DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 411 of 1502

•

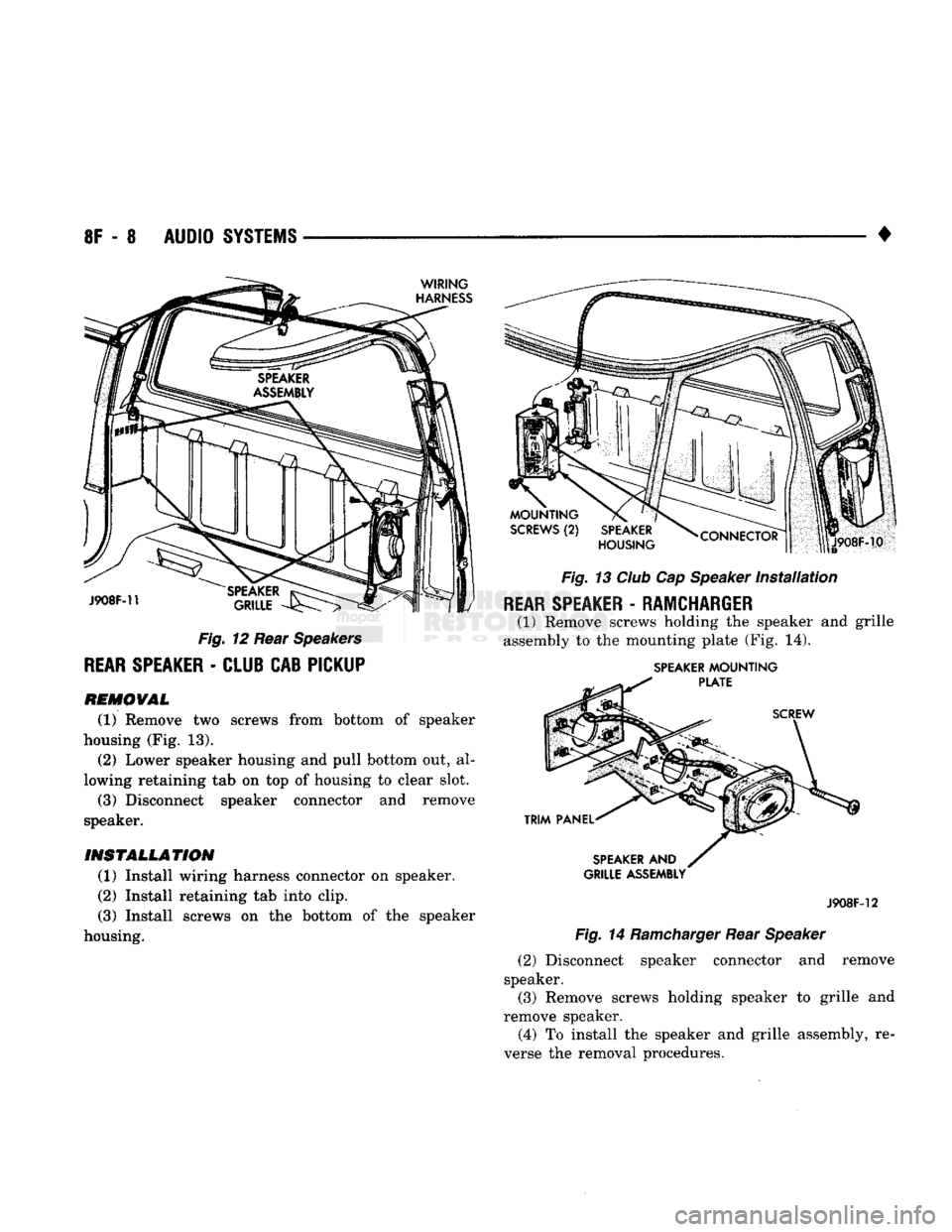

Fig.

12 Rear

Speakers

REAR

SPEAKER

-

CLUB CAB PICKUP

REMOVAL

(1) Remove two screws from bottom of speaker

housing (Fig. 13). (2) Lower speaker housing and pull bottom out, al

lowing retaining tab on top of housing to clear slot. (3) Disconnect speaker connector and remove

speaker.

INSTALLATION

(1) Install wiring harness connector on speaker.

(2) Install retaining tab into clip.

(3) Install screws on the bottom of the speaker

housing.

Fig.

13

Club

Cap

Speaker

Installation

REAR

SPEAKER

-

RAMCHARGER

(1) Remove screws holding the speaker and grille

assembly to the mounting plate (Fig. 14).

SPEAKER

MOUNTING

GRILLE

ASSEMBLY

J908F-12

Fig.

14

Ramcharger

Rear

Speaker

(2) Disconnect speaker connector and remove

speaker.

(3) Remove screws holding speaker to grille and

remove speaker.

(4) To install the speaker and grille assembly, re

verse the removal procedures.

Page 412 of 1502

•

HORNS

8G - 1

HORNS

CONTENTS

SERVICE

PROCEDURES

page

.. 3

TEST PROCEDURES

page

.. 1

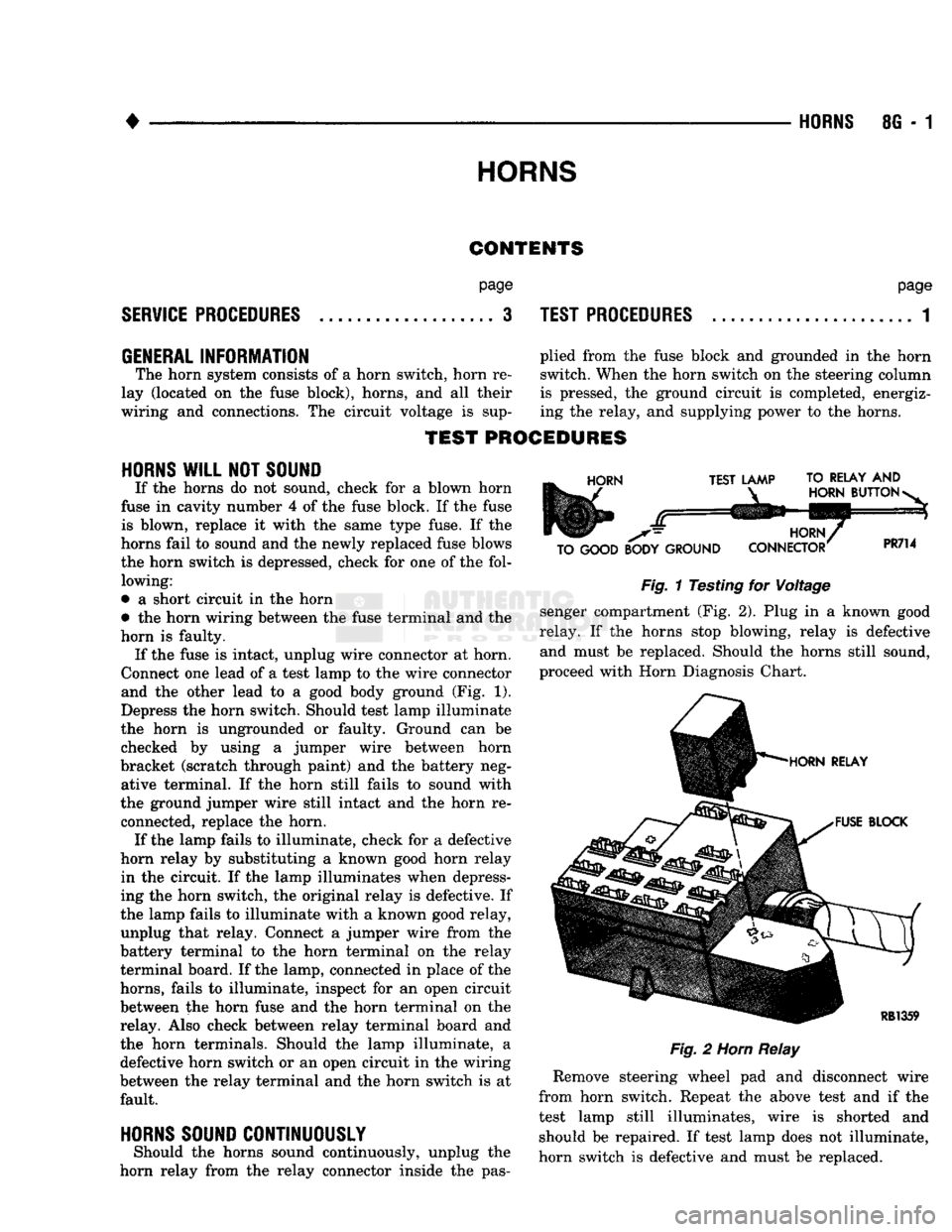

GENERAL

INFORMATION plied from the fuse block and grounded in the horn The horn system consists of a horn switch, horn re- switch. When the horn switch on the steering column

lay (located on the fuse block), horns, and all their is pressed, the ground circuit is completed, energiz-

wiring and connections. The circuit voltage is sup- ing the relay, and supplying power to the horns.

TEST PROCEDURES

HORNS

WILL

NOT

SOUND

If the horns do not sound, check for a blown horn

fuse in cavity number 4 of the fuse block. If the fuse is blown, replace it with the same type fuse. If the

horns fail to sound and the newly replaced fuse blows

the horn switch is depressed, check for one of the fol lowing:

• a short circuit in the horn

• the horn wiring between the fuse terminal and the

horn is faulty. If the fuse is intact, unplug wire connector at horn.

Connect one lead of a test lamp to the wire connector and the other lead to a good body ground (Fig. 1).

Depress the horn switch. Should test lamp illuminate

the horn is ungrounded or faulty. Ground can be checked by using a jumper wire between horn

bracket (scratch through paint) and the battery neg ative terminal. If the horn still fails to sound with

the ground jumper wire still intact and the horn re connected, replace the horn. If the lamp fails to illuminate, check for a defective

horn relay by substituting a known good horn relay in the circuit. If the lamp illuminates when depress

ing the horn switch, the original relay is defective. If

the lamp fails to illuminate with a known good relay, unplug that relay. Connect a jumper wire from the

battery terminal to the horn terminal on the relay

terminal board. If the lamp, connected in place of the

horns, fails to illuminate, inspect for an open circuit

between the horn fuse and the horn terminal on the relay. Also check between relay terminal board and

the horn terminals. Should the lamp illuminate, a defective horn switch or an open circuit in the wiring

between the relay terminal and the horn switch is at fault.

HORNS SOUND CONTINUOUSLY

Should the horns sound continuously, unplug the

horn relay from the relay connector inside the pas-

HORN

TEST LAMP TO RELAY

AND

HORN

BUTTON

-

TO GOOD BODY GROUND HORN,

CONNECTOR

PR714

Fig.

1 Testing for Voltage

senger compartment (Fig. 2). Plug in a known good

relay. If the horns stop blowing, relay is defective and must be replaced. Should the horns still sound,

proceed with Horn Diagnosis Chart.

HORN RELAY

FUSE BLOCK

RB1359

Fig.

2

Horn

Relay

Remove steering wheel pad and disconnect wire

from horn switch. Repeat the above test and if the

test lamp still illuminates, wire is shorted and should be repaired. If test lamp does not illuminate,

horn switch is defective and must be replaced.

Page 413 of 1502

8G

- 2

HORNS

•

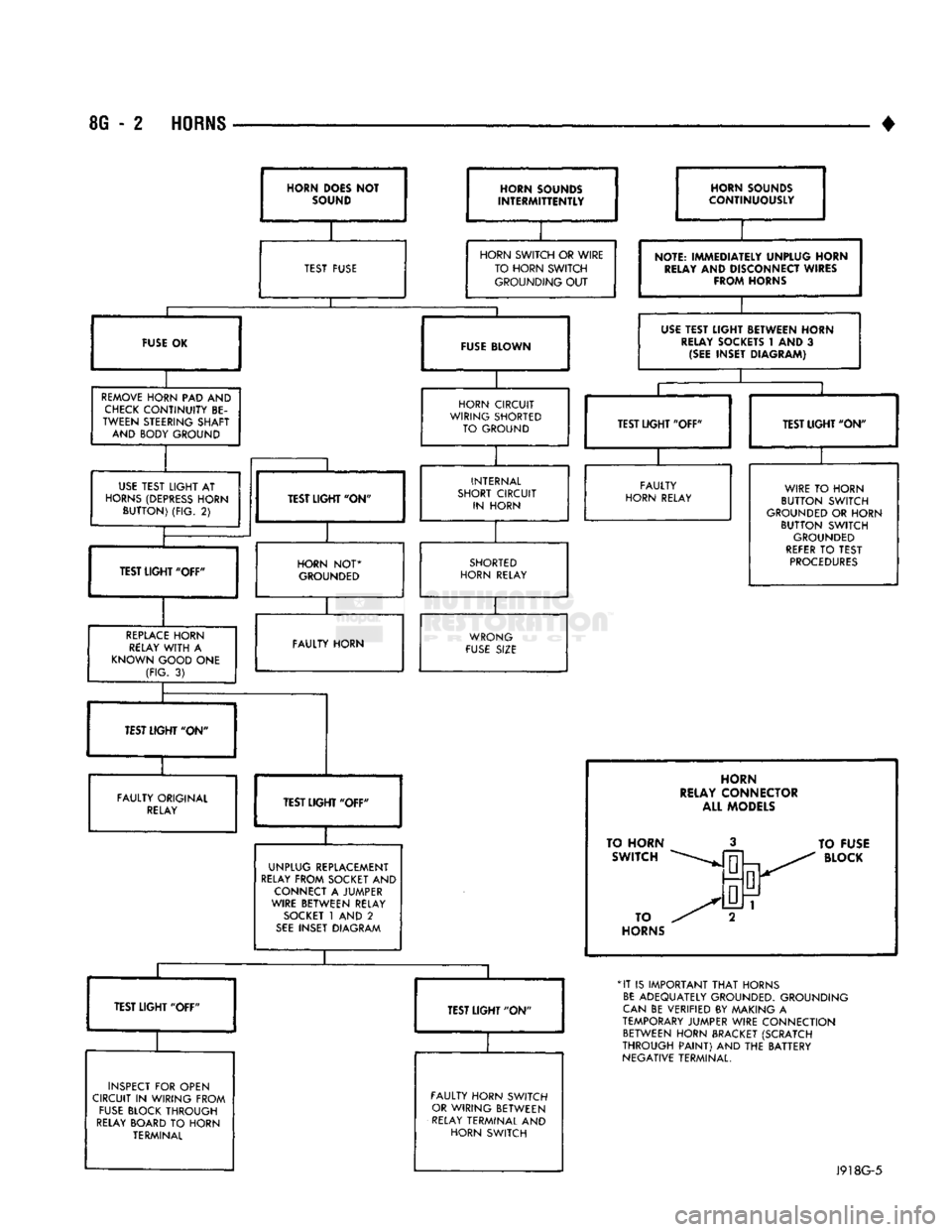

HORN

DOES NOT

SOUND HORN SOUNDS

INTERMITTENTLY

TEST FUSE

HORN SOUNDS

CONTINUOUSLY

HORN SWITCH

OR

WIRE TO HORN SWITCH GROUNDING

OUT

FUSE BLOWN

REMOVE

HORN

PAD AND

CHECK

CONTINUITY

BE

TWEEN STEERING SHAFT AND BODY GROUND

NOTE:

IMMEDIA1

RELAY

AND

Dl

FRO/V

rELY UNPLUG HORN

SCONNECT

WIRES

\HORNS

USE

TEST LIGHT BETWEEN HORN

RELAY

SOCKETS

t AND 3

(SEE

INSET DIAGRAM)

HORN CIRCUIT

WIRING SHORTED TO GROUND

USE

TEST

LIGHT

AT

HORNS

(DEPRESS

HORN

BUTTON)

(FIG.

2)

TEST LIGHT' ON

TEST

UGHT

"OFF" TEST LIGHT "OFF"

INTERNAL

SHORT CIRCUIT IN HORN

HORN

NOT*

GROUNDED

REPLACE

HORN

RELAY

WITH

A

KNOWN GOOD

ONE

(FIG.

3)

TEST LIGHT "ON"

FAULTY

HORN RELAY

SHORTED

HORN RELAY WIRE

TO

HORN

BUTTON SWITCH

GROUNDED

OR

HORN BUTTON SWITCH

GROUNDED

REFER

TO

TEST

PROCEDURES

FAULTY HORN WRONG

FUSE

SIZE

TEST LIGHT "ON"

FAULTY ORIGINAL

RELAY

TEST LIGI

HT

"OFF"

UNPLUG REPLACEMENT

RELAY

FROM SOCKET

AND

CONNECT

A

JUMPER

WIRE BETWEEN RELAY

SOCKET

1

AND

2

SEE

INSET DIAGRAM

INSPECT

FOR

OPEN

CIRCUIT

IN

WIRING FROM

FUSE

BLOCK THROUGH

RELAY

BOARD

TO

HORN TERMINAL FAULTY HORN SWITCH

OR

WIRING BETWEEN

RELAY

TERMINAL

AND

HORN SWITCH

HORN

RELAY CONNECTOR ALL MODELS

TO HORN SWITCH

TO

HORNS

TO

FUSE

BLOCK

*IT

IS

IMPORTANT

THAT

HORNS

BE

ADEQUATELY GROUNDED. GROUNDING

CAN

BE

VERIFIED

BY

MAKING

A

TEMPORARY

JUMPER WIRE CONNECTION BETWEEN HORN BRACKET (SCRATCH

THROUGH

PAINT)

AND THE

BATTERY

NEGATIVE TERMINAL.

J918G-5

Page 414 of 1502

•

HORNS

8G - 3

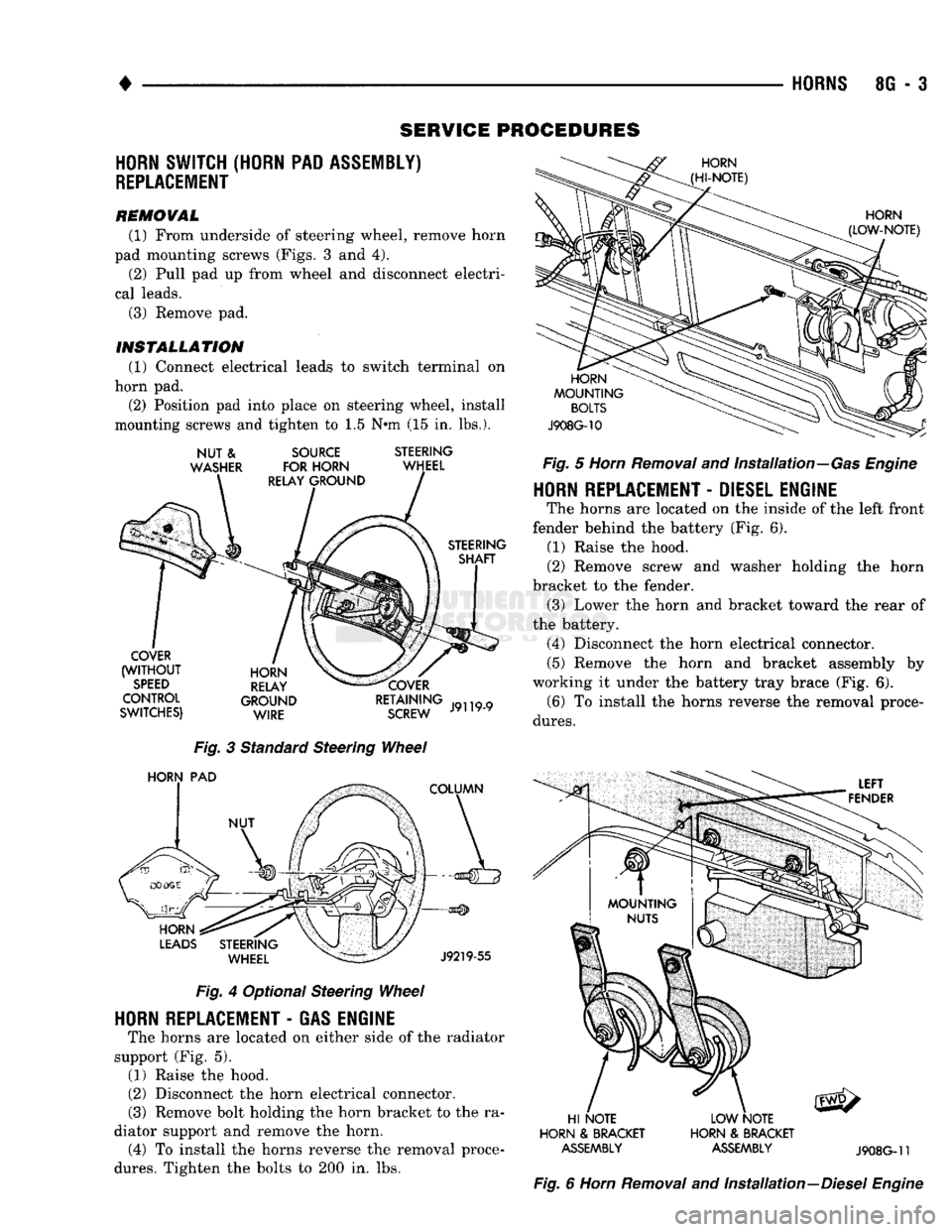

SERVICE

PROCEDURES

HORN

SWITCH (HORN PAD ASSEMBLY)

REPLACEMENT

REMOVAL (1) From underside of steering wheel, remove horn

pad mounting screws (Figs. 3 and 4). (2) Pull pad up from wheel and disconnect electri

cal leads. (3) Remove pad.

INSTALLATION

(1) Connect electrical leads to switch terminal on

horn pad. (2) Position pad into place on steering wheel, install

mounting screws and tighten to 1.5 N*m (15 in. lbs.).

NUT

&

WASHER

SOURCE

FOR HORN

RELAY GROUND STEERING

WHEEL

STEERING SHAFT

COVER

(WITHOUT

SPEED

CONTROL

SWITCHES) HORN

RELAY

GROUND WIRE COVER

RETAINING

SCREW

J9119-9

Fig.

3 Standard Steering

Wheel

HORN

PAD

COLUMN

HORN

LEADS

STEERING WHEEL

J9219-55

Fig.

4 Optional Steering

Wheel

HORN

REPLACEMENT

-

GAS ENGINE

The horns are located on either side of the radiator

support (Fig. 5). (1) Raise the hood.

(2) Disconnect the horn electrical connector.

(3) Remove bolt holding the horn bracket to the ra

diator support and remove the horn. (4) To install the horns reverse the removal proce

dures.

Tighten the bolts to 200 in. lbs.

HORN

(HI-NOTE)

HORN

(LOW-NOTE)

HORN

MOUNTING

BOLTS

J908G-10

Fig.

5

Horn

Removal

and Installation—Gas

Engine

HORN

REPLACEMENT

-

DIESEL ENGINE

The horns are located on the inside of the left front

fender behind the battery (Fig. 6). (1) Raise the hood.

(2) Remove screw and washer holding the horn

bracket to the fender. (3) Lower the horn and bracket toward the rear of

the battery. (4) Disconnect the horn electrical connector.

(5) Remove the horn and bracket assembly by

working it under the battery tray brace (Fig. 6). (6) To install the horns reverse the removal proce

dures.

LEFT

FENDER

HI NOTE

HORN

&

BRACKET

ASSEMBLY

LOW NOTE

HORN

&

BRACKET

ASSEMBLY

J908G-11

Fig.

6

Horn

Removal

and Installation—Diesel

Engine

Page 415 of 1502

Page 416 of 1502

•

VEHICLE SPEED CONTROL SYSTEM

8H - 1

VEHICLE SPEED CONTROL SYSTEM

CONTENTS

SERVICE

PROCEDURES

page

. 11

TEST PROCEDURES

page

.. 7

GENERAL

INFORMATION

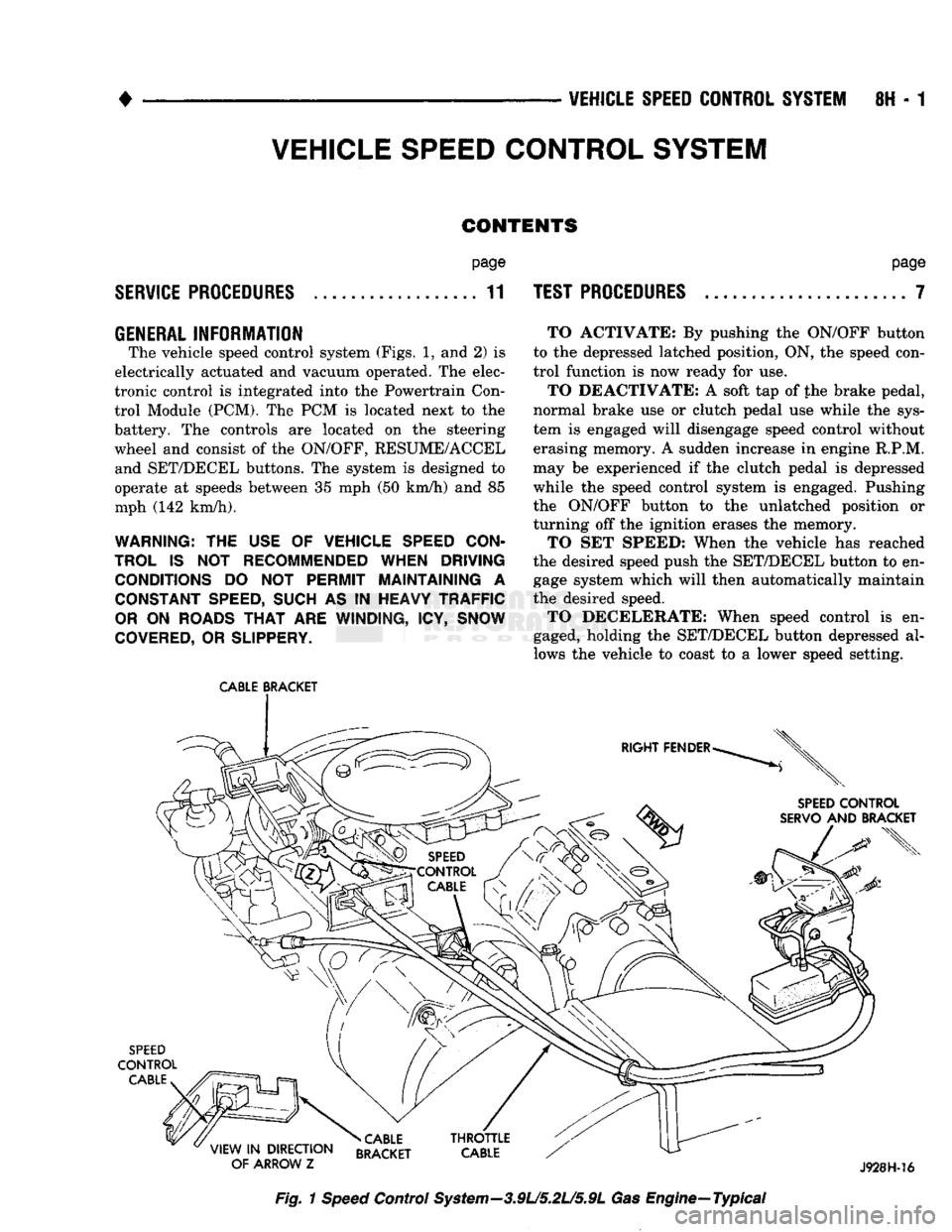

The vehicle speed control system (Figs. 1, and 2) is

electrically actuated and vacuum operated. The elec

tronic control is integrated into the Powertrain Con trol Module (PCM). The PCM is located next to the

battery. The controls are located on the steering

wheel and consist of the ON/OFF, RESUME/ACCEL and SET/DECEL buttons. The system is designed to

operate at speeds between 35 mph (50 km/h) and 85

mph (142 km/h).

WARNING: THE USE OF VEHICLE SPEED CON

TROL IS NOT RECOMMENDED WHEN DRIVING CONDITIONS DO NOT PERMIT MAINTAINING A CONSTANT SPEED, SUCH AS IN HEAVY TRAFFIC

OR ON ROADS THAT ARE WINDING, ICY, SNOW

COVERED, OR SLIPPERY.

CABLE

BRACKET

TO ACTIVATE: By pushing the ON/OFF button

to the depressed latched position, ON, the speed con

trol function is now ready for use.

TO DEACTIVATE: A soft tap of the brake pedal,

normal brake use or clutch pedal use while the sys

tem is engaged will disengage speed control without

erasing memory. A sudden increase in engine R.P.M.

may be experienced if the clutch pedal is depressed

while the speed control system is engaged. Pushing

the ON/OFF button to the unlatched position or

turning off the ignition erases the memory.

TO SET SPEED: When the vehicle has reached

the desired speed push the SET/DECEL button to en gage system which will then automatically maintain

the desired speed. TO DECELERATE: When speed control is en

gaged, holding the SET/DECEL button depressed al

lows the vehicle to coast to a lower speed setting.

SPEED

CONTROL

SERVO

AND BRACKET

SPEED

CONTROL

CABLE

»CABLE

VIEW

IN

DIRECTION RRAfKFT

OF ARROW

Z BRACKET J928H-16

Fig.

1

Speed

Control System—3.9L/5.2L/5.9L Gas Engine—Typical

Page 417 of 1502

8H - 2

VEHICLE SPEED CONTROL SYSTEM

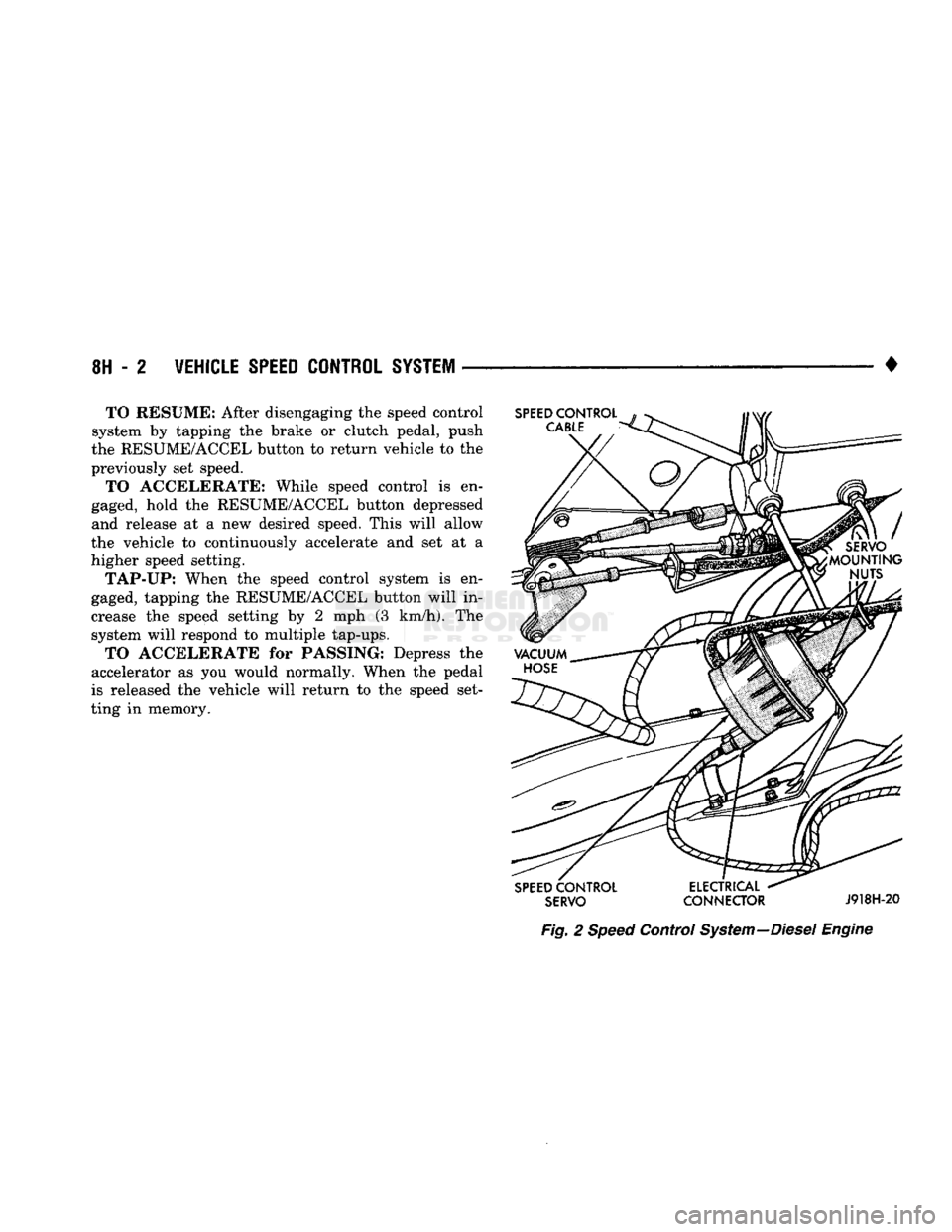

• TO RESUME: After disengaging the speed control

system by tapping the brake or clutch pedal, push

the RESUME/ACCEL button to return vehicle to the

previously set speed. TO ACCELERATE: While speed control is en

gaged, hold the RESUME/ACCEL button depressed and release at a new desired speed. This will allow

the vehicle to continuously accelerate and set at a

higher speed setting.

TAP-UP: When the speed control system is en

gaged, tapping the RESUME/ACCEL button will in

crease the speed setting by 2 mph (3 km/h). The system will respond to multiple tap-ups.

TO ACCELERATE for PASSING: Depress the

accelerator as you would normally. When the pedal

is released the vehicle will return to the speed set

ting in memory.

SERVO

CONNECTOR

J918H-20

Fig.

2

Speed

Control

System

—Diesel

Engine

Page 418 of 1502

VEHICLE

SPEED

CONTROL

SYSTEM

8H - 3

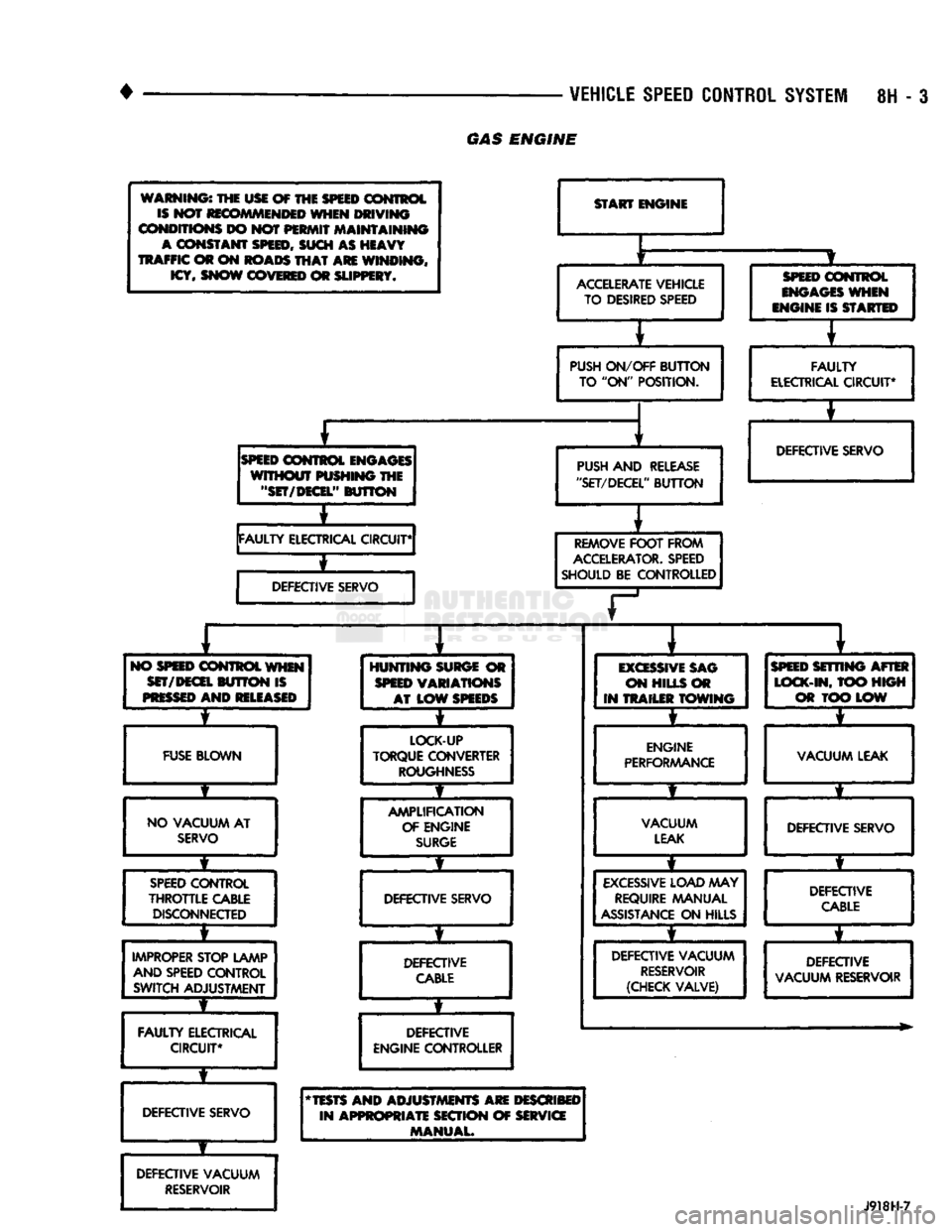

GAS

ENGINE

warnings the usi of THE

SPEED

control is NOT recommended when

DRIVING

CONDITIONS

DO not

PERMIT

maintaining

A

constant

SPEED, SUCH

AS

HEAVY

TRAFFIC

©r on

ROADS

THAT ARE

WINDING, ICY, SNOW COVERED

OR

SLIPPERY*

START

ENGINE

r

ACCELERATE

VEHICLE TO DESIRED SPEED

SPEED

CONTROL

ENGAGES

WHEN

mmm is

STARTED

PUSH

ON/OFF

BUTTON

TO "ON"

POSITION.

E

FAULTY

ELECTRICAL CIRCUIT*

SPEED

CONTROL ENGAGES

WITHOUT

PUSHING

THE

"SET/DECEL"

BUTTON

PUSH

AND

RELEASE

"SET/DECEL'

'

BUTTON

FAULTY

ELECTRICAL CIRCUIT* DEFECTIVE SERVO

i

DEFECTIVE SERVO

REMOVE

FOOT

FROM

ACCELERATOR.

SPEED

SHOULD

BE

CONTROLLED

T

1

i

1

*

NO

WEED

CONTROL

WHEN

SET/DECEL

BUTTON IS

PRESSED

AND RELEASED

HUNTING

SURGE

OR

SPEED

VARIATIONS AT

LOW

SPEEDS

EXCESSIVE

SAG

ON

HILLS

OR

IN

TRAILER TOWING

SPEED

SETTING AFTER

LOCK-IN,

TOO

HIGH

C3«t LOW

4 *

FUSE

BLOWN

LOCK-UP

TORQUE CONVERTER

ROUGHNESS

ENGINE

PERFORMANCE

VACUUM LEAK

# f

t f

NO

VACUUM

AT

SERVO

AMPLIFICATION

OF ENGINE

SURGE

VACUUM

LEAK

DEFECTIVE SERVO

1

f

it

t

t

SPEED

CONTROL

THROTTLE

CABLE

DISCONNECTED

DEFECTIVE SERVO

EXCESSIVE

LOAD

MAY

REQUIRE MANUAL

ASSISTANCE

ON

HILLS DEFECTIVE

CABLE

i

f

f • *

IMPROPER

STOP LAMP

AND

SPEED CONTROL SWITCH ADJUSTMENT DEFECTIVE

CABLE

DEFECTIVE VACUUM

RESERVOIR

(CHECK VALVE) DEFECTIVE

VACUUM RESERVOIR

1

f

*

FAULTY

ELECTRICAL CIRCUIT* DEFECTIVE

ENGINE

CONTROLLER

DEFECTIVE SERVO

* TESTS AND

ADJUSTMENTS

ARE DESCRIBED

IN

APPROPRIATE

SECTION

OF SERVICE

MANUAL.

DEFECTIVE VACUUM

RESERVOIR

J918H-7

Page 419 of 1502

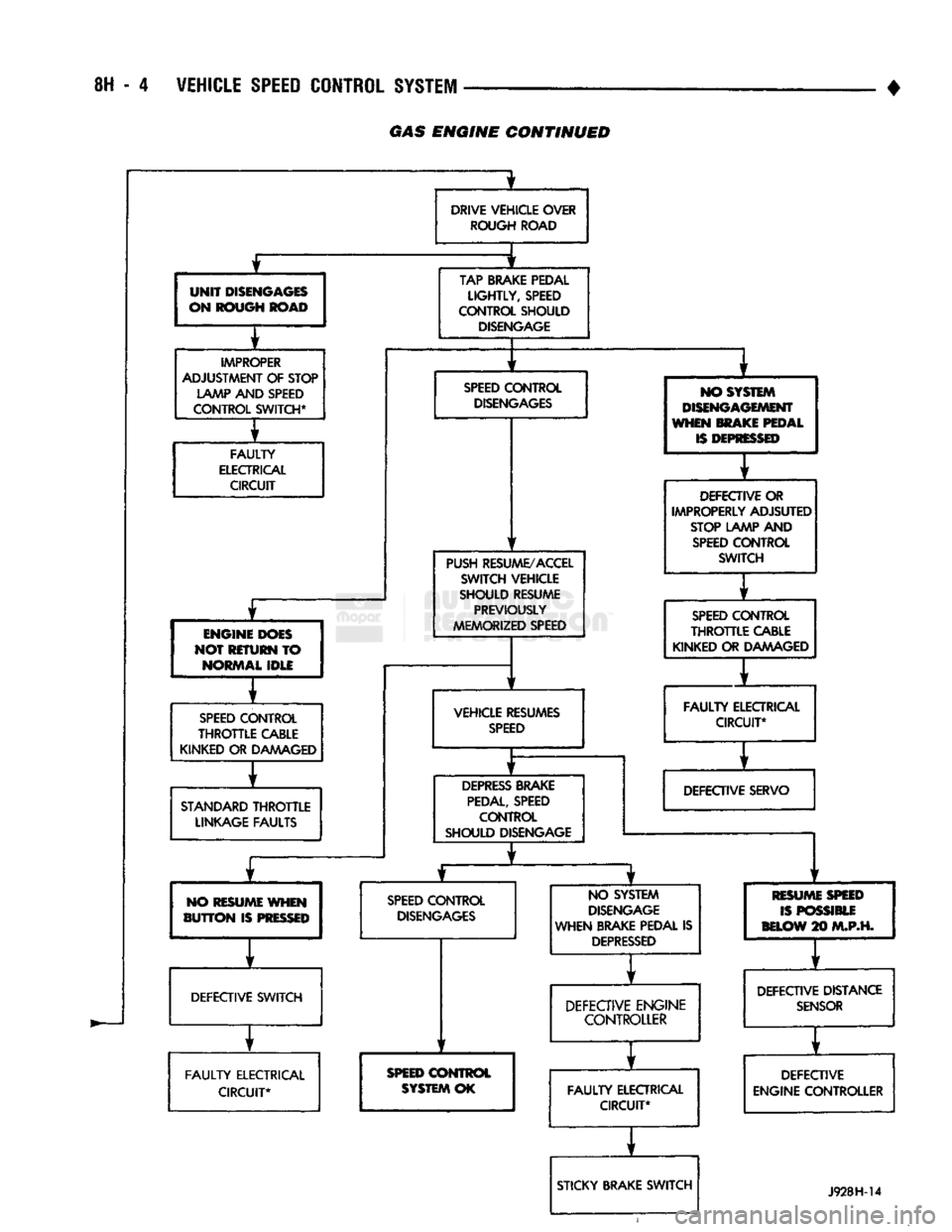

8H - 4 VEHICLE

SPEED

CONTROL SYSTEM

GAS

ENGINE

CONTINUED

UNIT

DISENGAGES

ON ROUGH ROAD

IMPROPER

ADJUSTMENT OF STOP LAMP AND SPEED

CONTROL SWITCH*

FAULTY

ELECTRICAL CIRCUIT

£

ENGINE DOES

NOT RETURN TO NORMAL IDLE

SPEED

CONTROL

THROTTLE

CABLE

KINKED OR DAMAGED

STANDARD

THROTTLE

LINKAGE FAULTS 1

DRIVE VEHICLE OVER

ROUGH ROAD

TAP BRAKE PEDAL

LIGHTLY,

SPEED

CONTROL SHOULD

DISENGAGE

SPEED

CONTROL

DISENGAGES

PUSH RESUME/ACCEL SWITCH VEHICLE

SHOULD RESUME PREVIOUSLY

MEMORIZED SPEED

VEHICLE RESUMES

SPEED

DEPRESS

BRAKE

PEDAL,

SPEED CONTROL

SHOULD DISENGAGE NO SYSTEM

DISENGAGEMENT

WHEN MAKE PEDAL

IS

DEPRESSED

DEFECTIVE OR

IMPROPERLY ADJSUTED

STOP LAMP AND

SPEED

CONTROL SWITCH

y

f

SPEED

CONTROL

THROTTLE

CABLE

KINKED OR DAAAAGED

1

FAULTY

ELECTRICAL CIRCUIT*

f

DEFECTIVE SERVO NO RESUME WHEN

BUTTON

IS

PRESSED

SPEED

CONTROL

DISENGAGES

DEFECTIVE SWITCH

FAULTY

ELECTRICAL CIRCUIT* NO SYSTEM

DISENGAGE

WHEN BRAKE PEDAL IS

DEPRESSED

SPEED

CONTROL

SYSTEM OK

1

f

DEFECTIVE ENGINE CONTROLLER

1

FAULTY

ELECTRICAL CIRCUIT*

r

STICKY BRAKE SWITCH RESUM

ISPO

BELOW

2

E

SPEED

SSIBLE

10

M.P.H.

y t

DEFECTIVE DISTANCE

SENSOR

y f

DEFECTIVE

ENGINE CONTROLLER

J928H-14

Page 420 of 1502

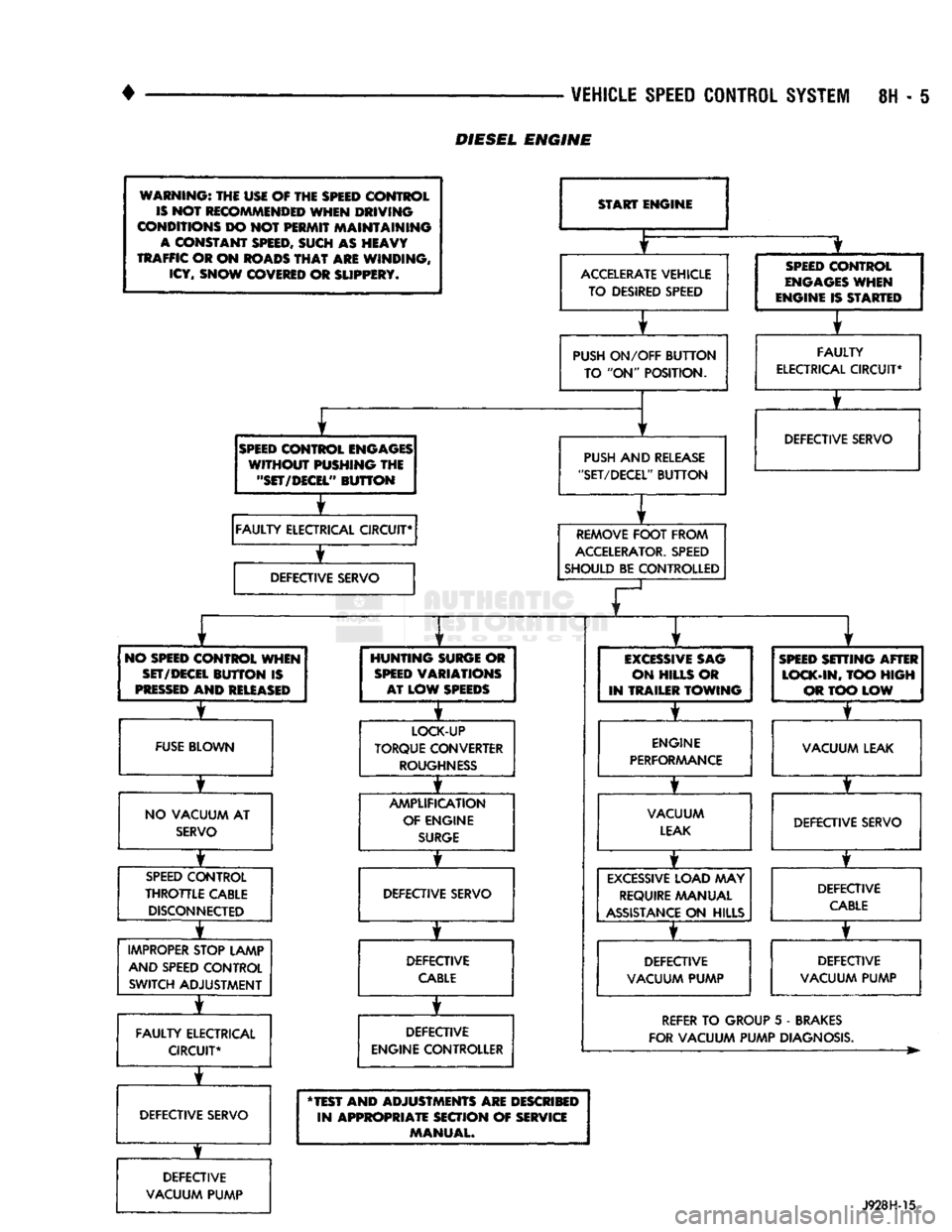

•

^ ^ VEHICLE

SPEED

CONTROL

SYSTEM

8H - I

WARNING:

THE USE OF THE

SPEED

CONTROL

IS

NOT

RECOMMENDED

WHEN DRIVING

CONDITIONS

DO NOT PERMIT MAINTAINING

A

CONSTANT

SPEED,

SUCH AS HEAVY

TRAFFIC

OR ON

ROADS

THAT

ARE WINDING,

ICY,

SNOW

COVERED

OR

SLIPPERY*

SPEED

CONTROL

ENGAGES

WITHOUT PUSHING THE

"SET/DECEL"

BUTTON

±

FAULTY

ELECTRICAL CIRCUIT*

±

DEFECTIVE

SERVO

START ENGINE

ACCELERATE

VEHICLE TO DESIRED SPEED

PUSH

ON/OFF

BUTTON

TO "ON" POSITION.

PUSH

AND

RELEASE

"SET/DECEL"

BUTTON

REMOVE

FOOT

FROM

ACCELERATOR.

SPEED

SHOULD BE CONTROLLED

SPEED

CONTROL

ENGAGES

WHEN

ENGINE IS STARTED

FAULTY

ELECTRICAL

CIRCUIT*

T

DEFECTIVE SERVO

NO

SPEED

CONTROL WHEN

SET/DECEL

BUTTON

IS

PRESSED

AND

RELEASED

FUSE

BLOWN

NO VACUUM AT

SERVO

T

SPEED

CONTROL

THROTTLE

CABLE DISCONNECTED

IMPROPER

STOP LAMP AND SPEED CONTROL SWITCH ADJUSTMENT

FAULTY

ELECTRICAL CIRCUIT*

T

DEFECTIVE SERVO

DEFECTIVE

VACUUM PUMP

HUNTING

SURGE

OR

SPEED

VARIATIONS AT LOW

SPEEDS

I

LOCK-UP

TORQUE CONVERTER

ROUGHNESS

AMPLIFICATION OF ENGINE

SURGE

DEFECTIVE SERVO

DEFECTIVE

CABLE

DEFECTIVE

ENGINE CONTROLLER

EXCESSIVE

SAG

ON HILLS OR

IN TRAILER

TOWING

ENGINE

PERFORAAANCE

VACUUM

LEAK

EXCESSIVE

LOAD MAY

REQUIRE

MANUAL

ASSISTANCE

ON HILLS

DEFECTIVE

VACUUM PUMP

SPEED

SETTING AFTER

LOCK-IN,

TOO

HIGH

OR TOO LOW

T

VACUUM LEAK

DEFECTIVE SERVO DEFECTIVE

CABLE

T

DEFECTIVE

VACUUM PUMP

REFER

TO GROUP 5 - BRAKES

FOR VACUUM PUMP DIAGNOSIS.

"TEST AND ADJUSTMENTS ARE DESCRIBED IN APPROPRIATE SECTION OF SERVICE MANUAL.

J928H-15

DIESEL

ENGINE