belt DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 272 of 1502

COOLING SYSTEM

CONTENTS page

DIAGNOSIS

... 4

ENGINE

ACCESSORY

DRIVE BELTS

40

ENGINE

BLOCK HEATERS

48

GENERAL

INFORMATION

Throughout this group, references are made to partic

ular vehicle models by alphabetical designation or by

the particular vehicle nameplate. A chart showing a

breakdown of alphabetical designations is included in

the Introduction section at the beginning of this man

ual.

5.9L gas powered engines will be' referred to as ei

ther: LDC (Light Duty Cycle) or HDC (Heavy Duty

Cycle).

COOLING

SYSTEM

The cooling system regulates engine operating tem

perature. It allows the engine to reach normal oper-

page

SERVICE

PROCEDURES

15

SPECIFICATIONS

; 49

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre

vents overheating.

The cooling system also provides a means of heat

ing the passenger compartment and cooling the auto

matic transmission fluid (if equipped). The cooling system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

An optional factory installed maximum duty cool

ing package is available on most models. This pack age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

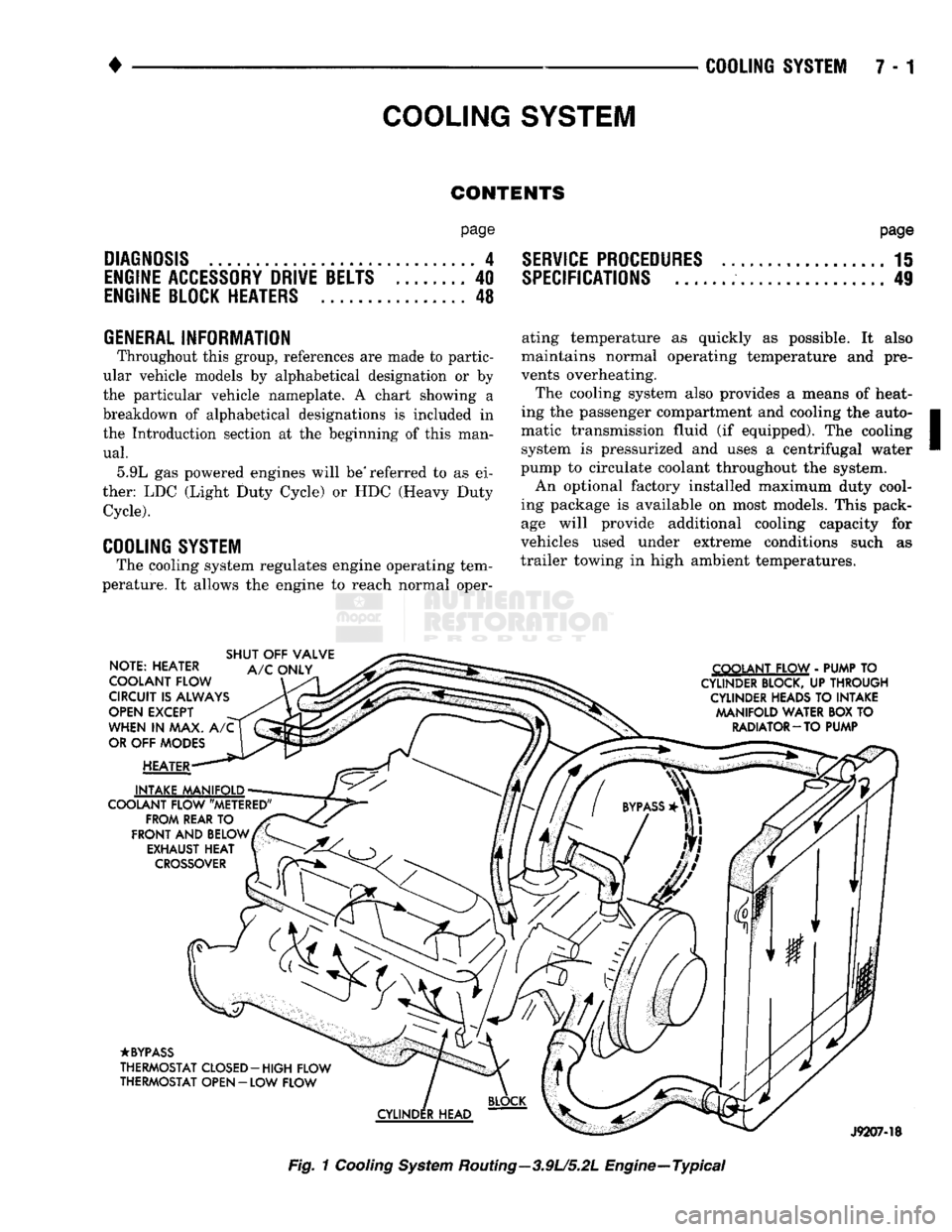

NOTE: HEATER

COOLANT FLOW

CIRCUIT

IS

ALWAYS

OPEN

EXCEPT

WHEN

IN MAX. A/C

OR

OFF

MODES

HEATER

INTAKE MANIFOLD

COOLANT FLOW "METERED" FROM REAR

TO

FRONT

AND

BELOW EXHAUST

HEAT

CROSSOVER

SHUT

OFF

VALVE

A/C

ONLY COOLANT FLOW

-

PUMP

TO

CYLINDER BLOCK,

UP

THROUGH CYLINDER HEADS

TO

INTAKE MANIFOLD WATER

BOX TO

RADIATOR-TO PUMP

•BYPASS

THERMOSTAT CLOSED-HIGH FLOW

THERMOSTAT OPEN

- LOW

FLOW

J9207-18

Fig.

1

Cooling

System

Routing—3.9U5.2L Engine—Typical

Page 275 of 1502

DIAGNOSIS

PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING Establish what driving conditions caused the com

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

1.

PROLONGED IDLE, VERY HIGH AMBI

ENT TEMPERATURE, SLIGHT TAIL WIND AT

IDLE, SLOW TRAFFIC, TRAFFIC JAMS, HIGH SPEED OR STEEP GRADES.

Driving techniques that avoid overheating are:

• Idle with A/C off when temperature gauge is at

end of normal range. * Increasing engine speed for more air flow is recom

mended.

2.

TRAILER TOWING: Consult Trailer Towing section of owners manual.

Do not exceed limits.

3.

AIR CONDITIONING; ADD-ON OR AFTER

MARKET: A maximum cooling package should have been or

dered with vehicle if add-on or after market A/C is

SYMPTOM AND ACTION

SYMPTOM

installed. If not, maximum cooling system compo

nents should be installed for model involved per

manufacturer's specifications.

4.

RECENT SERVICE OR ACCIDENT RE

PAIR:

Determine if any recent service has been performed

on vehicle that may effect cooling system. This may

be:

• Engine adjustments (incorrect timing)

• Slipping engine accessory drive belt(s) • Brakes (possibly dragging)

• Changed parts. Incorrect water pump or pump ro

tating in wrong direction due to belt not correctly

routed

• Reconditioned radiator or cooling system refilling (possibly under filled or air trapped in system).

If investigation reveals none of the above as a

cause for an engine overheating complaint, refer to

the following Symptom and Action chart:

PRELIMINARY FIRST) ACTION

Blinking Engine Temperature

Warning Light or High Gauge indication - Without Coolant Loss

Normal during temporary operation

with

heavy load, towing

a

trailer,

high

outdoor temperatures, and/or on

a

steep

Loss

grade.

Coolant Loss

Hot Vehicle (Not Engine) Heat Damage,

Hot Carpet, Seat,

Hot

Catalytic

Converter,

Smoke, Burnt Odor

Hot Engine Crackling Noise Hot Smell

Severe Local Hot Spots

Coolant Color

Coolant Reserve Bottle Level Changes

Coolant Not Returning To Radiator

Improper refilling procedures

can

result

in

trapped air

in

the

system.

Subsequent

operation

of the

pressure cap and coolant reserve system

will

deaereate

the

cooling

system.

A low

coolant

level

will

then result

in the

Coolant Reserve

Tank. Add coolant.

If

condition persists,

refer

to

System

Diagnosis.

Check

heat shielding, exhaust

system,

engine emission controls, ignition

timing, engine misfiring.

A

moderate amount

of

sound from heating

metal

can

be

expected

with

any

vehicle. However,

a

crackling sound from

trie

thermostat

housing,

a hot

smell and/or severe local

hot

spots on

an

engine can indicate blocked coolant

passages,

bad castina, core sand deposits and subsequent blockage,

cracked cylinder block

or

head,

or

blown cylinder head gasket. Usually

accompanied

with

coolant

loss.

Coolant

color is

not

necessarily

an

indication

of

adequate

temperature

or

corrosion

protection.

Level changes

are to be

expected as coolant volume fluctuates

with

engine

temperature.

If the

level

in the

bottle

is

between

the

Maximum and Minimum

marks

at

normal engine operating temperature,

the

level

should

return

to

within

that

range

after

operation

at

elevated temperatures.

Coolant

will

not

return

to the

radiator

if the

radiator cap vent valve does

not

function,

if

an

air

leak destroys vacuum,

or if the

overflow

passage

is

blocked

or

restricted. Inspect

all

portions

of the

overflow

passage,

pressure

cap,

filler

neck nipple, hose, and

passages

within

the

bottle

for

vacuum leak

only. Coolant

return

failure

will

be

evident

by a low

level

in the

radiator.

Reserve

bottle

level

should increase during heat-up.

J9207-31

Page 278 of 1502

•

COOLING

SYSTEM

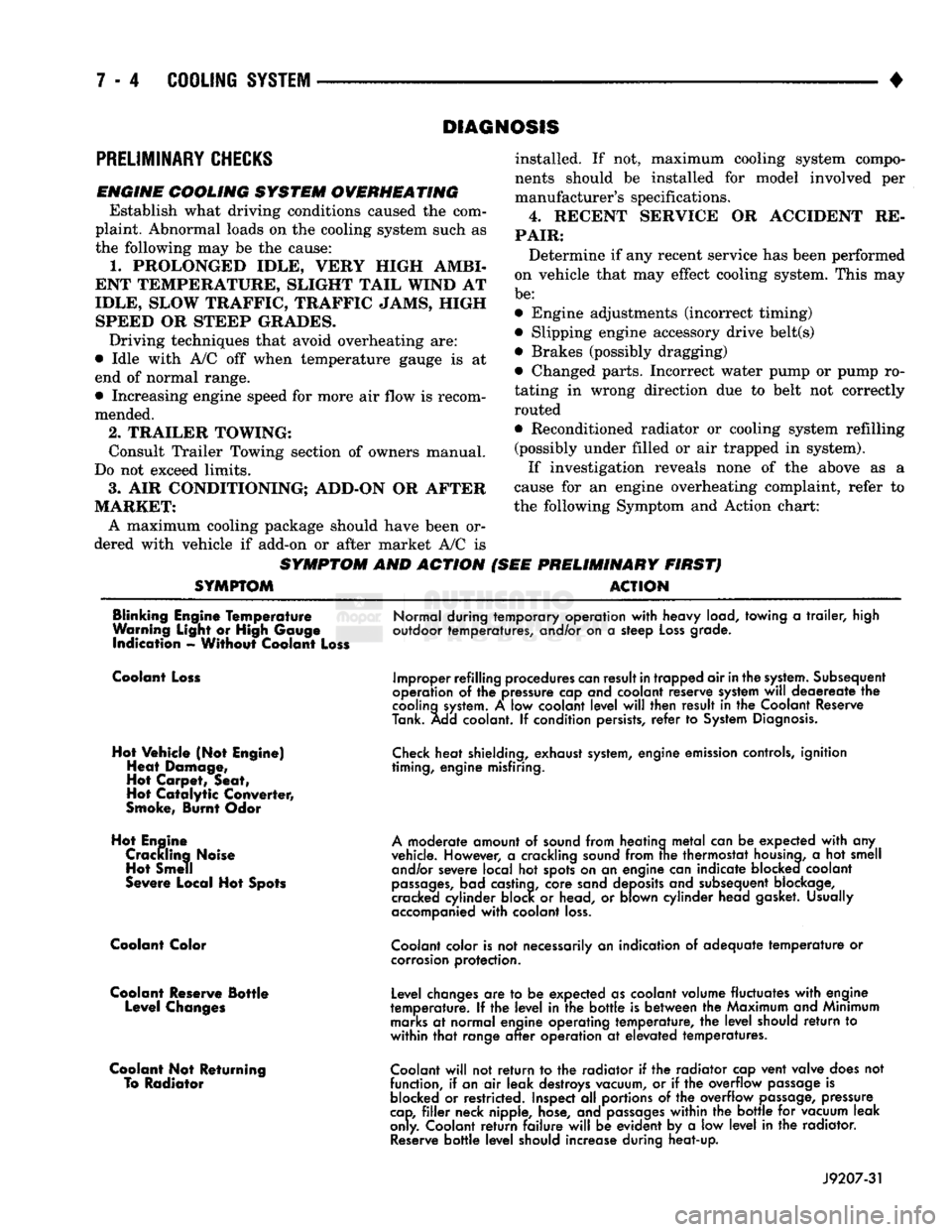

7 - 7 COOLING SYSTEM DIAGNOSIS (EXCEPT DIESELJ-GONTINUED

CONDITION

AND

CHECKS

DIAGNOSIS

TEMPERATURE

GAUGE

IS

INCONSISTENT,

CYCLES

AND/OR

IS

ERRATIC.

(1) Is cycle normal.

MID

(a)

Normal Gauge Reaction to Thermostat Cycle.

MID

(b) Normal Gauge Reaction at Stop After Heavy Use.

(c) Hot Water Build-Up is Normal at

Stop

after

Heavy Use.

(2)

Is

coolant in radiator low (air

will

build up in the cooling

system

(2)

Fill

system,

vent trapped air and check for leaks,

and

cause

the thermostat to open

late).

(3)

Is

a cylinder head gasket leak allowing exhaust

gas

to

enter

(3) a — Test for leaking cylinder head

gasket

leak

with

a

cooling

system

(exhaust

gas

building up in the cooling

system

will

commercially available Block Leak Tester,

cause

the thermostat to open

late).

b

— Check for coolant in engine oil.

c

— Inspect for

white

steam from exhaust

system.

(4)

Water pump impeller loose on shaft.

Loose

accessory

drive belt. (4) Repair or replace as necessary.

(5)

Air leak

on

the

suction

side of the

water

pump (allows air to build (5) Find leak and repair,

up

in cooling

system

causing

thermostat to open

late).

WARNING

LIGHT

GLOWS

ALL

THE

TIME

(VEHICLE

NOT

EQUIPPED

WITH

GAUGE).

(1) Inspect

temperature

gauge

sending

unit. The warning light

sending

(1)

Ensure

that

a warning light

sending

unit

is

installed, unit

has

a screwdriver slot in the electrode (used for calibration).

Gauge

sending

units do not have a slot in the electrode.

NO

GAUGE

READING

INITIALLY

THEN

HOT

INDICATION

(VEHICLE

EQUIPPED

WITH

GAUGE).

(1)

Gauge

stationary

until

very hot, then

moves

immediately to "H"

(1)

Vehicle

is

equipped

with

sending

unit for light not

gauge.

J9007-70

Page 283 of 1502

7

- 12

COOLING

SYSTEM

• DIESEL COOLING SYSTEM DIAGNOSIS-CONTINUED

CONDITION

AND

CHECKS

DIAGNOSIS

TEMPERATURE GAUGE

IS

INCONSISTENT,

CYCLES

AND/OR

IS

ERRATIC.

J

(1)

Is

cycle

normal.

(a)

Normal

Gauge

Reaction

to Thermostat

Cycle.

Normal

Gauge

Reaction

to Thermostat

Cycle.

MID

(b)

Normal

Gauge

Reaction

at

Stop

After

Heavy

Use.

(c)

Hot

Water

Build-Up

Is

Normal

at

Stop

after

Heavy

Use.

(2)

Is

coolant

in

radiator

low

(air

will

build

up in

the

cooling

system and cause

the

thermostat

to

open

late). (2)

Fill

system,

vent

trapped

air

and

check

for

leaks.

(3)

Is

a

cylinder

head

gasket

leak

allowing

exhaust

gas

to

enter

cooling

system

(exhaust

gas

building

up in

the

cooling

system

will

cause

the

thermostat

to

open

late).

(3)

a

—

Test

for

leaking

cylinder

gasket

leak

with

a

commercially

available

Block

Leak

Tester,

b

—

Check

for

coolant

in

enaine

oil.

c

—

Inspect

for

white

steam

from

exhaust

system.

(4)

Water

pump

impeller

loose

on

shaft.

Loose

accessory

drive

belt. (4)

Repair or

replace

as

necessary.

(5)

Air

leak

on

the

suction

side

of the

water

pump

(allows

air

to

build

up in

cooling

system causing

thermostat

to

open

late). (5)

Find

leak

and

repair.

PRESSURE

CAP

VENTS

TO

ATMOSPHERE

AND

COOL

ANT

RESERVE

TANK.

TEMPERATURE GAUGE

READ

ING ABOVE NORMAL

BUT NOT

HIGH.

(1)

Test

radiator

pressure

cap

relief

pressure.

Refer

to

Radiator

Pressure

cap

section

in

this

group.

ID

Replace

cap

if relief

pressure

is

lower

than

14

psi.

COOLANT

LOSS

VISIBLE

ON

GROUND BELOW VEHI

CLE,

BUT NO

PRESSURE

CAP

BLOW

OFF.

(1)

Inspect

system

for

leaks.

(1)

Repair

as

necessary.

J9107-23

Page 286 of 1502

•

COOLING SYSTEM

7 - 15

SERVICE

PROCEDURES

INDEX

page

Coolant

26

Coolant Reserve/Overflow System

30

Cooling System Cleaning/Reverse Flushing

28

Cooling System Fan—Diesel Engine

. 37

Cooling System

Fan—Gas

Engines

36

Cooling System

Hoses

34

Draining Cooling System

27

Pressure

Testing

Radiator

Caps

............. 32

Radiator Pressure

Cap 31

Radiators

32

Refilling

the

Cooling System

28

WATER PUMPS—EXCEPT DIESEL

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a drive belt. The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven

tilation. The water pump seals are lubricated by an

tifreeze in the coolant mixture. Additional lubrication is not necessary. A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core. The water pump on all models can be removed

without discharging the air conditioning system (if equipped).

REMOVAL The water pump on all gas powered engines is

bolted directly to the engine timing chain case/cover.

A gasket is used as a seal between the water pump

and timing chain case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for fa tigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if any of these conditions are found. Also check condi

tion of the thermal viscous fan drive. Refer to Vis

cous Fan Drive in this group. (1) Disconnect negative battery cable from battery.

(2) Drain cooling system. Refer to Draining Cool

ing System in this group. Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3)

Disconnect throttle cable from clip at top of fan

shroud.

page

Testing

Cooling System

for

Leaks

. 29

Thermostat

22

Transmission

Oil

Cooler—Diesel

35

Transmission

Oil

Cooler—Except Diesel

35

Transmission Oil-To-Air Cooler

36

Viscous

Fan

Drive

38

Water

Pump

Bypass

Hose—All

Gas

Powered

Engines

.............................. 19

Water

Pumps—5.9L Diesel

18

Water

Pumps—Except Diesel

15

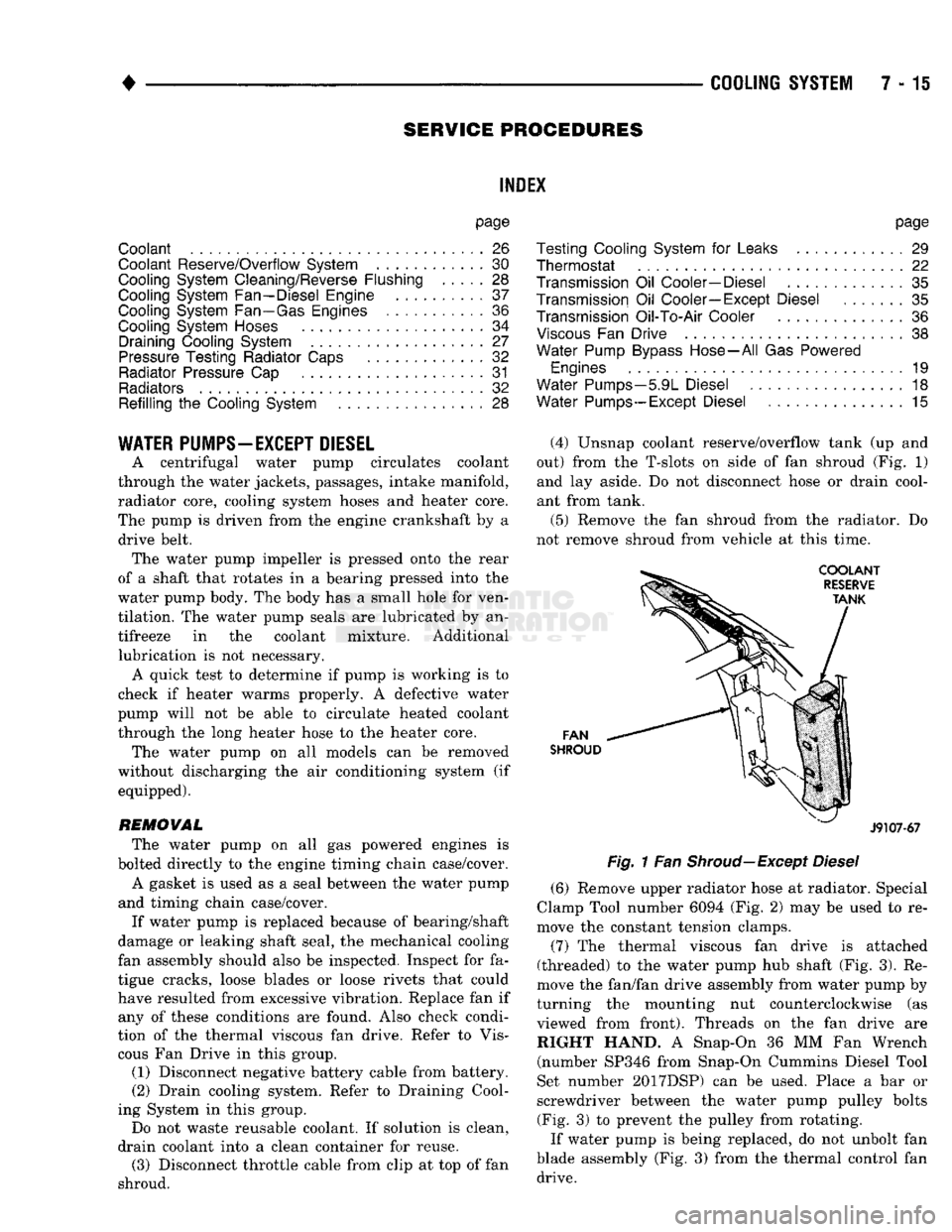

(4) Unsnap coolant reserve/overflow tank (up and

out) from the T-slots on side of fan shroud (Fig. 1) and lay aside. Do not disconnect hose or drain cool

ant from tank.

(5) Remove the fan shroud from the radiator. Do

not remove shroud from vehicle at this time.

FAN

SHROUD

J9107-67

Fig.

1 Fan

Shroud—Except

Diesel

(6) Remove upper radiator hose at radiator. Special

Clamp Tool number 6094 (Fig. 2) may be used to re

move the constant tension clamps.

(7) The thermal viscous fan drive is attached

(threaded) to the water pump hub shaft (Fig. 3). Re

move the fan/fan drive assembly from water pump by

turning the mounting nut counterclockwise (as viewed from front). Threads on the fan drive are RIGHT HAND. A Snap-On 36 MM Fan Wrench (number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used. Place a bar or

screwdriver between the water pump pulley bolts (Fig. 3) to prevent the pulley from rotating.

If water pump is being replaced, do not unbolt fan

blade assembly (Fig. 3) from the thermal control fan drive.

Page 287 of 1502

7 - 16

COOLING

SYSTEM

•

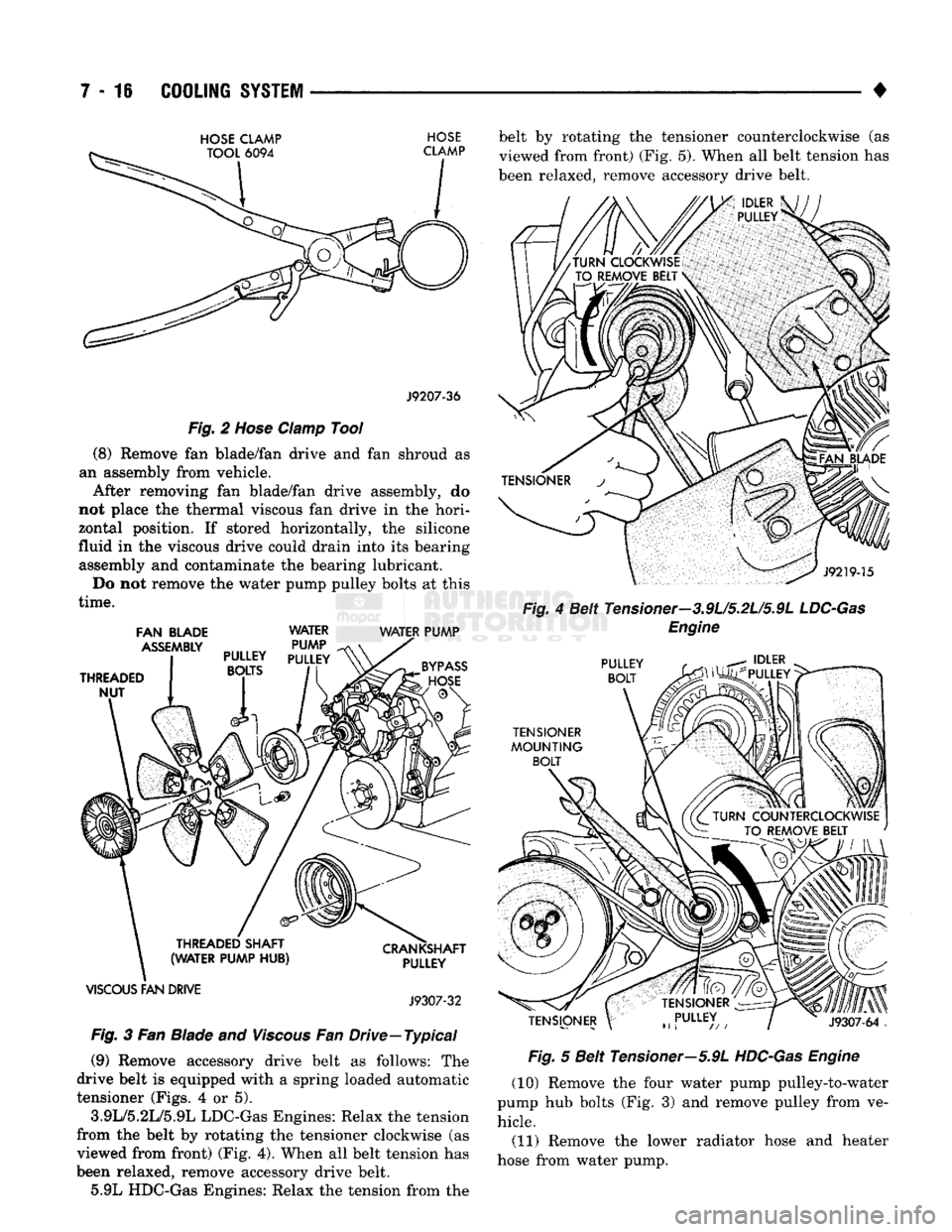

HOSE

CLAMP

HOSE

J9207-36

Fig.

2

Hose

Clamp

Tool

(8) Remove fan blade/fan drive and fan shroud as

an assembly from vehicle. After removing fan blade/fan drive assembly, do

not place the thermal viscous fan drive in the hori

zontal position. If stored horizontally, the silicone

fluid in the viscous drive could drain into its bearing assembly and contaminate the bearing lubricant.

Do not remove the water pump pulley bolts at this

time.

FAN

BLADE

WATER WATER

PUMP

VISCOUS

FAN

DRIVE

J9307-32

Fig.

3 Fan Blade and

Viscous

Fan Drive—Typical (9) Remove accessory drive belt as follows: The

drive belt is equipped with a spring loaded automatic

tensioner (Figs. 4 or 5).

3.9L/5.2L/5.9L LDC-Gas Engines: Relax the tension

from the belt by rotating the tensioner clockwise (as

viewed from front) (Fig. 4). When all belt tension has

been relaxed, remove accessory drive belt. 5.9L HDC-Gas Engines: Relax the tension from the belt by rotating the tensioner counterclockwise (as

viewed from front) (Fig. 5). When all belt tension has

been relaxed, remove accessory drive belt.

Fig.

4 Belt Tensioner—3.9L/5.2L/5.9L

LDC-Gas

Engine

Fig.

5 Belt Tensioner—5.9L

HDC-Gas

Engine

(10) Remove the four water pump pulley-to-water

pump hub bolts (Fig. 3) and remove pulley from ve hicle.

(11) Remove the lower radiator hose and heater

hose from water pump.

Page 289 of 1502

7 - 18

COOLING

SYSTEM

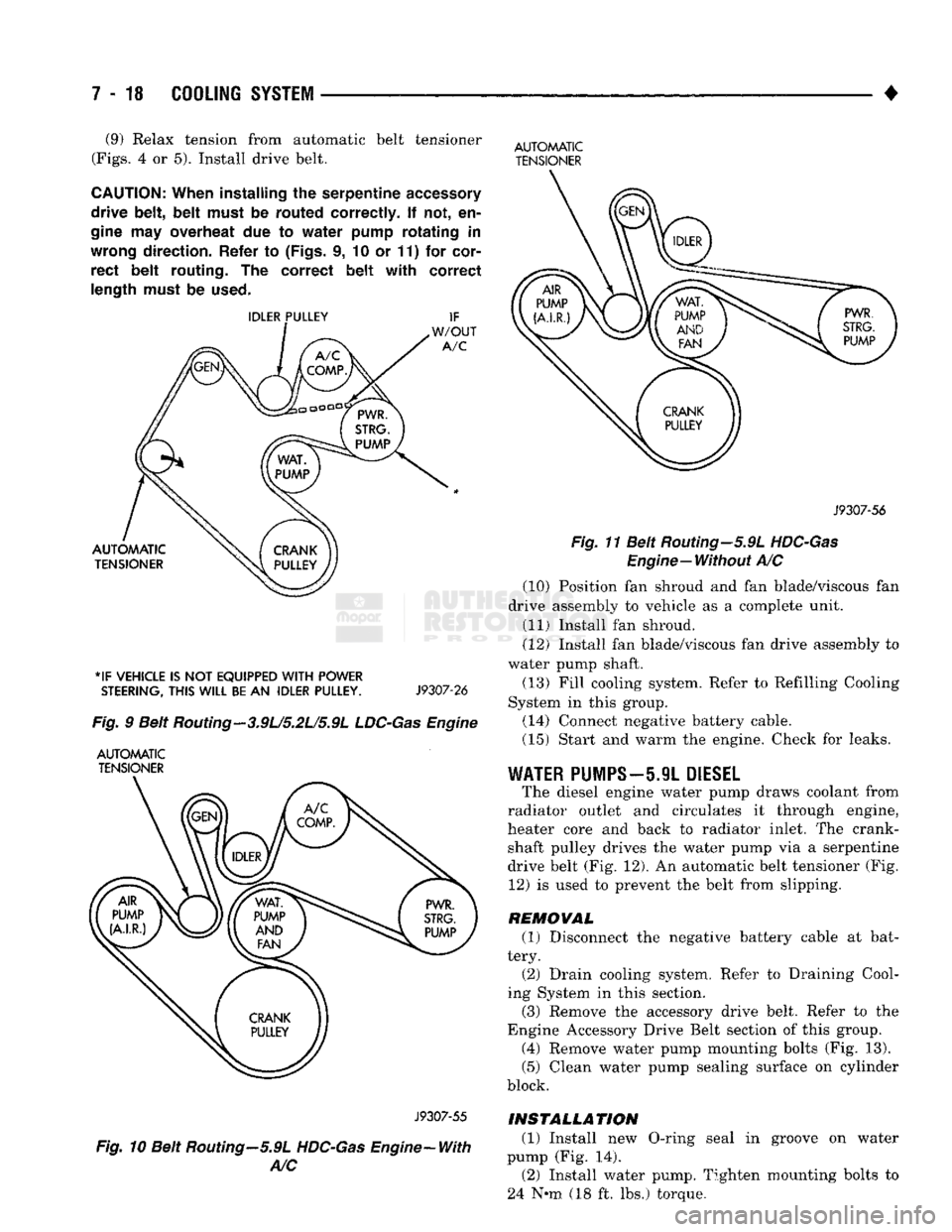

• (9) Relax tension from automatic belt tensioner

(Figs.

4 or 5). Install drive belt.

CAUTION:

When

installing

the

serpentine

accessory

drive

belt, belt

must

be

routed

correctly.

If not, en

gine

may

overheat

due to

water

pump

rotating

in

wrong

direction.

Refer

to

(Figs,

i, 10 or 11) for

cor

rect

belt

routing.

The

correct

belt with

correct

length

must

be

used.

*IF

VEHICLE

IS NOT

EQUIPPED

WITH

POWER

STEERING,

THIS

WILL

BE

AN

IDLER

PULLEY.

J9307-26

Fig.

9 Belt Routing—3.9U5.2L/5.9L

LDC-Gas

Engine

AUTOMATIC

TENSIONER

AUTOMATIC

TENSIONER

J9307-56

Fig.

11 Belt Routing—5.9L

HDC-Gas

Engine—Without

A/C (10) Position fan shroud and fan blade/viscous fan

drive assembly to vehicle as a complete unit. (11) Install fan shroud.

(12) Install fan blade/viscous fan drive assembly to

water pump shaft.

(13) Fill cooling system. Refer to Refilling Cooling

System in this group. (14) Connect negative battery cable.

(15) Start and warm the engine. Check for leaks.

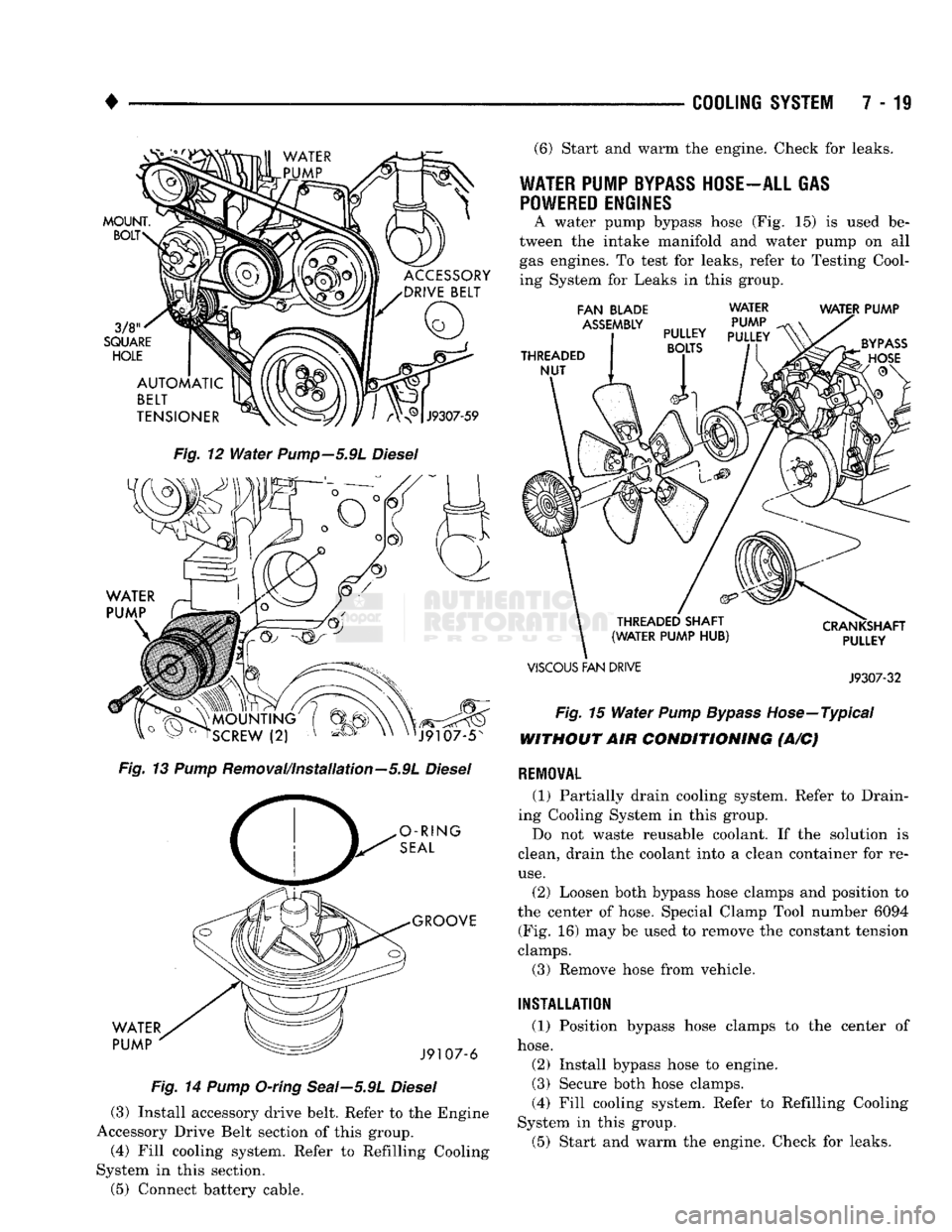

WATER

PUMPS—5.9L

DIESEL

The diesel engine water pump draws coolant from

radiator outlet and circulates it through engine,

heater core and back to radiator inlet. The crank shaft pulley drives the water pump via a serpentine

drive belt (Fig. 12). An automatic belt tensioner (Fig. 12) is used to prevent the belt from slipping.

REMOVAL (1) Disconnect the negative battery cable at bat

tery. (2) Drain cooling system. Refer to Draining Cool

ing System in this section.

(3) Remove the accessory drive belt. Refer to the

Engine Accessory Drive Belt section of this group. (4) Remove water pump mounting bolts (Fig. 13).

(5) Clean water pump sealing surface on cylinder

block.

J9307-55

Fig.

10 Belt Routing—5.9L

HDC-Gas

Engine-With

A/C

INSTALLATION

(1) Install new O-ring seal in groove on water

pump (Fig. 14). (2) Install water pump. Tighten mounting bolts to

24 N-m (18 ft. lbs.) torque.

Page 290 of 1502

•

COOLING

SYSTEM

7-11

MOUNT.

BOLT

3/8

SQUARE

HOLE

ACCESSORY

DRIVE

BELT AUTOMATIC

BELT

TENSIONER

J9307-59

Fig.

12

Water

Pump—5.91

Diesel

o ~ " o

rSCREW

(2) v '^ov XN

nJ9107-5N

Fig.

13

Pump

Removal/Installation—5.9L

Diesel

O-RING

SEAL

WATER

PUMP

GROOVE

J9107-6

Fig.

14

Pump

O-ring Seal—5.9L

Diesel

(3) Install accessory drive belt. Refer to the Engine

Accessory Drive Belt section of this group.

(4) Fill cooling system. Refer to Refilling Cooling

System in this section.

(5) Connect battery cable. (6) Start and warm the engine. Check for leaks.

WATER PUMP

BYPASS

HOSE-ALL GAS POWERED ENGINES

A water pump bypass hose (Fig. 15) is used be

tween the intake manifold and water pump on all gas engines. To test for leaks, refer to Testing Cool

ing System for Leaks in this group.

FAN

BLADE

ASSEMBLY

THREADED

NUT

WATER

PUMP

PULLEY

PULLEY BOLTS WATER PUMP

THREADED SHAFT

(WATER PUMP

HUB)

VISCOUS

FAN DRIVE CRANKSHAFT

PULLEY

J9307-32

Fig.

15

Water

Pump Bypass

Hose—Typical

WITHOUT AIR CONDITIONING (A/C)

RE10WAL

(1) Partially drain cooling system. Refer to Drain

ing Cooling System in this group.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for re

use.

(2) Loosen both bypass hose clamps and position to

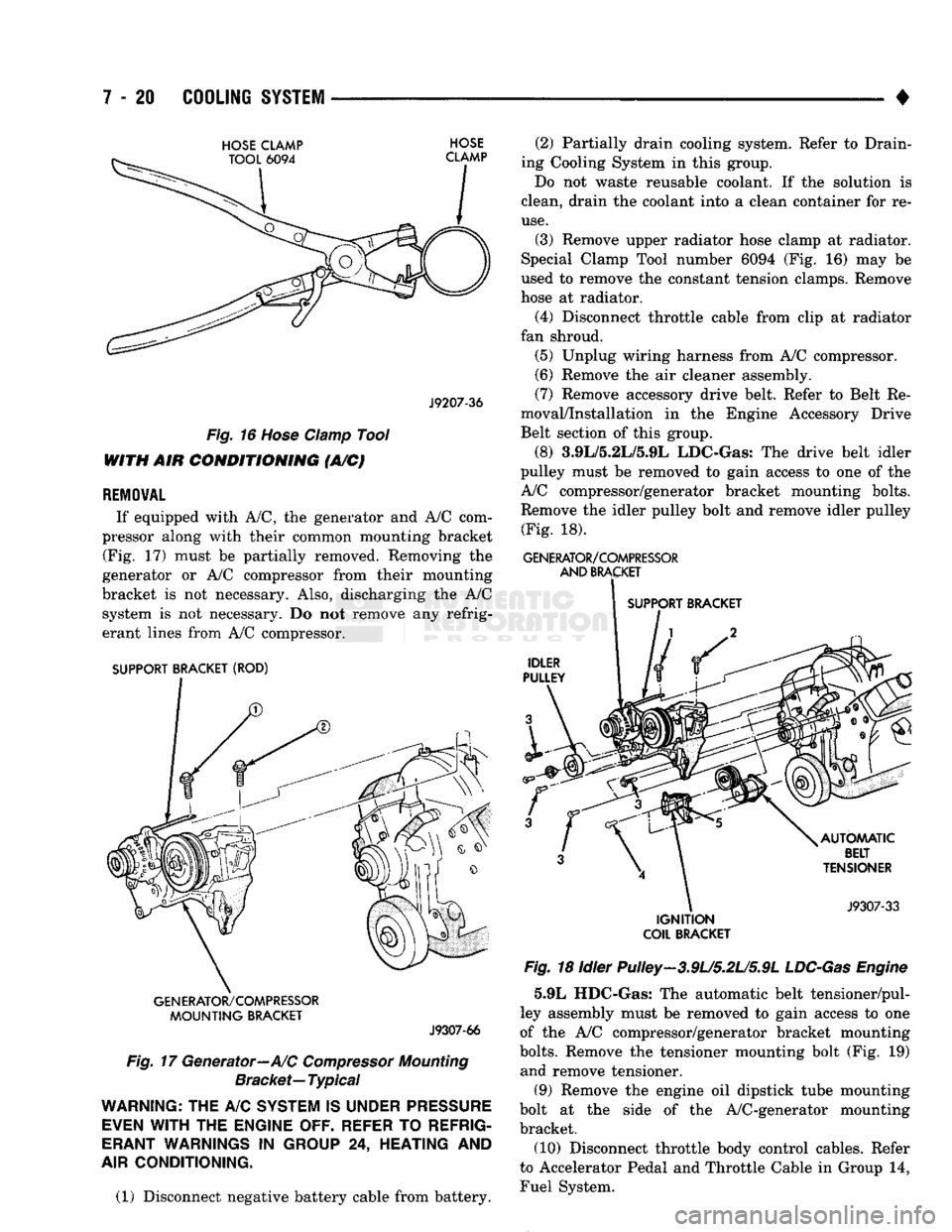

the center of hose. Special Clamp Tool number 6094 (Fig. 16) may be used to remove the constant tension

clamps.

(3) Remove hose from vehicle.

INSTALLATION

(1) Position bypass hose clamps to the center of

hose.

(2) Install bypass hose to engine.

(3) Secure both hose clamps.

(4) Fill cooling system. Refer to Refilling Cooling

System in this group.

(5) Start and warm the engine. Check for leaks.

Page 291 of 1502

7 - 20

COOLING

SYSTEM

•

HOSE

CLAMP

HOSE

J9207-36

Fig.

16

Hose

Clamp

Tool

WITH AIR

CONDITIONING

(A/C)

REMOVAL

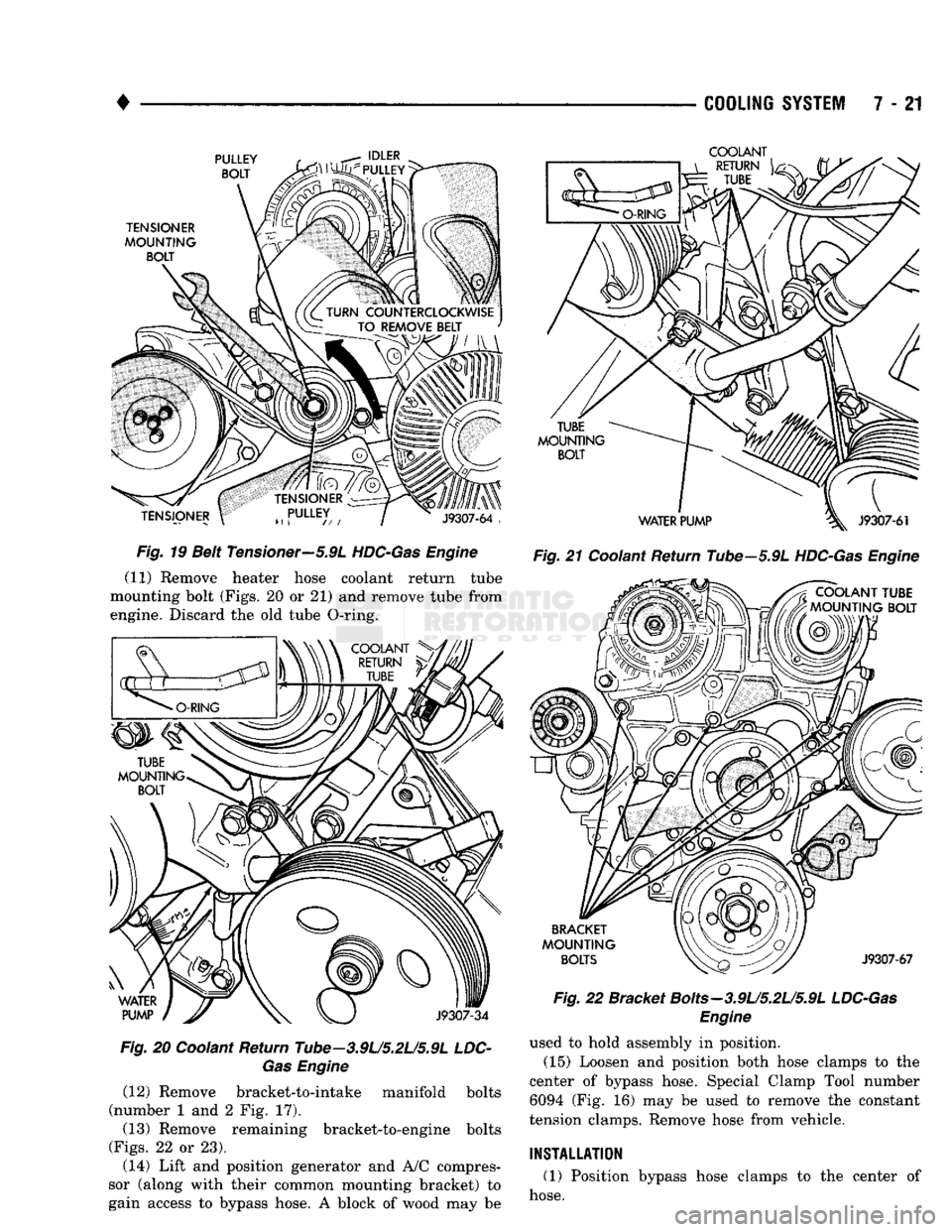

If equipped with A/C, the generator and A/C com

pressor along with their common mounting bracket (Fig. 17) must be partially removed. Removing the

generator or A/C compressor from their mounting

bracket is not necessary. Also, discharging the A/C system is not necessary. Do not remove any refrig

erant lines from A/C compressor.

SUPPORT BRACKET (ROD)

GENERATOR/COMPRESSOR

MOUNTING

BRACKET

J9307-66

Fig.

17 Generator—A/C

Compressor

Mounting

Bracket—

Typical

WARNING;

THE A/C

SYSTEM

IS

UNDER

PRESSURE

EVEN

WITH

THE

ENGINE OFF. REFER

TO

REFRIG

ERANT

WARNINGS

IN

GROUP

24,

HEATING

AND

AIR

CONDITIONING.

(1) Disconnect negative battery cable from battery. (2) Partially drain cooling system. Refer to Drain

ing Cooling System in this group.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for re

use.

(3) Remove upper radiator hose clamp at radiator.

Special Clamp Tool number 6094 (Fig. 16) may be

used to remove the constant tension clamps. Remove

hose at radiator.

(4) Disconnect throttle cable from clip at radiator

fan shroud. (5) Unplug wiring harness from A/C compressor.

(6) Remove the air cleaner assembly.

(7) Remove accessory drive belt. Refer to Belt Re

moval/Installation in the Engine Accessory Drive

Belt section of this group.

(8) 3.9L/5.2L/5.9L LDC-Gas: The drive belt idler

pulley must be removed to gain access to one of the

A/C compressor/generator bracket mounting bolts. Remove the idler pulley bolt and remove idler pulley (Fig. 18).

GENERATOR/COMPRESSOR

AND

BRACKET

SUPPORT BRACKET

IGNITION

COIL

BRACKET

Fig.

18 Idler Pulley-3.9U5.2U5.9L

LDC-Gas

Engine

5.9L HDC-Gas: The automatic belt tensioner/pul-

ley assembly must be removed to gain access to one

of the A/C compressor/generator bracket mounting

bolts.

Remove the tensioner mounting bolt (Fig. 19) and remove tensioner.

(9) Remove the engine oil dipstick tube mounting

bolt at the side of the A/C-generator mounting

bracket.

(10) Disconnect throttle body control cables. Refer

to Accelerator Pedal and Throttle Cable in Group 14,

Fuel System.

Page 292 of 1502

•

COOLING

SYSTEM

7 - 21

Fig.

19 Belt Tensioner—5.9L

HDC-Gas

Engine

(11) Remove heater hose coolant return tube

mounting bolt (Figs. 20 or 21) and remove tube from

engine. Discard the old tube O-ring,

Fig.

20 Coolant Return Tube-3.9U5.2U5.9L LDC-

Gas

Engine

(12) Remove bracket-to-intake manifold bolts

(number 1 and 2 Fig. 17).

(13) Remove remaining bracket-to-engine bolts

(Figs.

22 or 23). (14) Lift and position generator and A/C compres

sor (along with their common mounting bracket) to

gain access to bypass hose. A block of wood may be

Fig.

21 Coolant Return Tube—5.9L

HDC-Gas

Engine

Fig.

22 Bracket Bolts-3.9U5.2U5.9L

LDC-Gas

Engine

used to hold assembly in position.

(15) Loosen and position both hose clamps to the

center of bypass hose. Special Clamp Tool number

6094 (Fig. 16) may be used to remove the constant

tension clamps. Remove hose from vehicle.

INSTALLATION

(1) Position bypass hose clamps to the center of

hose.