DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 601 of 1502

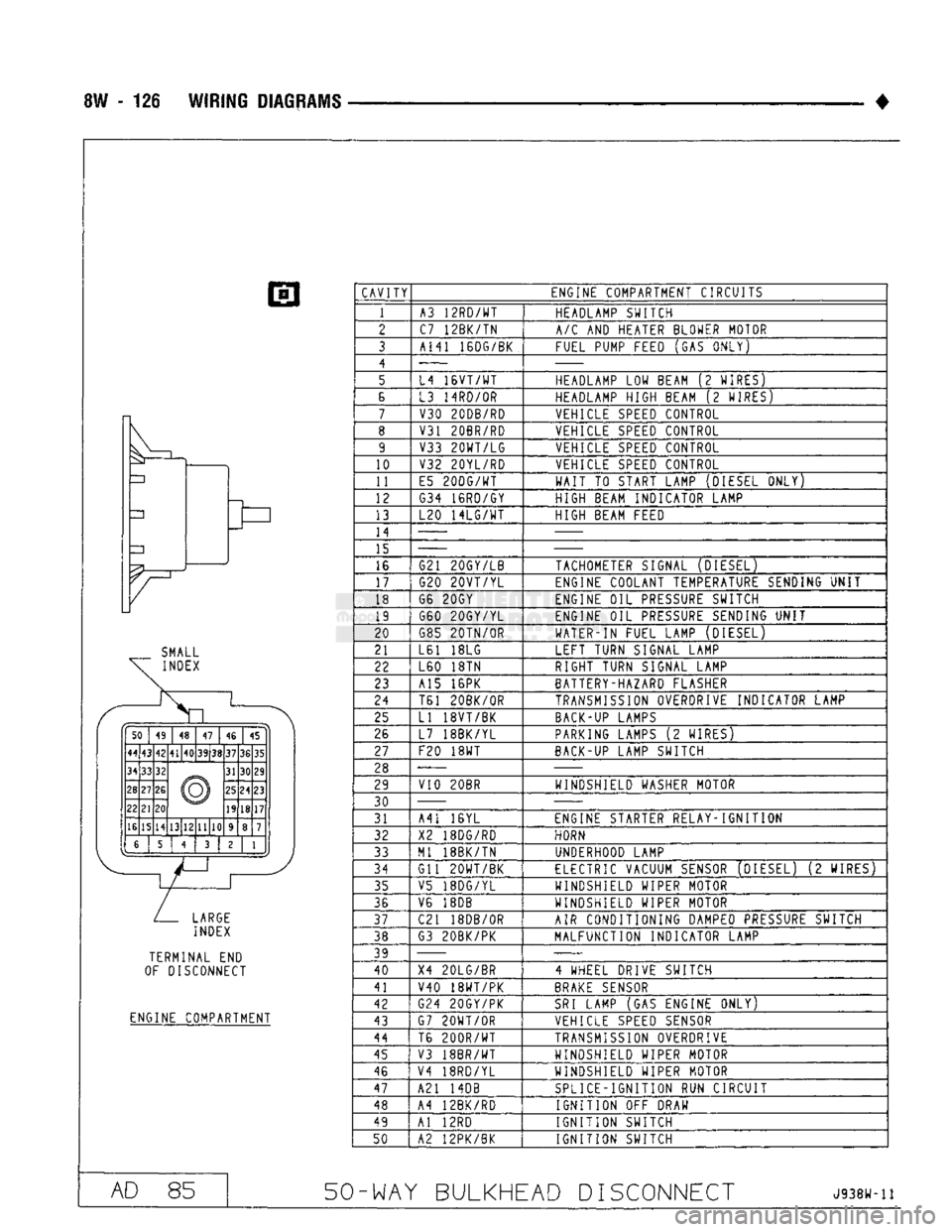

8W - 126

WIRING

DIAGRAMS

SMALL

INDEX

50 49 48

47

46 45

44 43 42 41

40 39

38 37

36 35

34 33 32

© 31

30 29

28 27

26

© 25

24 23

22 21

20 ©

19 18

17

16 15 14 13 12 11 10 9 8 7

6 5 4

3 2

1

LARGE

INDEX TERMINAL END

OF DISCONNECT

ENGINE COMPARTMENT CAVITY

1

10

11

12

13

14 15

16

17

18 19

20

21

22

23

24

25

26

27

28

29

30 31

32 33

34

35

36

37

38

39 40

41

42

43

44

45

46

47

48

50 ENGINE COMPARTMENT CIRCUITS

A3 12RD/WT C7 12BK/TN

A141 16DG/BK

L4

16VT/WT

L3 14RD/0R

V30 20DB/RD

V31 20BR/RD V33

20WT/LG

V32 20YL/RD

E5

20DG/WT

G34 16RD/GY

L20

14LG/WT

G21 20GY/LB G20

20VT/YL

G6 20GY

G60 20GY/YL

G85 20TN/OR

L61 18LG L60 18TN

A15 16PK

T61 20BK/0R

LI 18VT/BK

L7 18BK/YL

F20 18WT

V10 20BR

A41 16YL

X2 18DG/RD

Ml 18BK/TN

Gil

20WT/BK

V5 18DG/YL

V6 18DB

C21 18DB/0R

G3 20BK/PK

X4 20LG/BR V40 18WT/PK

G24 20GY/PK

G7 2GWT/0R T6

200R/WT

V3 18BR/WT

V4 18RD/YL

A21 14DB

A4 12BK/RD Al 12RD

A2 12PK/BK HEADLAMP SWITCH

A/C

AND HEATER BLOWER MOTOR

FUEL PUMP FEED (GAS ONLY)

HEADLAMP LOW BEAM (2 WIRES)

HEADLAMP HIGH BEAM (2 WIRES)

VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL

WAIT

TO START LAMP (DIESEL

QNLYr

HIGH BEAM INDICATOR LAMP

HIGH BEAM FEED

TACHOMETER SIGNAL (DIESEL)

ENGINE COOLANT TEMPERATURE SENDING

UNIT

ENGINE OIL

PRESSURE

SWITCH

ENGINE OIL

PRESSURE

SENDING

UNIT

WATER-IN FUEL LAMP (DIESEL)

LEFT TURN SIGNAL LAMP RIGHT TURN SIGNAL LAMP

BATTERY-HAZARD FLASHER

TRANSMISSION

OVERDRIVE INDICATOR LAMP

BACK-UP LAMPS

PARKING LAMPS (2 WIRES)

BACK-UP LAMP SWITCH

WINDSHIELD WASHER MOTOR

ENGINE STARTER RELAY

-1GNITI

ON HORN

UNDERHOOD LAMP

ELECTRIC

VACUUM

SENSOR

(DIESEL) (2 WIRES)

WINDSHIELD WIPER MOTOR

WINDSHIELD WIPER MOTOR

AIR CONDITIONING DAMPED

PRESSURE

SWITCH

MALFUNCTION INDICATOR LAMP

4 WHEEL DRIVE SWITCH

BRAKE

SENSOR

SRI

LAMP (GAS ENGINE ONLY)

VEHICLE

SPEED SENSOR

TRANSMISSION

OVERDRIVE

WINDSHIELD WIPER MOTOR

WINDSHIELD WIPER MOTOR

SPLICE-IGNITION RUN CIRCUIT

IGNITION

OFF DRAW

IGNITION

SWITCH

IGNITION

SWITCH

AD 85 50-WAY BULKHEAD DISCONNECT

J938W-11

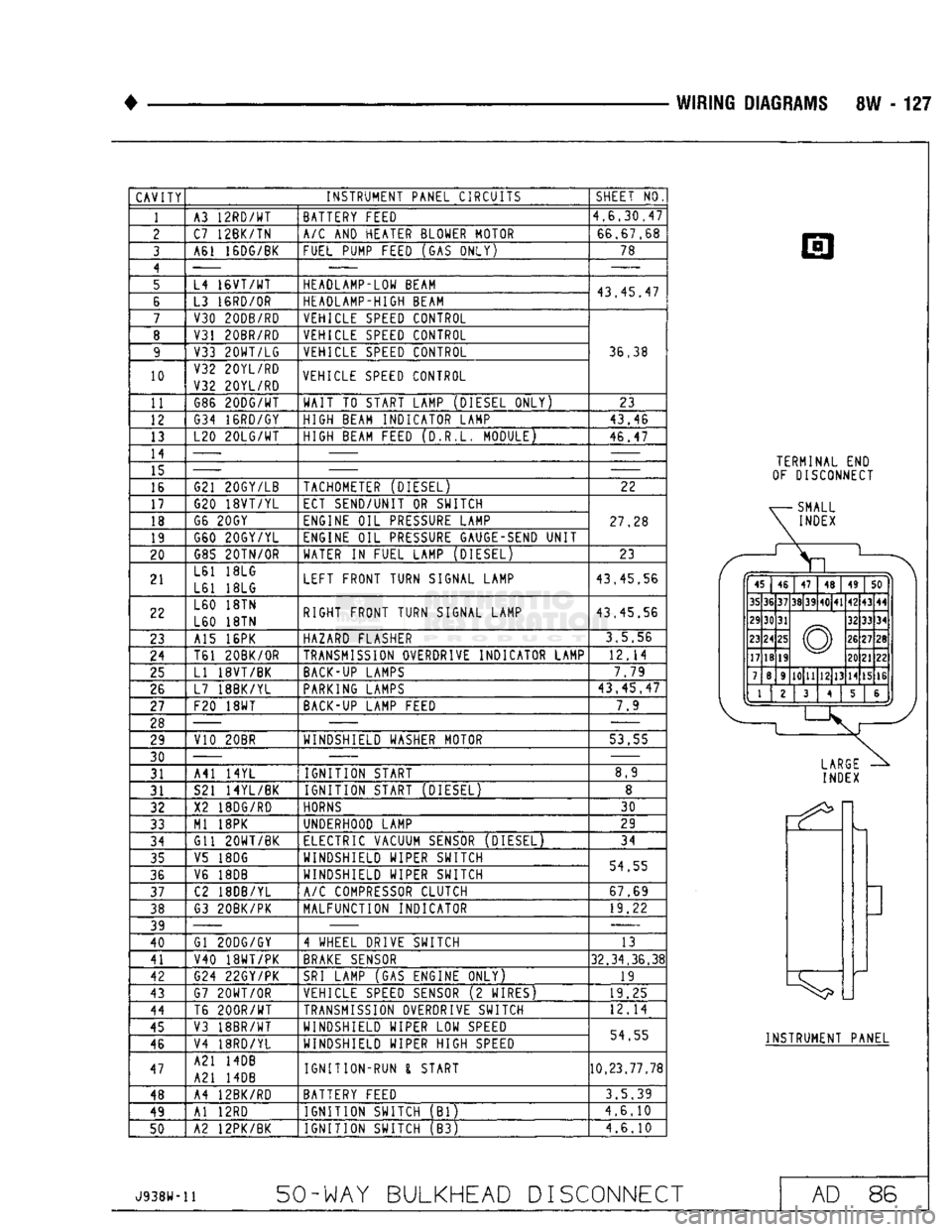

Page 602 of 1502

•

WIRING

DIAGRAMS

8W - 127

CAVITY

INSTRUMENT PANEL CIRCUITS

1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28 29

30 31

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

A3

12RD/WT

C7 12BK/TN

A61 16DG/BK

L4

16VT/WT

L3

16RD/0R

V30 20DB/RD

V31 20BR/RD

V33

20WT/LG

V32 20YL/RD

V32 20YL/RD G86

20DG/WT

G34 16RD/GY

L20

20LG/WT

G21 20GY/LB

G20

18VT/YL

G6

20GY

G60 20GY/YL G85

20TN/0R

L61

18LG

L61

18LG

L60

18TN

L60

18TN

A15

16PK

T61 20BK/OR

LI

18VT/BK

L7 18BK/YL

F20

18WT

V10 20BR

A41

14YL

S21 14YL/BK

X2

18DG/R0

Ml

18PK

Gil

20WT/BK

V5

18DG

V6

18DB

C2 18DB/YL

G3 20BK/PK

Gl 20DG/GY

V40

18WT/PK

G24 22GY/PK

G7

20WT/0R

T6

200R/WT

V3 18BR/WT

V4 18RD/YL

A21

14DB

A21

14DB

A4 12BK/RD

Al

12RD

A2 12PK/BK BATTERY FEED

A/C

AND

HEATER BLOWER MOTOR

FUEL PUMP FEED

(GAS

ONLY)

HEADLAMP-LOW BEAM

HEADLAMP-HIGH BEAM VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL VEHICLE

SPEED

CONTROL

VEHICLE

SPEED

CONTROL

WAIT

TO

START LAMP (DIESEL ONLY)

HIGH BEAM INDICATOR LAMP

HIGH BEAM FEED (D.R.L. MODULE)

TACHOMETER (DIESEL)

ECT SEND/UNIT

OR

SWITCH

ENGINE

OIL

PRESSURE

LAMP

ENGINE

OIL

PRESSURE

GAUGE-SEND

UNIT

WATER

IN

FUEL LAMP (DIESEL)

LEFT FRONT TURN SIGNAL LAMP

RIGHT FRONT TURN SIGNAL LAMP

HAZARD FLASHER

TRANSMISSION

OVERDRIVE INDICATOR LAMP

BACK-UP

LAMPS

PARKING

LAMPS

BACK-UP

LAMP FEED

WINDSHIELD WASHER MOTOR

IGNITION START

IGNITION START (DIESEL)

HORNS

UNDERHOOD LAMP

ELECTRIC VACUUM

SENSOR

(DIESEL) WINDSHIELD WIPER SWITCH

WINDSHIELD WIPER SWITCH

A/C

COMPRESSOR CLUTCH

MALFUNCTION INDICATOR

4 WHEEL DRIVE SWITCH

BRAKE

SENSOR

SRI

LAMP

(GAS

ENGINE ONLY)

VEHICLE

SPEED

SENSOR

(2

WIRES)

TRANSMISSION

OVERDRIVE SWITCH

WINDSHIELD WIPER

LOW

SPEED

WINDSHIELD WIPER HIGH

SPEED

IGNITION-RUN

I

START

BATTERY FEED IGNITION SWITCH

(Bl)

IGNITION SWITCH

(B3)

SHEET

NO

4,6.30,47

66,67,68 78

43,45,47

36,38

23

43,46

46,47

22

27,28

23

43.45,56

43,45.56

3,5,56

12,14 7.79

43,45,47

7.9

53.55 8,9

30

29

34

54,55 67,69 19,22

13

32,34,36,38

19

19,25

12,14

54.55

10,23.77,78

3.5.39

4,6.10

4.6.10

TERMINAL

END

OF DISCONNECT

ff

p

45 46

47

48 49

50

35 36 37

38 39

40 41

42

43 44

29 30 31

© 32

33 34

23 24

25

© 26

27 28

17 18

19 ©

20 21 22

7 8 9

10 11

12 13

14 15 16

1

^

1.

2

3

4 5 &

J *j

LARGE

INDEX

INSTRUMENT PANEL

J938W-11

50-WAY BULKHEAD

DISCONNECT

AD

86

Page 603 of 1502

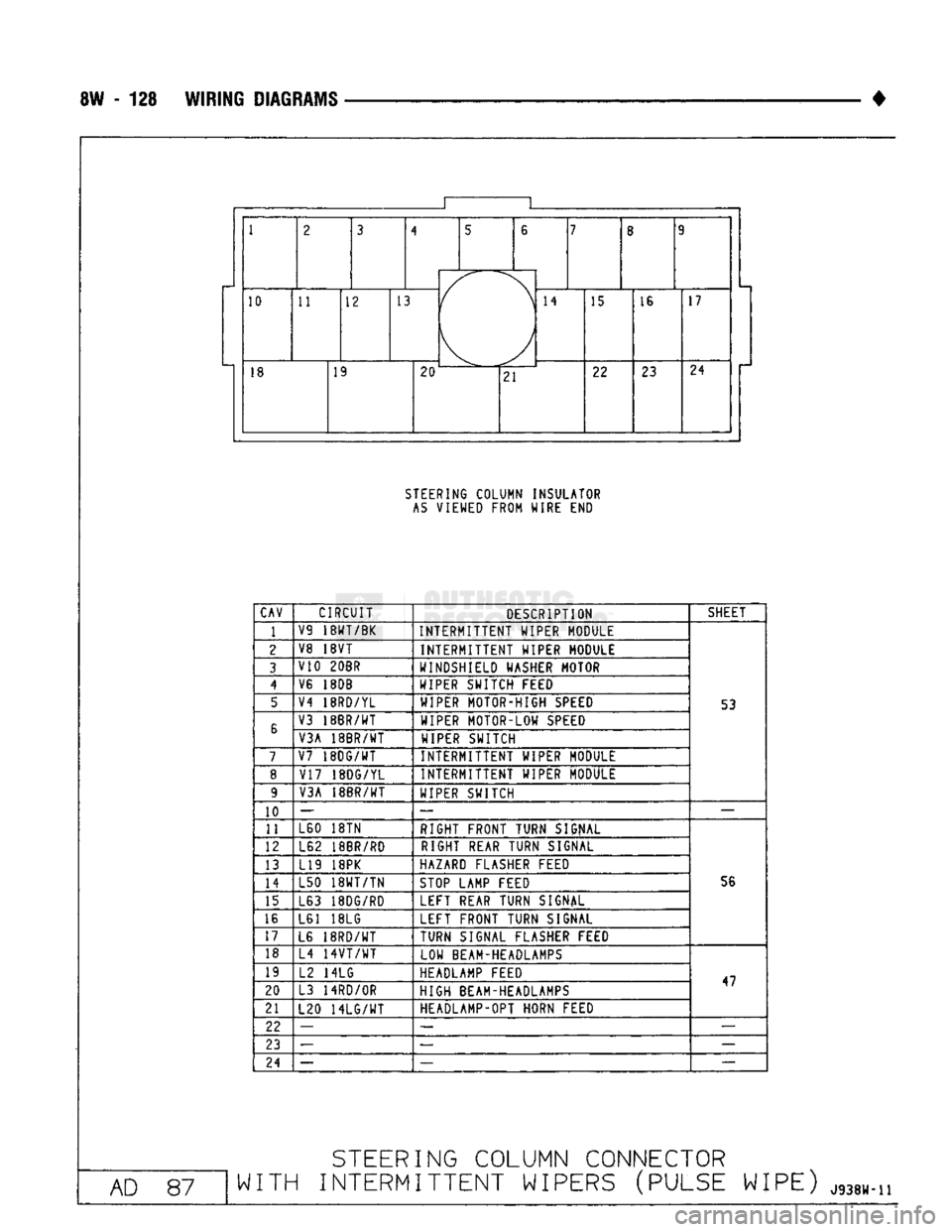

8W - 128 WIRING

DIAGRAMS

• 10

11 12

13

14

15 16 17

18 19

20

21 22

23 24

STEERING

COLUMN INSULATOR

AS

VIEWED FROM WIRE END

CAV

CIRCUIT

DESCRIPTION SHEET

1

V9

18WT/BK

INTERMITTENT WIPER MODULE

2 V8 18VT

INTERMITTENT WIPER MODULE

3 V10 20BR

WINDSHIELD WASHER MOTOR

4 V6 18DB

WIPER SWITCH FEED

5 V4 18RD/YL

WIPER MOTOR-HIGH SPEED

53

6 V3 18BR/WT

WIPER MOTOR-LOW SPEED

6

V3A 18BR/WT WIPER SWITCH

7 V7

18DG/WT

INTERMITTENT WIPER MODULE

8

V17 18DG/YL INTERMITTENT WIPER MODULE

9 V3A 18BR/WT

WIPER SWITCH

10 —

— —

11 L60 18TN

RIGHT FRONT TURN SIGNAL

12 L62 18BR/RD RIGHT REAR TURN SIGNAL

13 L19 18PK HAZARD FLASHER FEED

14 L50

18WT/TN

STOP LAMP FEED 56

15 L63 18DG/RD LEFT REAR TURN SIGNAL

16 L61 18LG LEFT FRONT TURN SIGNAL

17 L6

18RD/WT

TURN SIGNAL FLASHER FEED

18 L4

14VT/WT

LOW BEAM-HEADLAMPS

19 L2 14LG HEADLAMP FEED

47

20 L3

14RD/0R

HIGH BEAM-HEADLAMPS 47

21 L20

14LG/WT

HEADLAMP-OPT HORN FEED

22 —

— —

23 —

—

24 — —-

—

AD

87

STEERING

COLUMN CONNECTOR

WITH

INTERMITTENT WIPERS (PULSE WIPE)

J938W.n

Page 604 of 1502

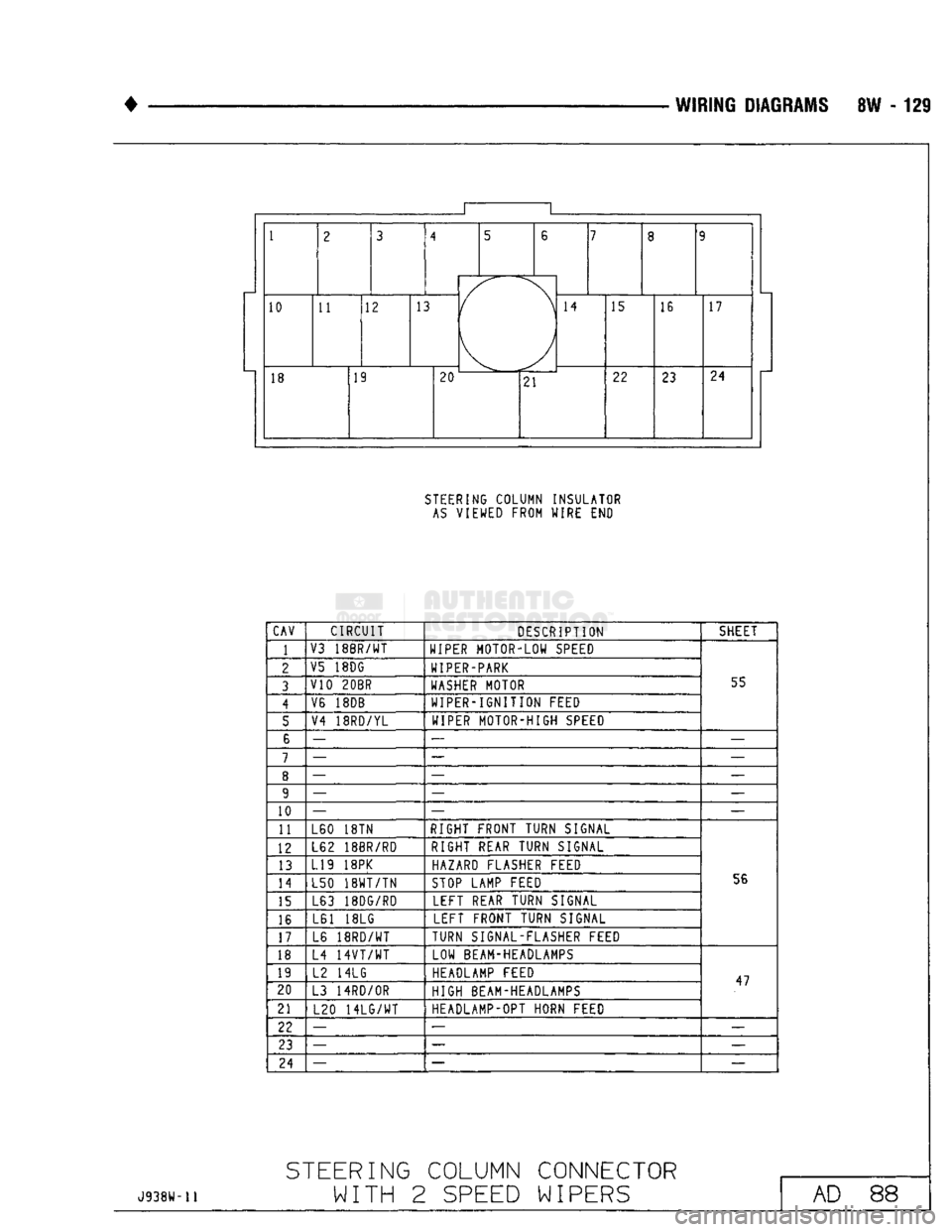

•

WIRING DIAGRAMS 8W - 129 1

1

2 3

4 5

6

7

8 9

1

2 3

(

\ ) 7

8 9

10 11 12 13

(

\ ) 14

15 16 17

18 19

20 ^-— -

21 22

23 24

STEERING COLUMN INSULATOR

AS

VIEWED FROM WIRE END

CAV CIRCUIT

DESCRIPTION SHEET

1

V3

18BR/WT

WIPER MOTOR-LOW SPEED

55

2

V5 18DG

WIPER-PARK

55

3 V10

20BR

WASHER MOTOR 55

4 V6 18DB

WIPER-IGNITION FEED 55

5 V4

18RD/YL

WIPER MOTOR-HIGH SPEED 55

6 —

— —

7 —

— —

8 —

— —

9 —

— —

10 —

— —

11 L60 18TN

RIGHT FRONT TURN SIGNAL

56

12

L62 18BR/RD

RIGHT REAR TURN SIGNAL

56

13

L19 18PK

HAZARD FLASHER FEED

56

14 L50

18WT/TN

STOP LAMP FEED 56

15 L63 18DG/RD

LEFT REAR TURN SIGNAL 56

16 L61 18LG

LEFT FRONT TURN SIGNAL 56

17 L6

18RD/WT

TURN SIGNAL-FLASHER FEED 56

18 L4

14VT/WT

LOW BEAM-HEADLAMPS

47

19

L2 14LG HEADLAMP FEED

47

20 L3 14RD/OR

HIGH BEAM-HEADLAMPS 47

21 L20

14LG/WT

HEADLAMP-OPT HORN FEED 47

22 —

— —

23 —

— —

24 —

—

—

J938H-11

STEERING

COLUMN CONNECTOR

WITH 2

SPEED

WIPERS

AD 88

Page 605 of 1502

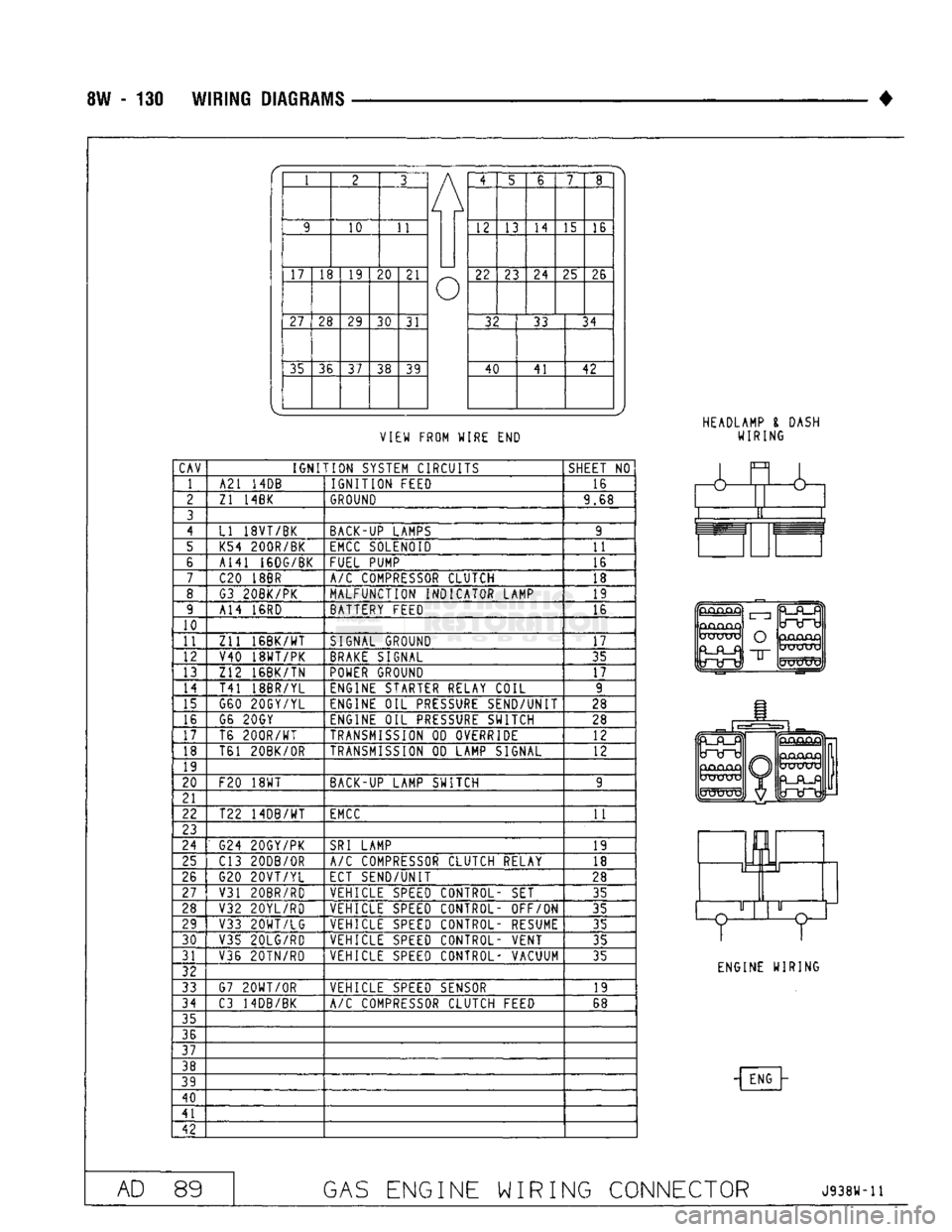

8W - 130

WIRING

DIAGRAMS

•

1 2 3

A 4

5 6

7

8

/

9

10

11

/

12 13

14

15 16

/

17

18

19

20

21

u

22

23

24

25 26

u

27

28 29

30

31

u

32 33

34

u

35 36

37

38 39

u

40

41 42

u

VIEW FROM WIRE

END

HEADLAMP

I

DASH

WIRING

CAV

IGNITION

SYSTEM CIRCUITS

SHEET

NO

1 A21

14DB

IGNITION

FEED 16

2

Zl 14BK

GROUND

9.68

3

4

LI 18VT/BK BACK-UP LAMPS 9

5 K54 200R/BK

EMCC

SOLENOID

11

6 A141 16DG/BK

FUEL PUMP 16

7

C20

18BR

A/C

COMPRESSOR CLUTCH 18

8 G3 20BK/PK MALFUNCTION INDICATOR LAMP 19

9 A14

16RD

BATTERY FEED 16

10

11

Zll

16BK/WT

SIGNAL GROUND

17

12 V40 18WT/PK

BRAKE

SIGNAL 35

13 Z12 16BK/TN

POWER

GROUND

17

14

T41 18BR/YL ENGINE STARTER RELAY COIL 9

15 G60 20GY/YL ENGINE

OIL

PRESSURE

SEND/UNIT 28

16 G6 20GY

ENGINE

OIL

PRESSURE

SWITCH 28

17 T6

200R/WT

TRANSMISSION

OD

OVERRIDE 12

18 T61 20BK/0R

TRANSMISSION

OD

LAMP SIGNAL

12

19

20

F20

18WT

BACK-UP LAMP SWITCH 9

21

22 T22 14DB/WT

EMCC

11

23

24

G24 20GY/PK

SRI

LAMP

19

25 C13 20DB/0R

A/C

COMPRESSOR CLUTCH RELAY

18

26 G20

20VT/YL

ECT SEND/UNIT

28

27

V31 20BR/RD VEHICLE

SPEED

CONTROL-

SET

35

28 V32 20YL/RD VEHICLE

SPEED

CONTROL- OFF/ON

35

29 V33

20WT/LG

VEHICLE

SPEED

CONTROL- RESUME 35

30

V35 20LG/RD VEHICLE

SPEED

CONTROL- VENT

35

31 V36 20TN/RD VEHICLE

SPEED

CONTROL- VACUUM

35

32

33 G7

20WT/0R

VEHICLE

SPEED

SENSOR 19

34

C3 14DB/BK

A/C

COMPRESSOR CLUTCH FEED 68

35

36

37

38

39

40

41

42

&

GjCUQjQ

UXJUXj

O

"IT

mJKXTV

ENGINE WIRING

- ENG

AD

89

GAS

ENGINE WIRING CONNECTOR

J938W-11

Page 606 of 1502

•

ENGINES ENGINES

9 - 1

CONTENTS

page page

3.9L

ENGINE SERVICE PROCEDURES

17 5.9L

ENGINE SERVICE PROCEDURES

77

5.2L

ENGINE SERVICE PROCEDURES

47

ENGINE DIAGNOSIS

5

5.9L

(DIESEL) ENGINE SERVICE PROCEDURES

. 107

STANDARD SERVICE PROCEDURES

1

STANDARD SERVICE PROCEDURES INDEX

page

Engine

Performance 2

Form-ln-Place

Gaskets

1

Honing

Cylinder

Bores

2

FORM-IN-PLACE GASKETS

There are several places where form-in-place gas

kets are used on the engine. DO NOT use form-in-

place gasket material unless specified. Care must

be taken when applying form-in-place gaskets. Bead

size,

continuity and location are of great importance.

Too thin a bead can result in leakage while too much can result in spill-over. A continuous bead of the

proper width is essential to obtain a leak-free joint. Two types of form-in-place gasket materials are

used in the engine area (Mopar Silicone Rubber Ad

hesive Sealant and Mopar Gasket Maker). Each have different properties and cannot be used interchange ably.

MOPAR SILICONE RUBBER ADHESIWE

SEALANT

Mopar Silicone Rubber Adhesive Sealant, normally

black in color, is available in 3 ounce tubes. Moisture in the air causes the sealant material to cure. This

material is normally used on flexible metal flanges.

It has a shelf life of 1 year and will not properly cure

if over aged. Always inspect the package for the ex

piration date before use.

MOPAR

GASKET MAKER Mopar Gasket Maker, normally red in color, is

available in 6 cc tubes. This anaerobic type gasket

material cures in the absence of air when squeezed

between smooth machined metallic surfaces. It will not cure if left in the uncovered tube. DO NOT use on flexible metal flanges.

page

Hydrostatic

Lock

4

Measuring

with

Plastigage 3

Repair

Damaged

or Worn

Threads

. 4

SURFACE PREPARA

TION

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some in

stances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET

APPLICATION

Assembling parts using a form-in-place gasket re

quires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm (0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing, a 3 or 6 mm (1/8 or 1/4

inch) drop is placed in the center of the gasket con

tact area. Uncured sealant may be removed with a shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

minutes). The use of a locating dowel is recom

mended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.Q0 mm (0.04 inch) or less. Be certain the mate-

Page 607 of 1502

9

- 2

ENGINES

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a lo cating dowel is recommended during assembly to pre

vent smearing the material off location.

ENGINE PERFORMANCE

To provide best vehicle performance and lowest ve

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label found on the engine compartment hood.

(1) Test cranking amperage draw (refer to Group

8B,

Battery/Starter/Generator Service for the proper

procedures).

(2) Tighten the intake manifold bolts (refer to

Group 11, Exhaust System and Intake Manifold for

the proper specifications). (3) Perform cylinder compression test:

(a) Check engine oil level and add oil, if neces

sary.

(b) Drive the vehicle until engine reaches normal

operating temperature. (c) Select a route free from traffic and other

forms of congestion, observe all traffic laws and

briskly accelerate through the gears several times. The higher engine speed may help clean out valve seat deposits which can prevent accurate compres

sion readings.

CAUTION:

DO NOT

overspeed

the

engine.

(d) Remove all spark plugs from engine. As

spark plugs are being removed, check electrodes for

abnormal firing indicators - fouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference.

(e) Disconnect coil wire from distributor and se

cure to good ground to prevent a spark from start

ing a fire.

(f) Be sure throttle blades are fully open during

the compression check. (g) Insert compression gage adaptor into the

No.l spark plug hole. Crank engine until maxi

mum pressure is reached on gauge. Record this

pressure as No.l cylinder pressure.

(h) Repeat Step 3g for all remaining cylinders.

(i) Compression should not be less than 689 kPa

(100 psi) and not vary more than 172 kPa (25 psi)

from cylinder to cylinder.

(j) If cylinder(s) have abnormally low compres

sion pressures, repeat steps 3a through 3h. (k) If the same cylinder(s) repeat an abnormally

low reading, it could indicate the existence of a

problem in the cylinder.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should NOT be disassem bled to determine the cause of low compression

unless some malfunction is present. (4) Clean or replace spark plugs as necessary. Ad

just gap (refer to Group 8D, Ignition System for gap adjustment and torque).

(5) Test resistance of spark plug cables (refer to

Group 8D, Ignition System.

(6) Inspect the primary wire. Test coil output volt

age,

primary and secondary resistance. Replace parts as necessary (refer to Group 8D, Ignition System and

make necessary adjustment).

(7) Set ignition timing to specifications (refer to

Specification Label on engine compartment hood).

(8) Perform a combustion analysis.

(9) Test fuel pump for pressure and vacuum (refer

to Group 14, Fuel System for the proper specifica

tions).

(10) Inspect air filter element (refer to Group 0,

Lubrication and Maintenance for the proper proce

dure).

(11) Inspect crankcase ventilation system (refer to

Group 0, Lubrication and Maintenance for the proper

procedure).

(12) For emission controls refer to Group 25, Emis

sion Controls System for service procedures.

(13) Inspect and adjust accessory belt drives (refer

to Group 7, Cooling System for the proper adjust

ments).

(14) Road test vehicle as a final test.

H0NIN6

CYLINDER

BORES

Before honing, stuff plenty of clean shop towels un

der the bores and over the crankshaft to keep abra sive materials from entering the crankshaft area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim

its.

CAUTION:

DO NOT use rigid type

hones

to remove

cylinder

wall

glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). 20-60 strokes, de

pending on the bore condition, will be sufficient to

provide a satisfactory surface. Using honing oil C-3501-3880 or a light honing oil available from ma

jor oil distributors.

CAUTION:

DO NOT use engine or

transmission

oil, mineral

spirits

or

kerosene.

Page 608 of 1502

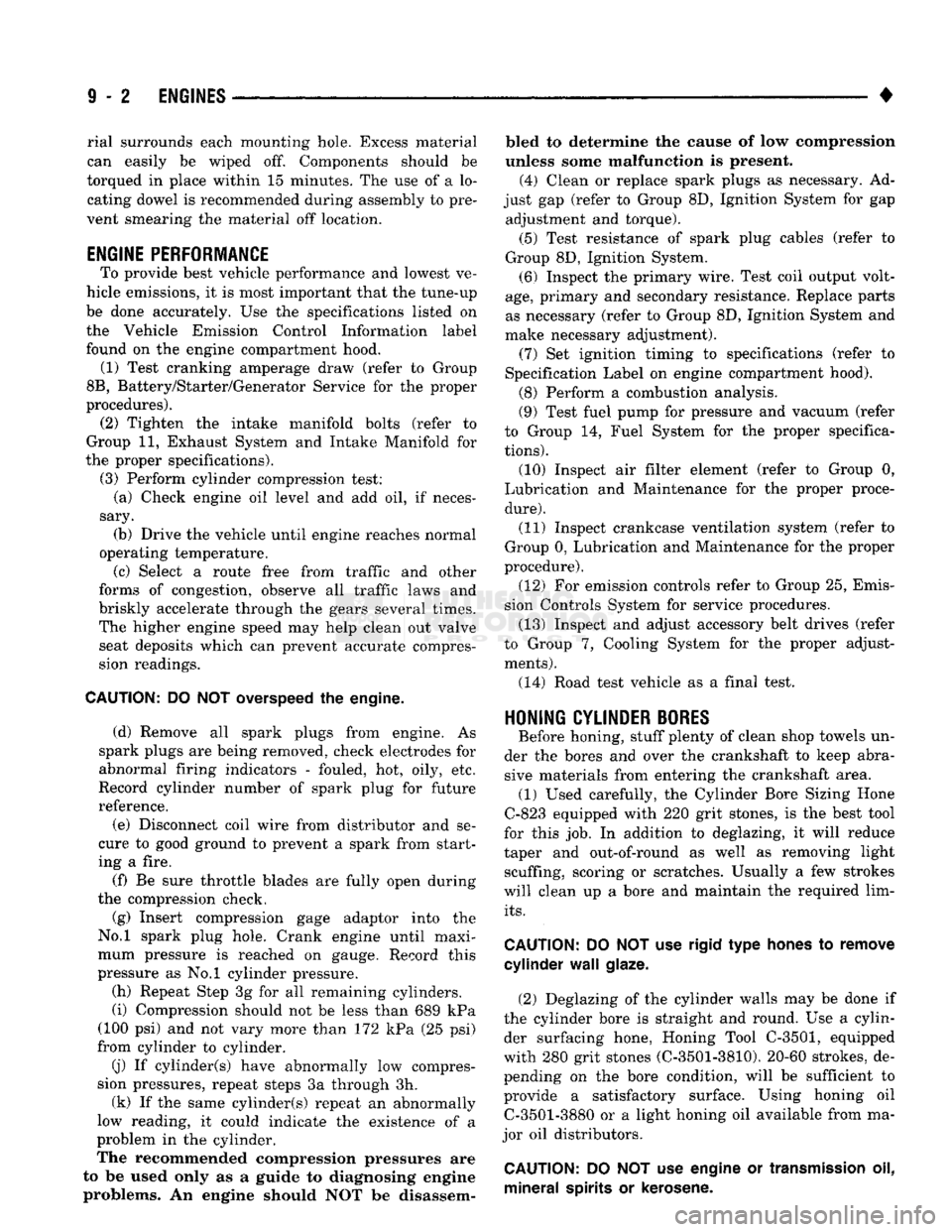

•

ENGINES

9 - 3

(3) Honing

should be

done

by moving the

hone

up

and down

fast

enough

to get a Crosshatch pattern.

The hone

marks should

INTERSECT

at 50° to 60° for

proper seating

of

rings (Fig.

1).

Fig.

1

Cylinder

Bore

Crosshatch

Pattern

(4)

A

controlled hone motor speed between

200 and

300

RPM is

necessary

to

obtain

the

proper Crosshatch angle.

The

number

of up and

down strokes

per

minute

can be

regulated

to get the

desired

50° to 60°

angle. Faster

up and

down strokes increase

the

cross-

hatch angle.

(5) After honing,

it is

necessary that

the

block

be

cleaned

to

remove

all

traces

of

abrasive.

Use a

brush

to wash parts with

a

solution

of hot

water

and

deter gent.

Dry

parts thoroughly.

Use a

clean, white, lint-

free cloth

to

check that

the

bore

is

clean.

Oil the

bores after cleaning

to

prevent rusting.

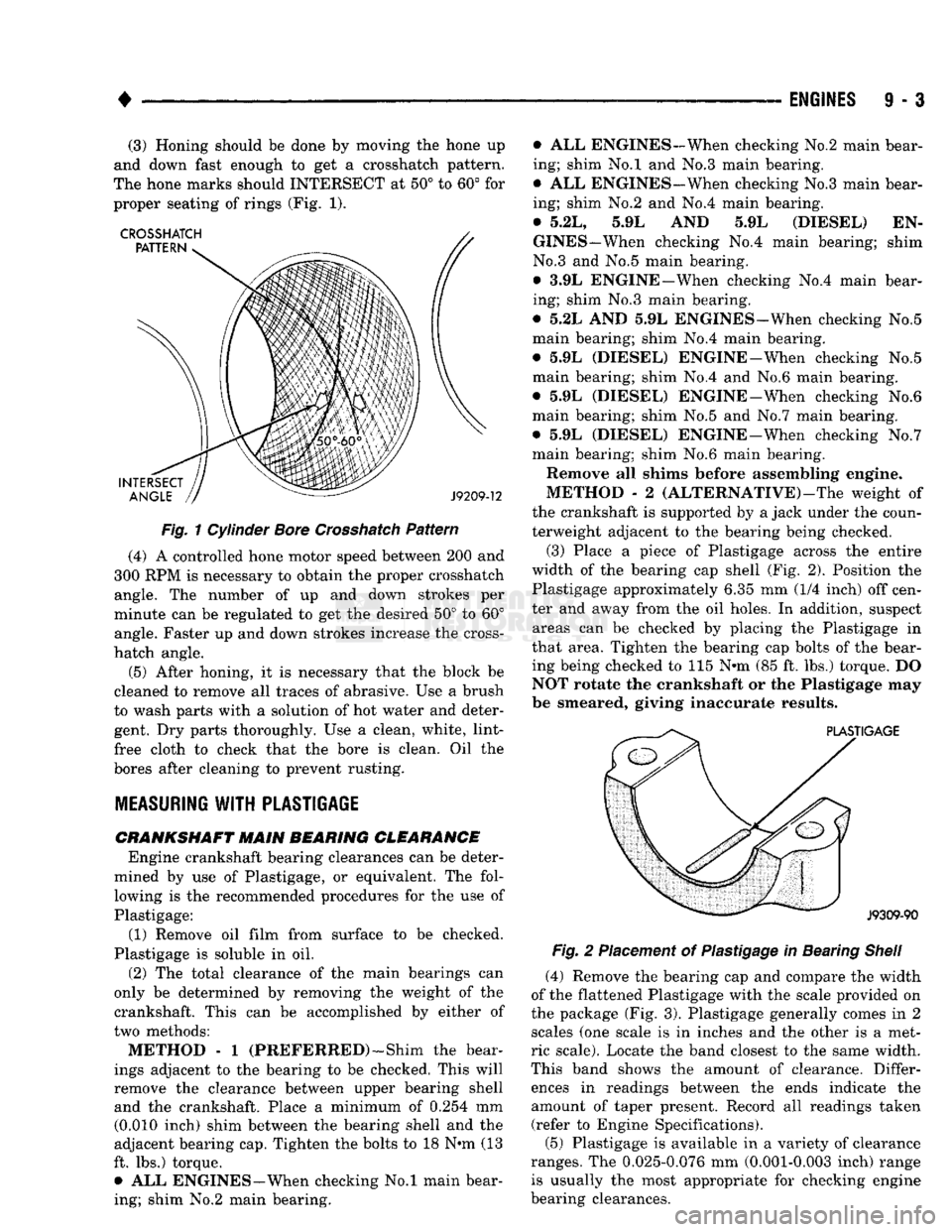

MEASURING

WITH

PLASTIGAGE

CRANKSHAFT

MAIN BEARING CLEARANCE Engine crankshaft bearing clearances

can be

deter

mined

by use of

Plastigage,

or

equivalent.

The

fol lowing

is the

recommended procedures

for the use of

Plastigage:

(1) Remove

oil

film from surface

to be

checked.

Plastigage

is

soluble

in oil.

(2)

The

total clearance

of the

main bearings

can

only

be

determined

by

removing

the

weight

of the

crankshaft. This

can be

accomplished

by

either

of

two methods:

METHOD - 1

(PREFERRED)—Shim

the

bear

ings adjacent

to the

bearing

to be

checked. This will

remove

the

clearance between upper bearing shell and

the

crankshaft. Place

a

minimum

of

0.254

mm

(0.010 inch) shim between

the

bearing shell

and the

adjacent bearing cap. Tighten

the

bolts

to 18 N*m (13

ft.

lbs.)

torque. •

ALL

ENGINES—When checking

No.l

main bear

ing; shim

No.2

main bearing. •

ALL

ENGINES-When checking

No.2

main bear

ing; shim

No.l and No.3

main bearing.

•

ALL

ENGINES-When checking No.3 main bear

ing; shim

No.2 and No.4

main bearing.

•

5.2L, 5.9L AND 5.9L

(DIESEL)

EN

GINES—When checking

No.4

main bearing; shim

No.3

and No.5

main bearing.

•

3.9L

ENGINE—When checking

No.4

main bear

ing; shim

No.3

main bearing.

•

5.2L AND 5.9L

ENGINES—When checking

No.5

main bearing; shim

No.4

main bearing.

•

5.9L

(DIESEL) ENGINE-When checking

No.5

main bearing; shim

No.4 and No.6

main bearing.

•

5.9L

(DIESEL) ENGINE-When checking

No.6

main bearing; shim

No.5 and No.7

main bearing.

•

5.9L

(DIESEL) ENGINE-When checking

No.7

main bearing; shim

No.6

main bearing.

Remove

all

shims before assembling engine.

METHOD

- 2

(ALTERNATIVE)—The weight

of

the crankshaft

is

supported

by a

jack under

the

coun

terweight adjacent

to the

bearing being checked.

(3) Place

a

piece

of

Plastigage across

the

entire

width

of the

bearing

cap

shell

(Fig. 2).

Position

the

Plastigage approximately

6.35 mm (1/4

inch)

off

cen

ter

and

away from

the oil

holes.

In

addition, suspect areas

can be

checked

by

placing

the

Plastigage

in

that area. Tighten

the

bearing

cap

bolts

of the

bear

ing being checked

to 115 N»m (85 ft. lbs.)

torque.

DO

NOT rotate

the

crankshaft

or the

Plastigage

may

be smeared, giving inaccurate results.

Fig.

2

Placement

of

Plastigage

in

Bearing

Shell

(4) Remove

the

bearing

cap and

compare

the

width

of

the

flattened Plastigage with

the

scale provided

on

the package

(Fig. 3).

Plastigage generally comes

in 2

scales

(one

scale

is in

inches

and the

other

is a

met

ric scale). Locate

the

band closest

to the

same width.

This band shows

the

amount

of

clearance. Differ ences

in

readings between

the

ends indicate

the

amount

of

taper present. Record

all

readings taken (refer

to

Engine Specifications).

(5) Plastigage

is

available

in a

variety

of

clearance

ranges.

The

0.025-0.076

mm

(0.001-0.003 inch) range is usually

the

most appropriate

for

checking engine

bearing clearances.

Page 609 of 1502

9

- 4 ENGINES

•

RN861

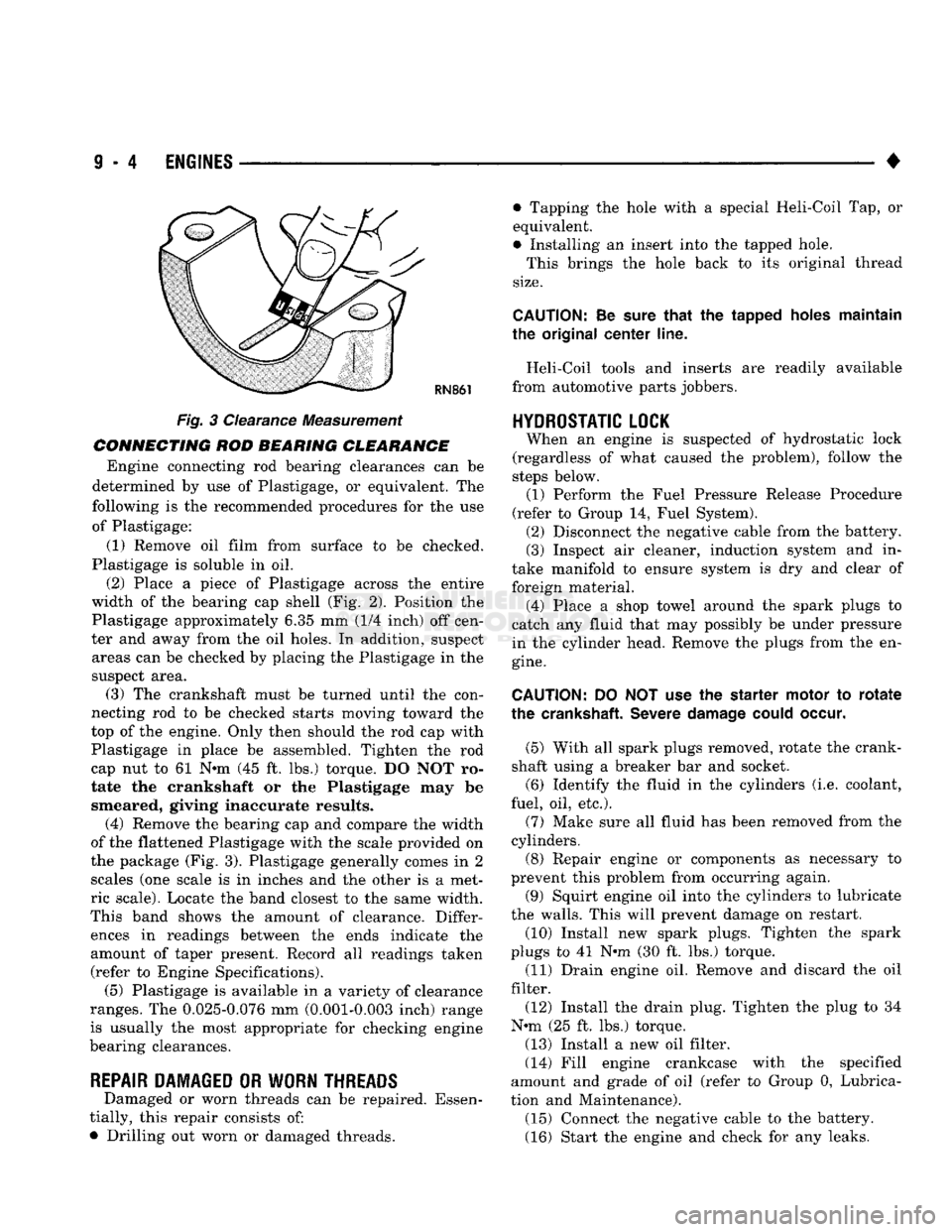

Fig. 3 Clearance Measurement

CONNECTING ROD BEARING CLEARANCE Engine connecting rod bearing clearances can be

determined by use of Plastigage, or equivalent. The

following is the recommended procedures for the use of Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing cap shell (Fig. 2). Position the

Plastigage approximately 6.35 mm (1/4 inch) off cen

ter and away from the oil holes. In addition, suspect areas can be checked by placing the Plastigage in the

suspect area. (3) The crankshaft must be turned until the con

necting rod to be checked starts moving toward the

top of the engine. Only then should the rod cap with

Plastigage in place be assembled. Tighten the rod

cap nut to 61 Nnn (45 ft. lbs.) torque. DO NOT ro

tate the crankshaft or the Plastigage may be smeared, giving inaccurate results. (4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2 scales (one scale is in inches and the other is a met

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ ences in readings between the ends indicate the

amount of taper present. Record all readings taken (refer to Engine Specifications). (5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

REPAIR DAMAGED OR WORN THREADS Damaged or worn threads can be repaired. Essen

tially, this repair consists of:

• Drilling out worn or damaged threads. • Tapping the hole with a special Heli-Coil Tap, or

equivalent.

• Installing an insert into the tapped hole.

This brings the hole back to its original thread

size.

CAUTION:

Be

sure

that

the tapped holes maintain

the original

center

line.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC

LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below. (1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System). (2) Disconnect the negative cable from the battery.

(3) Inspect air cleaner, induction system and in

take manifold to ensure system is dry and clear of

foreign material. (4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the plugs from the en

gine.

CAUTION:

DO NOT use the starter motor to

rotate

the

crankshaft.

Severe

damage

could

occur.

(5) With all spark plugs removed, rotate the crank

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders. (8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N#m (30 ft. lbs.) torque. (11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N-m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil (refer to Group 0, Lubrica

tion and Maintenance). (15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

Page 610 of 1502

•

ENGINES

9 - S

ENGINE

DIAGNOSIS

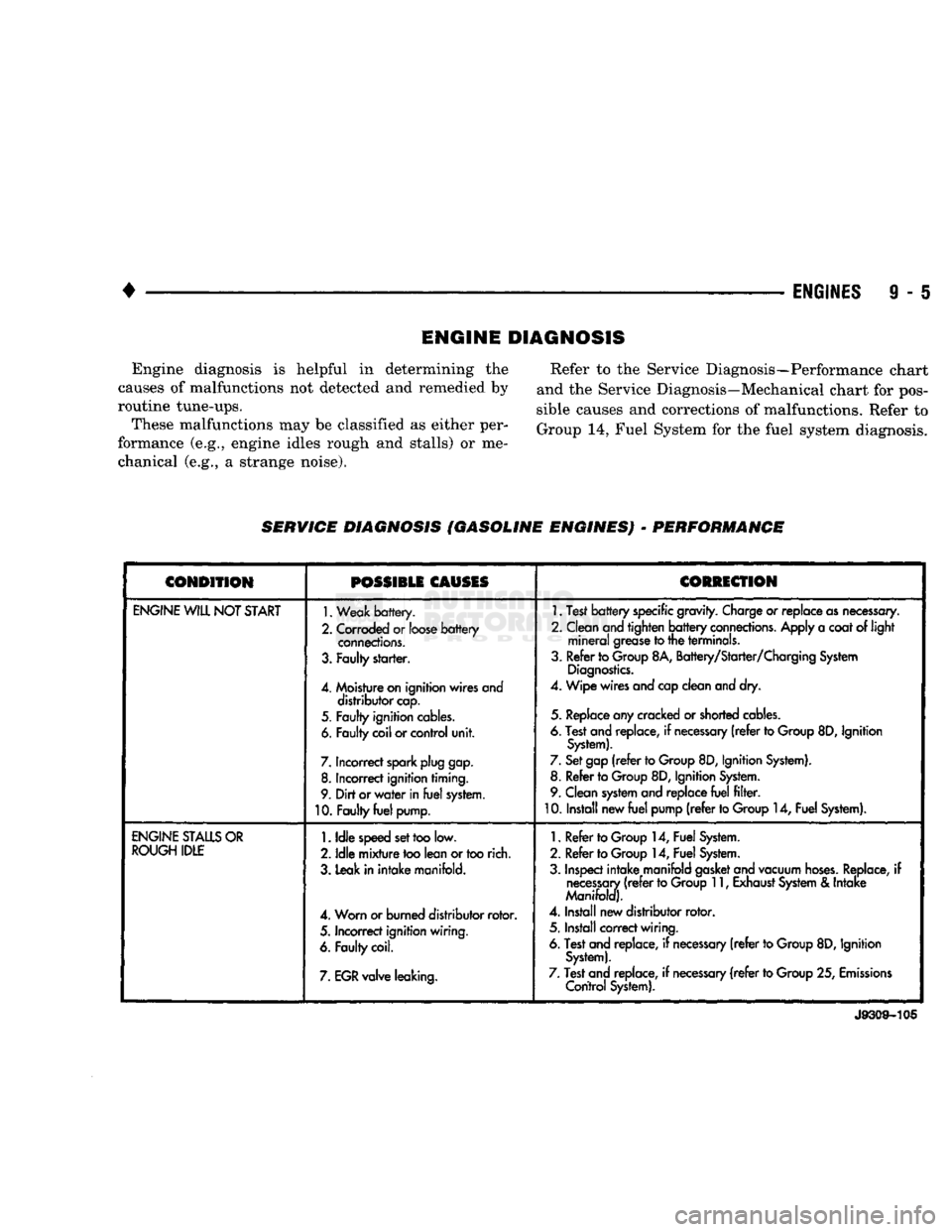

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine tune-ups. These malfunctions may be classified as either per

formance (e.g., engine idles rough and stalls) or me chanical (e.g., a strange noise). Refer to the Service Diagnosis—Performance chart

and the Service Diagnosis—Mechanical chart for pos

sible causes and corrections of malfunctions. Refer to

Group 14, Fuel System for the fuel system diagnosis.

SERWIGE DIAGNOSIS (GASOLINE ENGINES)

-

PERFORMANCE

CONDITION

POSSIBLE

CAUSES

CORRECTION

ENGINE

WILL

NOT

START

1.

Weak

battery.

2.

Corroded

or

loose

battery

connections.

3.

Faulty

starter.

4.

Moisture

on

ignition wires and distributor

cap.

5.

Faulty

ignition

cables.

6.

Faulty

coil

or

control

unit.

7.

Incorrect

spark

plug

gap.

8.

Incorrect

ignition timing.

9.

Dirt

or

water

in

fuel

system.

10.

Faulty

fuel

pump.

1.

Test

battery

specific

gravity.

Charge

or

replace

as

necessary.

2. Clean

and

tighten

battery

connections.

Apply

a

coat

of light

mineral

grease

to

the terminals.

3. Refer to

Group

8A, Battery/Starter/Charging

System

Diagnostics.

4. Wipe

wires

and

cap

clean

and

dry.

5.

Replace

any

cracked

or

shorted

cables.

6.

Test

and

replace,

if

necessary

(refer

to

Group

8D,

Ignition

System).

7.

Set

gap

(refer

to

Group

8D, Ignition

System).

8. Refer to

Group

8D, Ignition

System.

9. Clean

system

and

replace

fuel

filter.

10. Install new

fuel

pump

(refer

to

Group

14,

Fuel

System).

ENGINE

STALLS

OR

ROUGH

IDLE

1.

Idle

speed

set

too

low.

2.

Idle

mixture

too

lean

or

too

rich.

3. Leak in

intake

manifold.

4. Worn or burned distributor

rotor.

5.

Incorrect

ignition wiring.

6.

Faulty

coil.

7.

EGR

valve leaking.

1.

Refer to

Group

14,

Fuel

System.

2. Refer to

Group

14,

Fuel

System.

3.

Inspect

intake

manifold

gasket

and

vacuum

hoses.

Replace,

if

necessary

(refer

to

Group

11,

Exhaust

System

&

Intake

Manifold).

4.

Install new distributor

rotor.

5. Install

correct

wiring.

6.

Test

and

replace,

if

necessary

(refer

to

Group

8D,

Ignition

System).

7.

Test

and

replace,

if

necessary

(refer

to

Group

25,

Emissions

Control

System).

J9309-105