DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1321 of 1502

21

- 320

TRANSMISSION

0¥ERHAUL-46RH

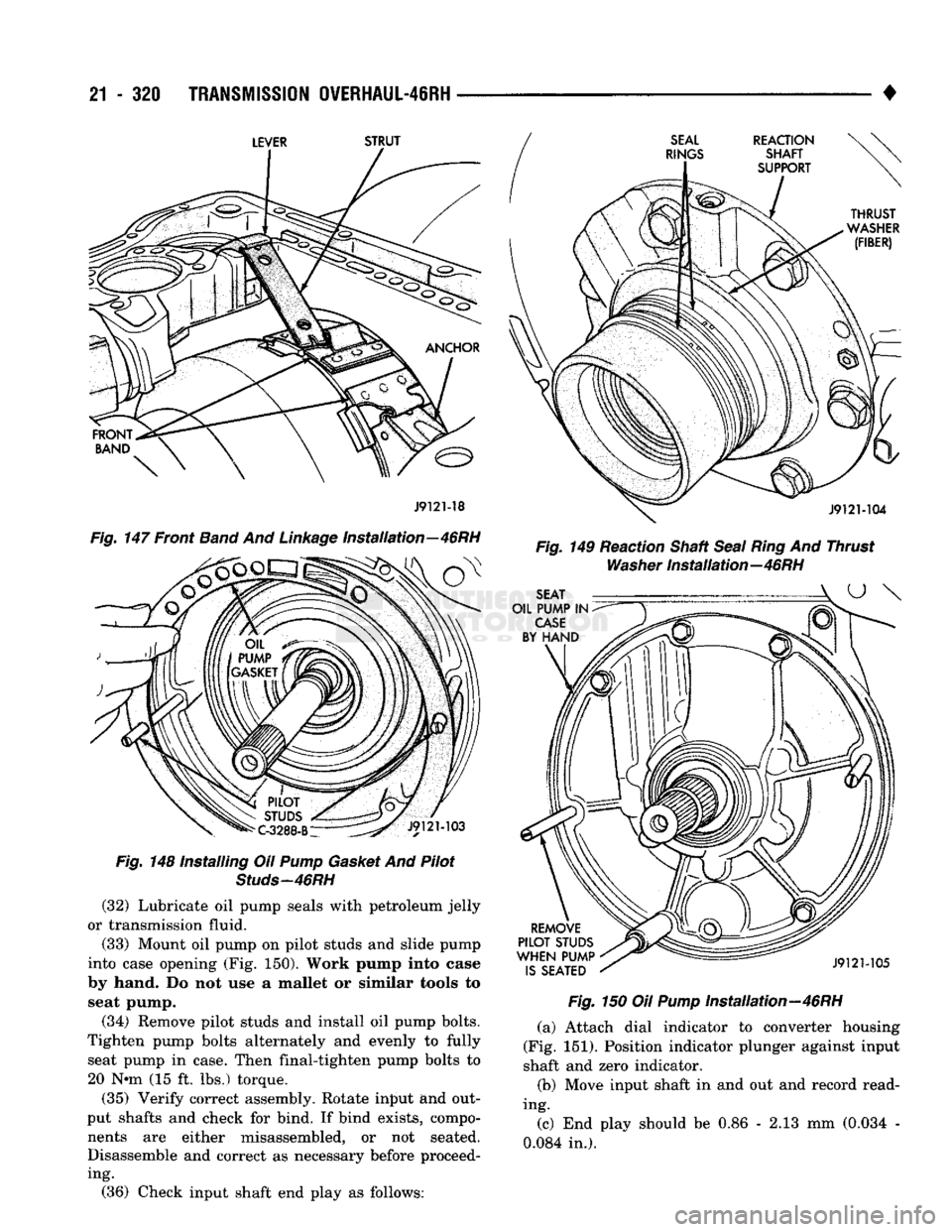

LEVER

STRUT

J9121-18

Fig.

147 Front

Band

And

Linkage

Installation—46RH

Fig.

148 Installing Oil

Pump

Gasket

And Pilot

Studs-46RH

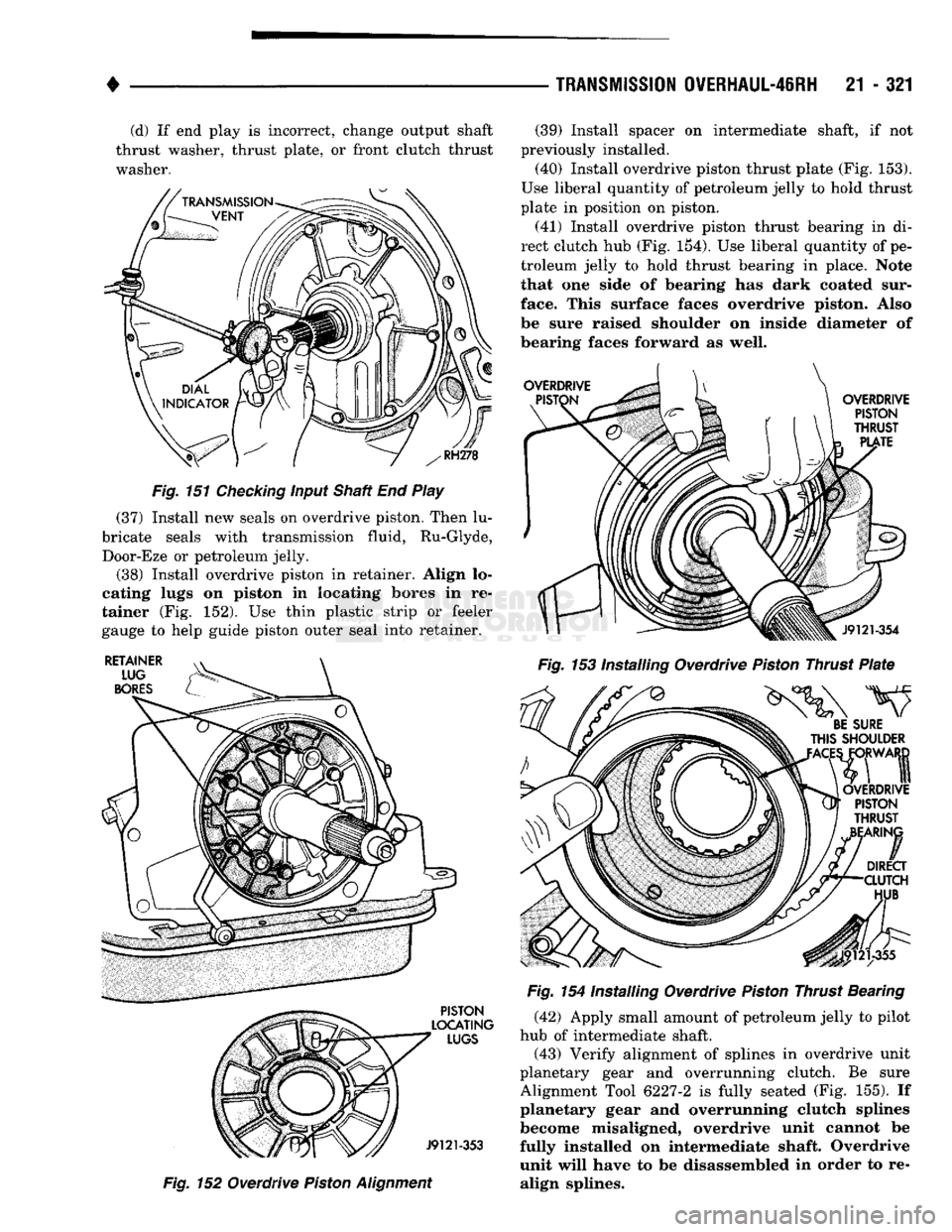

(32) Lubricate oil pump seals with petroleum jelly

or transmission fluid.

(33) Mount oil pump on pilot studs and slide pump

into case opening (Fig. 150). Work pump into case

by hand. Do not use a mallet or similar tools to seat pump.

(34) Remove pilot studs and install oil pump bolts.

Tighten pump bolts alternately and evenly to fully seat pump in case. Then final-tighten pump bolts to 20 N-m (15 ft. lbs.) torque.

(35) Verify correct assembly. Rotate input and out

put shafts and check for bind. If bind exists, compo nents are either misassembled, or not seated.

Disassemble and correct as necessary before proceeding. •

Fig.

149 Reaction Shaft

Seal Ring

And Thrust

Washer

installation—46RH

Fig.

150 Oil

Pump

installation—46RH (a) Attach dial indicator to converter housing

(Fig. 151). Position indicator plunger against input

shaft and zero indicator.

(b) Move input shaft in and out and record read

ing.

(c) End play should be 0.86 - 2.13 mm (0.034 -

0.084 in.). (36) Check input shaft end play as follows:

Page 1322 of 1502

•

TRANSMISSION

0VERHAUL-4IRH

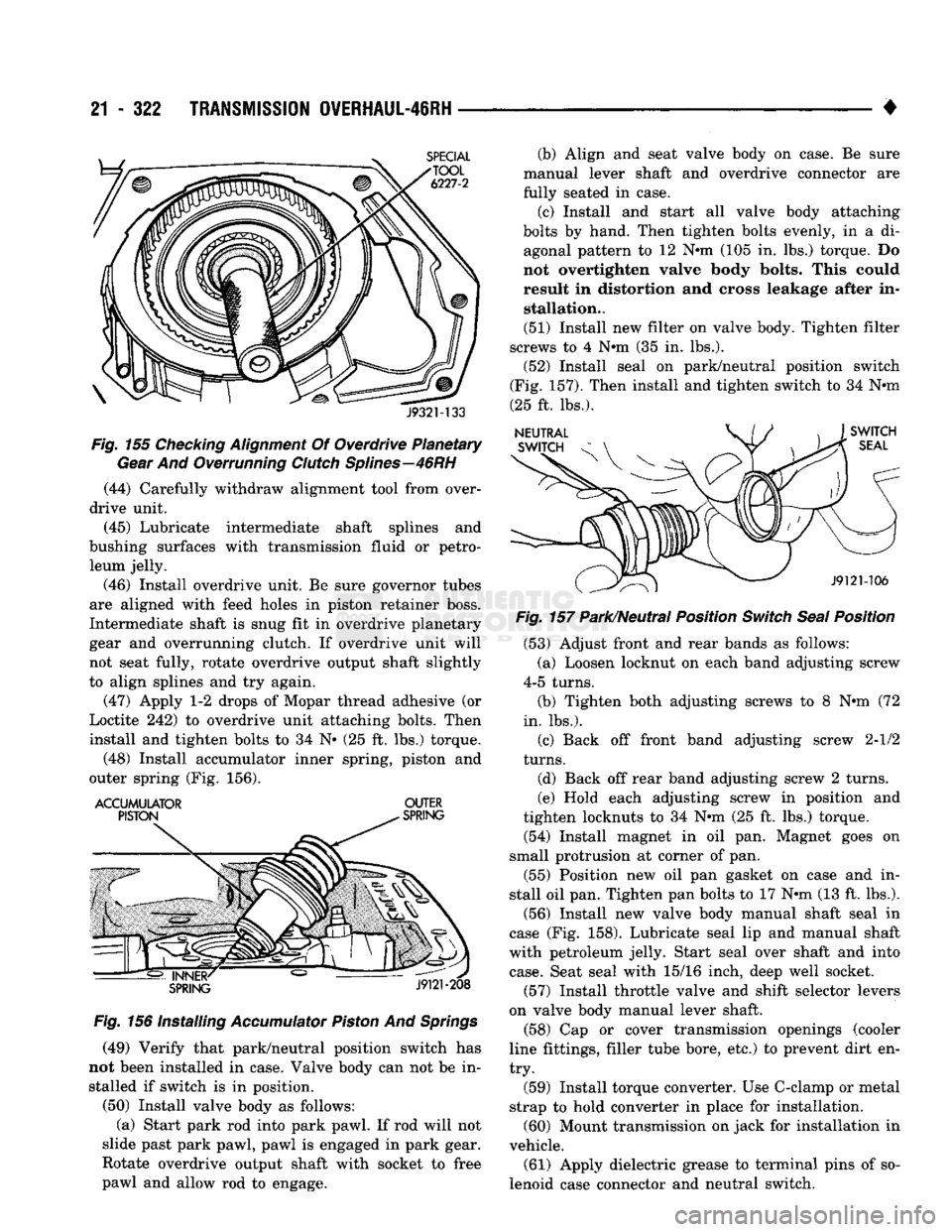

21 - 321 (d) If end play is incorrect, change output shaft

thrust washer, thrust plate, or front clutch thrust washer.

Fig.

151

Checking

input Shaft End Play

(37) Install new seals on overdrive piston. Then lu

bricate seals with transmission fluid, Ru-Glyde, Door-Eze or petroleum jelly.

(38) Install overdrive piston in retainer. Align lo

cating lugs on piston in locating bores in re

tainer (Fig. 152). Use thin plastic strip or feeler

gauge to help guide piston outer seal into retainer.

Fig.

152 Overdrive

Piston

Alignment

(39) Install spacer on intermediate shaft, if not

previously installed. (40) Install overdrive piston thrust plate (Fig. 153).

Use liberal quantity of petroleum jelly to hold thrust

plate in position on piston.

(41) Install overdrive piston thrust bearing in di

rect clutch hub (Fig. 154). Use liberal quantity of pe

troleum jelly to hold thrust bearing in place. Note

that one side of bearing has dark coated sur

face. This surface faces overdrive piston. Also

be sure raised shoulder on inside diameter of

bearing faces forward as well.

Fig.

153 Installing Overdrive

Piston

Thrust

Plate

Fig.

154 Installing Overdrive

Piston

Thrust Bearing (42) Apply small amount of petroleum jelly to pilot

hub of intermediate shaft. (43) Verify alignment of splines in overdrive unit

planetary gear and overrunning clutch. Be sure

Alignment Tool 6227-2 is fully seated (Fig. 155). If

planetary gear and overrunning clutch splines

become misaligned, overdrive unit cannot be

fully installed on intermediate shaft. Overdrive

unit will have to be disassembled in order to re align splines.

Page 1323 of 1502

21

- 322

TRANSMISSION

OVERHAUL-46RH

•

J932M33

Fig.

155

Checking

Alignment

Of Overdrive Planetary

Gear

And Overrunning

Clutch

Splines—46RH

(44) Carefully withdraw alignment tool from over

drive unit.

(45) Lubricate intermediate shaft splines and

bushing surfaces with transmission fluid or petro leum jelly.

(46) Install overdrive unit. Be sure governor tubes

are aligned with feed holes in piston retainer boss.

Intermediate shaft is snug fit in overdrive planetary

gear and overrunning clutch. If overdrive unit will

not seat fully, rotate overdrive output shaft slightly

to align splines and try again.

(47) Apply 1-2 drops of Mopar thread adhesive (or

Loctite 242) to overdrive unit attaching bolts. Then

install and tighten bolts to 34 N» (25 ft. lbs.) torque.

(48) Install accumulator inner spring, piston and

outer spring (Fig. 156).

ACCUMULATOR

OUTER

Fig.

156 Installing

Accumulator

Piston

And

Springs

(49) Verify that park/neutral position switch has

not been installed in case. Valve body can not be in stalled if switch is in position.

(50) Install valve body as follows: (a) Start park rod into park pawl. If rod will not

slide past park pawl, pawl is engaged in park gear.

Rotate overdrive output shaft with socket to free

pawl and allow rod to engage. (b) Align and seat valve body on case. Be sure

manual lever shaft and overdrive connector are

fully seated in case.

(c) Install and start all valve body attaching

bolts by hand. Then tighten bolts evenly, in a di agonal pattern to 12 Nnn (105 in. lbs.) torque. Do

not overtighten valve body bolts. This could result in distortion and cross leakage after in stallation..

(51) Install new filter on valve body. Tighten filter

screws to 4 Nnn (35 in. lbs.).

(52) Install seal on park/neutral position switch

(Fig. 157). Then install and tighten switch to 34 Nnn

(25 ft. lbs.).

Fig.

157 Park/Neutral Position

Switch

Seal

Position

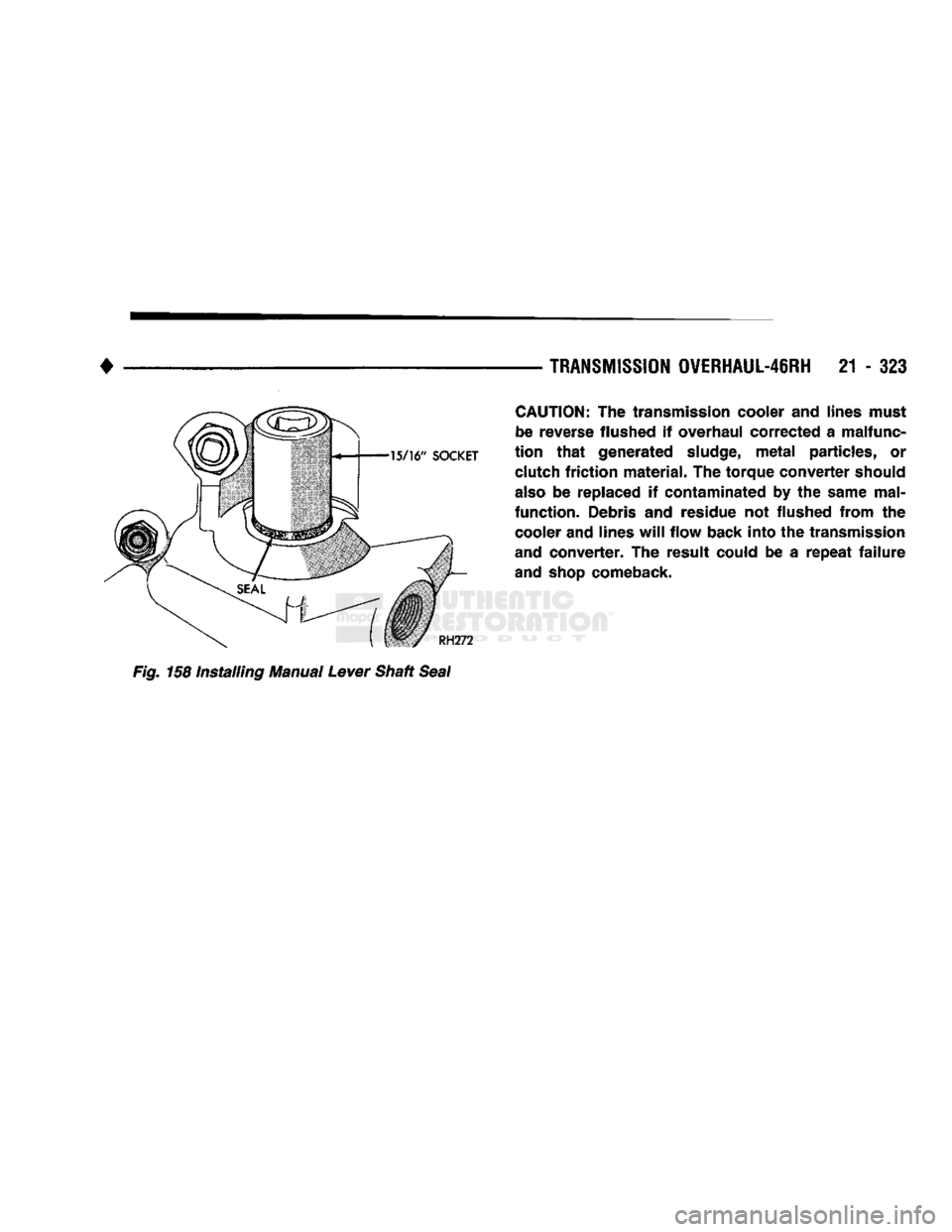

(53) Adjust front and rear bands as follows:

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 Nnn (72

in. lbs.).

(c) Back off front band adjusting screw 2-1/2

turns.

(d) Back off rear band adjusting screw 2 turns.

(e) Hold each adjusting screw in position and

tighten locknuts to 34 Nnn (25 ft. lbs.) torque.

(54) Install magnet in oil pan. Magnet goes on

small protrusion at corner of pan.

(55) Position new oil pan gasket on case and in

stall oil pan. Tighten pan bolts to 17 Nnn (13 ft. lbs.).

(56) Install new valve body manual shaft seal in

case (Fig. 158). Lubricate seal lip and manual shaft

with petroleum jelly. Start seal over shaft and into

case.

Seat seal with 15/16 inch, deep well socket.

(57) Install throttle valve and shift selector levers

on valve body manual lever shaft. (58) Cap or cover transmission openings (cooler

line fittings, filler tube bore, etc.) to prevent dirt en

try.

(59) Install torque converter. Use C-clamp or metal

strap to hold converter in place for installation. (60) Mount transmission on jack for installation in

vehicle.

(61) Apply dielectric grease to terminal pins of so

lenoid case connector and neutral switch.

Page 1324 of 1502

•

TRANSMISSION

OVERHAUL-46RH

21 - 323

CAUTION:

The transmission cooler and lines must

be reverse flushed if overhaul corrected a malfunc

tion

that

generated

sludge,

metal

particles, or clutch

friction

material. The torque converter should

also

be replaced if contaminated by the same mal

function. Debris and residue not flushed from the cooler and lines

will

flow back into the transmission

and converter. The result could be a

repeat

failure

and

shop

comeback. Fig. 158 Installing Manual Lever Shaft Seal

Page 1325 of 1502

21 - 324

OVERDRIVE

UNIT

OVERHAUL—42RH/46RH

•

OVERDRIVE

UNIT

OVERHAUL—42RH/46RH

INDEX

page

Overdrive

Geartrain

Assembly

333

Overdrive

Geartrain

Disassembly

326

Overdrive

Unit

Assembly

and

Adjustment

338

OVERDRIVE

UNIT

DISASSEMBLY

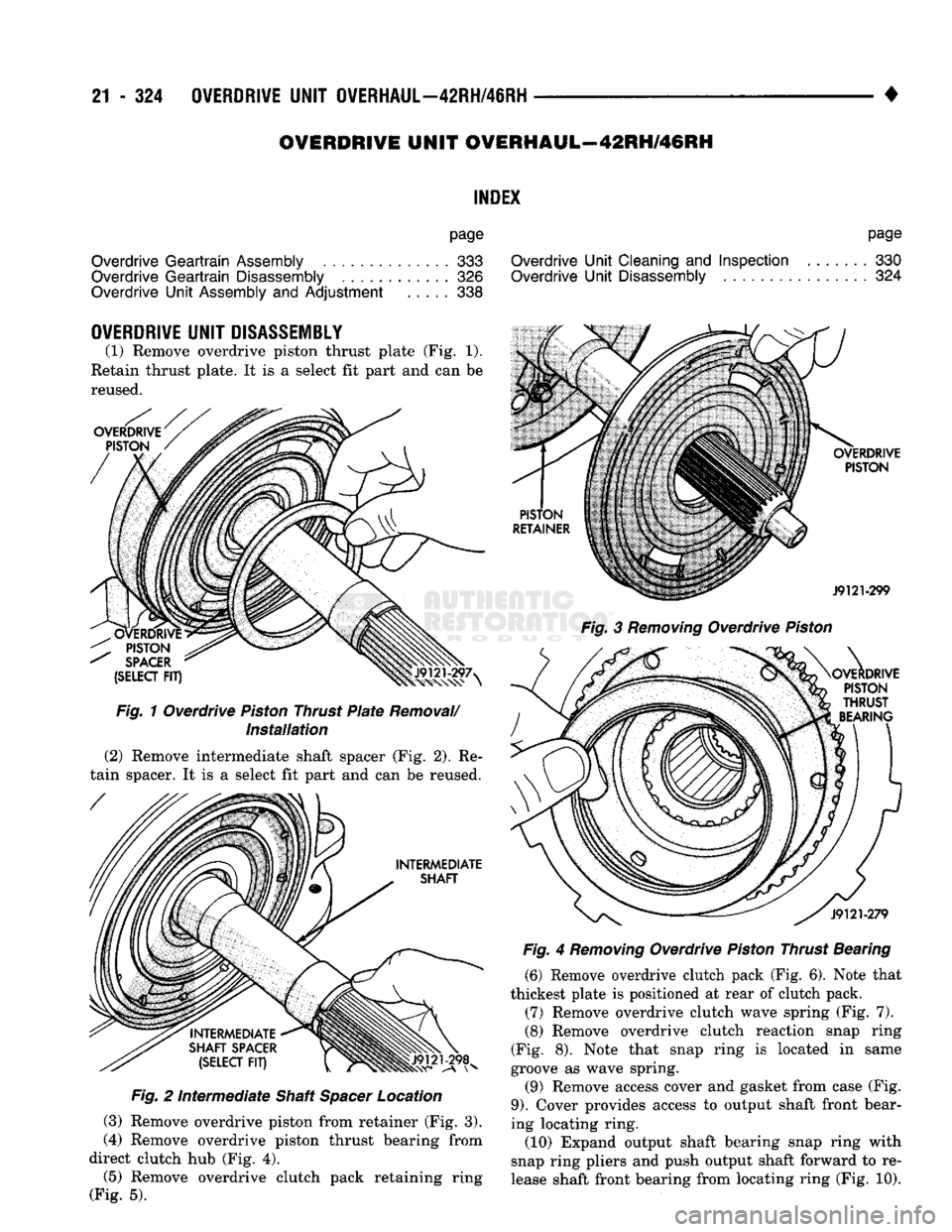

(1) Remove overdrive piston thrust plate (Fig. 1).

Retain thrust plate. It is a select fit part and can be reused.

Fig.

2

Intermediate

Shaft

Spacer

Location

(3) Remove overdrive piston from retainer (Fig. 3).

(4) Remove overdrive piston thrust bearing from

direct clutch hub (Fig. 4).

(5)

Remove overdrive clutch pack retaining ring

(Fig. 5).

page

Overdrive

Unit

Cleaning

and

Inspection

....... 330

Overdrive

Unit

Disassembly

324

Fig.

3

Removing

Overdrive

Piston

Fig.

4

Removing

Overdrive

Piston

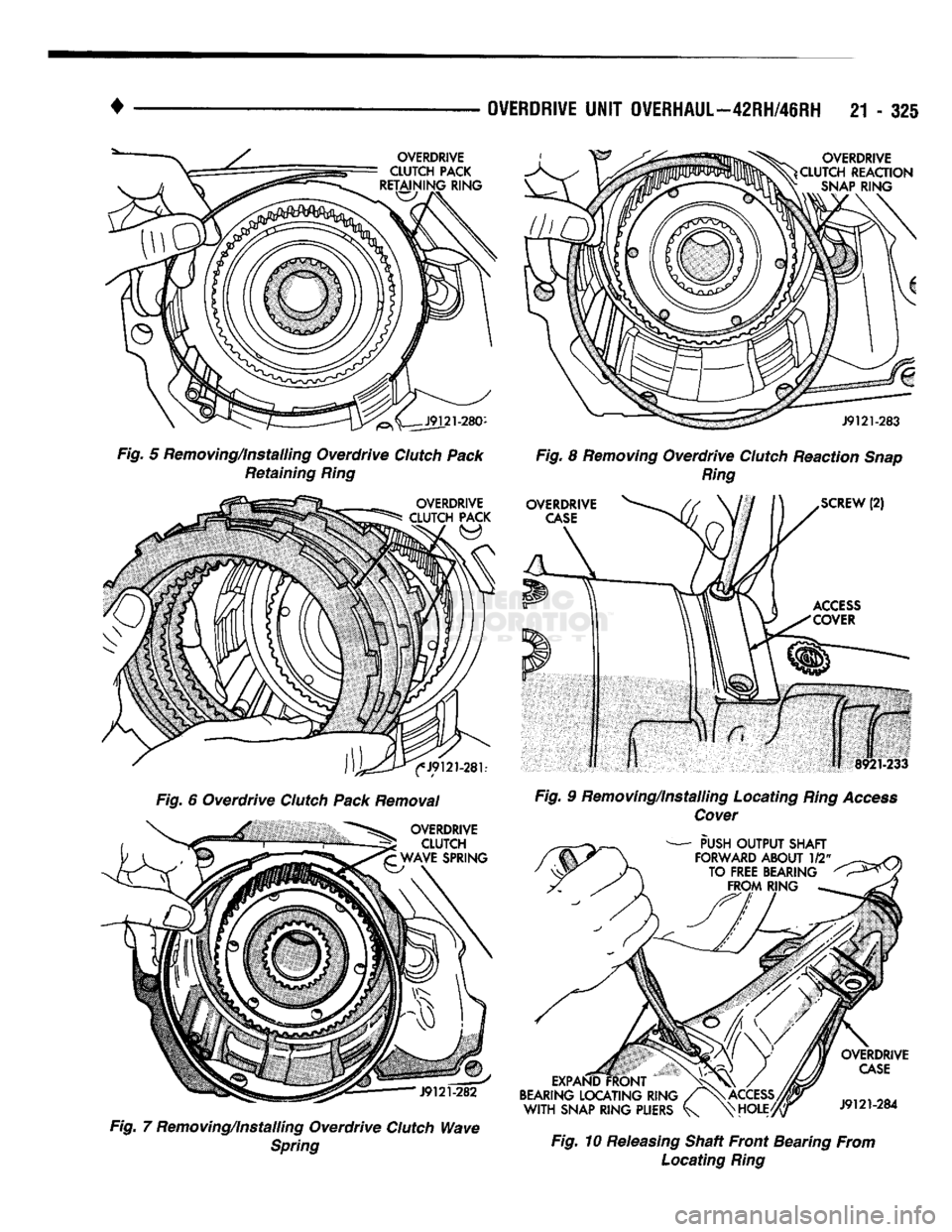

Thrust Bearing (6) Remove overdrive clutch pack (Fig. 6). Note that

thickest plate is positioned at rear of clutch pack.

(7) Remove overdrive clutch wave spring (Fig. 7).

(8) Remove overdrive clutch reaction snap ring

(Fig. 8). Note that snap ring is located in same

groove as wave spring.

(9) Remove access cover and gasket from case (Fig.

9).

Cover provides access to output shaft front bear

ing locating ring.

(10) Expand output shaft bearing snap ring with

snap ring pliers and push output shaft forward to re

lease shaft front bearing from locating ring (Fig. 10).

Page 1326 of 1502

•

OVERDRIVE UNIT OVERHAUL—42RH/46RH 21 - 325

Fig. 5 Removing/Installing Overdrive Clutch Pack Retaining Ring

Fig. 6 Overdrive Clutch Pack Removal

Fig. 7 Removing/installing Overdrive Clutch Wave Spring Fig. 8 Removing Overdrive Clutch Reaction Snap

Ring

Fig. 9 Removing/Installing Locating Ring Access Cover

Fig. 10 Releasing Shaft Front Bearing From Locating Ring

Page 1327 of 1502

21 - 326

OVERDRIVE

UNIT

OVERHAUL—42RH/46RH

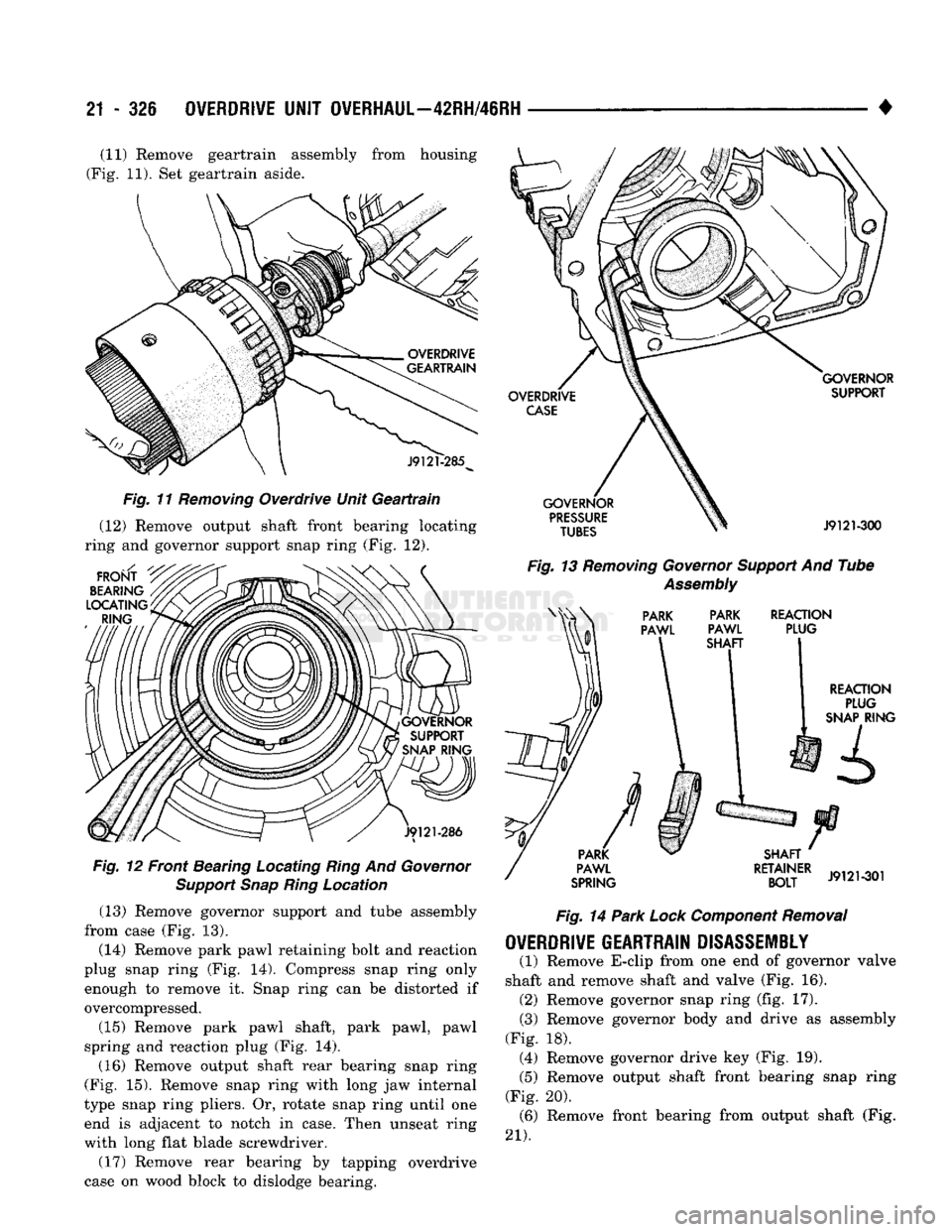

• (11) Remove geartrain assembly from housing

(Fig. 11). Set geartrain aside.

Fig. 11 Removing Overdrive Unit Geartrain

(12) Remove output shaft front bearing locating

ring and governor support snap ring (Fig. 12). Fig. 12 Front Bearing Locating Ring And Governor

Support Snap Ring Location (13) Remove governor support and tube assembly

from case (Fig. 13).

(14) Remove park pawl retaining bolt and reaction

plug snap ring (Fig. 14). Compress snap ring only enough to remove it. Snap ring can be distorted if

overcompressed.

(15) Remove park pawl shaft, park pawl, pawl

spring and reaction plug (Fig. 14). (16) Remove output shaft rear bearing snap ring

(Fig. 15). Remove snap ring with long jaw internal

type snap ring pliers. Or, rotate snap ring until one end is adjacent to notch in case. Then unseat ring

with long flat blade screwdriver.

(17) Remove rear bearing by tapping overdrive

case on wood block to dislodge bearing. Fig. 13 Removing Governor Support And Tube

Assembly

Fig. 14 Park Lock Component Removal

OVERDRIVE

GEARTRAIN

DISASSEMBLY

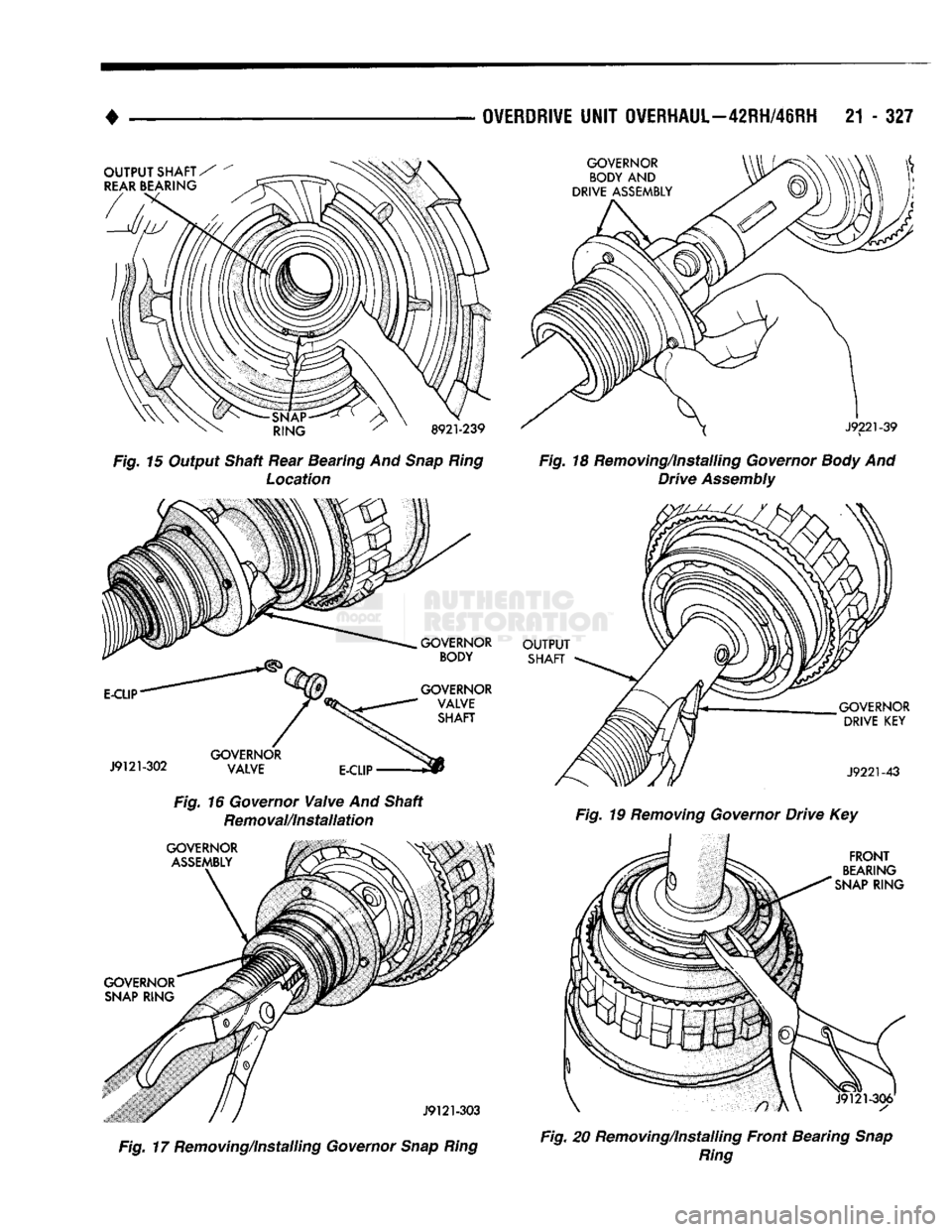

(1) Remove E-clip from one end of governor valve

shaft and remove shaft and valve (Fig. 16). (2) Remove governor snap ring (fig. 17). (3) Remove governor body and drive as assembly

(Fig. 18). (4) Remove governor drive key (Fig. 19).

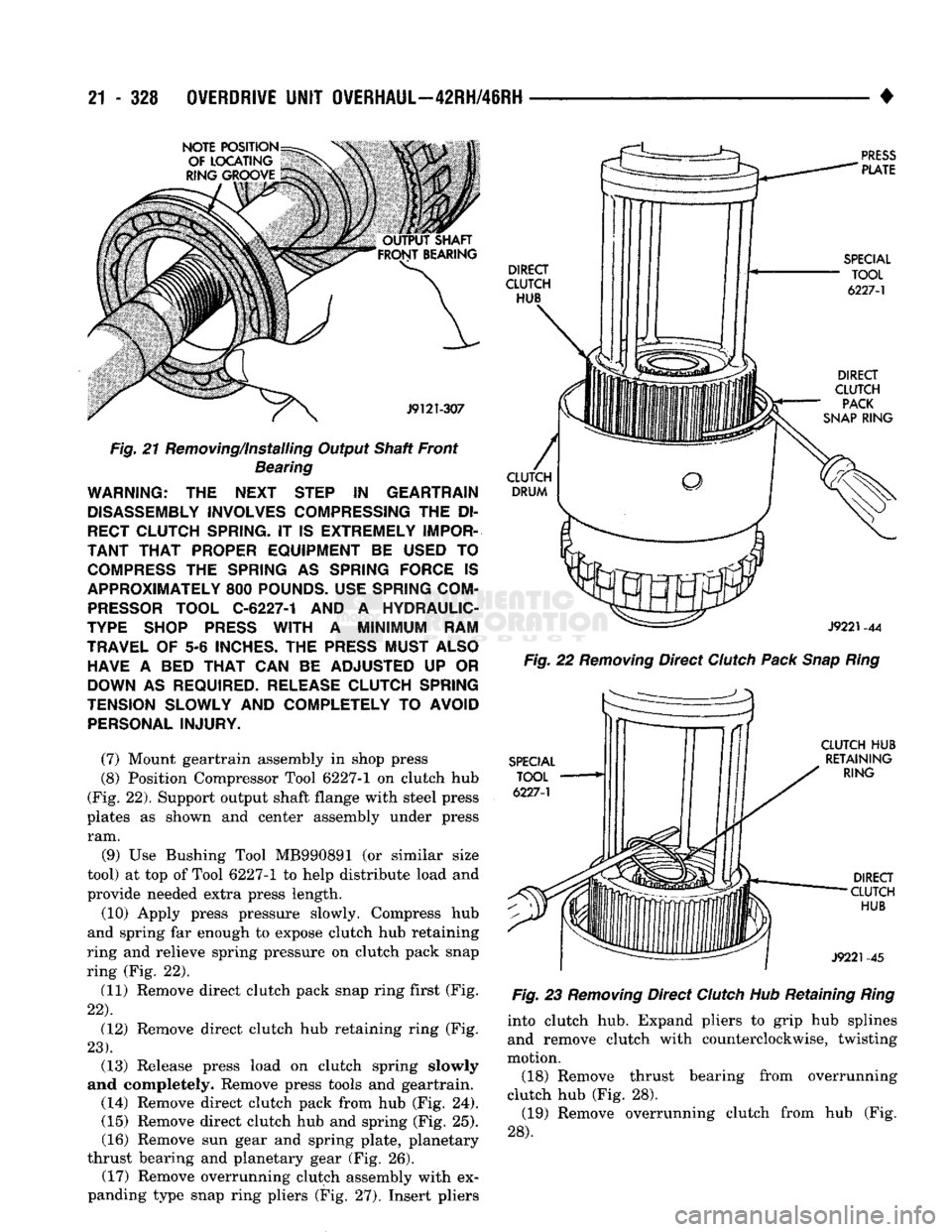

(5) Remove output shaft front bearing snap ring

(Fig. 20). (6) Remove front bearing from output shaft (Fig.

21).

Page 1328 of 1502

OVERDRIVE

UNIT OVERHAUL—42RH/48RH

21 - 327

OUTPUT

SHAFT/

REAR

BEARING

•SNAP-

RING

8921-239

Fig. 15 Output Shaft Rear Bearing And

Snap Ring

Location

E-CLIP

J9121-302

GOVERNOR

BODY

GOVERNOR VALVE SHAFT

GOVERNOR VALVE E-CLIP-

Fig. 16 Governor

Valve

And Shaft Removal/Installation

GOVERNOR

ASSEMBLY

GOVERNOR

SNAP

RING

jmr

r / j9121-303

Fig. 17 Removing/Installing Governor

Snap Ring GOVERNOR

BODY

AND

DRIVE ASSEMBLY

J9221-39

Fig. 18 Removing/Installing Governor

Body

And Drive

Assembly

OUTPUT

SHAFT

GOVERNOR DRIVE

KEY

J9221-43

Fig. 19 Removing Governor Drive Key

FRONT

BEARING

SNAP

RING

Fig. 20 Removing/Installing Front Bearing

Snap

Ring

Page 1329 of 1502

21

- 328

OVERDRIVE UNIT OVERHAUL—42RH/46RH

•

Fig.

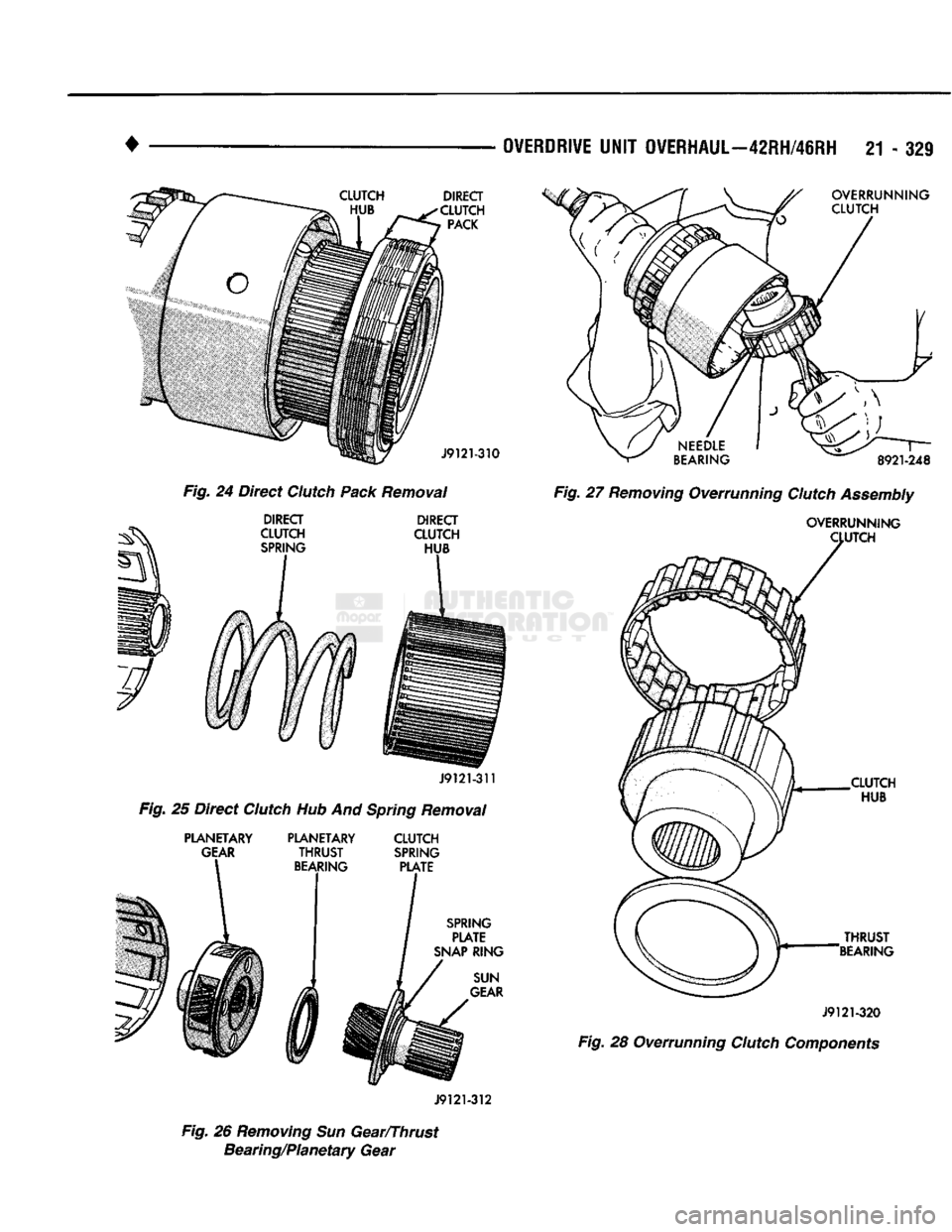

21 Removing/Installing Output Shaft Front Bearing WARNING: THE NEXT STEP IN GEARTRAIN

DISASSEMBLY INVOLVES COMPRESSING THE DI

RECT CLUTCH SPRING. IT IS EXTREMELY IMPOR

TANT THAT PROPER EQUIPMENT BE USED TO COMPRESS THE SPRING AS SPRING FORCE IS

APPROXIMATELY 800 POUNDS. USE SPRING COM PRESSOR TOOL C-6227-1 AND A HYDRAULIC-

TYPE SHOP PRESS WITH A MINIMUM RAM

TRAVEL OF 5-6 INCHES. THE PRESS MUST ALSO HAVE A BED THAT CAN BE ADJUSTED UP OR

DOWN AS REQUIRED. RELEASE CLUTCH SPRING

TENSION SLOWLY AND COMPLETELY TO AVOID PERSONAL INJURY.

(7) Mount geartrain assembly in shop press

(8) Position Compressor Tool 6227-1 on clutch hub

(Fig. 22). Support output shaft flange with steel press

plates as shown and center assembly under press ram.

(9) Use Bushing Tool MB990891 (or similar size

tool) at top of Tool 6227-1 to help distribute load and

provide needed extra press length.

(10) Apply press pressure slowly. Compress hub

and spring far enough to expose clutch hub retaining

ring and relieve spring pressure on clutch pack snap

ring (Fig. 22).

(11) Remove direct clutch pack snap ring first (Fig.

22).

(12) Remove direct clutch hub retaining ring (Fig.

23).

(13) Release press load on clutch spring slowly

and completely. Remove press tools and geartrain. (14) Remove direct clutch pack from hub (Fig. 24). (15) Remove direct clutch hub and spring (Fig. 25).

(16) Remove sun gear and spring plate, planetary

thrust bearing and planetary gear (Fig. 26). (17) Remove overrunning clutch assembly with ex

panding type snap ring pliers (Fig. 27). Insert pliers

Fig.

22

Removing

Direct

Clutch

Pack

Snap

Ring

Fig.

23

Removing

Direct

Clutch

Hub Retaining

Ring

into clutch hub. Expand pliers to grip hub splines and remove clutch with counterclockwise, twisting

motion.

(18) Remove thrust bearing from overrunning

clutch hub (Fig. 28). (19) Remove overrunning clutch from hub (Fig.

28).

Page 1330 of 1502

•

OVERDRIVE

UNIT OVERHAUL—42RH/46RH 21 - 321

Fig. 24 Direct Clutch Pack Removal Fig. 27 Removing Overrunning Clutch Assembly

J9121-312

Fig. 26 Removing Sun Gear/Thrust Bearing/Planetary Gear