belt DODGE TRUCK 1993 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 316 of 1502

•

COOLING

SYSTEM

7 - 45 (3) Rotate socket/wrench counterclockwise. Install

belt over tensioner pulley. Let tensioner rotate back into place. Remove wrench. Be sure belt is properly

seated on all pulleys.

5«9L

DIESEL ENGINE

REMOVAL

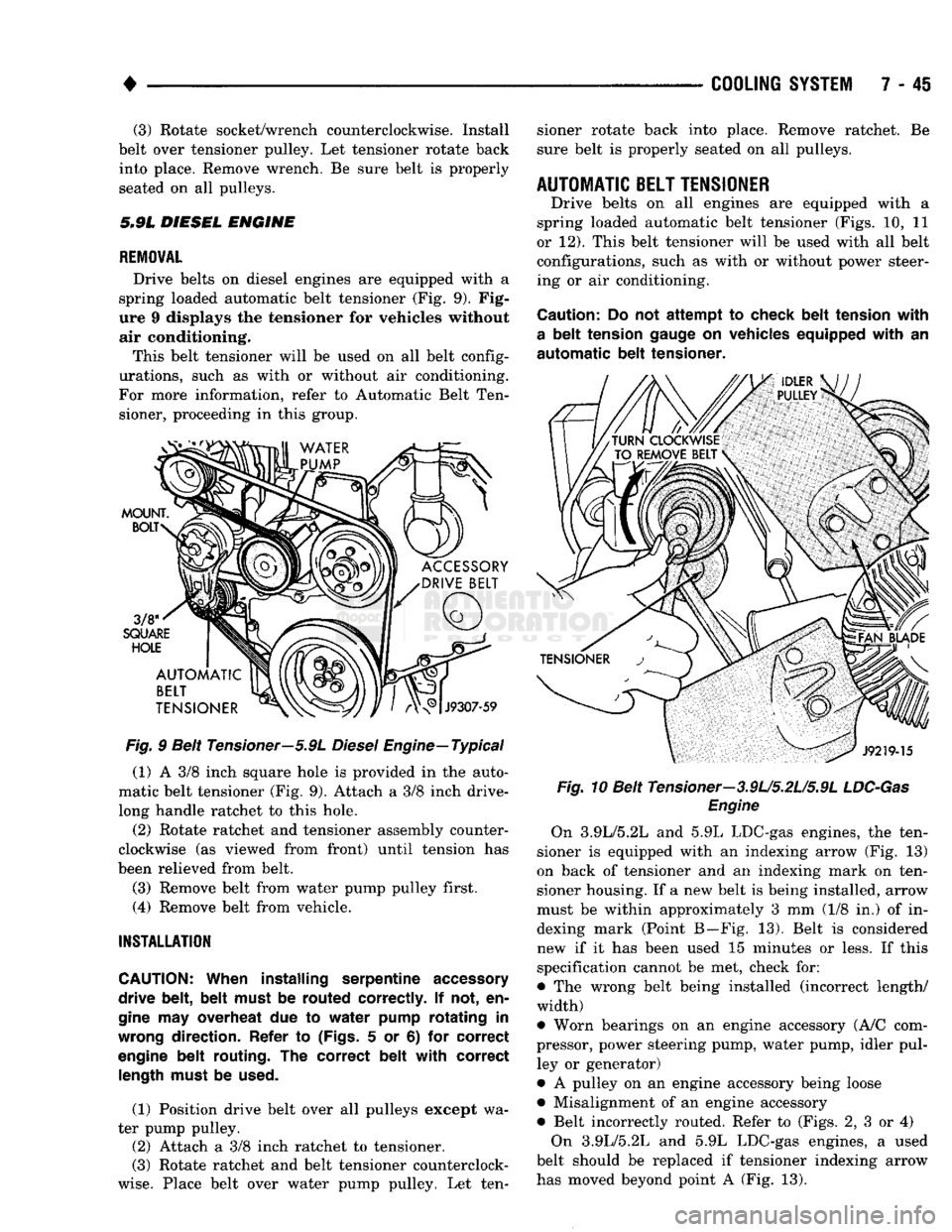

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner (Fig. 9). Fig

ure 9 displays the tensioner for vehicles without air conditioning.

This belt tensioner will be used on all belt config

urations, such as with or without air conditioning.

For more information, refer to Automatic Belt Ten sioner, proceeding in this group.

Fig.

9 Belt Tensioner—5.9L

Diesel

Engine—Typical

(1) A 3/8 inch square hole is provided in the auto

matic belt tensioner (Fig. 9). Attach a 3/8 inch drive-

long handle ratchet to this hole.

(2) Rotate ratchet and tensioner assembly counter

clockwise (as viewed from front) until tension has

been relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION:

When installing serpentine

accessory

drive belt, belt must

be

routed correctly.

If not, en

gine

may

overheat

due to

water pump rotating

in

wrong

direction. Refer

to

(Figs.

5 or 6) for

correct

engine

belt routing.

The

correct belt with correct

length

must

be

used.

(1) Position drive belt over all pulleys except wa

ter pump pulley. (2) Attach a 3/8 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner counterclock

wise.

Place belt over water pump pulley. Let ten sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

AUTOMATIC

BELT

TENSIONER

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Figs. 10, 11

or 12). This belt tensioner will be used with all belt configurations, such as with or without power steer

ing or air conditioning.

Caution:

Do not

attempt

to

check belt tension with

a

belt tension

gauge

on

vehicles equipped with

an

automatic

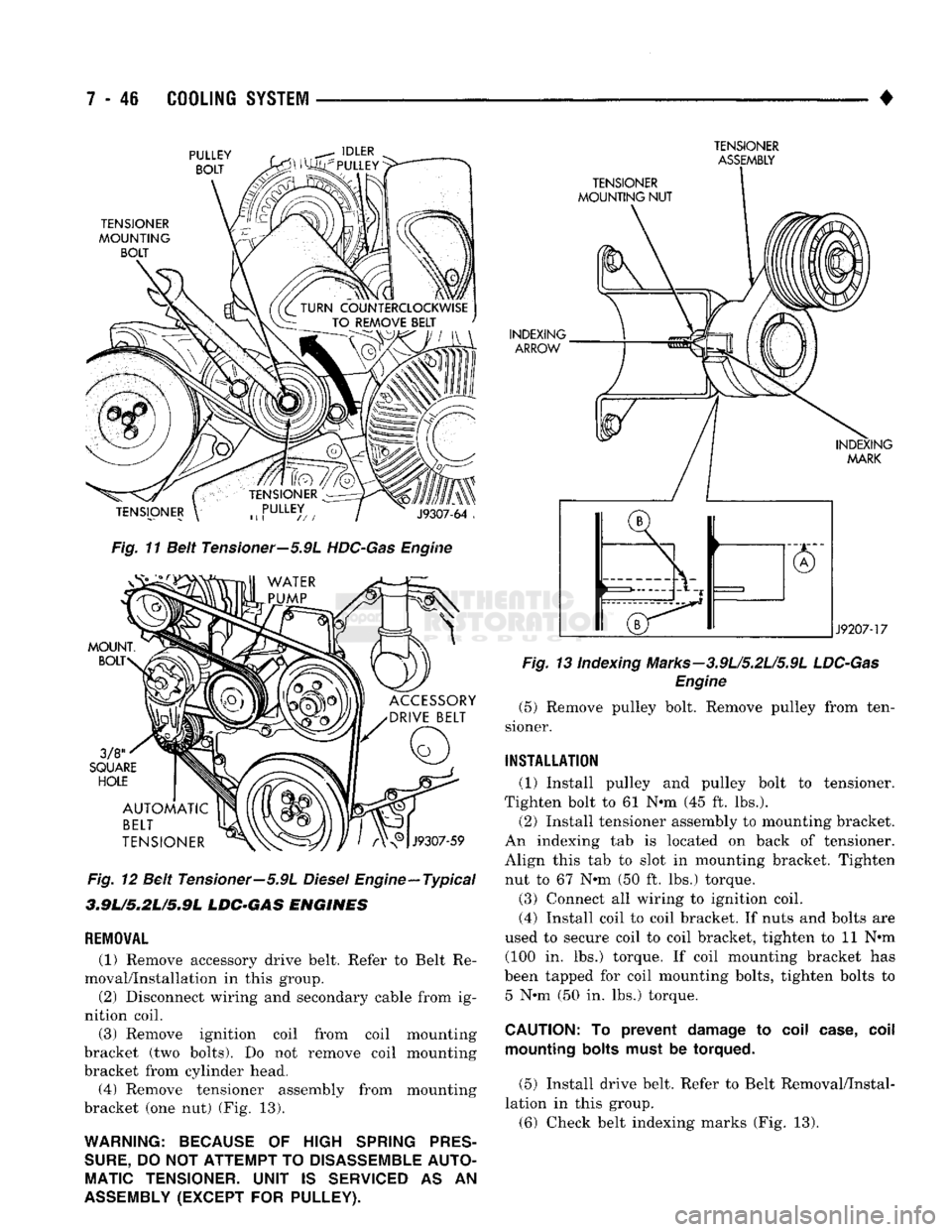

belt tensioner. Fig.

10 Belt Tensioner—3.9U5.2U5.9L

LDC-Gas

Engine

On 3.9L/5.2L and 5.9L LDC-gas engines, the ten

sioner is equipped with an indexing arrow (Fig. 13)

on back of tensioner and an indexing mark on ten

sioner housing. If a new belt is being installed, arrow

must be within approximately 3 mm (1/8 in.) of in dexing mark (Point B—Fig. 13). Belt is considered

new if it has been used 15 minutes or less. If this

specification cannot be met, check for:

• The wrong belt being installed (incorrect length/

width)

• Worn bearings on an engine accessory (A/C com

pressor, power steering pump, water pump, idler pul ley or generator)

• A pulley on an engine accessory being loose

• Misalignment of an engine accessory

• Belt incorrectly routed. Refer to (Figs. 2, 3 or 4) On 3.9L/5.2L and 5.9L LDC-gas engines, a used

belt should be replaced if tensioner indexing arrow

has moved beyond point A (Fig. 13).

Page 317 of 1502

7

- 4S

COOLING

SYSTEM

•

PULLEY BOLT IDLER

iUlLTPULLEY-

TENSIONER

MOUNTING

BOLT TENSIONER

ASSEMBLY

TENSIONER \

rULLC,\

, / ^ J9307-64 ,

Fig.

11 Beit Tensioner—5.9L

HDC-Gas

Engine

MOUNT.

BOLT

3/8

SQUARE HOLE

ACCESSORY

DRIVE

BELT AUTOMATIC

BELT

TENSIONER

J9307-59

Fig.

12 Belt Tensioner—5.9L

Diesel

Engine—Typical

3MLm.2Lm.9L

LDG°GA8

ENGINES

REMOVAL

(1) Remove accessory drive belt. Refer to Belt Re

moval/Installation in this group. (2) Disconnect wiring and secondary cable from ig

nition coil.

(3) Remove ignition coil from coil mounting

bracket (two bolts). Do not remove coil mounting

bracket from cylinder head. (4) Remove tensioner assembly from mounting

bracket (one nut) (Fig. 13).

WARNING: BECAUSE

OF

HIGH

SPRING

PRES

SURE,

DO

NOT ATTEMPT

TO

DISASSEMBLE

AUTO

MATIC

TENSIONER.

UNIT

IS

SERVICED

AS AN

ASSEMBLY

(EXCEPT

FOR

PULLEY).

TENSIONER

MOUNTING NUT

INDEXING ARROW

INDEXING MARK

J9207-17

Fig.

13 indexing Marks-3.9L/5.2L/5.9L

LDC-Gas

Engine

(5) Remove pulley bolt. Remove pulley from ten

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 Nnn (45 ft. lbs.).

(2) Install tensioner assembly to mounting bracket.

An indexing tab is located on back of tensioner.

Align this tab to slot in mounting bracket. Tighten nut to 67 Nnn (50 ft. lbs.) torque.

(3) Connect all wiring to ignition coil. (4) Install coil to coil bracket. If nuts and bolts are

used to secure coil to coil bracket, tighten to 11 Nnn (100 in. lbs.) torque. If coil mounting bracket has

been tapped for coil mounting bolts, tighten bolts to 5 Nnn (50 in. lbs.) torque.

CAUTION:

To

prevent damage

to

coil case, coil mounting bolts must

be

torqued.

(5) Install drive belt. Refer to Belt Removal/Instal

lation in this group. (6) Check belt indexing marks (Fig. 13).

Page 318 of 1502

•

COOLING

SYSTEM

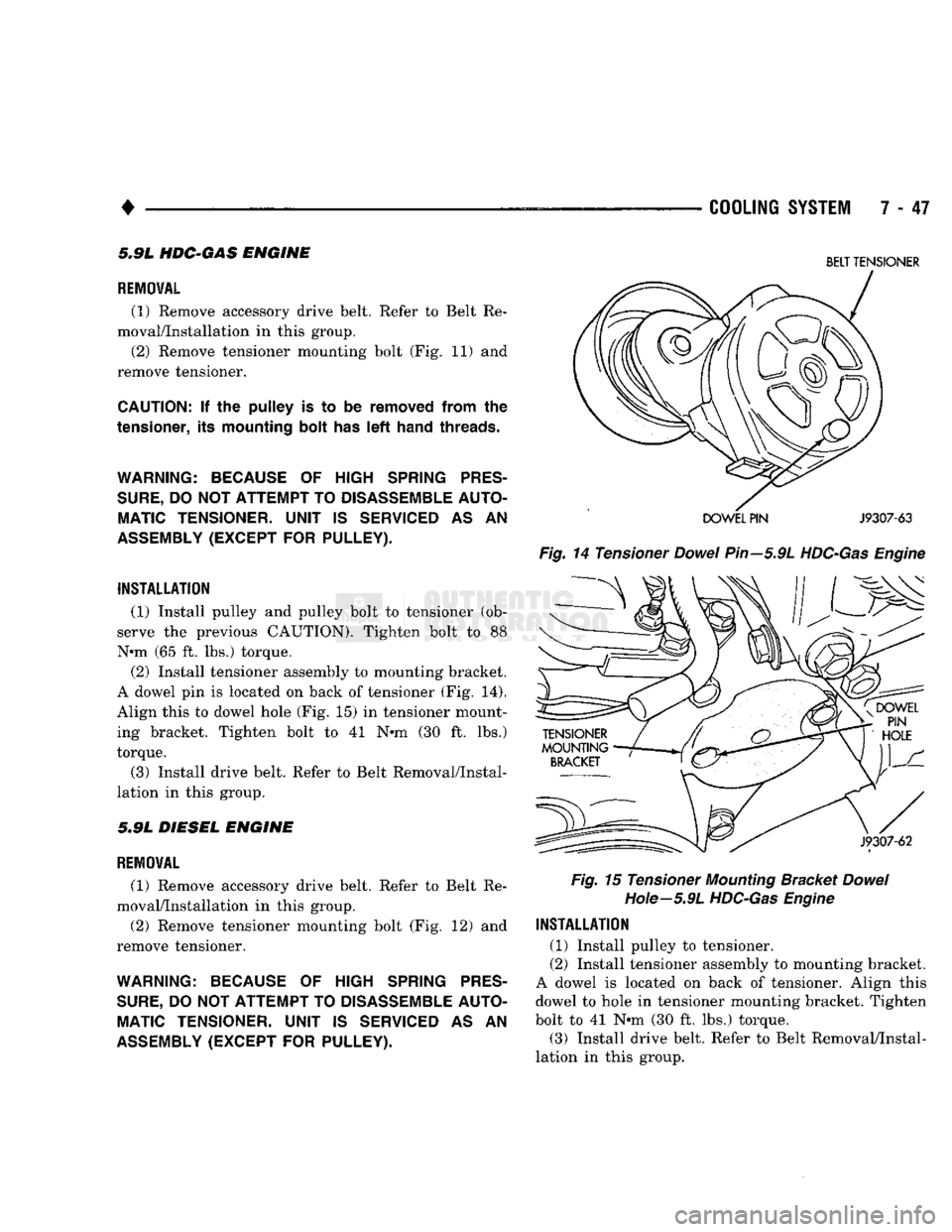

7 - 47 5.9L HDC'GAS ENGINE

REMOVAL

(1) Remove accessory drive belt. Refer to Belt Re

moval/Installation in this group. (2) Remove tensioner mounting bolt (Fig. 11) and

remove tensioner.

CAUTION:

If the

pulley

is to be

removed

from

the

tensioner,

its

mounting

bolt has

left

hand

threads.

WARNING:

BECAUSE

OF

HIGH SPRING

PRES

SURE,

DO

NOT ATTEMPT TO

DISASSEMBLE

AUTO MATIC TENSIONER. UNIT

IS

SERVICED

AS AN

ASSEMBLY

(EXCEPT FOR PULLEY).

INSTALLATION

(1) Install pulley and pulley bolt to tensioner (ob

serve the previous CAUTION). Tighten bolt to 88

N*m (65 ft. lbs.) torque.

(2) Install tensioner assembly to mounting bracket.

A dowel pin is located on back of tensioner (Fig. 14).

Align this to dowel hole (Fig. 15) in tensioner mount

ing bracket. Tighten bolt to 41 N-m (30 ft. lbs.)

torque.

(3) Install drive belt. Refer to Belt Removal/Instal

lation in this group.

5.9L DIESEL ENGINE

REMOVAL

(1) Remove accessory drive belt. Refer to Belt Re

moval/Installation in this group. (2) Remove tensioner mounting bolt (Fig. 12) and

remove tensioner.

WARNING:

BECAUSE

OF

HIGH SPRING

PRES

SURE,

DO

NOT ATTEMPT

TO

DISASSEMBLE

AUTO MATIC TENSIONER. UNIT

IS

SERVICED

AS AN

ASSEMBLY

(EXCEPT FOR PULLEY).

BELT

TENSIONER

DOWEL

PIN

J9307-63

Fig.

14 Tensioner

Dowel

Pin—5.9L

HDC-Gas

Engine

Fig.

15 Tensioner

Mounting

Bracket

Dowel

Hole—5.9L

HDC-Gas

Engine

INSTALLATION

(1) Install pulley to tensioner.

(2) Install tensioner assembly to mounting bracket.

A dowel is located on back of tensioner. Align this

dowel to hole in tensioner mounting bracket. Tighten

bolt to 41 N*m (30 ft. lbs.) torque.

(3) Install drive belt. Refer to Belt Removal/Instal

lation in this group.

Page 320 of 1502

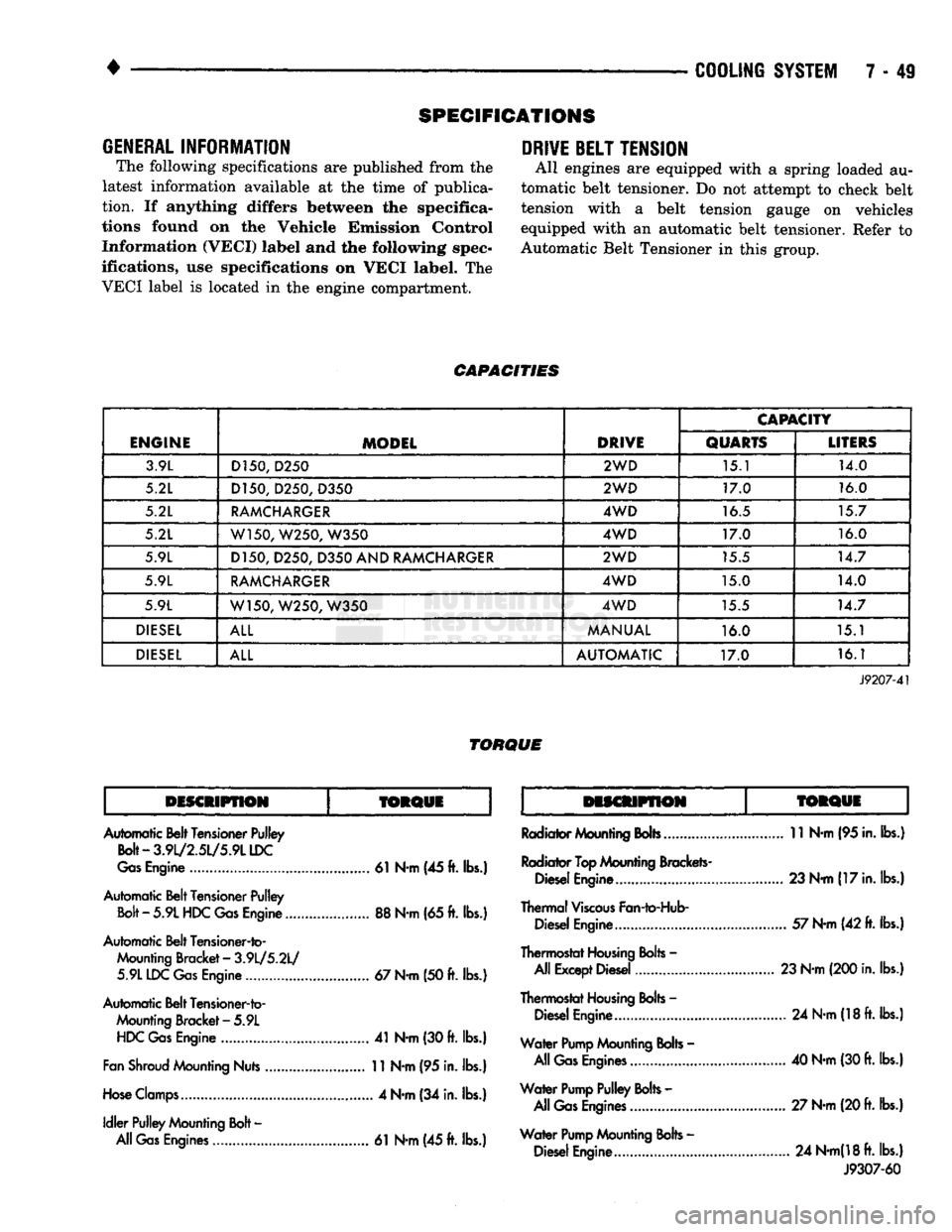

SPECIFICATIONS

GENERAL

INFORMATION

The following specifications are published from the

latest information available at the time of publica

tion. If anything differs between the specifica

tions found on the Vehicle Emission Control

Information (VECI) label and the following spec

ifications, use specifications on VECI label. The

VECI label is located in the engine compartment.

DRIVE

BELT

TENSION

All engines are equipped with a spring loaded au

tomatic belt tensioner. Do not attempt to check belt

tension with a belt tension gauge on vehicles

equipped with an automatic belt tensioner. Refer to

Automatic Belt Tensioner in this group.

CAPACITIES

ENGINE

MODEL

DRIVE

CAPACITY

ENGINE

MODEL

DRIVE

QUARTS

LITERS

3.9L D150,

D250

2WD

15.1 14.0

5.2L D150, D250,

D350

2WD

17.0 16.0

5.2L

RAMCHARGER

4WD

16.5 15.7

5.2L W150, W250,

W350

4WD

17.0 16.0

5.9L D150, D250,

D350

AND

RAMCHARGER

2WD

15.5 14.7

5.9L

RAMCHARGER

4WD

15.0 14.0

5.9L W150, W250,

W350

4WD

15.5 14.7

DIESEL

ALL

MANUAL

16.0 15.1

DIESEL

ALL

AUTOMATIC

17.0 16.1

J9207-41

TORQUE

DISCMPflON

TORQUE

TORQUi

Automatic Belt Tensioner Pulley

Bolt-3.9l/2.5L/5.9LLDC

Gas

Engine

61

N-m (45

ft.

lbs.)

Automatic Belt Tensioner Pulley

Bolt

-

5.9L

HDC

Gas

Engine

88

N-m

(65

ft.

lbs.)

Automatic Belt Tensioner-to- Mounting Bracket

-

3.9L/5.2L/ 5.9L IDC

Gas

Engine

67

N-m

(50

ft.

lbs.)

Automatic Belt Tensioner-to- Mounting Bracket

-

5.9L

HDC

Gas

Engine

41

N-m

(30

ft.

lbs.)

Fan

Shroud

Mounting Nuts

11

N-m

(95

in. lbs.)

Hose

Clamps

4

N-m

(34

in. lbs.)

Idler

Pulley Mounting

Bolt

-

All

Gas

Engines

61

N-m

(45

ft.

lbs.)

Radiator Mounting

Bobs

11

N-m

(95

in. lbs.)

Radiator

Top

Mounting Brackets- Diesel Engine...... 23 N-m

(17

in. lbs.)

Thermal

Viscous

Fan-to-Hub- Diesel Engine

57

N-m

(42

ft.

lbs.)

Thermostat

Housing

Bolts

-

All Except Diesel 23 N-m (200 in. lbs.)

Thermostat

Housing

Bolts

-

Diesel Engine

24

N-m

(18

ft.

lbs.)

Water

Pump

Mounting

Bolts

-

All

Gas

Engines

40

N-m

(30

ft.

lbs.)

Water

Pump

Pulley

Bolts

-

All

Gas

Engines

27 N-m (20

ft.

lbs.)

Water

Pump

Mounting

Bolts

-

Diesel Engine

24

N-m(18ft.

lbs.) J9307-60

Page 324 of 1502

•

ELECTRICAL

8A - 3

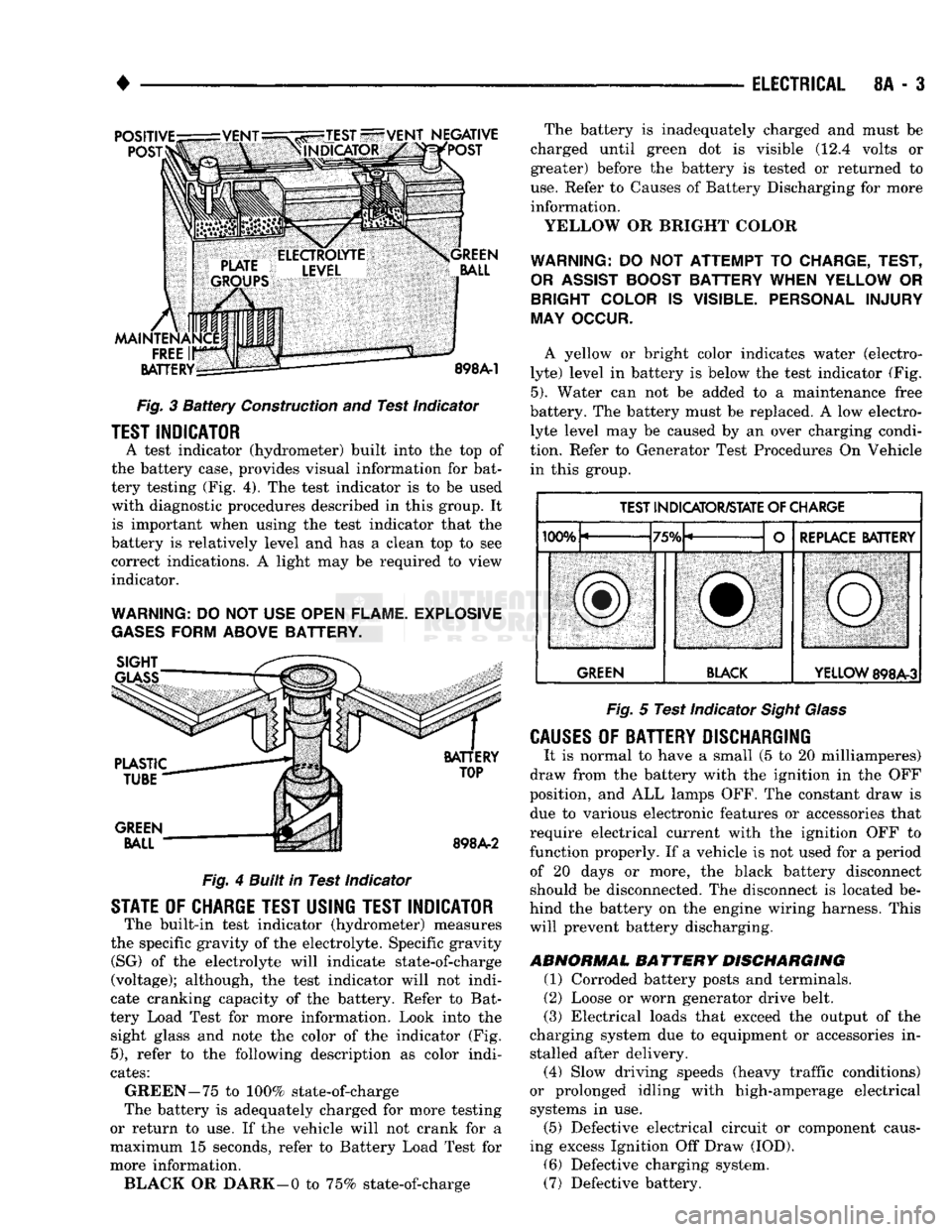

Fig.

3

Battery

Construction

and

Test Indicator

TEST INDICATOR

A test indicator (hydrometer) built into

the top of

the battery case, provides visual information

for

bat

tery testing (Fig.

4). The

test indicator

is to be

used with diagnostic procedures described

in

this group.

It

is important when using

the

test indicator that

the

battery

is

relatively level

and has a

clean

top to see

correct indications.

A

light

may be

required

to

view

indicator.

WARNING:

DO

NOT USE

OPEN FLAME. EXPLOSIVE

GASES

FORM ABOVE BATTERY.

Fig.

4

Built in Test Indicator

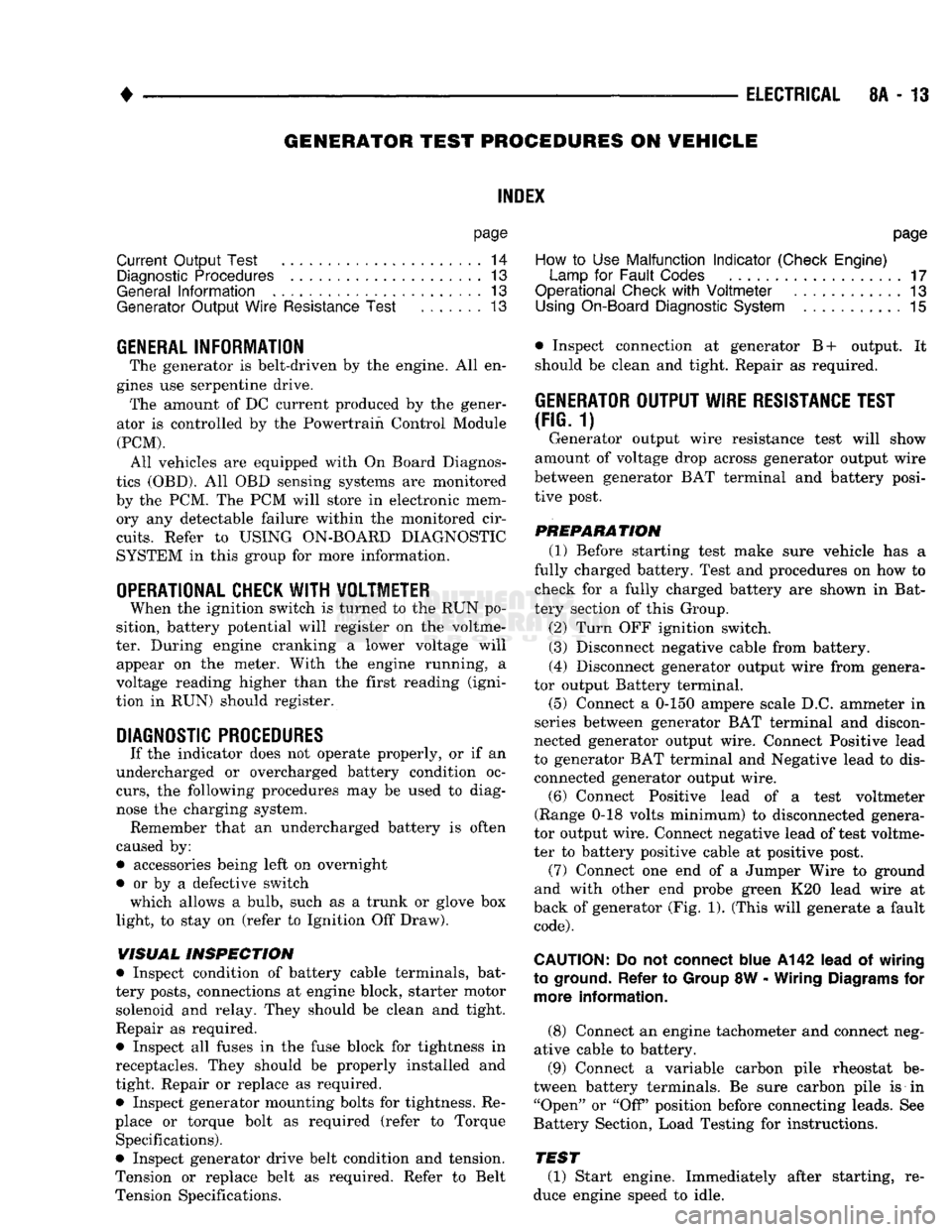

STATE

OF

CHARGE TEST USING TEST INDICATOR

The built-in test indicator (hydrometer) measures

the specific gravity

of

the electrolyte. Specific gravity (SG)

of the

electrolyte will indicate state-of-charge

(voltage); although,

the

test indicator will

not

indi

cate cranking capacity

of the

battery. Refer

to

Bat

tery Load Test

for

more information. Look into

the

sight glass

and

note

the

color

of the

indicator

(Fig.

5),

refer

to the

following description

as

color indi

cates:

GREEN-75

to

100% state-of-charge

The battery

is

adequately charged

for

more testing

or return

to use. If the

vehicle will

not

crank

for a

maximum

15

seconds, refer

to

Battery Load Test

for

more information. BLACK

OR

DARK—0

to

75% state-of-charge The battery

is

inadequately charged

and

must

be

charged until green

dot is

visible

(12.4

volts

or

greater) before

the

battery

is

tested

or

returned

to

use.

Refer

to

Causes

of

Battery Discharging

for

more information.

YELLOW

OR

BRIGHT COLOR

WARNING:

DO NOT

ATTEMPT

TO

CHARGE, TEST,

OR

ASSIST

BOOST BATTERY WHEN YELLOW

OR

BRIGHT COLOR

IS

VISIBLE. PERSONAL INJURY

MAY OCCUR.

A yellow

or

bright color indicates water (electro

lyte) level

in

battery

is

below

the

test indicator

(Fig.

5).

Water

can not be

added

to a

maintenance free

battery.

The

battery must

be

replaced.

A low

electro lyte level

may be

caused

by an

over charging condi

tion. Refer

to

Generator Test Procedures

On

Vehicle in this group.

TEST INDICATOR/STATE

OF

CHARGE

IfVW,

"TCfV

REPLACE BATTERY

lUUTu

/Otu L

f

REPLACE BATTERY

SBl

ill,

iMMiMMMMSMM^MM

GREEN BLACK

YELLOW

898A-3

Fig.

5

Test Indicator

Sight Glass

CAUSES

OF

BATTERY DISCHARGING

It

is

normal

to

have

a

small

(5 to 20

milliamperes)

draw from

the

battery with

the

ignition

in the OFF

position,

and ALL

lamps OFF.

The

constant draw

is

due

to

various electronic features

or

accessories that

require electrical current with

the

ignition

OFF to

function properly.

If a

vehicle

is not

used

for a

period of

20

days

or

more,

the

black battery disconnect

should

be

disconnected.

The

disconnect

is

located

be

hind

the

battery

on the

engine wiring harness. This will prevent battery discharging.

ABNORMAL

BATTERY

DISCHARGING

(1) Corroded battery posts

and

terminals.

(2) Loose

or

worn generator drive belt.

(3) Electrical loads that exceed

the

output

of the

charging system

due to

equipment

or

accessories

in

stalled after delivery. (4) Slow driving speeds (heavy traffic conditions)

or prolonged idling with high-amperage electrical systems

in use.

(5) Defective electrical circuit

or

component caus

ing excess Ignition

Off

Draw (IOD).

(6) Defective charging system.

(7) Defective battery.

Page 331 of 1502

8A

- 10

ELECTRICAL

•

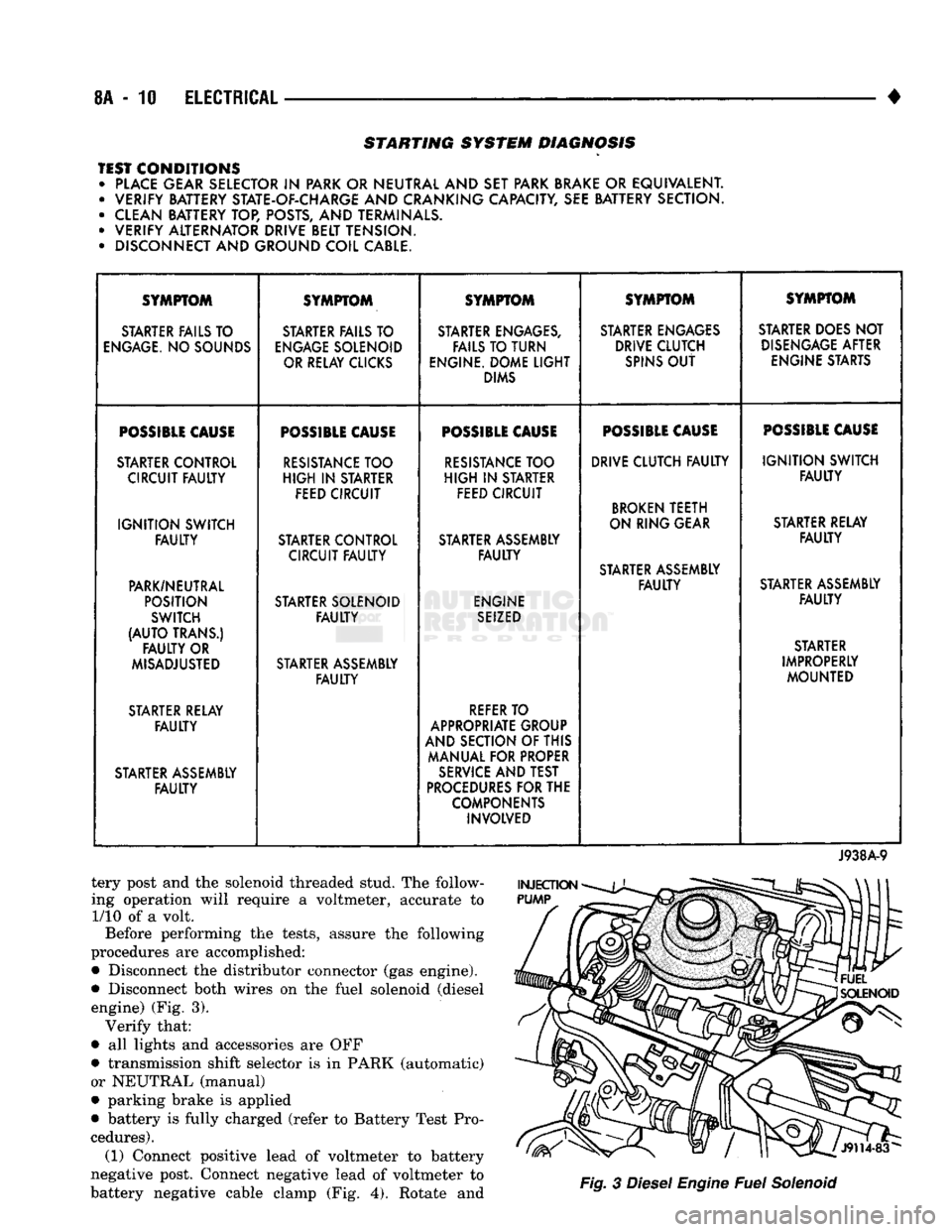

STARTING SYSTEM DIAGNOSIS

TEST CONDITIONS • PLACE GEAR SELECTOR

IN

PARK OR NEUTRAL AND SET PARK BRAKE

OR

EQUIVALENT. • VERIFY BATTERY STATE-OF-CHARGE AND CRANKING CAPACITY, SEE BATTERY SECTION.

• CLEAN BATTERY TOP, POSTS, AND TERMINALS.

• VERIFY ALTERNATOR DRIVE BELT TENSION.

• DISCONNECT AND GROUND COIL CABLE. SYMPTOM

SYMPTOM SYMPTOM SYMPTOM SYMPTOM

STARTER FAILS TO STARTER FAILS TO STARTER ENGAGES, STARTER ENGAGES STARTER DOES NOT

ENGAGE.

NO SOUNDS

ENGAGE

SOLENOID FAILS TO TURN DRIVE CLUTCH

DISENGAGE

AFTER

OR RELAY CLICKS ENGINE. DOME

LIGHT

SPINS

OUT

ENGINE STARTS

DIMS

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

STARTER CONTROL

RESISTANCE

TOO

RESISTANCE

TOO DRIVE CLUTCH

FAULTY

IGNITION

SWITCH

CIRCUIT

FAULTY

HIGH

IN

STARTER

HIGH

IN

STARTER

FAULTY

FEED CIRCUIT FEED CIRCUIT

BROKEN

TEETH

IGNITION

SWITCH ON RING GEAR

STARTER RELAY

FAULTY

STARTER CONTROL STARTER ASSEMBLY

FAULTY

CIRCUIT

FAULTY FAULTY

STARTER ASSEMBLY

PARK/NEUTRAL

FAULTY

STARTER ASSEMBLY

POSITION STARTER SOLENOID ENGINE

FAULTY

SWITCH

FAULTY

SEIZED

(AUTO

TRANS.) STARTER

FAULTY

OR STARTER

MISADJUSTED STARTER ASSEMBLY IMPROPERLY

FAULTY

MOUNTED

STARTER RELAY

REFER

TO

FAULTY

APPROPRIATE GROUP

AND SECTION OF THIS

MANUAL FOR PROPER

STARTER ASSEMBLY

SERVICE

AND TEST

FAULTY

PROCEDURES

FOR THE

COMPONENTS INVOLVED

J938A-9

tery post and the solenoid threaded stud. The follow

ing operation will require a voltmeter, accurate to 1/10 of a volt.

Before performing the tests, assure the following

procedures are accomplished:

•

Disconnect the distributor connector (gas engine).

•

Disconnect both wires on the fuel solenoid (diesel engine) (Fig. 3). Verify that:

•

all lights and accessories are OFF

•

transmission shift selector is in PARK (automatic)

or NEUTRAL (manual)

•

parking brake is applied

•

battery is fully charged (refer to Battery Test Pro

cedures). (1) Connect positive lead of voltmeter to battery

negative post. Connect negative lead of voltmeter to

battery negative cable clamp (Fig. 4). Rotate and

Fig.

3

Diesel

Engine

Fuel

Solenoid

Page 334 of 1502

•

ELECTRICAL

8A - 13 GENERATOR TEST PROCEDURES ON

VEHICLE

INDEX

page

Current

Output

Test

......................

14

Diagnostic Procedures

13

General

Information

13

Generator

Output

Wire Resistance Test

.......

13

page

How

to

Use

Malfunction

Indicator

(Check Engine) Lamp

for

Fault

Codes

17

Operational Check

with

Voltmeter

............

13

Using

On-Board Diagnostic System

15

GENERAL

INFORMATION

The generator

is

belt-driven

by the

engine.

All en

gines

use

serpentine drive. The amount

of DC

current produced

by the

gener

ator

is

controlled

by the

Powertrain Control Module (PCM).

All vehicles

are

equipped with

On

Board Diagnos

tics (OBD).

All OBD

sensing systems

are

monitored

by

the PCM. The PCM

will store

in

electronic mem ory

any

detectable failure within

the

monitored cir

cuits.

Refer

to

USING ON-BOARD DIAGNOSTIC SYSTEM

in

this group

for

more information.

OPERATIONAL CHECK

WITH

VOLTMETER

When

the

ignition switch

is

turned

to the RUN po

sition, battery potential will register

on the

voltme

ter. During engine cranking

a

lower voltage will appear

on the

meter. With

the

engine running,

a

voltage reading higher than

the

first reading (igni

tion

in RUN)

should register.

DIAGNOSTIC PROCEDURES

If

the

indicator does

not

operate properly,

or if an

undercharged

or

overcharged battery condition

oc

curs,

the

following procedures

may be

used

to

diag

nose

the

charging system. Remember that

an

undercharged battery

is

often

caused

by:

• accessories being left

on

overnight

•

or by a

defective switch which allows

a

bulb, such

as a

trunk

or

glove

box

light,

to

stay

on

(refer

to

Ignition

Off

Draw).

WISUAL

INSPECTION

• Inspect condition

of

battery cable terminals, bat

tery posts, connections

at

engine block, starter motor solenoid

and

relay. They should

be

clean

and

tight.

Repair

as

required.

• Inspect

all

fuses

in the

fuse block

for

tightness

in

receptacles. They should

be

properly installed

and

tight. Repair

or

replace

as

required.

• Inspect generator mounting bolts

for

tightness.

Re

place

or

torque bolt

as

required (refer

to

Torque Specifications).

• Inspect generator drive belt condition

and

tension.

Tension

or

replace belt

as

required. Refer

to

Belt

Tension Specifications. • Inspect connection

at

generator

B+

output.

It

should

be

clean

and

tight. Repair

as

required.

GENERATOR

OUTPUT

WIRE RESISTANCE TEST

(FIG.

1)

Generator output wire resistance test will show

amount

of

voltage drop across generator output wire

between generator

BAT

terminal

and

battery posi tive post.

PREPARATION

(1) Before starting test make sure vehicle

has a

fully charged battery. Test

and

procedures

on how to

check

for a

fully charged battery

are

shown

in

Bat

tery section

of

this Group.

(2) Turn

OFF

ignition switch.

(3)

Disconnect negative cable from battery.

(4)

Disconnect generator output wire from genera

tor output Battery terminal. (5) Connect

a 0-150

ampere scale

D.C.

ammeter

in

series between generator

BAT

terminal

and

discon

nected generator output wire. Connect Positive lead

to generator

BAT

terminal

and

Negative lead

to

dis connected generator output wire. (6) Connect Positive lead

of a

test voltmeter

(Range

0-18

volts minimum)

to

disconnected genera

tor output wire. Connect negative lead

of

test voltme

ter

to

battery positive cable

at

positive post. (7) Connect

one end of a

Jumper Wire

to

ground

and with other

end

probe green

K20

lead wire

at

back

of

generator

(Fig. 1).

(This will generate

a

fault

code).

CAUTION:

Do not

connect blue

A142

lead

of

wiring

to ground. Refer

to

Group

8W

-

Wiring Diagrams

for

more information.

(8) Connect

an

engine tachometer

and

connect neg

ative cable

to

battery.

(9) Connect

a

variable carbon pile rheostat

be

tween battery terminals.

Be

sure carbon pile

is in

"Open"

or "Off

position before connecting leads.

See

Battery Section, Load Testing

for

instructions.

TEST

(1) Start engine. Immediately after starting,

re

duce engine speed

to

idle.

Page 337 of 1502

8A

- 16

ELECTRICAL

CHARGING

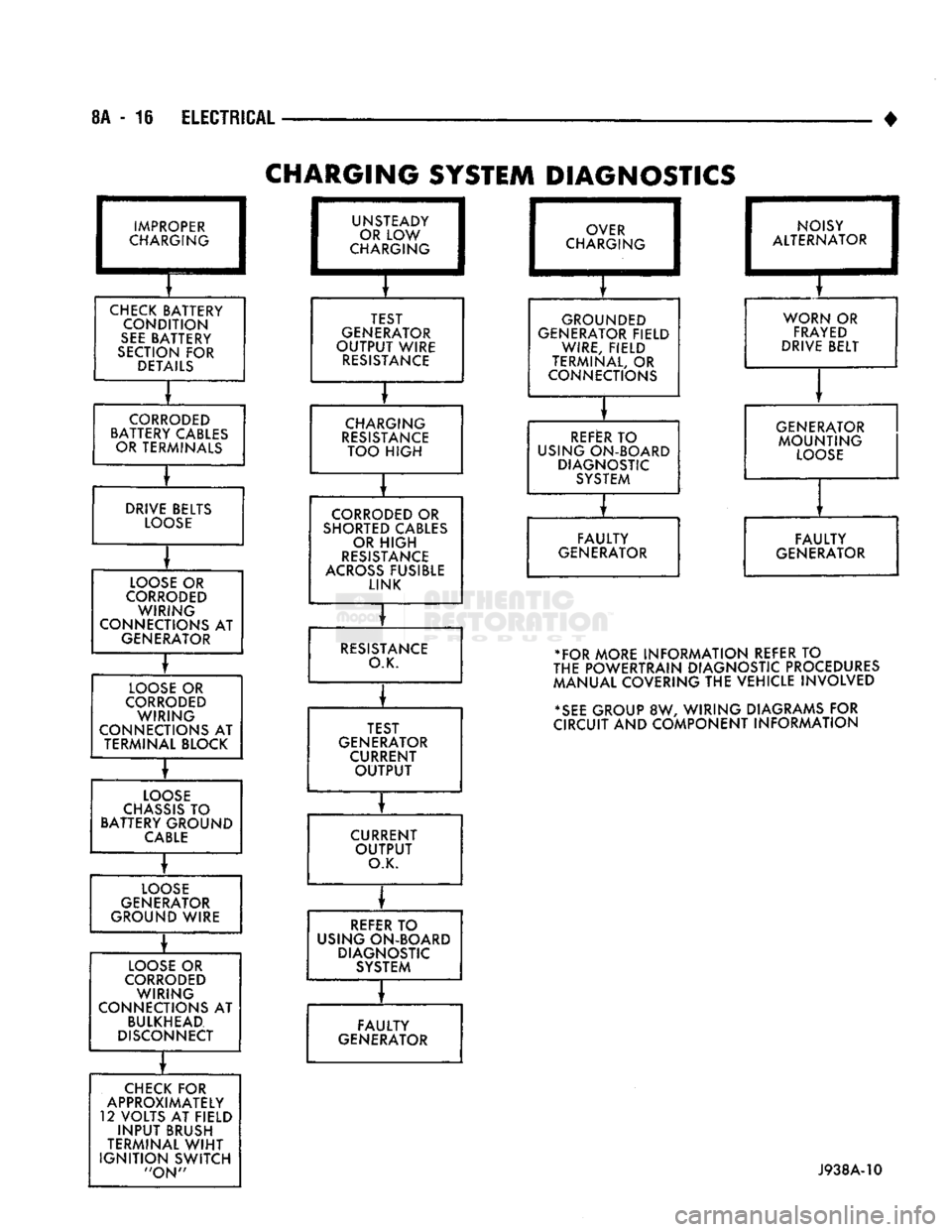

SYSTEM DIAGNOSTICS

IMPROPER

CHARGING

CHECK

BATTERY CONDITION

SEE

BATTERY

SECTION

FOR

DETAILS

CORRODED

BATTERY CABLES OR TERMINALS

DRIVE BELTS

LOOSE

LOOSE

OR

CORRODED

WIRING

CONNECTIONS

AT

GENERATOR

LOOSE

OR

CORRODED

WIRING

CONNECTIONS

AT

TERMINAL BLOCK

LOOSE

CHASSIS

TO

BATTERY GROUND

CABLE

LOOSE

GENERATOR

GROUND WIRE

LOOSE

OR

CORRODED

WIRING

CONNECTIONS

AT

BULKHEAD

DISCONNECT

CHECK

FOR

APPROXIMATELY

12 VOLTS

AT

FIELD

INPUT

BRUSH

TERMINAL

WIHT

IGNITION

SWITCH

"ON"

UNS'

OR

CHAF rEADY

LOW

K3ING

TEST

GENERATOR

OUTPUT

WIRE

RESISTANCE

CHARGING

RESISTANCE

TOO

HIGH

CORRODED

OR

SHORTED CABLES OR

HIGH

RESISTANCE

ACROSS

FUSIBLE LINK

RESISTANCE

O.K.

TEST

GENERATOR CURRENT

OUTPUT

CURRENT

OUTPUT

O.K.

REFER

TO

USING ON-BOARD DIAGNOSTIC SYSTEM

o

CHAR

/ER

.GING

GROUNDED

GENERATOR FIELD WIRE, FIELD

TERMINAL,

OR

CONNECTIONS

1 NO

1

ALTERf

ISY

MATOR

WORN

OR

FRAYED

DRIVE BELT

REFER

TO

USING ON-BOARD DIAGNOSTIC SYSTEM GENERATOR

MOUNTING

LOOSE

FAULTY

GENERATOR

FAULTY

GENERATOR •FOR MORE INFORMATION REFER

TO

THE POWERTRAIN DIAGNOSTIC PROCEDURES

MANUAL COVERING

THE

VEHICLE INVOLVED

*SEE

GROUP

8W,

WIRING DIAGRAMS

FOR

CIRCUIT

AND

COMPONENT INFORMATION

FAULTY

GENERATOR

J938A-V0

Page 347 of 1502

8B

- 6

BATTERY/STARTER/GENERATOR

SERVICE

•

GENERATOR SERVICE

CONTENTS

page

GENERATOR

REPLACEMENT-

DIESEL

ENGINE

8

GENERAL

INFORMATION

6

GENERAL

INFORMATION This section will cover generator removal

and in

stallation.

The

generator

is not

serviceable. Informa

tion covering on-vehicle testing

can be

found

in

Group

8A -

Battery/Starting/Charging/System Diag

nostics. The standard equipment generator

on the D and W

bodies

is the 75 amp

generator.

The

Ramcharger

is

equipped with

the 90 amp

generator. When

a

vehicle

is equipped with

a

heavy duty package

or

diesel

en

gine,

a 120 amp

generator

is

used.

GENERATOR

REPLACEMENT

-3.9L/5.2L/5.9L-LDC

GAS

ENGINE

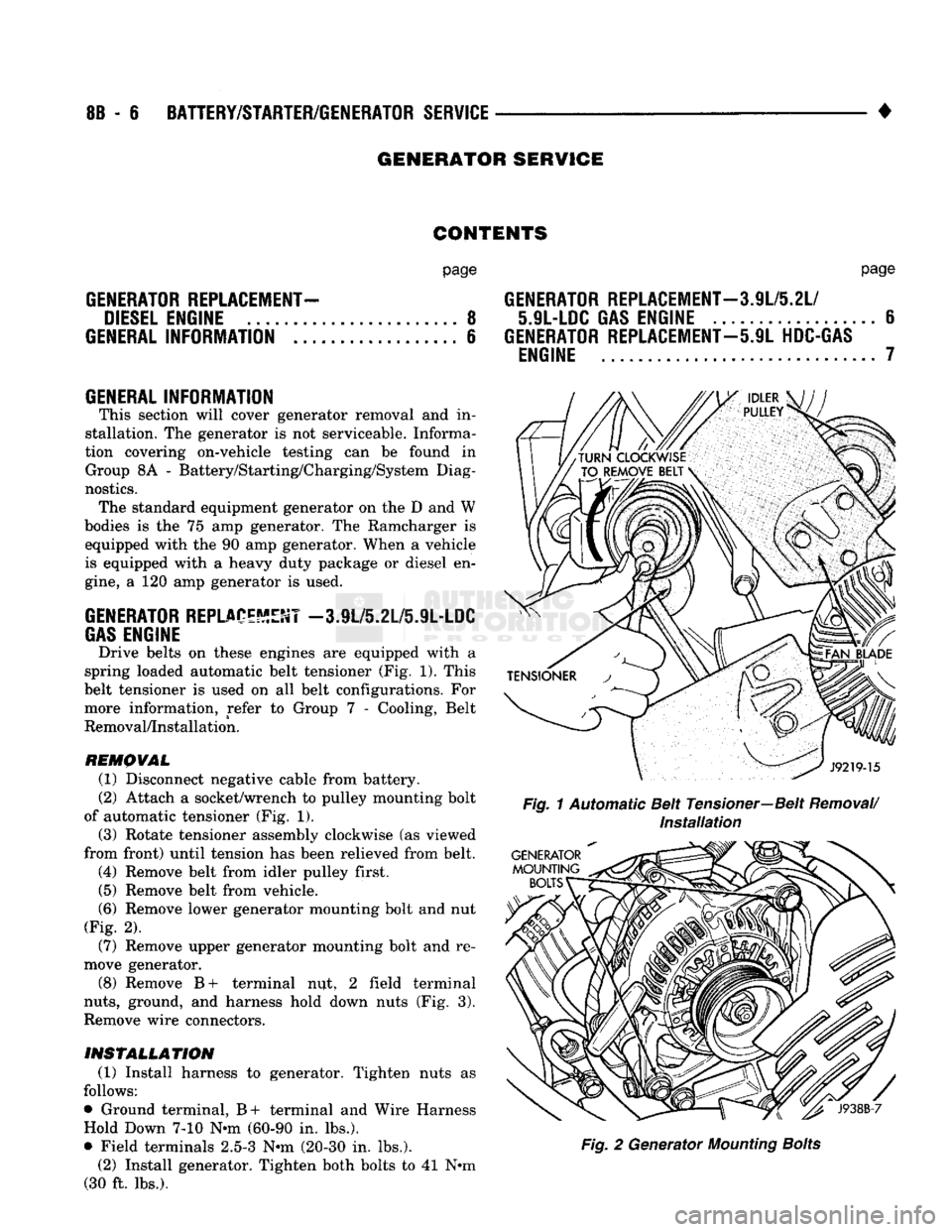

Drive belts

on

these engines

are

equipped with

a

spring loaded automatic belt tensioner

(Fig. 1).

This

belt tensioner

is

used

on all

belt configurations.

For

more information, refer

to

Group

7 -

Cooling, Belt

Removal/Installation.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Attach

a

socket/wrench

to

pulley mounting bolt

of automatic tensioner

(Fig. 1).

(3) Rotate tensioner assembly clockwise

(as

viewed

from front) until tension

has

been relieved from belt. (4) Remove belt from idler pulley first.

(5) Remove belt from vehicle.

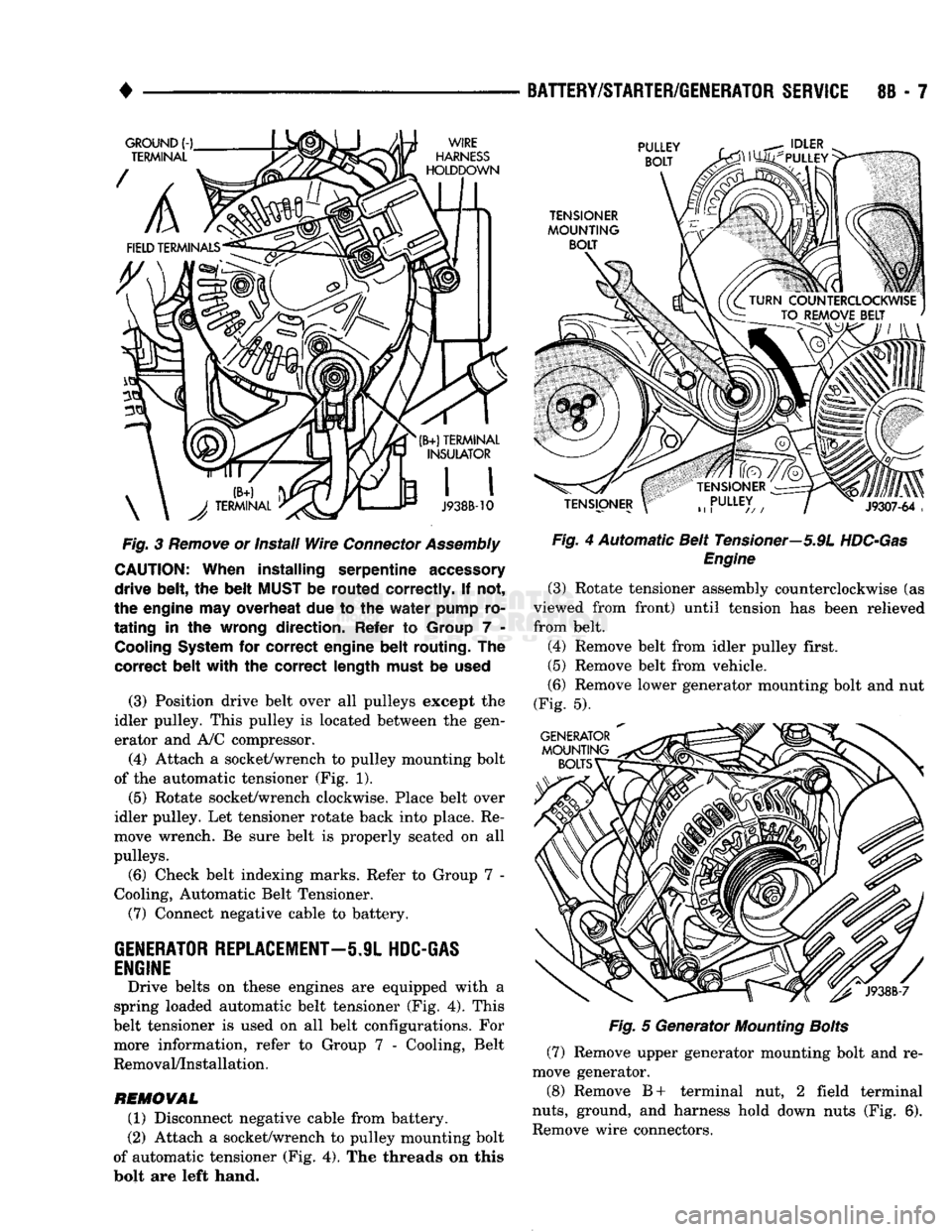

(6)

Remove lower generator mounting bolt

and nut

(Fig.

2).

(7) Remove upper generator mounting bolt

and re

move generator.

(8) Remove

B+

terminal

nut, 2

field terminal

nuts,

ground,

and

harness hold down nuts

(Fig. 3).

Remove wire connectors.

INSTALLATION

(1) Install harness

to

generator. Tighten nuts

as

follows:

• Ground terminal,

B+

terminal

and

Wire Harness Hold Down

7-10 N*m

(60-90

in.

lbs.).

• Field terminals

2.5-3 N-m

(20-30

in.

lbs.). (2) Install generator. Tighten both bolts

to 41 N»m

(30

ft.

lbs.).

page

GENERATOR

REPLACEMENT—3.9L/5.2L/

5.9L-LDC

GAS

ENGINE

6

GENERATOR

REPLACEMENT—5.9L

HDC-GAS

ENGINE

7

Fig.

1 Automatic Belt Tensioner—Belt

Removal/

Installation

Fig.

2

Generator

Mounting

Bolts

Page 348 of 1502

•

Fig.

3

Remove

or install

Wire

Connector

Assembly

CAUTION:

When

installing

serpentine

accessory

drive

belt,

the

belt

MUST

be

routed

correctly.

If not,

the engine may overheat due to the

water

pump ro

tating

in the wrong

direction.

Refer to Group 7 -

Cooling

System

for

correct

engine

belt

routing.

The

correct

belt

with

the

correct

length

must be

used

(3) Position drive belt over all pulleys except the

idler pulley. This pulley is located between the gen

erator and A/C compressor.

(4) Attach a socket/wrench to pulley mounting bolt

of the automatic tensioner (Fig. 1).

(5)

Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place. Re

move wrench. Be sure belt is properly seated on all

pulleys.

(6) Check belt indexing marks. Refer to Group 7 -

Cooling, Automatic Belt Tensioner.

(7) Connect negative cable to battery.

GENERATOR

REPLACEMENT—5.9L

HDC-GAS

ENGINE

Drive belts on these engines are equipped with a

spring loaded automatic belt tensioner (Fig. 4). This

belt tensioner is used on all belt configurations. For more information, refer to Group 7 - Cooling, Belt

Removal/Installation.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 4). The threads on this

bolt are left hand.

BATTERY/STARTER/GENERATOR

SERVICE

8B - 7

Fig.

4 Automatic Belt Tensioner—5.9L

HDC-Gas

Engine

(3) Rotate tensioner assembly counterclockwise (as

viewed from front) until tension has been relieved

from belt.

(4) Remove belt from idler pulley first.

(5) Remove belt from vehicle.

(6) Remove lower generator mounting bolt and nut

(Fig. 5).

Fig.

5 Generator

Mounting

Bolts

(7) Remove upper generator mounting bolt and re

move generator.

(8) Remove B+ terminal nut, 2 field terminal

nuts,

ground, and harness hold down nuts (Fig. 6).

Remove wire connectors.