check engine DODGE TRUCK 1993 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 335 of 1502

8A

- 14

ELECTRICAL

CASE

GROUND

FIELD

TERMINALS

142-DG/OR

BATTERY

VOLTAGE

ALTERNATOR

CASE

GROUND

GROUND ALTERNATOR

BATTERY

TERMINAL

ENGINE

CONTROLLER TO ENGINE

CONTROLLER TERMINAL

51

LESS

THAN

"BATTERY VOLTAGE

m^mm i

A21 DB-

20

AMP FUSE

A14

RD

AUTO

SHUTDOWN

RELAY

IGNITION

SWITCH

POWER

DISTRIBUTION

CENTER

JUMPER WIRE TO GROUND TEST

AMMETER TEST

VOLTMETER

2

i

DISCONNEaED

ALTERNATOR

OUTPUT

WIRE

ACC

OFF

J938A-17

CARBON

PILE

RHEOSTAT

Fig.

1 Generator Output

Wire

Resistance

Test

(Typical)

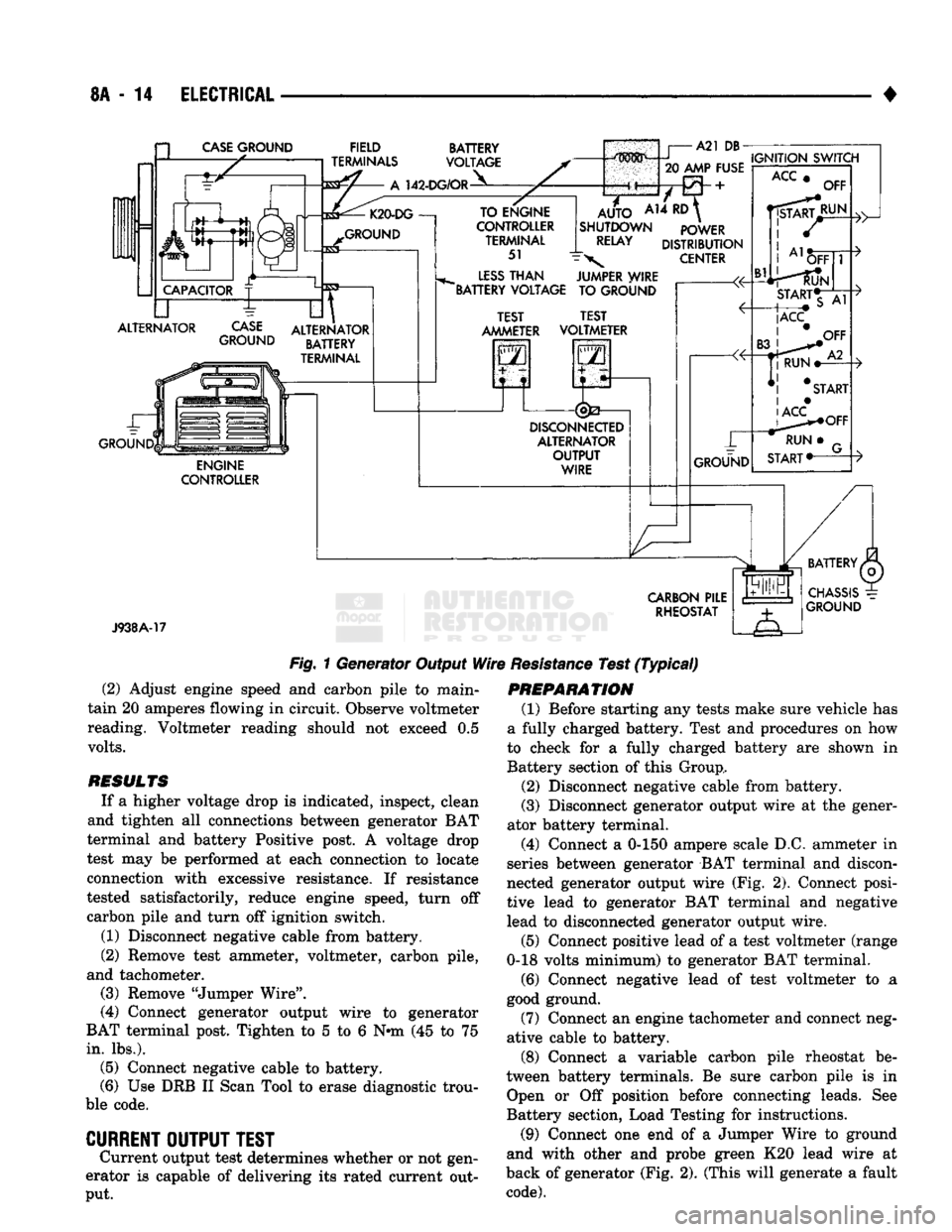

(2) Adjust engine speed and carbon pile to main

tain 20 amperes flowing in circuit. Observe voltmeter

reading. Voltmeter reading should not exceed 0.5

volts.

RESULTS

If a higher voltage drop is indicated, inspect, clean

and tighten all connections between generator BAT

terminal and battery Positive post. A voltage drop

test may be performed at each connection to locate

connection with excessive resistance. If resistance

tested satisfactorily, reduce engine speed, turn off carbon pile and turn off ignition switch.

(1) Disconnect negative cable from battery.

(2) Remove test ammeter, voltmeter, carbon pile,

and tachometer. (3) Remove "Jumper Wire".

(4) Connect generator output wire to generator

BAT terminal post. Tighten to 5 to 6 Nnn (45 to 75

in.

lbs.). (5) Connect negative cable to battery.

(6) Use DRB II Scan Tool to erase diagnostic trou

ble code.

CURRENT

OUTPUT

TEST

Current output test determines whether or not gen

erator is capable of delivering its rated current out

put.

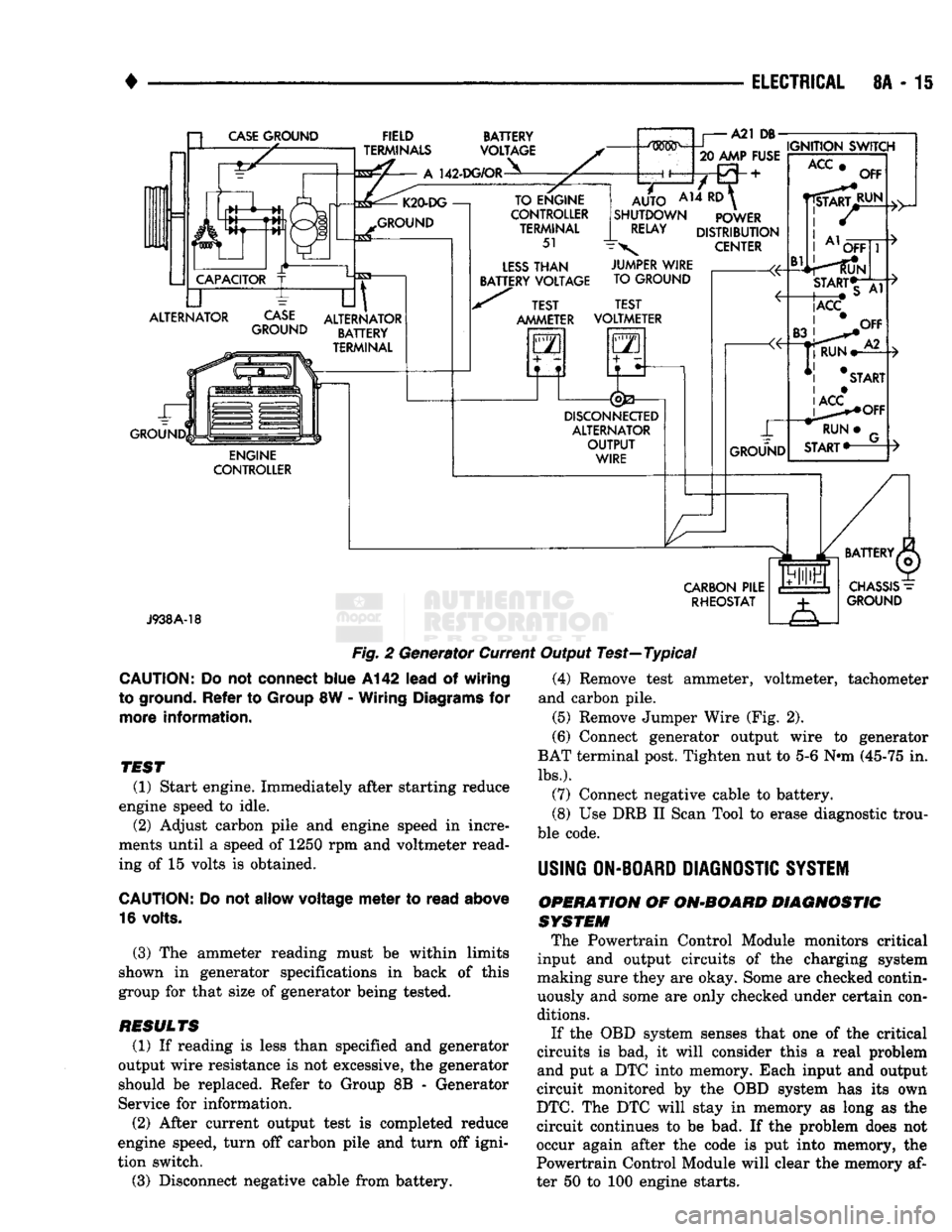

PREPARATION

(1) Before starting any tests make sure vehicle has

a fully charged battery. Test and procedures on how

to check for a fully charged battery are shown in

Battery section of this Group,

(2) Disconnect negative cable from battery.

(3) Disconnect generator output wire at the gener

ator battery terminal.

(4) Connect a 0-150 ampere scale D.C. ammeter in

series between generator BAT terminal and discon

nected generator output wire (Fig. 2). Connect posi

tive lead to generator BAT terminal and negative

lead to disconnected generator output wire.

(5) Connect positive lead of a test voltmeter (range

0-18 volts minimum) to generator BAT terminal.

(6) Connect negative lead of test voltmeter to a

good ground.

(7) Connect an engine tachometer and connect neg

ative cable to battery.

(8) Connect a variable carbon pile rheostat be

tween battery terminals. Be sure carbon pile is in Open or Off position before connecting leads. See

Battery section, Load Testing for instructions.

(9) Connect one end of a Jumper Wire to ground

and with other and probe green K20 lead wire at

back of generator (Fig. 2). (This will generate a fault

code).

Page 336 of 1502

•

ELECTRICAL

8A - 15 a

CASE

GROUND

CAPACITOR

ALTERNATOR ~L FIELD

TERMINALS

A

142-DG/OR BATTERY

VOLTAGE K20-DG

—!

GROUND

CASE

GROUND

til

ALTERNATOR BATTERY

TERMINAL ENGINE

CONTROLLER TO ENGINE

CONTROLLER TERMINAL

51

LESS

THAN

BATTERY VOLTAGE A21

DB-

.....

IGNITION SWITCH

20 AMP FUSE

AUTO

AH ^

SHUTDOWN POWER

RELAY

DISTRIBUTION

\

CENTER TEST

AMMETER JUMPER WIRE

TO GROUND

TEST

VOLTMETER

GO

5—n

DISCONNECTED

ALTERNATOR OUTPUT WIRE GROUND

ACC

Bl

OFF

RUN OFF

START*T

|ACC

CARBON

PILE RHEOSTAT

J938A-18

Fig.

2 Generator Current Output Test—Typical

CAUTION:

Do not

connect

blue

A142

lead

of

wiring

to ground.

Refer

to

Group

8W -

Wiring

Diagrams

for

more

information.

TEST

(1) Start engine. Immediately after starting reduce

engine speed to idle. (2) Adjust carbon pile and engine speed in incre

ments until a speed of 1250 rpm and voltmeter read

ing of 15 volts is obtained.

CAUTION:

Do not

allow

voltage

meter

to

read

above

16 volts.

(3) The ammeter reading must be within limits

shown in generator specifications in back of this

group for that size of generator being tested.

RESULTS

(1) If reading is less than specified and generator

output wire resistance is not excessive, the generator

should be replaced. Refer to Group 8B - Generator

Service for information.

(2) After current output test is completed reduce

engine speed, turn off carbon pile and turn off igni

tion switch.

(3) Disconnect negative cable from battery. (4) Remove test ammeter, voltmeter, tachometer

and carbon pile. (5) Remove Jumper Wire (Fig. 2).

(6) Connect generator output wire to generator

BAT terminal post. Tighten nut to 5-6 Nnn (45-75 in.

lbs.).

(7) Connect negative cable to battery.

(8) Use DRB II Scan Tool to erase diagnostic trou

ble code.

USING

ON-BOARD

DIAGNOSTIC

SYSTEM

OPERATION

OF

ON-BOARD

DIAGNOSTIC

SYSTEM

The Powertrain Control Module monitors critical

input and output circuits of the charging system

making sure they are okay. Some are checked contin

uously and some are only checked under certain con

ditions.

If the OBD system senses that one of the critical

circuits is bad, it will consider this a real problem

and put a DTC into memory. Each input and output

circuit monitored by the OBD system has its own

DTC.

The DTC will stay in memory as long as the

circuit continues to be bad. If the problem does not

occur again after the code is put into memory, the

Powertrain Control Module will clear the memory af

ter 50 to 100 engine starts.

Page 338 of 1502

•

ELECTRICAL

8A - 17

DIAGNOSTIC

TROUBLE

CODES

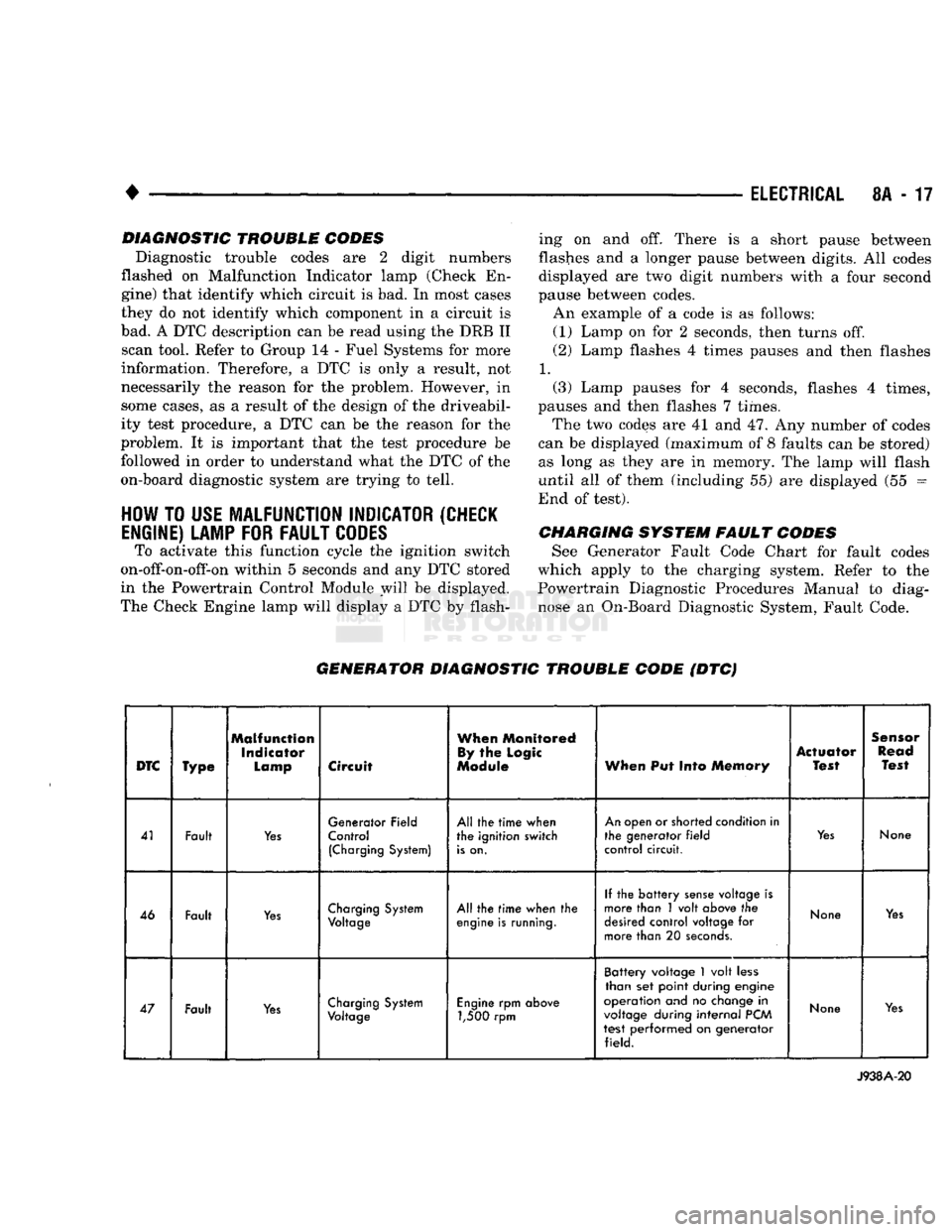

Diagnostic trouble codes are 2 digit numbers

flashed on Malfunction Indicator lamp (Check En

gine) that identify which circuit is bad. In most cases

they do not identify which component in a circuit is

bad. A DTC description can be read using the DRB II scan tool. Refer to Group 14 - Fuel Systems for more

information. Therefore, a DTC is only a result, not

necessarily the reason for the problem. However, in

some cases, as a result of the design of the driveabil- ity test procedure, a DTC can be the reason for the

problem. It is important that the test procedure be followed in order to understand what the DTC of the

on-board diagnostic system are trying to tell.

HOW

TO

USE

MALFUNCTION

INDICATOR

(CHECK

ENGINE)

LAMP

FOR

FAULT

CODES

To activate this function cycle the ignition switch

on-off-on-off-on within 5 seconds and any DTC stored

in the Powertrain Control Module will be displayed.

The Check Engine lamp will display a DTC by flash ing on and off. There is a short pause between

flashes and a longer pause between digits. All codes

displayed are two digit numbers with a four second

pause between codes. An example of a code is as follows:

(1) Lamp on for 2 seconds, then turns off.

(2) Lamp flashes 4 times pauses and then flashes

1.

(3) Lamp pauses for 4 seconds, flashes 4 times,

pauses and then flashes 7 times.

The two codes are 41 and 47. Any number of codes

can be displayed (maximum of 8 faults can be stored) as long as they are in memory. The lamp will flash

until all of them (including 55) are displayed (55 =

End of test).

CHARGING

SYSTEM

FAULT

CODES

See Generator Fault Code Chart for fault codes

which apply to the charging system. Refer to the

Powertrain Diagnostic Procedures Manual to diag

nose an On-Board Diagnostic System, Fault Code.

GENERATOR

DIAGNOSTIC

TROUBLE

CODE

(DTC)

DTC

Type

Malfunction

Indicator

Lamp

Circuit

When

Monitored

By

the

Logic

Module

When

Put Into

Memory

Actuator

Test

Sensor

Read

Test

41 Fault

Yes

Generator Field

Control

(Charging

System)

All the

time

when

the ignition switch

is

on.

An

open or shorted condition in

the generator

field

control circuit.

Yes

None

46 Fault

Yes

Charging

System

Voltage

All the

time

when the

engine

is

running.

If the

battery

sense

voltage is

more than 1 volt

above

the

desired

control voltage for

more than 20

seconds.

None

Yes

47 Fault

Yes

Charging

System

Voltage

Engine

rpm

above

1,500 rpm Battery voltage

1

volt

less

than set point during engine

operation and no

change

in

voltage

during

internal

PCM

test performed on generator field.

None

Yes

J938A-20

Page 348 of 1502

•

Fig.

3

Remove

or install

Wire

Connector

Assembly

CAUTION:

When

installing

serpentine

accessory

drive

belt,

the

belt

MUST

be

routed

correctly.

If not,

the engine may overheat due to the

water

pump ro

tating

in the wrong

direction.

Refer to Group 7 -

Cooling

System

for

correct

engine

belt

routing.

The

correct

belt

with

the

correct

length

must be

used

(3) Position drive belt over all pulleys except the

idler pulley. This pulley is located between the gen

erator and A/C compressor.

(4) Attach a socket/wrench to pulley mounting bolt

of the automatic tensioner (Fig. 1).

(5)

Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place. Re

move wrench. Be sure belt is properly seated on all

pulleys.

(6) Check belt indexing marks. Refer to Group 7 -

Cooling, Automatic Belt Tensioner.

(7) Connect negative cable to battery.

GENERATOR

REPLACEMENT—5.9L

HDC-GAS

ENGINE

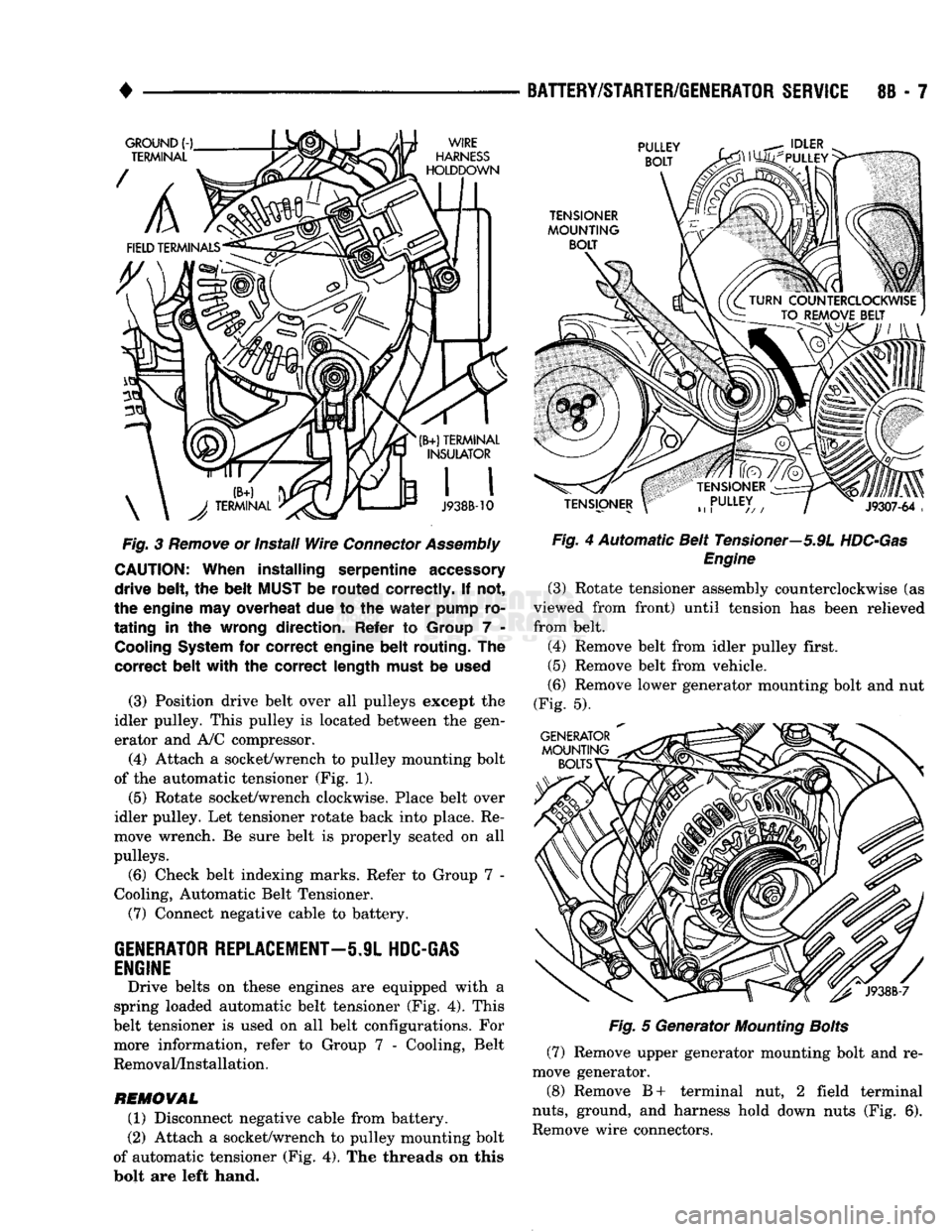

Drive belts on these engines are equipped with a

spring loaded automatic belt tensioner (Fig. 4). This

belt tensioner is used on all belt configurations. For more information, refer to Group 7 - Cooling, Belt

Removal/Installation.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 4). The threads on this

bolt are left hand.

BATTERY/STARTER/GENERATOR

SERVICE

8B - 7

Fig.

4 Automatic Belt Tensioner—5.9L

HDC-Gas

Engine

(3) Rotate tensioner assembly counterclockwise (as

viewed from front) until tension has been relieved

from belt.

(4) Remove belt from idler pulley first.

(5) Remove belt from vehicle.

(6) Remove lower generator mounting bolt and nut

(Fig. 5).

Fig.

5 Generator

Mounting

Bolts

(7) Remove upper generator mounting bolt and re

move generator.

(8) Remove B+ terminal nut, 2 field terminal

nuts,

ground, and harness hold down nuts (Fig. 6).

Remove wire connectors.

Page 358 of 1502

•

IGNITION

SYSTEMS

80 - 7

DIAGNOSTICS/SERW1CE

PROCEDURES

INDEX

page

Automatic Shut Down (ASD) Relay

7

Camshaft Position

Sensor

Test

...............

7

Crankshaft Position

Sensor

Test

8

Distributor

Cap

8

Distributor

Rotor

8

Engine

Coolant Temperature

Sensor

Test

10

General

Information

7

Ignition

Coil

8

Ignition

Secondary

Circuit

Diagnosis

10

GENERAL

INFORMATION

This section

of the

group, Diagnostics/Service Pro

cedures, will discuss basic ignition system diagnos

tics

and

service adjustments. For system operation

and

component identification,

refer

to the

Component Identification/System Opera

tion section

of

this group. For removal

or

installation

of

ignition system com

ponents, refer

to the

Component Removal/Installa

tion section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

AUTOMATIC SHUT DOWN

(ASD)

RELAY

Refer

to

Relays—Operation/Testing

in the

Group

14,

Fuel System section

of

this service manual.

CAMSHAFT POSITION SENSOR TEST

The camshaft position sensor

is

located

in the

dis

tributor

on all

engines. To perform

a

complete test

of

this sensor

and its

circuitry, refer

to the DRB II

diagnostic scan tool.

Also refer

to the

appropriate Powertrain Diagnostics

Procedures manual.

To

test

the

sensor only, refer

to

the following: For this test,

an

analog (non-digital) voltmeter

is needed.

Do not

remove

the

distributor connector from

the

distributor. Using small paper clips, insert

them into

the

backside

of the

distributor wire har ness connector

to

make contact with

the

terminals.

Be sure that

the

connector

is not

damaged when

in

serting

the

paper clips. Attach voltmeter leads

to

these paper clips. (1) Connect

the

positive (

+

)

voltmeter lead into

the sensor output wire. This

is at

done

the

distribu tor wire harness connector.

For

wire identification,

refer

to

Group

8W,

Wiring Diagrams.

page

Ignition

Timing

12

Intake Manifold Charge

Air

Temperature

Sensor

Test

12

Manifold Absolute Pressure (MAP)

Sensor

Test

. 12

Oxygen

Sensor

Tests

17

Powertrain Control Module (PCM)

............

14

Spark

Plug Secondary Cables

16

Spark

Plugs

............................

14

Throttle

Position

Sensor

Test

17

(2) Connect

the

negative

(-)

voltmeter lead into

the

ground wire.

For

wire identification, refer

to

Group

8W, Wiring Diagrams.

(3)

Set the

voltmeter

to the 15

Volt

DC

scale. (4) Remove distributor

cap

from distributor

(two

screws). Rotate (crank)

the

engine until

the

distribu

tor rotor

is

pointed towards

the

rear

of

vehicle.

The

movable pulse ring should

now be

within

the

sensor

pickup.

(5) Turn ignition

key to ON

position. Voltmeter

should read approximately

5.0

volts.

(6)

If

voltage

is not

present, check

the

voltmeter

leads

for a

good connection.

(7)

If

voltage

is

still

not

present, check

for

voltage

at

the

supply wire.

For

wire identification, refer

to

Group

8W,

Wiring Diagrams.

(8)

If

voltage

is not

present

at

supply wire, check

for voltage

at

pin-7

of

powertrain control module (PCM) 60-way connector. Leave

the PCM

connector

connected

for

this test. (9)

If

voltage

is

still

not

present, perform vehicle

test using

the DRB II

diagnostic scan tool. (10)

If

voltage

is

present

at

pin-7,

but not at the

supply wire: (a) Check continuity between

the

supply wire.

This

is

checked between

the

distributor connector and pin-7

at the PCM. If

continuity

is not

present,

repair

the

harness

as

necessary. (b) Check

for

continuity between

the

camshaft

position sensor output wire

and

pin-44

at the PCM.

If continuity

is not

present, repair

the

harness

as

necessary. (c) Check

for

continuity between

the

ground cir

cuit wire

at the

distributor connector

and

ground.

If continuity

is not

present, repair

the

harness

as

necessary. (11) While observing

the

voltmeter, crank

the en

gine with ignition switch.

The

voltmeter needle should fluctuate between

0 and 5

volts while

the en

gine

is

cranking. This verifies that

the

camshaft

po

sition sensor

in the

distributor

is

operating properly

and

a

sync pulse signal

is

being generated.

Page 360 of 1502

•

IGNITION

SYSTEMS

80 - 9

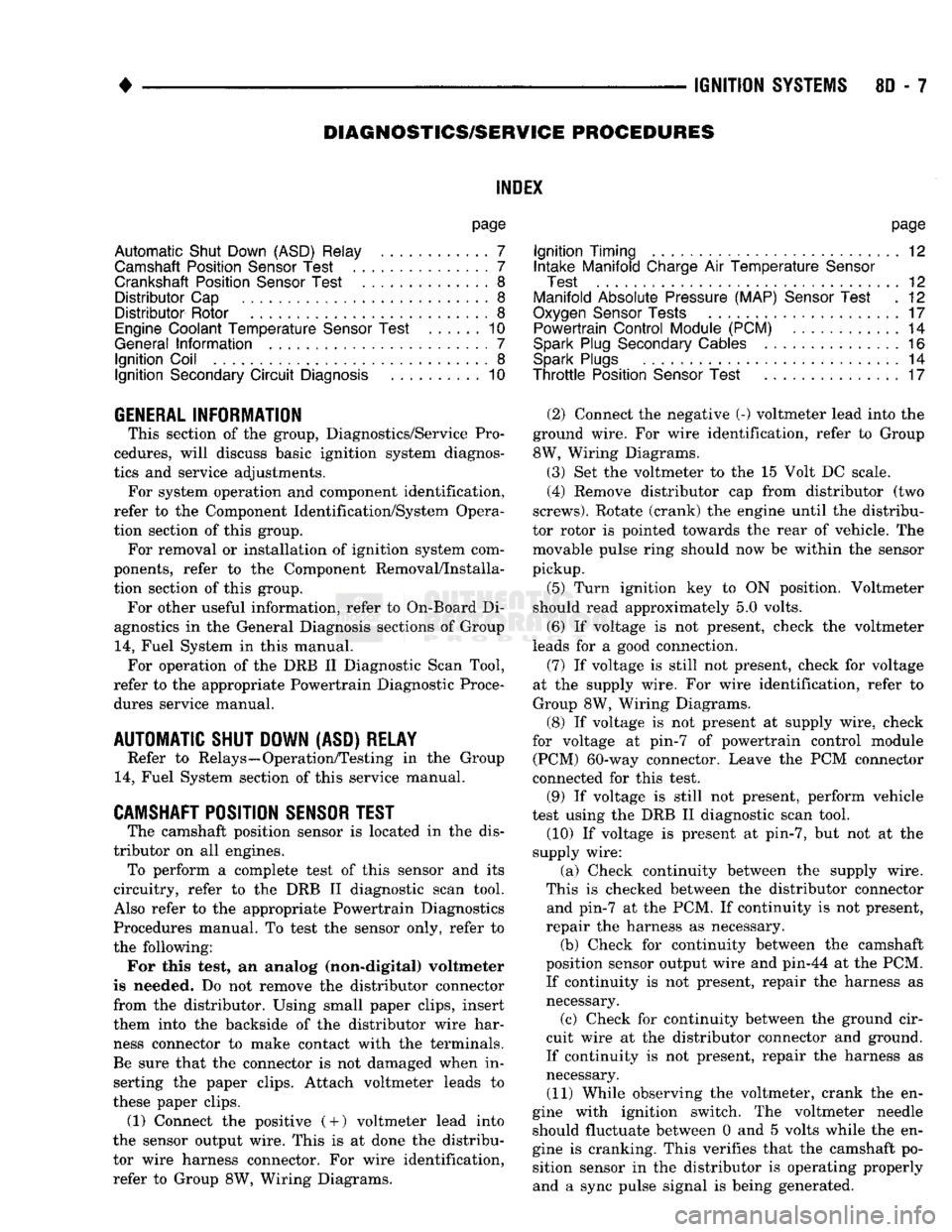

Fig.

4 Cap Inspection—internal—Typical

INSUFFICIENT

SPRING

TENSION

CORRODED

EVIDENCE

OF

PHYSICAL

CONTACT

WITH

CAP

J908D-48

Fig.

5 Rotor Inspection—Typical

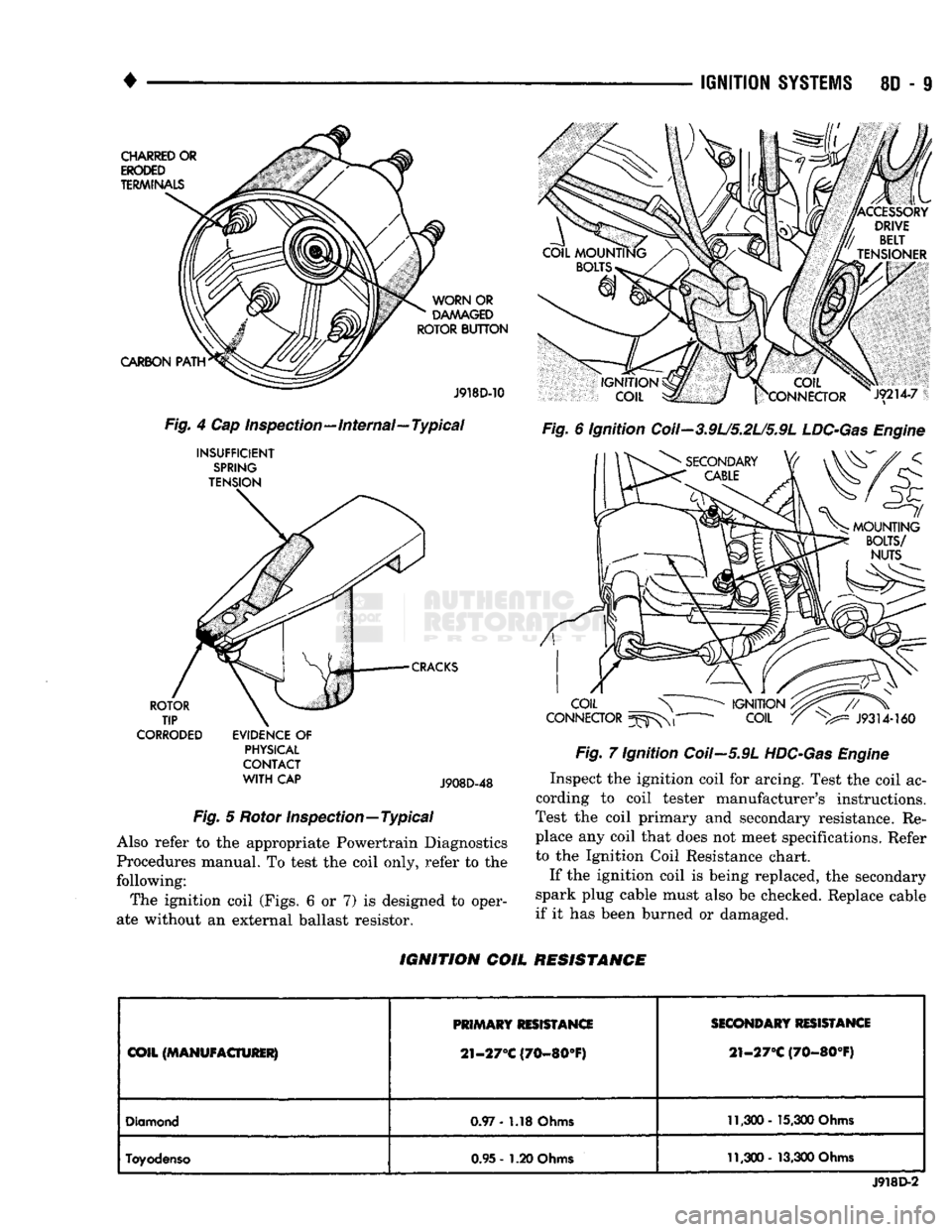

Also refer to the appropriate Powertrain Diagnostics

Procedures manual. To test the coil only, refer to the

following:

The ignition coil (Figs. 6 or 7) is designed to oper

ate without an external ballast resistor.

Fig.

6 Ignition Coil-3.9U5.2U5.9L

LDC-Gas

Engine

Fig.

7 Ignition Coil—5.9L

HDC-Gas

Engine

Inspect the ignition coil for arcing. Test the coil ac

cording to coil tester manufacturer's instructions.

Test the coil primary and secondary resistance. Re

place any coil that does not meet specifications. Refer

to the Ignition Coil Resistance chart.

If the ignition coil is being replaced, the secondary

spark plug cable must also be checked. Replace cable

if it has been burned or damaged.

IGNITION

COIL RESISTANCE

PRIMARY RESISTANCE SECONDARY RESISTANCE

COIL

(MANUFACTURER)

2!-27°C (70-80°F)

21-27°C

(70-80°F)

Diamond

0.97 - 1.18

Ohms

11,300-

15,300

Ohms

Toyodenso

0.95- 1.20

Ohms

11,300-

13,300

Ohms

J918D-2

Page 361 of 1502

8D

- 10

IGNITION

SYSTEMS

• Arcing at the tower will carbonize the cable boot,

which if it is connected to a new ignition coil, will cause the coil to fail. If the secondary coil cable shows any signs of dam

age,

it should be replaced with a new cable and new

terminal. Carbon tracking on the old cable can cause

arcing and the failure of a new ignition coil.

ENGINE

COOLANT

TEMPERATURE

SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB II diagnostic scan tool.

Also refer to the appropriate Powertrain Diagnostics

Procedures manual. To test the sensor only, refer to

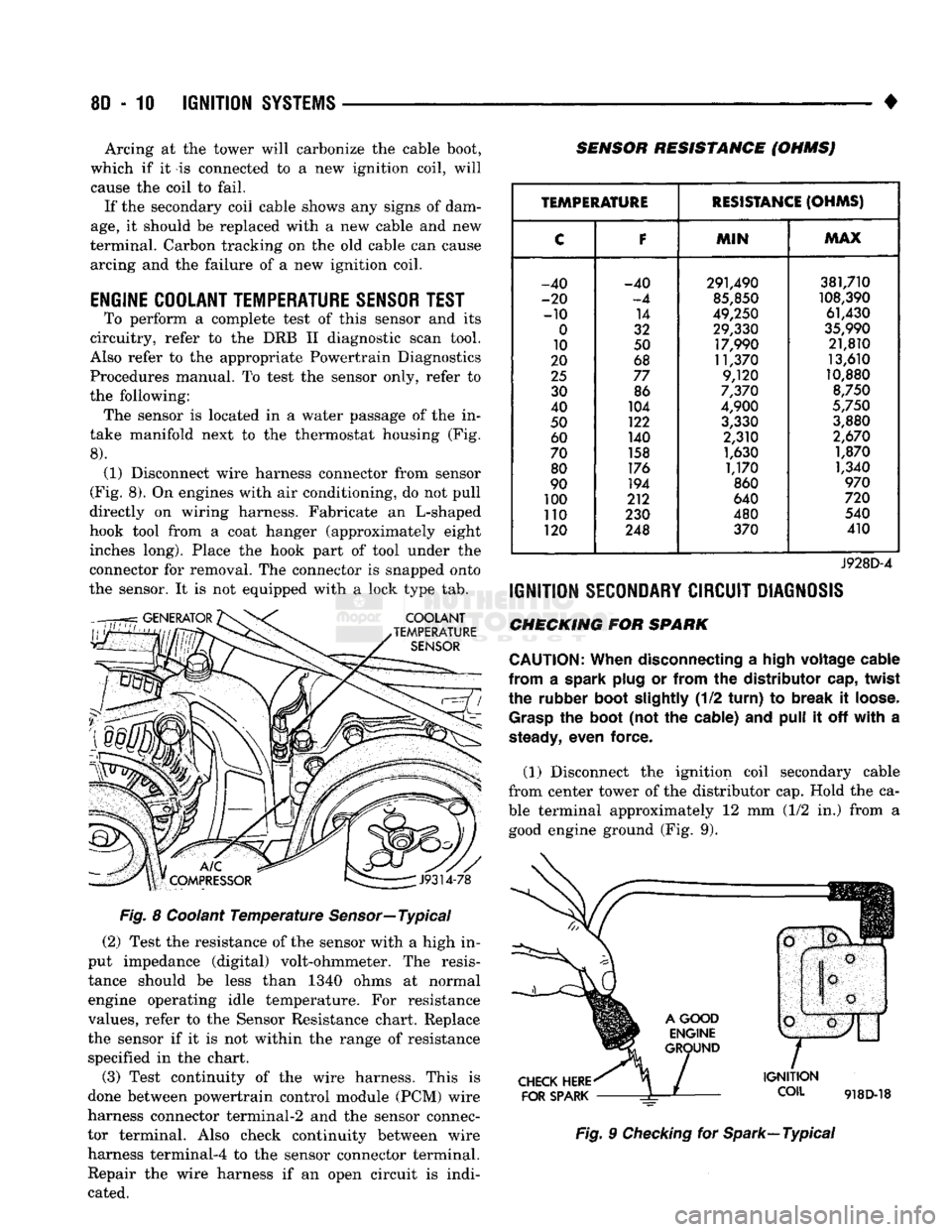

the following: The sensor is located in a water passage of the in

take manifold next to the thermostat housing (Fig.

8).

(1) Disconnect wire harness connector from sensor

(Fig. 8). On engines with air conditioning, do not pull

directly on wiring harness. Fabricate an L-shaped

hook tool from a coat hanger (approximately eight inches long). Place the hook part of tool under the

connector for removal. The connector is snapped onto

the sensor. It is not equipped with a lock type tab.

COOLANT

TEMPERATURE

SENSOR

SENSOR RESISTANCE (OHMSJ

V

J9314-78

Fig. 8 Coolant Temperature Sensor—Typical (2) Test the resistance of the sensor with a high in

put impedance (digital) volt-ohmmeter. The resis tance should be less than 1340 ohms at normal

engine operating idle temperature. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance specified in the chart.

(3) Test continuity of the wire harness. This is

done between powertrain control module (PCM) wire

harness connector terminal-2 and the sensor connec

tor terminal. Also check continuity between wire harness terminal-4 to the sensor connector terminal. Repair the wire harness if an open circuit is indi

cated.

TEMPERATURE

RESISTANCE

(OHMS)

C

F

MIN

MAX

-40 -40 291,490 381,710

-20

-4

85,850

108,390

-10 14

49,250 61,430

0

32 29,330

35,990

10 50 17,990 21,810

20 68 11,370 13,610

25

77 9,120 10,880

30 86

7,370

8,750

40 104

4,900

5,750

50 122

3,330 3,880

60 140 2,310

2,670

70 158

1,630 1,870

80 176

1,170 1,340

90 194

860

970

100 212 640

720

110 230 480 540

120 248 370 410

J928D-4

IGNITION

SECONDARY

CIRCUIT

DIAGNOSIS

CHECKING FOR SPARK

CAUTION:

When

disconnecting a

high

voltage

cable

from

a spark

plug

or

from

the

distributor

cap,

twist

the rubber

boot

slightly

(1/2

turn)

to

break

it

loose.

Grasp

the

boot

(not the cable) and

pull

it off

with

a

steady,

even force.

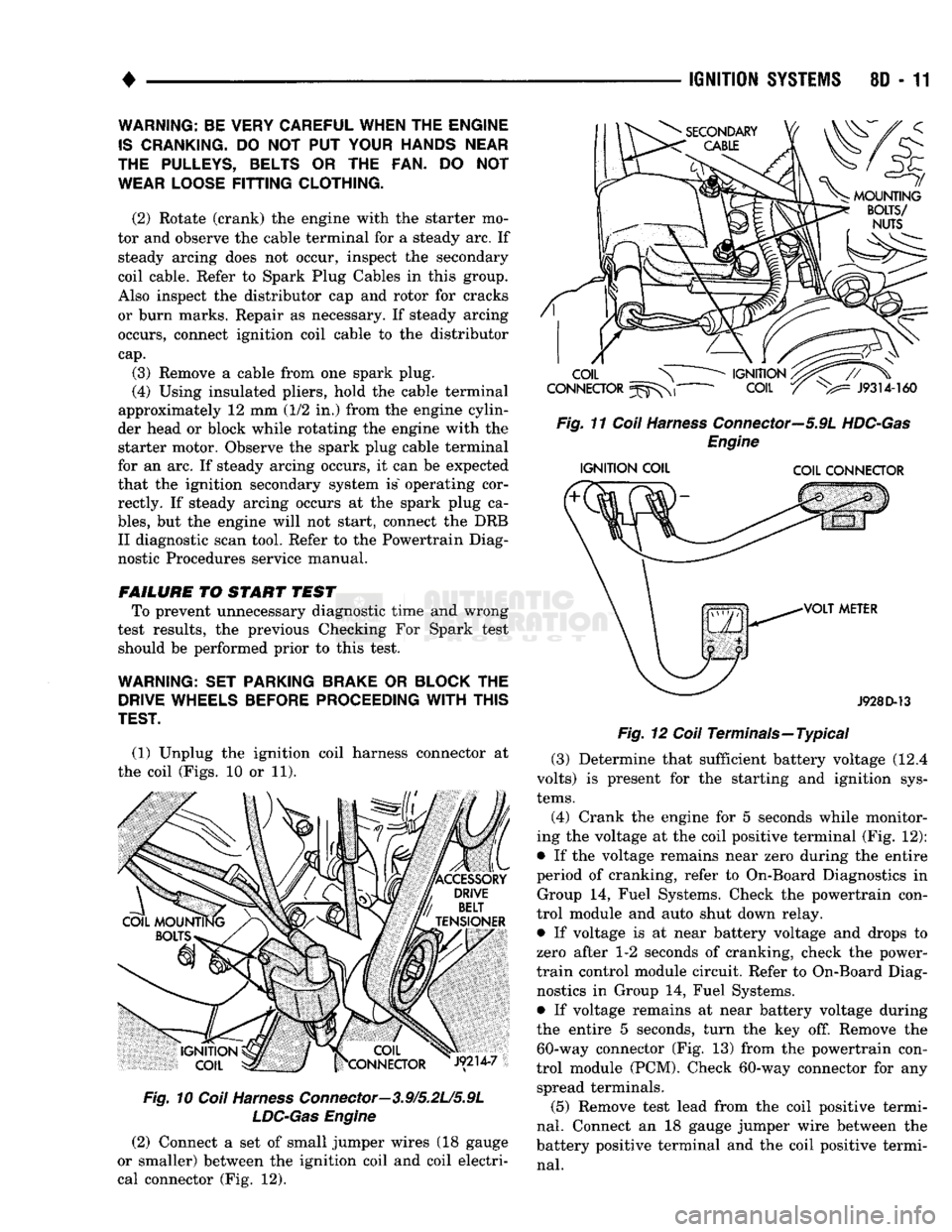

(1) Disconnect the ignition coil secondary cable

from center tower of the distributor cap. Hold the ca

ble terminal approximately 12 mm (1/2 in.) from a good engine ground (Fig. 9).

CHECK

HERE

FOR

SPARK

IGNITION

COIL

918D-18

Fig. 9 Checking for Spark—Typical

Page 362 of 1502

*

(1) Unplug the ignition coil harness connector at

the coil (Figs. 10 or 11).

Fig.

10

Coil

Harness

Connector—3.9/5.2L/5.9L

LDC-Gas

Engine

(2) Connect a set of small jumper wires (18 gauge

or smaller) between the ignition coil and coil electri

cal connector (Fig. 12).

IGNITION

SYSTEMS

80 - 11

Fig.

11

Coil

Harness

Connector—5.9L

HDC-Gas

Engine

IGNITION

COIL COIL CONNECTOR

J928D-13

Fig.

12

Coil

Terminals—Typical (3) Determine that sufficient battery voltage (12.4

volts) is present for the starting and ignition sys

tems.

(4) Crank the engine for 5 seconds while monitor

ing the voltage at the coil positive terminal (Fig. 12):

• If the voltage remains near zero during the entire

period of cranking, refer to On-Board Diagnostics in Group 14, Fuel Systems. Check the powertrain con

trol module and auto shut down relay.

• If voltage is at near battery voltage and drops to

zero after 1-2 seconds of cranking, check the power-

train control module circuit. Refer to On-Board Diag nostics in Group 14, Fuel Systems.

• If voltage remains at near battery voltage during

the entire 5 seconds, turn the key off. Remove the 60-way connector (Fig. 13) from the powertrain con

trol module (PCM). Check 60-way connector for any spread terminals.

(5) Remove test lead from the coil positive termi

nal.

Connect an 18 gauge jumper wire between the

battery positive terminal and the coil positive termi

nal.

WARNING: BE VERY CAREFUL WHEN THE ENGINE

IS

CRANKING.

DO NOT PUT

YOUR HANDS NEAR

THE PULLEYS, BELTS

OR THE FAN. DO NOT

WEAR LOOSE

FITTING

CLOTHING.

(2) Rotate (crank) the engine with the starter mo

tor and observe the cable terminal for a steady arc. If steady arcing does not occur, inspect the secondary

coil cable. Refer to Spark Plug Cables in this group.

Also inspect the distributor cap and rotor for cracks

or burn marks. Repair as necessary. If steady arcing occurs, connect ignition coil cable to the distributor

cap.

(3) Remove a cable from one spark plug.

(4) Using insulated pliers, hold the cable terminal

approximately 12 mm (1/2 in.) from the engine cylin

der head or block while rotating the engine with the starter motor. Observe the spark plug cable terminal

for an arc. If steady arcing occurs, it can be expected

that the ignition secondary system is" operating cor rectly. If steady arcing occurs at the spark plug ca

bles,

but the engine will not start, connect the DRB II diagnostic scan tool. Refer to the Powertrain Diag

nostic Procedures service manual.

FAILURE

TO START TEST To prevent unnecessary diagnostic time and wrong

test results, the previous Checking For Spark test should be performed prior to this test.

WARNING: SET PARKING BRAKE

OR

BLOCK

THE

DRIVE WHEELS BEFORE PROCEEDING

WITH

THIS

TEST.

Page 363 of 1502

8D

- 12

IGNITION

SYSTEMS

•

XX

oooooooooo

,0000000000

\2141

3%

lOOOOOOOOOO

OOOOOOOOOO

si

20

fcji^OQOOOOOOJ

«r

~

• • -

•

- - #

•oooooooooo.

CONNECTOR

TERMINAL

SIDE

SHOWN

J908D-42

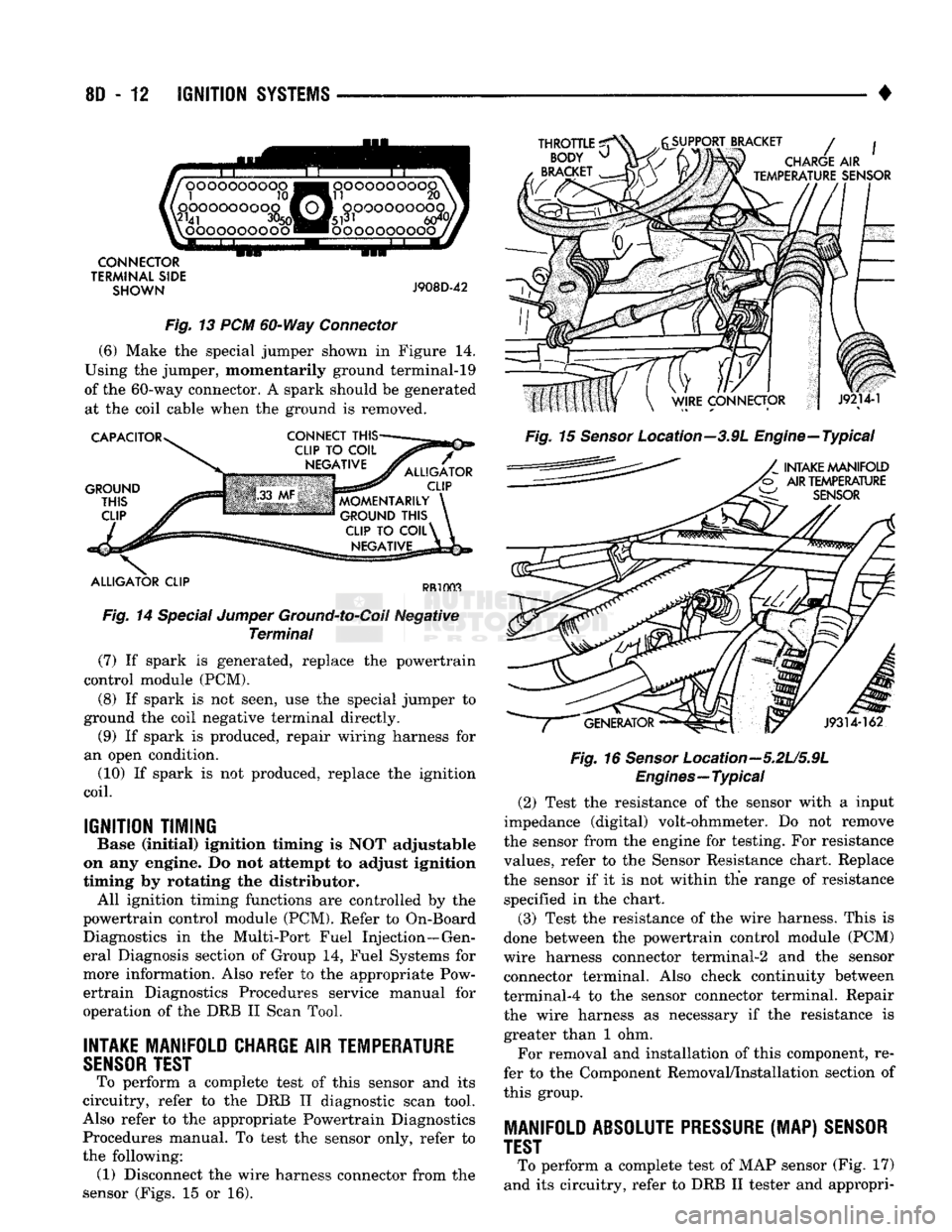

Fig. 13 PCM 60-Way Connector

(6) Make the special jumper shown in Figure 14.

Using the jumper, momentarily ground terminal-19

of the 60-way connector. A spark should be generated at the coil cable when the ground is removed.

CAPACITOR

GROUND

THIS

CLIP

CONNECT

THIS-

ALLIGATOR

CLIP

MOMENTARILY

GROUND

THIS

CLIP

TO

COIL^

NEGATIVE

ALLIGATOR

CLIP

PR1003

Fig. 14 Special Jumper Ground-to-Coil Negative Terminal (7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly. (9) If spark is produced, repair wiring harness for

an open condition. (10) If spark is not produced, replace the ignition

coil.

IGNITION TIMING

Base (Initial) ignition timing Is NOT adjustable

on any engine. Do not attempt to adjust Ignition

timing by rotating the distributor. All ignition timing functions are controlled by the

powertrain control module (PCM). Refer to On-Board Diagnostics in the Multi-Port Fuel Injection—Gen

eral Diagnosis section of Group 14, Fuel Systems for

more information. Also refer to the appropriate Pow ertrain Diagnostics Procedures service manual for

operation of the DRB II Scan Tool.

INTAKE

MANIFOLD

CHARGE

AIR

TEMPERATURE

SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB II diagnostic scan tool.

Also refer to the appropriate Powertrain Diagnostics Procedures manual. To test the sensor only, refer to

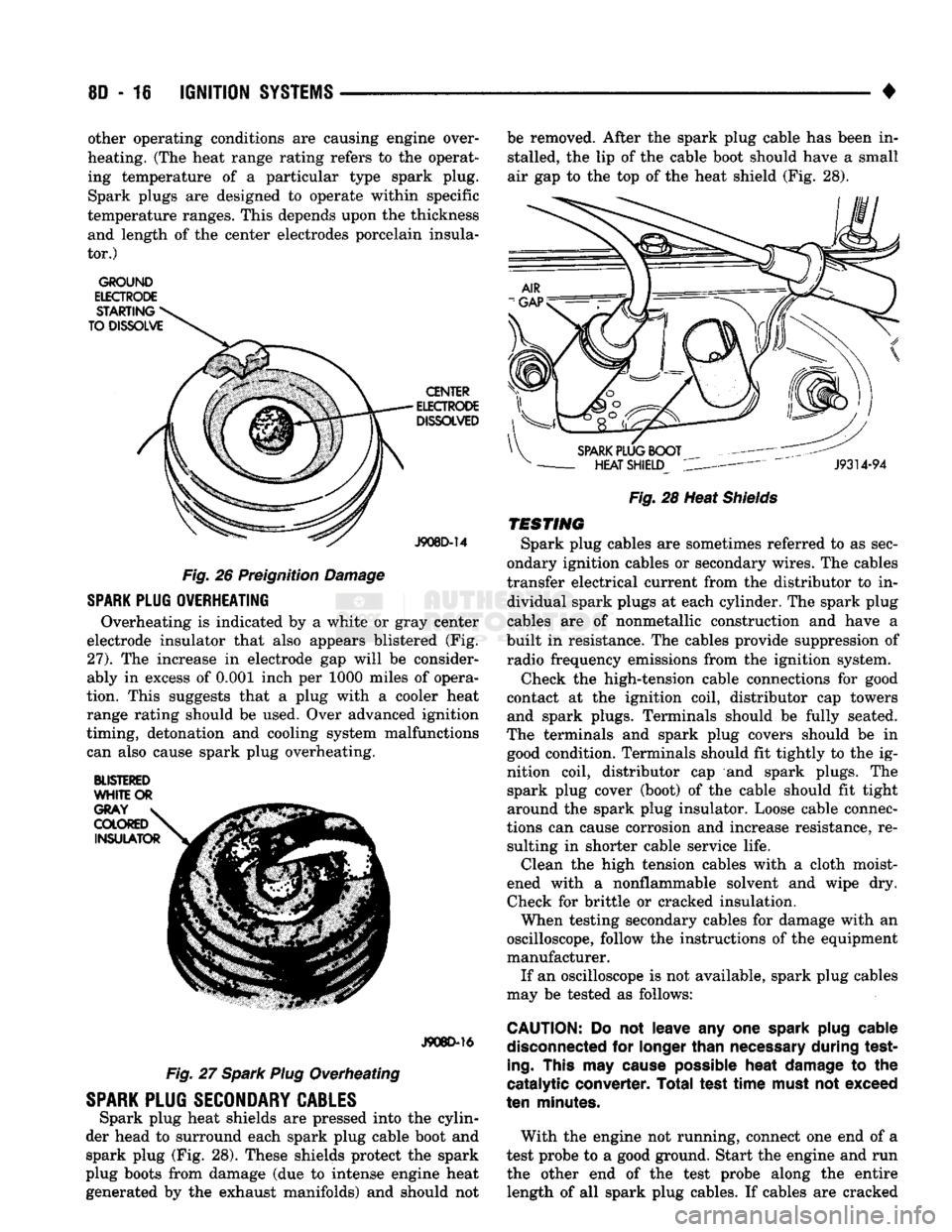

the following: (1) Disconnect the wire harness connector from the

sensor (Figs. 15 or 16).

THROTTLE

^

BODY

^

BRACKET

SUPPORT BRACKET

/

CHARGE

AIR

TEMPERATURE

SENSOR

Fig. 15 Sensor Location--3.9L Engine—Typical

INTAKE

MANIFOLD

AIR

TEMPERATURE

W

SENSOR

J9314-162

Fig. 16

Sensor

Location—5.2U5.9L

Engines—Typical

(2) Test the resistance of the sensor with a input

impedance (digital) volt-ohmmeter. Do not remove

the sensor from the engine for testing. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance specified in the chart.

(3) Test the resistance of the wire harness. This is

done between the powertrain control module (PCM)

wire harness connector terminal-2 and the sensor connector terminal. Also check continuity between

terminal-4 to the sensor connector terminal. Repair

the wire harness as necessary if the resistance is greater than 1 ohm.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD

ABSOLUTE PRESSURE

(MAP)

SENSOR

TEST

To perform a complete test of MAP sensor (Fig. 17)

and its circuitry, refer to DRB II tester and appropri-

Page 367 of 1502

8D

- 16

IGNITION

SYSTEMS

• other operating conditions are causing engine over

heating. (The heat range rating refers to the operat

ing temperature of a particular type spark plug.

Spark plugs are designed to operate within specific

temperature ranges. This depends upon the thickness and length of the center electrodes porcelain insula

tor.)

GROUND

ELECTRODE

CENTER

ELECTRODE

DISSOLVED

J908D-14 Fig. 26 Preignition Damage

SPARK

PLUG

OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

27).

The increase in electrode gap will be consider

ably in excess of 0.001 inch per 1000 miles of opera

tion. This suggests that a plug with a cooler heat

range rating should be used. Over advanced ignition

timing, detonation and cooling system malfunctions can also cause spark plug overheating.

BLISTERED

WHITE

OR

J908D-16

Fig. 27 Spark Plug Overheating

SPARK

PLUG

SECONDARY

CABLES

Spark plug heat shields are pressed into the cylin

der head to surround each spark plug cable boot and spark plug (Fig. 28). These shields protect the spark

plug boots from damage (due to intense engine heat

generated by the exhaust manifolds) and should not be removed. After the spark plug cable has been in

stalled, the lip of the cable boot should have a small

air gap to the top of the heat shield (Fig. 28).

Fig.

28 Heat

Shields

TESTING

Spark plug cables are sometimes referred to as sec

ondary ignition cables or secondary wires. The cables

transfer electrical current from the distributor to in dividual spark plugs at each cylinder. The spark plug

cables are of nonmetallic construction and have a

built in resistance. The cables provide suppression of radio frequency emissions from the ignition system.

Check the high-tension cable connections for good

contact at the ignition coil, distributor cap towers and spark plugs. Terminals should be fully seated.

The terminals and spark plug covers should be in good condition. Terminals should fit tightly to the ig

nition coil, distributor cap and spark plugs. The spark plug cover (boot) of the cable should fit tight

around the spark plug insulator. Loose cable connec

tions can cause corrosion and increase resistance, re sulting in shorter cable service life. Clean the high tension cables with a cloth moist

ened with a nonflammable solvent and wipe dry.

Check for brittle or cracked insulation. When testing secondary cables for damage with an

oscilloscope, follow the instructions of the equipment

manufacturer. If an oscilloscope is not available, spark plug cables

may be tested as follows:

CAUTION:

Do not leave any one

spark

plug

cable

disconnected

for

longer

than

necessary

during test

ing.

This

may

cause

possible

heat

damage

to the

catalytic converter. Total test

time

must

not exceed

ten

minutes.

With the engine not running, connect one end of a

test probe to a good ground. Start the engine and run the other end of the test probe along the entire length of all spark plug cables. If cables are cracked