DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 461 of 1502

8P

- 2 POWER DOOR LOCKS

• SERVICE PROCEDURES

DOOR LOCK MOTOR REPLACEMENT

REMOVAL

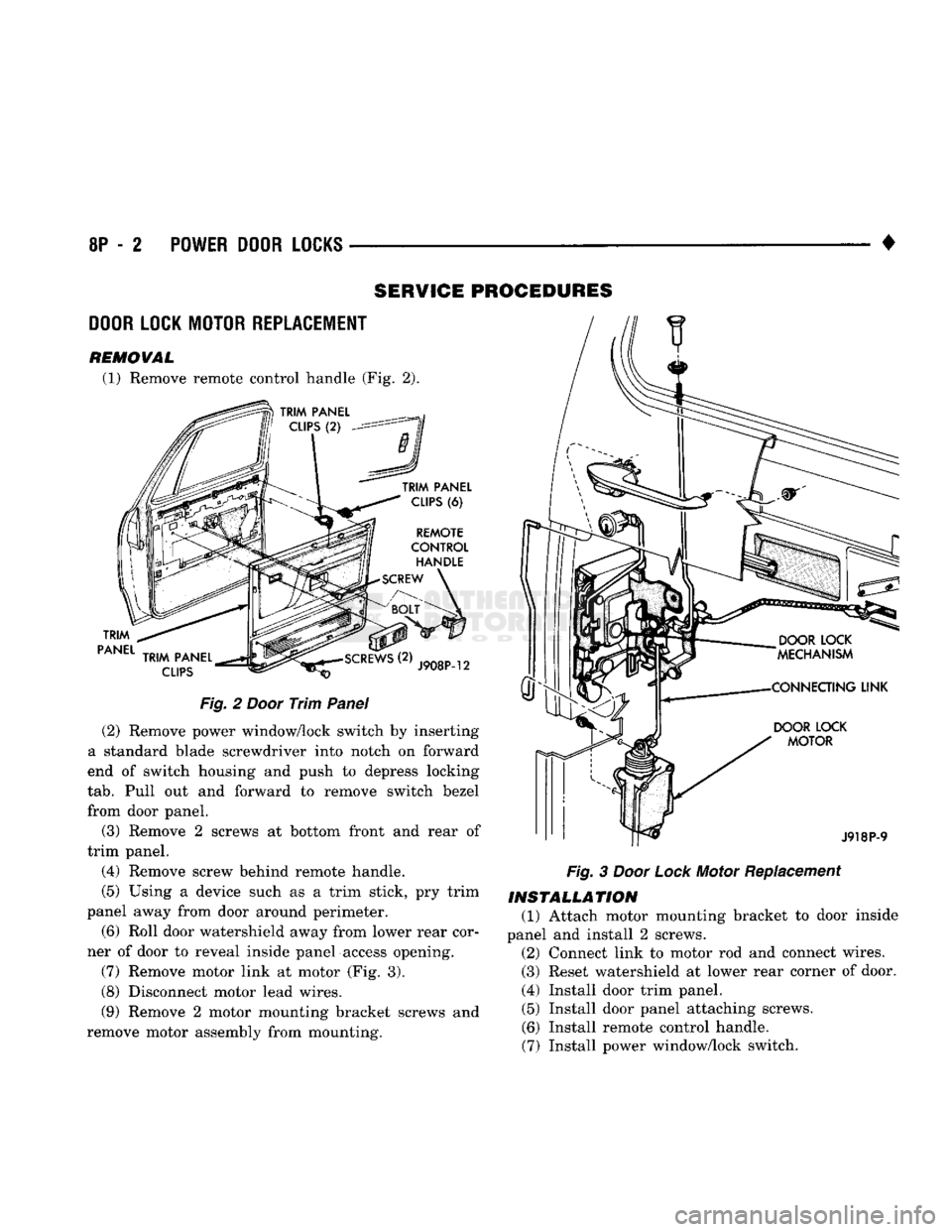

(1) Remove remote control handle (Fig. 2).

TRIM

PANEL

TRIM

PANEL

CLIPS

(6)

REMOTE

CONTROL

HANDLE

SCREW

TRIM

PANEL

CLIPS

J908P-12

Fig.

2

Door

Trim

Panel

(2) Remove power window/lock switch by inserting

a standard blade screwdriver into notch on forward

end of switch housing and push to depress locking

tab.

Pull out and forward to remove switch bezel

from door panel.

(3) Remove 2 screws at bottom front and rear of

trim panel.

(4) Remove screw behind remote handle.

(5) Using a device such as a trim stick, pry trim

panel away from door around perimeter.

(6) Roll door watershield away from lower rear cor

ner of door to reveal inside panel access opening.

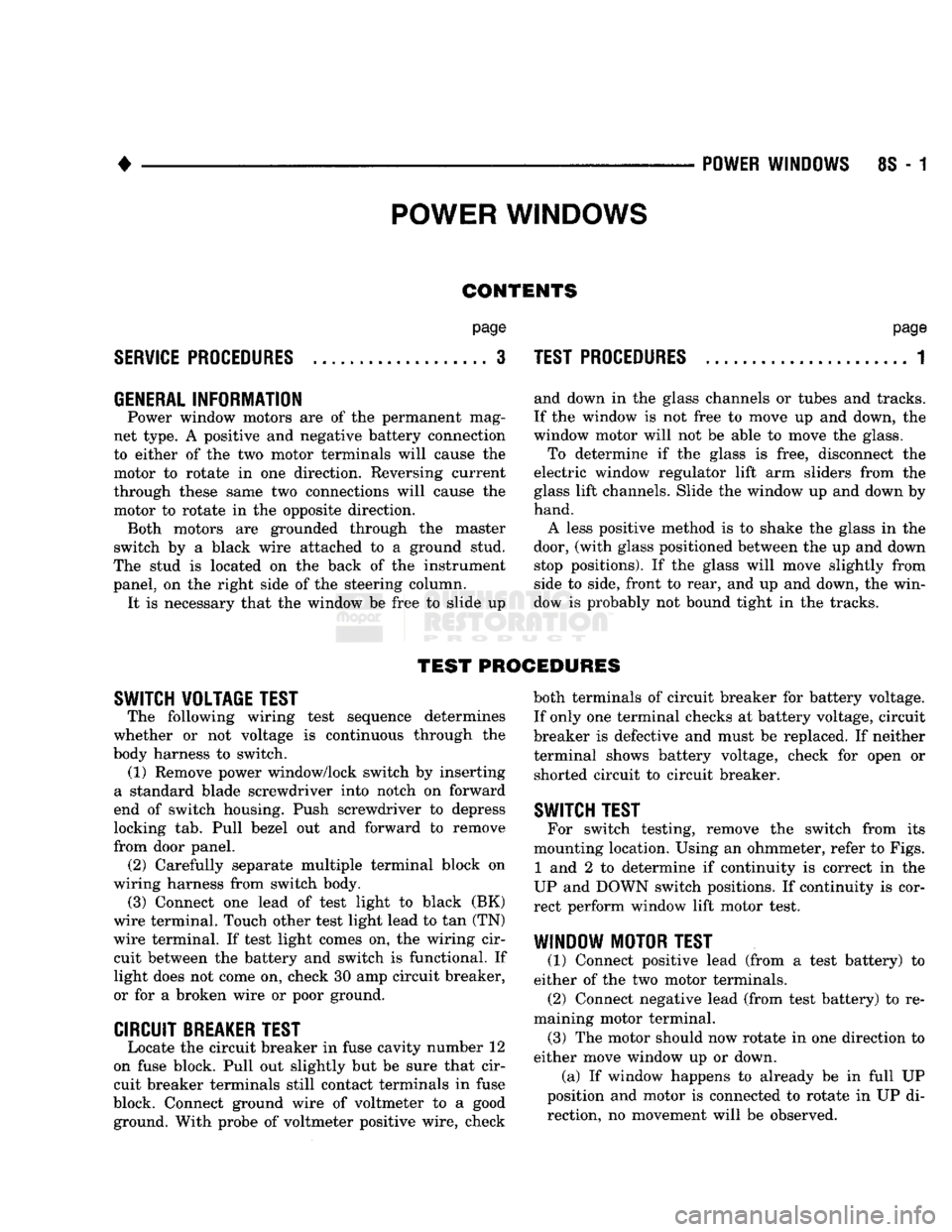

(7) Remove motor link at motor (Fig. 3).

(8) Disconnect motor lead wires.

(9) Remove 2 motor mounting bracket screws and

remove motor assembly from mounting.

DOOR

LOCK

MOTOR

J918P-9

Fig.

3

Door

Lock

Motor Replacement

INSTALLATION

(1) Attach motor mounting bracket to door inside

panel and install 2 screws. (2) Connect link to motor rod and connect wires.

(3) Reset watershield at lower rear corner of door.

(4) Install door trim panel. (5) Install door panel attaching screws.

(6) Install remote control handle.

(7) Install power window/lock switch.

Page 462 of 1502

•

POWER

WINDOWS

8S - 1

POWER WINDOWS

CONTENTS

page

SERVICE

PROCEDURES

3

GENERAL

INFORMATION

Power window motors are of the permanent mag

net type. A positive and negative battery connection

to either of the two motor terminals will cause the motor to rotate in one direction. Reversing current

through these same two connections will cause the motor to rotate in the opposite direction. Both motors are grounded through the master

switch by a black wire attached to a ground stud.

The stud is located on the back of the instrument

panel, on the right side of the steering column. It is necessary that the window be free to slide up

page

TEST

PROCEDURES

....................... 1

and down in the glass channels or tubes and tracks.

If the window is not free to move up and down, the

window motor will not be able to move the glass.

To determine if the glass is free, disconnect the

electric window regulator lift arm sliders from the

glass lift channels. Slide the window up and down by

hand.

A less positive method is to shake the glass in the

door, (with glass positioned between the up and down

stop positions). If the glass will move slightly from

side to side, front to rear, and up and down, the win

dow is probably not bound tight in the tracks.

TEST

PROCEDURES

SWITCH

VOLTAGE TEST

The following wiring test sequence determines

whether or not voltage is continuous through the

body harness to switch. (1) Remove power window/lock switch by inserting

a standard blade screwdriver into notch on forward

end of switch housing. Push screwdriver to depress

locking tab. Pull bezel out and forward to remove

from door panel. (2) Carefully separate multiple terminal block on

wiring harness from switch body. (3) Connect one lead of test light to black (BK)

wire terminal. Touch other test light lead to tan (TN)

wire terminal. If test light comes on, the wiring cir cuit between the battery and switch is functional. If

light does not come on, check 30 amp circuit breaker,

or for a broken wire or poor ground.

CIRCUIT

BREAKER

TEST

Locate the circuit breaker in fuse cavity number 12

on fuse block. Pull out slightly but be sure that cir

cuit breaker terminals still contact terminals in fuse

block. Connect ground wire of voltmeter to a good ground. With probe of voltmeter positive wire, check both terminals of circuit breaker for battery voltage.

If only one terminal checks at battery voltage, circuit

breaker is defective and must be replaced. If neither

terminal shows battery voltage, check for open or shorted circuit to circuit breaker.

SWITCH TEST

For switch testing, remove the switch from its

mounting location. Using an ohmmeter, refer to Figs. 1 and 2 to determine if continuity is correct in the

UP and DOWN switch positions. If continuity is cor

rect perform window lift motor test.

WINDOW

MOTOR TEST

(1) Connect positive lead (from a test battery) to

either of the two motor terminals. (2) Connect negative lead (from test battery) to re

maining motor terminal. (3) The motor should now rotate in one direction to

either move window up or down. (a) If window happens to already be in full UP

position and motor is connected to rotate in UP di rection, no movement will be observed.

Page 463 of 1502

8S

- 2 POWER WINDOWS

•

POWER

WINDOW

SYSf

EM

DIAGNOSIS

SYSTEM

OPERATES

BUT

GLASS

TRAVEL IS COCKED OR INCOMPLETE

I

MANUALLY

CHECK

TRAVEL OF

GLASS

I

GLASS

TRAVEL

OKAY

REMOVE MOTOR

FROM REGULATOR

ASSEMBLY

REPLACE

ARM & SECTOR PORTION OF REGULATOR

I

REASSEMBLE

REGULATOR

REINSTALL

REGULATOR

INTO

DOOR

IF PROBLEM

STILL EXISTS

CORRECT GLASS GUIDANCE PROBLEM SYSTEM

DOES

NOT OPERATE

CHECK

SYSTEM

OPERATION SYSTEM

OPERATES

CORRECTLY

CHECK

FOR

12 VOLTS AT MOTOR

TERMINAL

I NO VOLTAGE

CHECK

WIRING

AND/OR SWITCHES

VOLTAGE OKAY REMOVE

REGULATOR

FROM DOOR

GLASS

MOVES FREELY

CHECK

FOR

BINDING OF GLASS GUIDANCE SYSTEM

*

COUNTERBALANCE SPRING MUST BE REMOVED BEFORE REMOVING MOTOR FROM

REGULATOR. IF NOT,

INJURY MAY RESULT

BENCH

TEST

REGULATOR

ASSEMBLY

REMOVE

MOTOR FROM REGULATOR* I SYSTEM BINDING

CORRECT BINDING

CONDITION

REGULATOR

OPERATES

CORRECTLY

REGULATOR

DOES

NOT OPERATE I

REINSTALL

REGULATOR

INTO

DOOR

CHECK

ARM & SECTOR

ASSEMBLY

FOR

FREE

MOVEMENT,

MISSING

AND/OR DAMAGED

GEAR

TEETH,

MISSING

OR DAMAGED ROLLER,

OR BENT ARM ANY OF THESE

CONDITIONS EXIST

REPLACE

ARM & SECTOR

ASSEMBLY

PINION DOES NOT ROTATE

REMOVE GEAR & PINION AND EXAMINE FOR

MISSING

AND/OR

DAMAGED GEAR

TEETH

APPLY VOLTAGE TO

MOTOR AND CHECK FOR PINION ROTATION NONE OF THESE

CONDITIONS EXIST

PINION ROTATES CORRECTLY

REASSEMBLE

REGULATOR AND

INSTALL

INTO

DOOR

MISSING

AND/OR

DAMAGED GEAR

TEETH

REPLACE

GEAR

& PINION

ASSEMBLY

GEAR

& PINION

ASSEMBLY

TEETH

CHECK OKAY

REASSEMBLE

REGULATOR

ASSEMBLY

ARMATURE SHAFT

DOES

NOT ROTATE

REPLACE

MOTOR

WITH

GEAR

& PINION REMOVED

APPLY VOLTAGE TO MOTOR TERMINAL AND CHECK FOR

ARMATURE

SHAFT ROTATION

I

ARMATURE SHAFT ROTATES

CORRECTLY

J918S-7

Page 464 of 1502

•

POWER

WINDOWS

8S - 3

FROM PIN

SIDE

OF

SWITCH

MASTER

WINDOW

LIFT

SWITCH

SWITCH

POSITION CONTINUITY

BETWEEN

OFF

PINS

1 & 2

PINS

2 & 3

PINS

2 &4

PINS

2 & 6

DRIVER'S

MP

PINS

3 & 5

PINS

2 & 6

PASSENGER'S

PINS

1 & 5

PINS

2 &4

DRIVER'S

PINS

5 & 6

PINS

2 & 3

TOWN

PASSENGER'S

PINS

1 & 2

PINS

4 & 5 898S-11

Fig.

1 Master Window

Lift

Switch

Continuity

(b) Likewise, motor connected to DOWN direc

tion rotation, no movement will be observed if win

dow is already in full down position.

PIN IDENTIFICATION SHOWN

FROM

PIN

SIDE

OF

SWITCH

SWITCH CONTINUITY

POSITION

BETWEEN

PINS

1 & 4

OFF

PINS

2 & 5

PINS

3 & 4

UP

PINS

2 & 5

PINS

2 & 3

DOWN

PINS

1 & 4

898S-12

Fig.

2

Passenger's Door

Mounted

Switch

Continuity

(4) Reverse battery leads (opposite to steps 1 and

2) and window should now move. If window does not

move, remove motor. Refer to Service Procedures for

motor removal from vehicle for bench test.

If window moved completely up or down, motor

should be reversed one more time (reverse leads from

step 4) to complete a full window travel inspection.

SERVICE

PROCEDURES

GEAR

AND PINION

REPLACEMENT

AND

LUBRICATION

If gear and pinion assembly are replaced in gear

box, lubrication of gear box, gear pinion and seal is necessary. In the event there is no lubricant in gear box, fill

with MOPAR, multi-mileage lubricant or equivalent. Apply a liberal amount of lubricant to inside area of seal and sealing surface at center area of gear and

pinion coupling. Also lubricate center housing shaft and worm gear.

REGULATOR

AND

MOTOR

ASSEMBLY

REMOVAL To repair or inspect the entire electric window reg

ulator, remove from door as follows: (1) Remove remote control handle (Fig. 3).

(2) Remove power window/lock switch by inserting

a standard blade screwdriver into notch on forward

end of switch housing. Push screwdriver to depress

locking tab. Pull bezel out and forward to remove

from door panel.

(3) Remove screws at bottom front and rear of trim

panel.

(4) Remove screw behind remote handle.

(5)

Using a device such as a trim stick, pry trim

panel away from door around perimeter and remove

trim panel. (6) Roll door watershield away from bottom of door

to reveal inside panel access opening. (7) Remove speaker if equipped.

(8) Lower glass to full down position.

(9) Disconnect wiring connectors from motor.

Page 465 of 1502

8S

- 4

POWER WINDOWS

•

Fig.

3

Door

Trim

Panel

(10) Remove inner weatherstrip being careful not

to scratch the belt-line paint.

(11) Free the clip on the inner section of the

weatherstrip with a wire hook or suitable tool.

(12) Pull back upper glass run 8 to 20-25 cm (10

inches). (13) Remove upper and lower vent wing attaching

screws.

(14) Remove vent wing, being careful to avoid

paint damage from glass lower pivot adjusting screws.

(15) Remove down stop bumper bracket (Fig. 4).

Fig.

4 Electric Window Regulator

Mounting

(16) Disengage glass from regulator arms and

lower to door bottom. (17) Remove regulator mounting screws.

(18) Remove regulator through large access hole.

BENCH REPAIR

If entire regulator is not being replaced, repair as

follows: (1) Remove regulator as previously described.

WARNING:

STEPS

(2) AND (3) ARE

VERY IMPOR-

TANT.

IF NOT

DONE BEFORE MOTOR REMOVAL

INJURY

MAY

RESULT.

(2) Secure regulator in vise to prevent sector gear

from rotating.

(3) Remove counter balance spring. (Must be done

for safety before removing motor). (4) Remove 3 motor attaching screws and remove

motor (Fig. 5).

Fig.

5 Motor Attaching

Screws

(5) Inspect regulator for: (a) Sector gear teeth must not be broken or se

verely worn. (b) All rivets and sliders must be securely at

tached.

(c) Parts must not be bent or cracked.

(d) Sector gear must rotate freely.

(e) Perform window lift motor test as described

above.

(6) Install motor and attach with three motor at

taching screws.

(7) Install counter balance spring.

INSTALLATION

(1) Insert upper regulator arm into door mounted

channel. (2) Mount regulator to door panel with

1/4-20

screws torqued to 11 N*m (105 in. lbs.).

(3) Slide glass onto regulator arms and into rear

glass run.

Page 466 of 1502

•

POWER

WINDOWS

88 - § (4) Connect motor electrical connector.

(5) Install plastic nut and "U" nut on vent wing

assembly.

(6) Install vent wing assembly into door.

(7) Install upper and lower vent wing attachment

screws. (8) Move glass run back to vent wing by placing

run adjacent to door channel and press into channel

using wide blade screwdriver or similar tool. Press in

both inside corners to ensure hidden lip engages in channel. (9) Install belt weatherstrip by aligning clips to

holes in door and press in.

(10) Raise or lower vent to maintain a 1.6mm (.06

in.) fore-aft glass free-play then with glass up,

tighten upper screws.

(11) Hold vent against glass (glass down) and

tighten lower screws.

(12) Raise glass to full up position.

(13) Install speaker if equipped.

(14) Install down stop bumper.

(15) Install watershield and trim panel.

Page 467 of 1502

Page 468 of 1502

POWER

MIRRORS

CONTENTS

page

SERVICE PROCEDURES

2

GENERAL

INFORMATION

Electrically-operated remote control mirrors are

available as an option on D-body vehicles. The mir

rors are controlled by a single switch assembly lo

cated on the instrument panel to the right of the

headlamp switch (Fig. 1). D-body vehicles use a toggle-type switch. The

switch is rotated clockwise (Right mirror) or counter

clockwise (Left mirror) for mirror selection. The

switch is moved UP, DOWN, RIGHT, or LEFT for

mirror movement direction. The motors which operate the mirrors are part of

the mirror assembly and cannot be serviced sepa

rately.

page

TEST PROCEDURES

...................... 1 Fig. 1 Power Mirror and Headlamp Switches

TEST

PROCEDURES

MIRROR MOTOR TEST PROCEDURE

(1) Remove power mirror switch from mounting

position (refer to Service Procedures). (2) Disconnect wiring harness at switch connector.

(3) Use 2 jumper wires. Connect one to a

12-volt

source, and the other to a good body ground. Refer to

the MIRROR TEST CHART for wire hookups at the switch connector (harness side, not switch side), (4) If results shown in chart are not obtained,

check for broken or shorted circuit, or replace mirror assembly as necessary. MIRROR

TEST

CHART

12 Volts Ground MIRROR REACTION

12 Volts Ground Right

Left

Yl/BK

1

WT/BK UP

YL WT UP

WT/BK

YL/BK

DOWN

WT YL DOWN

WT/BK DB/WT RIGHT

WT

DB

RIGHT

DB/WT WT/BK LEFT

DB

WT LEFT

J908K-22

Page 469 of 1502

8T - 2

POWER MIRRORS

•

MIRROR

SWITCH TEST PROCEDURE

(1) Remove power mirror switch from mounting

position (refer to Service Procedures). (2) Disconnect wiring harness at switch connector.

(3) Test for continuity (no resistance) between the

terminals of the switch as shown in the MIRROR SWITCH CONTINUITY CHART. (4) If results shown in the chart are not obtained,

replace the switch.

MIRROR

SWITCH

CONTINUITY

CHART

MIRROR SELECTOR KNOB

IN

"L"

POSITION Move

Lever Continuity Between

WT

and BK

YL

and

PK

and

YL/BK

and PK

WT

and

PK,

DB/WT

and

BK

and

DB

&

BK

YL/BK

and

BK, YL

and

BK WT and PK

WT

and

BK, DB/WT

and PK

DB

and

PK

MIRROR SELECTOR KNOB

IN "R"

POSITION Move

Lever Continuity Between

WT/BK

and

BK,

YL and PK

YL/BK

and PK

•

WT/BK

and

PK, DB

and

BK

DB/WT

and

BK

WT/BK

and

PK, YL

and

BK

YL/BK

and

BK

«

WT/BK

and

BK, DB

and PK

DB/WT

and PK

J928T-6

SERVICE PROCEDURES

MIRROR

SWITCH REMOVAL AND INSTALLATION

(1) Disconnect negative cable from battery.

(2) Remove 2 screws holding map lamp and re

move map lamp. (3) Remove 6 screws which attach instrument clus

ter bezel to instrument panel (Fig. 2). Make sure the screw below the Heater/C control is removed.

INSTRUMENT

CLUSTER

BEZEL

J938E-51

Fig.

2 Instrument

Cluster

Bezel

(4) Place column shift lever in Position 1. (5) Remove bezel by pulling top edge rearward to

clear brow. Disengage attaching clips around bottom

of bezel and complete removal of bezel.

(6) If the bezel has a four wheel drive indicator, re

move bulb socket as bezel is removed. (7) Disconnect message center wires.

(8) Remove instrument cluster bezel assembly.

(9) Pull headlamp switch to ON position.

(10) Reach under instrument panel and depress

button on side of switch while pulling stem out.

(11) Remove switch bezel retaining screws and pull

bezel out of instrument panel (Fig. 1). (12) Pull harness out through opening in instru

ment panel and disconnect mirror switch connector.

(13) Remove 2 switch mounting-plate-to-bezel re

taining screws.

(14) Remove switch-to-mounting-plate nut.

For Installation, reverse removal procedures.

MIRROR

ASSEMBLY

REMOVAL

AND

INSTALLATION

(1) Remove remote control handle (Fig. 3).

(2) Remove power window/lock switch by inserting

a standard blade screwdriver into notch on forward

end of switch housing and push to depress locking

tab.

Pull out and forward to remove switch bezel

from door panel.

Page 470 of 1502

•

POWER

MIRRORS

8T - 3

Fig.

3

Door

Trim

Panel

(3) Remove 2 screws at bottom front and rear of

trim panel. (4) Remove screw behind remote handle.

(5) Using a device such as a trim stick, pry trim

panel away from door around perimeter.

(6) Roll door watershield away from lower rear cor

ner of door to reveal inside panel access opening. (7) Reach inside door and disconnect mirror wiring

at connector. Spray grommet on mounting bracket cover

with silicone to avoid grommet coming off when

cover is moved up on mirror stem. (8) Remove mirror mounting bracket cover (1

screw) and slide up on mirror stem (Fig. 4).

Fig.

4

Power

Mirror Replacement

(9) Remove 3 mirror mounting bracket nuts.

(10) Pull mirror loose from door, and feed wiring

harness out through hole in outer door panel.

For Installation, reverse Removal procedure.