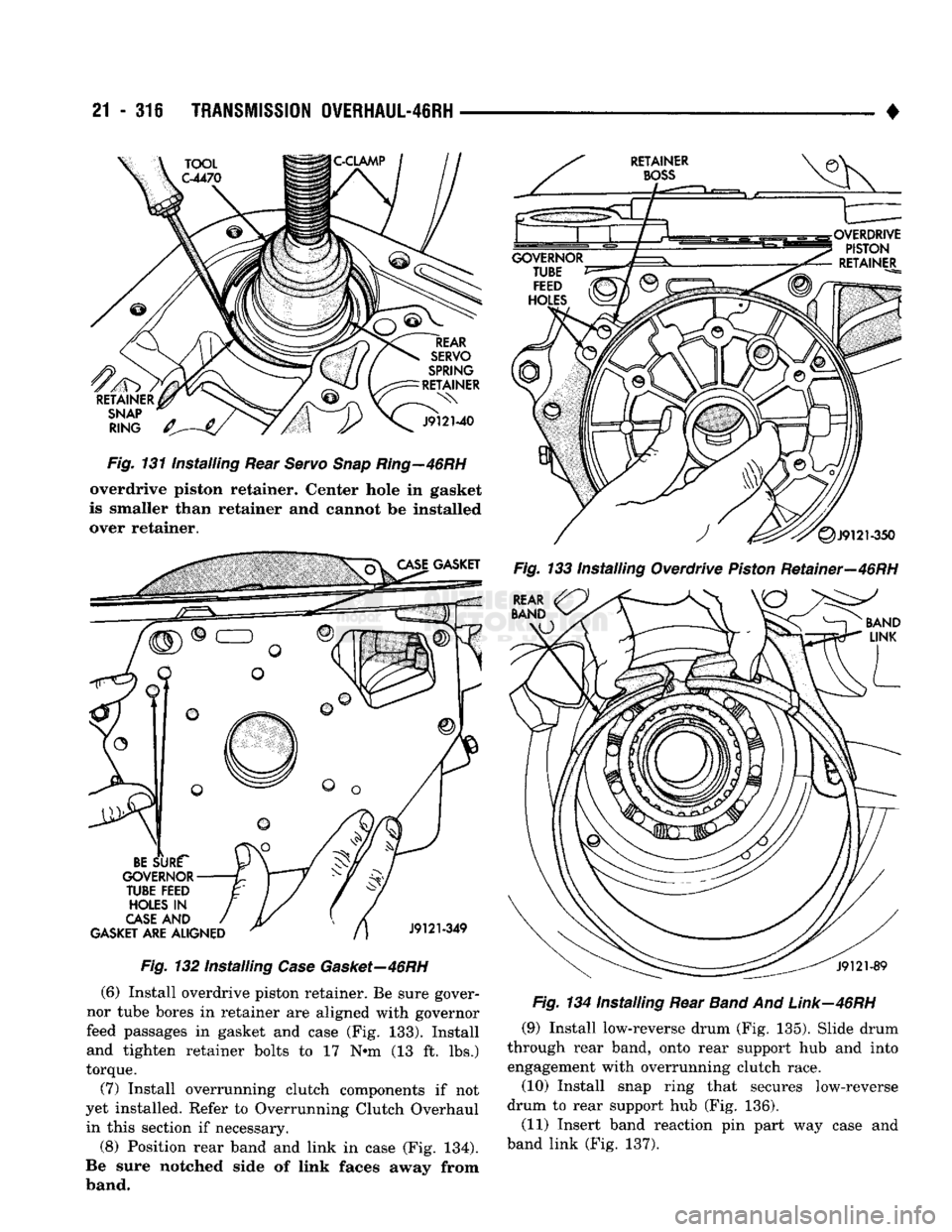

Adjustment Insert Gauge Tool C-3763 between the throttle le

ver cam and the kickdown valve stem (Fig. 128).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

(2) Position line pressure adjusting screw in ad

justing screw bracket.

(3) Install spring on end of line pressure regulator

valve. (4) Install switch valve spring on tang at end of

adjusting screw bracket. (5) Position adjusting screw bracket on valve body.

Align valve springs and press bracket into place. In stall short, upper bracket screws first and long bot

tom screw last. Verify that valve springs and bracket are properly aligned. Then tighten all three bracket

screws to 4 N*m (35 in. lbs.) torque.

(6) Install throttle lever in upper housing. Then in

stall manual lever over throttle lever and start man

ual lever into housing.

(7) Position detent ball on end of spring. Then hold

detent ball and spring in detent housing with Re

tainer Tool 6583 (Fig. 92). (8) Align manual lever with detent ball and man

ual valve. Hold throttle lever upward. Then press

down on manual lever until fully seated. Remove de

tent ball retainer fool after lever is seated.

(9) Then Install manual lever seal, washer and

E-clip.

(10) Lubricate solenoid case connector O-rings and

shaft of manual lever with light coat of petroleum

jelly. (11) Verify that throttle lever is aligned with end

of kickdown valve stem and that manual lever arm

is engaged in manual valve (Fig. 126).

(12) Install boost valve, valve spring, retainer and

cover plate. Tighten cover plate screws to 4 N»m (35

in. lbs.) torque.

(13) Obtain new fluid filter for valve body but do

not install filter at this time.

(14) If line pressure and/or throttle pressure ad

justment screw settings were not disturbed, continue with overhaul or reassembly. However, if adjustment screw settings were moved or changed, readjust as

described in Valve Body Control Pressure Adjust

ment procedure.

VALVE

BODY

CONTROL

PRESSURE

ADJUSTMENTS

There are two control pressure adjustments on the

valve body which are, line pressure and throttle pres

sure.

Line and throttle pressures are interdependent be

cause each affects shift quality and timing. As a re

sult, both adjustments must be performed properly and in the correct sequence. Adjust line pressure first

and throttle pressure last.

Line

Pressure

Adjustment Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel scale (Fig. 127). Distance should be 33.4 mm (1-5/16 in.).

Page 1316 of 1502

•

TRANSMISSION

OVERHAUL-46RH

21 - 315

The kickdown valve spring must be fully com

pressed and the kickdown valve completely bot

tomed to obtain correct adjustment.

Fig.

128

Throttle

Pressure

Adjustment

TRANSMISSION ASSEMBLY

Assembly

Tips

Do not allow dirt, grease, or foreign material to en

ter the case or transmission components during as sembly. Keep the transmission case and components

clean. Also make sure the tools and workbench area

used for reassembly operations are equally clean.

Shop towels used for wiping off tools and your

hands must be made from lint free materials. Lint

will stick to transmission parts and could interfere

with valve operation or even restrict fluid passages.

Lubricate transmission clutch and gear components

with Mopar ATF Plus or Dexron II™ during reassem

bly. Soak clutch discs in transmission fluid before in stallation.

Use Ru-Glyde, Door-Eze, or petroleum jelly on

seals and O-rings to ease installation. Petroleum

jelly can also be used to hold thrust washers and plates in position during assembly operations. However, do not use chassis grease, bearing grease,

white grease, or similar lubricants on any part.

These types of lubricants can eventually block or re strict fluid passages and valve operation. Use petro

leum jelly only.

Do not force parts into place. The transmission

components and sub-assemblies are easily installed

by hand when properly aligned. If a part seems diffi cult to install, it is either misaligned or incorrectly

assembled. Verify that thrust washers, thrust plates

and seal rings are correctly positioned. These parts

will prevent proper assembly is mispositioned (or "left out" by accident).

The planetary geartrain, front/rear clutch assem

blies and oil pump are all much easier to install

when the transmission case is upright or as close to

this position as possible. Either tilt the case upward with wood blocks, or cut a hole in the bench large

enough for the output shaft and rear support. Then

lower the shaft and support into the hole and support

the rear of the case directly on the bench.

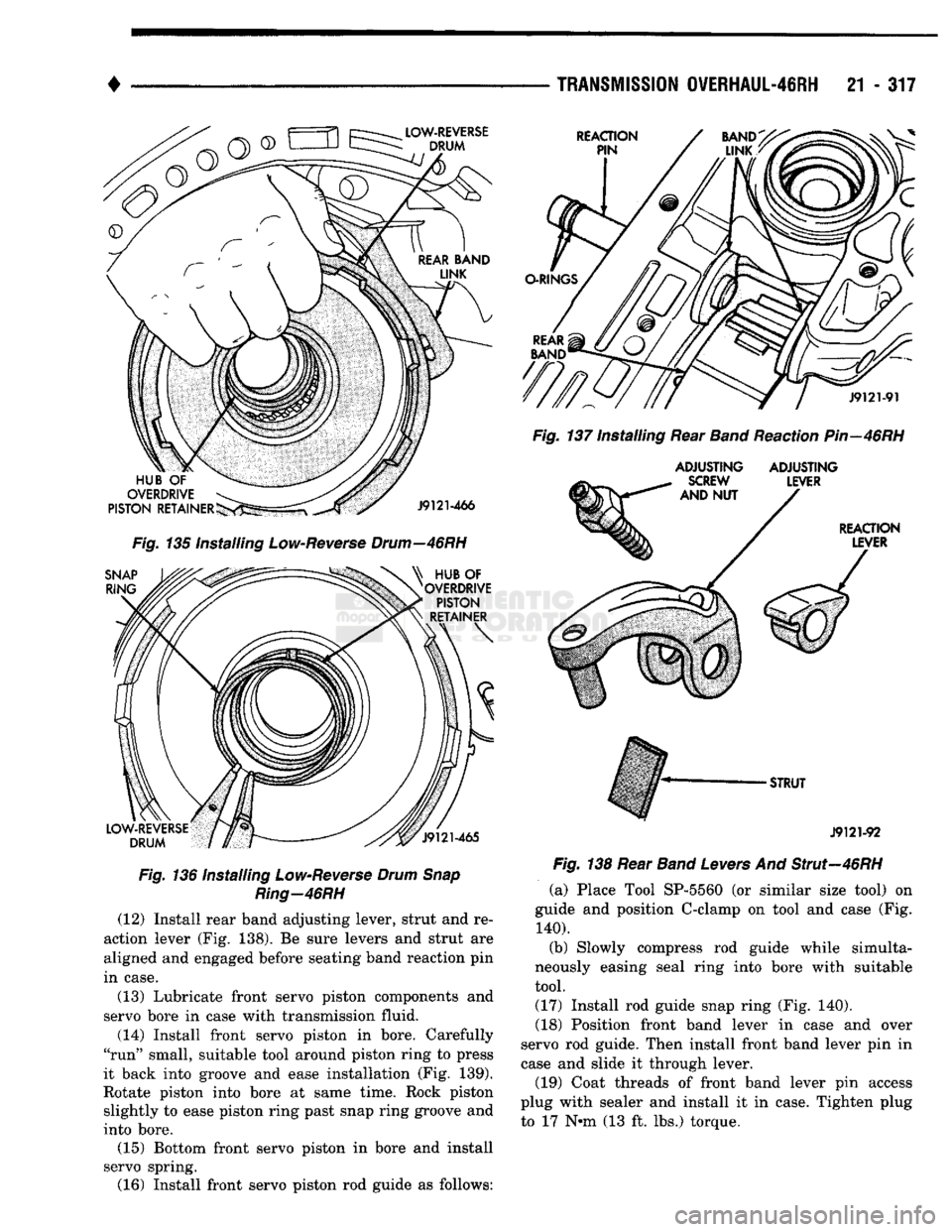

TRANSMISSION ASSEMBLY PROCEDURE

(1) Lubricate rear servo piston seal with petroleum

jelly, or Door Eze. Lubricate servo bore in case with transmission fluid.

(2) Install rear servo piston in case. Position piston

at slight angle to bore and insert piston with twist

ing motion (Fig. 129).

Fig.

129 Installing Rear

Servo

Piston—46RH

(3) Install rear servo spring and retainer in case

bore (Fig. 130). Be sure spring is seated on piston.

Fig.

130 Installing Rear

Servo

Piston

Spring

And Retainer—46RH (4) Compress rear servo piston with C-clamp or

Valve Spring Compressor C-3422-B and install servo

piston snap ring (Fig. 131).

(5) Install new gasket at rear of transmission case.

Use petroleum jelly to hold gasket in place. Be sure

to align governor feed holes in gasket with feed passages in case (Fig. 132). Install gasket before

Page 1317 of 1502

21

- 31S

TRANSMISSION

0VERHAUL-46RH

Fig.

131 Installing Rear

Servo

Snap

Ring—46RH

overdrive piston retainer. Center hole in gasket

is smaller than retainer and cannot be installed over retainer.

Fig.

132 Installing

Case

Gasket—46RH

(6) Install overdrive piston retainer. Be sure gover

nor tube bores in retainer are aligned with governor

feed passages in gasket and case (Fig. 133). Install and tighten retainer bolts to 17 N»m (13 ft. lbs.)

torque.

(7) Install overrunning clutch components if not

yet installed. Refer to Overrunning Clutch Overhaul in this section if necessary.

(8) Position rear band and link in case (Fig. 134).

Be sure notched side of link faces away from

band. •

Fig.

133 Installing Overdrive

Piston

Retainer—46RH

Fig.

134 Installing Rear

Band

And

Link—46RH

(9) Install low-reverse drum (Fig. 135). Slide drum

through rear band, onto rear support hub and into engagement with overrunning clutch race.

(10) Install snap ring that secures low-reverse

drum to rear support hub (Fig. 136).

(11) Insert band reaction pin part way case and

band link (Fig. 137).

Page 1318 of 1502

•

Fig.

136 Installing

Low-Reverse

Drum

Snap

Ring-46RH

(12) Install rear band adjusting lever, strut and re

action lever (Fig. 138). Be sure levers and strut are

aligned and engaged before seating band reaction pin

in case.

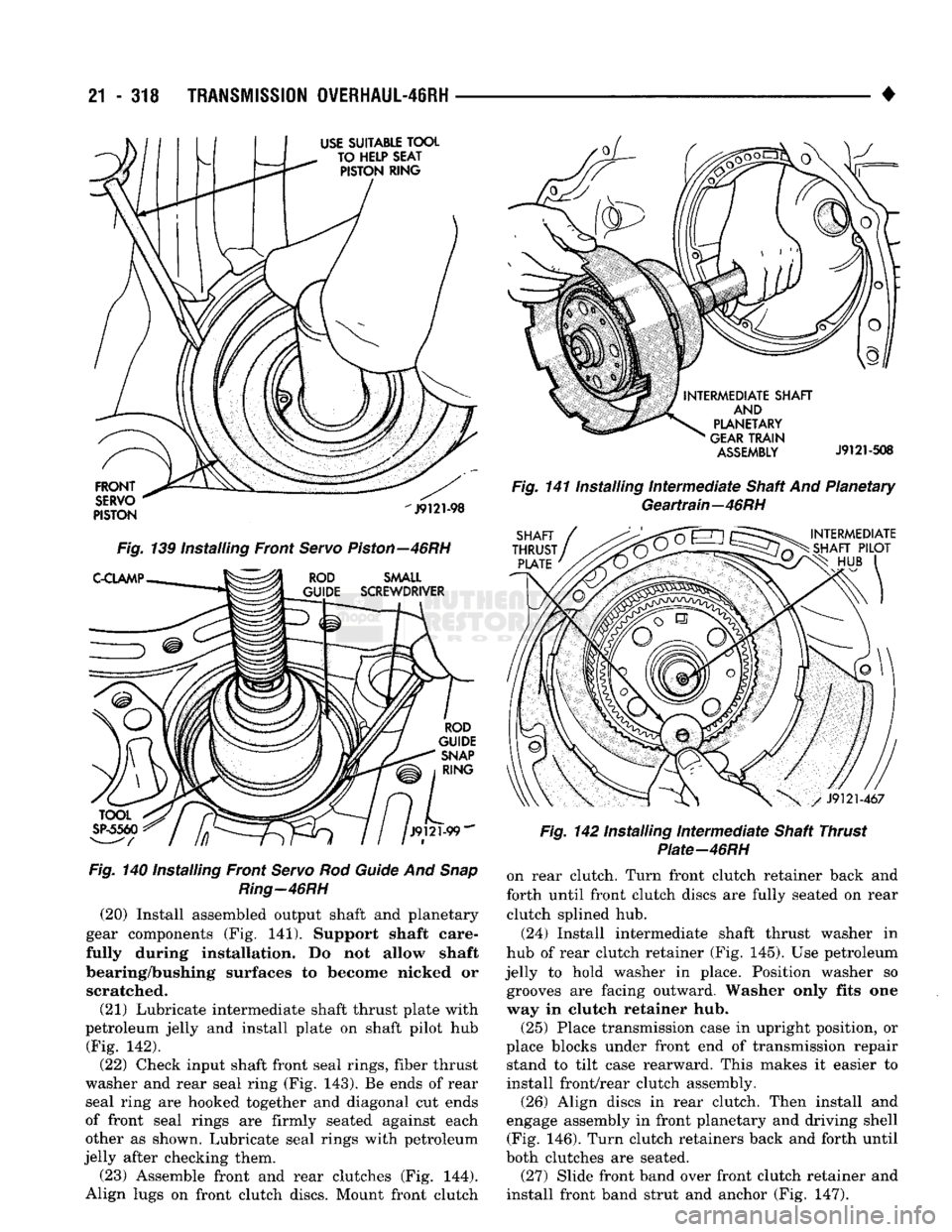

(13) Lubricate front servo piston components and

servo bore in case with transmission fluid.

(14) Install front servo piston in bore. Carefully

"run" small, suitable tool around piston ring to press

it back into groove and ease installation (Fig. 139).

Rotate piston into bore at same time. Rock piston slightly to ease piston ring past snap ring groove and

into bore. (15) Bottom front servo piston in bore and install

servo spring. (16) Install front servo piston rod guide as follows:

TRANSMISSION

0VERHAUL-4SRH

21 - 317

Fig,

137 Installing Rear

Band

Reaction

Pin—46RH

ADJUSTING ADJUSTING

J9121-92

Fig.

138 Rear

Band

Levers

And Strut—46RH (a) Place Tool SP-5560 (or similar size tool) on

guide and position C-clamp on tool and case (Fig.

140).

(b) Slowly compress rod guide while simulta

neously easing seal ring into bore with suitable

tool. (17) Install rod guide snap ring (Fig. 140).

(18) Position front band lever in case and over

servo rod guide. Then install front band lever pin in

case and slide it through lever.

(19) Coat threads of front band lever pin access

plug with sealer and install it in case. Tighten plug to 17 N-m (13 ft. lbs.) torque.

Page 1319 of 1502

21

- 318

TRANSMISSION

0WERHAUL-46RH

Fig.

140 Installing Front

Servo

Rod

Guide

And

Snap

Ring-46RH

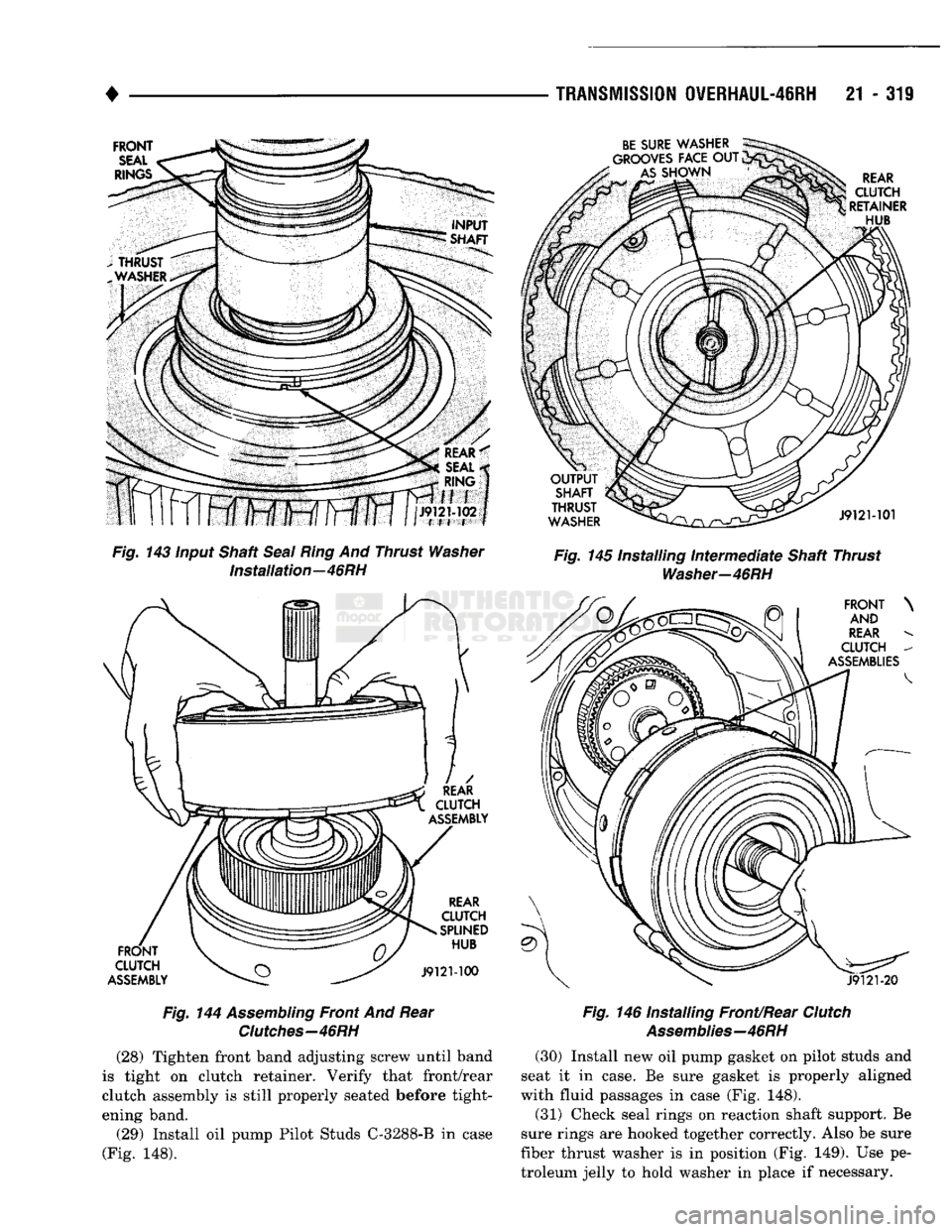

(20) Install assembled output shaft and planetary

gear components (Fig. 141). Support shaft care

fully during installation. Do not allow shaft

bearing/bushing surfaces to become nicked or scratched. (21) Lubricate intermediate shaft thrust plate with

petroleum jelly and install plate on shaft pilot hub (Fig. 142). (22) Check input shaft front seal rings, fiber thrust

washer and rear seal ring (Fig. 143). Be ends of rear seal ring are hooked together and diagonal cut ends

of front seal rings are firmly seated against each other as shown. Lubricate seal rings with petroleum

jelly after checking them.

(23) Assemble front and rear clutches (Fig. 144).

Align lugs on front clutch discs. Mount front clutch •

ASSEMBLY

J9121-508

Fig.

141 Installing

Intermediate

Shaft And Planetary Geartrain—46RH

Fig.

142 Installing

Intermediate

Shaft Thrust Plate-46RH on rear clutch. Turn front clutch retainer back and

forth until front clutch discs are fully seated on rear clutch splined hub.

(24) Install intermediate shaft thrust washer in

hub of rear clutch retainer (Fig. 145). Use petroleum

jelly to hold washer in place. Position washer so grooves are facing outward. Washer only fits one

way in clutch retainer hub.

(25) Place transmission case in upright position, or

place blocks under front end of transmission repair stand to tilt case rearward. This makes it easier to

install front/rear clutch assembly. (26) Align discs in rear clutch. Then install and

engage assembly in front planetary and driving shell (Fig. 146). Turn clutch retainers back and forth until

both clutches are seated. (27) Slide front band over front clutch retainer and

install front band strut and anchor (Fig. 147).

Page 1320 of 1502

•

TRANSMISSION

0VERHAUL-46RH

21 - 319

Fig. 143 input Shaft Seat Ring And Thrust Washer Installation—46RH

Fig. 144 Assembling Front And Rear Clutches-46RH (28) Tighten front band adjusting screw until band

is tight on clutch retainer. Verify that front/rear

clutch assembly is still properly seated before tight

ening band.

(29) Install oil pump Pilot Studs

C-3288-B

in case

(Fig. 148). Fig. 145 Installing intermediate Shaft Thrust

Washer-46RH

Fig. 146 Installing Front/Rear Clutch Assemblies—46RH (30) Install new oil pump gasket on pilot studs and

seat it in case. Be sure gasket is properly aligned

with fluid passages in case (Fig. 148). (31) Check seal rings on reaction shaft support. Be

sure rings are hooked together correctly. Also be sure

fiber thrust washer is in position (Fig. 149). Use pe

troleum jelly to hold washer in place if necessary.