belt DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 293 of 1502

7 - 22

COOLING

SYSTEM

•

Fig.

23 Bracket

Bolts—5.9L

HDC-Gas Engine

(2) Install bypass hose to engine.

(3) Secure both hose clamps.

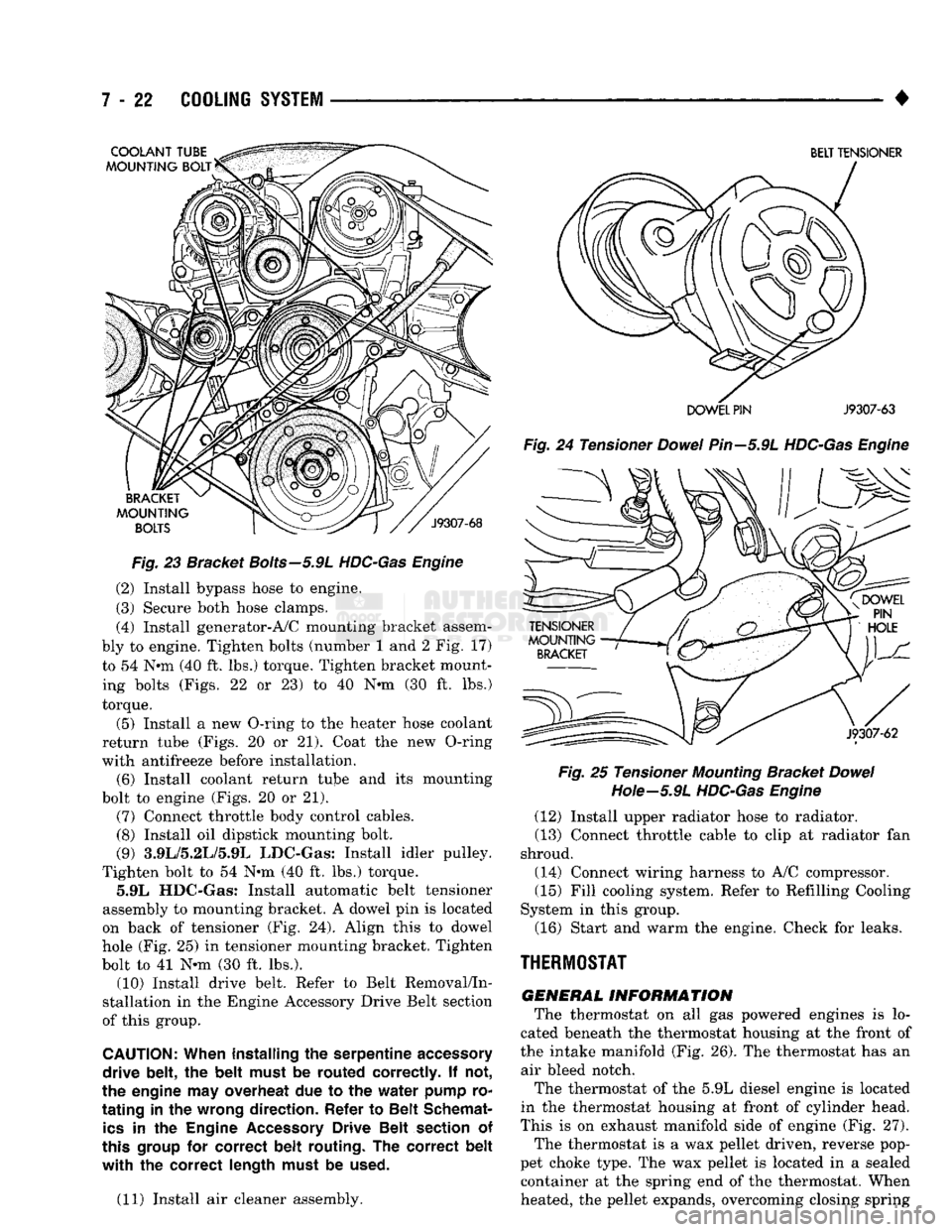

(4) Install generator-A/C mounting bracket assem

bly to engine. Tighten bolts (number 1 and 2 Fig. 17)

to 54 Nnn (40 ft. lbs.) torque. Tighten bracket mount ing bolts (Figs. 22 or 23) to 40 N-m (30 ft. lbs.)

torque.

(5) Install a new O-ring to the heater hose coolant

return tube (Figs. 20 or 21). Coat the new O-ring

with antifreeze before installation. (6) Install coolant return tube and its mounting

bolt to engine (Figs. 20 or 21). (7) Connect throttle body control cables.

(8) Install oil dipstick mounting bolt.

(9) 3.9L/5.2L/5.9L LDC-Gas: Install idler pulley.

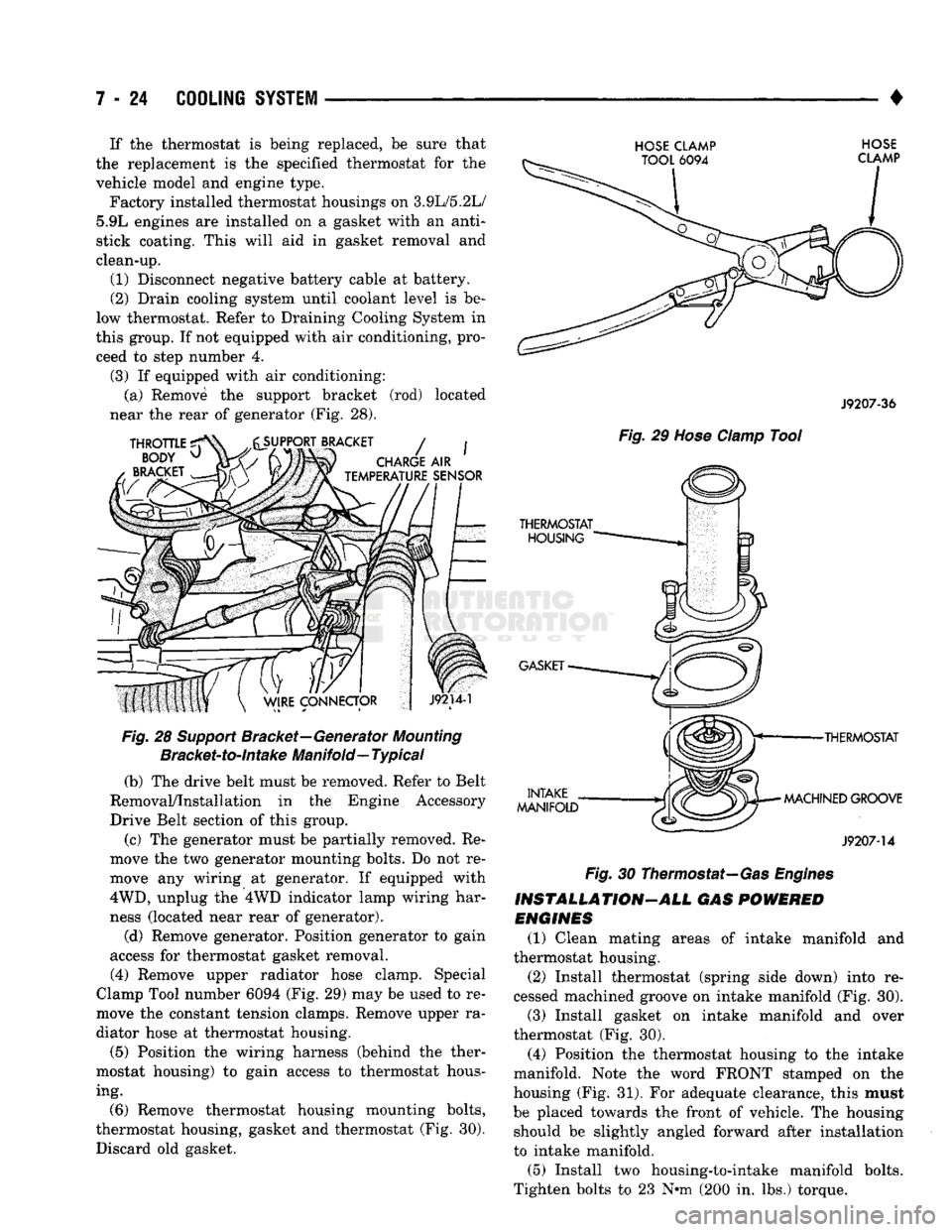

Tighten bolt to 54 Nnn (40 ft. lbs.) torque. 5.9L HDC-Gas: Install automatic belt tensioner

assembly to mounting bracket. A dowel pin is located

on back of tensioner (Fig. 24). Align this to dowel

hole (Fig. 25) in tensioner mounting bracket. Tighten

bolt to 41 N-m (30 ft. lbs.). (10) Install drive belt. Refer to Belt Removal/In

stallation in the Engine Accessory Drive Belt section

of this group.

CAUTION:

When installing

the

serpentine

accessory

drive belt,

the

belt must

be

routed correctly.

If not,

the engine

may

overheat

due to the

water pump

ro

tating

in the

wrong direction. Refer

to

Belt Schemat

ics

in the

Engine

Accessory

Drive Belt section

of

this

group

for

correct belt routing.

The

correct belt

with the

correct length must

be

used.

(11) Install air cleaner assembly.

BELT TENSIONER

DOWEL PIN

J9307-63

Fig.

24 Tensioner

Dowel

Pin—5.9L

HDC-Gas Engine Fig.

25 Tensioner

Mounting

Bracket

Dowel

Hote—5.9L

HDC-Gas Engine

(12) Install upper radiator hose to radiator.

(13) Connect throttle cable to clip at radiator fan

shroud.

(14) Connect wiring harness to A/C compressor. (15) Fill cooling system. Refer to Refilling Cooling

System in this group.

(16) Start and warm the engine. Check for leaks.

THERMOSTAT

GENERAL

INFORMATION

The thermostat on all gas powered engines is lo

cated beneath the thermostat housing at the front of

the intake manifold (Fig. 26). The thermostat has an air bleed notch.

The thermostat of the 5.9L diesel engine is located

in the thermostat housing at front of cylinder head.

This is on exhaust manifold side of engine (Fig. 27). The thermostat is a wax pellet driven, reverse pop

pet choke type. The wax pellet is located in a sealed container at the spring end of the thermostat. When

heated, the pellet expands, overcoming closing spring

Page 295 of 1502

7 - 24

COOLING SYSTEM

• If the thermostat is being replaced, be sure that

the replacement is the specified thermostat for the vehicle model and engine type. Factory installed thermostat housings on 3.9L/5.2L/

5.9L engines are installed on a gasket with an anti-

stick coating. This will aid in gasket removal and

clean-up.

(1) Disconnect negative battery cable at battery.

(2) Drain cooling system until coolant level is be

low thermostat. Refer to Draining Cooling System in

this group. If not equipped with air conditioning, pro ceed to step number 4.

(3) If equipped with air conditioning: (a) Remove the support bracket (rod) located

near the rear of generator (Fig. 28).

Fig.

28

Support

Bracket—Generator

Mounting

Bracket-to-intake

Manifold—

Typical

(b) The drive belt must be removed. Refer to Belt

Removal/Installation in the Engine Accessory

Drive Belt section of this group.

(c) The generator must be partially removed. Re

move the two generator mounting bolts. Do not re

move any wiring at generator. If equipped with

4WD,

unplug the 4WD indicator lamp wiring har

ness (located near rear of generator).

(d) Remove generator. Position generator to gain

access for thermostat gasket removal.

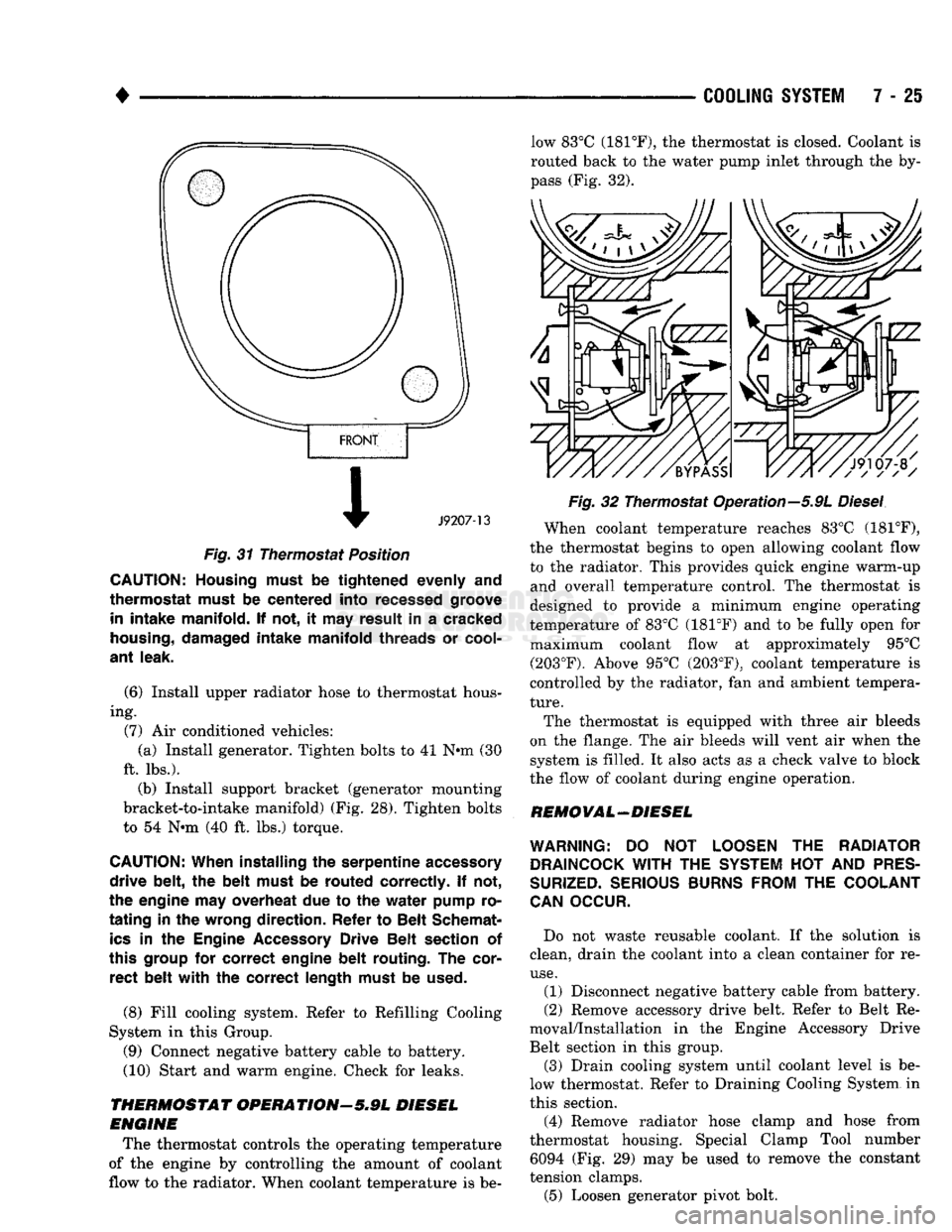

(4) Remove upper radiator hose clamp. Special

Clamp Tool number 6094 (Fig. 29) may be used to re

move the constant tension clamps. Remove upper ra

diator hose at thermostat housing.

(5) Position the wiring harness (behind the ther

mostat housing) to gain access to thermostat hous ing.

(6) Remove thermostat housing mounting bolts,

thermostat housing, gasket and thermostat (Fig. 30). Discard old gasket.

HOSE CLAMP HOSE

J9207-36

Fig.

29

Hose

Clamp

Tool

•THERMOSTAT

MACHINED GROOVE

J9207-14

Fig.

30 Thermostat—Gas

Engines

INSTALLATION-ALL GAS

POWERED

ENGINES

(1) Clean mating areas of intake manifold and

thermostat housing. (2) Install thermostat (spring side down) into re

cessed machined groove on intake manifold (Fig. 30).

(3) Install gasket on intake manifold and over

thermostat (Fig. 30).

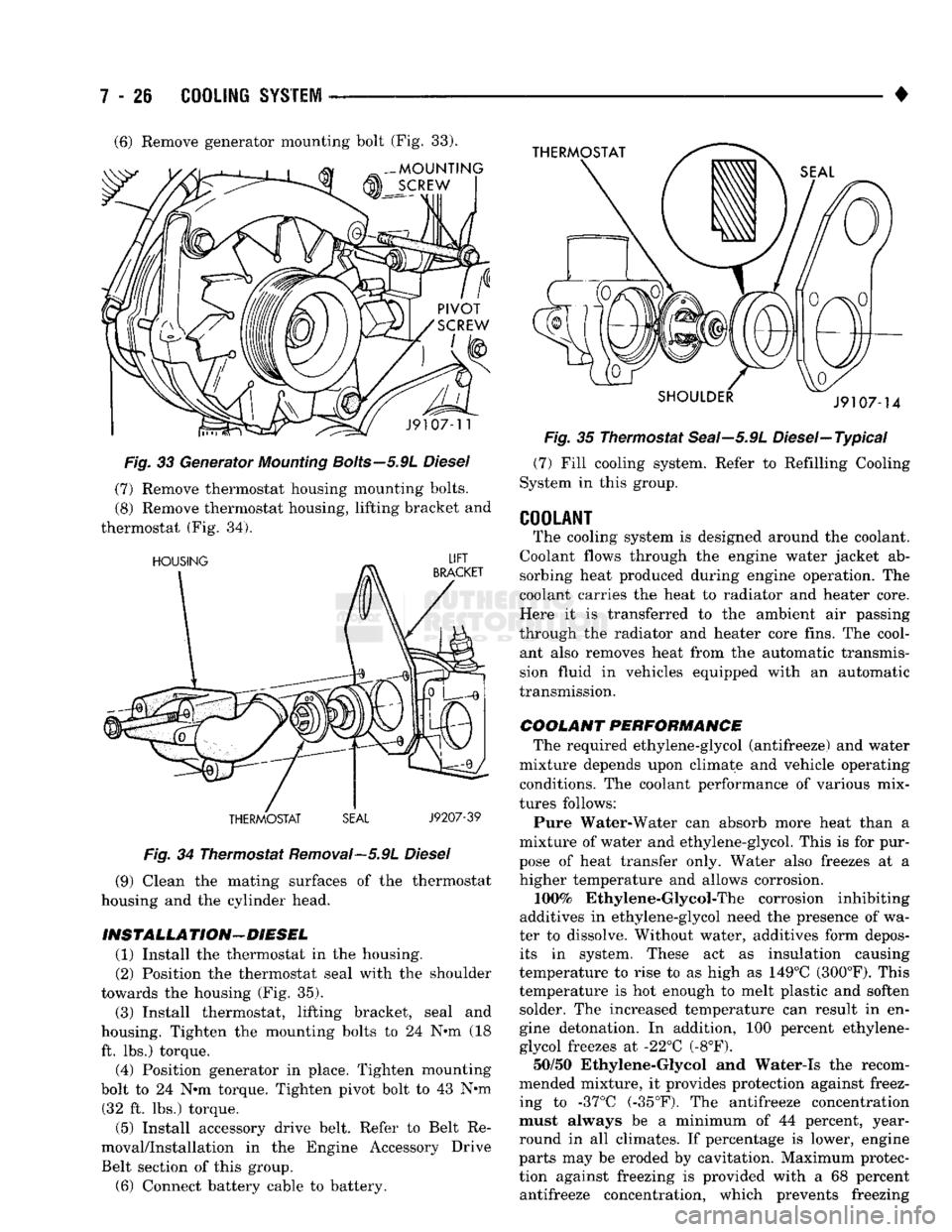

(4) Position the thermostat housing to the intake

manifold. Note the word FRONT stamped on the

housing (Fig. 31). For adequate clearance, this must

be placed towards the front of vehicle. The housing should be slightly angled forward after installation

to intake manifold.

(5) Install two housing-to-intake manifold bolts.

Tighten bolts to 23 N-m (200 in. lbs.) torque.

Page 296 of 1502

•

COOLING

SYSTEM

7 - 25

Fig.

31 Thermostat Position

CAUTION; Housing must

be

tightened

evenly and

thermostat must

be

centered into recessed groove in

intake manifold. If not, it may

result

in a

cracked

housing,

damaged intake manifold threads

or

cool

ant

leak.

(6) Install upper radiator hose to thermostat hous

ing. (7) Air conditioned vehicles: (a) Install generator. Tighten bolts to 41 N-m (30

ft. lbs.). (b) Install support bracket (generator mounting

bracket-to-intake manifold) (Fig. 28). Tighten bolts

to 54 N-m (40 ft. lbs.) torque.

CAUTION:

When installing

the

serpentine accessory

drive belt,

the

belt must

be

routed correctly.

If not,

the engine

may overheat due to the

water pump

ro

tating in the

wrong direction. Refer

to

Belt Schemat

ics

in the

Engine

Accessory

Drive Belt section

of

this group

for

correct engine belt routing.

The

cor rect belt with

the

correct length must

be

used.

(8) Fill cooling system. Refer to Refilling Cooling

System in this Group. (9) Connect negative battery cable to battery.

(10) Start and warm engine. Check for leaks.

THERMOSTAT OPERATIONr-5.9L DIESEL

ENGINE

The thermostat controls the operating temperature

of the engine by controlling the amount of coolant

flow to the radiator. When coolant temperature is be low 83°C (181°F), the thermostat is closed. Coolant is

routed back to the water pump inlet through the by

pass (Fig. 32).

Fig.

32 Thermostat Operation—5.9L

Diesel

When coolant temperature reaches 83°C (181°F),

the thermostat begins to open allowing coolant flow

to the radiator. This provides quick engine warm-up and overall temperature control. The thermostat is

designed to provide a minimum engine operating

temperature of 83°C (181°F) and to be fully open for maximum coolant flow at approximately 95°C (203°F). Above 95°C (203°F), coolant temperature is

controlled by the radiator, fan and ambient tempera

ture.

The thermostat is equipped with three air bleeds

on the flange. The air bleeds will vent air when the system is filled. It also acts as a check valve to block

the flow of coolant during engine operation.

REMOVAL-DIESEL

WARNING:

DO NOT

LOOSEN

THE

RADIATOR

DRAINCOCK

WITH

THE

SYSTEM

HOT

AND

PRES

SURIZED.

SERIOUS

BURNS

FROM

THE

COOLANT

CAN

OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for re

use.

(1) Disconnect negative battery cable from battery.

(2) Remove accessory drive belt. Refer to Belt Re

moval/Installation in the Engine Accessory Drive

Belt section in this group.

(3) Drain cooling system until coolant level is be

low thermostat. Refer to Draining Cooling System in

this section.

(4) Remove radiator hose clamp and hose from

thermostat housing. Special Clamp Tool number 6094 (Fig. 29) may be used to remove the constant

tension clamps.

(5) Loosen generator pivot bolt.

Page 297 of 1502

7 - 26

COOLING

SYSTEM

————

Fig. 33 Generator

Mounting

Bolts—5.9L

Diesel (7) Remove thermostat housing mounting bolts.

(8) Remove thermostat housing, lifting bracket and

thermostat (Fig. 34).

Fig.

34 Thermostat Removal—5.9L

Diesel

(9) Clean the mating surfaces of the thermostat

housing and the cylinder head.

INSTALLA TION—DIESEL (1) Install the thermostat in the housing.

(2) Position the thermostat seal with the shoulder

towards the housing (Fig. 35).

(3) Install thermostat, lifting bracket, seal and

housing. Tighten the mounting bolts to 24 N°m (18 ft. lbs.) torque. (4) Position generator in place. Tighten mounting

bolt to 24 N*m torque. Tighten pivot bolt to 43 N*m (32 ft. lbs.) torque.

(5) Install accessory drive belt. Refer to Belt Re

moval/Installation in the Engine Accessory Drive

Belt section of this group.

(6) Connect battery cable to battery. •

Fig.

35 Thermostat Seai—5.9L Diesel—Typical (7) Fill cooling system. Refer to Refilling Cooling

System in this group.

COOLANT

The cooling system is designed around the coolant.

Coolant flows through the engine water jacket ab sorbing heat produced during engine operation. The

coolant carries the heat to radiator and heater core.

Here it is transferred to the ambient air passing

through the radiator and heater core fins. The cool ant also removes heat from the automatic transmission fluid in vehicles equipped with an automatic

transmission.

COOLANT PERFORMANCE The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating conditions. The coolant performance of various mix

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur

pose of heat transfer only. Water also freezes at a higher temperature and allows corrosion.

100%

Ethylene-Glycol-The corrosion inhibiting

additives in ethylene-glycol need the presence of wa

ter to dissolve. Without water, additives form depos its in system. These act as insulation causing

temperature to rise to as high as 149°C (300°F). This

temperature is hot enough to melt plastic and soften solder. The increased temperature can result in en

gine detonation. In addition, 100 percent ethylene-

glycol freezes at -22°C (-8°F). 50/50 Ethylene-Glycol and Water-Is the recom

mended mixture, it provides protection against freez

ing to -37°C (-35°F). The antifreeze concentration

must always be a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec

tion against freezing is provided with a 68 percent antifreeze concentration, which prevents freezing (6) Remove generator mounting bolt (Fig. 33).

Page 301 of 1502

7 - 30

COOLING

SYSTEM

•

COOLING

SYSTEM

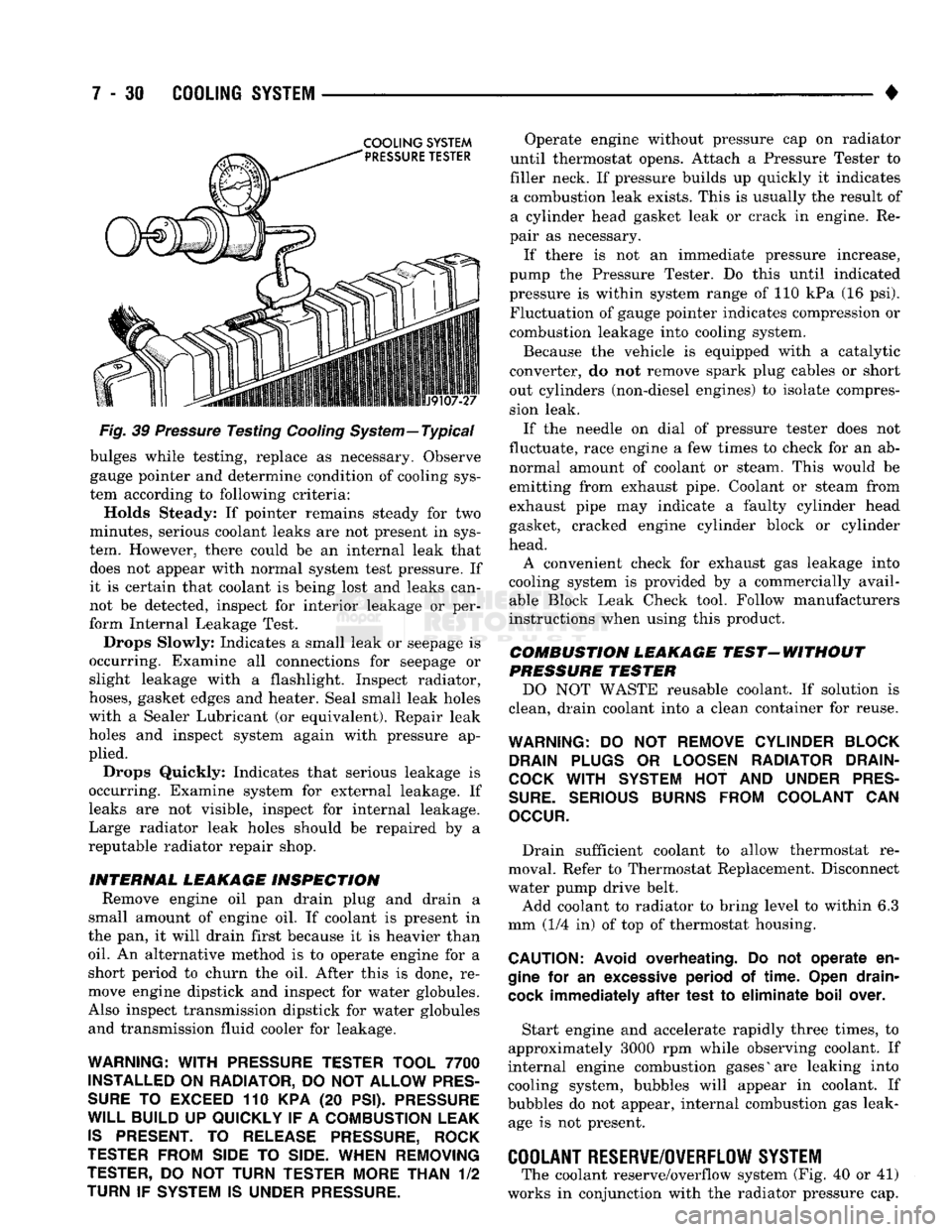

Fig.

39

Pressure

Testing

Cooling

System—Typical bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys

tem according to following criteria:

Holds Steady: If pointer remains steady for two

minutes, serious coolant leaks are not present in sys

tem. However, there could be an internal leak that does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can

not be detected, inspect for interior leakage or per

form Internal Leakage Test.

Drops Slowly: Indicates a small leak or seepage is

occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses,

gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure ap

plied.

Drops Quickly: Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil.

An alternative method is to operate engine for a

short period to churn the oil. After this is done, re

move engine dipstick and inspect for water globules.

Also inspect transmission dipstick for water globules and transmission fluid cooler for leakage.

WARNING:

WITH

PRESSURE TESTER TOOL

7700

INSTALLED

ON

RADIATOR,

DO

NOT ALLOW

PRES

SURE

TO

EXCEED

110 KPA (20

PSI). PRESSURE

WILL

BUILD

UP

QUICKLY

IF A

COMBUSTION LEAK

IS

PRESENT.

TO

RELEASE

PRESSURE,

ROCK

TESTER

FROM SIDE

TO

SIDE. WHEN REMOVING

TESTER,

DO NOT

TURN TESTER MORE THAN

1/2

TURN

IF

SYSTEM

IS

UNDER

PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates a combustion leak exists. This is usually the result of

a cylinder head gasket leak or crack in engine. Re

pair as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi). Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter, do not remove spark plug cables or short

out cylinders (non-diesel engines) to isolate compres

sion leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an ab normal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head

gasket, cracked engine cylinder block or cylinder

head. A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST-WITHOUT

PRESSURE TESTER DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING:

DO NOT

REMOVE CYLINDER BLOCK DRAIN PLUGS

OR

LOOSEN RADIATOR DRAIN-

COCK

WITH

SYSTEM

HOT AND

UNDER PRES

SURE.

SERIOUS BURNS FROM COOLANT

CAN

OCCUR.

Drain sufficient coolant to allow thermostat re

moval. Refer to Thermostat Replacement. Disconnect

water pump drive belt. Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of top of thermostat housing.

CAUTION:

Avoid

overheating.

Do not

operate

en

gine

for an

excessive

period

of

time.

Open

drain-

cock

immediately

after

test

to

eliminate

boil

over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases% are leaking into

cooling system, bubbles will appear in coolant. If

bubbles do not appear, internal combustion gas leak age is not present.

COOLANT

RESERVE/0WERFL0W

SYSTEM

The coolant reserve/overflow system (Fig. 40 or 41)

works in conjunction with the radiator pressure cap.

Page 311 of 1502

ENGINE ACCESSORY DRIVE BELTS

INDEX

page

Automatic Belt Tensioner

45

Belt Diagnosis

40

Belt Removal/Installation

. 40

page

Belt Schematics

40

Belt Tension

40

General

Information

40

GENERAL

INFORMATION

All vehicles are available with either

a

3.9L (V-6),

a 5.2L (V-8),

a

5.9L (gas V-8) or

a

5.9L (in-line 6 cyl

inder diesel) engine. The accessory drive components

are

operated

by a

single, crankshaft driven, serpentine drive belt on all

engines. An automatic belt tensioner

is

used to main

tain correct belt tension

at all

times. Refer

to

Auto matic Belt Tensioner proceeding

in

this group.

BELT DIAGNOSIS SERPENTINE DRIVE BELT DIAGNOSIS-ALL

ENGINES

When diagnosing serpentine drive belts, small

cracks that run across ribbed surface of belt from rib

to rib (Fig. 1), are considered normal. These are not

a

reason

to

replace belt. However, cracks running along

a rib (not

across)

are not

normal.

Any

belt

with cracks running along

a rib

must

be

replaced (Fig.

1).

Also replace belt

if it has

excessive wear,

frayed cords

or

severe glazing.

Refer to the Serpentine Drive Belt Diagnosis charts

for further belt diagnosis. Also refer

to

Automatic Belt Tensioner proceeding

in

this group.

BELT SCHEMATICS

The following belt routing schematics

are

pub

lished from

the

latest information available

at the

time

of

publication.

If

anything differs between

these schematics

and the

Belt Routing Label,

use

the

schematics

on

Belt Routing Label. This

label

is

located

in

the engine compartment.

BELT TENSION

ALL

ENGINES

Correct accessory drive belt tension

is

required

to

be sure

of

optimum performance

of

belt driven

en

gine accessories.

If

specified tension

is not

main

tained, belt slippage may cause; engine overheating, lack

of

power steering assist, loss

of

air conditioning

capacity, reduced generator output rate and greatly

reduced belt life.

It

is

not necessary

to

adjust belt tension on any en

gine.

All

engines

are

equipped with

an

automatic

belt tensioner. The tensioner maintains correct belt tension

at all

times. For other tensioner information

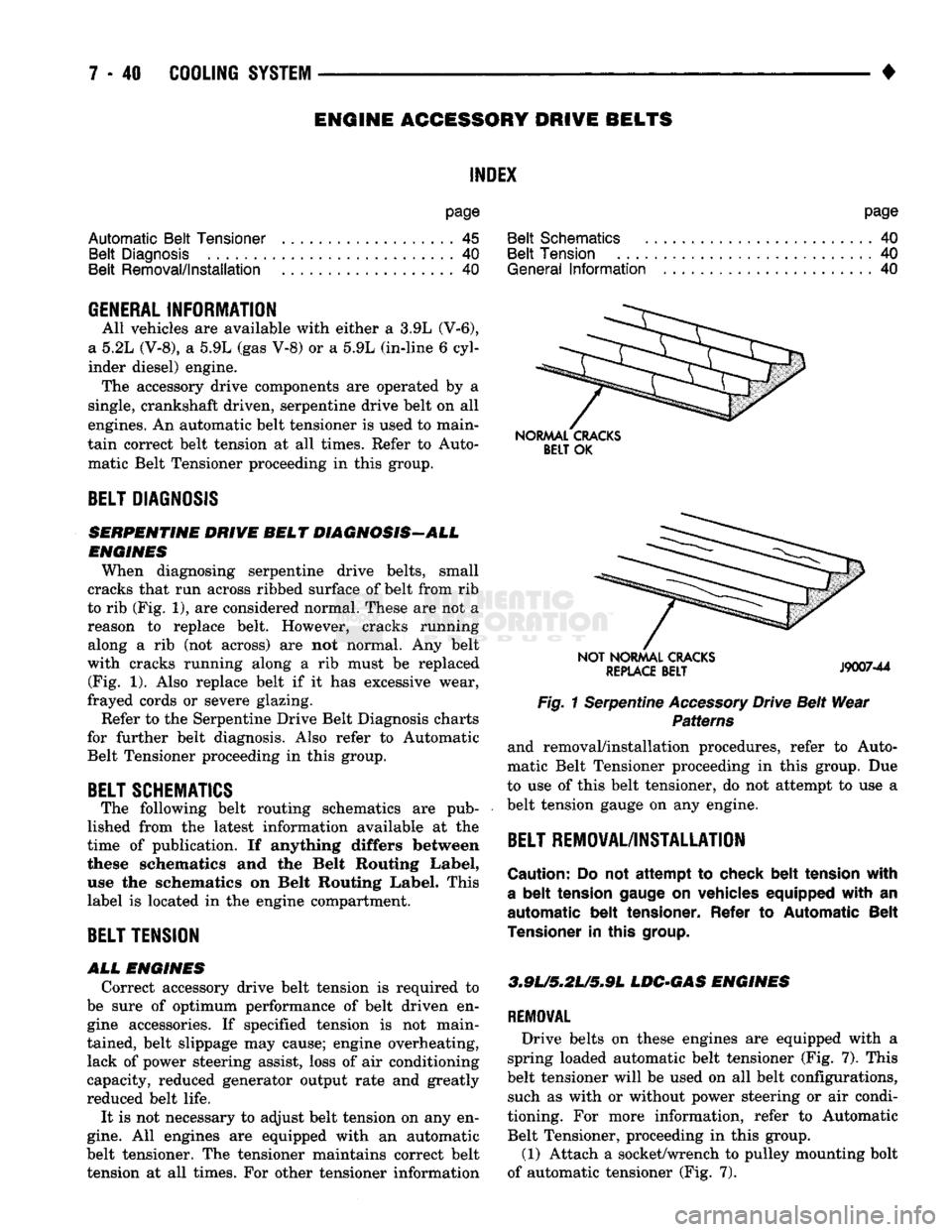

NORMAL CRACKS

BELT

OK

NOT NORMAL CRACKS

REPLACE

BELT

J9007-44

Fig. 1 Serpentine Accessory Drive Belt Wear Patterns

and removal/installation procedures, refer

to

Auto

matic Belt Tensioner proceeding

in

this group.

Due

to use

of

this belt tensioner, do not attempt

to

use

a

belt tension gauge

on

any engine.

BELT REMOVAL/INSTALLATION

Caution:

Do not

attempt

to

check belt tension with

a

belt

tension gauge

on

vehicles equipped with

an

automatic belt tensioner. Refer

to

Automatic Belt

Tensioner

in

this

group.

3.9L/5,2U5*9L

LDC-GAS ENGINES

REMOVAL

Drive belts

on

these engines

are

equipped with

a

spring loaded automatic belt tensioner (Fig.

7).

This

belt tensioner will

be

used on

all

belt configurations, such

as

with

or

without power steering

or

air condi

tioning.

For

more information, refer

to

Automatic Belt Tensioner, proceeding

in

this group.

(1) Attach

a

socket/wrench

to

pulley mounting bolt

of automatic tensioner (Fig.

7).

Page 312 of 1502

•

COOLING

SYSTEM

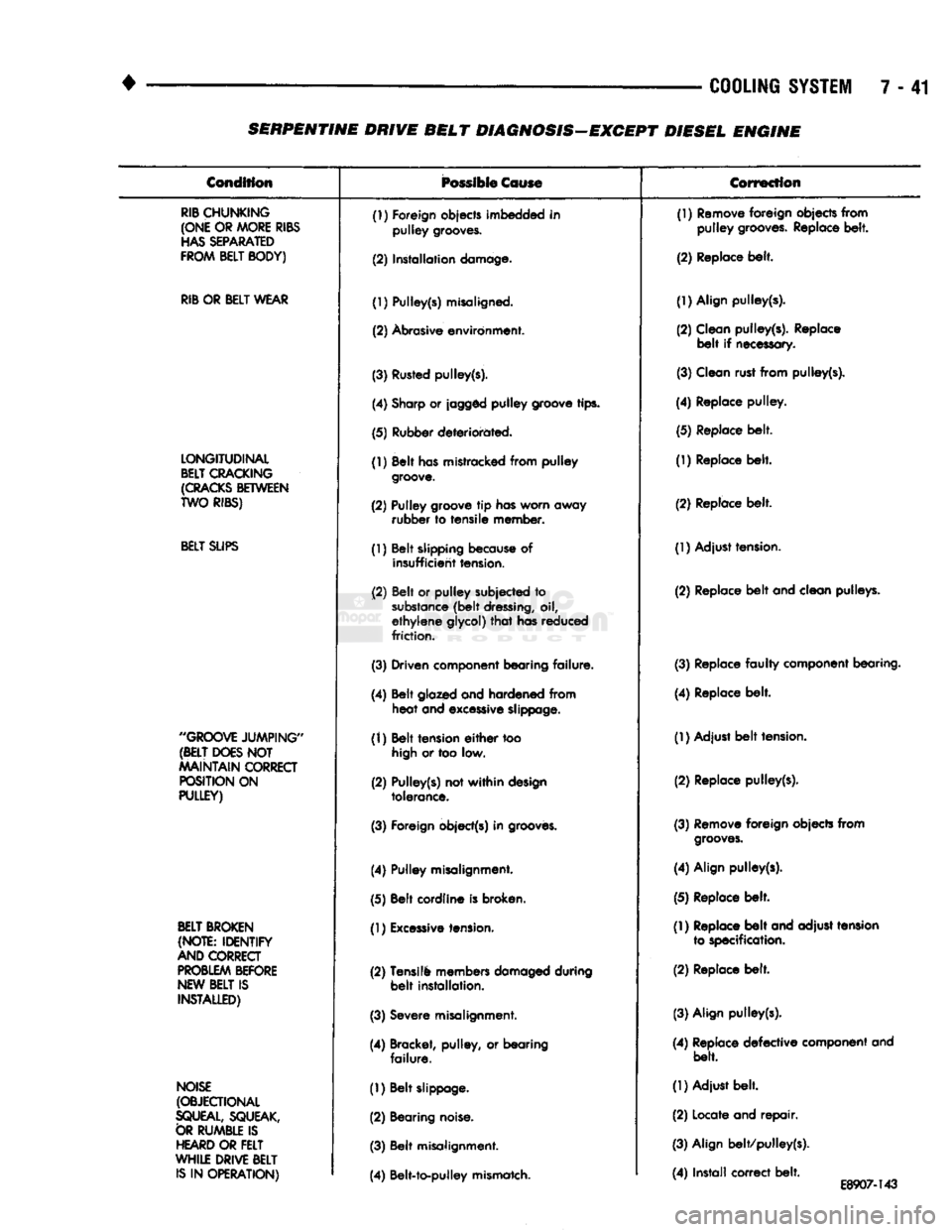

7 - 41 SERPENTINE DRIVE BELT DIAGNOSIS-EXCEPT DIESEL ENGINE

Condition

Possible

Cause

Correction

RIB

CHUNKING

(ONE

OR

MORE

RIBS

HAS

SEPARATED

FROM

BELT

BODY)

(1)

Foreign objects imbedded in

pulley

grooves.

(2) Installation damage. (1) Remove foreign objects from

pulley

grooves.

Replace belt.

(2) Replace belt.

RIB

OR

BELT

WEAR

(1)

Put ley

(s)

misaligned. (1) Align pulley(s).

(2) Abrasive environment. (2) Clean pulley(s). Replace

belt

if

necessary.

(3)

Rusted

pulley(s). (3) Clean rust from pulley(s).

(4)

Sharp

or jagged pulley groove tips. (4) Replace pulley.

(5) Rubber deteriorated. (5) Replace belt.

LONGITUDINAL

BELT

CRACKING

(CRACKS

BETWEEN

TWO

RIBS)

(1) Belt has mistracked from pulley

groove.

(2) Pulley groove tip

has

worn away rubber to tensile member. (1) Replace belt.

(2) Replace belt.

BELT

SLIPS

(1) Belt

slipping

because of

insufficient tension. (1) Adjust tension.

(2) Belt or pulley subjected to

substance

(belt

dressing,

oil,

ethylene glycol)

that

has

reduced

friction. (2) Replace

belt

and clean pulleys.

(3) Driven component bearing failure. (3) Replace faulty component bearing.

(4)

Belt glazed and hardened from heat and

excessive

slippage.

(4) Replace belt.

"GROOVE

JUMPING"

(BELT

DOES

NOT

MAINTAIN

CORRECT

POSITION

ON

PULLEY)

(1)

Belt tension

either

too

high

or too low.

(2) Pulley(s) not within design tolerance. (1) Adjust

belt

tension.

(2) Replace pulley(s).

(3) Foreign object(s) in

grooves.

(3) Remove foreign objects from

grooves.

(4) Pulley misalignment. (4)

Align

pulley(s).

(5) Belt cordline is broken. (5) Replace belt.

BELT

BROKEN

(NOTE:

IDENTIFY

AND

CORRECT

PROBLEM

BEFORE

NEW

BELT

IS

INSTALLED)

(1)

Excessive

tension.

(2) Tensile members damaged during

belt

installation.

(3) Severe misalignment. (1) Replace

belt

and adjust tension

to specification.

(2) Replace belt.

(3) Align pulley(s).

(4)

Bracket, pulley, or bearing failure. (4) Replace defective component and

belt.

NOISE

(OBJECTIONAL

SQUEAL,

SQUEAK,

bR

RUMBLE

IS

HEARD

OR

FELT

WHILE

DRIVE

BELT

IS

IN

OPERATION)

(1)

Belt

slippage.

(2) Bearing noise.

(3) Belt misalignment.

(4) Beit-to-pulley mismatch. (1) Adjust belt.

(2) Locate and repair.

(3)

Align

belt/pulley(s).

(4) Install correct belt. E8907-143

Page 313 of 1502

7 - 42 COOLING SYSTEM

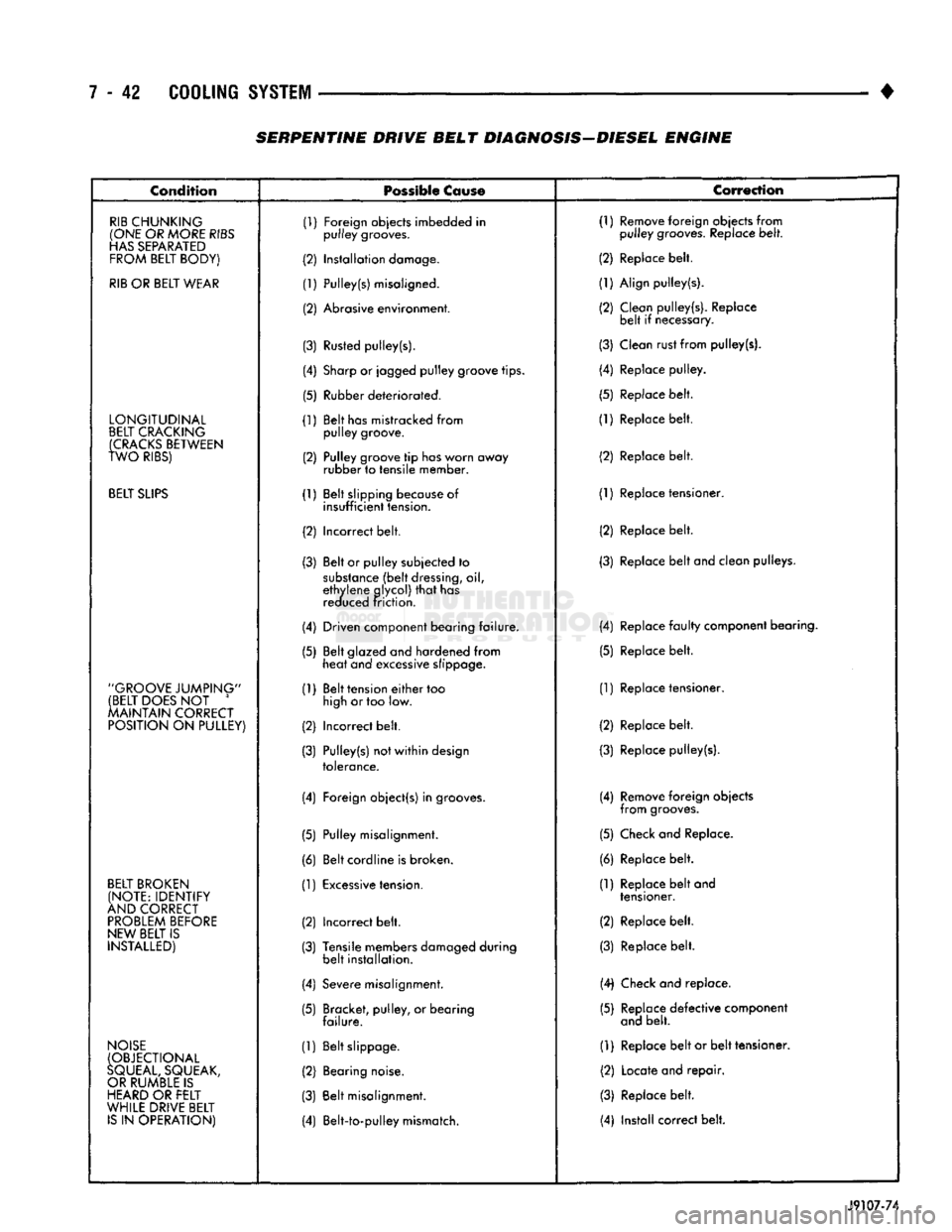

• SERPENTINE DRIVE BELT DIAGNOSIS-DIESEL ENGINE

Condition

Possible

Cause

Correction

RIB

CHUNKING (1) Foreign objects imbedded in

(1) Remove foreign objects from

(ONE

OR

MORE

RIBS

(1)

pulley grooves.

pulley

grooves.

Replace

belt.

HAS

SEPARATED

pulley grooves.

Replace

belt.

FROM

BELT BODY) (2) Installation damage.

(2) Replace

belt.

RIB

OR

BELT

WEAR

(1) Pulley(s) misaligned.

(1)

Align

pulley(s).

(2) Abrasive environment.

(2)

Clean pulley(s). Replace

(2)

belt

if necessary.

(3)

Rusted

pulley(s).

(3) Clean rust from pulley(s).

(4)

Sharp

or jagged pulley groove tips.

(4)

Replace pulley.

(5) Rubber

deteriorated.

(5)

Replace

belt.

LONGITUDINAL

(1) Belt has mistracked from

(1)

Replace

belt.

BELT

CRACKING

(1)

pulley groove. Replace

belt.

(CRACKS

BETWEEN

TWO

RIBS)

pulley groove.

Replace

belt.

(CRACKS

BETWEEN

TWO

RIBS)

(2) Pulley groove tip has worn away

(2) Replace

belt.

(2)

rubber to tensile member.

BELT

SLIPS

(1) Belt slipping because of

0) Replace tensioner.

(1)

insufficient tension.

(2) Incorrect

belt.

(2)

Replace

belt.

(3) Belt or pulley subjected to

(3)

Replace

belt

and clean pulleys.

substance

(belt

dressing,

oil,

ethylene

glycol)

that

has reciuced friction.

(4) Driven component bearing

failure.

(4)

Replace

faulty

component bearing.

(5) Belt glazed and hardened from

(5)

Replace

belt.

(5)

heat

and excessive slippage.

"GROOVE

JUMPING" (1) Belt tension

either

too

(1) Replace tensioner.

(BELT

DOES

NOT 5 (1)

high

or too low. Replace tensioner.

MAINTAIN

CORRECT

high

or too low.

POSITION

ON PULLEY) (2) Incorrect

belt.

(2) Replace

belt.

(3) Pulley(s) not

within

design

(3)

Replace pulley(s).

tolerance.

(4) Foreign object(s) in grooves.

(4)

Remove foreign objects

from grooves.

(5) Pulley misalignment.

(5)

Check and Replace.

(6) Belt cordline is broken.

(6)

Replace

belt.

BELT

BROKEN

0)

Excessive

tension.

0) Replace

belt

and

(NOTE:

IDENTIFY 0)

tensioner.

AND

CORRECT

PROBLEM

BEFORE

(2) Incorrect

belt.

(2) Replace

belt.

NEW

BELT

IS (2)

Replace

belt.

INSTALLED)

(3) Tensile members damaged during

(3) Replace

belt.

(3)

belt

installation.

(4) Severe misalignment.

(4)

Check and replace.

(5) Bracket, pulley, or bearing

(5)

Replace

defective

component

(5)

failure.

ana

belt.

NOISE

0) Belt slippage.

(1) Replace

belt

or

belt

tensioner.

(OBJECTIONAL

0)

Belt slippage.

Replace

belt

or

belt

tensioner.

SQUEAL,

SQUEAK,

(2) Bearing noise.

(2) Locate and

repair.

OR

RUMBLE

IS (2)

Bearing noise.

HEARD

OR FELT (3) Belt misalignment.

(3) Replace

belt.

WHILE

DRIVE

BELT (3)

Belt misalignment.

Replace

belt.

IS

IN OPERATION) (4) Belt-to-pulley mismatch.

(4) Install correct

belt.

J9107-74

Page 314 of 1502

•

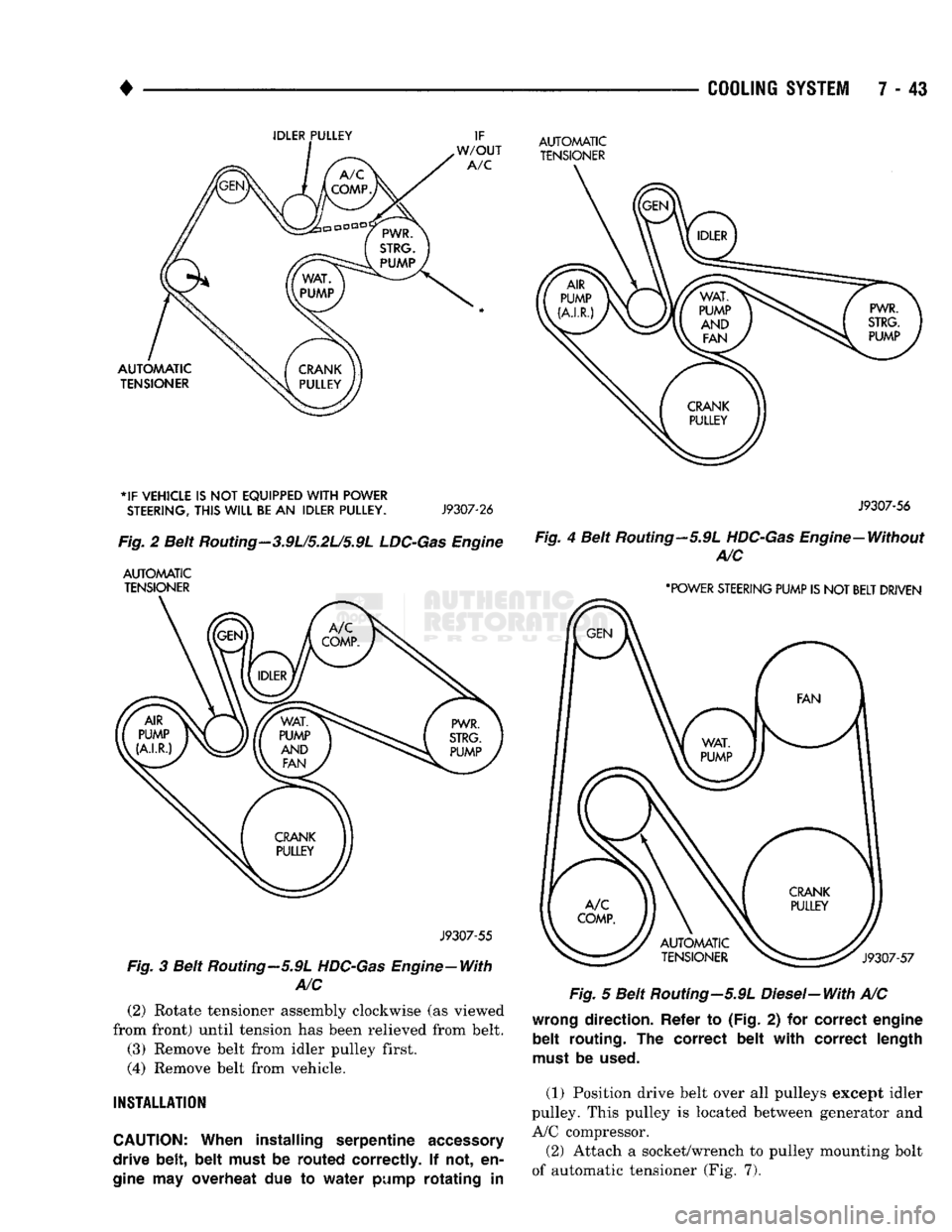

*IF VEHICLE IS NOT EQUIPPED

WITH

POWER

STEERING,

THIS

WILL

BE

AN

IDLER PULLEY.

J9307-26

Fig.

2 Beit

Routing

- 3.9U5.2L/5.9L

LDC-Gas

Engine

AUTOMATIC TENSIONER

J9307-55

Fig.

3 Beit Routing—5.9L HDC-Gas Engine—With

A/C

(2)

Rotate tensioner assembly clockwise (as viewed

from front) until tension has been relieved from belt.

(3) Remove belt from idler pulley first.

(4)

Remove belt from vehicle.

INSTALLATION

CAUTION:

When

installing

serpentine accessory

drive

belt, belt

must

be

routed

correctly.

If not, en

gine

may

overheat

due to

water

pump

rotating in

COOLING

SYSTEM

7 - 43

AUTOMATIC TENSIONER

J9307-56

Fig.

4 Belt Routing—5.9L

HDC-Gas

Engine—Without A/C

'POWER STEERING PUMP IS

NOT

BELT DRIVEN

Fig.

5 Belt Routing-5.9L Diesel-With A/C

wrong

direction. Refer

to

(Fig.

2) for

correct engine

belt routing.

The

correct belt with correct length

must

be

used.

(1) Position drive belt over all pulleys except idler

pulley. This pulley is located between generator and

A/C compressor.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 7).

Page 315 of 1502

7 - 44

COOLING

SYSTEM

•

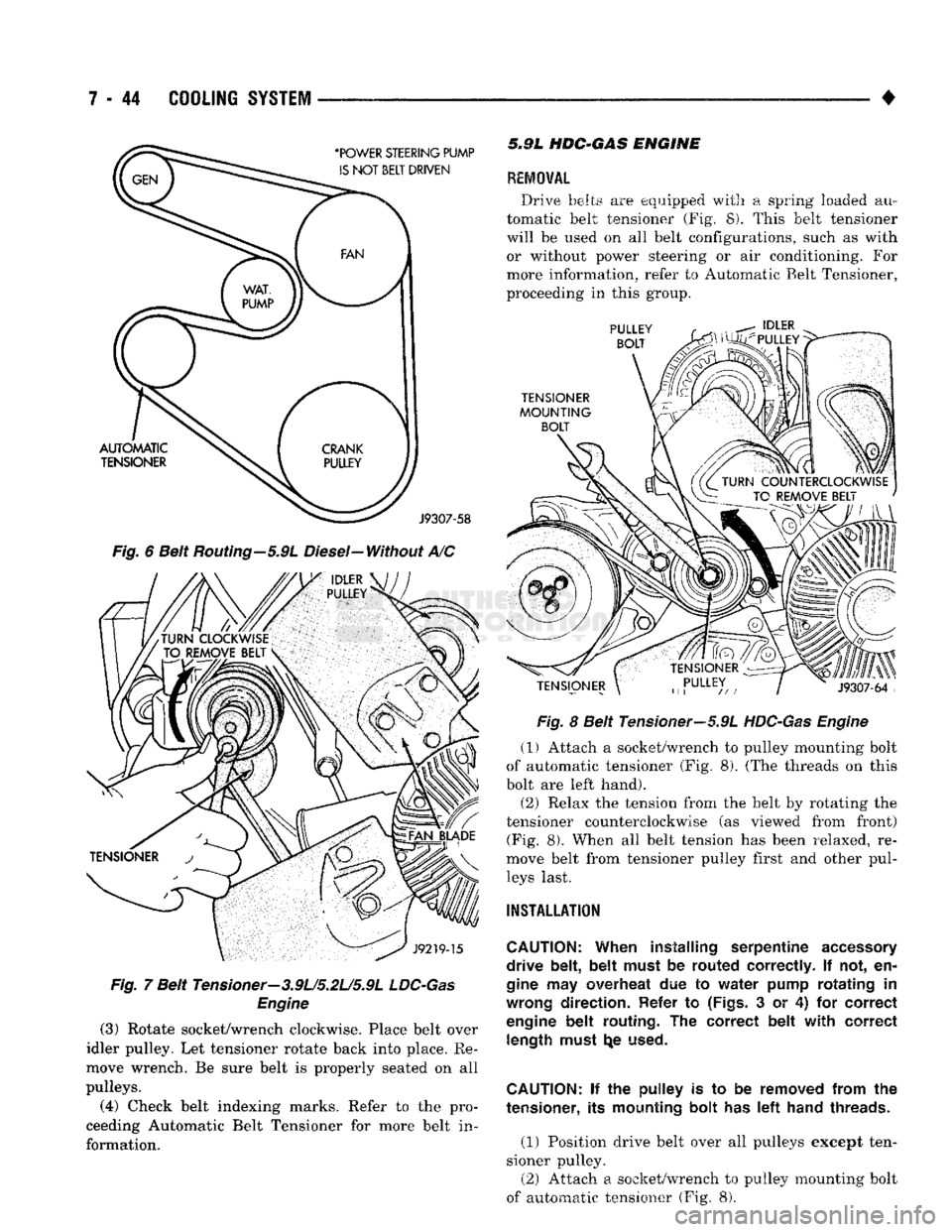

Fig.

6 Belt Routing-5.9L Diesel-Without A/C

Fig.

7 Belt Tensioner-3.9L/5.2U5.9L

LDC-Gas

Engine

(3)

Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place. Re

move wrench. Be sure belt is properly seated on all

pulleys.

(4)

Check belt indexing marks. Refer to the pro

ceeding Automatic Belt Tensioner for more belt in

formation. 5.9L

HDC-GAS

ENGINE

REMOVAL

Drive belts are equipped with a spring loaded au

tomatic belt tensioner (Fig. 8). This belt tensioner

will be used on all belt configurations, such as with or without power steering or air conditioning. For

more information, refer to Automatic Belt Tensioner,

proceeding in this group.

Fig.

8 Belt Tensioner—5.9L

HDC-Gas Engine

(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 8). (The threads on this

bolt are left hand).

(2) Relax the tension from the belt by rotating the

tensioner counterclockwise (as viewed from front) (Fig. 8). When all belt tension has been relaxed, re

move belt from tensioner pulley first and other pul leys last.

INSTALLATION

CAUTION:

When installing serpentine

accessory

drive belt, belt must

be

routed correctly.

If not, en

gine

may

overheat

due to

water pump rotating

in

wrong

direction. Refer

to

(Figs.

3 or 4) for

correct

engine

belt routing.

The

correct belt with correct length must

t^e

used.

CAUTION:

if the

pulley

is to be

removed from

the

tensioner,

its

mounting bolt

has left

hand threads.

(1) Position drive belt over all pulleys except ten

sioner pulley. (2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 8).