check engine DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 207 of 1502

5

- 20

BRAKES

•

POWER BRAKE BOOSTER—BRAKE PEDAL

INDEX

page

Brake Pedal

Installation

21

Brake Pedal Removal

21

General

Information

.......................

20

page

Power Brake Booster

Installation

.............

21

Power Brake Booster Removal

21

GENERAL

INFORMATION

Power brakes

are

standard

on all AD

models.

A

single

or

dual diaphragm, vacuum power brake

booster

is

used. AD

and W150

models

are

equipped with

a

single

diaphragm booster unit

(Fig. 1). D and

W250/350

models

are

equipped with

a

dual diaphragm booster. The booster unit consists

of a

single housing

di

vided into separate chambers

by one or two

internal

diaphragms.

The

outer edge

of the

diaphragm

is se

cured

to the

housing. The booster push

rod,

which connects

the

booster

to

the brake pedal

and

master cylinder,

is

attached

to

the center

of the

diaphragm.

A

check valve

is

used

in

the booster outlet connected

to the

engine intake manifold. Power assist

is

produced

by a

combination

of

vac

uum

and

atmospheric pressure

to

boost brake assist. The power brake booster

is not a

repairable

component.

The

booster must

be

replaced

as an

assembly

if

diagnosis indicates

a

malfunction

has occurred.

AD models with

the

Cummins diesel engine

are

equipped with

a

dual diaphragm power brake

booster.

A

separate vacuum pump assembly supplies the vacuum needed

for

booster operation

(Fig. 2).

The diesel vacuum pump

and the

power steering

pump

are

combined into

a

single assembly. Both

pumps

are

operated

by a

drive gear pressed onto

the

vacuum pump shaft.

The

drive gear

is

operated

by

the camshaft gear. A suspended-type brake pedal

is

used

for all

appli

cations.

The

pedal

is

attached

to the

pedal support

bracket with

a

pivot shaft.

The

pedal, bolt

and

bush ings

are all

serviceable components.

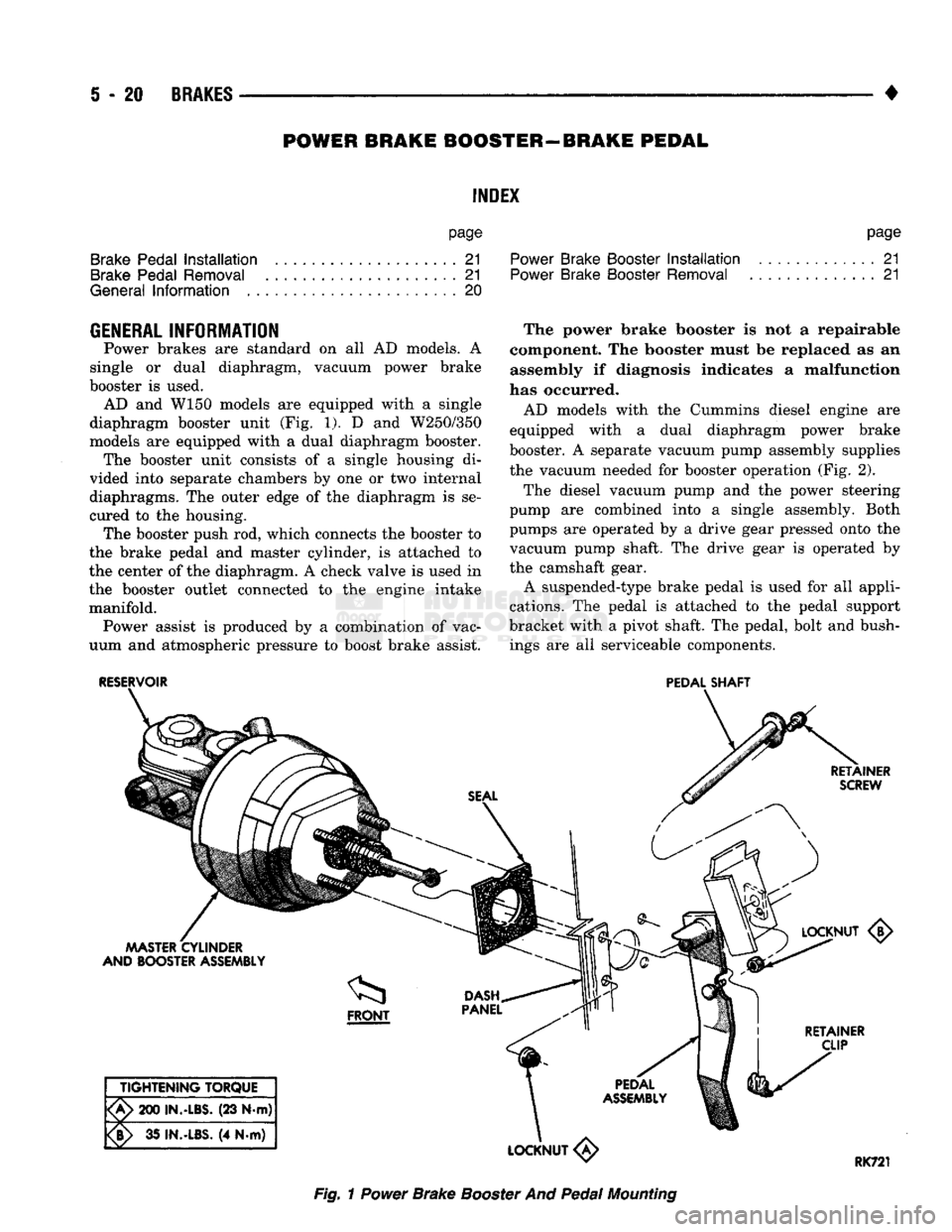

RESERVOIR

PEDAL

SHAFT

RETAINER

SCREW

MASTER

CYLINDER

AND BOOSTER

ASSEMBLY <5>

I

RETAINER

CLIP

TIGHTENING

TORQUE

'A>

200

IN.-LBS.

(23 N-m)

¥>

35

IN.-LBS.

(4 N.m)

LOCKNUT

«

RK721

Fig.

1

Power

Brake

Booster

And

Pedal

Mounting

Page 208 of 1502

•

BRAKES

5 - 21

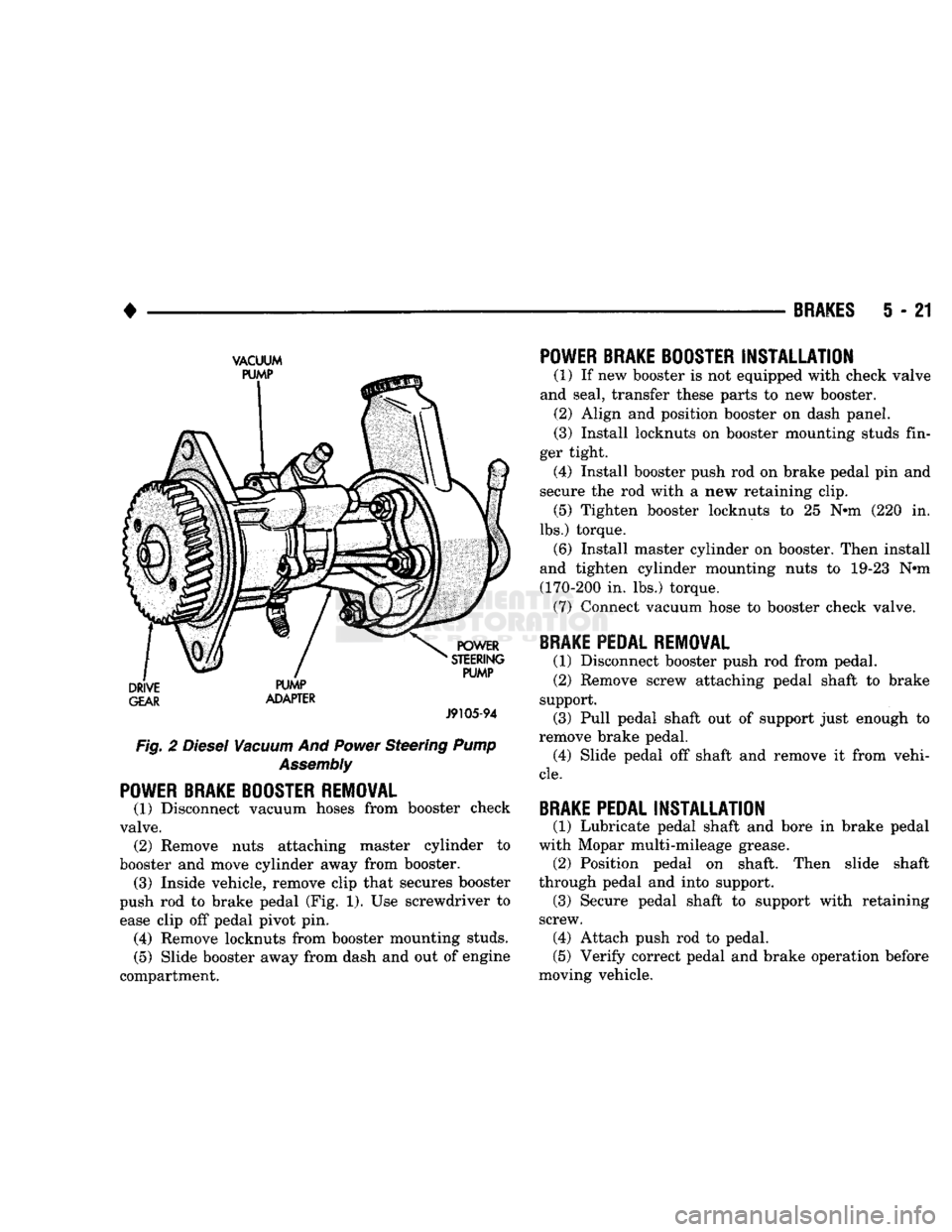

VACUUM

GEAR

ADAPTER

J9105-94

Fig. 2

Diesel

Vacuum

And

Power

Steering

Pump

Assembly

POWER BRAKE BOOSTER REMOVAL

(1) Disconnect vacuum hoses from booster check

valve. (2) Remove nuts attaching master cylinder to

booster and move cylinder away from booster. (3) Inside vehicle, remove clip that secures booster

push rod to brake pedal (Fig. 1). Use screwdriver to ease clip off pedal pivot pin. (4) Remove locknuts from booster mounting studs.

(5) Slide booster away from dash and out of engine

compartment.

POWER BRAKE BOOSTER

INSTALLATION

(1) If new booster is not equipped with check valve

and seal, transfer these parts to new booster. (2) Align and position booster on dash panel.

(3) Install locknuts on booster mounting studs fin

ger tight. (4) Install booster push rod on brake pedal pin and

secure the rod with a new retaining clip. (5) Tighten booster locknuts to 25 Nth (220 in.

lbs.) torque. (6) Install master cylinder on booster. Then install

and tighten cylinder mounting nuts to 19-23 Nnn

(170-200 in. lbs.) torque. (7) Connect vacuum hose to booster check valve.

BRAKE PEDAL REMOVAL

(1) Disconnect booster push rod from pedal. (2) Remove screw attaching pedal shaft to brake

support. (3) Pull pedal shaft out of support just enough to

remove brake pedal. (4) Slide pedal off shaft and remove it from vehi

cle.

BRAKE PEDAL

INSTALLATION

(1) Lubricate pedal shaft and bore in brake pedal

with Mopar multi-mileage grease. (2) Position pedal on shaft. Then slide shaft

through pedal and into support. (3) Secure pedal shaft to support with retaining

screw. (4) Attach push rod to pedal.

(5) Verify correct pedal and brake operation before

moving vehicle.

Page 210 of 1502

•

BRAKES

5 - 23

VACUUM PUMP OPERATION

Vacuum pump output is transmitted to the power

brake booster through a supply hose. The hose is con nected to an outlet port on the pump housing and to

the check valve in the power brake booster.

Pump output ranges from a minimum of 8.5 to 25

inches vacuum. The pump rotor and vanes are rotated by the pump

drive gear. The drive gear is operated by the cam

shaft gear. Booster vacuum level is monitored by a warning

switch (Fig. 2). The switch consists of a vacuum

chamber that measures vacuum level and a sensor in

circuit with the brake warning light. The vacuum chamber is connected to the booster

check valve by a vacuum supply hose. A wire har

ness connects the switch sensor to the brake warning

light. If booster vacuum falls below 8.5 inches for 8-10 seconds or more, the switch sensor completes

the circuit to the warning light causing it to illumi

nate.

VACUUM PUMP DIAGNOSIS

Vacuum pump diagnosis involves checking pump

output with a vacuum gauge. The low vacuum warn

ing switch can also be checked with a vacuum gauge.

Refer to the diagnosis procedure in this section. A standard vacuum gauge can be used to check

pump output when necessary. Simply disconnect the

pump supply hose and connect a vacuum gauge to

the outlet port for testing purposes. Vacuum should

hold steady in a range of approximately 8.5 to 25 inches at various engine speeds.

DIAGNOSING LOW VACUUM OUTPUT CONDITION A low booster vacuum condition or a faulty low

vacuum warning switch will cause the brake warn ing light to illuminate. If the light does go on and in

dicates the existence of a low vacuum condition,

check the vacuum pump, booster and warning switch

as follows:

(1) Check vacuum pump oil feed line. Verify that

line connections are secure and not leaking. If leak age is noted and pump is noisy, replace pump.

(2) Disconnect supply hose to booster. Connect vac

uum gauge to this hose and run engine at various

throttle openings. Output should range from 8.5 to 25 inches vacuum. If vacuum is consistently below

8.5 inches, problem is with vacuum hoses or pump

component. If output is within specified limits, con

tinue testing.

(3) Check booster operation as described in diagno

sis section. Replace check valve, vacuum hoses, or

booster if necessary. However, if booster operation is correct but warning light is still on, continue testing. (4) Disconnect vacuum hose at warning switch.

Plug hose and connect hand vacuum pump to switch. (5) Start and run engine.

(6) Apply 8.5 to 9 inches of vacuum to warning

switch and observe warning light. If light goes out,

switch vacuum hose is either loose or leaking. If

light remains on, leave engine running and continue

testing.

(7) Apply 20-25 inches vacuum to switch and ob

serve warning light operation. If light now goes out,

switch is at fault and should be replaced. If light re

mains on, continue testing.

(8) Reconnect vacuum hoses and replace original

warning switch with known good switch. Run engine and observe warning light operation. If light is now

off, old switch is faulty. If light remains on, problem

is in wiring between switch and warning light.

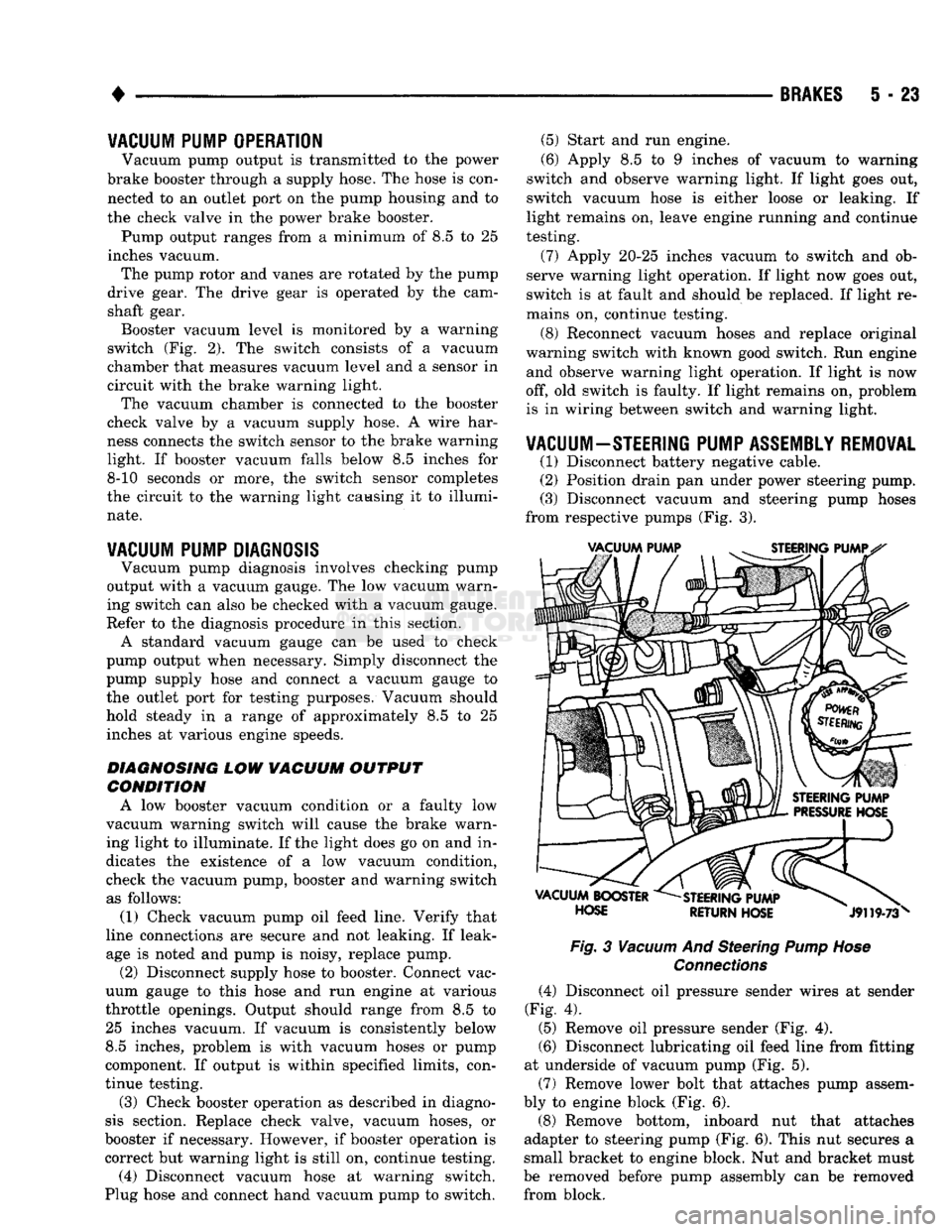

VACUUM-STEERING PUMP

ASSEMBLY

REMOVAL

(1) Disconnect battery negative cable.

(2) Position drain pan under power steering pump.

(3) Disconnect vacuum and steering pump hoses

from respective pumps (Fig. 3).

Fig.

3

Vacuum

And Steering

Pump Hose

Connections

(4) Disconnect oil pressure sender wires at sender

(Fig. 4).

(5) Remove oil pressure sender (Fig. 4).

(6) Disconnect lubricating oil feed line from fitting

at underside of vacuum pump (Fig. 5).

(7) Remove lower bolt that attaches pump assem

bly to engine block (Fig. 6).

(8) Remove bottom, inboard nut that attaches

adapter to steering pump (Fig. 6). This nut secures a

small bracket to engine block. Nut and bracket must

be removed before pump assembly can be removed from block.

Page 213 of 1502

5

- 26

BRAKES

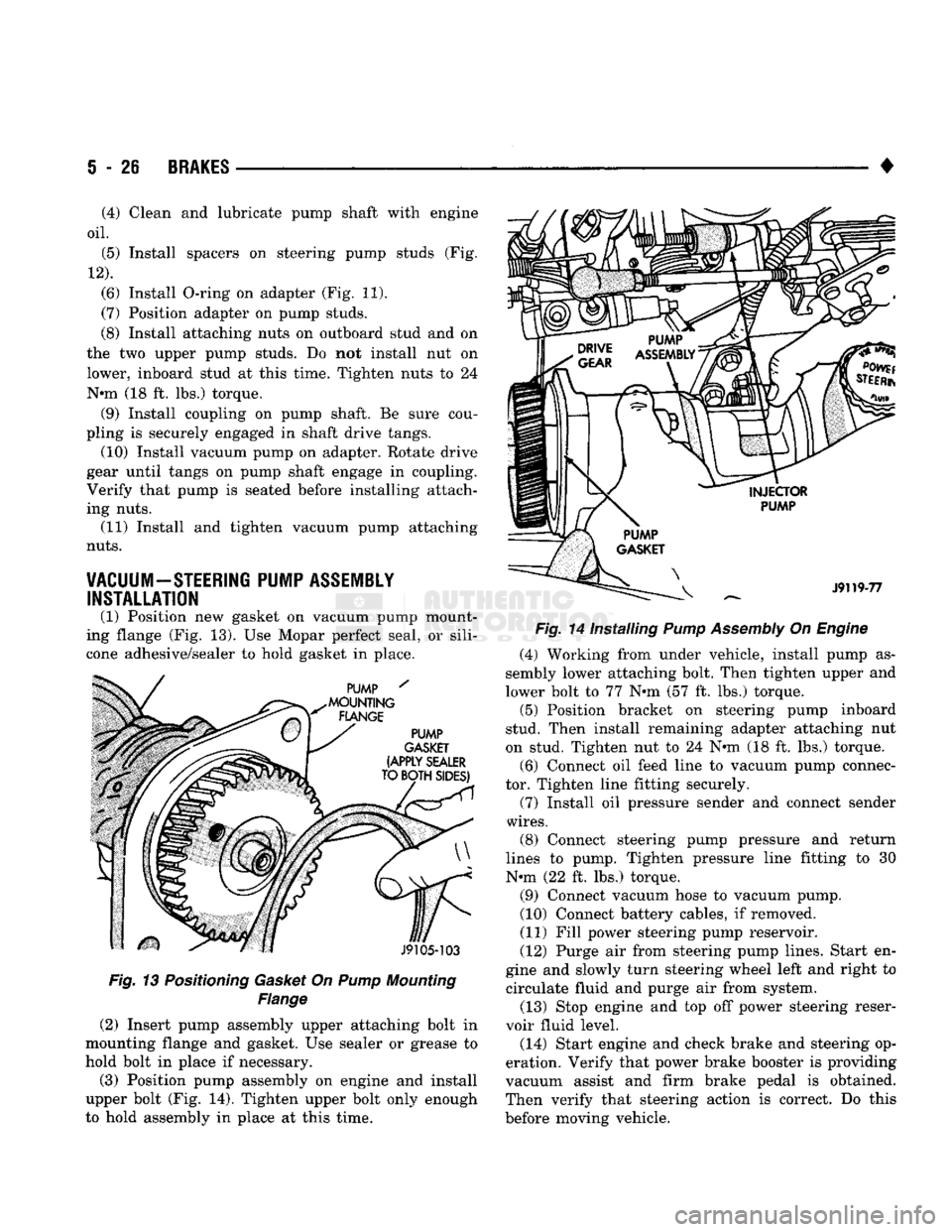

Fig. 13 Positioning Gasket On Pump Mounting

Flange

(2) Insert pump assembly upper attaching bolt in

mounting flange and gasket. Use sealer or grease to

hold bolt in place if necessary.

(3) Position pump assembly on engine and install

upper bolt (Fig. 14). Tighten upper bolt only enough

to hold assembly in place at this time. •

Fig. 14 Installing Pump Assembly On Engine (4) Working from under vehicle, install pump as

sembly lower attaching bolt. Then tighten upper and

lower bolt to 77 N»m (57 ft. lbs.) torque. (5) Position bracket on steering pump inboard

stud. Then install remaining adapter attaching nut

on stud. Tighten nut to 24 N«m (18 ft. lbs.) torque.

(6) Connect oil feed line to vacuum pump connec

tor. Tighten line fitting securely.

(7) Install oil pressure sender and connect sender

wires.

(8) Connect steering pump pressure and return

lines to pump. Tighten pressure line fitting to 30

N-m (22 ft. lbs.) torque.

(9) Connect vacuum hose to vacuum pump.

(10) Connect battery cables, if removed.

(11) Fill power steering pump reservoir.

(12) Purge air from steering pump lines. Start en

gine and slowly turn steering wheel left and right to circulate fluid and purge air from system.

(13) Stop engine and top off power steering reser

voir fluid level.

(14) Start engine and check brake and steering op

eration. Verify that power brake booster is providing

vacuum assist and firm brake pedal is obtained.

Then verify that steering action is correct. Do this

before moving vehicle.

(4) Clean and lubricate pump shaft with engine

oil.

(5) Install spacers on steering pump studs (Fig.

12).

(6) Install O-ring on adapter (Fig. 11).

(7) Position adapter on pump studs.

(8) Install attaching nuts on outboard stud and on

the two upper pump studs. Do not install nut on

lower, inboard stud at this time. Tighten nuts to 24

N-m (18 ft. lbs.) torque. (9) Install coupling on pump shaft. Be sure cou

pling is securely engaged in shaft drive tangs. (10) Install vacuum pump on adapter. Rotate drive

gear until tangs on pump shaft engage in coupling.

Verify that pump is seated before installing attach

ing nuts. (11) Install and tighten vacuum pump attaching

nuts.

VACUUM-STEERING PUMP ASSEMBLY INSTALLATION

(1) Position new gasket on vacuum pump mount

ing flange (Fig. 13). Use Mopar perfect seal, or sili

cone adhesive/sealer to hold gasket in place.

Page 256 of 1502

•

CLUTCH

6 - 3 Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab and incomplete release or engagement.

Be careful when handling the cover and disc. Im

pact can distort the cover, diaphragm spring, release

fingers and the hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten

ing. To avoid warping the cover, tighten the bolts al

ternately (in a diagonal pattern) and evenly (2-3

threads at a time) to specified torque.

Clutch

Housing

Misalignment And Runout Clutch housing alignment is important to proper

operation. The housing bore maintains alignment be

tween the crankshaft and transmission input shaft.

Misalignment can cause noise, incomplete clutch

release and chatter. It can also result in premature

wear of the pilot bearing, cover release fingers and

clutch disc. In severe cases, misalignment can also cause premature wear of the transmission input

shaft and bearing.

Housing face misalignment is generally caused by

incorrect seating on the engine or transmission, loose

housing bolts, missing alignment dowels or housing damage. Infrequently, misalignment may also be

caused by housing mounting surfaces that are not

parallel. If housing misalignment is suspected, housing bore

and face runout can be checked with a dial indicator

as described in the following two procedures:

MEASURING

CLUTCH HOUSING BORE

RUNOUT

(1) Remove the clutch housing and strut.

(2) Remove the clutch cover and disc.

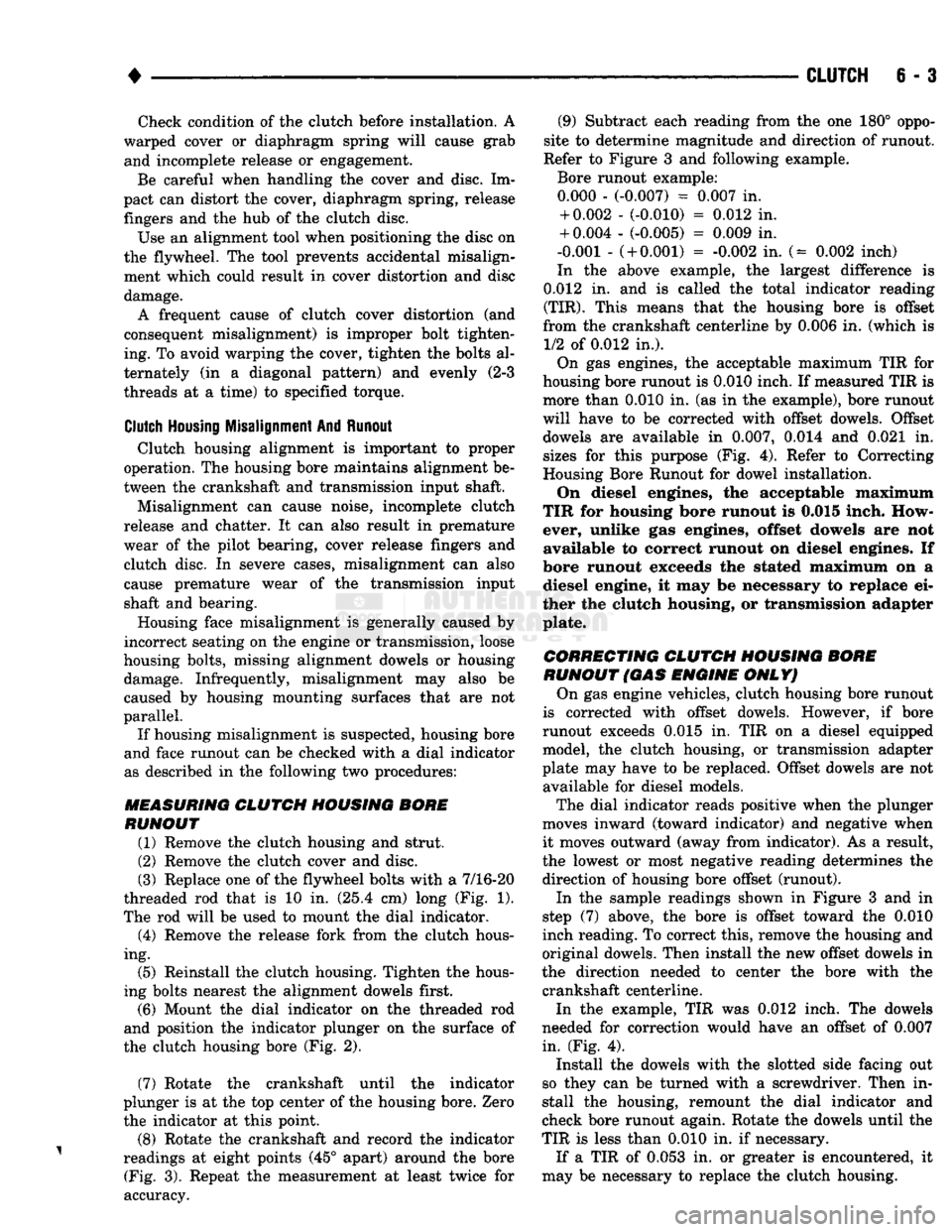

(3) Replace one of the flywheel bolts with a 7/16-20

threaded rod that is 10 in. (25.4 cm) long (Fig. 1).

The rod will be used to mount the dial indicator.

(4) Remove the release fork from the clutch hous

ing. (5) Reinstall the clutch housing. Tighten the hous

ing bolts nearest the alignment dowels first. (6) Mount the dial indicator on the threaded rod

and position the indicator plunger on the surface of

the clutch housing bore (Fig. 2).

(7) Rotate the crankshaft until the indicator

plunger is at the top center of the housing bore. Zero the indicator at this point.

(8) Rotate the crankshaft and record the indicator

readings at eight points (45° apart) around the bore (Fig. 3). Repeat the measurement at least twice for

accuracy. (9) Subtract each reading from the one 180° oppo

site to determine magnitude and direction of runout.

Refer to Figure 3 and following example.

Bore runout example: 0.000 - (-0.007) = 0.007 in. + 0.002 - (-0.010) = 0.012 in.

+ 0.004 - (-0.005) = 0.009 in.

-0.001 -

(

+ 0.001) = -0.002 in. (= 0.002 inch)

In the above example, the largest difference is

0.012 in. and is called the total indicator reading

(TIR).

This means that the housing bore is offset

from the crankshaft centerline by 0.006 in. (which is 1/2 of 0.012 in.).

On gas engines, the acceptable maximum TIR for

housing bore runout is 0.010 inch. If measured TIR is more than 0.010 in. (as in the example), bore runout

will have to be corrected with offset dowels. Offset dowels are available in 0.007, 0.014 and 0.021 in.

sizes for this purpose (Fig. 4). Refer to Correcting

Housing Bore Runout for dowel installation.

On diesel engines, the acceptable maximum

TIR for housing bore runout is 0.015 inch. How

ever, unlike gas engines, offset dowels are not available to correct runout on diesel engines. If

bore runout exceeds the stated maximum on a diesel engine, it may be necessary to replace ei

ther the clutch housing, or transmission adapter

plate.

CORRECTING CLUTCH HOUSING BORE

RUNOUT

(GAS

ENGINE

ONLY)

On gas engine vehicles, clutch housing bore runout

is corrected with offset dowels. However, if bore

runout exceeds 0.015 in. TIR on a diesel equipped model, the clutch housing, or transmission adapter

plate may have to be replaced. Offset dowels are not available for diesel models.

The dial indicator reads positive when the plunger

moves inward (toward indicator) and negative when it moves outward (away from indicator). As a result,

the lowest or most negative reading determines the

direction of housing bore offset (runout).

In the sample readings shown in Figure 3 and in

step (7) above, the bore is offset toward the 0.010

inch reading. To correct this, remove the housing and

original dowels. Then install the new offset dowels in

the direction needed to center the bore with the crankshaft centerline.

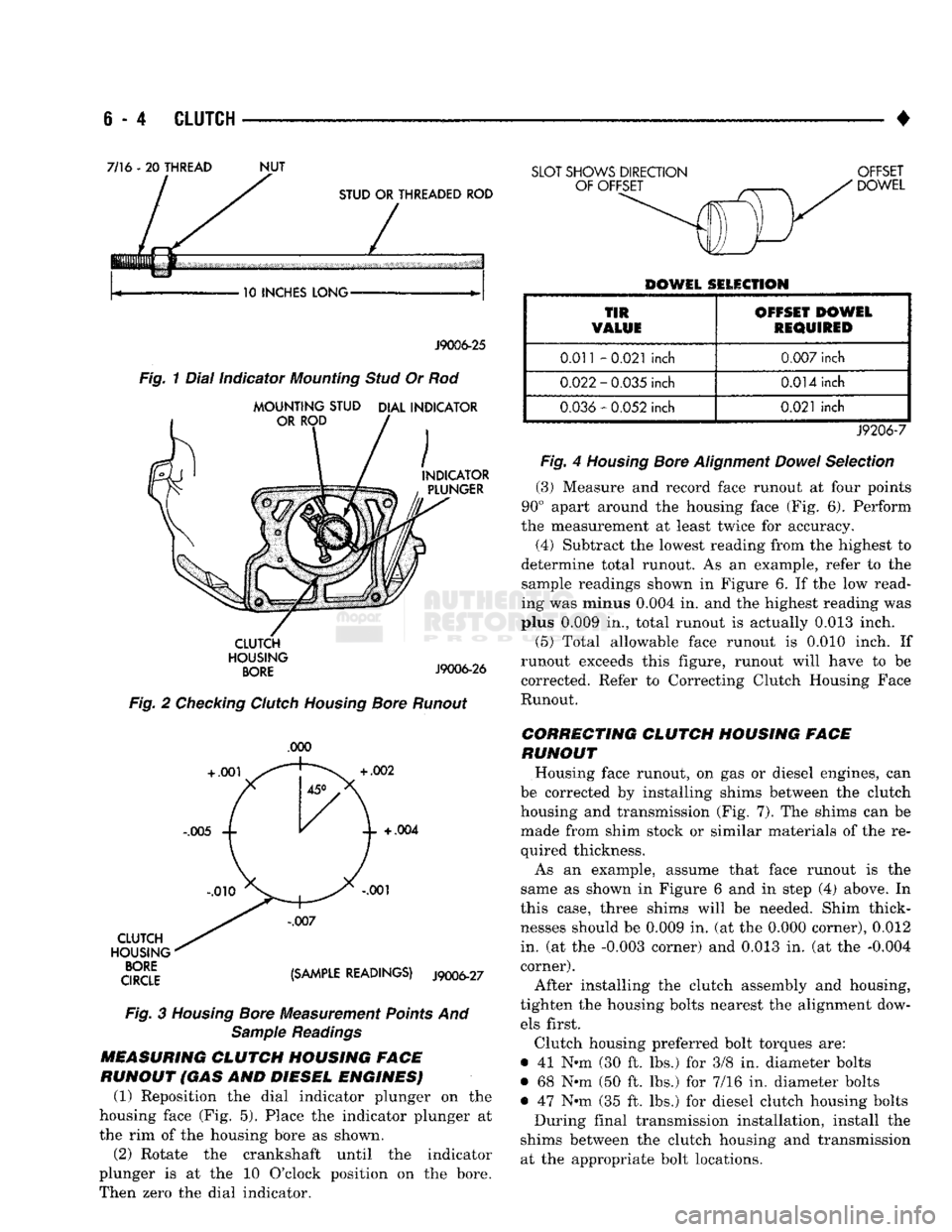

In the example, TIR was 0.012 inch. The dowels

needed for correction would have an offset of 0.007

in. (Fig. 4).

Install the dowels with the slotted side facing out

so they can be turned with a screwdriver. Then in

stall the housing, remount the dial indicator and

check bore runout again. Rotate the dowels until the

TIR is less than 0.010 in. if necessary.

If a TIR of 0.053 in. or greater is encountered, it

may be necessary to replace the clutch housing.

Page 257 of 1502

e - 4

CLUTCH

•

7/16 - 20

THREAD

NUT

10 INCHES LONG J9006-25

CLUTCH

HOUSING

BORE

J9006-26

Fig.

2 Checking Clutch Housing Bore Runout

.000

CLUTCH

HOUSING

qroe {Smm READINGS) J9006-27

Fig.

3

Housing

Bore Measurement Points And Sample Readings

MEASURING

CLUTCH

HOUSING FACE

RUNOUT (GAS AND DIESEL ENGINES) (1) Reposition the dial indicator plunger on the

housing face (Fig. 5). Place the indicator plunger at

the rim of the housing bore as shown.

(2) Rotate the crankshaft until the indicator

plunger is at the 10 O'clock position on the bore.

Then zero the dial indicator.

SLOT SHOWS DIRECTION OFFSET

DOWEL

DOWEL SELECTION

TIR

VALUE OFFSET DOWEL

REQUIRED

0.011

-0.021

inch

0.007

inch

0.022

-

0.035

inch

0.014

inch

0.036

-

0.052

inch

0.021

inch

J9206-7

Fig.

4

Housing

Bore

Alignment

Dowel

Selection

(3)

Measure and record face runout at four points

90° apart around the housing face (Fig. 6). Perform

the measurement at least twice for accuracy.

(4)

Subtract the lowest reading from the highest to

determine total runout. As an example, refer to the

sample readings shown in Figure 6. If the low read

ing was minus

0.004

in. and the highest reading was

plus

0.009

in., total runout is actually

0.013

inch.

(5)

Total allowable face runout is 0.010 inch. If

runout exceeds this figure, runout will have to be

corrected. Refer to Correcting Clutch Housing Face

Runout.

CORRECTING CLUTCH HOUSING FACE

RUNOUT

Housing face runout, on gas or diesel engines, can

be corrected by installing shims between the clutch

housing and transmission (Fig. 7). The shims can be made from shim stock or similar materials of the re

quired thickness.

As an example, assume that face runout is the

same as shown in Figure 6 and in step (4) above. In

this case, three shims will be needed. Shim thick

nesses should be

0.009

in. (at the

0.000

corner),

0.012

in. (at the

-0.003

corner) and

0.013

in. (at the

-0.004

corner).

After installing the clutch assembly and housing,

tighten the housing bolts nearest the alignment dow els first.

Clutch housing preferred bolt torques are:

• 41 N-m (30 ft. lbs.) for 3/8 in. diameter bolts

• 68 Nnn (50 ft. lbs.) for 7/16 in. diameter bolts

• 47 Nth (35 ft. lbs.) for diesel clutch housing bolts During final transmission installation, install the

shims between the clutch housing and transmission at the appropriate bolt locations.

Page 259 of 1502

6 - 6

CLUTCH

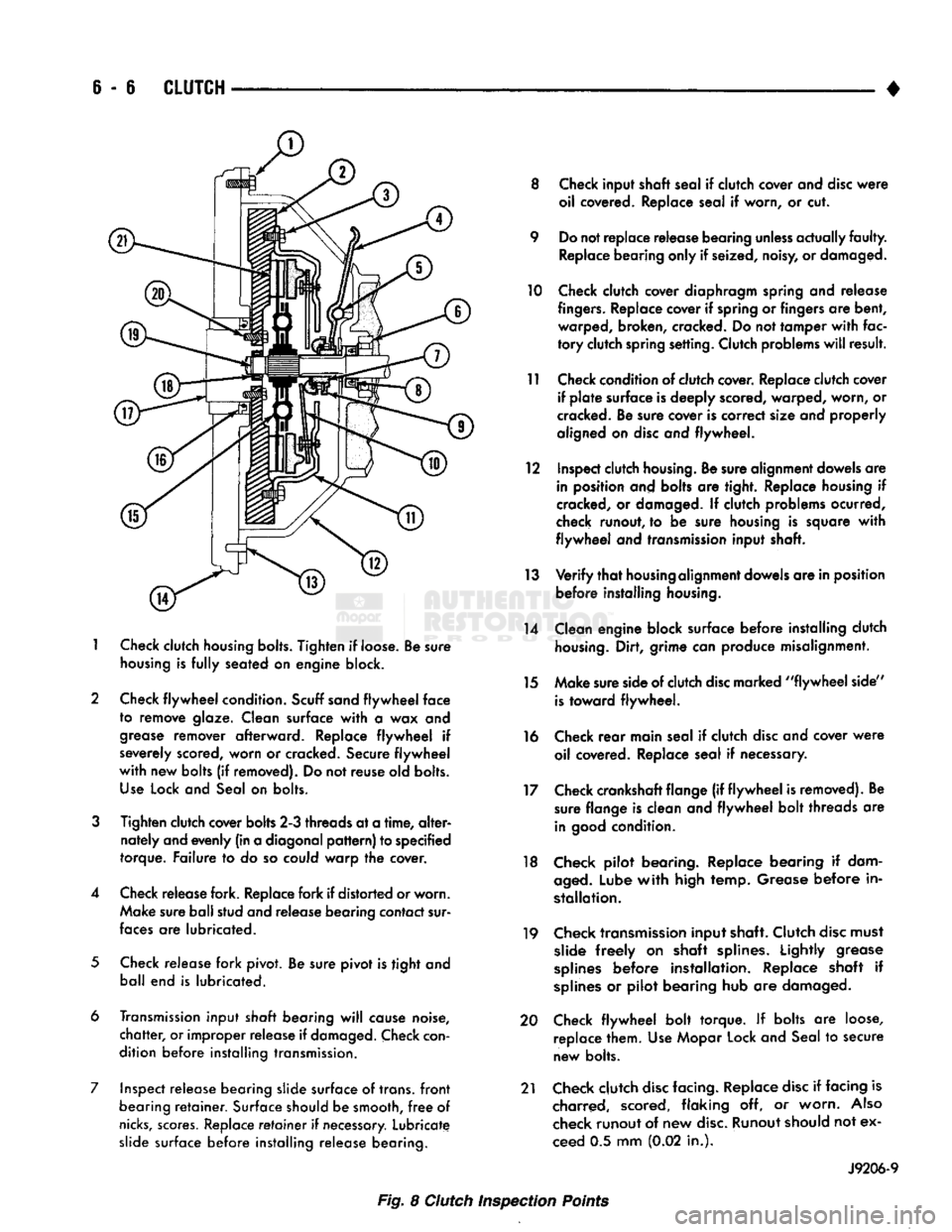

1

Check

clutch

housing bolts.

Tighten

if loose. Be sure

housing

is

fully

seated on engine block.

2 Check

flywheel

condition.

Scuff sand

flywheel

face

to remove glaze. Clean surface

with

a wax and

grease

remover afterward. Replace

flywheel

if

severely scored, worn or cracked. Secure

flywheel

with

new bolts (if removed). Do not reuse old bolts.

Use

Lock and Seal on bolts.

3

Tighten clutch cover bolts 2-3 threads at a

time,

alter

nately and evenly (in a diagonal

pattern)

to specified

torque. Failure to do so could warp the cover.

4 Check release fork. Replace fork if distorted or worn. Make sure ball stud and release bearing contact sur

faces

are lubricated.

5

Check release fork pivot. Be sure pivot is tight and ball end is lubricated.

6 Transmission input

shaft

bearing

will

cause noise,

chatter,

or improper release if

damaged.

Check

con

dition before installing transmission.

7 Inspect release bearing slide surface of trans,

front

bearing

retainer.

Surface should be smooth,

free

of

nicks,

scores.

Replace

retainer

if

necessary.

Lubricate slide surface before installing release bearing. 8 Check input shaft seal if clutch cover and

disc

were

oil covered. Replace seal if worn, or cut.

9 Do not replace release bearing

unless

actually

faulty.

Replace bearing only if seized, noisy, or damaged.

10 Check clutch cover diaphragm spring and release

fingers.

Replace cover if spring or fingers are bent, warped, broken, cracked. Do not tamper

with

fac

tory

clutch spring setting. Clutch problems

will

result.

11 Check condition of clutch cover. Replace clutch cover if

plate

surface is deeply scored, warped, worn, or

cracked. Be sure cover is correct size and properly

aligned on

disc

and flywheel.

12 Inspect clutch

housing.

Be sure alignment dowels are in position and bolts are tight. Replace housing if

cracked, or damaged. If clutch problems ocurred,

check runout, to be sure housing is square

with

flywheel

and transmission input shaft.

13

Verify

that

housing

alignment dowels are in position before installing

housing.

14 Clean engine block surface before installing clutch

housing.

Dirt, grime can produce misalignment.

15 Make sure side of clutch

disc

marked

"flywheel

side"

is

toward flywheel.

16 Check

rear

main seal if clutch

disc

and cover

were

oil covered. Replace seal if necessary.

17 Check crankshaft flange (if

flywheel

is removed). Be sure flange is clean and

flywheel

bolt threads are

in

good

condition.

18 Check pilot bearing. Replace bearing if dam

aged.

Lube

with

high temp. Grease before in

stallation.

19 Check transmission input shaft. Clutch

disc

must slide

freely

on shaft splines. Lightly grease

splines

before installation. Replace shaft if

splines

or pilot bearing hub are damaged.

20 Check

flywheel

bolt torque. If bolts are loose, replace them. Use Mopar Lock and Seal to secure

new bolts.

21 Check clutch

disc

facing. Replace

disc

if facing is charred, scored, flaking off, or worn.

Also

check runout of new

disc.

Runout should not ex

ceed 0.5 mm (0.02 in.).

J9206-9

Fig. 8 Clutch Inspection Points

Page 262 of 1502

•

CLUTCH

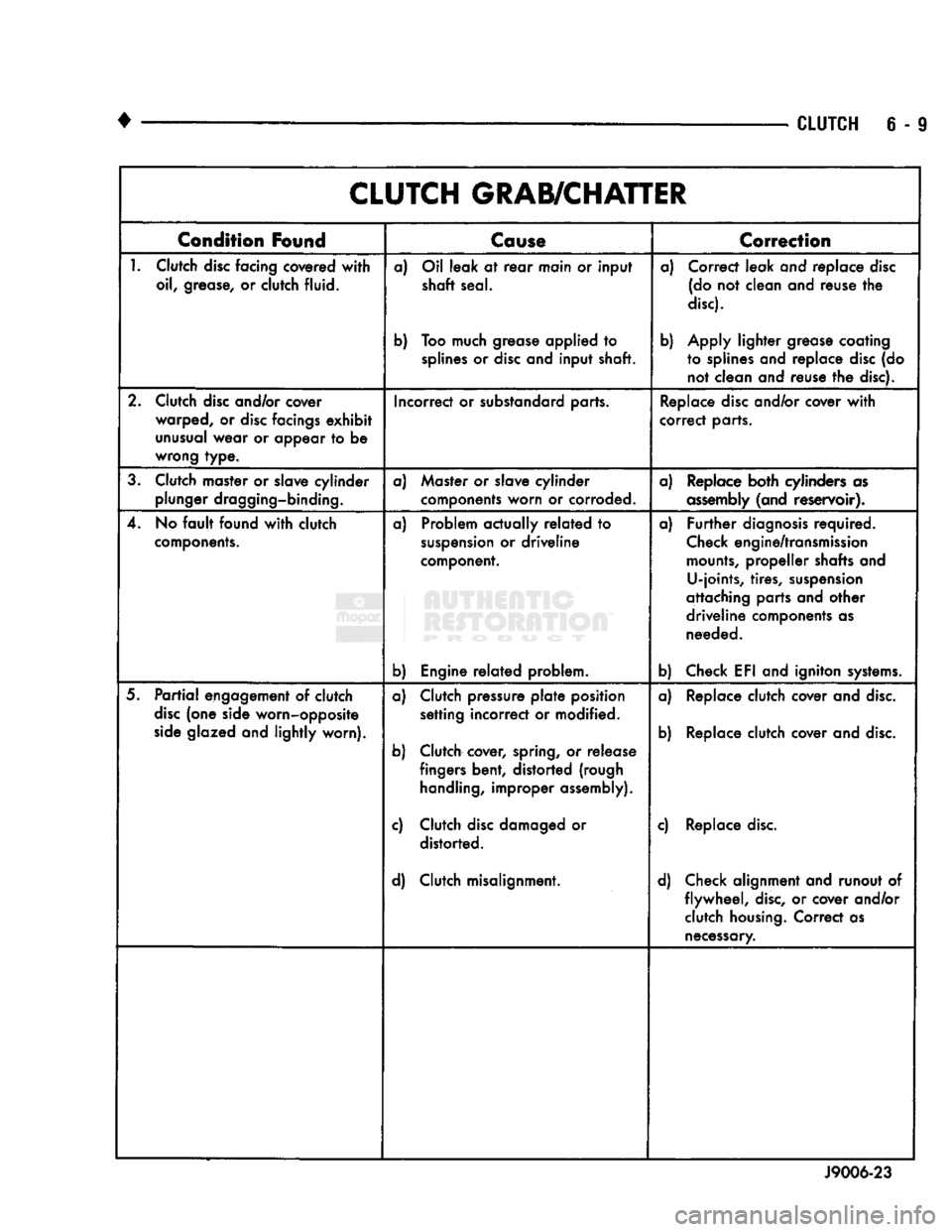

6 - 9 CLUTCH GRAB/CHATTER

Condition

Found

Cause

T

Correction

1.

Clutch

disc

facing covered

with

oil, grease, or clutch fluid. a) Oil leak at

rear

main or input

shaft seal.

b) Too much grease applied to

splines

or

disc

and input shaft. a) Correct leak and replace

disc

(do not clean and reuse the

disc).

b) Apply lighter grease coating to splines and replace

disc

(do not clean and reuse the disc).

2. Clutch

disc

and/or cover warped, or

disc

facings

exhibit

unusual

wear or appear to be

wrong type. Incorrect or substandard parts.

Replace

disc

and/or cover

with

correct parts.

3. Clutch master or slave cylinder plunger dragging-binding. a) Master or slave cylinder

components worn or corroded. a) Replace both cylinders as

assembly

(and reservoir).

4. No

fault

found

with

clutch

components.

a) Problem actually

related

to

suspension

or driveline

component.

b) Engine

related

problem. a)

Further

diagnosis

required.

Check

engine/transmission

mounts,

propeller shafts and U-joints, tires,

suspension

attaching parts and other

driveline components as needed.

b) Check EFI and igniton

systems.

5.

Partial

engagement of clutch

disc

(one side worn-opposite

side

glazed and lightly worn). a) Clutch pressure

plate

position

setting incorrect or modified.

b) Clutch cover, spring, or release fingers bent, distorted (rough

handling,

improper assembly).

c) Clutch

disc

damaged or distorted.

d) Clutch misalignment. a) Replace clutch cover and

disc.

b) Replace clutch cover and

disc.

c) Replace

disc.

d) Check alignment and runout of flywheel,

disc,

or cover and/or clutch

housing.

Correct as

necessary.

J9006-23

Page 264 of 1502

•

CLUTCH

S - 11

CLUTCH

SERVICE

INDEX

page

Clutch

Cover

and

Disc

Installation—All

11

Clutch

Cover

and

Disc

Removal—All

. 11

Clutch

Housing

Installation

13

Clutch

Housing

Removal

12

Clutch

Linkage

Service

14

CLUTCH

COVER

AND

DISC

REMOVAL—ALL

(1) Raise vehicle.

(2) Remove transmission and remove transfer case

if equipped. Refer to Group 21 for procedures. (3) Remove clutch housing from engine.

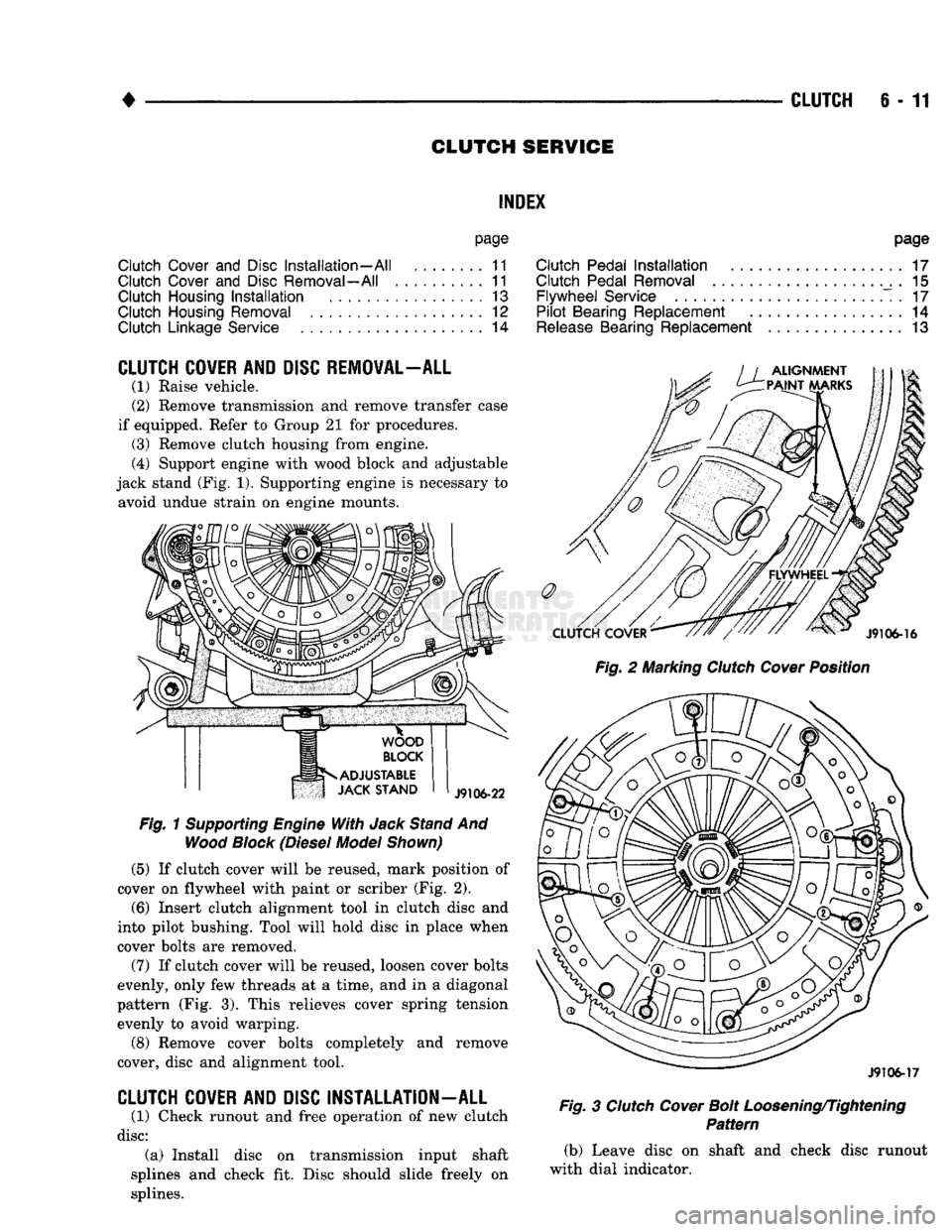

(4) Support engine with wood block and adjustable

jack stand (Fig. 1). Supporting engine is necessary to avoid undue strain on engine mounts.

Fig.

1

Supporting

Engine

With

Jack

Stand

And

Wood

Block

(Diesel

Model

Shown)

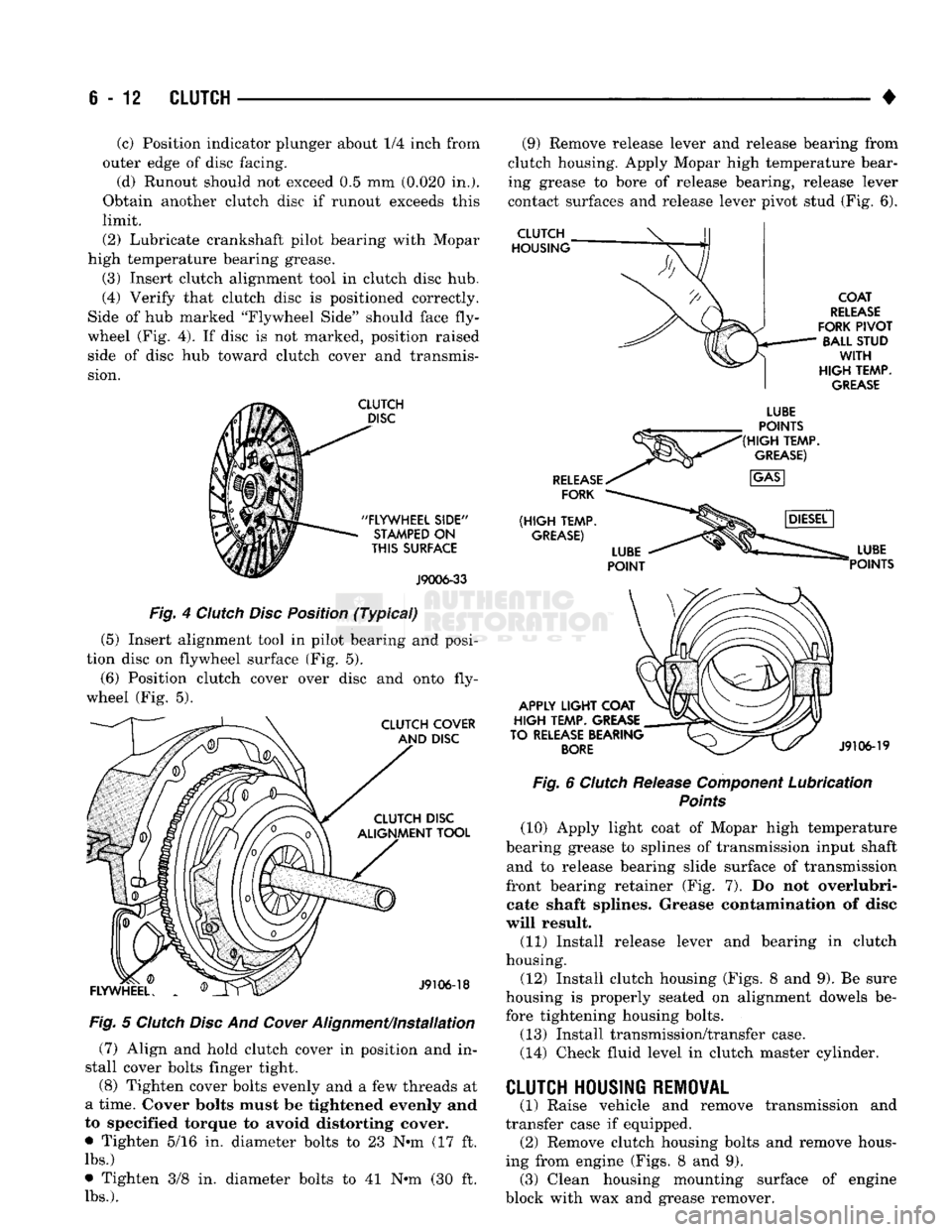

(5)

If clutch cover will be reused, mark position of

cover on flywheel with paint or scriber (Fig. 2).

(6)

Insert clutch alignment tool in clutch disc and

into pilot bushing. Tool will hold disc in place when

cover bolts are removed.

(7) If clutch cover will be reused, loosen cover bolts

evenly, only few threads at a time, and in a diagonal

pattern (Fig. 3). This relieves cover spring tension evenly to avoid warping.

(8) Remove cover bolts completely and remove

cover, disc and alignment tool.

CLUTCH

COVER

AND

DISC

INSTALLATION

-

ALL

(1) Check runout and free operation of new clutch

disc:

(a) Install disc on transmission input shaft

splines and check fit. Disc should slide freely on

splines.

page

Clutch

Pedal

Installation

17

Clutch

Pedal

Removal

. 15

Flywheel

Service

. 17

Pilot

Bearing

Replacement

14

Release

Bearing

Replacement

13

Fig.

2 Marking

Clutch

Cover

Position

J9106-17

Fig.

3

Clutch

Cover

Bolt

Loosening/Tightening

Pattern

(b) Leave disc on shaft and check disc runout

with dial indicator.

Page 265 of 1502

6-12

CLUTCH

(c) Position indicator plunger about 1/4 inch from

outer edge of disc facing.

(d) Runout should not exceed 0.5 mm (0.020 in.).

Obtain another clutch disc if runout exceeds this

limit.

(2) Lubricate crankshaft pilot bearing with Mopar

high temperature bearing grease.

(3) Insert clutch alignment tool in clutch disc hub,

(4) Verify that clutch disc is positioned correctly.

Side of hub marked "Flywheel Side" should face fly

wheel (Fig. 4). If disc is not marked, position raised side of disc hub toward clutch cover and transmis

sion.

CLUTCH

DISC

"FLYWHEEL

SIDE"

STAMPED

ON

THIS

SURFACE

J9006-33

Fig. 4 Clutch Disc Position (Typical)

(5) Insert alignment tool in pilot bearing and posi

tion disc on flywheel surface (Fig. 5).

(6) Position clutch cover over disc and onto fly

wheel (Fig. 5).

CLUTCH COVER AND DISC CLUTCH DISC

ALIGNMENT TOOL

FLYWHEEL.

J9106-18

Fig. 5 Clutch Disc And

Cower

Alignment/installation (7) Align and hold clutch cover in position and in

stall cover bolts finger tight.

(8) Tighten cover bolts evenly and a few threads at

a time. Cover bolts must be tightened evenly and

to specified torque to avoid distorting cover.

• Tighten 5/16 in. diameter bolts to 23 N-m (17 ft.

lbs.)

• Tighten 3/8 in. diameter bolts to 41 N-m (30 ft.

lbs.).

(9) Remove release lever and release bearing from

clutch housing. Apply Mopar high temperature bear

ing grease to bore of release bearing, release lever

contact surfaces and release lever pivot stud (Fig. 6).

CLUTCH

HOUSING

COAT

RELEASE

FORK

PIVOT

BALL STUD

WITH

HIGH

TEMP.

GREASE

RELEASE

FORK

(HIGH

TEMP.

GREASE)

LUBE

POINTS

(HIGH

TEMP.

GREASE)

APPLY

LIGHT

COAT

HIGH

TEMP. GREASE

TO RELEASE BEARING

BORE

LUBE

POINTS

J9106-19

Fig. 6 Clutch Release Component Lubrication

Points

(10) Apply light coat of Mopar high temperature

bearing grease to splines of transmission input shaft and to release bearing slide surface of transmission

front bearing retainer (Fig. 7). Do not overlubri- cate shaft splines. Grease contamination of disc

will result. (11) Install release lever and bearing in clutch

housing.

(12) Install clutch housing (Figs. 8 and 9). Be sure

housing is properly seated on alignment dowels be fore tightening housing bolts.

(13) Install transmission/transfer case.

(14) Check fluid level in clutch master cylinder. transmission and

CLUTCH HOUSING REMOVAL

(1) Raise vehicle and remove

transfer case if equipped. (2) Remove clutch housing bolts and remove hous

ing from engine (Figs. 8 and 9). (3) Clean housing mounting surface of engine

block with wax and grease remover.