check engine DODGE TRUCK 1993 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 290 of 1502

•

COOLING

SYSTEM

7-11

MOUNT.

BOLT

3/8

SQUARE

HOLE

ACCESSORY

DRIVE

BELT AUTOMATIC

BELT

TENSIONER

J9307-59

Fig.

12

Water

Pump—5.91

Diesel

o ~ " o

rSCREW

(2) v '^ov XN

nJ9107-5N

Fig.

13

Pump

Removal/Installation—5.9L

Diesel

O-RING

SEAL

WATER

PUMP

GROOVE

J9107-6

Fig.

14

Pump

O-ring Seal—5.9L

Diesel

(3) Install accessory drive belt. Refer to the Engine

Accessory Drive Belt section of this group.

(4) Fill cooling system. Refer to Refilling Cooling

System in this section.

(5) Connect battery cable. (6) Start and warm the engine. Check for leaks.

WATER PUMP

BYPASS

HOSE-ALL GAS POWERED ENGINES

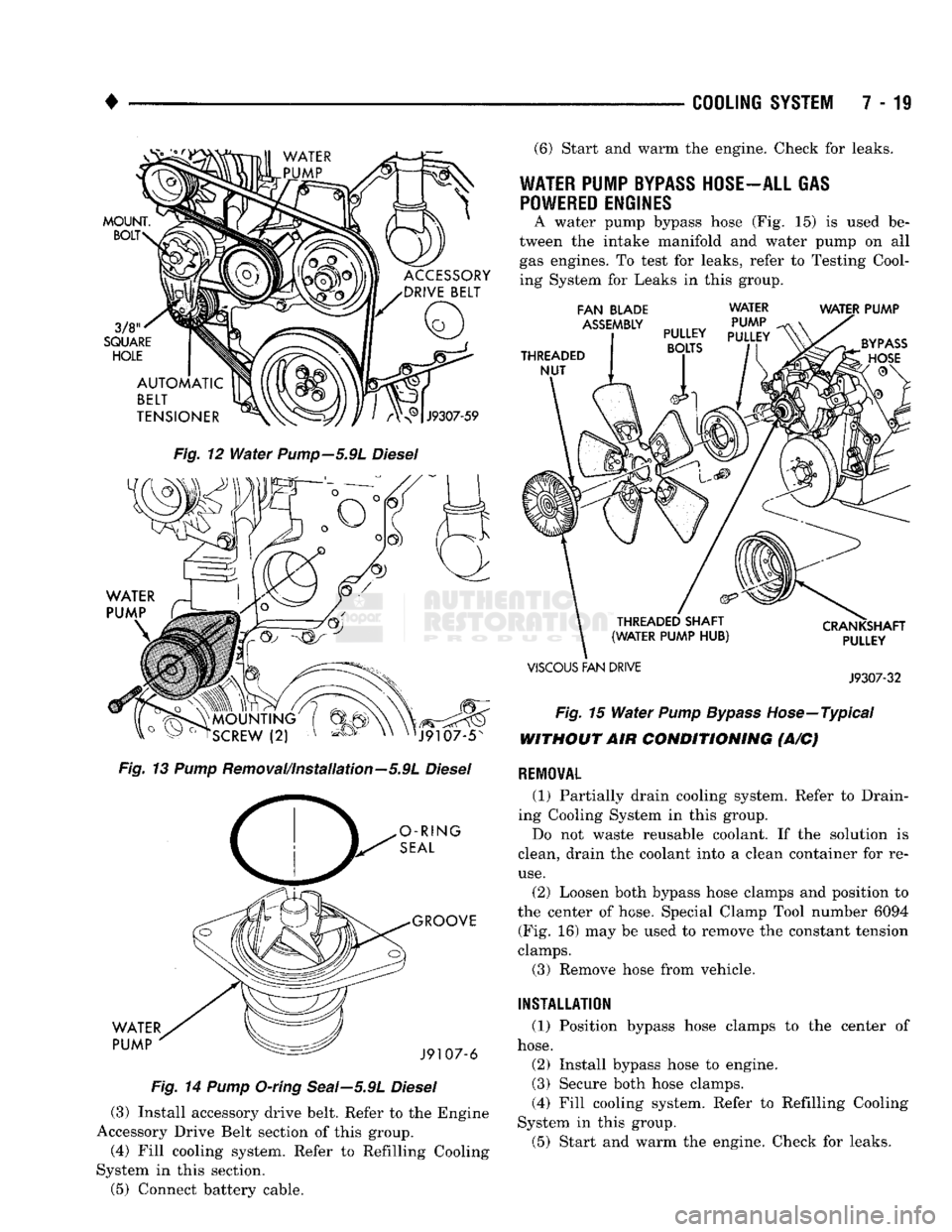

A water pump bypass hose (Fig. 15) is used be

tween the intake manifold and water pump on all gas engines. To test for leaks, refer to Testing Cool

ing System for Leaks in this group.

FAN

BLADE

ASSEMBLY

THREADED

NUT

WATER

PUMP

PULLEY

PULLEY BOLTS WATER PUMP

THREADED SHAFT

(WATER PUMP

HUB)

VISCOUS

FAN DRIVE CRANKSHAFT

PULLEY

J9307-32

Fig.

15

Water

Pump Bypass

Hose—Typical

WITHOUT AIR CONDITIONING (A/C)

RE10WAL

(1) Partially drain cooling system. Refer to Drain

ing Cooling System in this group.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for re

use.

(2) Loosen both bypass hose clamps and position to

the center of hose. Special Clamp Tool number 6094 (Fig. 16) may be used to remove the constant tension

clamps.

(3) Remove hose from vehicle.

INSTALLATION

(1) Position bypass hose clamps to the center of

hose.

(2) Install bypass hose to engine.

(3) Secure both hose clamps.

(4) Fill cooling system. Refer to Refilling Cooling

System in this group.

(5) Start and warm the engine. Check for leaks.

Page 293 of 1502

7 - 22

COOLING

SYSTEM

•

Fig.

23 Bracket

Bolts—5.9L

HDC-Gas Engine

(2) Install bypass hose to engine.

(3) Secure both hose clamps.

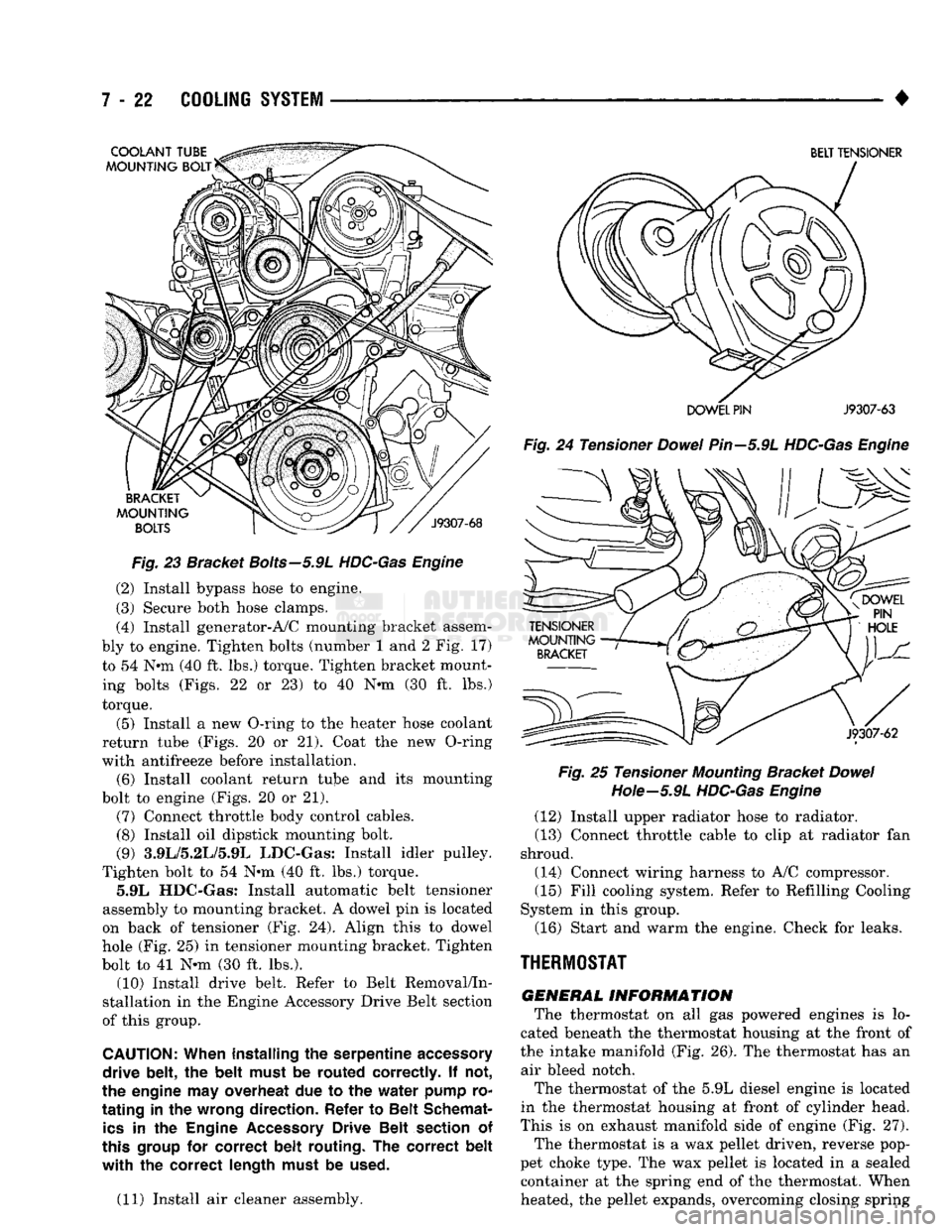

(4) Install generator-A/C mounting bracket assem

bly to engine. Tighten bolts (number 1 and 2 Fig. 17)

to 54 Nnn (40 ft. lbs.) torque. Tighten bracket mount ing bolts (Figs. 22 or 23) to 40 N-m (30 ft. lbs.)

torque.

(5) Install a new O-ring to the heater hose coolant

return tube (Figs. 20 or 21). Coat the new O-ring

with antifreeze before installation. (6) Install coolant return tube and its mounting

bolt to engine (Figs. 20 or 21). (7) Connect throttle body control cables.

(8) Install oil dipstick mounting bolt.

(9) 3.9L/5.2L/5.9L LDC-Gas: Install idler pulley.

Tighten bolt to 54 Nnn (40 ft. lbs.) torque. 5.9L HDC-Gas: Install automatic belt tensioner

assembly to mounting bracket. A dowel pin is located

on back of tensioner (Fig. 24). Align this to dowel

hole (Fig. 25) in tensioner mounting bracket. Tighten

bolt to 41 N-m (30 ft. lbs.). (10) Install drive belt. Refer to Belt Removal/In

stallation in the Engine Accessory Drive Belt section

of this group.

CAUTION:

When installing

the

serpentine

accessory

drive belt,

the

belt must

be

routed correctly.

If not,

the engine

may

overheat

due to the

water pump

ro

tating

in the

wrong direction. Refer

to

Belt Schemat

ics

in the

Engine

Accessory

Drive Belt section

of

this

group

for

correct belt routing.

The

correct belt

with the

correct length must

be

used.

(11) Install air cleaner assembly.

BELT TENSIONER

DOWEL PIN

J9307-63

Fig.

24 Tensioner

Dowel

Pin—5.9L

HDC-Gas Engine Fig.

25 Tensioner

Mounting

Bracket

Dowel

Hote—5.9L

HDC-Gas Engine

(12) Install upper radiator hose to radiator.

(13) Connect throttle cable to clip at radiator fan

shroud.

(14) Connect wiring harness to A/C compressor. (15) Fill cooling system. Refer to Refilling Cooling

System in this group.

(16) Start and warm the engine. Check for leaks.

THERMOSTAT

GENERAL

INFORMATION

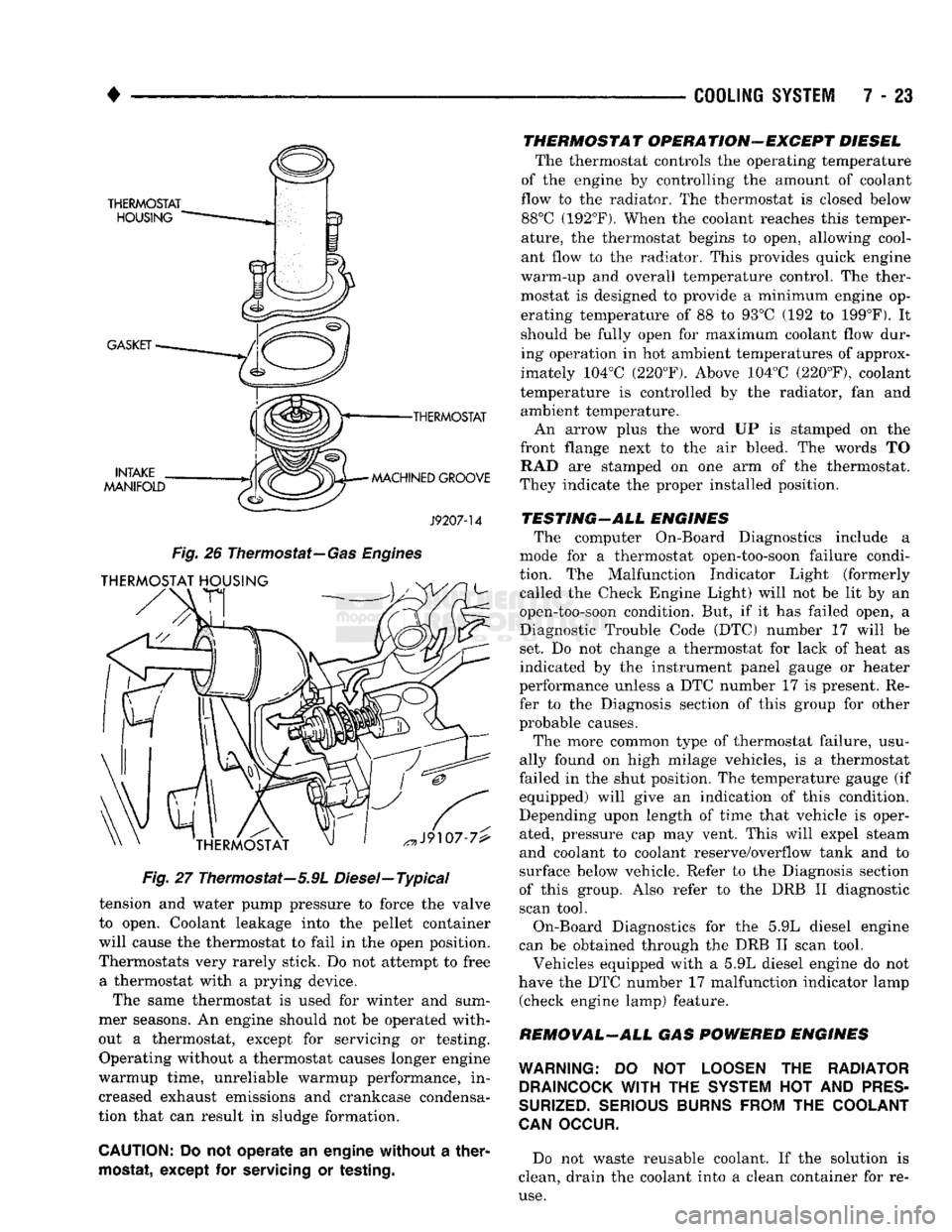

The thermostat on all gas powered engines is lo

cated beneath the thermostat housing at the front of

the intake manifold (Fig. 26). The thermostat has an air bleed notch.

The thermostat of the 5.9L diesel engine is located

in the thermostat housing at front of cylinder head.

This is on exhaust manifold side of engine (Fig. 27). The thermostat is a wax pellet driven, reverse pop

pet choke type. The wax pellet is located in a sealed container at the spring end of the thermostat. When

heated, the pellet expands, overcoming closing spring

Page 294 of 1502

•

COOLING SYSTEM

7 - 23

•THERMOSTAT

MACHINED GROOVE

J9207-14

Fig.

26

Thermostat—

Gas Engines

Fig.

27 Thermostat—5.9L Diesel—Typical

tension and water pump pressure to force the valve

to open. Coolant leakage into the pellet container

will cause the thermostat to fail in the open position.

Thermostats very rarely stick. Do not attempt to free a thermostat with a prying device.

The same thermostat is used for winter and sum

mer seasons. An engine should not be operated with

out a thermostat, except for servicing or testing. Operating without a thermostat causes longer engine

warmup time, unreliable warmup performance, in

creased exhaust emissions and crankcase condensa

tion that can result in sludge formation.

CAUTION:

Do not operate an engine without a

ther

mostat,

except for

servicing

or

testing.

THERMOSTAT OPERATION-EXCEPT DIESEL

The thermostat controls the operating temperature

of the engine by controlling the amount of coolant

flow to the radiator. The thermostat is closed below 88°C (192°F). When the coolant reaches this temper

ature, the thermostat begins to open, allowing cool

ant flow to the radiator. This provides quick engine

warm-up and overall temperature control. The ther

mostat is designed to provide a minimum engine op erating temperature of 88 to 93°C (192 to 199°F). It

should be fully open for maximum coolant flow dur

ing operation in hot ambient temperatures of approx

imately 104°C (220°F). Above 104°C (220°F), coolant

temperature is controlled by the radiator, fan and ambient temperature.

An arrow plus the word UP is stamped on the

front flange next to the air bleed. The words TO RAD are stamped on one arm of the thermostat.

They indicate the proper installed position.

TESTING-ALL ENGINES The computer On-Board Diagnostics include a

mode for a thermostat open-too-soon failure condi

tion. The Malfunction Indicator Light (formerly called the Check Engine Light) will not be lit by an

open-too-soon condition. But, if it has failed open, a

Diagnostic Trouble Code (DTC) number 17 will be

set. Do not change a thermostat for lack of heat as

indicated by the instrument panel gauge or heater

performance unless a DTC number 17 is present. Re

fer to the Diagnosis section of this group for other

probable causes.

The more common type of thermostat failure, usu

ally found on high milage vehicles, is a thermostat

failed in the shut position. The temperature gauge (if equipped) will give an indication of this condition.

Depending upon length of time that vehicle is oper

ated, pressure cap may vent. This will expel steam

and coolant to coolant reserve/overflow tank and to

surface below vehicle. Refer to the Diagnosis section

of this group. Also refer to the DRB II diagnostic

scan tool.

On-Board Diagnostics for the 5.9L diesel engine

can be obtained through the DRB II scan tool.

Vehicles equipped with a 5.9L diesel engine do not

have the DTC number 17 malfunction indicator lamp (check engine lamp) feature.

REMOVAL-ALL GAS POWERED ENGINES

WARNING:

DO NOT

LOOSEN

THE

RADIATOR DRAINCOCK

WITH

THE

SYSTEM

HOT AND

PRES

SURIZED.

SERIOUS BURNS FROM

THE

COOLANT

CAN

OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for re

use.

Page 296 of 1502

•

COOLING

SYSTEM

7 - 25

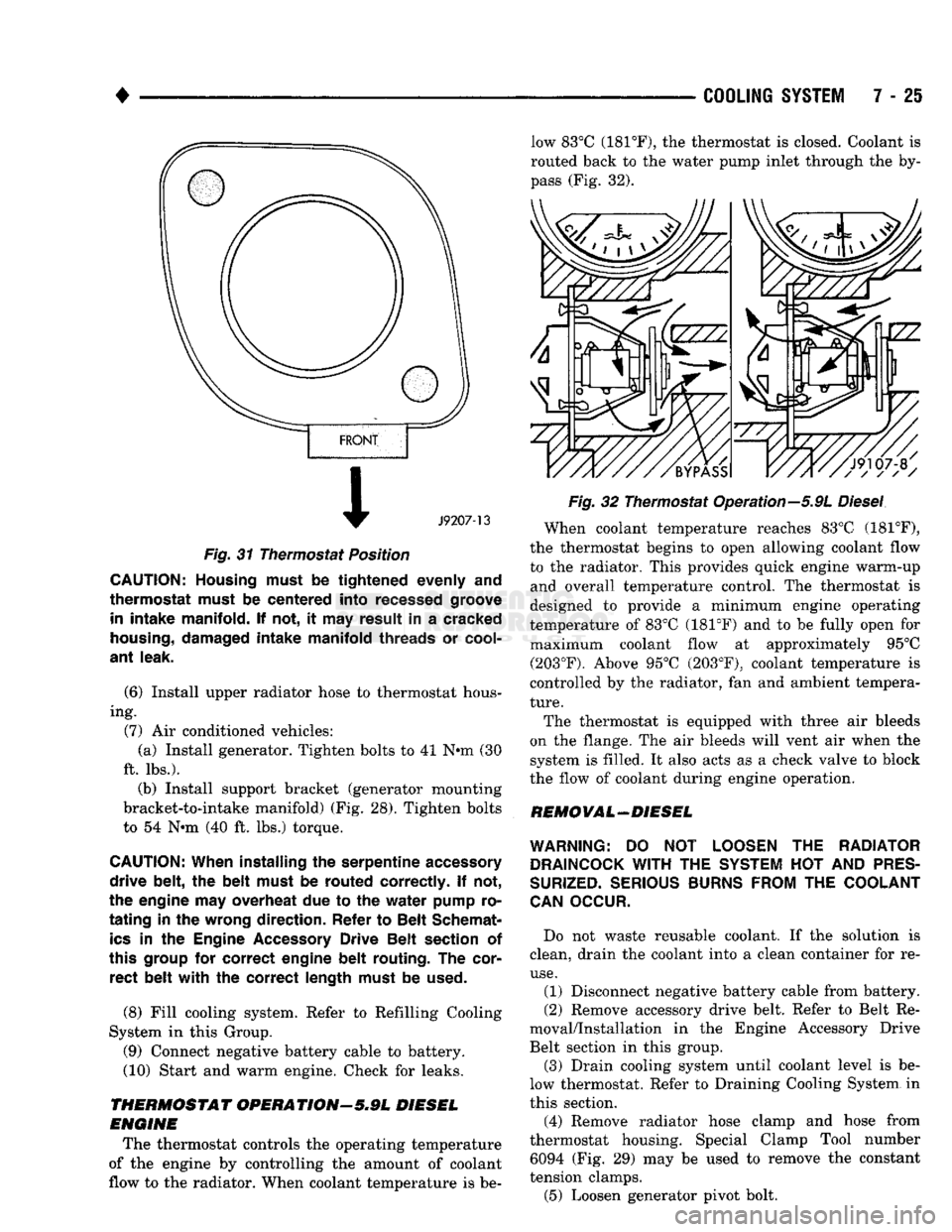

Fig.

31 Thermostat Position

CAUTION; Housing must

be

tightened

evenly and

thermostat must

be

centered into recessed groove in

intake manifold. If not, it may

result

in a

cracked

housing,

damaged intake manifold threads

or

cool

ant

leak.

(6) Install upper radiator hose to thermostat hous

ing. (7) Air conditioned vehicles: (a) Install generator. Tighten bolts to 41 N-m (30

ft. lbs.). (b) Install support bracket (generator mounting

bracket-to-intake manifold) (Fig. 28). Tighten bolts

to 54 N-m (40 ft. lbs.) torque.

CAUTION:

When installing

the

serpentine accessory

drive belt,

the

belt must

be

routed correctly.

If not,

the engine

may overheat due to the

water pump

ro

tating in the

wrong direction. Refer

to

Belt Schemat

ics

in the

Engine

Accessory

Drive Belt section

of

this group

for

correct engine belt routing.

The

cor rect belt with

the

correct length must

be

used.

(8) Fill cooling system. Refer to Refilling Cooling

System in this Group. (9) Connect negative battery cable to battery.

(10) Start and warm engine. Check for leaks.

THERMOSTAT OPERATIONr-5.9L DIESEL

ENGINE

The thermostat controls the operating temperature

of the engine by controlling the amount of coolant

flow to the radiator. When coolant temperature is be low 83°C (181°F), the thermostat is closed. Coolant is

routed back to the water pump inlet through the by

pass (Fig. 32).

Fig.

32 Thermostat Operation—5.9L

Diesel

When coolant temperature reaches 83°C (181°F),

the thermostat begins to open allowing coolant flow

to the radiator. This provides quick engine warm-up and overall temperature control. The thermostat is

designed to provide a minimum engine operating

temperature of 83°C (181°F) and to be fully open for maximum coolant flow at approximately 95°C (203°F). Above 95°C (203°F), coolant temperature is

controlled by the radiator, fan and ambient tempera

ture.

The thermostat is equipped with three air bleeds

on the flange. The air bleeds will vent air when the system is filled. It also acts as a check valve to block

the flow of coolant during engine operation.

REMOVAL-DIESEL

WARNING:

DO NOT

LOOSEN

THE

RADIATOR

DRAINCOCK

WITH

THE

SYSTEM

HOT

AND

PRES

SURIZED.

SERIOUS

BURNS

FROM

THE

COOLANT

CAN

OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for re

use.

(1) Disconnect negative battery cable from battery.

(2) Remove accessory drive belt. Refer to Belt Re

moval/Installation in the Engine Accessory Drive

Belt section in this group.

(3) Drain cooling system until coolant level is be

low thermostat. Refer to Draining Cooling System in

this section.

(4) Remove radiator hose clamp and hose from

thermostat housing. Special Clamp Tool number 6094 (Fig. 29) may be used to remove the constant

tension clamps.

(5) Loosen generator pivot bolt.

Page 298 of 1502

•

COOLING

SYSTEM

7 - 27 down to -67.7°C (-90°F). A higher percentage will

freeze at a warmer temperature. Also, a higher per centage of antifreeze can cause the engine to over

heat because specific heat of antifreeze is lower than

that of water.

CAUTION:

Richer

antifreeze

mixtures

cannot

be

measured

with

normal

field

equipment

and can

cause

problems

associated

with 100

percent

ethyl

ene-glycol.

COOLANT SELECTION-ADDITIVES The presence of aluminum components in the cool

ing system requires strict corrosion protection. Main

tain coolant at specified level with a mixture of ethylene-glycol based antifreeze and water. Only use an antifreeze containing ALUGARD 340-2

™

such as

Mopar Antifreeze. If coolant becomes contaminated

or looses color, drain and flush cooling system and

fill with correctly mixed solution.

A 0.25 percent emulsifiable oil is added to the ra

diator at the factory to prevent solder corrosion.

CAUTION:

Do not use

coolant

additives

that are

claimed

to

improve

engine

cooling.

COOLANT SERVICE-EXCEPT DIESEL It is recommended that the cooling system be

drained and flushed at 84,000 kilometers (52,500

miles) or 3 years, whichever occurs first. Then every

two years or 48,000 kilometers (30,000 miles), which ever occurs first.

COOLANT SERVICE-DIESEL ENGINE It is recommended that the cooling system be

drained and flushed every 24 months or 38,600 kilo meters (24,000 miles), whichever occurs first.

COOLANT LEVEL CHECK-ROUTINE Do not remove radiator cap for routine coolant

level inspections. The coolant level can be checked at the coolant reserve/overflow tank.

The coolant reserve/overflow system provides a

quick visual method for determining the coolant

level without removing the radiator pressure cap.

With engine idling and at normal operating temper ature, observe coolant level in coolant reserve/over

flow tank. The coolant level should be between the MIN and MAX (diesel engine) or ADD and FULL (gas engines) marks.

ADDING ADDITIONAL COOLANT-ROUTINE Do not remove the radiator cap to add coolant

to the system. When adding coolant to maintain the correct level, do so at the coolant reserve/overflow

tank with a 50/50 mixture of ethylene-glycol anti

freeze (containing Alugard 340-2 ™) and water. Re move the radiator cap only for testing or when

refilling the system after service. Removing cap un necessarily can cause loss of coolant and allow air to

enter system. This produces corrosion.

COOLANT LEVEL CHECK-SERVICE The cooling system is closed and designed to main

tain coolant level to the top of the radiator.

WARNING:

DO

NOT OPEN RADIATOR DRAINCOCK

WITH

ENGINE RUNNING

OR

WHILE ENGINE

IS HOT

AND COOLING

SYSTEM

IS

UNDER

PRESSURE.

When vehicle servicing requires a coolant level

check in the radiator, drain several ounces of coolant

from the radiator drain cock. Do this while observing

the coolant reserve/overflow system tank. The cool ant level in the reserve/overflow tank should drop

slightly. If not, inspect for a leak between radiator and coolant reserve/overflow system connection. Re

move radiator cap. The coolant level should be to the

top of the radiator. If not and if coolant level in re serve/overflow tank is at the ADD (gas engines) or

MIN (5.9L diesel engine) mark, check for:

• An air leak in the coolant reserve/overflow tank

• An air leak in the radiator filler neck

• Leak in the pressure cap seal to the radiator filler

neck

LOW COOLANT LEVEL-AERATION If the coolant level in the radiator drops below the

top of the radiator core tubes, air will enter the sys

tem. Low coolant level can cause the thermostat pellet

to be suspended in air instead of coolant. This will cause the thermostat to open later, which in turn causes higher coolant temperature. Air trapped in

cooling system also reduces the amount of coolant

circulating in the heater core. This may result in low

heat output.

DEAERATION As the engine operates, air trapped in the cooling

system gathers under the radiator cap. The next time

engine is operated, thermal expansion of coolant will

push trapped air past radiator cap into coolant re serve/overflow tank. Here it escapes to atmosphere in

the tank. When engine cools down the coolant, it will

be drawn from reserve/overflow tank into radiator to replace removed air.

DRAINING

COOLING

SYSTEM

WARNING:

DO NOT

REMOVE

THE

CYLINDER BLOCK DRAIN PLUGS

OR

LOOSEN THE RADIATOR

DRAIN PLUG

WITH

SYSTEM

HOT AND

UNDER

PRESSURE.

SERIOUS BURNS

FROM

COOLANT

CAN OCCUR.

Page 300 of 1502

+

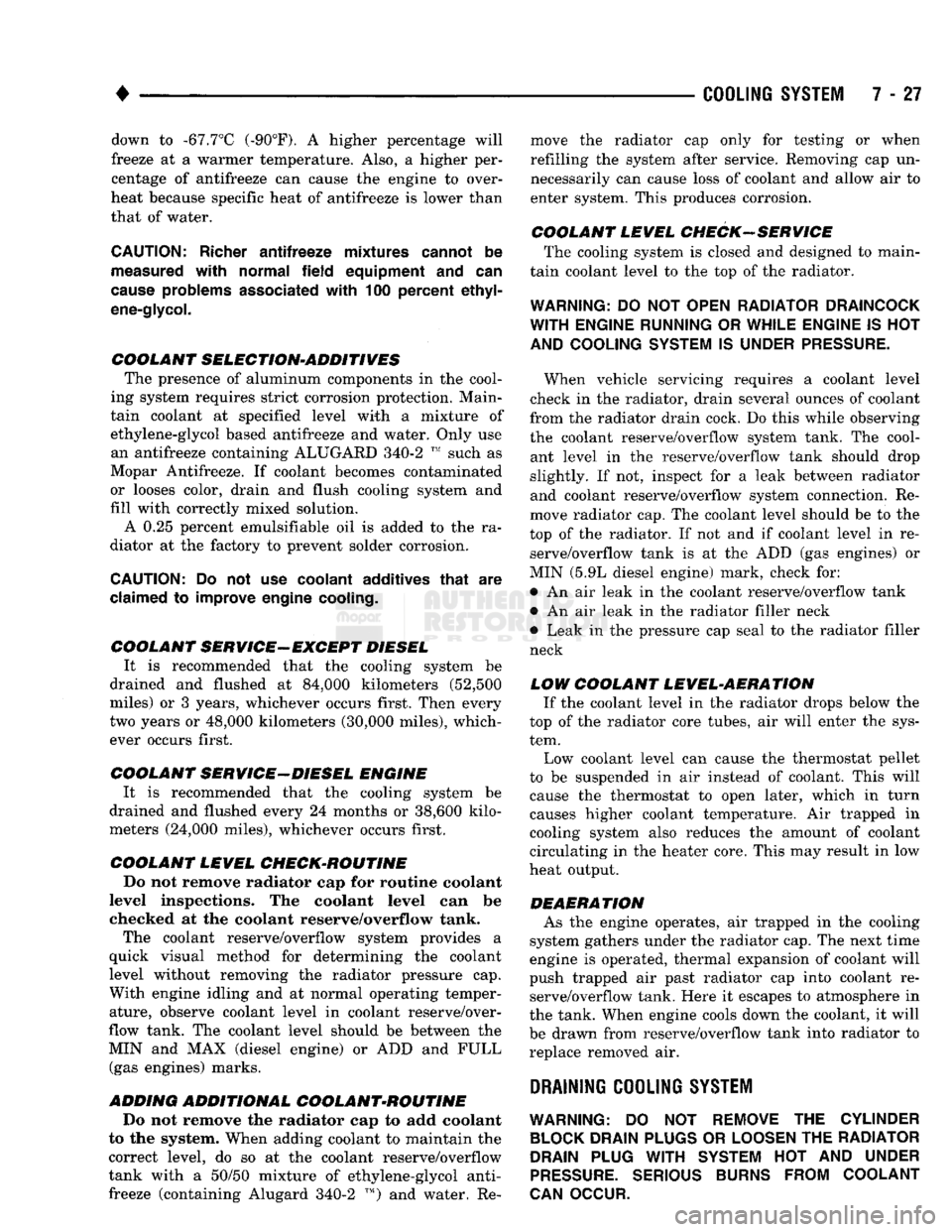

Fig.

37

Reverse-flushing—5.9L

Diesel

(5) Attach water supply hose to heater tube.

(6) Back-flush the engine until clean water exits

the water pump inlet.

CHEMICAL

CLEANING

In some instances, use a radiator cleaner (Mopar

Radiator Kleen or equivalent) before flushing. This

will soften scale and other deposits and aid flushing operation.

CAUTION;

Follow manufacturers instructions when

using

these

products.

TESTING

COOLING

SYSTEM

FOR

LEAKS

ULTRAVIOLET

LIGHT

METHOD

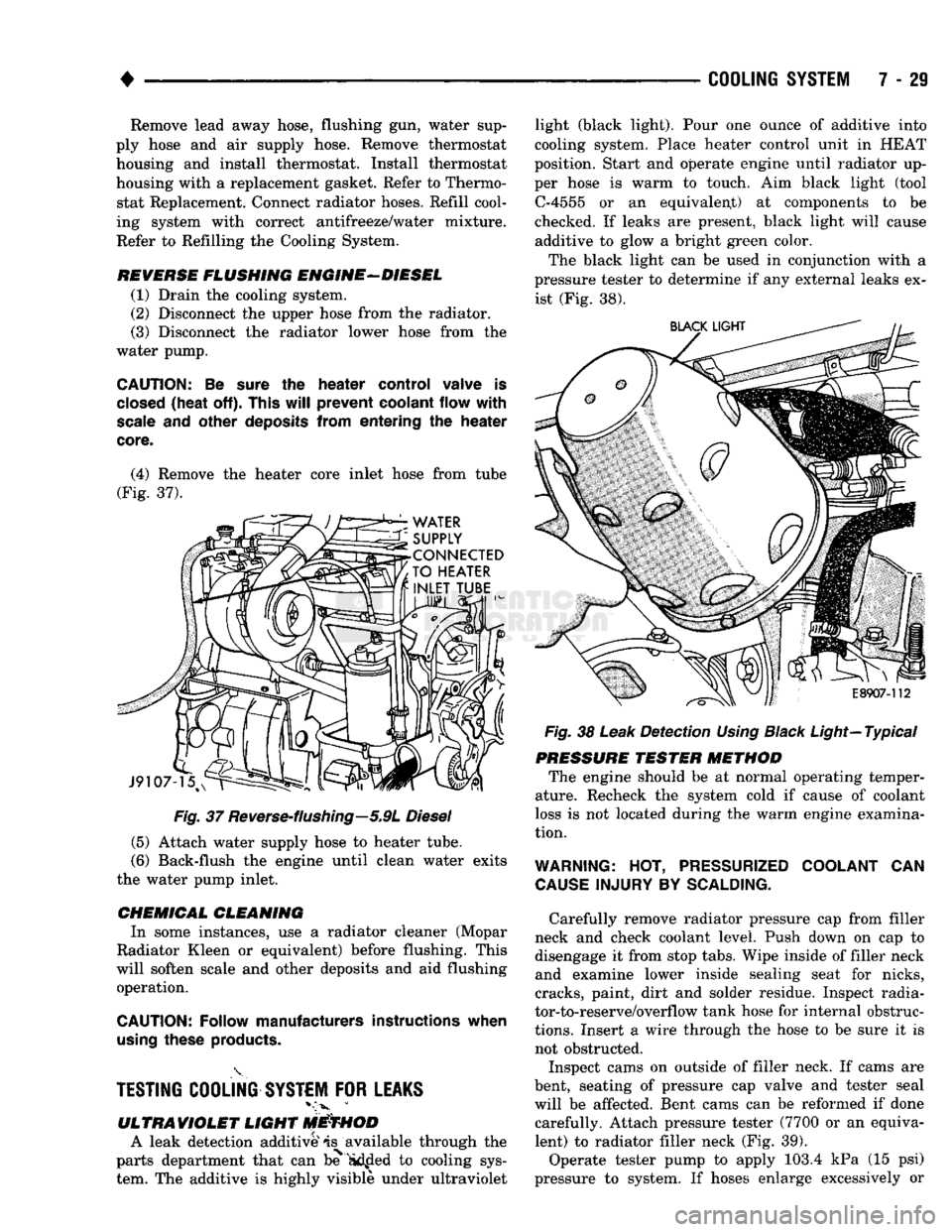

A leak detection additive is available through the

parts department that can be Sidfled to cooling sys

tem. The additive is highly visible under ultraviolet

COOLING

SYSTEM

7 - 29

Fig.

38

Leak

Detection

Using

Black

Light—Typical

PRESSURE

TESTER

METHOD

The engine should be at normal operating temper

ature. Recheck the system cold if cause of coolant

loss is not located during the warm engine examina

tion.

WARNING:

HOT,

PRESSURIZED

COOLANT

CAN

CAUSE

INJURY

BY

SCALDING.

Carefully remove radiator pressure cap from filler

neck and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck and examine lower inside sealing seat for nicks,

cracks, paint, dirt and solder residue. Inspect radia

tor-to-reserve/overflow tank hose for internal obstruc

tions.

Insert a wire through the hose to be sure it is

not obstructed.

Inspect cams on outside of filler neck. If cams are

bent, seating of pressure cap valve and tester seal

will be affected. Bent cams can be reformed if done carefully. Attach pressure tester (7700 or an equivalent) to radiator filler neck (Fig. 39).

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

Remove lead away hose, flushing gun, water sup

ply hose and air supply hose. Remove thermostat housing and install thermostat. Install thermostat

housing with a replacement gasket. Refer to Thermo stat Replacement. Connect radiator hoses. Refill cool

ing system with correct antifreeze/water mixture.

Refer to Refilling the Cooling System.

REVERSE

FLUSHING

ENGINE-DIESEL

(1) Drain the cooling system. (2) Disconnect the upper hose from the radiator.

(3) Disconnect the radiator lower hose from the

water pump.

CAUTION;

Be

sure

the

heater

control valve is

closed

(heat

off).

This

will

prevent coolant flow

with

scale

and other

deposits

from entering the

heater

core.

(4) Remove the heater core inlet hose from tube

(Fig. 37). light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator up

per hose is warm to touch. Aim black light (tool C-4555 or an equivalent) at components to be

checked. If leaks are present, black light will cause additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks ex ist (Fig. 38).

Page 301 of 1502

7 - 30

COOLING

SYSTEM

•

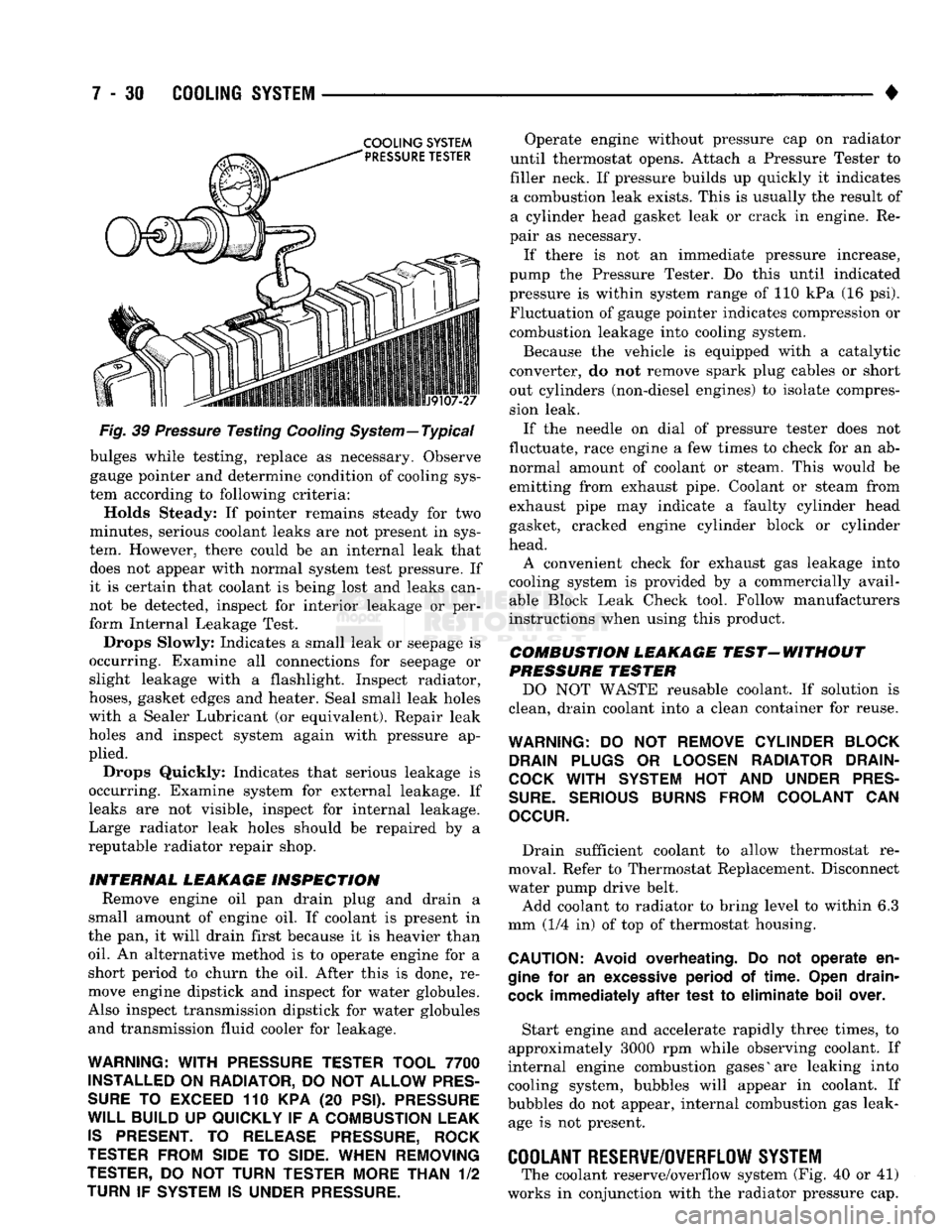

COOLING

SYSTEM

Fig.

39

Pressure

Testing

Cooling

System—Typical bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys

tem according to following criteria:

Holds Steady: If pointer remains steady for two

minutes, serious coolant leaks are not present in sys

tem. However, there could be an internal leak that does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can

not be detected, inspect for interior leakage or per

form Internal Leakage Test.

Drops Slowly: Indicates a small leak or seepage is

occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses,

gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure ap

plied.

Drops Quickly: Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil.

An alternative method is to operate engine for a

short period to churn the oil. After this is done, re

move engine dipstick and inspect for water globules.

Also inspect transmission dipstick for water globules and transmission fluid cooler for leakage.

WARNING:

WITH

PRESSURE TESTER TOOL

7700

INSTALLED

ON

RADIATOR,

DO

NOT ALLOW

PRES

SURE

TO

EXCEED

110 KPA (20

PSI). PRESSURE

WILL

BUILD

UP

QUICKLY

IF A

COMBUSTION LEAK

IS

PRESENT.

TO

RELEASE

PRESSURE,

ROCK

TESTER

FROM SIDE

TO

SIDE. WHEN REMOVING

TESTER,

DO NOT

TURN TESTER MORE THAN

1/2

TURN

IF

SYSTEM

IS

UNDER

PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates a combustion leak exists. This is usually the result of

a cylinder head gasket leak or crack in engine. Re

pair as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi). Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter, do not remove spark plug cables or short

out cylinders (non-diesel engines) to isolate compres

sion leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an ab normal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head

gasket, cracked engine cylinder block or cylinder

head. A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST-WITHOUT

PRESSURE TESTER DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING:

DO NOT

REMOVE CYLINDER BLOCK DRAIN PLUGS

OR

LOOSEN RADIATOR DRAIN-

COCK

WITH

SYSTEM

HOT AND

UNDER PRES

SURE.

SERIOUS BURNS FROM COOLANT

CAN

OCCUR.

Drain sufficient coolant to allow thermostat re

moval. Refer to Thermostat Replacement. Disconnect

water pump drive belt. Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of top of thermostat housing.

CAUTION:

Avoid

overheating.

Do not

operate

en

gine

for an

excessive

period

of

time.

Open

drain-

cock

immediately

after

test

to

eliminate

boil

over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases% are leaking into

cooling system, bubbles will appear in coolant. If

bubbles do not appear, internal combustion gas leak age is not present.

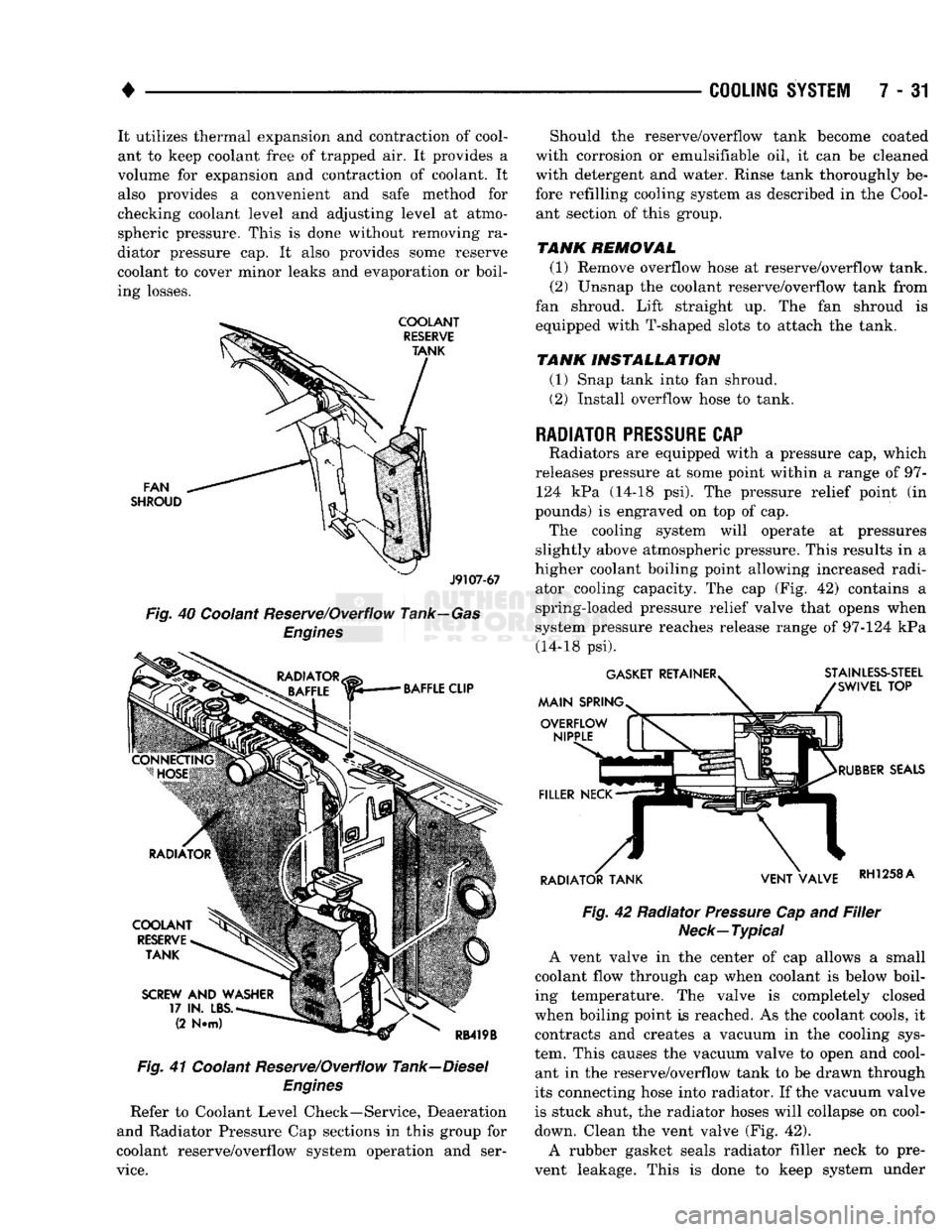

COOLANT

RESERVE/0WERFL0W

SYSTEM

The coolant reserve/overflow system (Fig. 40 or 41)

works in conjunction with the radiator pressure cap.

Page 302 of 1502

•

COOLING

SYSTEM

7 - 31 It utilizes thermal expansion and contraction of cool

ant to keep coolant free of trapped air. It provides a

volume for expansion and contraction of coolant. It

also provides a convenient and safe method for

checking coolant level and adjusting level at atmo

spheric pressure. This is done without removing ra

diator pressure cap. It also provides some reserve

coolant to cover minor leaks and evaporation or boil

ing losses.

FAN

SHROUD

J9107-67

Fig.

40 Coolant Reserve/Overflow Tank—Gas

Engines

Fig.

41 Coolant Reserve/Overflow Tank—Diesel

Engines

Refer to Coolant Level Check—Service, Deaeration

and Radiator Pressure Cap sections in this group for

coolant reserve/overflow system operation and ser

vice.

Should the reserve/overflow tank become coated

with corrosion or emulsifiable oil, it can be cleaned

with detergent and water. Rinse tank thoroughly be

fore refilling cooling system as described in the Cool ant section of this group.

TANK REMOVAL

(1) Remove overflow hose at reserve/overflow tank.

(2) Unsnap the coolant reserve/overflow tank from

fan shroud. Lift straight up. The fan shroud is

equipped with T-shaped slots to attach the tank.

TANK INSTALLATION

(1) Snap tank into fan shroud.

(2) Install overflow hose to tank.

RADIATOR

PRESSURE

CAP

Radiators are equipped with a pressure cap, which

releases pressure at some point within a range of 97- 124 kPa (14-18 psi). The pressure relief point (in

pounds) is engraved on top of cap. The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi ator cooling capacity. The cap (Fig. 42) contains a

spring-loaded pressure relief valve that opens when

system pressure reaches release range of 97-124 kPa (14-18 psi).

Fig.

42 Radiator

Pressure

Cap and

Filler

Neck—Typical

A vent valve in the center of cap allows a small

coolant flow through cap when coolant is below boil

ing temperature. The valve is completely closed

when boiling point is reached. As the coolant cools, it contracts and creates a vacuum in the cooling sys

tem. This causes the vacuum valve to open and cool ant in the reserve/overflow tank to be drawn through

its connecting hose into radiator. If the vacuum valve

is stuck shut, the radiator hoses will collapse on cool-

down. Clean the vent valve (Fig. 42).

A rubber gasket seals radiator filler neck to pre

vent leakage. This is done to keep system under

Page 303 of 1502

7 - 32

COOLING

SYSTEM

• pressure. It also maintains vacuum during coolant

cool-down allowing coolant to return from reserve/

overflow tank.

RADIATOR

CAP-TO-FILLER

NECK

SEAL-PRESSURE RELIEF CHECK The pressure cap upper gasket (seal) pressure relief

can be tested by removing overflow hose from radia

tor filler neck nipple. Attach hose of pressure tester

tool 7700 or equivalent to nipple. It will be necessary

to disconnect hose from its adapter for filler neck.

Pump air into radiator. The pressure cap upper gas

ket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at a minimum of 55 kPa (8 psi).

WARNING;

THE

WARNING WORDS

-DO NOT

OPEN HOT—

ON

RADIATOR PRESSURE CAP, ARE

A SAFETY PRECAUTION. WHEN

HOT,

PRESSURE BUILDS

UP IN

COOLING SYSTEM.

TO

PREVENT

SCALDING

OR

INJURY, RADIATOR

CAP

SHOULD NOT

BE

REMOVED WHILE SYSTEM

IS HOT

AND/OR UNDER

PRESSURE.

Do not remove radiator cap at any time except for

the following purposes: • Check and adjust antifreeze freeze point

• Refill system with new antifreeze

• Conducting service procedures

• Checking for vacuum leaks

WARNING;

IF

VEHICLE HAS BEEN RUN RECENTLY,

WAIT

AT

LEAST

15

MINUTES BEFORE REMOVING

RADIATOR CAP.

WITH

A

RAG, SQUEEZE RADIA

TOR UPPER HOSE

TO

CHECK

IF

SYSTEM

IS UN

DER

PRESSURE.

PLACE

A RAG

OVER

CAP AND

WITHOUT

PUSHING

CAP

DOWN, ROTATE

IT

COUNTER-CLOCKWISE

TO

FIRST STOP. ALLOW FLUID

TO

ESCAPE THROUGH

THE

COOLANT RE

SERVE/OVERFLOW HOSE

INTO

RESERVE/OVER FLOW TANK. SQUEEZE RADIATOR UPPER HOSE

TO DETERMINE WHEN PRESSURE HAS BEEN RE

LEASED.

WHEN COOLANT AND STEAM STOP BE

ING PUSHED

INTO

TANK AND SYSTEM PRESSURE

DROPS,

REMOVE RADIATOR CAP COMPLETELY.

PRESSURE

TESTING

RADIATOR

CAPS

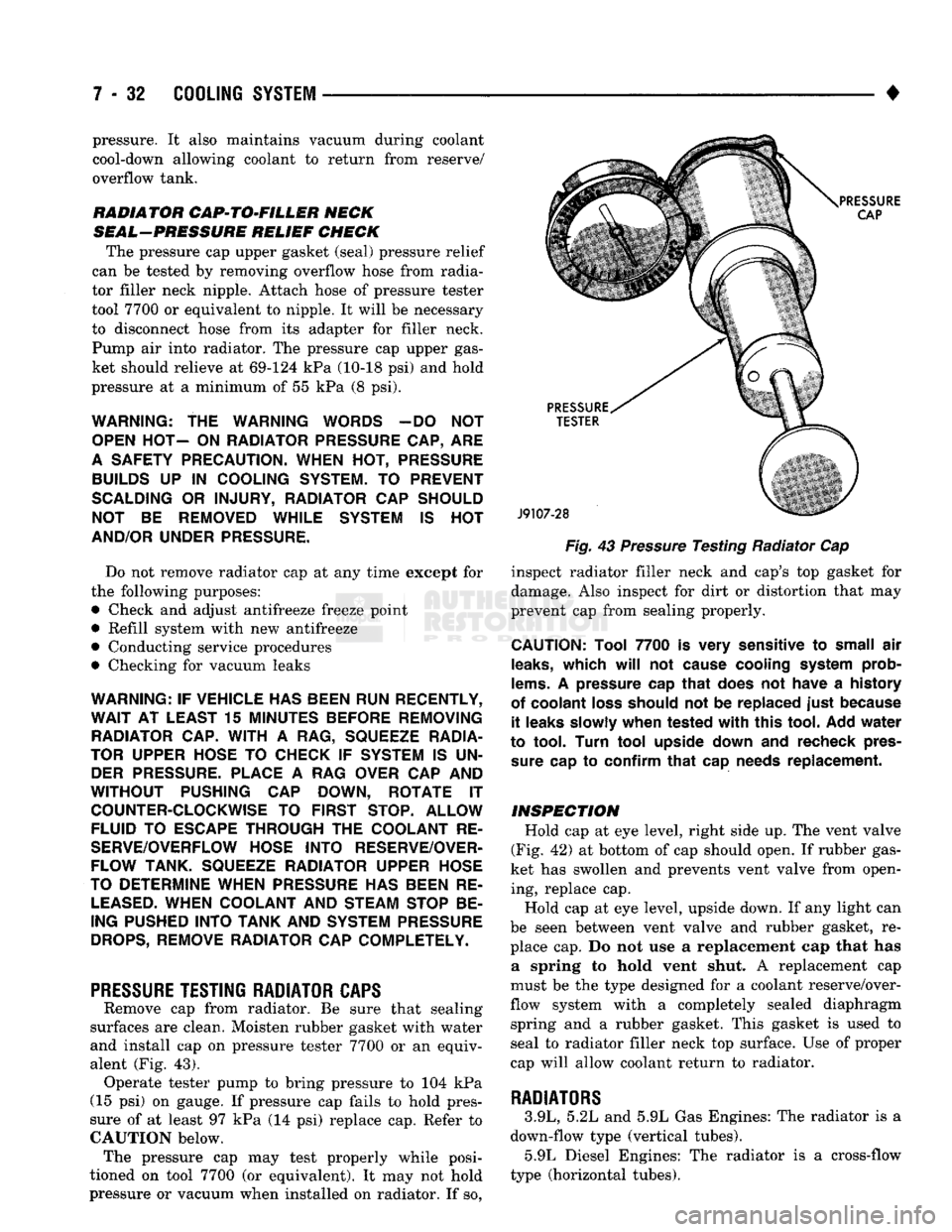

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install cap on pressure tester 7700 or an equiv

alent (Fig. 43). Operate tester pump to bring pressure to 104 kPa

(15 psi) on gauge. If pressure cap fails to hold pres

sure of at least 97 kPa (14 psi) replace cap. Refer to

CAUTION below. The pressure cap may test properly while posi

tioned on tool 7700 (or equivalent). It may not hold

pressure or vacuum when installed on radiator. If so,

Fig.

43

Pressure

Testing Radiator Cap

inspect radiator filler neck and cap's top gasket for

damage. Also inspect for dirt or distortion that may

prevent cap from sealing properly.

CAUTION:

Tool

7700

is

very

sensitive

to

small

air

leaks,

which

will

not

cause

cooling

system

prob

lems.

A

pressure

cap

that

does

not

have

a

history

of

coolant

loss

should

not be

replaced

just

because

it

leaks

slowly

when

tested

with

this

tool.

Add

water

to

tool.

Turn

tool

upside

down

and

recheck

pres

sure

cap to

confirm

that

cap

needs

replacement.

INSPECTION

Hold cap at eye level, right side up. The vent valve

(Fig. 42) at bottom of cap should open. If rubber gas

ket has swollen and prevents vent valve from open ing, replace cap.

Hold cap at eye level, upside down. If any light can

be seen between vent valve and rubber gasket, re place cap. Do not use a replacement cap that has a spring to hold vent shut. A replacement cap

must be the type designed for a coolant reserve/over

flow system with a completely sealed diaphragm spring and a rubber gasket. This gasket is used to

seal to radiator filler neck top surface. Use of proper

cap will allow coolant return to radiator.

RADIATORS

3.9L, 5.2L and 5.9L Gas Engines: The radiator is a

down-flow type (vertical tubes). 5.9L Diesel Engines: The radiator is a cross-flow

type (horizontal tubes).

Page 304 of 1502

•

COOLING

SYSTEM

7 - 33 The radiator supplies sufficient heat transfer to

cool the engine and automatic transmission (if equipped).

RADIATOR COOLANT FLOW CHECK

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow ing to the radiator.

WARNING:

HOT,

PRESSURIZED COOLANT

CAN

CAUSE

INJURY

BY

SCALDING. USING

A

RAG

TO

COVER

THE

RADIATOR

PRESSURE

CAP,

OPEN RADIATOR

CAP

SLOWLY

TO THE

FIRST STOP.

THIS

WILL

ALLOW

ANY

BUILT-UP

PRESSURE

TO

VENT

TO

THE

RESERVE/OVERFLOW TANK. AFTER

PRESSURE

BUILD-UP

HAS

BEEN RELEASED,

RE

MOVE

CAP

FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal op

erating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

RADIATOR REMOVAL-EXCEPT DIESEL

(1) Disconnect negative battery cable from battery.

WARNING;

DO NOT

REMOVE

THE

CYLINDER BLOCK DRAIN PLUGS

OR

LOOSEN

THE

RADIATOR

DRAINCOCK

WITH

THE

SYSTEM

HOT AND

UNDER

PRESSURE.

SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system. Refer to Draining

Cooling System.

(3) Disconnect throttle cable from clip at radiator

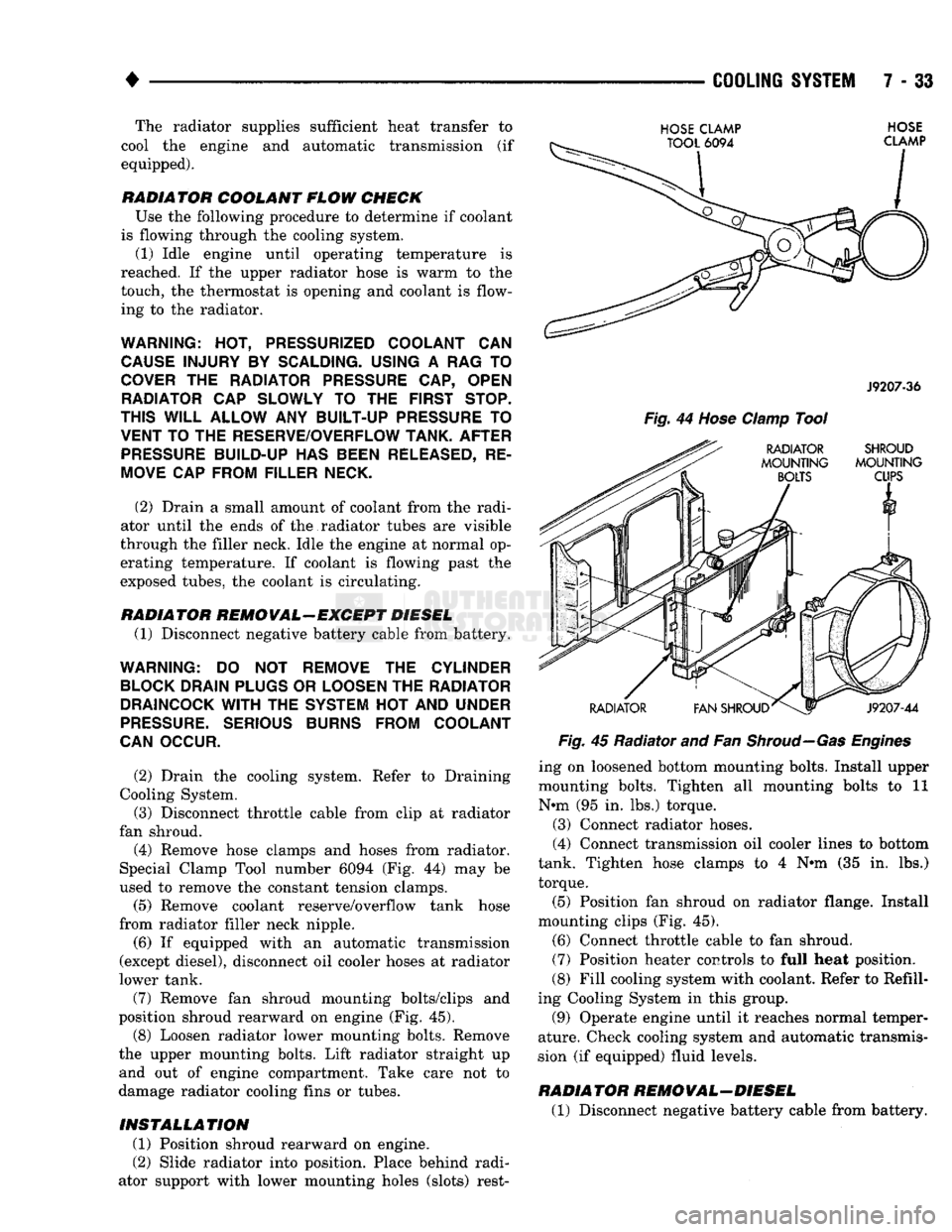

fan shroud. (4) Remove hose clamps and hoses from radiator.

Special Clamp Tool number 6094 (Fig. 44) may be

used to remove the constant tension clamps.

(5) Remove coolant reserve/overflow tank hose

from radiator filler neck nipple.

(6) If equipped with an automatic transmission

(except diesel), disconnect oil cooler hoses at radiator

lower tank.

(7) Remove fan shroud mounting bolts/clips and

position shroud rearward on engine (Fig. 45). (8) Loosen radiator lower mounting bolts. Remove

the upper mounting bolts. Lift radiator straight up and out of engine compartment. Take care not to

damage radiator cooling fins or tubes.

INSTALLATION

(1) Position shroud rearward on engine.

(2) Slide radiator into position. Place behind radi

ator support with lower mounting holes (slots) rest-

HOSE

CLAMP

TOOL

6094

HOSE

CLAMP

J9207-36

Fig.

44

Hose

Clamp

Tool

RADIATOR SHROUD

MOUNTING MOUNTING

BOLTS

CUPS

RADIATOR

V1

FAN SHROUD^

J9207-44

Fig.

45 Radiator and Fan

Shroud—Gas Engines

ing on loosened bottom mounting bolts. Install upper

mounting bolts. Tighten all mounting bolts to 11

N*m (95 in. lbs.) torque.

(3) Connect radiator hoses.

(4) Connect transmission oil cooler lines to bottom

tank. Tighten hose clamps to 4 N#m (35 in. lbs.)

torque.

(5) Position fan shroud on radiator flange. Install

mounting clips (Fig. 45).

(6) Connect throttle cable to fan shroud.

(7) Position heater controls to full heat position.

(8) Fill cooling system with coolant. Refer to Refill

ing Cooling System in this group.

(9) Operate engine until it reaches normal temper

ature. Check cooling system and automatic transmis

sion (if equipped) fluid levels.

RADIATOR REMOVAL-DIESEL

(1) Disconnect negative battery cable from battery.