sensor DODGE TRUCK 1993 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 419 of 1502

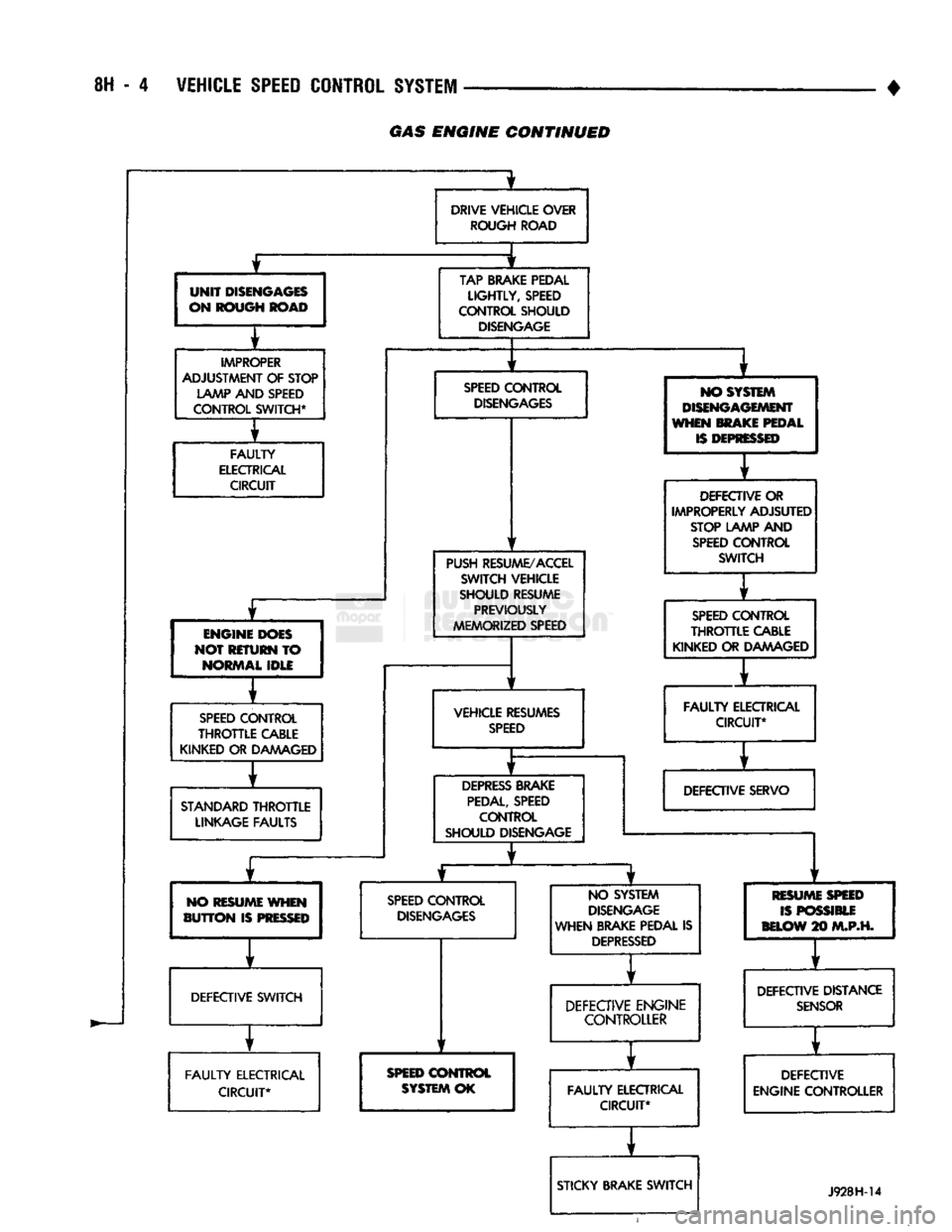

8H - 4 VEHICLE

SPEED

CONTROL SYSTEM

GAS

ENGINE

CONTINUED

UNIT

DISENGAGES

ON ROUGH ROAD

IMPROPER

ADJUSTMENT OF STOP LAMP AND SPEED

CONTROL SWITCH*

FAULTY

ELECTRICAL CIRCUIT

£

ENGINE DOES

NOT RETURN TO NORMAL IDLE

SPEED

CONTROL

THROTTLE

CABLE

KINKED OR DAMAGED

STANDARD

THROTTLE

LINKAGE FAULTS 1

DRIVE VEHICLE OVER

ROUGH ROAD

TAP BRAKE PEDAL

LIGHTLY,

SPEED

CONTROL SHOULD

DISENGAGE

SPEED

CONTROL

DISENGAGES

PUSH RESUME/ACCEL SWITCH VEHICLE

SHOULD RESUME PREVIOUSLY

MEMORIZED SPEED

VEHICLE RESUMES

SPEED

DEPRESS

BRAKE

PEDAL,

SPEED CONTROL

SHOULD DISENGAGE NO SYSTEM

DISENGAGEMENT

WHEN MAKE PEDAL

IS

DEPRESSED

DEFECTIVE OR

IMPROPERLY ADJSUTED

STOP LAMP AND

SPEED

CONTROL SWITCH

y

f

SPEED

CONTROL

THROTTLE

CABLE

KINKED OR DAAAAGED

1

FAULTY

ELECTRICAL CIRCUIT*

f

DEFECTIVE SERVO NO RESUME WHEN

BUTTON

IS

PRESSED

SPEED

CONTROL

DISENGAGES

DEFECTIVE SWITCH

FAULTY

ELECTRICAL CIRCUIT* NO SYSTEM

DISENGAGE

WHEN BRAKE PEDAL IS

DEPRESSED

SPEED

CONTROL

SYSTEM OK

1

f

DEFECTIVE ENGINE CONTROLLER

1

FAULTY

ELECTRICAL CIRCUIT*

r

STICKY BRAKE SWITCH RESUM

ISPO

BELOW

2

E

SPEED

SSIBLE

10

M.P.H.

y t

DEFECTIVE DISTANCE

SENSOR

y f

DEFECTIVE

ENGINE CONTROLLER

J928H-14

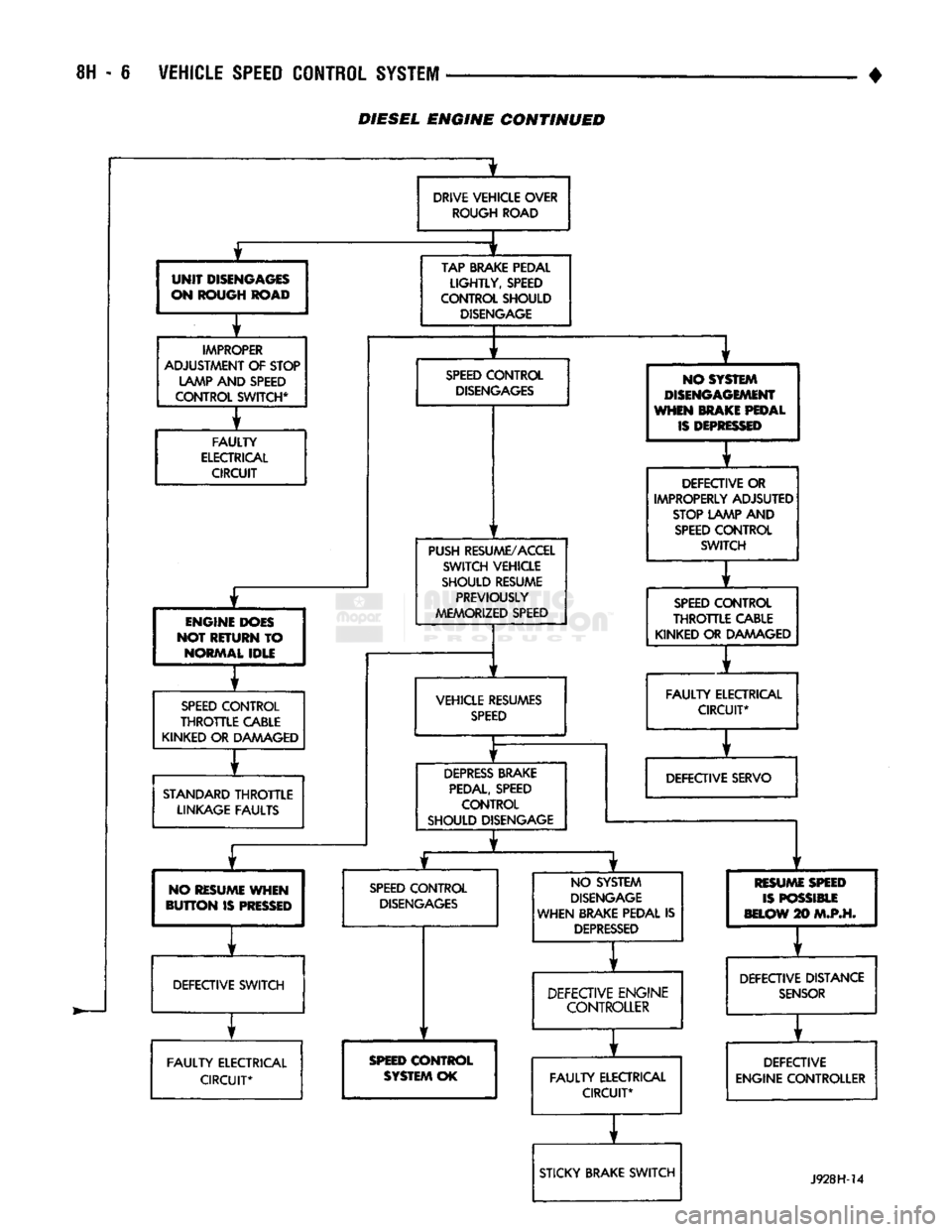

Page 421 of 1502

- 6

VEHICLE SPEED CONTROL SYSTEM

• £

UNIT

DISENGAGES

ON ROUGH ROAD

IMPROPER

ADJUSTMENT

OF

STOP LAMP AND SPEED

CONTROL SWITCH*

i

FAULTY

ELECTRICAL CIRCUIT

ENGINE DOES

NOT RETURN

TO

NORMAL IDLE

SPEED

CONTROL

THROTTLE

CABLE

KINKED OR DAAAAGED

STANDARD

THROTTLE

LINKAGE FAULTS

NO RESUME WHEN

BUTTON

IS

PRESSED

DRIVE VEHICLE OVER

ROUGH ROAD

±

TAP BRAKE PEDAL

LIGHTLY,

SPEED

CONTROL SHOULD

DISENGAGE

SPEED

CONTROL

DISENGAGES

PUSH RESUME/ACCEL SWITCH VEHICLE

SHOULD RESUME PREVIOUSLY

MEMORIZED SPEED

VEHICLE RESUMES

SPEED

DEPRESS

BRAKE

PEDAL,

SPEED CONTROL

SHOULD DISENGAGE NO SYSTEM

DISENGAGEMENT

WHEN MAKE PEDAL

IS

DEPRESSED

DEFECTIVE OR

IMPROPERLY ADJSUTED STOP LAMP

AND

SPEED

CONTROL SWITCH

1

1

SPEED

CONTROL

THROTTLE

CABLE

KINKED

OR

DAAAAGED

1

FAULTY

ELECTRICAL CIRCUIT*

1

DEFECTIVE SERVO

SPEED

CONTROL

DISENGAGES

DEFECTIVE SWITCH

FAULTY

ELECTRICAL CIRCUIT*

1

NO SYSTEM

DISENGAGE

WHEN BRAKE PEDAL

IS

DEPRESSED

SPEED

CONTROL

SYSTEM

OK

1

r

DEFECTIVE ENGINE CONTROLLER

* r

FAULTY

ELECTRICAL CIRCUIT*

r

STICKY BRAKE SWITCH RESUM

ISPO

BELOW*

E

SPEED

SSIBLE

10

M.P.H.

1

DEFECTIVE DISTANCE

SENSOR

f

DEFECTIVE

ENGINE CONTROLLER

J928H-14 DIESEL ENGINE CONTINUED

Page 422 of 1502

•

VEHICLE

SPEED

CONTROL SYSTEM

8H - 7

TEST

PROCEDURES

INDEX

page

Checking

for

Diagnostic

Trouble

Code

7

General

Information

7

Inoperative

System

7

Road

Test

7

Speed

Control

Cable Adjustment—Diesel Engine

. 9

Speed

Control

Cable

Attachment

10

GENERAL

INFORMATION

Before starting diagnosis and repair procedures for

a speed control malfunction, verify that the speed

control wire harness is properly connected to all con nectors. Refer to Diagnosis Chart.

ROAD

TEST

Road test vehicle to verify reports of speed control

system malfunction. The road test should include at

tention to the speedometer. Speedometer operation should be smooth and without flutter at all speeds. Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys

tem. The cause of any speedometer deficiencies should be corrected before proceeding.

INOPERATIVE SYSTEM

If road test verifies a system problem and the

speedometer operates properly, check for:

• loose electrical and vacuum connections at the

servo.

• check for correct installation of the vacuum check

valve in the hose from servo to vacuum source (Gas

Engine Only). The word VAC on the valve must

point toward the vacuum source. • corrosion that should be removed from electrical

terminals and a light coating of Mopar Multi-Pur

pose Grease, or equivalent, applied. • secure attachment of both ends of speed control ca

ble.

CHECKING

FOR DIAGNOSTIC TROUBLE CODE

(1) When trying to verify a speed control system

electrical problem, use a DRB II Scan Tool to find

the cause. Refer to Powertrain Diagnostic Procedures manual. If the DRBII is not available, the Diagnostic Trou

ble Code (DTC) may be determined with the follow ing method: (a) With key inserted in ignition switch, cycle

switch to ON position 3 times. On third cycle, leave

switch in ON position. (b) After switch has been cycled 3 times, observe

Malfunction Indicator Lamp (CHECK ENGINE) on instrument cluster. If a DTC is present, the code

page

Speed

Control

Cable Attachment—Servo

10

Stop Lamp Switch Test

9

Vacuum Supply Test

....................... 9

Vehicle Speed

Control

Switch Test

. 9

Vehicle Speed

Control

System

Electrical

Tests

... 7

Vehicle Speed Sensor Test

7

will be displayed in a series of flashes representing

digits.

Three flashes in rapid succession, a slight

pause, then 4 flashes in rapid succession would in dicate DTC 34.

(2) If a DTC 34 is observed, perform the tests in

the sections Electrical Tests at Servo and Electrical

Tests at Powertrain Control Module.

If a DTC 15 is observed, perform the test for a

faulty Vehicle Speed Sensor.

(3) If a fault code 11 is observed (Diesel only), per

form the test for a faulty engine speed sensor. Refer

to the Powertrain Diagnostics Procedures Manual.

(4) Correct any problems found when performing

these tests and recheck for DTC if changes were made.

VEHICLE SPEED SENSOR TEST

For testing of the Vehicle Speed Sensor and related

components refer to the Powertrain Diagnostic Proce

dures manual.

VEHICLE SPEED CONTROL SYSTEM ELECTRICAL

TESTS

Vehicle speed control systems may be tested using

two different methods. One involves the use of the DRBII Scan Tool. If this test method is desired,

please refer to the Powertrain Diagnostic Procedures manual. The other test method uses a voltmeter. The volt

meter method is described in the following tests.

If any information is needed concerning wiring, re

fer to Group 8W - Wiring Diagrams.

CAUTION:

When test probing

for

voltage

or

continuity

at

electrical

connectors, care must

be

taken

not

to

damage connector, terminals,

or

seals.

If

these components

are

damaged,

intermittent

or

complete system

failure

may

occur.

ELECTRICAL

TESTS

AT

SERVO

(1) Turn ignition switch to ON position.

(2) Push speed control switch to ON position.

(3) Connect the negative lead of a voltmeter to a

good chassis ground near the servo.

Page 451 of 1502

8L

- 8

LAMPS

CONNECTOR

CUP

FRONT

LAMP

ASSEMBLY

LICENSE

PLATE

SCREW

LAMP

ASSEMBLY

LICENSE

PLATE

RR8LD24

Fig.

15

License

Plate

Lamps

-

Step

Bumper

TO

TAIL,

STOP,

TURN

SIG. AND

BACK

UP

LAMPS

LICENSE

PLATE

LICENSE

PLATE

LAMP

AND

LAMP

CONNECTOR

BRACKET

ASSEMBLY

J908L-74

Fig.

16

License

Plate

Lamp

Without Rear

Bumper

UNDERHOOD

LAMP

When equipped, the underhood lamp is installed on

the hood left, rear inner panel (Fig, 17). The lamp is

illuminated when the hood is opened (Fig. 18). UNDERHOOD LAMP BULB REPLACEMENT

REMOVAL

(1) Disconnect the wire connector from the under

hood lamp (Fig. 17).

(2) Rotate the bulb counter-clockwise. Remove it

from the lamp base socket (Fig. 18).

INSTALLATION

(1) Insert the replacement bulb in the lamp base

socket. Rotate it clockwise.

(2) Connect the wire connector to the lamp (Fig.

17).

UNDERHOOD LAMP REPLACEMENT

REMOVAL

(1) Disconnect the wire connector from the lamp

(Fig. 17). (2) Rotate the bulb counter-clockwise. Remove it

from the lamp base socket (Fig. 18). (3) Remove the screw that attaches the lamp re

flector and support bracket to the hood inner panel (Fig. 17).

(4) Remove the lamp from the hood inner panel.

INSTALLATION (1) Position the underhood lamp on the hood inner

panel. (2) Install the screw through the lamp and into the

hood panel (Fig. 17). Tighten the screw securely. (3) Insert a replacement bulb in the lamp base

socket (Fig. 18). Rotate it clockwise. (4) Connect the wire connector to the lamp (Fig.

17).

HOOD

J9223-446

Fig.

17

Underhood

Lamp

DAYTIME

RUNNING

LIGHT

MODULE

(CANADA

ONLY)

The headlamps on vehicles sold in Canada will il

luminate when the ignition is ON. The module also

receives a signal from the distance sensor. This pro-

SUPPORT

BRACKET RETAINER

LIQUID

TAB SWITCH

ENCLOSURE

WIRE

HARNESS

CONNECTOR

\

1

d1^—1—l

L/

CMD>

LAMP

REFLECTOR

BULB

(105)

BASE

J9281"1

Fig.

18

Underhood

Lamp

Components

Page 477 of 1502

8W

- 2

WIRING

DIAGRAMS

•

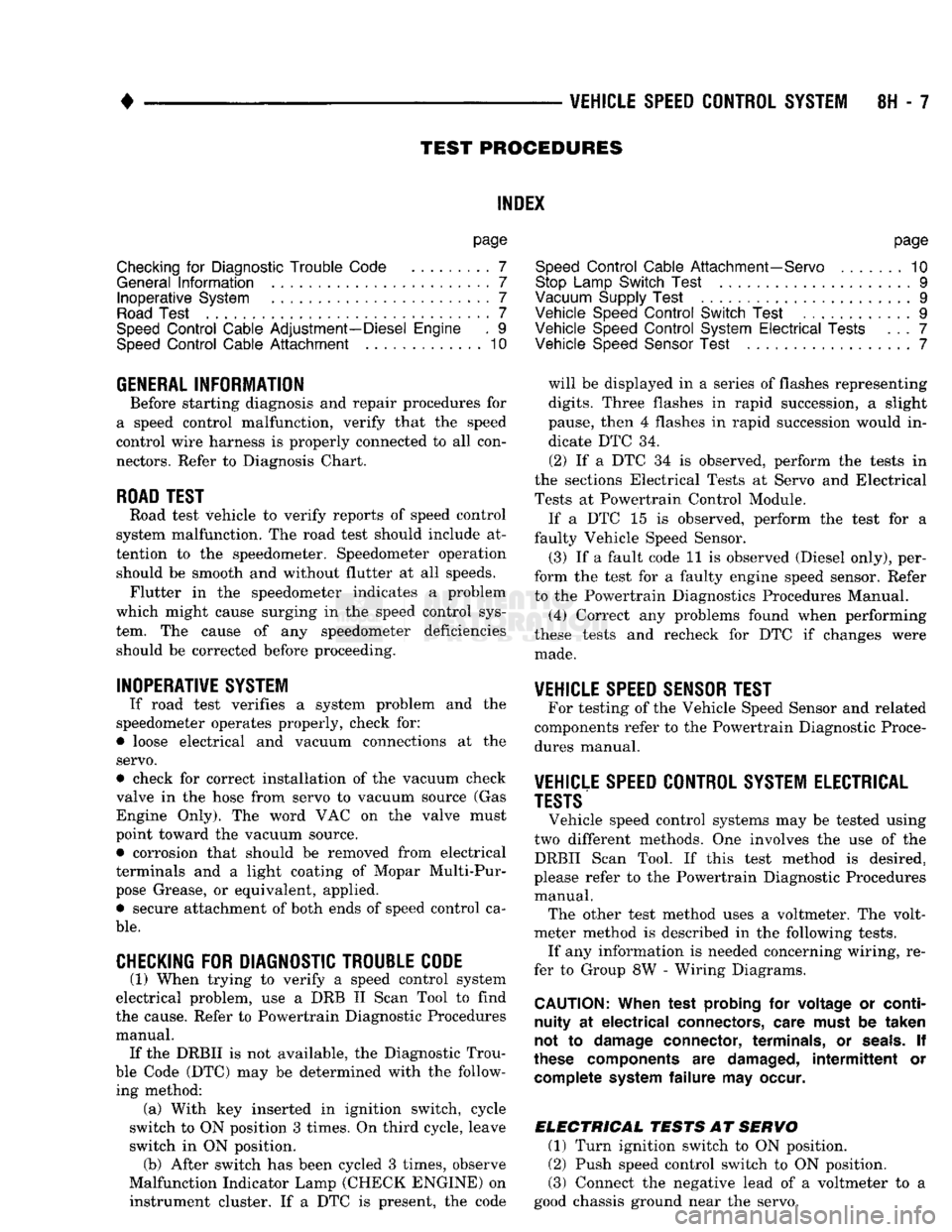

WIRE CODE

IDENTIFICATION

Each wire shown in the diagrams contains a code

(Fig. 3) which identifies the main circuit, part of the

main circuit, gauge of wire, and color. The color is shown as a two letter code which can be identified by

referring to the Wire Color Code Chart (Fig. 4). If

the wire has a tracer and it is a standard color an asterisk will follow the main wire color. If the tracer

is non-standard the main wire color will have a slash (/) after it followed by the tracer color. 18

LB/YL*

COLOR

OF

WIRE

(Light

Blue

with

Yellow

Tracer)

.

GAUGE

OF

WIRE

(18

Gauge)

PART

OF

AAAIN CIRCUIT

(Varies

Depending

on

Equipment)

AAAIN CIRCUIT

IDENTIFICATION

918W-16

Fig.

3

Wire

Color

Code

Identification

CIRCUIT IDENTIFICATION

All circuits in the diagrams use an alpha/numeric

code to identify the, wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second ary codes that may apply to some models.

COLOR

CODE COLOR

STANDARD

TRACER

COLOR COLOR

CODE

COLOR

STANDARD

TRACER

CODE

BL BLUE WT

OR ORANGE

BK

BK

BLACK

WT PK

PINK

BK

OR WT

BR

BROWN

WT RD

RED WT

DB DARK

BLUE WT

TN

TAN WT

DG DARK

GREEN WT

VT

VIOLET

WT

GY GRAY

BK

WT

WHITE

BK

LB

LIGHT

BLUE

BK

YL YELLOW

BK

LG

LIGHT

GREEN

BK

*

WITH

TRACER

918W-136

Fig.

4

Wire

Color

Code

Chart

LOCATING

A

SYSTEM

OR

COMPONENT

To locate a system or component in the diagrams,

refer to the alphabetical index at the front of the di agrams. Determine the diagram sheet number. Sheet

numbers are located at the lower right or left hand

corner of each sheet. Page numbers at the top of

the page do not apply to diagram sheets. The diagram index identifies the main system and

all components that relate to that system. There are

also sections of the index that identify specific com

ponents only (for example modules, lamps, etc.). Re-

MAIN

CIRCUIT IDENTIFICATION

CIRCUIT

DESCRIPTION

CIRCUIT

DESCRIPTION

A

Battery

Feed: Fused and Unfused

P

Power

Assist

System:

Locks,

Mirrors

B

ABS

System Q Power

Assist

System: Windows

C

Air Conditioning System

R

Airbag System

D

CCD

(+),

CCD

(-)

S

Air Suspension, Automatic Load Leveling

E

Interior

Lamp

Illumination

T Electronic Automatic Transaxle

F

Battery

Feed: Fused and Unfused

V

Windshield Wipers and Washers,

G

Sensors,

Sending Units, Switches Vehicle Speed Control System

K

Powertrain

Central

Module W Power

Assist

System: Windows

L

Exterior

Lighting, Stop Lamp Switch

X

Horn, Radio, Radio Speakers, Power Locks

M

Interior

Lamps

Z

Ground Circuits: Includes power and signal

Interior

Lamps

grounds

for PCM

938W-17

Page 481 of 1502

8W

-6

WIRING DIAGRAMS

•

LEGEND

OF SYMBOLS

USED

ON

WIRING DIAGRAMS

+

POSITIVE

CONNECTOR

—

NEGATIVE

—>

MALE

CONNECTOR

_L_

GROUND

>

FEMALE CONNECTOR

FUSE

S DENOTES WIRE CONTINUES ELSEWHERE

GANG

FUSES

WITH

BUSS

BAR

DENOTES WIRE GOES

TO

ONE

OF TWO

CIRCUITS

CIRCUIT

BREAKER

SPLICE

CAPACITOR

<3>2

i

SPLICE

IDENTIFICATION

A

OHMS

cftP—

THERMAL ELEMENT

RESISTOR

| TIMER

|

TIMER

VARIABLE

RESISTOR

1

^ ^ ^ |

'YY Y1

MULTIPLE CONNECTOR

SERIES

RESISTOR

o-l

WIRING

WITH

OPTIONAL WIRING

WITHOUT

COIL Y "Y" WINDINGS

—o

STEP

UP COIL

BB-BB

DIGITAL READOUT

OPEN CONTACT

-0-

SINGLE

FILAMENT LAMP

M

K #

CLOSED

CONTACT

-(5-DUAL FILAMENT LAMP

CLOSED

SWITCH

LE.D.

-

LIGHT

EMITTING

DIODE

OPEN SWITCH —^— THERMISTOR

CLOSED

GANGED SWITCH

GAUGE

mi OPEN GANGED SWITCH

SENSOR

TWO POLE SINGLE THROW SWITCH FUEL INJECTOR

PRESSURE

SWITCH

E

|

#36

DENOTES WIRE

GOES

THROUGH

BULKHEAD DISCONNECT

3i

SOLENOID SWITCH

#" STRG

COLUMN DENOTES WIRE GOES THROUGH

STEERING

COLUMN CONNECTOR

frt

MERCURY

SWITCH

| PANEL

J

DENOTES WIRE GOES THROUGH

INSTRUMENT PANEL CONNECTOR

H«- DIODE

OR

RECTIFIER

j

ENG |

DENOTES WIRE GOES THROUGH GROMMET

TO ENGINE COMPARTMENT

BY-DIRECTIONAL ZENER DIODE DENOTES WIRE GOES THROUGH GROMMET

-o-

MOTOR

HEATED GRID ELEMENTS

0 ARMATURE AND BRUSHES

908W-191

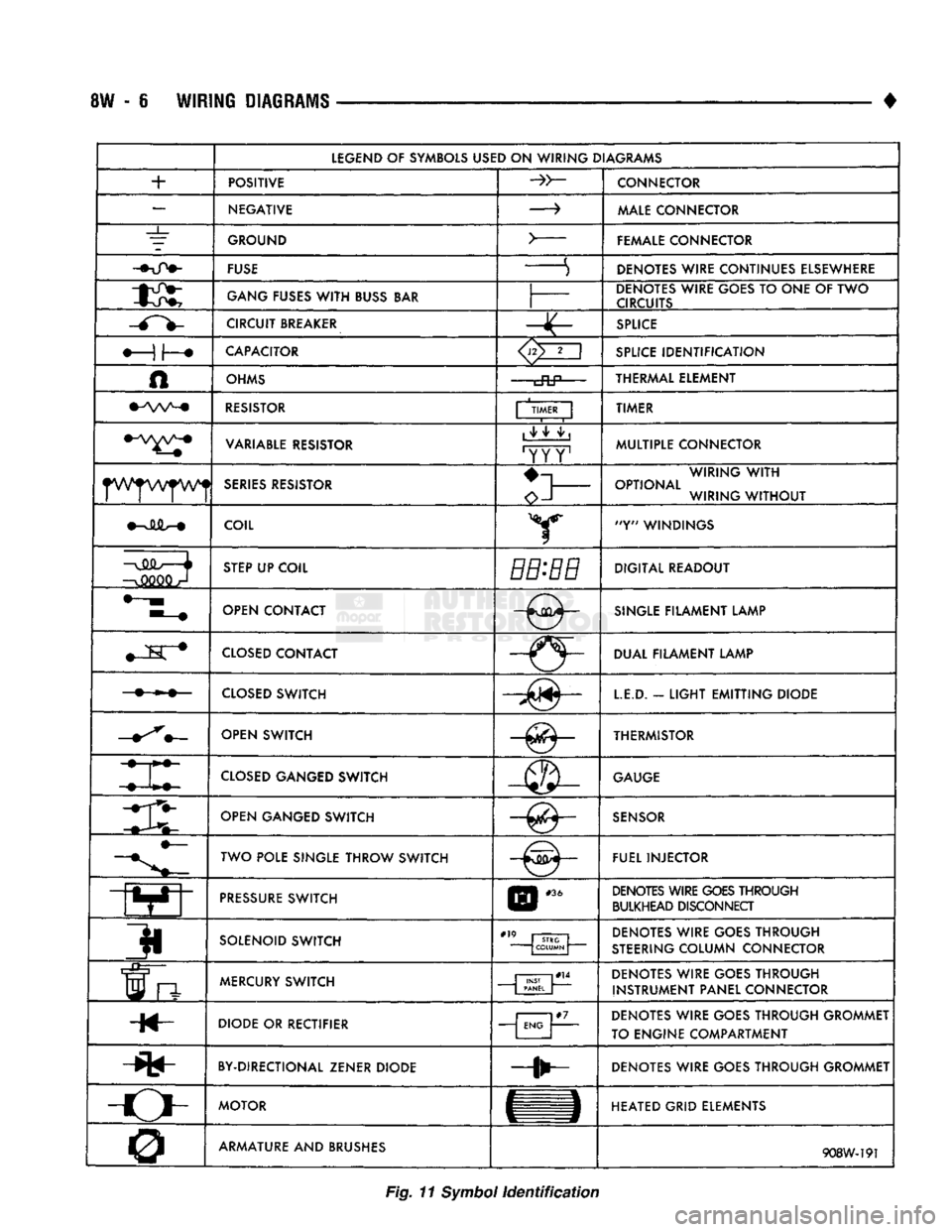

Fig.

11

Symbol

identification

Page 499 of 1502

CRANKSHAFT

POSITION

SENSOR

TO CRANKSHAFT POSITION

(SEE

VIEW

X)

VEHICLE

SPEED

SENSOR

CONVERTER

CLUTCH

SOLENOID

TO

VEHICLE SPEED SENSOR BEYOND THIS POINT

SEE MAIN VIEW

TO HEATED OXYGEN SENSOR

(SEE VIEW X)

VIEW

A

4X4 TRANSFER

CASE

(TYPICAL)

VEHICLE

SPEED

SENSOR

1 >

a

so

>

w

J938W-102

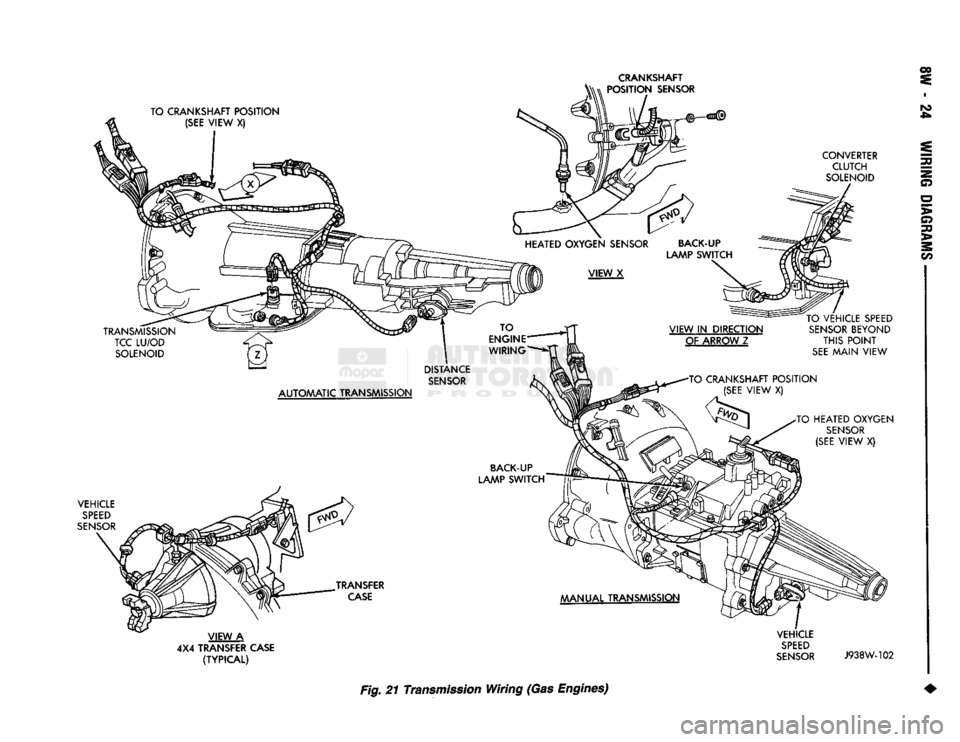

Fig. 21 Transmission Wiring (Gas Engines) 2

Page 501 of 1502

FUEL

INJECTOR

#6

FUEL

INJECTOR

#4

FUEL

INJECTOR

#2

BEYOND

THIS

POINT

SEE

VIEW

Z

EGR

SOLENOID/

TRANSDUCER

ASSEMBLY

A/C

COMPRESSOR

CLUTCH

GENERATOR

GROUND

POWER

STEERING

PUMP

AAAP

SENSOR

THROTTLE

EVAP/

POSITION

PURGE

(SENSOR)

SOLENOID IDLE

AIR

CONTROL MOTOR

TO

A/C

COMPRESSOR

CLUTCH

DISTRIBUTOR

IGNITION

COIL

ENGINE

COOLANT

TEMPERATURE

ENGINE

COOLANT

SENSOR

(PCM)

TEMPERATURE

SENSOR

(GAUGE)

ENGINE

OIL

PRESSURE

SENDING

UNIT/

SWITCH

DISTRIBUTOR

CONNER ,NJECTOR#1

INJECTOR

#3

VIEW

IN

DIRECTION OF ARROW

1

FUEL

INJECTOR

#5

TO

'TRANSMISSION

WIRING

J938W-85 INS

m

a

o

>

o

>

2

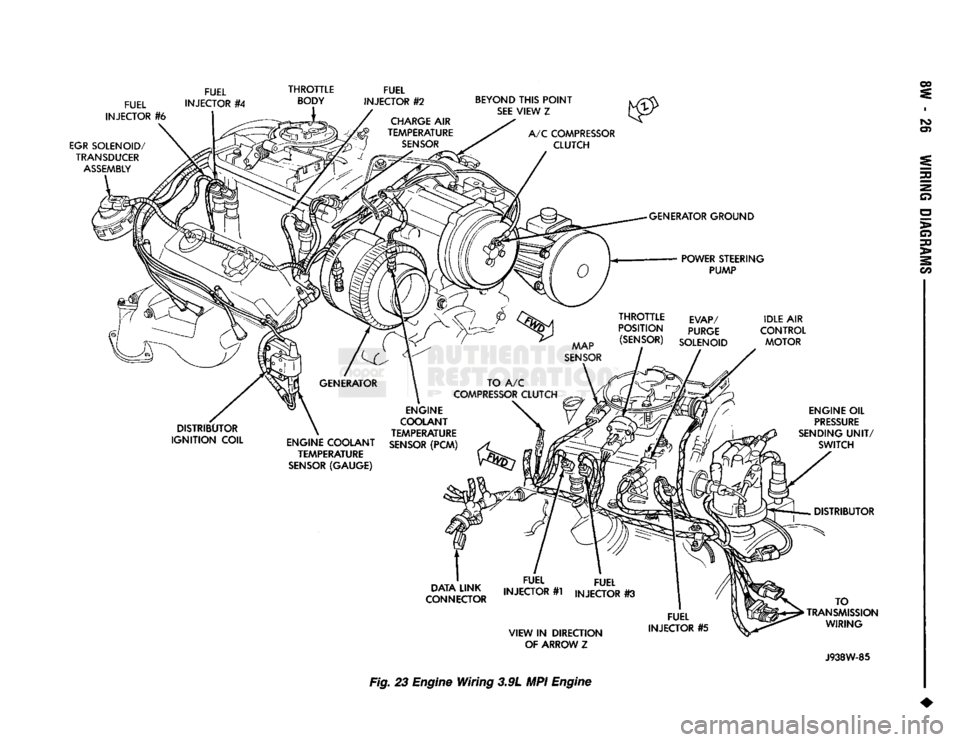

m Fig. 23 Engine

Wiring

3.9L MPI Engine

Page 502 of 1502

FUEL

INJECTOR

#8

FUEL

INJECTOR #4 FUEL

INJECTOR

#2

EGR

SOLENOID/

TRANSDUCER

DISTRIBUTOR

IGNITION

COIL

THROTTLE

BODY

CHARGE

AIR

TEMPERATURE

SENSOR

BEYOND

THIS

POINT

SEE

VIEW,

Z

TO

A/C

COMPRESSOR

CLUTCH ^DISTRIBUTOR

GENERATOR

GROUND

POWER

STEERING

PUMP ENGINE

OIL

PRESSURE

SENDING

UNIT/SWITCH

VIEW

IN

DIRECTION OF ARROW

Y

TO TRANSMISSION WIRING

THROTTLE

POSITION

(SENSOR)

IDLE AIR

CONTROL MOTOR

GENERATOR

ENGINE COOLANT

TEMPERATURE

SENSOR

(PCM)

ENGINE

COOLANT

TEMPERATURE

SENSOR

(GAUGE)

MAP

SENSOR

FUEL

INJECTOR

#3

EVAP/PURGE

SOLENOID

FUEL

INJECTOR #7

FUEL

INJECTOR.

#5

FUEL

INJECTOR

#1

A/C

CLUTCH VIEW

IN

DIRECTION

OF ARROW

Z

J938W-86

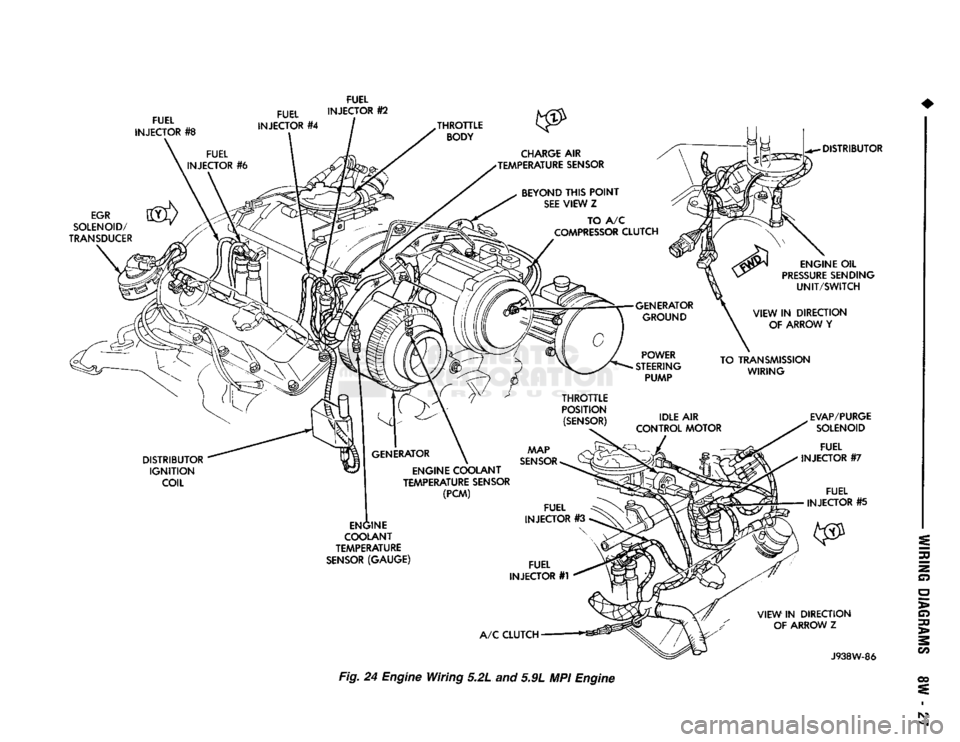

Fig.

24 Engine Wiring 5.2L and 5.9L MPI Engine o

>

30

>

2

w

oo !\3

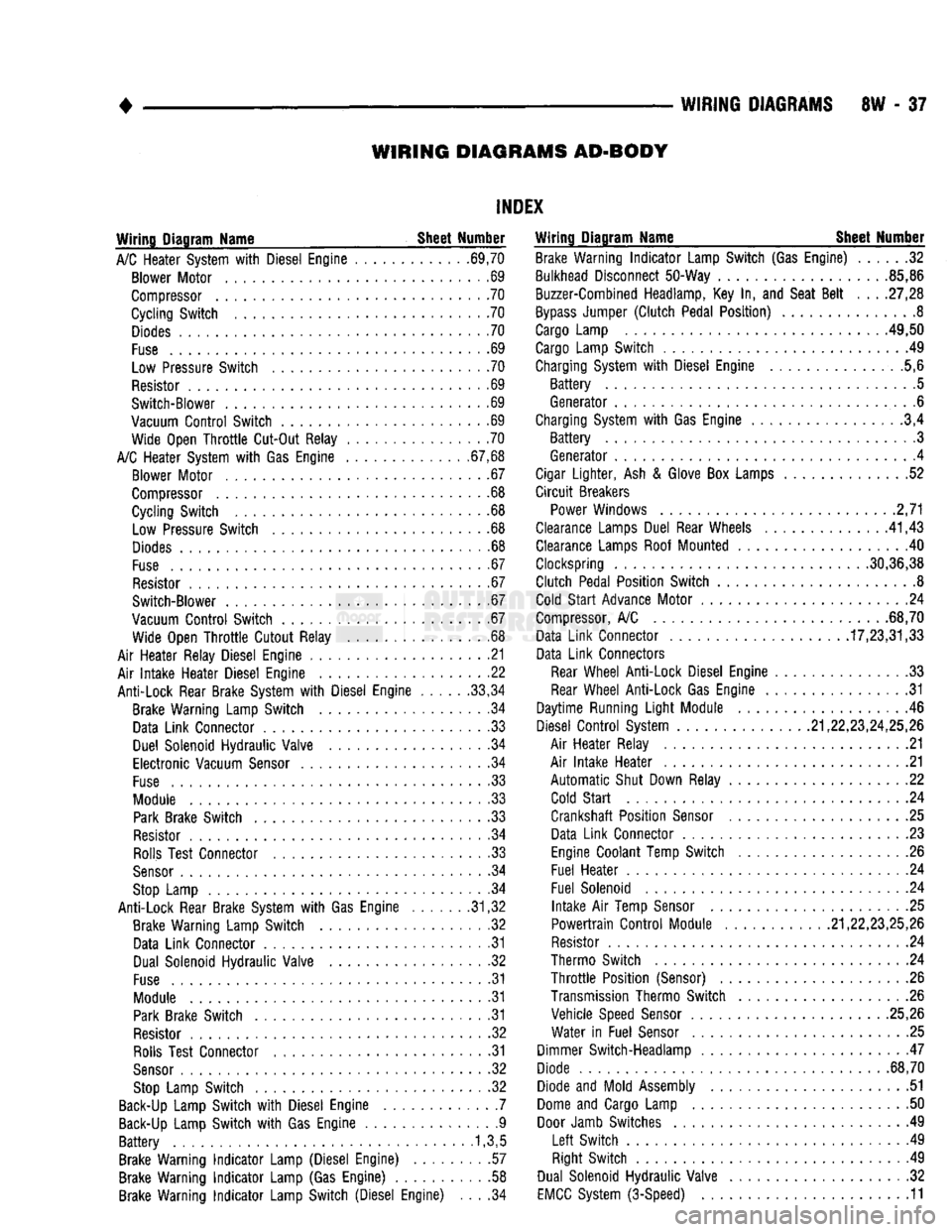

Page 512 of 1502

WIRING

DIAGRAMS

8W

- 37

WIRING DIAGRAMS AD-BODY

INDEX

Wiring Diagram Name Sheet Number

A/C

Heater System

with

Diesel Engine ............ .69,70 Blower Motor

. .69

Compressor

.70

Cycling Switch

.70

Diodes

70

Fuse

69

Low Pressure Switch

70

Resistor

. 69

Switch-Blower

. 69

Vacuum

Control

Switch

.69

Wide Open

Throttle

Cut-Out Relay

70

A/C

Heater System

with Gas

Engine .67,68 Blower Motor

.67

Compressor

.68

Cycling Switch

68

Low Pressure Switch

.68

Diodes

. .68

Fuse

. .67

Resistor

67

Switch-Blower

67

Vacuum

Control

Switch

.67

Wide Open

Throttle

Cutout Relay

68

Air Heater Relay Diesel Engine

.21

Air

Intake

Heater Diesel Engine

22

Anti-Lock Rear Brake System

with

Diesel Engine

.....

.33,34 Brake Warning Lamp Switch

34

Data Link Connector

33

Duel Solenoid Hydraulic Valve

34

Electronic Vacuum

Sensor

.34

Fuse

33

Module

.33

Park

Brake Switch

.33

Resistor

34

Rolls

Test Connector

33

Sensor

34

Stop

Lamp

34

Anti-Lock Rear Brake System

with Gas

Engine .31,32 Brake Warning Lamp Switch

.32

Data Link Connector

. .31

Dual Solenoid Hydraulic Valve

32

Fuse

31

Module

31

Park

Brake Switch

.31

Resistor

32

Rolls

Test Connector

31

Sensor

32

Stop

Lamp Switch

32

Back-Up

Lamp Switch

with

Diesel Engine

.7

Back-Up

Lamp Switch

with Gas

Engine

.9

Battery

.1,3,5

Brake Warning

Indicator

Lamp (Diesel Engine)

.57

Brake Warning

Indicator

Lamp

(Gas

Engine)

58

Brake Warning

Indicator

Lamp Switch (Diesel Engine)

. . . .34

Wiring Diagram Name Sheet Number

Brake Warning

Indicator

Lamp Switch

(Gas

Engine)

32

Bulkhead Disconnect 50-Way .85,86

Buzzer-Combined Headlamp,

Key In, and

Seat

Belt

. . .

.27,28

Bypass

Jumper

(Clutch

Pedal Position)

8

Cargo

Lamp .49,50

Cargo

Lamp Switch

49

Charging System

with

Diesel Engine ..............

.5,6

Battery

5

Generator

. .6

Charging System

with

Gas Engine

.3,4

Battery

3

Generator

, . .4

Cigar

Lighter,

Ash &

Glove

Box

Lamps

52

Circuit

Breakers Power Windows

2,71

Clearance Lamps Duel Rear Wheels

.

.41,43 Clearance Lamps Roof Mounted

40

Clockspring 30,36,38

Clutch Pedal Position Switch

.8

Cold

Start

Advance Motor

24

Compressor,

A/C

68,70 Data Link Connector 17,23,31,33

Data Link Connectors

Rear

Wheel Anti-Lock Diesel Engine

.33

Rear

Wheel Anti-Lock Gas Engine

31

Daytime Running

Light

Module

46

Diesel

Control

System .21,22,23,24,25,26

Air Heater Relay

. .21

Air

Intake

Heater

21

Automatic

Shut Down Relay

22

Cold

Start

24

Crankshaft Position

Sensor

. .25

Data Link Connector

. .23

Engine

Coolant Temp Switch

.26

Fuel Heater

24

Fuel Solenoid

24

Intake

Air

Temp

Sensor

25

Powertrain

Control

Module 21,22,23,25,26

Resistor

.24

Thermo Switch

24

Throttle

Position (Sensor)

26

Transmission Thermo Switch

. . .26

Vehicle Speed

Sensor

25,26 Water

in

Fuel

Sensor

.25

Dimmer Switch-Headlamp

. .47

Diode 68,70

Diode

and

Mold Assembly

51

Dome

and

Cargo Lamp

50

Door

Jamb Switches

49

Left

Switch

.49

Right Switch

49

Dual Solenoid Hydraulic Valve

.32

EMCC

System (3-Speed)

. .11