belt DODGE TRUCK 1993 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 349 of 1502

8B

- 8

BATTERY/STARTER/GENERATOR

SERVICE

•

Fig.

6

Remove

or Install

Wire

Connector

Assembly

INSTALLATION

(1) Install harness to generator. Tighten nuts as

follows:

• Ground terminal, B+ terminal and Wire Harness

Hold Down 7-10 Nun (60-90 in. lbs.).

• Field terminals 2.5-3 Nun (20-30 in. lbs.).

(2) Install generator. Tighten both bolts to 41 Nun

(30 ft. lbs.).

CAUTION:

When

installing

the

serpentine

accessory

drive

belt,

the

belt

MUST

be

routed

correctly.

If not,

the

engine

may

overheat

due to the

water

pump

ro

tating

in the

wrong

direction.

Refer

to

Group

7 -

Cooling

System

for

correct

engine

belt

routing.

The

correct

belt

with

the

correct

length

must

be

used

(3) Position drive belt over all pulleys except wa

ter pump pulley.

(4) Attach a 3/8 inch rachet to tensioner.

(5) Rotate ratchet and belt tensioner counterclock

wise.

Place belt over water pump pulley. Let ten sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

(6) Connect negative cable to battery.

GENERATOR

REPLACEMENT—DIESEL

ENGINE

(1) Remove negative cable from battery.

(2) Remove generator drive belt. See Group 7 -

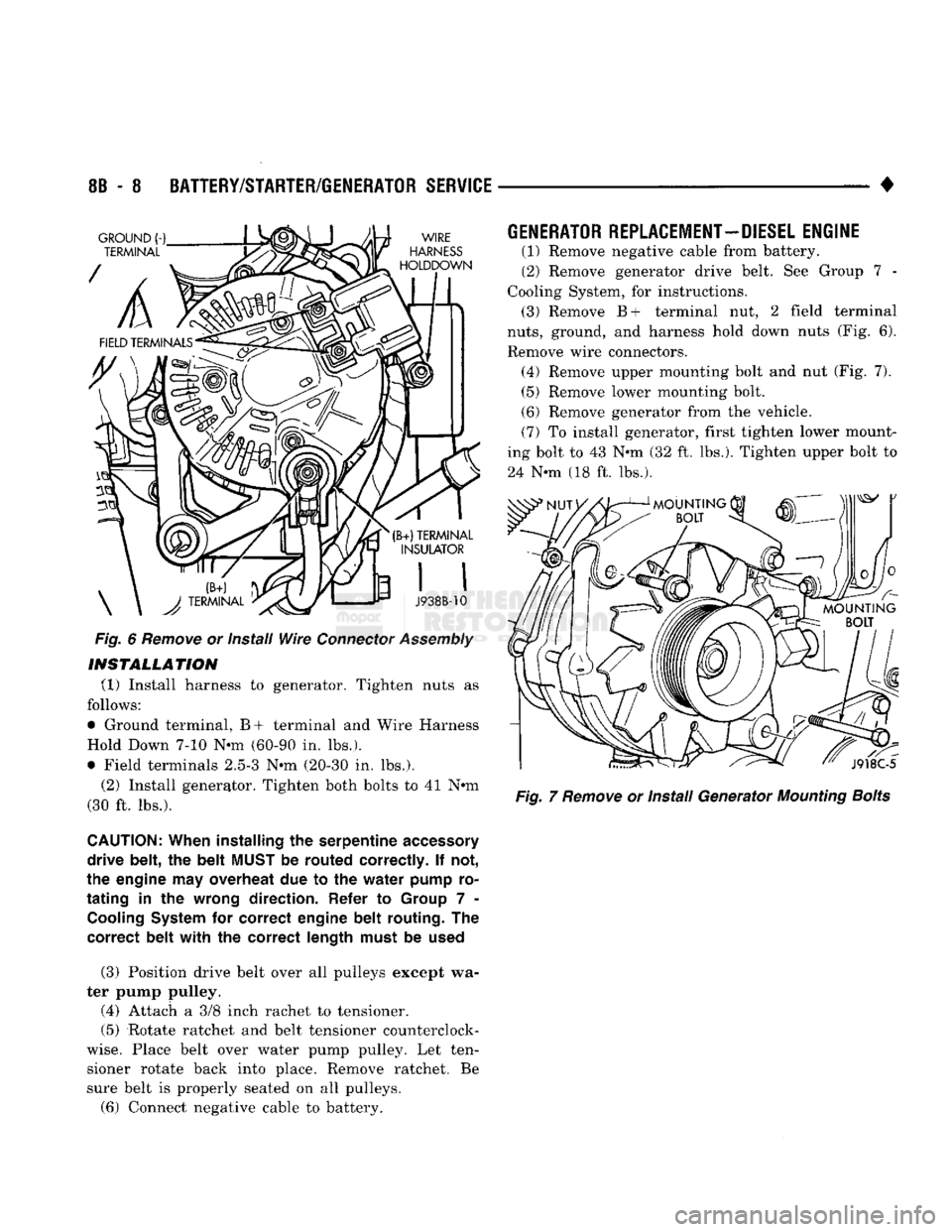

Cooling System, for instructions. (3) Remove B+ terminal nut, 2 field terminal

nuts,

ground, and harness hold down nuts (Fig. 6).

Remove wire connectors. (4) Remove upper mounting bolt and nut (Fig. 7). (5) Remove lower mounting bolt.

(6) Remove generator from the vehicle.

(7) To install generator, first tighten lower mount

ing bolt to 43 Nun (32 ft. lbs.). Tighten upper bolt to

24 Nun (18 ft. lbs.).

Fig.

7

Remove

or Install Generator

Mounting

Bolts

Page 354 of 1502

•

IGNITION

SYSTEMS

8D - 3 For removal and installation of this sensor, refer to

the Component Removal/Installation section of this

group.

CRANKSHAFT

POSITION

SENSOR

NOTCHES- FLYWHEEL CRANKSHAFT

POSITION-

SENSOR

NOTCHES* .FLYWHEEL

J9314-88

—^^j^jV^

J9314-89

Fig.

4

Sensor

Operation—3.9L

Engine

SENSOR

OPERATION'-5.2U5.9L

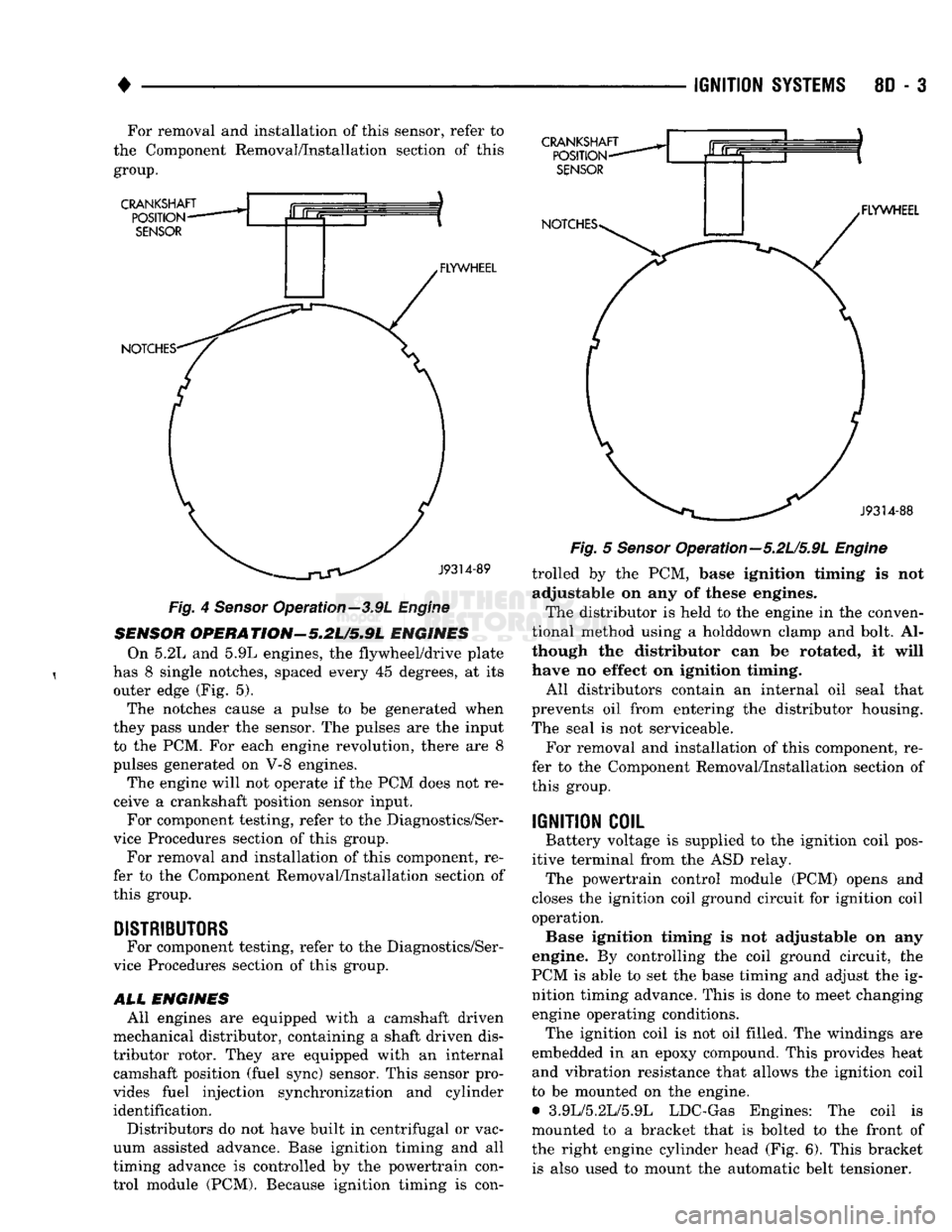

ENGINES On 5.2L and 5.9L engines, the flywheel/drive plate

has 8 single notches, spaced every 45 degrees, at its outer edge (Fig. 5).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input to the PCM. For each engine revolution, there are 8

pulses generated on V-8 engines.

The engine will not operate if the PCM does not re

ceive a crankshaft position sensor input. For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

DISTRIBUTORS

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

ALL

ENGINES All engines are equipped with a camshaft driven

mechanical distributor, containing a shaft driven dis

tributor rotor. They are equipped with an internal camshaft position (fuel sync) sensor. This sensor pro

vides fuel injection synchronization and cylinder identification.

Distributors do not have built in centrifugal or vac

uum assisted advance. Base ignition timing and all

timing advance is controlled by the powertrain con

trol module (PCM). Because ignition timing is con-

Fig.

5

Sensor

Opera tion—5.2L/5.9L

Engine

trolled by the PCM, base ignition timing is not adjustable on any of these engines.

The distributor is held to the engine in the conven

tional method using a holddown clamp and bolt. Al

though the distributor can be rotated, it will

have no effect on ignition timing.

All distributors contain an internal oil seal that

prevents oil from entering the distributor housing.

The seal is not serviceable.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

IGNITION

COIL

Battery voltage is supplied to the ignition coil pos

itive terminal from the ASD relay. The powertrain control module (PCM) opens and

closes the ignition coil ground circuit for ignition coil operation. Base ignition timing is not adjustable on any

engine. By controlling the coil ground circuit, the

PCM is able to set the base timing and adjust the ig nition timing advance. This is done to meet changing engine operating conditions. The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat and vibration resistance that allows the ignition coil

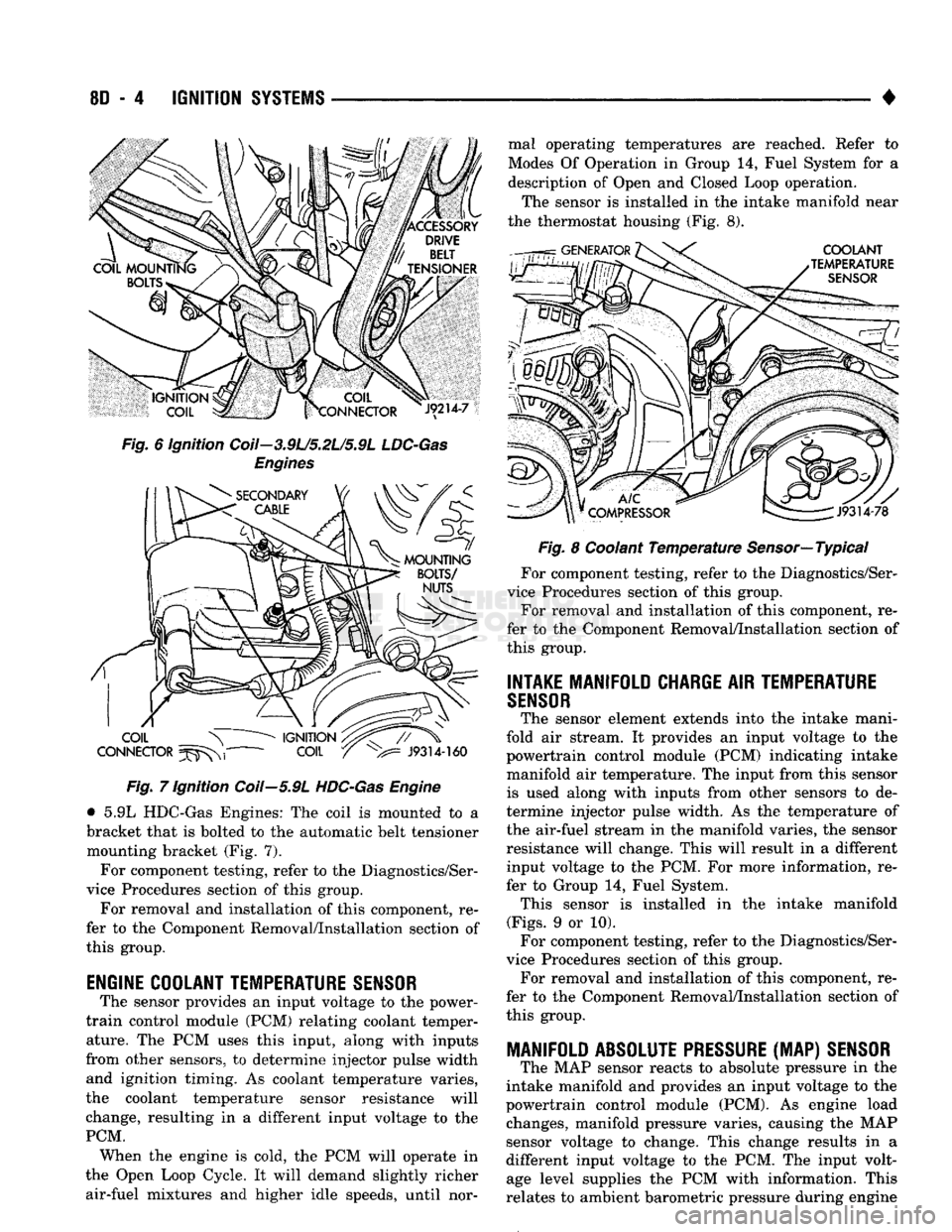

to be mounted on the engine. • 3.9L/5.2L/5.9L LDC-Gas Engines: The coil is

mounted to a bracket that is bolted to the front of the right engine cylinder head (Fig. 6). This bracket is also used to mount the automatic belt tensioner.

Page 355 of 1502

8D

- 4

IGNITION

SYSTEMS

•

Fig. 6 ignition Coil—3.9L/5.2L/5.9L

LDC-Gas

Engines Fig. 7 Ignition Coil—5.9L

HDC-Gas

Engine

• 5.9L HDC-Gas Engines: The coil is mounted to a

bracket that is bolted to the automatic belt tensioner mounting bracket (Fig. 7).

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor provides an input voltage to the power-

train control module (PCM) relating coolant temper ature. The PCM uses this input, along with inputs

from other sensors, to determine injector pulse width and ignition timing. As coolant temperature varies,

the coolant temperature sensor resistance will

change, resulting in a different input voltage to the

PCM. When the engine is cold, the PCM will operate in

the Open Loop Cycle. It will demand slightly richer air-fuel mixtures and higher idle speeds, until nor mal operating temperatures are reached. Refer to

Modes Of Operation in Group 14, Fuel System for a

description of Open and Closed Loop operation.

The sensor is installed in the intake manifold near

the thermostat housing (Fig. 8).

Fig. 8 Coolant Temperature Sensor—Typical

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

INTAKE MANIFOLD CHARGE

AIR

TEMPERATURE

SENSOR

The sensor element extends into the intake mani

fold air stream. It provides an input voltage to the

powertrain control module (PCM) indicating intake

manifold air temperature. The input from this sensor is used along with inputs from other sensors to de

termine injector pulse width. As the temperature of

the air-fuel stream in the manifold varies, the sensor

resistance will change. This will result in a different input voltage to the PCM. For more information, re

fer to Group 14, Fuel System. This sensor is installed in the intake manifold

(Figs.

9 or 10). For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load changes, manifold pressure varies, causing the MAP

sensor voltage to change. This change results in a

different input voltage to the PCM. The input volt age level supplies the PCM with information. This

relates to ambient barometric pressure during engine

Page 362 of 1502

*

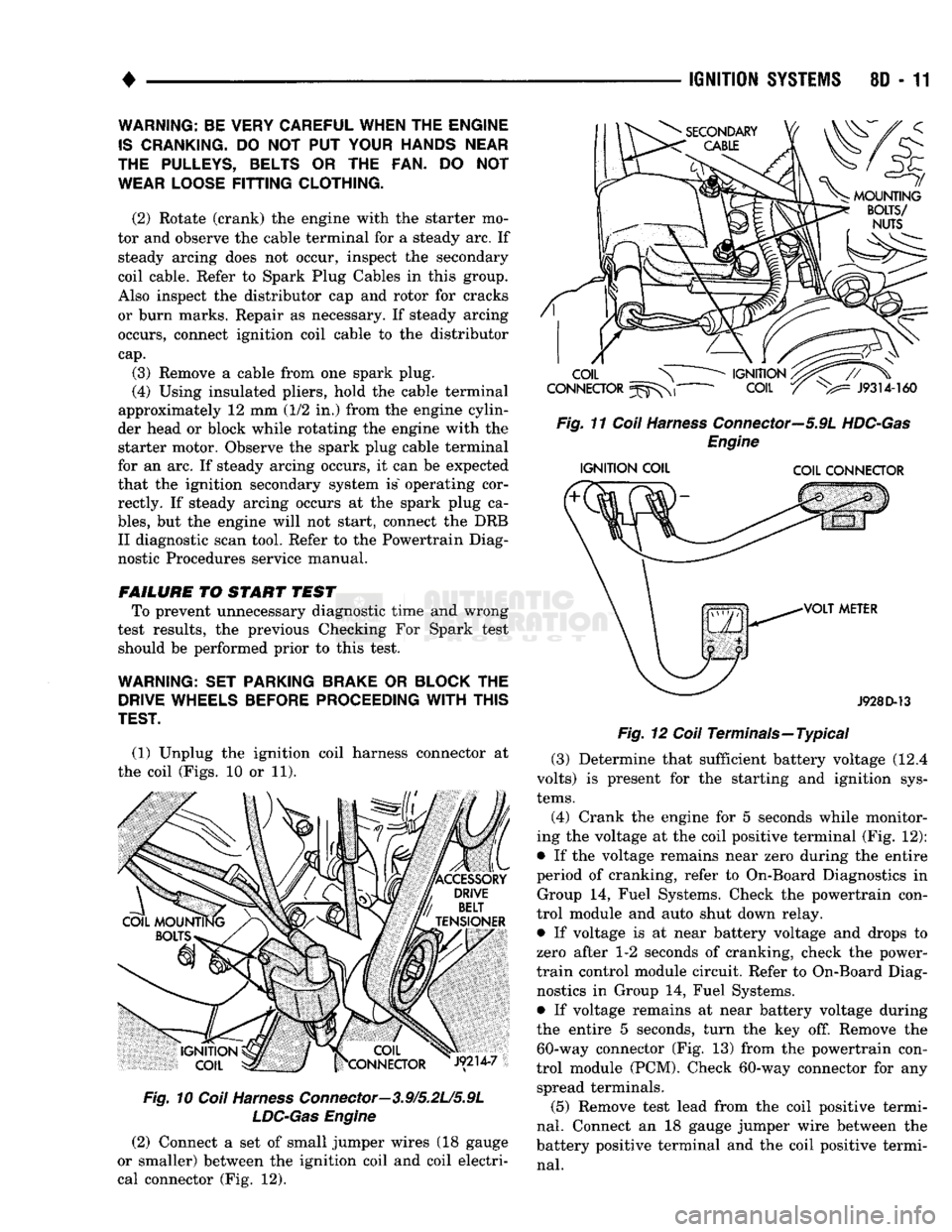

(1) Unplug the ignition coil harness connector at

the coil (Figs. 10 or 11).

Fig.

10

Coil

Harness

Connector—3.9/5.2L/5.9L

LDC-Gas

Engine

(2) Connect a set of small jumper wires (18 gauge

or smaller) between the ignition coil and coil electri

cal connector (Fig. 12).

IGNITION

SYSTEMS

80 - 11

Fig.

11

Coil

Harness

Connector—5.9L

HDC-Gas

Engine

IGNITION

COIL COIL CONNECTOR

J928D-13

Fig.

12

Coil

Terminals—Typical (3) Determine that sufficient battery voltage (12.4

volts) is present for the starting and ignition sys

tems.

(4) Crank the engine for 5 seconds while monitor

ing the voltage at the coil positive terminal (Fig. 12):

• If the voltage remains near zero during the entire

period of cranking, refer to On-Board Diagnostics in Group 14, Fuel Systems. Check the powertrain con

trol module and auto shut down relay.

• If voltage is at near battery voltage and drops to

zero after 1-2 seconds of cranking, check the power-

train control module circuit. Refer to On-Board Diag nostics in Group 14, Fuel Systems.

• If voltage remains at near battery voltage during

the entire 5 seconds, turn the key off. Remove the 60-way connector (Fig. 13) from the powertrain con

trol module (PCM). Check 60-way connector for any spread terminals.

(5) Remove test lead from the coil positive termi

nal.

Connect an 18 gauge jumper wire between the

battery positive terminal and the coil positive termi

nal.

WARNING: BE VERY CAREFUL WHEN THE ENGINE

IS

CRANKING.

DO NOT PUT

YOUR HANDS NEAR

THE PULLEYS, BELTS

OR THE FAN. DO NOT

WEAR LOOSE

FITTING

CLOTHING.

(2) Rotate (crank) the engine with the starter mo

tor and observe the cable terminal for a steady arc. If steady arcing does not occur, inspect the secondary

coil cable. Refer to Spark Plug Cables in this group.

Also inspect the distributor cap and rotor for cracks

or burn marks. Repair as necessary. If steady arcing occurs, connect ignition coil cable to the distributor

cap.

(3) Remove a cable from one spark plug.

(4) Using insulated pliers, hold the cable terminal

approximately 12 mm (1/2 in.) from the engine cylin

der head or block while rotating the engine with the starter motor. Observe the spark plug cable terminal

for an arc. If steady arcing occurs, it can be expected

that the ignition secondary system is" operating cor rectly. If steady arcing occurs at the spark plug ca

bles,

but the engine will not start, connect the DRB II diagnostic scan tool. Refer to the Powertrain Diag

nostic Procedures service manual.

FAILURE

TO START TEST To prevent unnecessary diagnostic time and wrong

test results, the previous Checking For Spark test should be performed prior to this test.

WARNING: SET PARKING BRAKE

OR

BLOCK

THE

DRIVE WHEELS BEFORE PROCEEDING

WITH

THIS

TEST.

Page 372 of 1502

IGNITION

SYSTEMS

80 - 21

DISTRIBUTOR

J9314-81

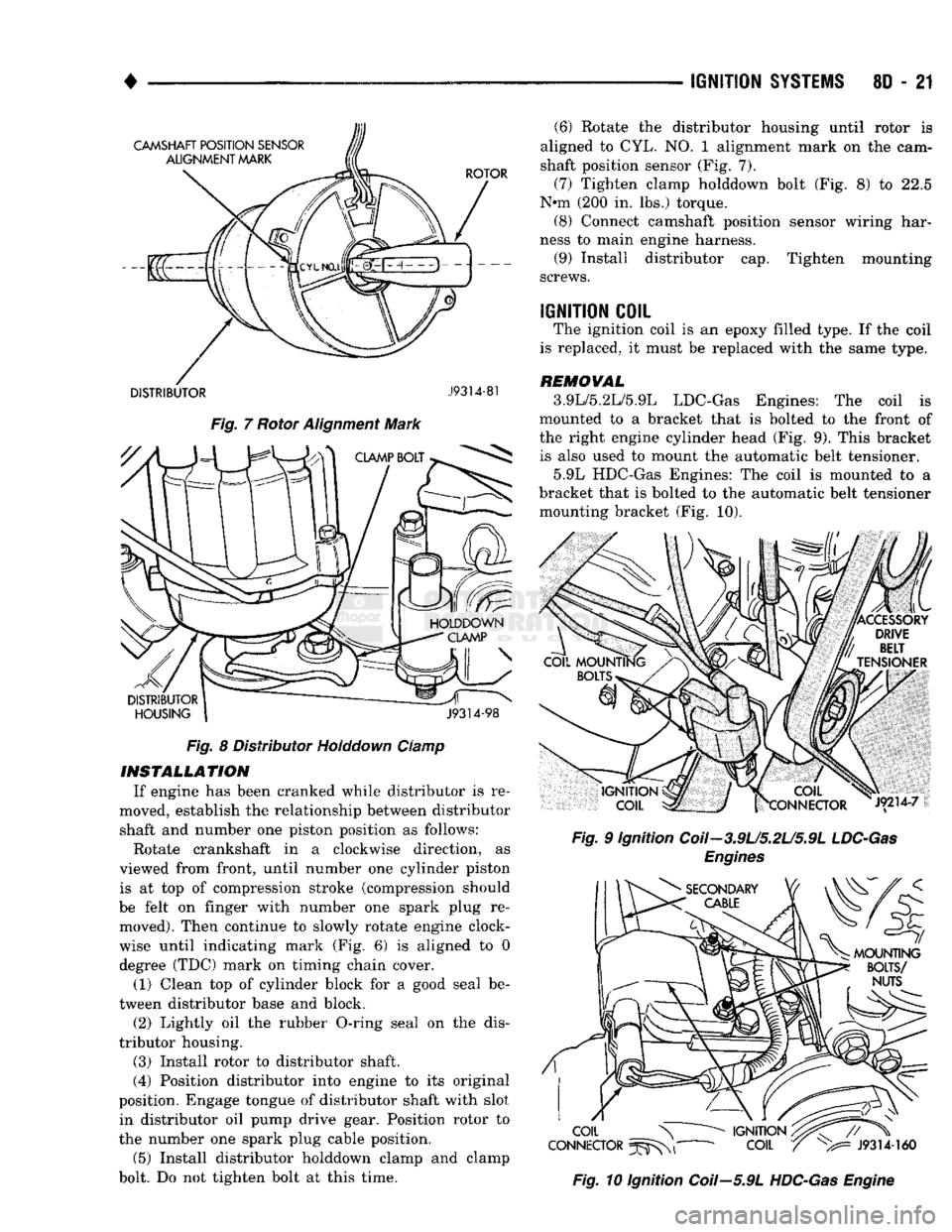

Fig.

7 Rotor Alignment Mark Fig. 8 Distributor Holddown Clamp

INSTALLATION

If engine has been cranked while distributor is re

moved, establish the relationship between distributor shaft and number one piston position as follows:

Rotate crankshaft in a clockwise direction, as

viewed from front, until number one cylinder piston is at top of compression stroke (compression should

be felt on finger with number one spark plug re moved). Then continue to slowly rotate engine clock

wise until indicating mark (Fig. 6) is aligned to 0

degree (TDC) mark on timing chain cover.

(1) Clean top of cylinder block for a good seal be

tween distributor base and block.

(2) Lightly oil the rubber O-ring seal on the dis

tributor housing.

(3) Install rotor to distributor shaft.

(4) Position distributor into engine to its original

position. Engage tongue of distributor shaft with slot in distributor oil pump drive gear. Position rotor to

the number one spark plug cable position.

(5) Install distributor holddown clamp and clamp

bolt. Do not tighten bolt at this time. (6) Rotate the distributor housing until rotor is

aligned to CYL. NO. 1 alignment mark on the cam

shaft position sensor (Fig. 7).

(7) Tighten clamp holddown bolt (Fig. 8) to 22.5

N*m (200 in. lbs.) torque. (8) Connect camshaft position sensor wiring har

ness to main engine harness. (9) Install distributor cap. Tighten mounting

screws.

IGNITION

COIL

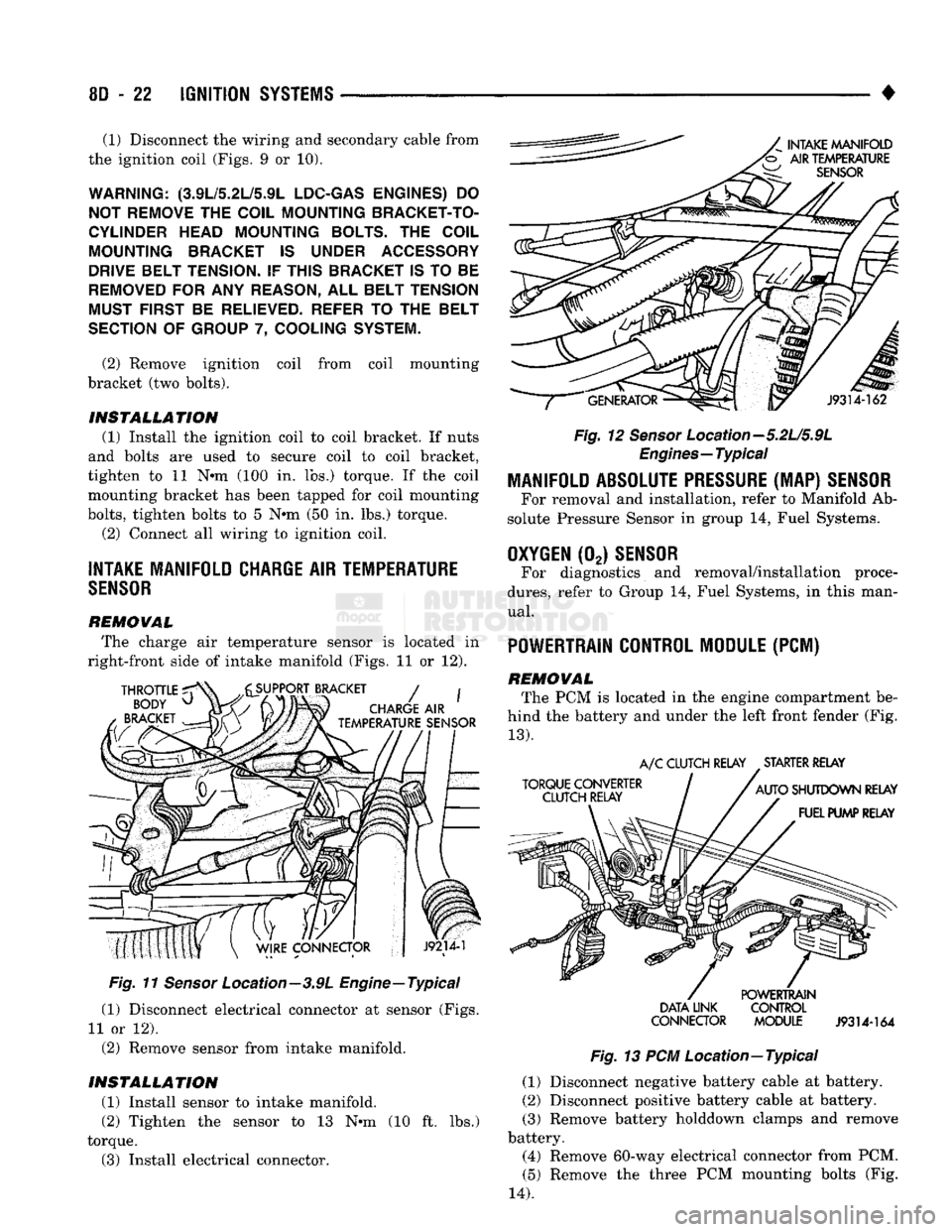

The ignition coil is an epoxy filled type. If the coil

is replaced, it must be replaced with the same type.

REMOVAL

3.9L/5.2L/5.9L LDC-Gas Engines: The coil is

mounted to a bracket that is bolted to the front of

the right engine cylinder head (Fig. 9). This bracket is also used to mount the automatic belt tensioner.

5.9L HDC-Gas Engines: The coil is mounted to a

bracket that is bolted to the automatic belt tensioner mounting bracket (Fig. 10).

Fig.

9 Ignition Coil-3.9U5.2U5.9L

LDC-Gas

Engines

Fig.

10 Ignition Coil—5.9L

HDC-Gas

Engine

Page 373 of 1502

8D

- 22

IGNITION

SYSTEMS

• (1) Disconnect the wiring and secondary cable from

the ignition coil (Figs. 9 or 10).

WARNING:

(3.9L/5.2L/5.9L

LDC-GAS ENGINES)

DO

NOT REMOVE

THE

COIL MOUNTING BRACKET-TO-

CYLINDER HEAD MOUNTING BOLTS.

THE

COIL MOUNTING BRACKET

IS

UNDER ACCESSORY

DRIVE BELT TENSION.

IF

THIS BRACKET

IS TO BE

REMOVED

FOR ANY

REASON,

ALL

BELT TENSION

MUST FIRST

BE

RELIEVED. REFER

TO THE

BELT

SECTION

OF

GROUP

7,

COOLING SYSTEM.

(2) Remove ignition coil from coil mounting

bracket (two bolts).

INSTALLATION (1) Install the ignition coil to coil bracket. If nuts

and bolts are used to secure coil to coil bracket,

tighten to 11 N«m (100 in. lbs.) torque. If the coil mounting bracket has been tapped for coil mounting

bolts,

tighten bolts to 5 N«m (50 in. lbs.) torque.

(2) Connect all wiring to ignition coil.

INTAKE MANIFOLD CHARGE

AIR

TEMPERATURE

SENSOR

REMOVAL The charge air temperature sensor is located in

right-front side of intake manifold (Figs. 11 or 12).

Fig.

11

Sensor

Location—3.9L Engine—Typical

(1) Disconnect electrical connector at sensor (Figs.

11 or 12).

(2) Remove sensor from intake manifold.

INSTALLATION (1) Install sensor to intake manifold. (2) Tighten the sensor to 13 N-m (10 ft. lbs.)

torque. (3) Install electrical connector.

Fig.

12

Sensor

Location—5.2L/5.9L

Engines—Typical

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

For removal and installation, refer to Manifold Ab

solute Pressure Sensor in group 14, Fuel Systems.

OXYGEN

(02)

SENSOR

For diagnostics and removal/installation proce

dures,

refer to Group 14, Fuel Systems, in this man

ual.

POWERTRAIN CONTROL MODULE

(PCM)

REMOVAL The PCM is located in the engine compartment be

hind the battery and under the left front fender (Fig.

13).

DATA

UNK CONTROL

CONNECTOR MODULE

J9314-164

Fig.

13 PCM Location—Typical (1) Disconnect negative battery cable at battery.

(2) Disconnect positive battery cable at battery.

(3) Remove battery holddown clamps and remove

battery.

(4) Remove 60-way electrical connector from PCM.

(5) Remove the three PCM mounting bolts (Fig.

14).

Page 382 of 1502

• • ^ ^ ^ INSTRUMENT PANEL AND GAUGES 8E - 1

CONTENTS

page

CLUSTER AND GAUGE SERVICE PROCEDURES . 12

CLUSTER AND GAUGE TEST PROCEDURES .. i

GENERAL INFORMATION . 1

page

MESSAGE CENTER-DIESEL ENGINE ........ 4

MESSAGE CENTER-GAS ENGINE .......... 3

SWITCH

AND PANEL COMPONENT SERVICE . 16

GENERAL

INFORMATION

INDEX

page

Generator

Indicating

System

2

Distance

Sensor

2

Electronic

Digital

Clock

3

Fuel

Level

Indicating

System

1

page

Malfunction

Indicator

(Check

Engine)

3

Oil

Pressure

Warning

Lamp

................. 2

Speedometer/Odometer

System

2

Temperature

and Oil

Indicating

System

......... 2

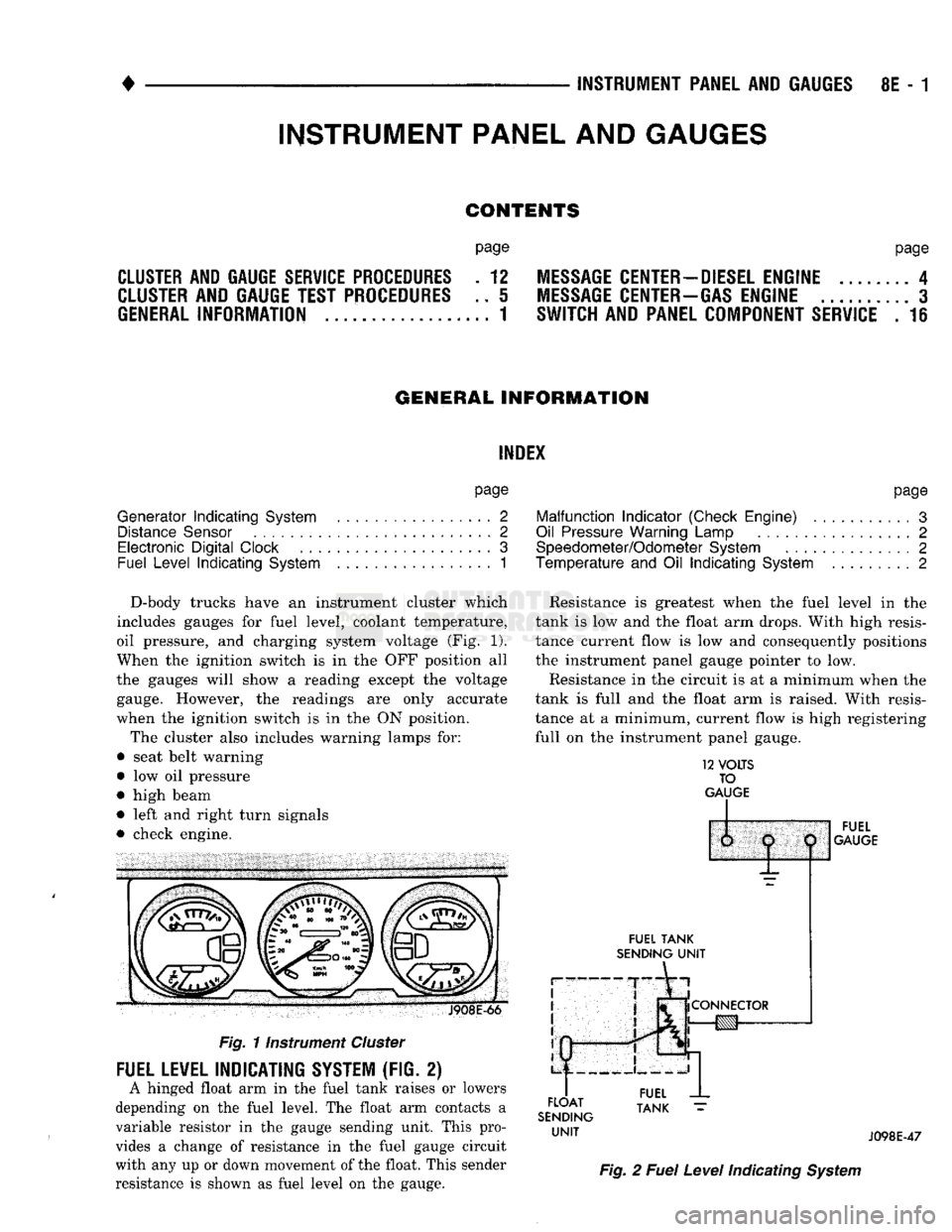

D-body trucks have an instrument cluster which

includes gauges for fuel level, coolant temperature,

oil pressure, and charging system voltage (Fig. 1).

When the ignition switch is in the OFF position all

the gauges will show a reading except the voltage gauge. However, the readings are only accurate

when the ignition switch is in the ON position.

The cluster also includes warning lamps for:

• seat belt warning

• low oil pressure

• high beam

• left and right turn signals

• check engine. J908E-66

Fig.

11nstrument

Cluster

FUEL LEVEL INDICATING SYSTEM (FIG. 2)

A hinged float arm in the fuel tank raises or lowers

depending on the fuel level. The float arm contacts a

variable resistor in the gauge sending unit. This pro

vides a change of resistance in the fuel gauge circuit

with any up or down movement of the float. This sender

resistance is shown as fuel level on the gauge. Resistance is greatest when the fuel level in the

tank is low and the float arm drops. With high resis

tance current flow is low and consequently positions

the instrument panel gauge pointer to low.

Resistance in the circuit is at a minimum when the

tank is full and the float arm is raised. With resis

tance at a minimum, current flow is high registering

full on the instrument panel gauge.

12

VOLTS

TO

GAUGE

IP

FUEL

TANK

SENDING

UNIT

FLOAT

SENDING

UNIT

1:

1

j

^

fCONNECTOR

!g|yj-»—

FUEL

GAUGE

FUEL

TANK

J098E-47

Fig.

2

Fuel

Level

Indicating

System

INSTRUMENT PANEL AND GAUGES

Page 388 of 1502

•

INSTRUMENT

PANEL

AND

GAUGES

8E - 7

STEERING PUMP

ENGINE

BLOCK

J9U9-74

Fig.

4 Oil

Pressure

Sending

Unit—Diesel

Engine

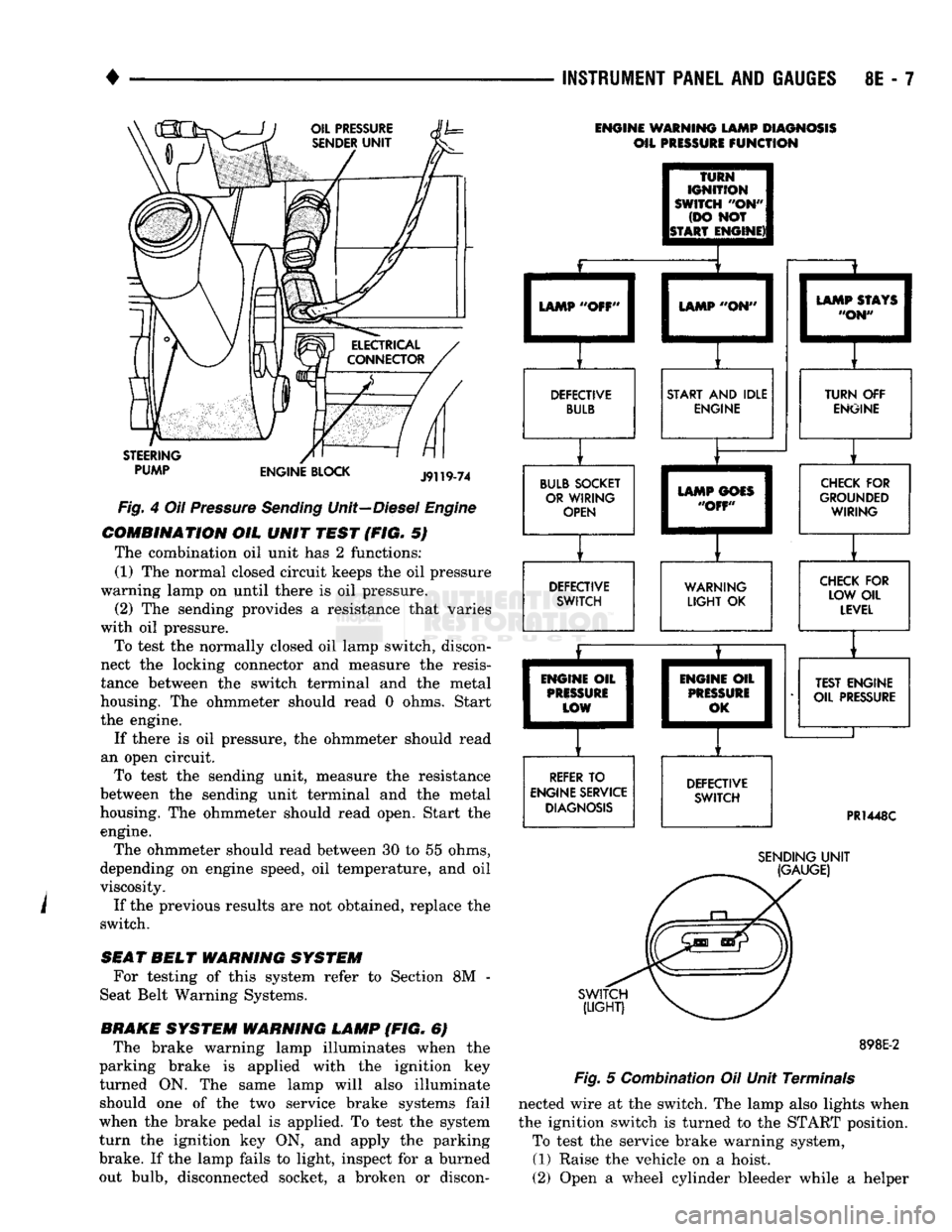

COMBINATION

OIL

UNIT

TEST

(FIG. 5)

The combination oil unit has 2 functions:

(1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure. (2) The sending provides a resistance that varies

with oil pressure.

To test the normally closed oil lamp switch, discon

nect the locking connector and measure the resis

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine.

If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should read open, Start the engine.

The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature, and oil

viscosity.

If the previous results are not obtained, replace the

switch.

SEAT

BELT

WARNING

SYSTEM

For testing of this system refer to Section 8M -

Seat Belt Warning Systems.

BRAKE

SYSTEM

WARNING

LAMP

(FIG. 6) The brake warning lamp illuminates when the

parking brake is applied with the ignition key

turned ON. The same lamp will also illuminate should one of the two service brake systems fail

when the brake pedal is applied. To test the system

turn the ignition key ON, and apply the parking

brake. If the lamp fails to light, inspect for a burned

out bulb, disconnected socket, a broken or discon-

ENGINE WARNING LAMP DIAGNOSIS

OIL PRESSURE

FUNCTION

TURN

IGNITION

SWITCH

"OH"

(DO NOT

ISTART ENGINE)! LAMP "OFF'

LAMP "ON"

DEFECTIVE BULB START AND IDLE

ENGINE

BULB SOCKET OR WIRING OPEN LAMP STAYS

"ON" TURN OFF

ENGINE LAMP GOES

"OFF" DEFECTIVE

SWITCH CHECK FOR

GROUNDED WIRING

WARNING

LIGHT

OK CHECK FOR

LOW OIL LEVEL

ENGINE OIL

PRISSURi

LOW

REFER TO

ENGINE SERVICE DIAGNOSIS ENGIM

PRES

0

IE OIL

1

SURE

1

,K I

DEFECTIVE SWITCH TEST ENGINE

OIL PRESSURE

PR1448C

SWITCH

(LIGHT)

SENDING

UNIT

(GAUGE)

898E-2

Fig.

5 Combination Oil Unit Terminals

nected wire at the switch. The lamp also lights when

the ignition switch is turned to the START position. To test the service brake warning system,

(1) Raise the vehicle on a hoist.

(2) Open a wheel cylinder bleeder while a helper

Page 396 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 15

PRND21 INDICATOR

REMOVAL

(1) Remove bezel. Refer to Cluster Bezel Removal.

(2)

Remove cluster mask and lens. Refer to Cluster

Mask and Lens Removal. (3) Remove cluster assembly. Refer to Instrument

Cluster Removal. (4) Remove screws attaching PRND21 mechanism

to cluster housing.

(5)

Remove PRND21 mechanism.

INSTALLATION (1) Position PRND21 mechanism to cluster hous

ing. (2) Install mounting screws.

(3)

Install cluster assembly. (4) Install mask-lens.

(5)

Install bezel.

LAMP BULBS

CLUSTER ILLUMINATION LAMPS TURN SIGNAL INDICATOR LAMPS

LOW OIL PRESSURE INDICATOR LAMP

HIGH BEAM INDICATOR LAMP CHECK ENGINE LAMP

SEAT BELT WARNING LAMP

REMOVAL (1) Disconnect negative cable from battery.

(2) Remove instrument cluster. See cluster re

moval.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket.

(2) Install socket assembly into printed circuit

board.

(3)

Position cluster into place in panel. See cluster

installation. (4) Connect battery negative cable.

LAMP BULB REPLACEMENT—MESSAGE CENTER

REMOVAL (1) Disconnect battery negative cable.

(2) Remove instrument cluster bezel assembly. Re

fer to Instrument Cluster removal.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket assembly. (2) Install lamp socket assembly into printed cir

cuit board.

(3)

Install Instrument Cluster bezel assembly to

instrument panel. Refer to Instrument Cluster instal

lation.

(4) Connect negative cable from battery.

FOUR WHEEL DRIVE INDICATOR LAMP (1) Pull bulb and socket assembly from rear of

housing. (2) Remove bulb from socket.

(3)

Reverse removal procedures to install.

SPECIFICATIONS

Fuel

Gauge Calibration

Mntar Position Resistance

Empty Graduation 90

ohms

± 3

ohms

Empty Stop

Greater

than

96.5 ohms

Full

Graduation 12 ohm

± 3

ohms

Full

Stop

Less

than

8

ohms

1/2

45.3 ohms

± 3

ohms

Temperature

Gauge

Calibration

Pointer

Position Resistance

Cold Graduation 655 ohms

Hot Graduation 64 ohms

Oil Pressure Gauge Calibration

Pointer

Position Resistance

Low Graduation 100 ohms

High Graduation 12 ohms

J908E-58

Page 454 of 1502

•

LAMPS

8L - 11

BULB

APPLICATION

GENERAL

INFORMATION

The following Bulb Application Table lists

the

lamp title

on the

left side

of the

column

and

part

number

on the

right.

CAUTION:

Do not use

bulbs

that

have

a

higher

can

dle power than

the

bulb

listed

in the

Bulb

Applica

tion Table.

Damage

to

lamp

can

result.

EXTERIOR LAMPS

Auxiliary Turn Signal (Snow Plow) 2057

Auxiliary Headlamps (Snow Plow) .6054

Back-up....................... .......1156 Cargo Lamp..

922

Clearance Lamps

194

Front Side Marker

168

Headlamp/Sealed Beam .6052

License Plate

168

Park/Turn Signal 2057

TaiyStop/Turn Signal ...2057

INTERIOR LAMPS

DIMMER CONTROLLED LAMPS Service procedures

for

most

of the

lamps

in the in

strument panel

are

located

in

Group

8E,

Instrument

Panel

and

Gauges. Some components have lamps

that

can

only

be

serviced

by an

Authorized Service Center (ASC). These components must

be

removed

from

the

vehicle

for

service. Contact local dealer

for

location

of

nearest

ASC.

A/C Heater Control

158

Ash Receiver

..158

Gear Shift Selector...........................................PC194

Heater Control

158

Instrument Cluster.. PC 194

Radio

ASC

Snow Plow Control

.158

INDICATOR LAMPS Service procedures

for

most

of the

lamps

in the in

strument panel,

and

switches

are

located

in

Group

8E,

Instrument Panel

and

Gauges. Anti-lock Brake PC194

Brake Warning PC194 Check Engine PC194

Engine

Oil

Pressure

158

Fasten Seat Belts.. PC 194 Four Wheel Drive ....158

Hazard Flasher

194

High Beam PC194

Low Fuel....... JPC194

Maintenance Required PC 194

Transmission Temperature ..PC 194 Turn Signal PC194

NON-DIMMING LAMPS Service procedures

for

most

of the

lamps

in the

fol

lowing list

can be

found

in

Group

23,

Body.

Dome

1004

Engine Compartment ...105 Glove Compartment....

1891

Ignition Lock

ASC

Reading Lamp

912