DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 421 of 1502

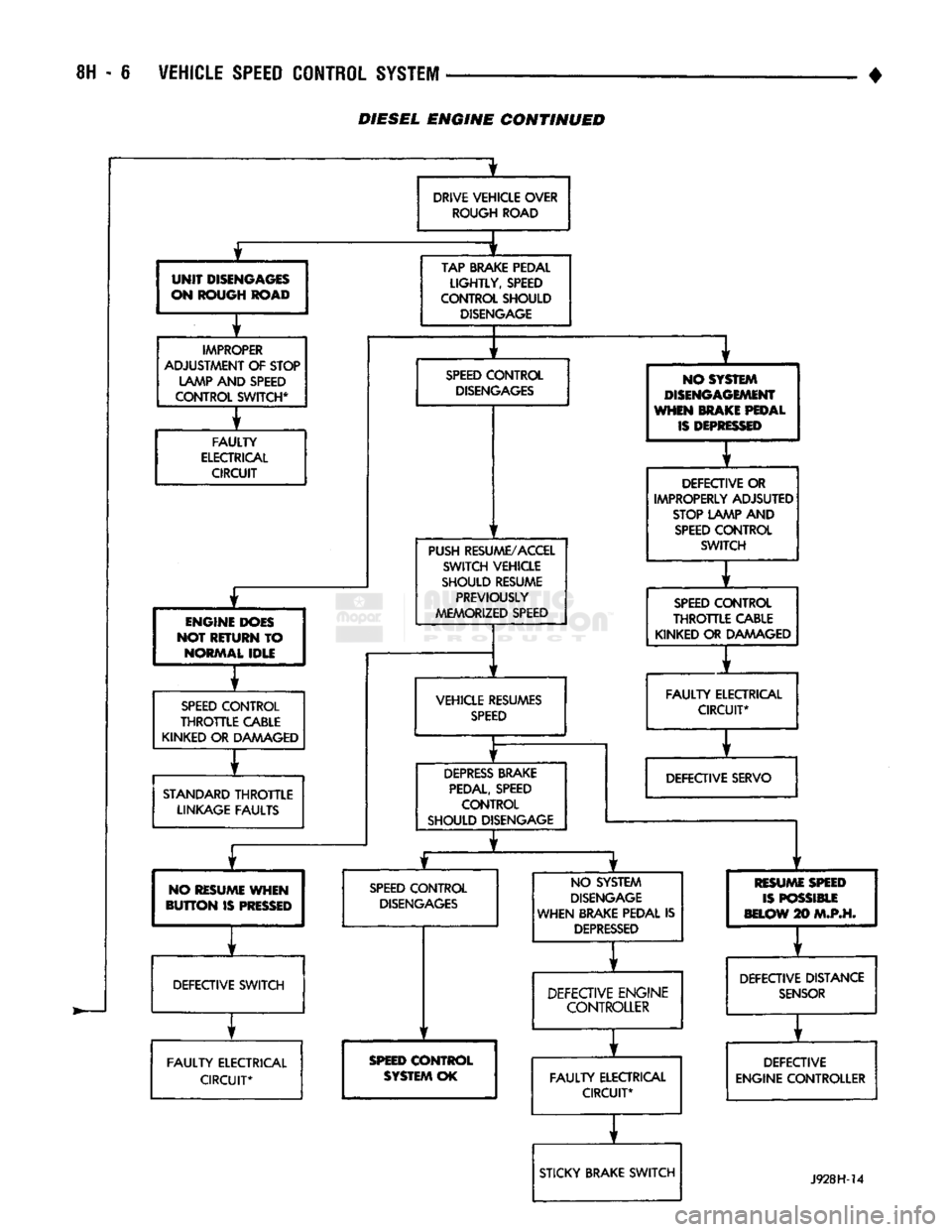

- 6

VEHICLE SPEED CONTROL SYSTEM

• £

UNIT

DISENGAGES

ON ROUGH ROAD

IMPROPER

ADJUSTMENT

OF

STOP LAMP AND SPEED

CONTROL SWITCH*

i

FAULTY

ELECTRICAL CIRCUIT

ENGINE DOES

NOT RETURN

TO

NORMAL IDLE

SPEED

CONTROL

THROTTLE

CABLE

KINKED OR DAAAAGED

STANDARD

THROTTLE

LINKAGE FAULTS

NO RESUME WHEN

BUTTON

IS

PRESSED

DRIVE VEHICLE OVER

ROUGH ROAD

±

TAP BRAKE PEDAL

LIGHTLY,

SPEED

CONTROL SHOULD

DISENGAGE

SPEED

CONTROL

DISENGAGES

PUSH RESUME/ACCEL SWITCH VEHICLE

SHOULD RESUME PREVIOUSLY

MEMORIZED SPEED

VEHICLE RESUMES

SPEED

DEPRESS

BRAKE

PEDAL,

SPEED CONTROL

SHOULD DISENGAGE NO SYSTEM

DISENGAGEMENT

WHEN MAKE PEDAL

IS

DEPRESSED

DEFECTIVE OR

IMPROPERLY ADJSUTED STOP LAMP

AND

SPEED

CONTROL SWITCH

1

1

SPEED

CONTROL

THROTTLE

CABLE

KINKED

OR

DAAAAGED

1

FAULTY

ELECTRICAL CIRCUIT*

1

DEFECTIVE SERVO

SPEED

CONTROL

DISENGAGES

DEFECTIVE SWITCH

FAULTY

ELECTRICAL CIRCUIT*

1

NO SYSTEM

DISENGAGE

WHEN BRAKE PEDAL

IS

DEPRESSED

SPEED

CONTROL

SYSTEM

OK

1

r

DEFECTIVE ENGINE CONTROLLER

* r

FAULTY

ELECTRICAL CIRCUIT*

r

STICKY BRAKE SWITCH RESUM

ISPO

BELOW*

E

SPEED

SSIBLE

10

M.P.H.

1

DEFECTIVE DISTANCE

SENSOR

f

DEFECTIVE

ENGINE CONTROLLER

J928H-14 DIESEL ENGINE CONTINUED

Page 422 of 1502

•

VEHICLE

SPEED

CONTROL SYSTEM

8H - 7

TEST

PROCEDURES

INDEX

page

Checking

for

Diagnostic

Trouble

Code

7

General

Information

7

Inoperative

System

7

Road

Test

7

Speed

Control

Cable Adjustment—Diesel Engine

. 9

Speed

Control

Cable

Attachment

10

GENERAL

INFORMATION

Before starting diagnosis and repair procedures for

a speed control malfunction, verify that the speed

control wire harness is properly connected to all con nectors. Refer to Diagnosis Chart.

ROAD

TEST

Road test vehicle to verify reports of speed control

system malfunction. The road test should include at

tention to the speedometer. Speedometer operation should be smooth and without flutter at all speeds. Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys

tem. The cause of any speedometer deficiencies should be corrected before proceeding.

INOPERATIVE SYSTEM

If road test verifies a system problem and the

speedometer operates properly, check for:

• loose electrical and vacuum connections at the

servo.

• check for correct installation of the vacuum check

valve in the hose from servo to vacuum source (Gas

Engine Only). The word VAC on the valve must

point toward the vacuum source. • corrosion that should be removed from electrical

terminals and a light coating of Mopar Multi-Pur

pose Grease, or equivalent, applied. • secure attachment of both ends of speed control ca

ble.

CHECKING

FOR DIAGNOSTIC TROUBLE CODE

(1) When trying to verify a speed control system

electrical problem, use a DRB II Scan Tool to find

the cause. Refer to Powertrain Diagnostic Procedures manual. If the DRBII is not available, the Diagnostic Trou

ble Code (DTC) may be determined with the follow ing method: (a) With key inserted in ignition switch, cycle

switch to ON position 3 times. On third cycle, leave

switch in ON position. (b) After switch has been cycled 3 times, observe

Malfunction Indicator Lamp (CHECK ENGINE) on instrument cluster. If a DTC is present, the code

page

Speed

Control

Cable Attachment—Servo

10

Stop Lamp Switch Test

9

Vacuum Supply Test

....................... 9

Vehicle Speed

Control

Switch Test

. 9

Vehicle Speed

Control

System

Electrical

Tests

... 7

Vehicle Speed Sensor Test

7

will be displayed in a series of flashes representing

digits.

Three flashes in rapid succession, a slight

pause, then 4 flashes in rapid succession would in dicate DTC 34.

(2) If a DTC 34 is observed, perform the tests in

the sections Electrical Tests at Servo and Electrical

Tests at Powertrain Control Module.

If a DTC 15 is observed, perform the test for a

faulty Vehicle Speed Sensor.

(3) If a fault code 11 is observed (Diesel only), per

form the test for a faulty engine speed sensor. Refer

to the Powertrain Diagnostics Procedures Manual.

(4) Correct any problems found when performing

these tests and recheck for DTC if changes were made.

VEHICLE SPEED SENSOR TEST

For testing of the Vehicle Speed Sensor and related

components refer to the Powertrain Diagnostic Proce

dures manual.

VEHICLE SPEED CONTROL SYSTEM ELECTRICAL

TESTS

Vehicle speed control systems may be tested using

two different methods. One involves the use of the DRBII Scan Tool. If this test method is desired,

please refer to the Powertrain Diagnostic Procedures manual. The other test method uses a voltmeter. The volt

meter method is described in the following tests.

If any information is needed concerning wiring, re

fer to Group 8W - Wiring Diagrams.

CAUTION:

When test probing

for

voltage

or

continuity

at

electrical

connectors, care must

be

taken

not

to

damage connector, terminals,

or

seals.

If

these components

are

damaged,

intermittent

or

complete system

failure

may

occur.

ELECTRICAL

TESTS

AT

SERVO

(1) Turn ignition switch to ON position.

(2) Push speed control switch to ON position.

(3) Connect the negative lead of a voltmeter to a

good chassis ground near the servo.

Page 423 of 1502

8H - 8

VEHICLE SPEED CONTROL SYSTEM

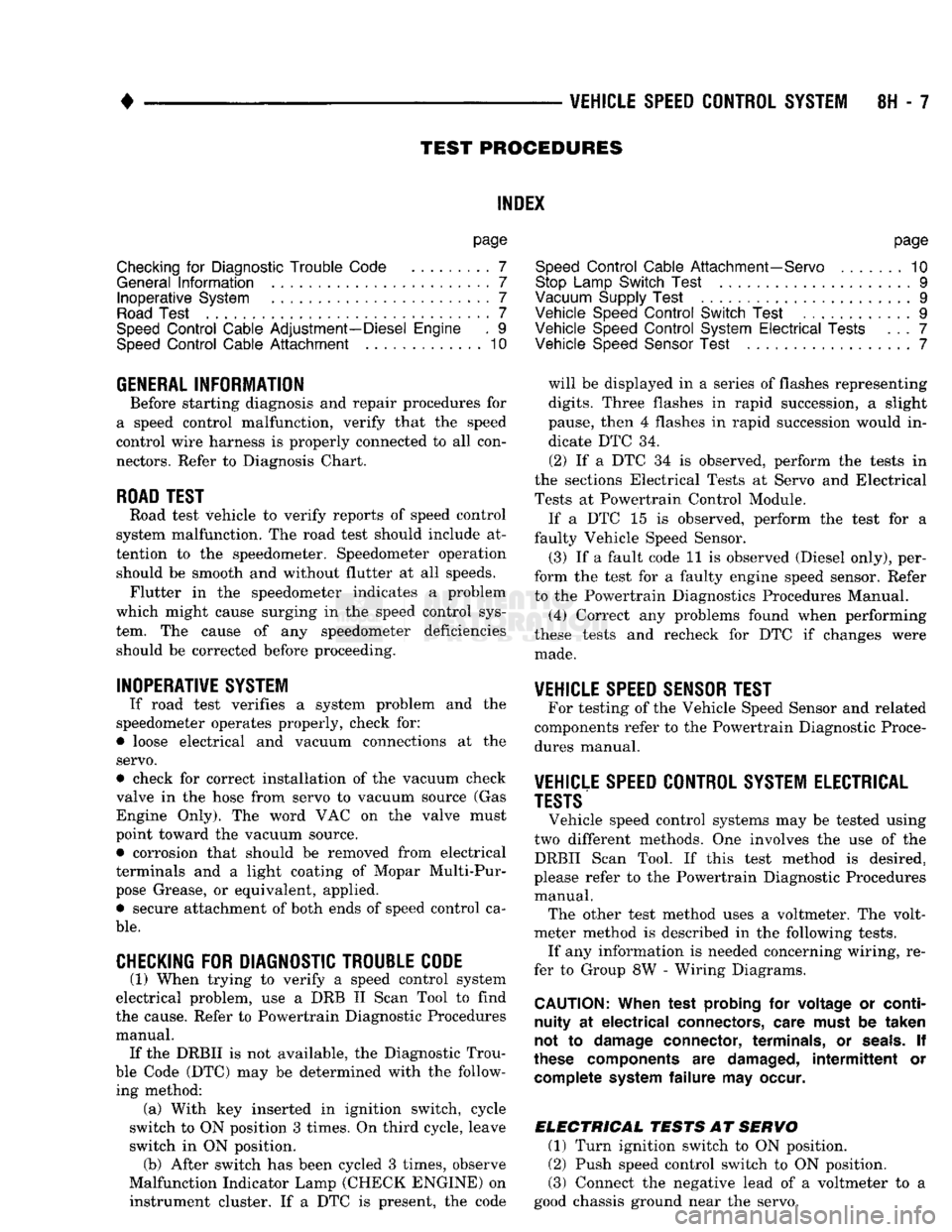

• (4) Disconnect the 4-way connector going to the

servo (Figs. 1 and 2), The blue wire with the red

tracer of the main harness 4-way connector should

read approximately battery voltage. If not, check for loose connections, brake switch adjustment or, repair

the main harness as necessary.

(5) Connect a jumper wire between the male and

female terminals of the blue wire with red tracer.

The other 3 male terminals from the servo should show battery voltage. If not, replace the servo. (6) Turn ignition OFF. Using an ohmmeter, con

nect one lead to a good body ground. Touch the other

lead to the black (BK) wire terminal in the 4-way

connector of the main harness. The meter should

show continuity. If not, repair the ground circuit as

necessary. A

VACUUM

y~

HOSE

J918H-24

Fig.

1 Servo And Harness Connector—Gas

Engine—Typical

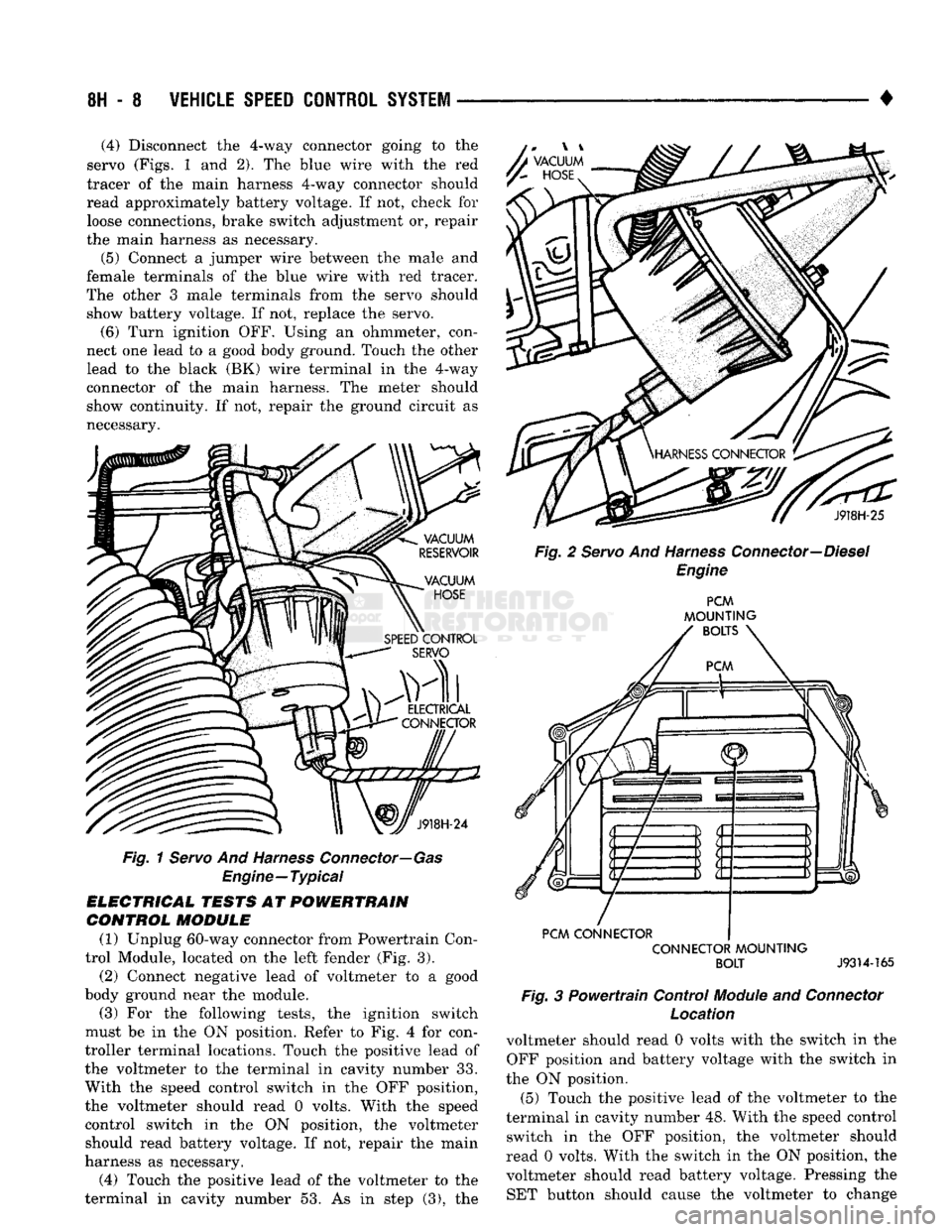

ELECTRICAL TESTS AT POWERTRAIN CONTROL MODULE

(1) Unplug 60-way connector from Powertrain Con

trol Module, located on the left fender (Fig. 3).

(2) Connect negative lead of voltmeter to a good

body ground near the module. (3) For the following tests, the ignition switch

must be in the ON position. Refer to Fig. 4 for con

troller terminal locations. Touch the positive lead of

the voltmeter to the terminal in cavity number 33.

With the speed control switch in the OFF position,

the voltmeter should read 0 volts. With the speed

control switch in the ON position, the voltmeter should read battery voltage. If not, repair the main

harness as necessary.

(4) Touch the positive lead of the voltmeter to the

terminal in cavity number 53. As in step (3), the J918H-25

Fig. 2 Servo And Harness Connector—Diesel Engine PCM

MOUNTING

BOLTS

PCM CONNECTOR CONNECTOR MOUNTING BOLT

J9314-165

Fig.

3 Powertrain Control

Module

and

Connector

Location

voltmeter should read 0 volts with the switch in the OFF position and battery voltage with the switch in

the ON position. (5) Touch the positive lead of the voltmeter to the

terminal in cavity number 48. With the speed control switch in the OFF position, the voltmeter should

read 0 volts. With the switch in the ON position, the voltmeter should read battery voltage. Pressing the SET button should cause the voltmeter to change

Page 424 of 1502

![DODGE TRUCK 1993 Service Repair Manual

VEHICLE

SPEED

CONTROL SYSTEM

8H - 9

rain

oooooooooo

1 10,

.oooooooooo

\21 30

„. \£] 50 x

OOOOOOOOOO OOOOOOOOOO^

11

20

OOOOOOOOOO

51

31 1 6ooooooooo60y/ Tratr

TJKT

RR8HC DODGE TRUCK 1993 Service Repair Manual

VEHICLE

SPEED

CONTROL SYSTEM

8H - 9

rain

oooooooooo

1 10,

.oooooooooo

\21 30

„. \£] 50 x

OOOOOOOOOO OOOOOOOOOO^

11

20

OOOOOOOOOO

51

31 1 6ooooooooo60y/ Tratr

TJKT

RR8HC](/img/12/56922/w960_56922-423.png)

VEHICLE

SPEED

CONTROL SYSTEM

8H - 9

rain

oooooooooo

1 10,

.oooooooooo

\21 30

„. \£] 50 x

OOOOOOOOOO OOOOOOOOOO^

11

20

OOOOOOOOOO

51

31 1 6ooooooooo60y/ Tratr

TJKT

RR8HC7

Fig.

4 Powertrain Control Module 60-Way Connector

Shown from Terminal End

from battery voltage to 0 volts for as long as the switch is held. If not, perform the speed control

switch test. If the switch is not at fault, then check

the main harness and repair as necessary.

(6) Touch the positive lead of the voltmeter to the

terminal in cavity number 50. The voltmeter should read 0 volts with the speed control switch in either

the OFF or ON position. With switch in either RE SUME or SET position, the voltmeter should read

battery voltage. If not, perform the speed control switch test. If the switch is not at fault, then check

the main harness and repair as necessary.

(7) Touch the positive lead of the voltmeter to the

terminal in cavity number 49. The voltmeter should read 0 volts with the switch in the OFF position.

With the switch in the ON position, the voltmeter should read battery voltage. The voltmeter will con

tinue to read battery voltage when either the SET or

RESUME switch is pressed. If not, perform the speed control switch test. If the switch is not at fault, then

check the main harness and repair as necessary . (8) Turn key OFF. Using an ohmmeter, connect

one lead to a good body ground and touch the other

lead to the terminal in cavity number 29. With the

brake pedal released, the meter should show continu ity. When the pedal is depressed, the meter should

show open circuit.

VEHICLE

SPEED

CONTROL SWITCH TEST

To check the switch, remove the switch from its

mounting position. Use an ohmmeter and refer to the

Switch Continuity Chart to determine if continuity is

correct. If there is no continuity at any one of the

switch positions, replace the switch.

STOP

LAMP SWITCH TEST

(1) Disconnect connector at stop lamp switch. Us

ing an ohmmeter, continuity may be checked at

switch side of connector as follows (Fig. 5): (a) With brake pedal released, there should be:

• continuity between black (BK) and white with

pink tracer (WT/PK) wires

• continuity between yellow with red tracer (YL/RD) and dark blue with red tracer (DB/RD) wires

• No continuity between pink (PK) and white (WT)

wires.

SPEED CONTROL SWITCH CONTINUITY

CHART

CONNECTOR

TERMINAL

END

JE

El

SWITCH

SPEED

CONTROL

SWITCH

CONTINUITY

SWITCH!

rea?!®^

CONTINUITY

BETWEEN

OFF PIN 1

AND PIN 4

ON PIN

1 AND PIN 4

PIN 1

AND PIN 2

PIN

2 AND PIN 4

ON

AND

SET PIN

1

AN D

PIN 2

ON

AND

RESUME PIN

1 AND PIN 3

J928H-4

(b) With brake pedal depressed, there should be:

• continuity between pink (PK) and white (WT)

wires.

• No continuity between black (BK) and white with

pink tracer (WT/PK) wires.

• No continuity between yellow with red tracer (YL/

RD) and dark blue with red tracer (DB/RD) wires. (2) If the above results are not obtained, the stop

lamp switch is defective or out of adjustment.

Stop lamp switch adjustment is detailed in Group 5 -

Brakes.

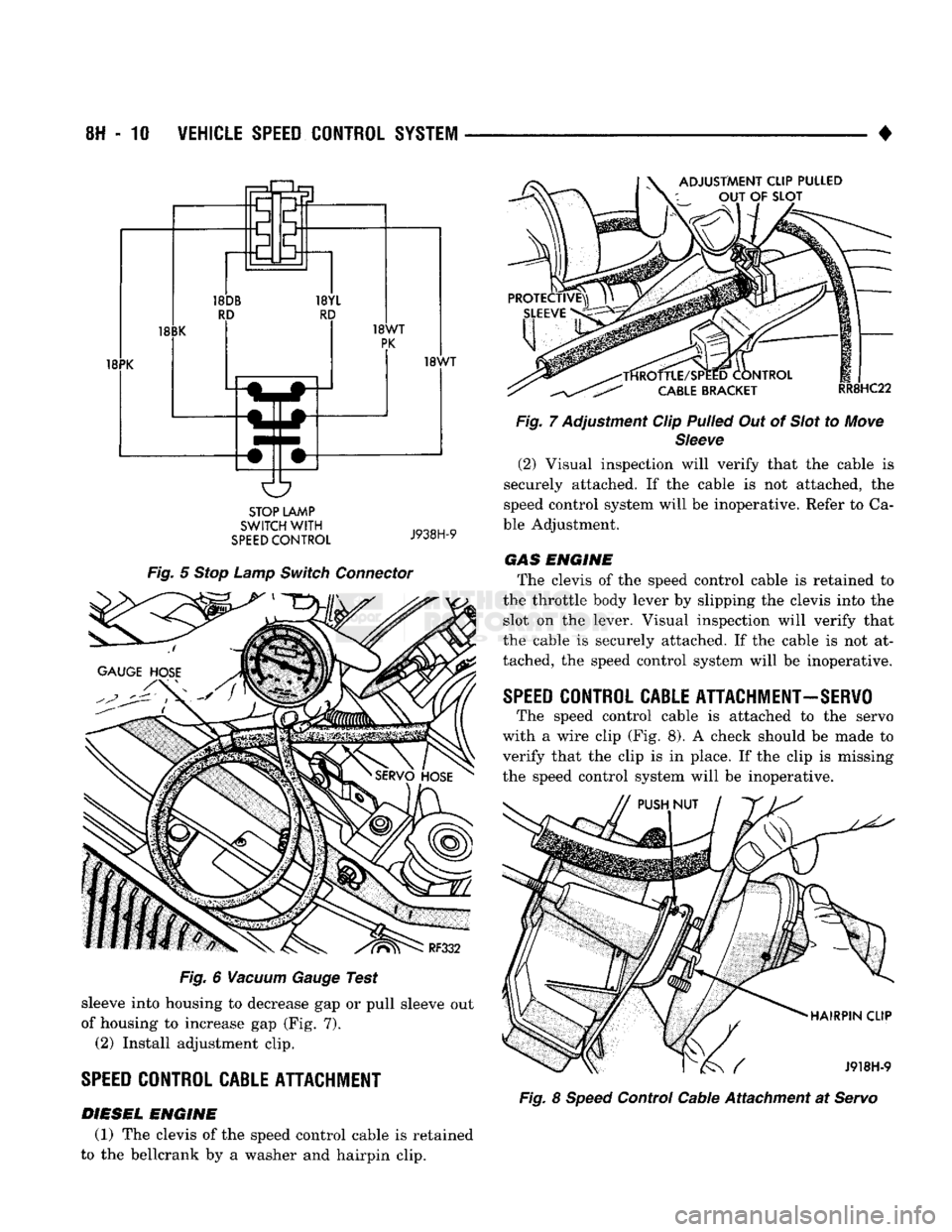

VACUUM SUPPLY TEST

(1) Disconnect vacuum hose at the servo and in

stall a vacuum gauge in the hose (Fig. 6). (2) Start engine and observe gauge at idle. Vac

uum gauge should read at least ten inches of mer

cury. (3) If vacuum does not meet this requirement,

check for vacuum leaks or poor engine performance.

SPEED

CONTROL

CABLE

ADJUSTMENT-DIESEL

ENGINE

(1) The gap between the end of the slot on the ca

ble and the bellcrank pin must be as small as possi

ble (0 to 1mm) without moving the throttle. If gap is not correct, remove adjustment clip. Push protective

Page 425 of 1502

8H

- 10

VEHICLE

SPEED

CONTROL

SYSTEM

•

18PK ADJUSTMENT CLIP PULLED

OUT

OF

SLOT

18WT

STOP LAMP

SWITCH

WITH

SPEED

CONTROL

J938H-9

Fig.

5

Stop

Lamp

Switch

Connector

Fig.

6

Vacuum

Gauge

Test

sleeve into housing to decrease gap or pull sleeve out

of housing to increase gap (Fig. 7). (2) Install adjustment clip.

SPEED

CONTROL CABLE ATTACHMENT

DIESEL

ENGINE

(1) The clevis of the speed control cable is retained

to the bellcrank by a washer and hairpin clip.

-TfiROTTLE/SPEED CONTROL

CABLE

BRACKET

RR8HC22

Fig.

7 Adjustment Clip

Pulled

Out of

Slot

to

Move

Sleeve

(2) Visual inspection will verify that the cable is

securely attached. If the cable is not attached, the

speed control system will be inoperative. Refer to Ca

ble Adjustment. GAS ENGINE

The clevis of the speed control cable is retained to

the throttle body lever by slipping the clevis into the slot on the lever. Visual inspection will verify that

the cable is securely attached. If the cable is not at

tached, the speed control system will be inoperative.

SPEED

CONTROL CABLE ATTACHMENT-SERVO

The speed control cable is attached to the servo

with a wire clip (Fig. 8). A check should be made to verify that the clip is in place. If the clip is missing

the speed control system will be inoperative.

HAIRPIN CLIP

/ J918H-9

Fig.

8

Speed

Control Cable Attachment at

Servo

Page 426 of 1502

•

VEHICLE

SPEED

CONTROL SYSTEM

8H - 11

SERVICE

PROCEDURES

INDEX

page

Servo

Throttle

Cable Assembly—Diesel Engine

. . 12

Servo

Throttle

Cable Assembly—Gas Engine

... 11

Servo

Unit

11

Speed

Control

Switch Replacement

12

page

Speed

Control

Vacuum Reservoir Replacement—Gas Engine

12

Vacuum Pump—Diesel Engine

. 12

SERVO

UNIT

REMOVAL

(1) Disconnect vacuum hose at servo.

(2)

Disconnect electrical connector at servo.

(3)

Remove 2 nuts from servo mounting bracket.

(4)

Pull servo away from mounting bracket.

(5)

Remove and discard push nuts on servo studs.

(6)

Pull speed control cable away from servo to ex

pose cable retaining clip.

(7) Remove clip attaching cable to servo.

INSTALLATION

(1) Block throttle to full open position (gas engine),

pivot bellcrank full rearward (diesel engine), and align hole in cable sleeve with hole in servo pin. In

stall retaining clip.

(2)

Insert servo studs through holes in the cable.

(3)

Install new push nuts on the servo studs.

(4)

Insert servo studs through holes in servo

mounting bracket. One stud mounts reservoir.

(5)

Install the 2 attaching nuts and tighten to 6

N*m (50 in. lbs.).

(6)

Connect vacuum hose to servo. (7) Connect the electrical connector to servo termi

nals.

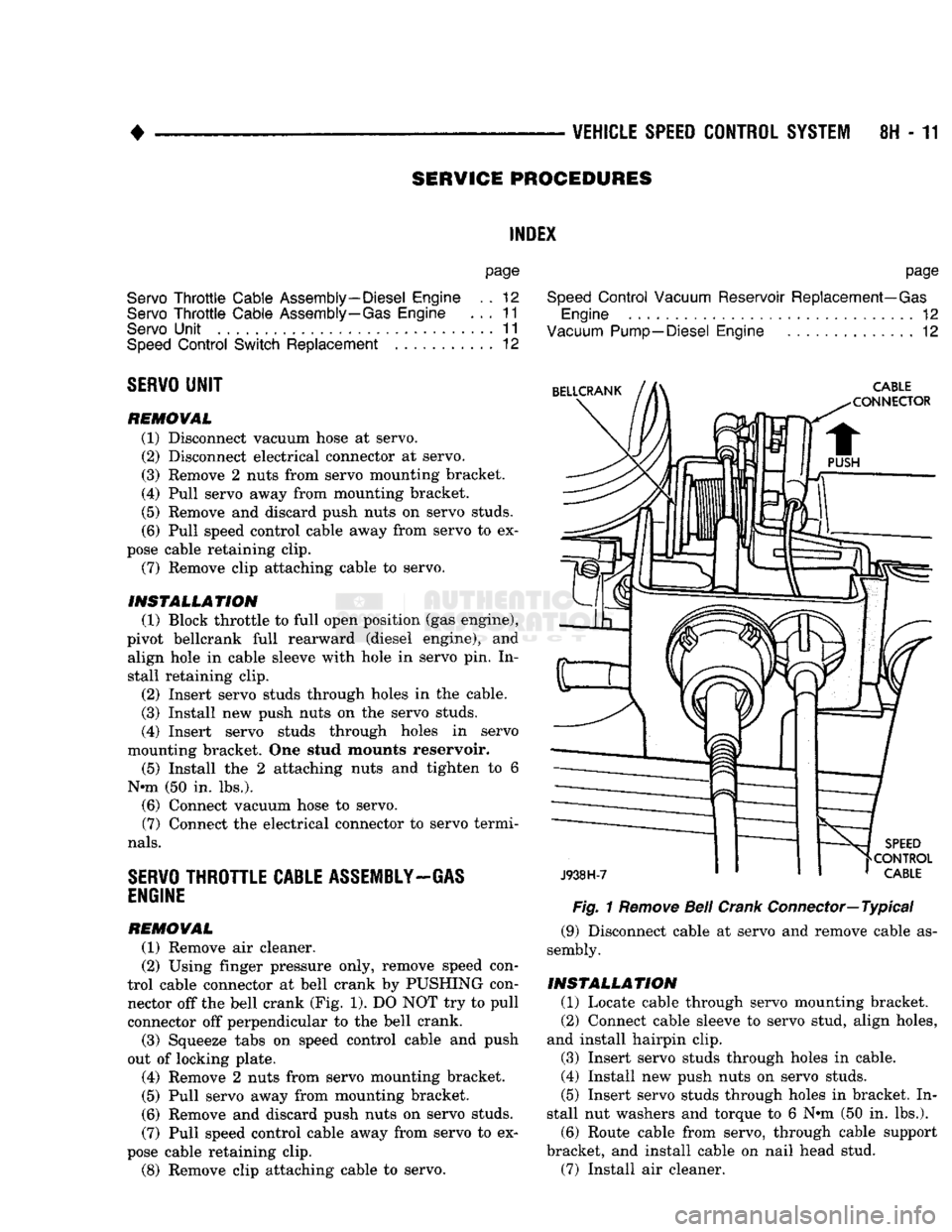

SERVO

THROTTLE CABLE ASSEMBLY-GAS

ENGINE

REMOVAL

(1) Remove air cleaner.

(2)

Using finger pressure only, remove speed con

trol cable connector at bell crank by PUSHING con nector off the bell crank (Fig. 1). DO NOT try to pull

connector off perpendicular to the bell crank.

(3)

Squeeze tabs on speed control cable and push

out of locking plate.

(4)

Remove 2 nuts from servo mounting bracket.

(5)

Pull servo away from mounting bracket.

(6)

Remove and discard push nuts on servo studs.

(7) Pull speed control cable away from servo to ex

pose cable retaining clip.

(8)

Remove clip attaching cable to servo.

Fig.

1

Remove

Bell

Crank

Connector—

Typical

(9) Disconnect cable at servo and remove cable as

sembly.

INSTALLATION

(1) Locate cable through servo mounting bracket.

(2)

Connect cable sleeve to servo stud, align holes,

and install hairpin clip.

(3)

Insert servo studs through holes in cable.

(4)

Install new push nuts on servo studs.

(5)

Insert servo studs through holes in bracket. In

stall nut washers and torque to 6 Nnn (50 in. lbs.).

(6)

Route cable from servo, through cable support

bracket, and install cable on nail head stud.

(7) Install air cleaner.

Page 427 of 1502

8H

- 12

VEHICLE SPEED CONTROL SYSTEM

•

SERVO

THROTTLE CABLE ASSEMBLY—DIESEL

ENGINE

REMOVAL (1) Remove hairpin clip and washer retaining ca

bles on bellcrank. Remove servo throttle cable from bellcrank.

(2) Remove servo throttle cable from cable support

bracket.

(3) Remove 2 nuts from servo mounting bracket.

(4) Pull servo away from mounting bracket.

(5) Remove and discard push nuts on servo studs. (6) Pull speed control cable away from servo to ex

pose cable retaining clip. (7) Remove clip attaching cable to servo.

(8) Disconnect cable at servo and remove cable as

sembly.

INSTALLATION (1) Locate cable through servo mounting bracket.

(2) Connect cable sleeve to servo stud, align holes,

and install hairpin clip.

(3) Insert servo studs through holes in cable.

(4) Install new push nuts on servo studs.

(5) Insert servo studs through holes in bracket. In

stall nut washers and torque to 6 N*m (50 in. lbs.).

(6) Route cable from servo, to cable support

bracket, (7) Install cable end on bellcrank rod.

(8) Adjust cable as described under speed control

cable adjustment. (9) Install washer and hairpin clip on end of bell

crank rod.

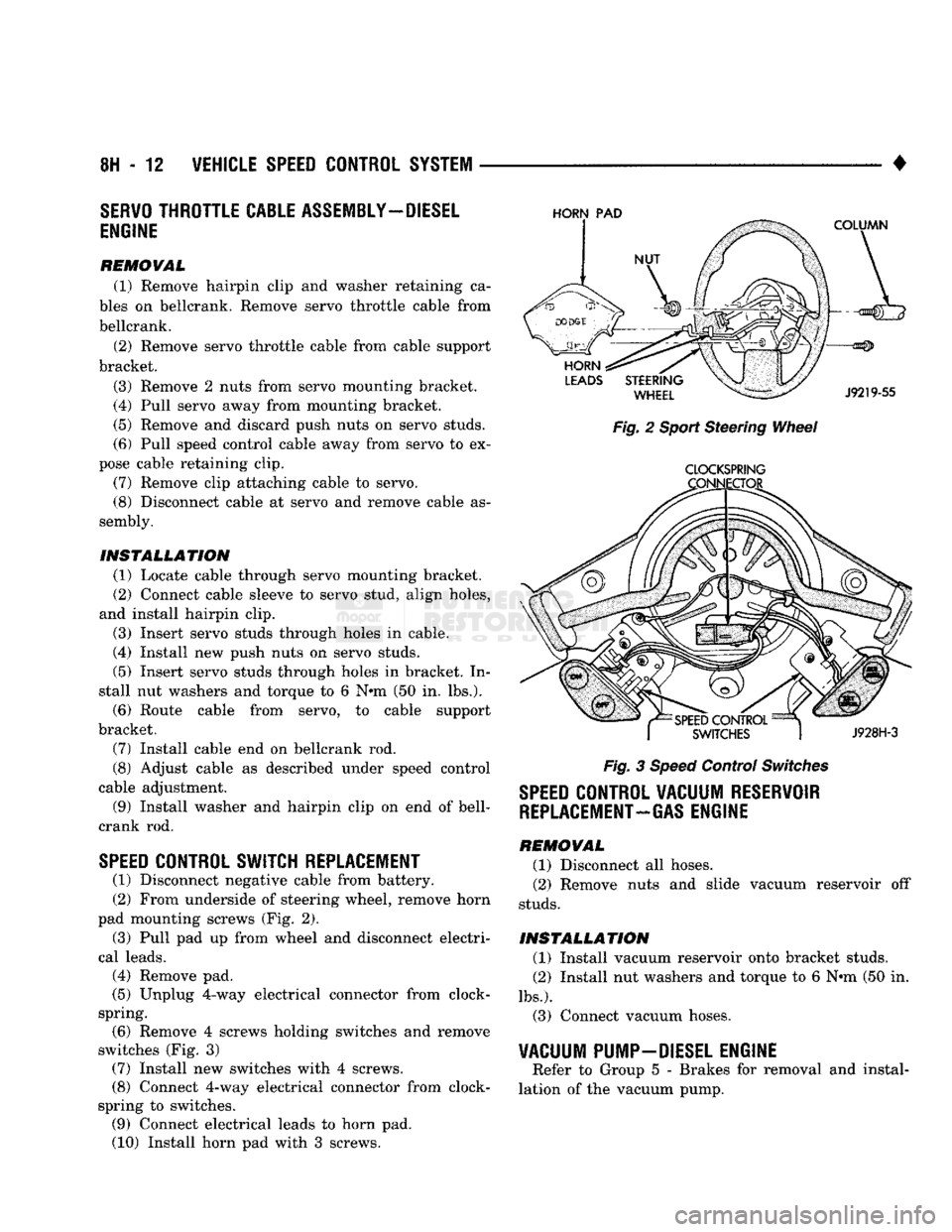

SPEED

CONTROL

SWITCH

REPLACEMENT

(1) Disconnect negative cable from battery.

(2) From underside of steering wheel, remove horn

pad mounting screws (Fig. 2).

(3) Pull pad up from wheel and disconnect electri

cal leads.

(4) Remove pad.

(5) Unplug 4-way electrical connector from clock-

spring. (6) Remove 4 screws holding switches and remove

switches (Fig. 3) (7) Install new switches with 4 screws.

(8) Connect 4-way electrical connector from clock-

spring to switches. (9) Connect electrical leads to horn pad.

(10) Install horn pad with 3 screws.

HORN

PAD

Fig. 2 Sport Steering Wheel

CLOCKSPRING

Fig. 3 Speed Control Switches

SPEED

CONTROL VACUUM RESERVOIR

REPLACEMENT-GAS

ENGINE

REMOVAL (1) Disconnect all hoses.

(2) Remove nuts and slide vacuum reservoir off

studs.

INSTALLATION (1) Install vacuum reservoir onto bracket studs.

(2) Install nut washers and torque to 6 Nrn (50 in.

lbs.).

(3) Connect vacuum hoses.

VACUUM PUMP-DIESEL ENGINE

Refer to Group 5 - Brakes for removal and instal

lation of the vacuum pump.

Page 428 of 1502

•

TURN SIGNALS

AND

HAZARD WARNING FLASHER

8J - 1

CONTENTS

page page

GENERAL

INFORMATION

1

MULTIFUNCTION SWITCH TESTING MULTIFUNCTION SWITCH SERVICE PROCEDURES

2

PROCEDURES

3

GENERAL

INFORMATION

TURN SIGNALS

DESCRIPTION With

the

ignition

key ON and the

multi-function

lever

in its UP or

DOWN position, current flows

through

the:

• turn signal flasher canister • Turn/Hazard switch

• turn indicator lamp

• front

and

rear bulbs. The selected turn signal indicator with front

and

rear turn signal bulbs will flash.

DIAGNOSIS High generator output voltage

can

burn

out

lamps rapidly. (1) Remove

and

inspect fuse

in

cavity

#9 of

fuse

block. Replace

if

necessary.

The

fuse block

is

behind

the lower instrument panel cover under steering wheel. (2) Turn

key to

ACCY. There should

be

battery

voltage

at the

fuse side

of the

turn signal flasher (bottom terminal).

If

not,

repair open circuit

in

wir

ing between fuse

and

flasher.

(3) Replace Turn Flasher with

2

lamp

12

volt rated

flasher that

is

know

to be

good.

The

lamps should

flash. If

not,

replace with original flasher

and

go to

next step.

(4) Measure voltage

at the

Turn/Hazard switch

connector cavity

#17.

Meter should read battery volt

age.

If

OK,

replace Turn/Hazard switch assembly.

If

not, repair open circuit

in

wiring between flasher

and Turn/Hazard switch connector.

HAZARD WARNING SYSTEM

DESCRIPTION

With

the

hazard switch

OUT,

current flows

through

the

• hazard flasher canister

• hazard switch

•

two

front turn signal bulbs

•

two

rear turn signal bulbs

• both indicator bulbs.

All

of the

turn lamps

and

both indicators will

flash.

DIAGNOSIS Hazard switch

in

ON.

The

park

and

stop lamps

should light.

If

not

replace

the 20

amp

fuse

in

fuse

block cavity

#13.

(1) Measure voltage

at

the

fuse side

of

the

flasher

(side terminal). Meter should read battery voltage.

If

not, repair open circuit

in

wiring

to

fuse. (2) Replace Hazard flasher with known good

flasher. Lamps should flash.

If

not, replace with orig

inal flasher

and go

to

next step.

(3) Measure voltage

at the

Turn/Hazard switch

connector cavity #13. Meter should read battery volt

age.

If

not,

repair open circuit

in

wiring

to

hazard

flasher.

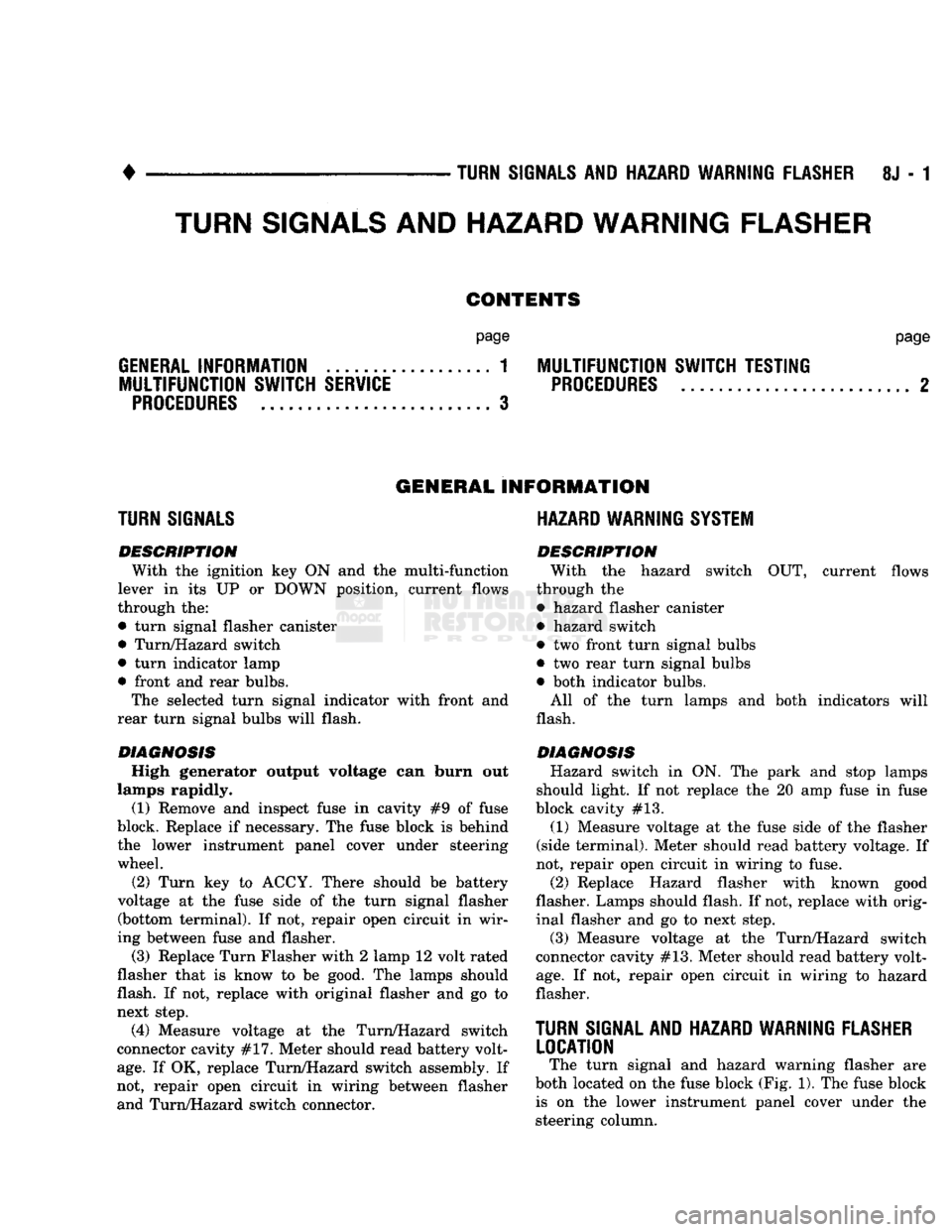

TURN

SIGNAL AND HAZARD

WARNING

FLASHER

LOCATION

The turn signal

and

hazard warning flasher

are

both located

on the

fuse block (Fig.

1). The

fuse block is

on the

lower instrument panel cover under

the

steering column.

TURN SIGNALS AND HAZARD WARNING

FLASHER

Page 429 of 1502

8J

- 2

TURN SIGNALS AND HAZARD WARNING FLASHER

•

FUSE

BLOCK

INSTRUMENT

PANEL

REAR

VIEW

HAZARD

WARNING

FLASHER

VIEW

IN DIRECTION OF

ARROW

RR8JC10

Fig.

1 Turn

Signal

and Hazard Warning

Flashers

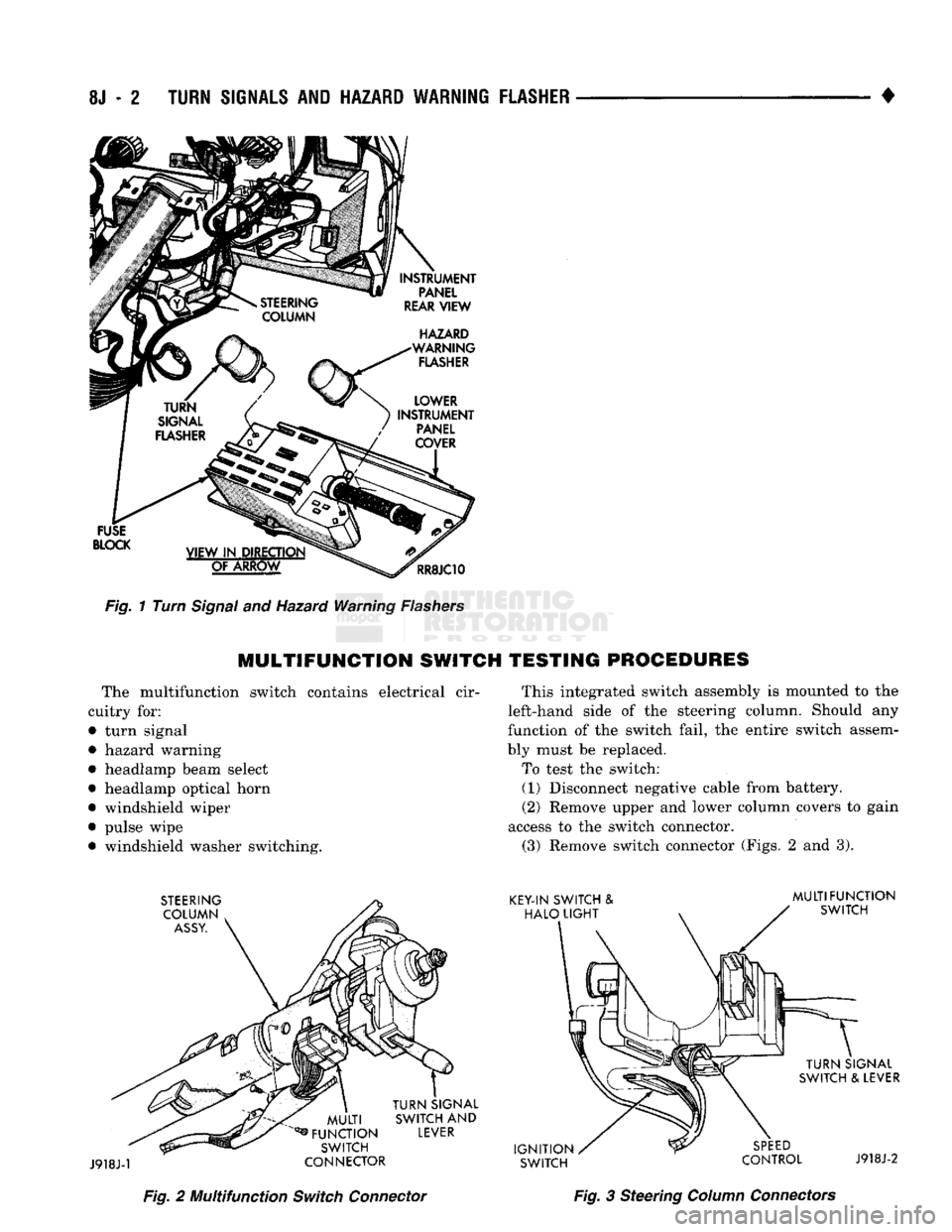

MULTIFUNCTION

SWITCH TESTING PROCEDURES

The multifunction switch contains electrical cir

cuitry for:

• turn signal

• hazard warning

• headlamp beam select

• headlamp optical horn

• windshield wiper

• pulse wipe • windshield washer switching. This integrated switch assembly is mounted to the

left-hand side of the steering column. Should any

function of the switch fail, the entire switch assem

bly must be replaced.

To test the switch: (1) Disconnect negative cable from battery.

(2) Remove upper and lower column covers to gain

access to the switch connector. (3) Remove switch connector (Figs. 2 and 3).

Fig.

2 Multifunction

Switch

Connector

Fig.

3 Steering

Column

Connectors

Page 430 of 1502

•

TURN

SIGNALS

AND

HAZARD WARNING FLASHER

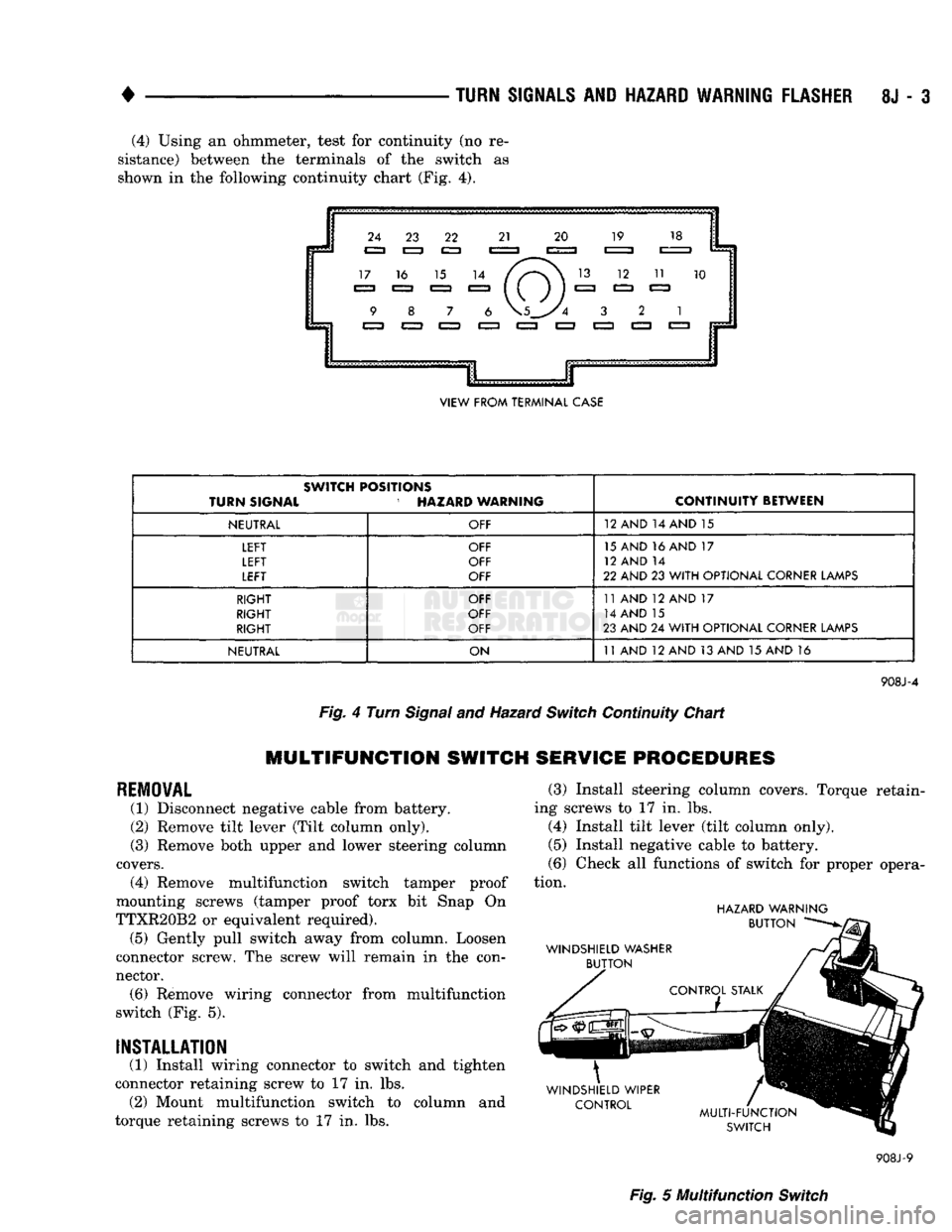

8J - 3 (4) Using an ohmmeter, test for continuity (no re

sistance) between the terminals of the switdh as shown in the following continuity chart (Pig. 4).

VIEW

FROM TERMINAL CASE

SWITCH POSITIONS

TURN

SIGNAL HAZARD WARNING

CONTINUITY

BETWEEN

NEUTRAL

OFF 12

AND 14 AND 15

LEFT

LEFT

LEFT

OFF

OFF

OFF 15

AND 16 AND 17

12

AND 14

22

AND 23 WITH OPTIONAL CORNER LAMPS

RIGHT

RIGHT

RIGHT

OFF

OFF

OFF 11

AND 12 AND 17

14

AND 15

23

AND 24 WITH OPTIONAL CORNER LAMPS

NEUTRAL

ON 11

AND 12 AND 13 AND 15 AND 16

908J-4

Fig.

4 Turn

Signal

and Hazard Switch Continuity Chart

MULTIFUNCTION SWITCH SERVICE PROCEDURES

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove tilt lever (Tilt column only).

(3) Remove both upper and lower steering column

covers. (4) Remove multifunction switch tamper proof

mounting screws (tamper proof torx bit Snap On

TTXR20B2 or equivalent required). (5) Gently pull switch away from column. Loosen

connector screw. The screw will remain in the con

nector. (6) Remove wiring connector from multifunction

switch (Fig. 5).

INSTALLATION

(1) Install wiring connector to switch and tighten

connector retaining screw to 17 in. lbs. (2) Mount multifunction switch to column and

torque retaining screws to 17 in. lbs. (3) Install steering column covers. Torque retain

ing screws to 17 in. lbs. (4) Install tilt lever (tilt column only).

(5) Install negative cable to battery.

(6) Check all functions of switch for proper opera

tion.

HAZARD

WARNING

908J-9

Fig.

5 Muitifunction Switch