check engine DODGE TRUCK 1993 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 305 of 1502

7 - 34

COOLING SYSTEM

•

WARNING;

DO NOT

REMOVE

THE

CYLINDER

BLOCK DRAIN PLUGS

OR

LOOSEN

THE

RADIATOR

DRAINCOCK

WITH

THE

SYSTEM

HOT AND

UNDER

PRESSURE.

SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system. Refer to Draining

Cooling System in this group. (3) Remove hose clamps and hoses from radiator.

Remove coolant reserve/overflow tank hose from ra diator filler neck nipple.

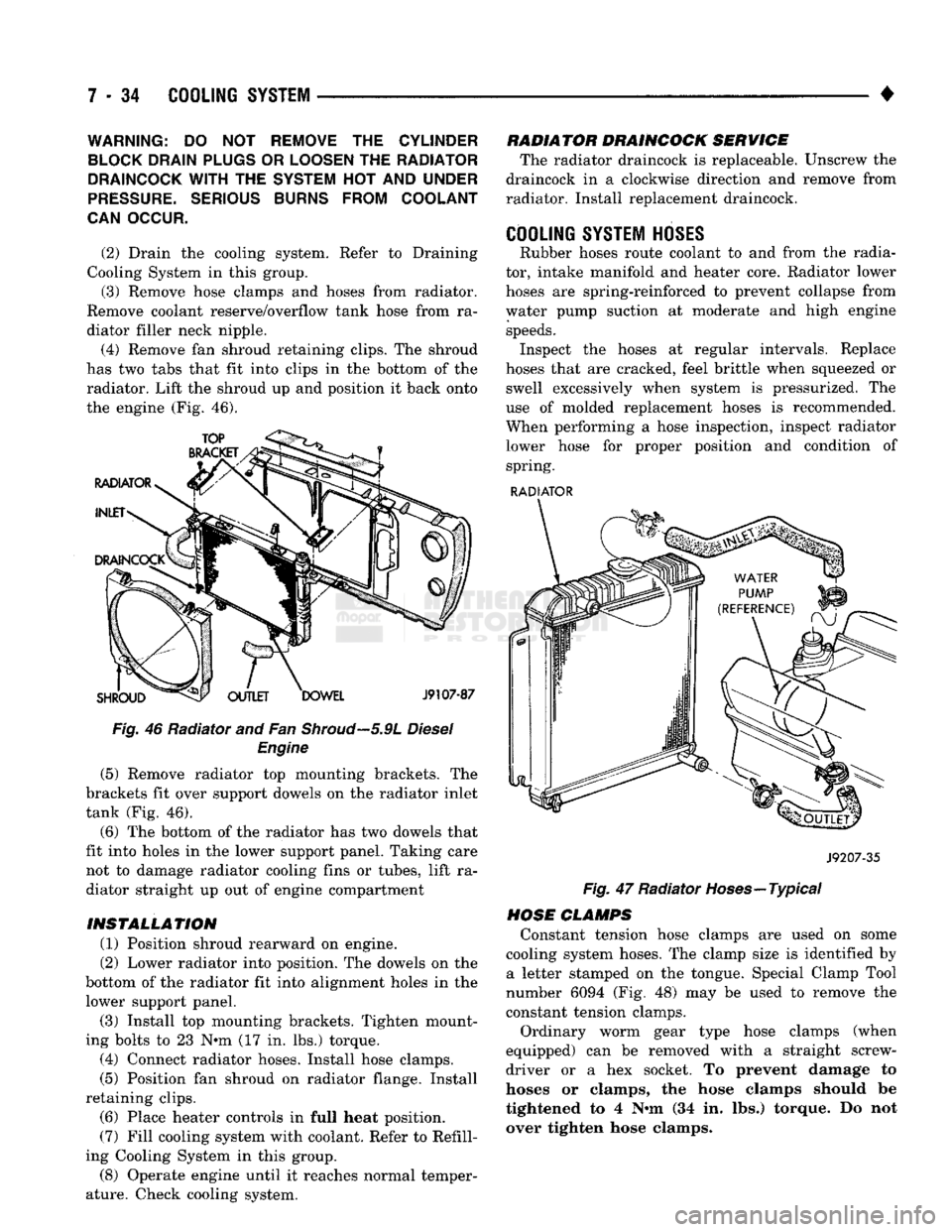

(4) Remove fan shroud retaining clips. The shroud

has two tabs that fit into clips in the bottom of the radiator. Lift the shroud up and position it back onto

the engine (Fig. 46).

Fig. 46 Radiator and Fan

Shroud—5.9L

Diesel Engine

(5) Remove radiator top mounting brackets. The

brackets fit over support dowels on the radiator inlet

tank (Fig. 46).

(6) The bottom of the radiator has two dowels that

fit into holes in the lower support panel. Taking care not to damage radiator cooling fins or tubes, lift ra

diator straight up out of engine compartment

INSTALLATION (1) Position shroud rearward on engine.

(2) Lower radiator into position. The dowels on the

bottom of the radiator fit into alignment holes in the lower support panel.

(3) Install top mounting brackets. Tighten mount

ing bolts to 23 N*m (17 in. lbs.) torque. (4) Connect radiator hoses. Install hose clamps.

(5) Position fan shroud on radiator flange. Install

retaining clips. (6) Place heater controls in full heat position.

(7) Fill cooling system with coolant. Refer to Refill

ing Cooling System in this group.

(8) Operate engine until it reaches normal temper

ature. Check cooling system. RADIATOR DRAINCOCK SERVICE

The radiator draincock is replaceable. Unscrew the

draincock in a clockwise direction and remove from

radiator. Install replacement draincock.

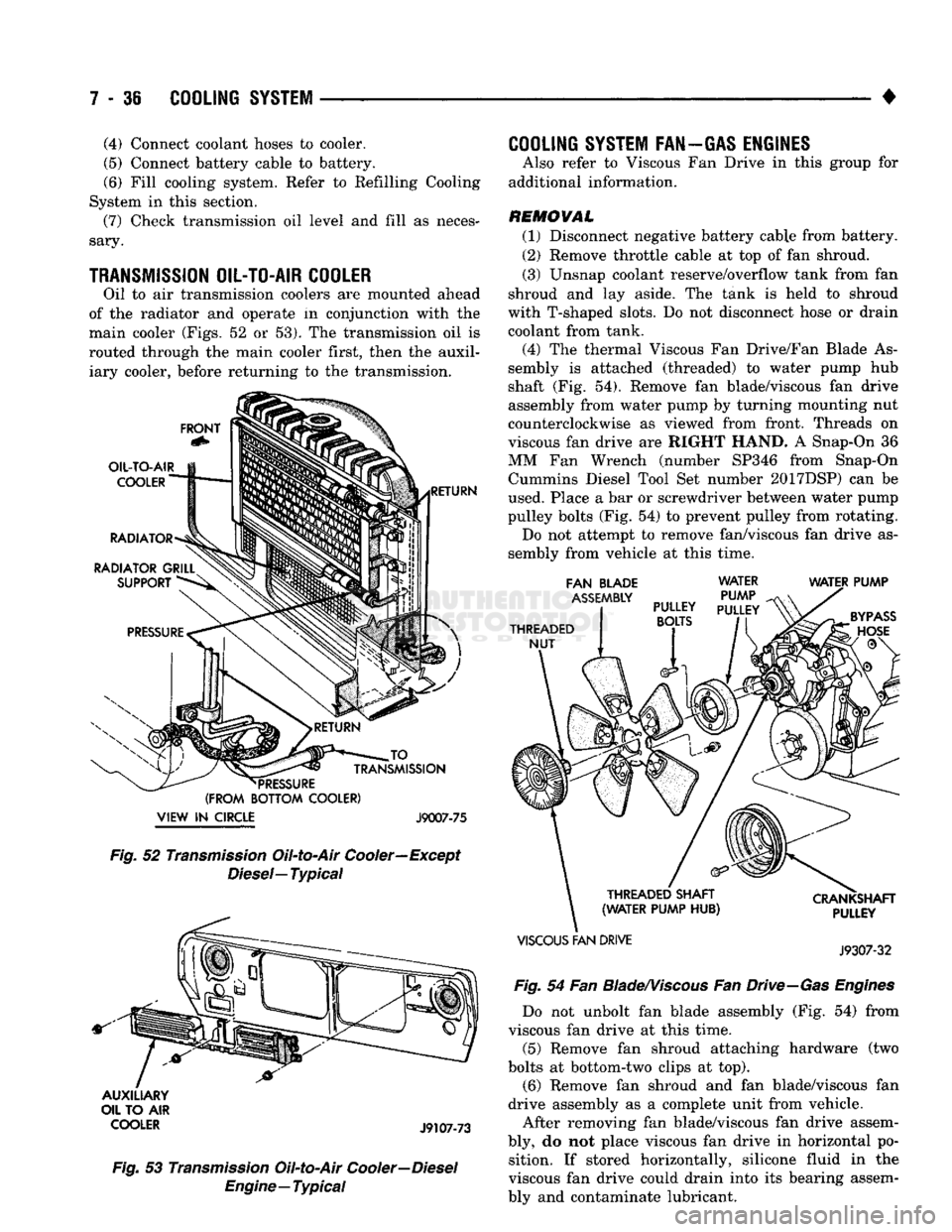

COOLING SYSTEM HOSES

Rubber hoses route coolant to and from the radia

tor, intake manifold and heater core. Radiator lower

hoses are spring-reinforced to prevent collapse from

water pump suction at moderate and high engine speeds. Inspect the hoses at regular intervals. Replace

hoses that are cracked, feel brittle when squeezed or swell excessively when system is pressurized. The

use of molded replacement hoses is recommended.

When performing a hose inspection, inspect radiator lower hose for proper position and condition of spring.

RADIATOR

J9207-35

Fig. 47 Radiator Hoses—Typical

HOSE CLAMPS Constant tension hose clamps are used on some

cooling system hoses. The clamp size is identified by a letter stamped on the tongue. Special Clamp Tool

number 6094 (Fig. 48) may be used to remove the

constant tension clamps.

Ordinary worm gear type hose clamps (when

equipped) can be removed with a straight screw

driver or a hex socket. To prevent damage to

hoses or clamps, the hose clamps should be

tightened to 4 N«m (34 in. lbs.) torque. Do not

over tighten hose clamps.

Page 307 of 1502

7 - 36

COOLING

SYSTEM

• (4) Connect coolant hoses to cooler.

(5)

Connect battery cable to battery.

(6)

Fill cooling system. Refer to Refilling Cooling

System in this section. (7) Check transmission oil level and fill as neces

sary.

TRANSMISSION

OIL/TO-AIR

COOLER

Oil to air transmission coolers are mounted ahead

of the radiator and operate in conjunction with the

main cooler (Figs, 52 or 53). The transmission oil is

routed through the main cooler first, then the auxil iary cooler, before returning to the transmission.

FRONT

OIL-TO-AIR

COOLER

RADIATOR

RADIATOR GRILL SUPPORT RETURN JO

_

TRANSMISSION

*

PRESSURE

(FROM BOTTOM COOLER)

VIEW

IN

CIRCLE J9007-75 Fig.

52

Transmission

Oil-to-Air Cooler—Except

Diesel—

Typical

AUXILIARY

OIL TO AIR

COOLER

J9107-73

Fig.

53

Transmission

Oil-to-Air

Cooler—Diesel

Engine—Typical

COOLING

SYSTEM FAN—GAS ENGINES

Also refer to Viscous Fan Drive in this group for

additional information.

REMOVAL (1) Disconnect negative battery cable from battery.

(2) Remove throttle cable at top of fan shroud.

(3) Unsnap coolant reserve/overflow tank from fan

shroud and lay aside. The tank is held to shroud

with T-shaped slots. Do not disconnect hose or drain

coolant from tank.

(4) The thermal Viscous Fan Drive/Fan Blade As

sembly is attached (threaded) to water pump hub

shaft (Fig. 54). Remove fan blade/viscous fan drive

assembly from water pump by turning mounting nut

counterclockwise as viewed from front. Threads on

viscous fan drive are RIGHT HAND. A Snap-On 36

MM Fan Wrench (number SP346 from Snap-On Cummins Diesel Tool Set number 2017DSP) can be

used. Place a bar or screwdriver between water pump

pulley bolts (Fig. 54) to prevent pulley from rotating. Do not attempt to remove fan/viscous fan drive as

sembly from vehicle at this time.

FAN BLADE

ASSEMBLY

THREADED NUT WATER

PUMP

PULLEY

PULLEY

BOLTS

WATER PUMP

THREADED SHAFT

(WATER PUMP HUB)

VISCOUS

FAN DRIVE CRANKSHAFT

PULLEY

J9307-32

Fig.

54 Fan

Blade/Viscous

Fan

Drive—Gas

Engines

Do not unbolt fan blade assembly (Fig. 54) from

viscous fan drive at this time.

(5) Remove fan shroud attaching hardware (two

bolts at bottom-two clips at top). (6) Remove fan shroud and fan blade/viscous fan

drive assembly as a complete unit from vehicle.

After removing fan blade/viscous fan drive assem

bly, do not place viscous fan drive in horizontal po sition. If stored horizontally, silicone fluid in the

viscous fan drive could drain into its bearing assem

bly and contaminate lubricant.

Page 311 of 1502

ENGINE ACCESSORY DRIVE BELTS

INDEX

page

Automatic Belt Tensioner

45

Belt Diagnosis

40

Belt Removal/Installation

. 40

page

Belt Schematics

40

Belt Tension

40

General

Information

40

GENERAL

INFORMATION

All vehicles are available with either

a

3.9L (V-6),

a 5.2L (V-8),

a

5.9L (gas V-8) or

a

5.9L (in-line 6 cyl

inder diesel) engine. The accessory drive components

are

operated

by a

single, crankshaft driven, serpentine drive belt on all

engines. An automatic belt tensioner

is

used to main

tain correct belt tension

at all

times. Refer

to

Auto matic Belt Tensioner proceeding

in

this group.

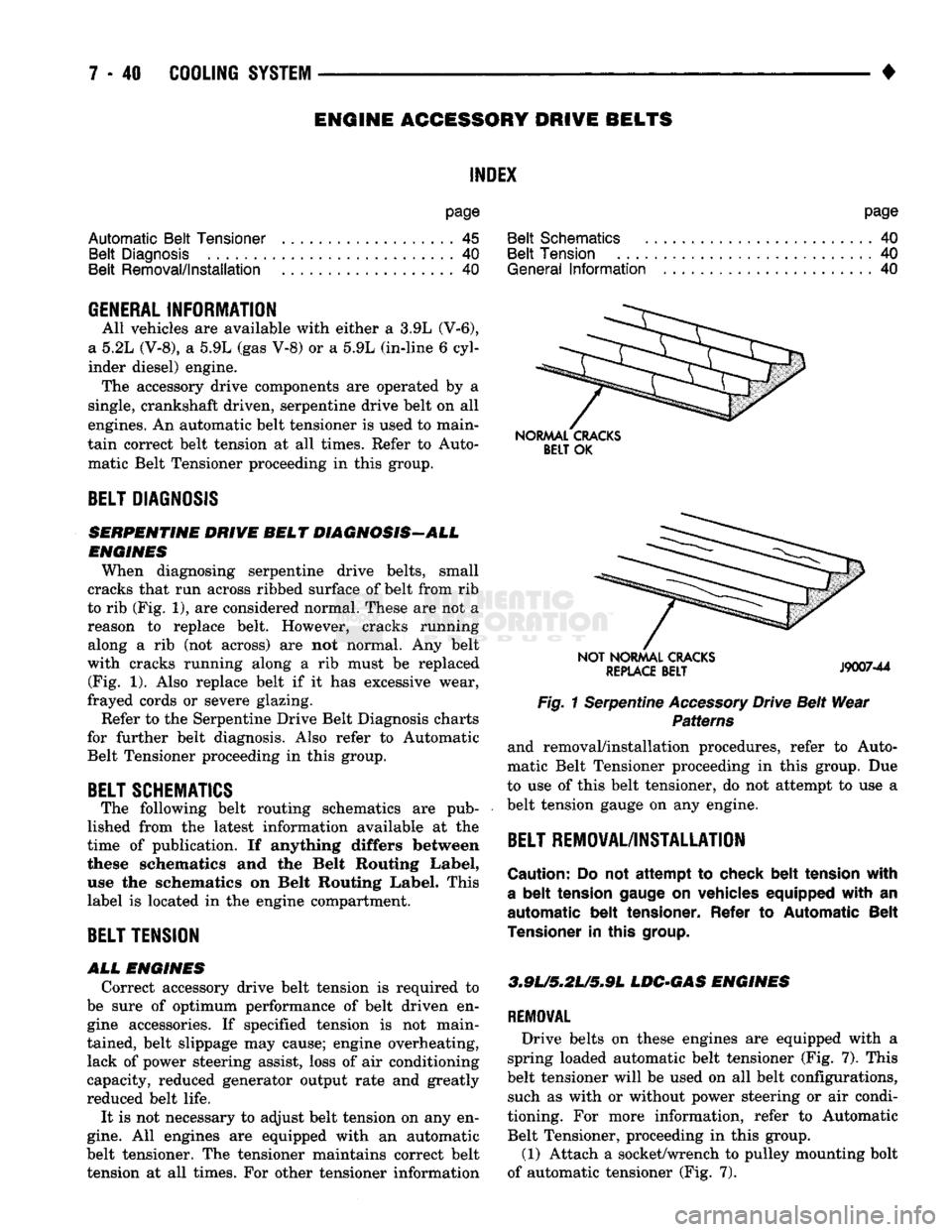

BELT DIAGNOSIS SERPENTINE DRIVE BELT DIAGNOSIS-ALL

ENGINES

When diagnosing serpentine drive belts, small

cracks that run across ribbed surface of belt from rib

to rib (Fig. 1), are considered normal. These are not

a

reason

to

replace belt. However, cracks running along

a rib (not

across)

are not

normal.

Any

belt

with cracks running along

a rib

must

be

replaced (Fig.

1).

Also replace belt

if it has

excessive wear,

frayed cords

or

severe glazing.

Refer to the Serpentine Drive Belt Diagnosis charts

for further belt diagnosis. Also refer

to

Automatic Belt Tensioner proceeding

in

this group.

BELT SCHEMATICS

The following belt routing schematics

are

pub

lished from

the

latest information available

at the

time

of

publication.

If

anything differs between

these schematics

and the

Belt Routing Label,

use

the

schematics

on

Belt Routing Label. This

label

is

located

in

the engine compartment.

BELT TENSION

ALL

ENGINES

Correct accessory drive belt tension

is

required

to

be sure

of

optimum performance

of

belt driven

en

gine accessories.

If

specified tension

is not

main

tained, belt slippage may cause; engine overheating, lack

of

power steering assist, loss

of

air conditioning

capacity, reduced generator output rate and greatly

reduced belt life.

It

is

not necessary

to

adjust belt tension on any en

gine.

All

engines

are

equipped with

an

automatic

belt tensioner. The tensioner maintains correct belt tension

at all

times. For other tensioner information

NORMAL CRACKS

BELT

OK

NOT NORMAL CRACKS

REPLACE

BELT

J9007-44

Fig. 1 Serpentine Accessory Drive Belt Wear Patterns

and removal/installation procedures, refer

to

Auto

matic Belt Tensioner proceeding

in

this group.

Due

to use

of

this belt tensioner, do not attempt

to

use

a

belt tension gauge

on

any engine.

BELT REMOVAL/INSTALLATION

Caution:

Do not

attempt

to

check belt tension with

a

belt

tension gauge

on

vehicles equipped with

an

automatic belt tensioner. Refer

to

Automatic Belt

Tensioner

in

this

group.

3.9L/5,2U5*9L

LDC-GAS ENGINES

REMOVAL

Drive belts

on

these engines

are

equipped with

a

spring loaded automatic belt tensioner (Fig.

7).

This

belt tensioner will

be

used on

all

belt configurations, such

as

with

or

without power steering

or

air condi

tioning.

For

more information, refer

to

Automatic Belt Tensioner, proceeding

in

this group.

(1) Attach

a

socket/wrench

to

pulley mounting bolt

of automatic tensioner (Fig.

7).

Page 313 of 1502

7 - 42 COOLING SYSTEM

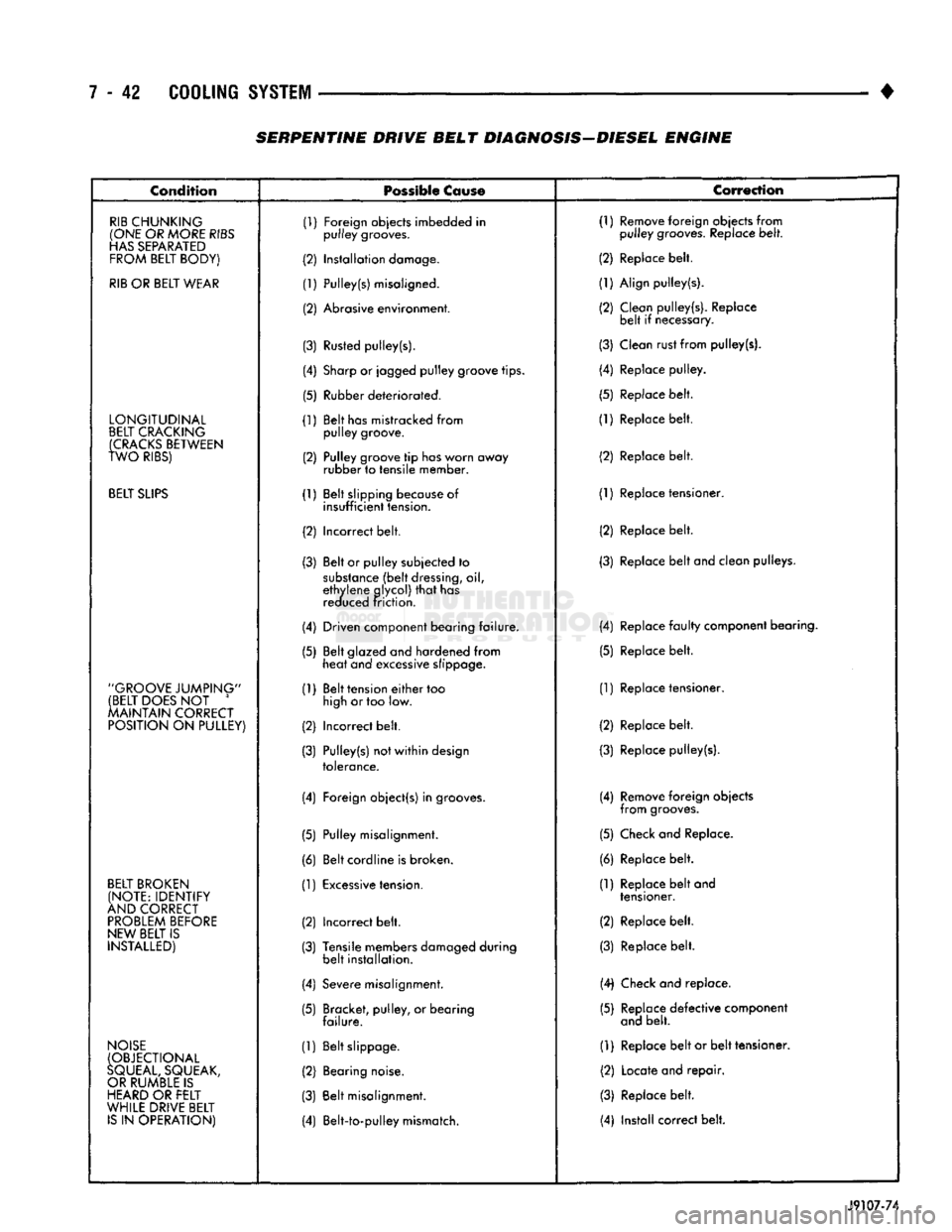

• SERPENTINE DRIVE BELT DIAGNOSIS-DIESEL ENGINE

Condition

Possible

Cause

Correction

RIB

CHUNKING (1) Foreign objects imbedded in

(1) Remove foreign objects from

(ONE

OR

MORE

RIBS

(1)

pulley grooves.

pulley

grooves.

Replace

belt.

HAS

SEPARATED

pulley grooves.

Replace

belt.

FROM

BELT BODY) (2) Installation damage.

(2) Replace

belt.

RIB

OR

BELT

WEAR

(1) Pulley(s) misaligned.

(1)

Align

pulley(s).

(2) Abrasive environment.

(2)

Clean pulley(s). Replace

(2)

belt

if necessary.

(3)

Rusted

pulley(s).

(3) Clean rust from pulley(s).

(4)

Sharp

or jagged pulley groove tips.

(4)

Replace pulley.

(5) Rubber

deteriorated.

(5)

Replace

belt.

LONGITUDINAL

(1) Belt has mistracked from

(1)

Replace

belt.

BELT

CRACKING

(1)

pulley groove. Replace

belt.

(CRACKS

BETWEEN

TWO

RIBS)

pulley groove.

Replace

belt.

(CRACKS

BETWEEN

TWO

RIBS)

(2) Pulley groove tip has worn away

(2) Replace

belt.

(2)

rubber to tensile member.

BELT

SLIPS

(1) Belt slipping because of

0) Replace tensioner.

(1)

insufficient tension.

(2) Incorrect

belt.

(2)

Replace

belt.

(3) Belt or pulley subjected to

(3)

Replace

belt

and clean pulleys.

substance

(belt

dressing,

oil,

ethylene

glycol)

that

has reciuced friction.

(4) Driven component bearing

failure.

(4)

Replace

faulty

component bearing.

(5) Belt glazed and hardened from

(5)

Replace

belt.

(5)

heat

and excessive slippage.

"GROOVE

JUMPING" (1) Belt tension

either

too

(1) Replace tensioner.

(BELT

DOES

NOT 5 (1)

high

or too low. Replace tensioner.

MAINTAIN

CORRECT

high

or too low.

POSITION

ON PULLEY) (2) Incorrect

belt.

(2) Replace

belt.

(3) Pulley(s) not

within

design

(3)

Replace pulley(s).

tolerance.

(4) Foreign object(s) in grooves.

(4)

Remove foreign objects

from grooves.

(5) Pulley misalignment.

(5)

Check and Replace.

(6) Belt cordline is broken.

(6)

Replace

belt.

BELT

BROKEN

0)

Excessive

tension.

0) Replace

belt

and

(NOTE:

IDENTIFY 0)

tensioner.

AND

CORRECT

PROBLEM

BEFORE

(2) Incorrect

belt.

(2) Replace

belt.

NEW

BELT

IS (2)

Replace

belt.

INSTALLED)

(3) Tensile members damaged during

(3) Replace

belt.

(3)

belt

installation.

(4) Severe misalignment.

(4)

Check and replace.

(5) Bracket, pulley, or bearing

(5)

Replace

defective

component

(5)

failure.

ana

belt.

NOISE

0) Belt slippage.

(1) Replace

belt

or

belt

tensioner.

(OBJECTIONAL

0)

Belt slippage.

Replace

belt

or

belt

tensioner.

SQUEAL,

SQUEAK,

(2) Bearing noise.

(2) Locate and

repair.

OR

RUMBLE

IS (2)

Bearing noise.

HEARD

OR FELT (3) Belt misalignment.

(3) Replace

belt.

WHILE

DRIVE

BELT (3)

Belt misalignment.

Replace

belt.

IS

IN OPERATION) (4) Belt-to-pulley mismatch.

(4) Install correct

belt.

J9107-74

Page 315 of 1502

7 - 44

COOLING

SYSTEM

•

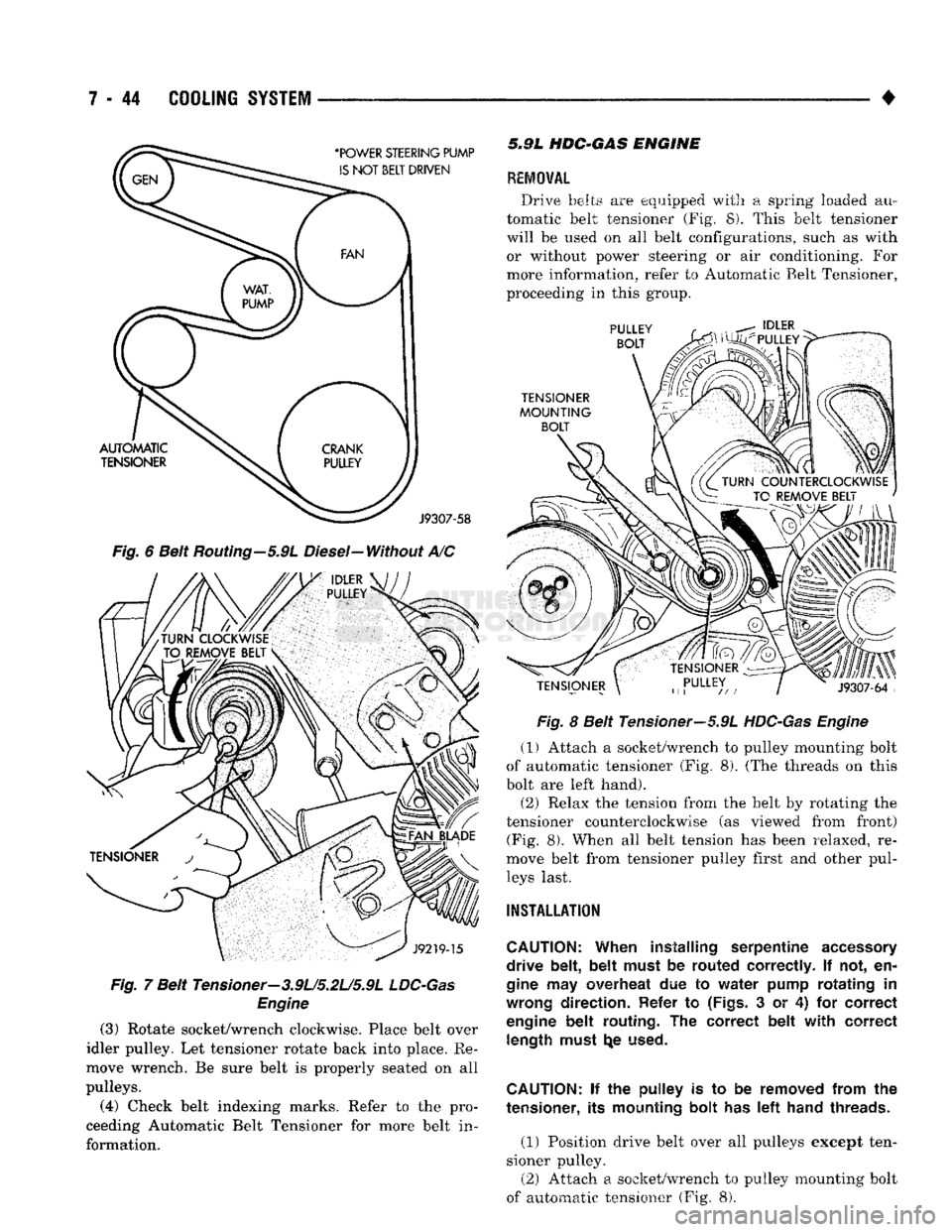

Fig.

6 Belt Routing-5.9L Diesel-Without A/C

Fig.

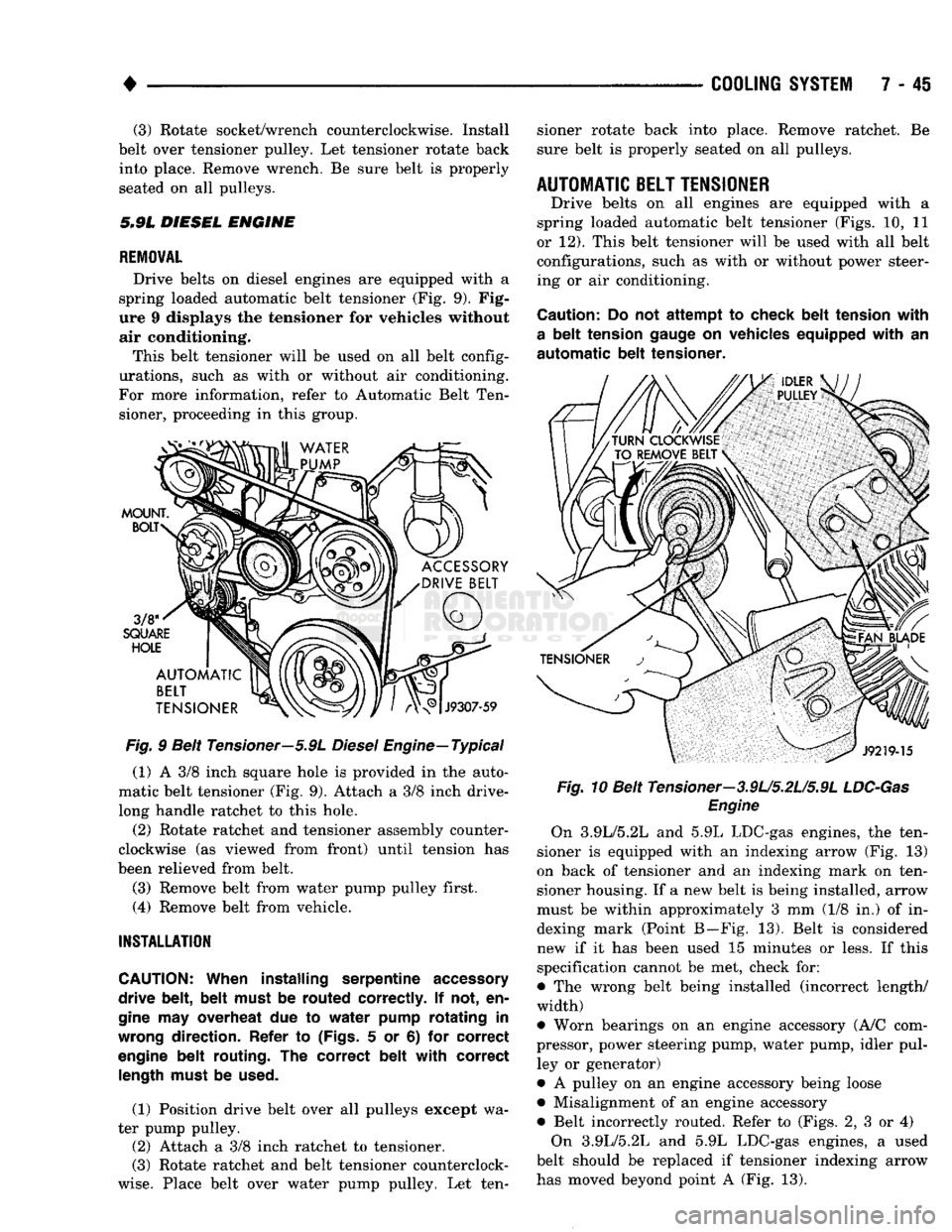

7 Belt Tensioner-3.9L/5.2U5.9L

LDC-Gas

Engine

(3)

Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place. Re

move wrench. Be sure belt is properly seated on all

pulleys.

(4)

Check belt indexing marks. Refer to the pro

ceeding Automatic Belt Tensioner for more belt in

formation. 5.9L

HDC-GAS

ENGINE

REMOVAL

Drive belts are equipped with a spring loaded au

tomatic belt tensioner (Fig. 8). This belt tensioner

will be used on all belt configurations, such as with or without power steering or air conditioning. For

more information, refer to Automatic Belt Tensioner,

proceeding in this group.

Fig.

8 Belt Tensioner—5.9L

HDC-Gas Engine

(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 8). (The threads on this

bolt are left hand).

(2) Relax the tension from the belt by rotating the

tensioner counterclockwise (as viewed from front) (Fig. 8). When all belt tension has been relaxed, re

move belt from tensioner pulley first and other pul leys last.

INSTALLATION

CAUTION:

When installing serpentine

accessory

drive belt, belt must

be

routed correctly.

If not, en

gine

may

overheat

due to

water pump rotating

in

wrong

direction. Refer

to

(Figs.

3 or 4) for

correct

engine

belt routing.

The

correct belt with correct length must

t^e

used.

CAUTION:

if the

pulley

is to be

removed from

the

tensioner,

its

mounting bolt

has left

hand threads.

(1) Position drive belt over all pulleys except ten

sioner pulley. (2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 8).

Page 316 of 1502

•

COOLING

SYSTEM

7 - 45 (3) Rotate socket/wrench counterclockwise. Install

belt over tensioner pulley. Let tensioner rotate back into place. Remove wrench. Be sure belt is properly

seated on all pulleys.

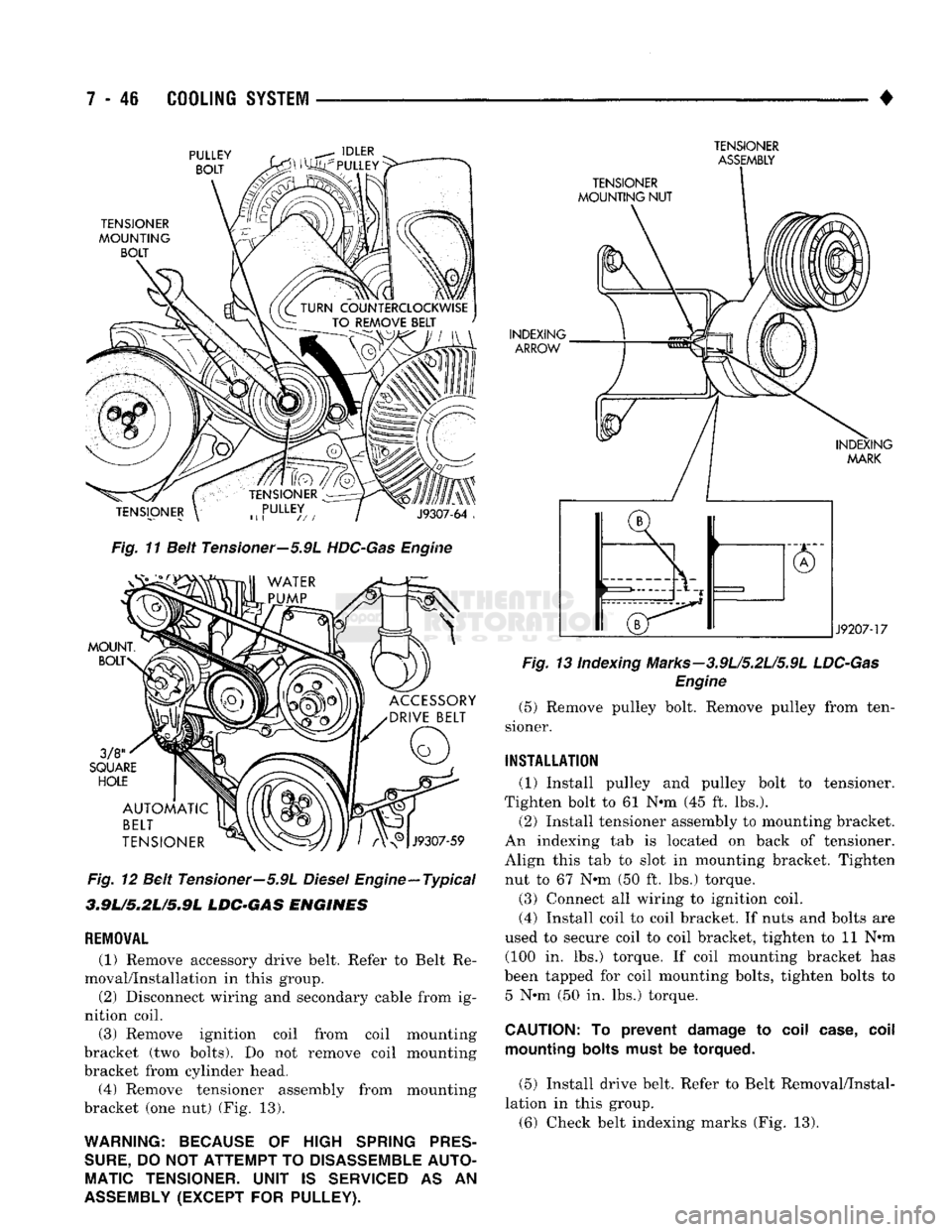

5«9L

DIESEL ENGINE

REMOVAL

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner (Fig. 9). Fig

ure 9 displays the tensioner for vehicles without air conditioning.

This belt tensioner will be used on all belt config

urations, such as with or without air conditioning.

For more information, refer to Automatic Belt Ten sioner, proceeding in this group.

Fig.

9 Belt Tensioner—5.9L

Diesel

Engine—Typical

(1) A 3/8 inch square hole is provided in the auto

matic belt tensioner (Fig. 9). Attach a 3/8 inch drive-

long handle ratchet to this hole.

(2) Rotate ratchet and tensioner assembly counter

clockwise (as viewed from front) until tension has

been relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION:

When installing serpentine

accessory

drive belt, belt must

be

routed correctly.

If not, en

gine

may

overheat

due to

water pump rotating

in

wrong

direction. Refer

to

(Figs.

5 or 6) for

correct

engine

belt routing.

The

correct belt with correct

length

must

be

used.

(1) Position drive belt over all pulleys except wa

ter pump pulley. (2) Attach a 3/8 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner counterclock

wise.

Place belt over water pump pulley. Let ten sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

AUTOMATIC

BELT

TENSIONER

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Figs. 10, 11

or 12). This belt tensioner will be used with all belt configurations, such as with or without power steer

ing or air conditioning.

Caution:

Do not

attempt

to

check belt tension with

a

belt tension

gauge

on

vehicles equipped with

an

automatic

belt tensioner. Fig.

10 Belt Tensioner—3.9U5.2U5.9L

LDC-Gas

Engine

On 3.9L/5.2L and 5.9L LDC-gas engines, the ten

sioner is equipped with an indexing arrow (Fig. 13)

on back of tensioner and an indexing mark on ten

sioner housing. If a new belt is being installed, arrow

must be within approximately 3 mm (1/8 in.) of in dexing mark (Point B—Fig. 13). Belt is considered

new if it has been used 15 minutes or less. If this

specification cannot be met, check for:

• The wrong belt being installed (incorrect length/

width)

• Worn bearings on an engine accessory (A/C com

pressor, power steering pump, water pump, idler pul ley or generator)

• A pulley on an engine accessory being loose

• Misalignment of an engine accessory

• Belt incorrectly routed. Refer to (Figs. 2, 3 or 4) On 3.9L/5.2L and 5.9L LDC-gas engines, a used

belt should be replaced if tensioner indexing arrow

has moved beyond point A (Fig. 13).

Page 317 of 1502

7

- 4S

COOLING

SYSTEM

•

PULLEY BOLT IDLER

iUlLTPULLEY-

TENSIONER

MOUNTING

BOLT TENSIONER

ASSEMBLY

TENSIONER \

rULLC,\

, / ^ J9307-64 ,

Fig.

11 Beit Tensioner—5.9L

HDC-Gas

Engine

MOUNT.

BOLT

3/8

SQUARE HOLE

ACCESSORY

DRIVE

BELT AUTOMATIC

BELT

TENSIONER

J9307-59

Fig.

12 Belt Tensioner—5.9L

Diesel

Engine—Typical

3MLm.2Lm.9L

LDG°GA8

ENGINES

REMOVAL

(1) Remove accessory drive belt. Refer to Belt Re

moval/Installation in this group. (2) Disconnect wiring and secondary cable from ig

nition coil.

(3) Remove ignition coil from coil mounting

bracket (two bolts). Do not remove coil mounting

bracket from cylinder head. (4) Remove tensioner assembly from mounting

bracket (one nut) (Fig. 13).

WARNING: BECAUSE

OF

HIGH

SPRING

PRES

SURE,

DO

NOT ATTEMPT

TO

DISASSEMBLE

AUTO

MATIC

TENSIONER.

UNIT

IS

SERVICED

AS AN

ASSEMBLY

(EXCEPT

FOR

PULLEY).

TENSIONER

MOUNTING NUT

INDEXING ARROW

INDEXING MARK

J9207-17

Fig.

13 indexing Marks-3.9L/5.2L/5.9L

LDC-Gas

Engine

(5) Remove pulley bolt. Remove pulley from ten

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 Nnn (45 ft. lbs.).

(2) Install tensioner assembly to mounting bracket.

An indexing tab is located on back of tensioner.

Align this tab to slot in mounting bracket. Tighten nut to 67 Nnn (50 ft. lbs.) torque.

(3) Connect all wiring to ignition coil. (4) Install coil to coil bracket. If nuts and bolts are

used to secure coil to coil bracket, tighten to 11 Nnn (100 in. lbs.) torque. If coil mounting bracket has

been tapped for coil mounting bolts, tighten bolts to 5 Nnn (50 in. lbs.) torque.

CAUTION:

To

prevent damage

to

coil case, coil mounting bolts must

be

torqued.

(5) Install drive belt. Refer to Belt Removal/Instal

lation in this group. (6) Check belt indexing marks (Fig. 13).

Page 320 of 1502

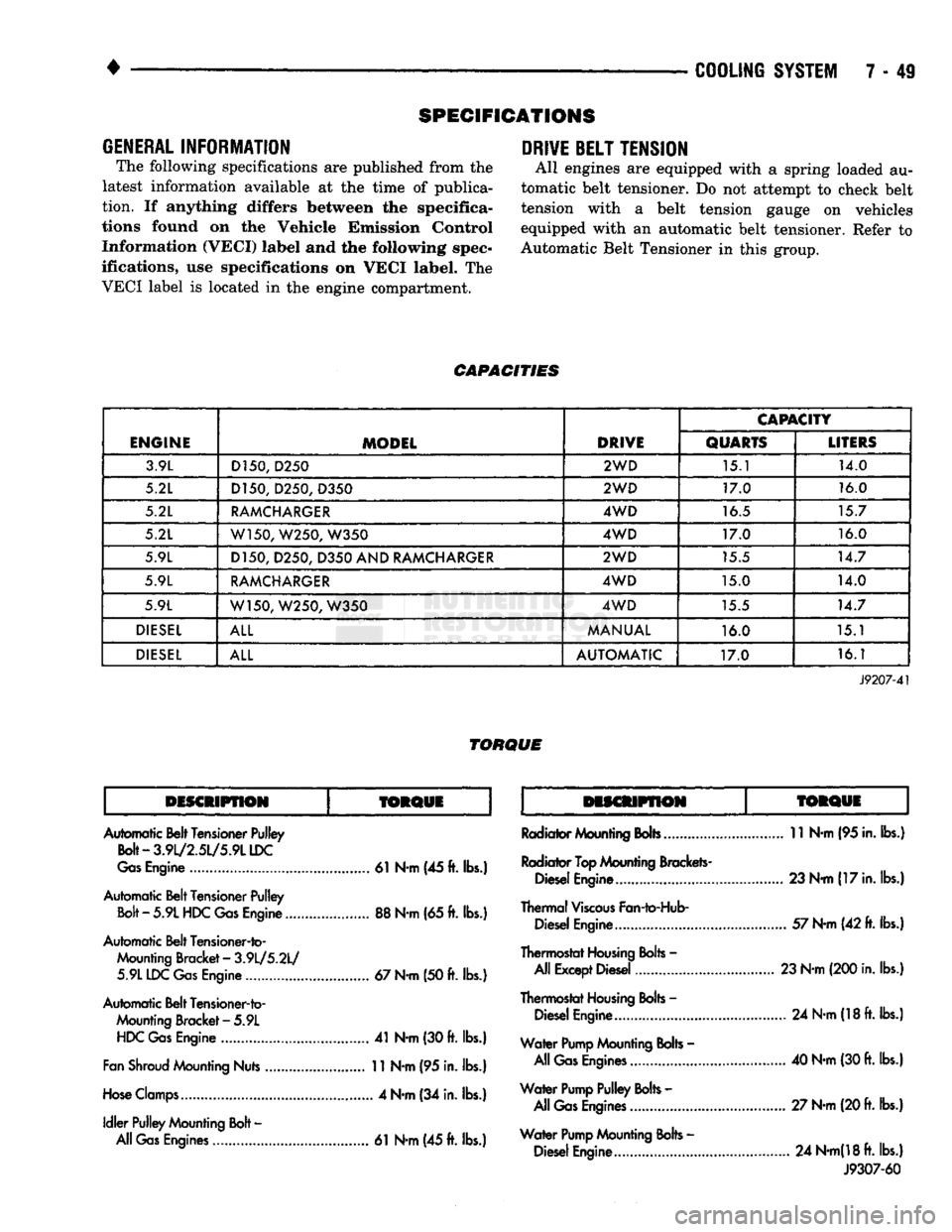

SPECIFICATIONS

GENERAL

INFORMATION

The following specifications are published from the

latest information available at the time of publica

tion. If anything differs between the specifica

tions found on the Vehicle Emission Control

Information (VECI) label and the following spec

ifications, use specifications on VECI label. The

VECI label is located in the engine compartment.

DRIVE

BELT

TENSION

All engines are equipped with a spring loaded au

tomatic belt tensioner. Do not attempt to check belt

tension with a belt tension gauge on vehicles

equipped with an automatic belt tensioner. Refer to

Automatic Belt Tensioner in this group.

CAPACITIES

ENGINE

MODEL

DRIVE

CAPACITY

ENGINE

MODEL

DRIVE

QUARTS

LITERS

3.9L D150,

D250

2WD

15.1 14.0

5.2L D150, D250,

D350

2WD

17.0 16.0

5.2L

RAMCHARGER

4WD

16.5 15.7

5.2L W150, W250,

W350

4WD

17.0 16.0

5.9L D150, D250,

D350

AND

RAMCHARGER

2WD

15.5 14.7

5.9L

RAMCHARGER

4WD

15.0 14.0

5.9L W150, W250,

W350

4WD

15.5 14.7

DIESEL

ALL

MANUAL

16.0 15.1

DIESEL

ALL

AUTOMATIC

17.0 16.1

J9207-41

TORQUE

DISCMPflON

TORQUE

TORQUi

Automatic Belt Tensioner Pulley

Bolt-3.9l/2.5L/5.9LLDC

Gas

Engine

61

N-m (45

ft.

lbs.)

Automatic Belt Tensioner Pulley

Bolt

-

5.9L

HDC

Gas

Engine

88

N-m

(65

ft.

lbs.)

Automatic Belt Tensioner-to- Mounting Bracket

-

3.9L/5.2L/ 5.9L IDC

Gas

Engine

67

N-m

(50

ft.

lbs.)

Automatic Belt Tensioner-to- Mounting Bracket

-

5.9L

HDC

Gas

Engine

41

N-m

(30

ft.

lbs.)

Fan

Shroud

Mounting Nuts

11

N-m

(95

in. lbs.)

Hose

Clamps

4

N-m

(34

in. lbs.)

Idler

Pulley Mounting

Bolt

-

All

Gas

Engines

61

N-m

(45

ft.

lbs.)

Radiator Mounting

Bobs

11

N-m

(95

in. lbs.)

Radiator

Top

Mounting Brackets- Diesel Engine...... 23 N-m

(17

in. lbs.)

Thermal

Viscous

Fan-to-Hub- Diesel Engine

57

N-m

(42

ft.

lbs.)

Thermostat

Housing

Bolts

-

All Except Diesel 23 N-m (200 in. lbs.)

Thermostat

Housing

Bolts

-

Diesel Engine

24

N-m

(18

ft.

lbs.)

Water

Pump

Mounting

Bolts

-

All

Gas

Engines

40

N-m

(30

ft.

lbs.)

Water

Pump

Pulley

Bolts

-

All

Gas

Engines

27 N-m (20

ft.

lbs.)

Water

Pump

Mounting

Bolts

-

Diesel Engine

24

N-m(18ft.

lbs.) J9307-60

Page 333 of 1502

8A

- 12

ELECTRICAL

•

ENGINE

STARTER

RELAY

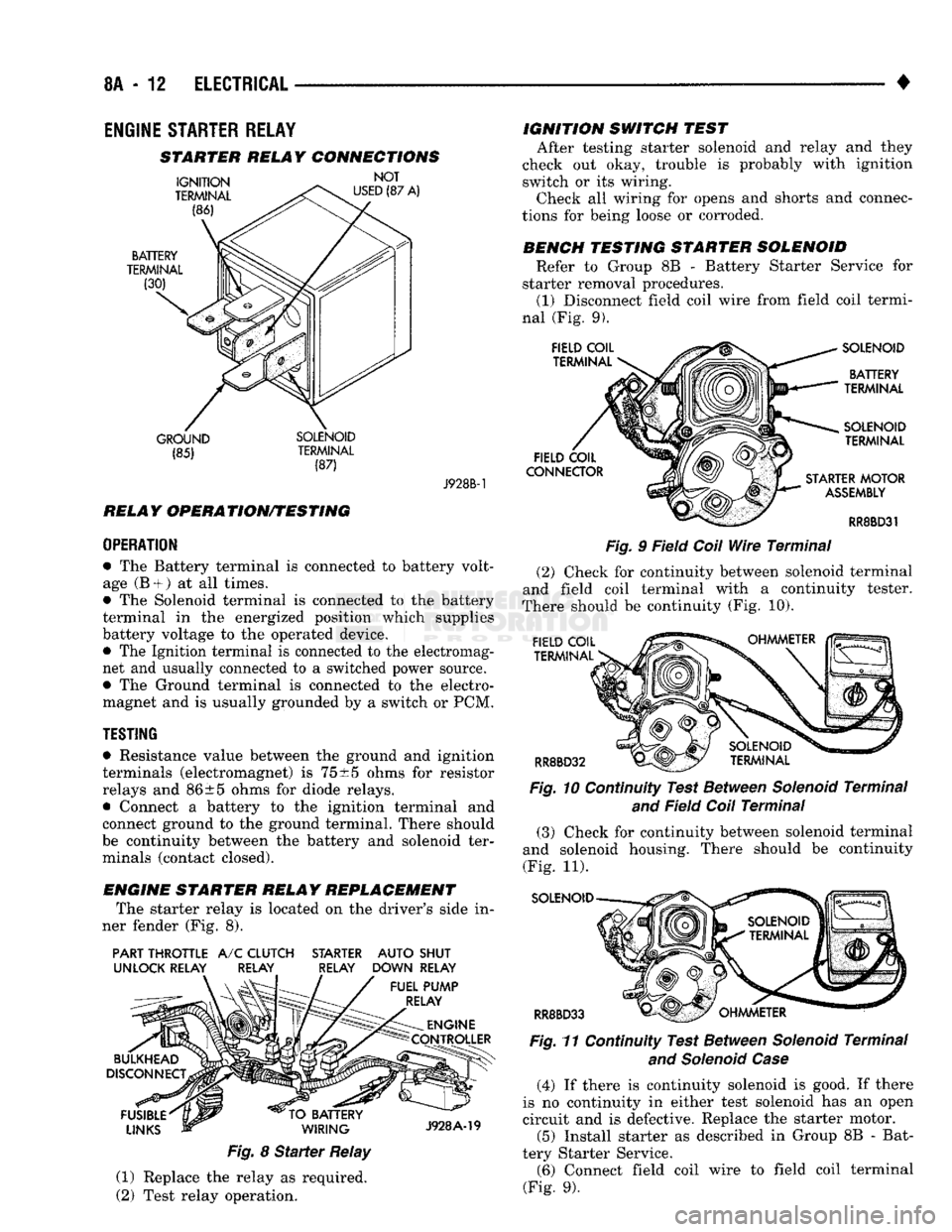

STARTER RELAY CONNECTIONS

GROUND SOLENOID (85) TERMINAL

(87) J928B-1

RELAY OPERATION/TESTING

OPERATION

• The Battery terminal is connected to battery volt

age (B +

)

at all times.

• The Solenoid terminal is connected to the battery

terminal in the energized position which supplies

battery voltage to the operated device. • The Ignition terminal is connected to the electromag

net and usually connected to a switched power source.

• The Ground terminal is connected to the electro

magnet and is usually grounded by a switch or PCM.

TESTING

• Resistance value between the ground and ignition

terminals (electromagnet) is

75

±5 ohms for resistor

relays and 86±5 ohms for diode relays.

• Connect a battery to the ignition terminal and

connect ground to the ground terminal. There should

be continuity between the battery and solenoid ter minals (contact closed).

ENGINE STARTER RELAY REPLACEMENT The starter relay is located on the driver's side in

ner fender (Fig. 8).

PART THROTTLE

A/C

CLUTCH STARTER AUTO SHUT

UNLOCK RELAY RELAY RELAY DOWN RELAY

Fig.

8

Starter

Relay

(1) Replace the relay as required.

(2) Test relay operation. IGNITION SWITCH TEST

After testing starter solenoid and relay and they

check out okay, trouble is probably with ignition

switch or its wiring. Check all wiring for opens and shorts and connec

tions for being loose or corroded.

BENCH TESTING STARTER SOLENOID Refer to Group 8B - Battery Starter Service for

starter removal procedures. (1) Disconnect field coil wire from field coil termi

nal (Fig. 9).

Fig.

9 Field

Coil

Wire

Terminal

(2) Check for continuity between solenoid terminal

and field coil terminal with a continuity tester.

There should be continuity (Fig. 10).

Fig.

10 Continuity Test Between

Solenoid

Terminal

and

Field

Coil

Terminal

(3) Check for continuity between solenoid terminal

and solenoid housing. There should be continuity

(Fig. 11).

SOLENOID

RR8BD33 Fig.

11 Continuity Test Between

Solenoid

Terminal

and Solenoid Case

(4) If there is continuity solenoid is good. If there

is no continuity in either test solenoid has an open

circuit and is defective. Replace the starter motor. (5) Install starter as described in Group 8B - Bat

tery Starter Service. (6) Connect field coil wire to field coil terminal

(Fig. 9).

Page 334 of 1502

•

ELECTRICAL

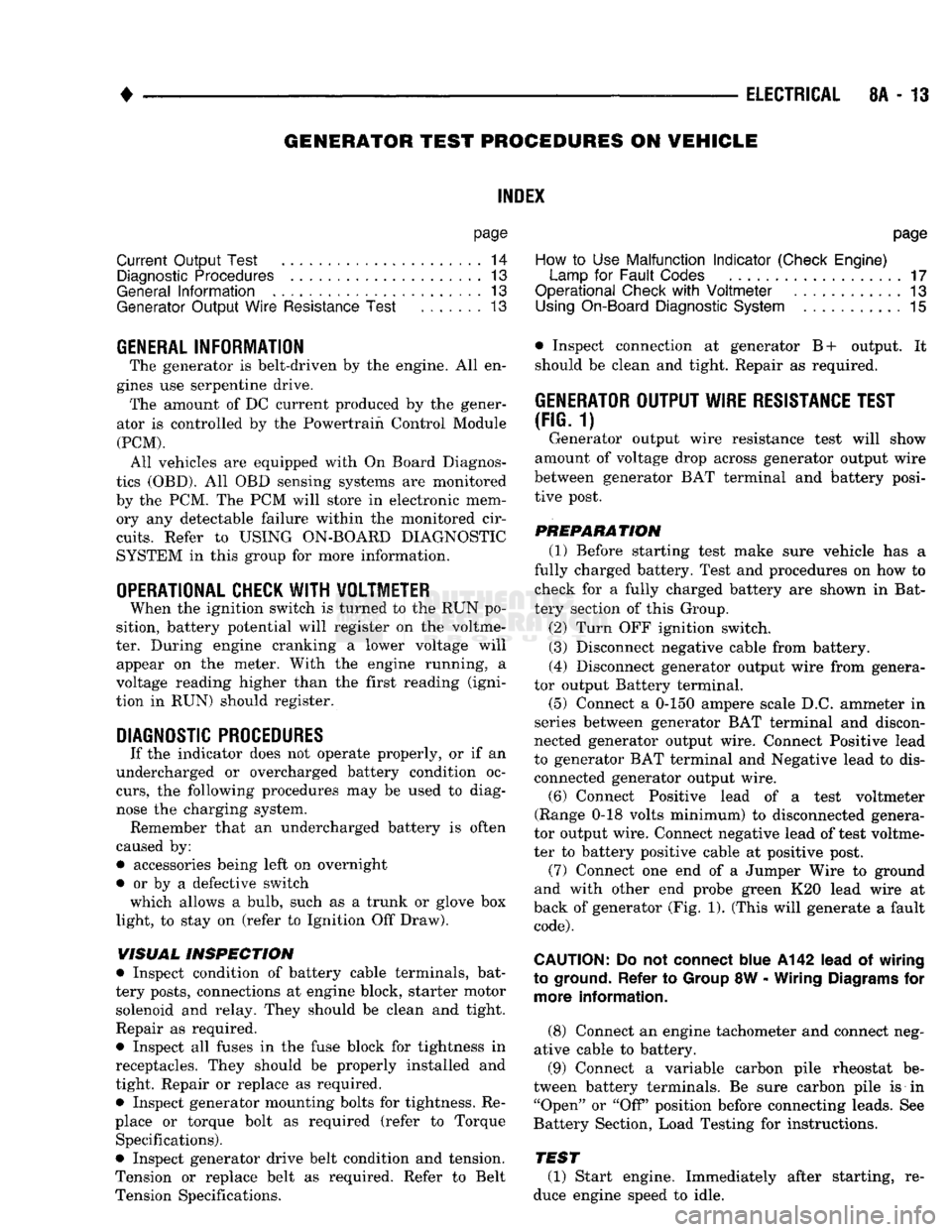

8A - 13 GENERATOR TEST PROCEDURES ON

VEHICLE

INDEX

page

Current

Output

Test

......................

14

Diagnostic Procedures

13

General

Information

13

Generator

Output

Wire Resistance Test

.......

13

page

How

to

Use

Malfunction

Indicator

(Check Engine) Lamp

for

Fault

Codes

17

Operational Check

with

Voltmeter

............

13

Using

On-Board Diagnostic System

15

GENERAL

INFORMATION

The generator

is

belt-driven

by the

engine.

All en

gines

use

serpentine drive. The amount

of DC

current produced

by the

gener

ator

is

controlled

by the

Powertrain Control Module (PCM).

All vehicles

are

equipped with

On

Board Diagnos

tics (OBD).

All OBD

sensing systems

are

monitored

by

the PCM. The PCM

will store

in

electronic mem ory

any

detectable failure within

the

monitored cir

cuits.

Refer

to

USING ON-BOARD DIAGNOSTIC SYSTEM

in

this group

for

more information.

OPERATIONAL CHECK

WITH

VOLTMETER

When

the

ignition switch

is

turned

to the RUN po

sition, battery potential will register

on the

voltme

ter. During engine cranking

a

lower voltage will appear

on the

meter. With

the

engine running,

a

voltage reading higher than

the

first reading (igni

tion

in RUN)

should register.

DIAGNOSTIC PROCEDURES

If

the

indicator does

not

operate properly,

or if an

undercharged

or

overcharged battery condition

oc

curs,

the

following procedures

may be

used

to

diag

nose

the

charging system. Remember that

an

undercharged battery

is

often

caused

by:

• accessories being left

on

overnight

•

or by a

defective switch which allows

a

bulb, such

as a

trunk

or

glove

box

light,

to

stay

on

(refer

to

Ignition

Off

Draw).

WISUAL

INSPECTION

• Inspect condition

of

battery cable terminals, bat

tery posts, connections

at

engine block, starter motor solenoid

and

relay. They should

be

clean

and

tight.

Repair

as

required.

• Inspect

all

fuses

in the

fuse block

for

tightness

in

receptacles. They should

be

properly installed

and

tight. Repair

or

replace

as

required.

• Inspect generator mounting bolts

for

tightness.

Re

place

or

torque bolt

as

required (refer

to

Torque Specifications).

• Inspect generator drive belt condition

and

tension.

Tension

or

replace belt

as

required. Refer

to

Belt

Tension Specifications. • Inspect connection

at

generator

B+

output.

It

should

be

clean

and

tight. Repair

as

required.

GENERATOR

OUTPUT

WIRE RESISTANCE TEST

(FIG.

1)

Generator output wire resistance test will show

amount

of

voltage drop across generator output wire

between generator

BAT

terminal

and

battery posi tive post.

PREPARATION

(1) Before starting test make sure vehicle

has a

fully charged battery. Test

and

procedures

on how to

check

for a

fully charged battery

are

shown

in

Bat

tery section

of

this Group.

(2) Turn

OFF

ignition switch.

(3)

Disconnect negative cable from battery.

(4)

Disconnect generator output wire from genera

tor output Battery terminal. (5) Connect

a 0-150

ampere scale

D.C.

ammeter

in

series between generator

BAT

terminal

and

discon

nected generator output wire. Connect Positive lead

to generator

BAT

terminal

and

Negative lead

to

dis connected generator output wire. (6) Connect Positive lead

of a

test voltmeter

(Range

0-18

volts minimum)

to

disconnected genera

tor output wire. Connect negative lead

of

test voltme

ter

to

battery positive cable

at

positive post. (7) Connect

one end of a

Jumper Wire

to

ground

and with other

end

probe green

K20

lead wire

at

back

of

generator

(Fig. 1).

(This will generate

a

fault

code).

CAUTION:

Do not

connect blue

A142

lead

of

wiring

to ground. Refer

to

Group

8W

-

Wiring Diagrams

for

more information.

(8) Connect

an

engine tachometer

and

connect neg

ative cable

to

battery.

(9) Connect

a

variable carbon pile rheostat

be

tween battery terminals.

Be

sure carbon pile

is in

"Open"

or "Off

position before connecting leads.

See

Battery Section, Load Testing

for

instructions.

TEST

(1) Start engine. Immediately after starting,

re

duce engine speed

to

idle.