check engine DODGE TRUCK 1993 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 369 of 1502

8D

- 18

IGNITION

SYSTEMS

•

COMPONENT REMGWAL/INSTALLATION

INDEX

page

Automatic

Shut Down (ASD) Relay

18

Camshaft

Position

Sensor

, 18

Crankshaft Position

Sensor

18

Distributor

Service

20

Engine

Coolant Temperature

Sensor

20

General

Information

18

Ignition

Coil

21

page

Intake

Manifold Charge

Air

Temperature

Sensor

. 22

Manifold Absolute Pressure (MAP)

Sensor

..... 22

Oxygen

(02)

Sensor

22

Powertrain

Control

Module (PCM)

22

Spark

Plug Secondary Cables

24

Spark

Plugs

23

Throttle

Position

Sensor

(TPS)

24

GENERAL

INFORMATION

This section

of the

group, Component Removal/In

stallation, will discuss

the

removal

and

installation

of ignition system components. For basic ignition system diagnostics

and

service

adjustments, refer

to the

Diagnostics/Service Proce

dures section

of

this group. For system operation

and

component identification,

refer

to the

Component Identification/System Opera

tion section

of

this group.

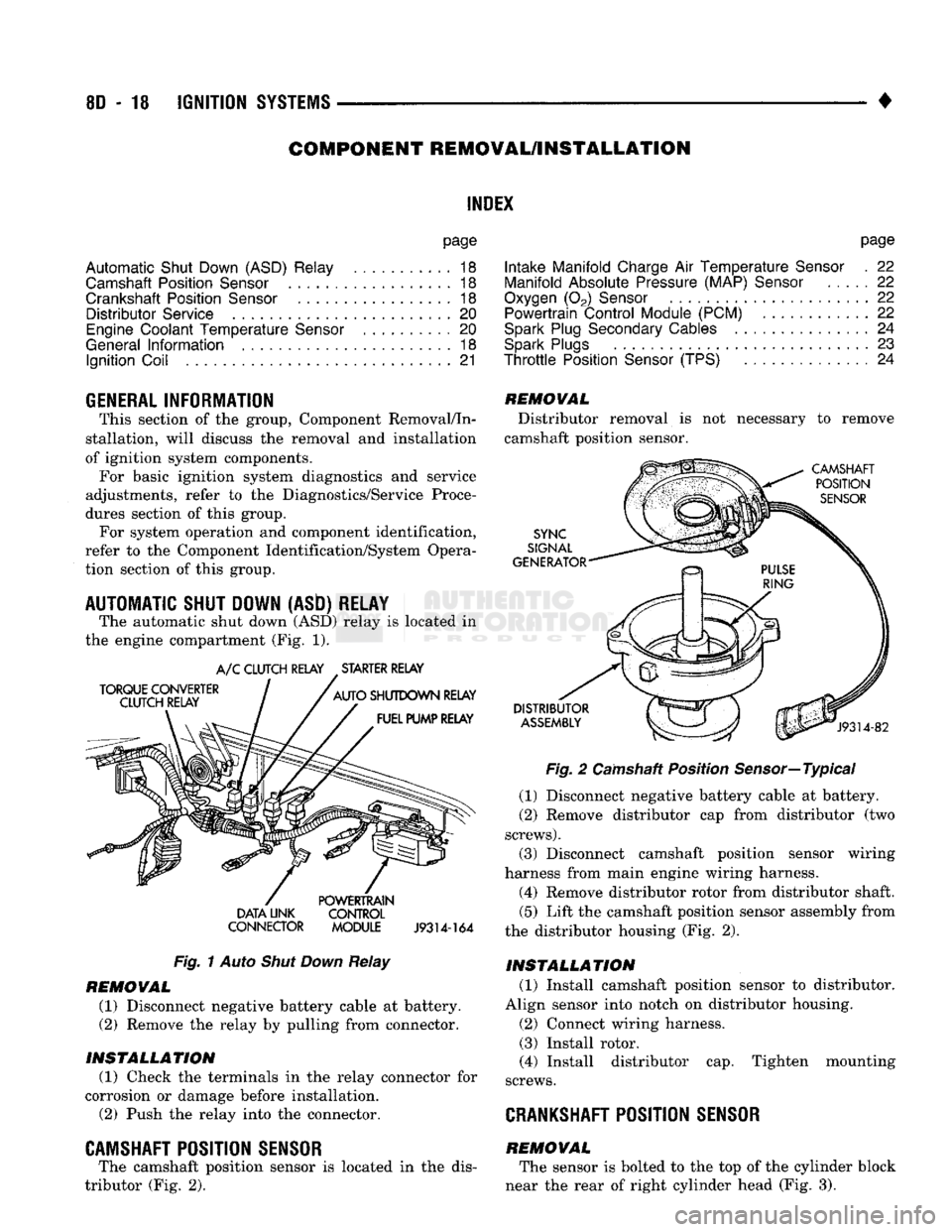

AUTOMATIC

SHUT DOWN

(ASb)

RELAY

The automatic shut down

(ASD)

relay

is

located

in

the engine compartment

(Fig. 1).

TORQUE CONVERTER

CLUTCH RELAY

A/C

CLUTCH RELAY STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY DATA UNK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig.

1

Auto

Shut Down

Relay

REMOVAL

(1) Disconnect negative battery cable

at

battery.

(2)

Remove

the

relay

by

pulling from connector.

INSTALLATION

(1) Check

the

terminals

in the

relay connector

for

corrosion

or

damage before installation.

(2)

Push

the

relay into

the

connector.

CAMSHAFT POSITION SENSOR

The camshaft position sensor

is

located

in the

dis

tributor

(Fig. 2).

REMOVAL

Distributor removal

is not

necessary

to

remove

camshaft position sensor.

CAMSHAFT POSITION

SENSOR

SYNC

SIGNAL

GENERATOR

DISTRIBUTOR

ASSEMBLY

J9314-82

Fig.

2

Camshaft Position Sensor—Typical

(1) Disconnect negative battery cable

at

battery.

(2)

Remove distributor

cap

from distributor

(two

screws).

(3) Disconnect camshaft position sensor wiring

harness from main engine wiring harness.

(4) Remove distributor rotor from distributor shaft.

(5)

Lift

the

camshaft position sensor assembly from

the distributor housing

(Fig. 2).

INSTALLATION

(1) Install camshaft position sensor

to

distributor.

Align sensor into notch

on

distributor housing.

(2)

Connect wiring harness.

(3) Install rotor.

(4) Install distributor

cap.

Tighten mounting

screws.

CRANKSHAFT

POSITION SENSOR

REMOVAL The sensor

is

bolted

to the top of the

cylinder block

near

the

rear

of

right cylinder head

(Fig. 3).

Page 374 of 1502

•

IGNITION

SYSTEMS

80 - 23

PCM

MOUNTING

PCM CONNECTOR CONNECTOR

MOUNTING

BOLT

J9314-165

Fig.

14 PCM Removal/Installation

(6) Remove PCM from vehicle.

INSTALLATION

(1) Check pins in PCM 60-way connector for dam

age.

Repair as necessary. (2) Position PCM and install mounting bolts.

Tighten bolts to 4 N»m (35 in. lbs.) torque. (3) Connect 60-way electrical connector to the

PCM. (4) Install battery.

(5) Connect battery cables to battery (positive ca

ble first).

SPARK

PLUGS

Spark plug cable heat shields are pressed into the

cylinder head to surround each cable boot and spark

plug (Fig. 15). These shields protect the spark plug

boots from damage (due to intense engine heat gen erated by the exhaust manifolds) and should not be

removed. After the spark plug cable has been in stalled, the lip of the cable boot should have a small

air gap to the top of the heat shield (Fig. 15). If removal of the heat shield(s) is necessary, re

move the spark plug cable and compress the sides of

shield for removal. Each shield is slotted to allow for

compression and removal. To install the shields, align shield to machined opening in cylinder head

and tap into place with a block of wood.

PLUG

REMOVAL

(1) Always remove spark plug or ignition coil ca

bles by grasping at the cable boot. Turn the cable

boot 1/2 turn and pull straight back in a steady mo

tion. Never pull directly on the cable. Internal dam age to cable will result.

Fig.

15 Heat

Shields

(2) Prior to removing the spark plug, spray com

pressed air around the spark plug hole and the area around the spark plug. This will help prevent foreign

material from entering the combustion chamber.

(3) Remove the spark plug using a quality socket

with a rubber or foam insert. (4) Inspect the spark plug condition. Refer to

Spark Plugs in the Diagnostics/Service Procedures

section of this group.

PLUG CLEANING The plugs may be cleaned using commercially

available spark plug cleaning equipment. After

cleaning, file the center electrode flat with a small

point file or jewelers file before adjusting gap.

PLUG GAP ADJUSTMENT Check the spark plug gap with a gap gauge tool. If

the gap is not correct, adjust it by bending the

ground electrode (Fig. 16). Never attempt to adjust

the gap by bending the center electrode.

SPARK

PLUG

GAP All Engines: .89 mm (.035 in).

PLUG INSTALLATION Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap.

When replacing the spark plug and ignition coil ca

bles,

route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition noise. It could cause cross ignition of the spark plugs,

or short circuit the cables to ground.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading. (2) Tighten spark plugs to 35-41 N-m (26-30 ft.

lbs.) torque. (3) Install spark plug cables over spark plugs.

Page 382 of 1502

• • ^ ^ ^ INSTRUMENT PANEL AND GAUGES 8E - 1

CONTENTS

page

CLUSTER AND GAUGE SERVICE PROCEDURES . 12

CLUSTER AND GAUGE TEST PROCEDURES .. i

GENERAL INFORMATION . 1

page

MESSAGE CENTER-DIESEL ENGINE ........ 4

MESSAGE CENTER-GAS ENGINE .......... 3

SWITCH

AND PANEL COMPONENT SERVICE . 16

GENERAL

INFORMATION

INDEX

page

Generator

Indicating

System

2

Distance

Sensor

2

Electronic

Digital

Clock

3

Fuel

Level

Indicating

System

1

page

Malfunction

Indicator

(Check

Engine)

3

Oil

Pressure

Warning

Lamp

................. 2

Speedometer/Odometer

System

2

Temperature

and Oil

Indicating

System

......... 2

D-body trucks have an instrument cluster which

includes gauges for fuel level, coolant temperature,

oil pressure, and charging system voltage (Fig. 1).

When the ignition switch is in the OFF position all

the gauges will show a reading except the voltage gauge. However, the readings are only accurate

when the ignition switch is in the ON position.

The cluster also includes warning lamps for:

• seat belt warning

• low oil pressure

• high beam

• left and right turn signals

• check engine. J908E-66

Fig.

11nstrument

Cluster

FUEL LEVEL INDICATING SYSTEM (FIG. 2)

A hinged float arm in the fuel tank raises or lowers

depending on the fuel level. The float arm contacts a

variable resistor in the gauge sending unit. This pro

vides a change of resistance in the fuel gauge circuit

with any up or down movement of the float. This sender

resistance is shown as fuel level on the gauge. Resistance is greatest when the fuel level in the

tank is low and the float arm drops. With high resis

tance current flow is low and consequently positions

the instrument panel gauge pointer to low.

Resistance in the circuit is at a minimum when the

tank is full and the float arm is raised. With resis

tance at a minimum, current flow is high registering

full on the instrument panel gauge.

12

VOLTS

TO

GAUGE

IP

FUEL

TANK

SENDING

UNIT

FLOAT

SENDING

UNIT

1:

1

j

^

fCONNECTOR

!g|yj-»—

FUEL

GAUGE

FUEL

TANK

J098E-47

Fig.

2

Fuel

Level

Indicating

System

INSTRUMENT PANEL AND GAUGES

Page 384 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 3

MALFUNCTION INDICATOR (CHECK ENGINE)

Fig.

5

Distance Sensor

If

the

input from

one of the

following sensors fails

an internal Powertrain Control Module

(PCM)

self

check,

the PCM

turns

on the

Check Engine Lamp. The

PCM

then substitutes

a

modified signal

in

place

of

the one

that failed until

a

repair

is

made:

• Manifold Absolute Pressure (MAP) Sensor

• Throttle Position Sensor

• Coolant Temperature Sensor

• Battery Voltage Sense

• Battery Voltage

Too

High

Refer

to the

appropriate Powertrain Diagnostic

Test Procedures manual

for

further information.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock

is in the

radio.

The

clock

and

radio each

use the

display panel built into

the radio.

A

digital readout indicates

the

time

in

hours

and

minutes whenever

the

ignition switch

is in

the

ON or ACC

position. When

the

ignition switch

is in the OFF

position

or

when

the

radio frequency

is

being displayed, time keeping

is

accurately maintained. The procedure

for

setting

the

clock varies slightly

with each radio.

The

correct procedure

is

described under

the

individual radio operating instructions

re

ferred

to in the

Owner Manual supplied with

the ve

hicle.

MESSAGE CENTER—GAS ENGINE

The message center

(Fig. 6),

located above

the

Heater-A/C controls, includes warning lamps

for the:

• brake systems (parking

and

service)

•

ABS

brakes • liftgate open (Ramcharger only)

• maintenance required.

O/D

BRAKE

(P)(7

GATE OPEN

MAINT

REQD.

J938E-54

Fig.

6

Message Center—Gas Engine

EMISSIONS

MAINTENANCE REMINDER

This system

is

designed

to act as a

reminder that

scheduled vehicle emissions maintenance should

be

performed.

It is not

intended

to

indicate

a

warn

ing

or

that

a

state

of

emergency exists which must

be

corrected

to

insure safe vehicle opera

tion.

The

components covered

by the

system include

the

EGR

system,

PCV

valve,

and

oxygen sensor. Refer

to

Group

25 -

Emissions,

for

further informa

tion.

ABS

WARNING

LIGHT

This light monitors

the ABS

Brake System. This

light will come

on

when

the

ignition

key is

turned

to

the

ON

position

and may

stay

on for as

long

as

thirty seconds.

If the ABS

light remains

on or

comes on during driving,

it

indicates that

the ABS

portion

of

the

brake system

is not

functioning. Refer

to

Group

5 -

Brakes

for

further information.

BRAKE

SYSTEM WARNING

LIGHT

The dual brake system provides

a

reserve braking

capability

in the

event

of a

failure

to a

portion

of the

hydraulic system. Failure

of

either

of the

dual sys

tem

is

indicated

by the

brake warning light which

will glow when

the

service brake pedal

is

depressed.

The light will remain

on

until

the

cause

is

corrected. The light will also come

on

when

the

parking

brake

is

applied with

the

ignition

in the ON

position.

Refer

to

Group

5 -

Brakes

for

further information.

Page 387 of 1502

8E

- 6

INSTRUMENT PANEL

AND

GAUGES

•

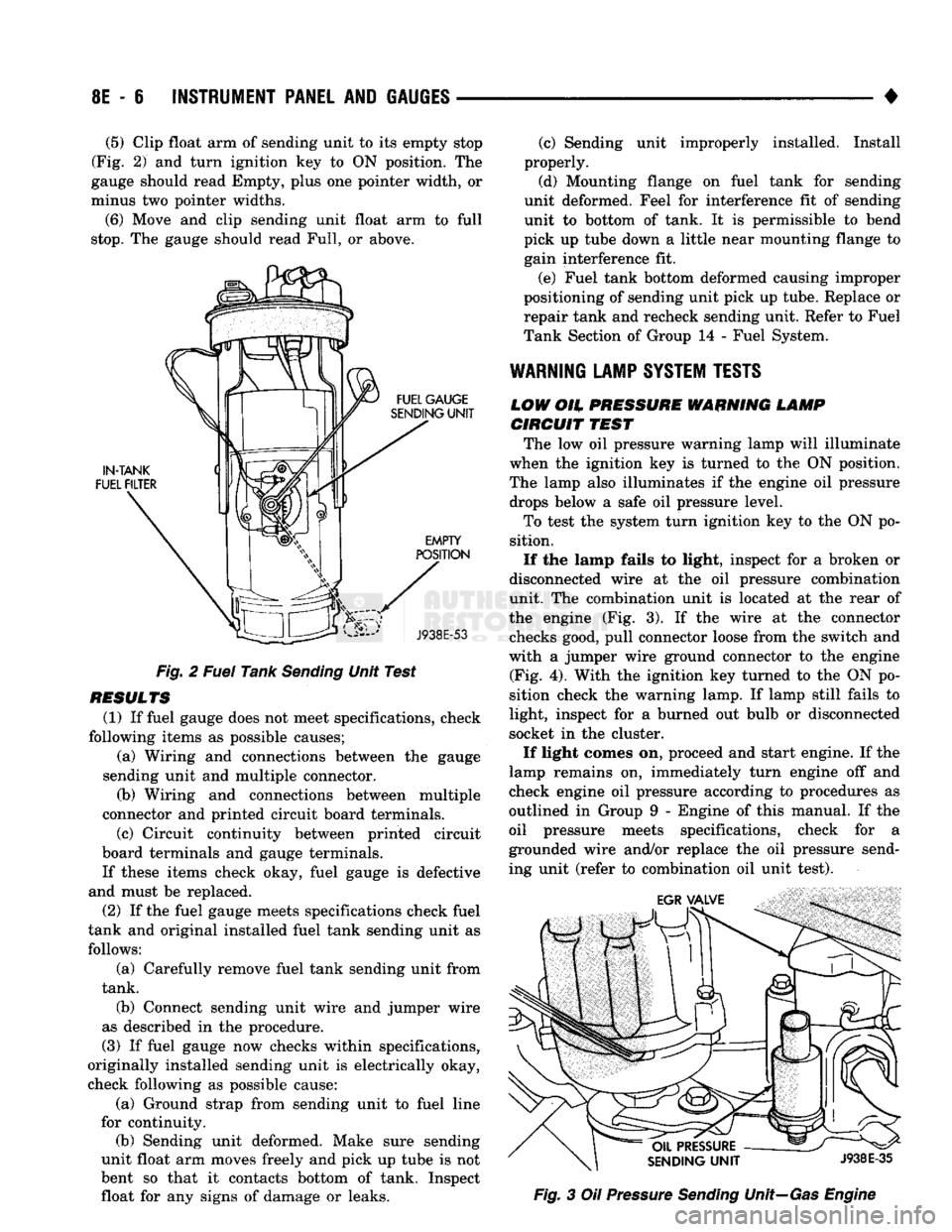

(5)

Clip float arm of sending unit to its empty stop

(Fig. 2) and turn ignition key to ON position. The

gauge should read Empty, plus one pointer width, or

minus two pointer widths.

(6) Move and clip sending unit float arm to full

stop.

The gauge should read Full, or above.

Fig. 2 Fuel Tank Sending Unit Test

RESULTS (1) If fuel gauge does not meet specifications, check

following items as possible causes; (a) Wiring and connections between the gauge

sending unit and multiple connector. (b) Wiring and connections between multiple

connector and printed circuit board terminals.

(c) Circuit continuity between printed circuit

board terminals and gauge terminals.

If these items check okay, fuel gauge is defective

and must be replaced.

(2) If the fuel gauge meets specifications check fuel

tank and original installed fuel tank sending unit as follows:

(a) Carefully remove fuel tank sending unit from

tank.

(b) Connect sending unit wire and jumper wire

as described in the procedure.

(3) If fuel gauge now checks within specifications,

originally installed sending unit is electrically okay,

check following as possible cause:

(a) Ground strap from sending unit to fuel line

for continuity. (b) Sending unit deformed. Make sure sending

unit float arm moves freely and pick up tube is not

bent so that it contacts bottom of tank. Inspect float for any signs of damage or leaks. (c) Sending unit improperly installed. Install

properly.

(d) Mounting flange on fuel tank for sending

unit deformed. Feel for interference fit of sending

unit to bottom of tank. It is permissible to bend

pick up tube down a little near mounting flange to gain interference fit.

(e) Fuel tank bottom deformed causing improper

positioning of sending unit pick up tube. Replace or

repair tank and recheck sending unit. Refer to Fuel

Tank Section of Group 14 - Fuel System.

WARNING

LAMP

SYSTEM

TESTS

LOW

OH.

PRESSURE WARNING LAMP CIRCUIT

TEST

The low oil pressure warning lamp will illuminate

when the ignition key is turned to the ON position.

The lamp also illuminates if the engine oil pressure drops below a safe oil pressure level.

To test the system turn ignition key to the ON po

sition.

If the lamp fails to light, inspect for a broken or

disconnected wire at the oil pressure combination

unit. The combination unit is located at the rear of

the engine (Fig. 3). If the wire at the connector checks good, pull connector loose from the switch and

with a jumper wire ground connector to the engine (Fig. 4). With the ignition key turned to the ON po

sition check the warning lamp. If lamp still fails to

light, inspect for a burned out bulb or disconnected

socket in the cluster.

If light comes on, proceed and start engine. If the

lamp remains on, immediately turn engine off and

check engine oil pressure according to procedures as

outlined in Group 9 - Engine of this manual. If the

oil pressure meets specifications, check for a

grounded wire and/or replace the oil pressure send

ing unit (refer to combination oil unit test). Fig. 3 Oil Pressure Sending Unit—Gas Engine

Page 388 of 1502

•

INSTRUMENT

PANEL

AND

GAUGES

8E - 7

STEERING PUMP

ENGINE

BLOCK

J9U9-74

Fig.

4 Oil

Pressure

Sending

Unit—Diesel

Engine

COMBINATION

OIL

UNIT

TEST

(FIG. 5)

The combination oil unit has 2 functions:

(1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure. (2) The sending provides a resistance that varies

with oil pressure.

To test the normally closed oil lamp switch, discon

nect the locking connector and measure the resis

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine.

If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should read open, Start the engine.

The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature, and oil

viscosity.

If the previous results are not obtained, replace the

switch.

SEAT

BELT

WARNING

SYSTEM

For testing of this system refer to Section 8M -

Seat Belt Warning Systems.

BRAKE

SYSTEM

WARNING

LAMP

(FIG. 6) The brake warning lamp illuminates when the

parking brake is applied with the ignition key

turned ON. The same lamp will also illuminate should one of the two service brake systems fail

when the brake pedal is applied. To test the system

turn the ignition key ON, and apply the parking

brake. If the lamp fails to light, inspect for a burned

out bulb, disconnected socket, a broken or discon-

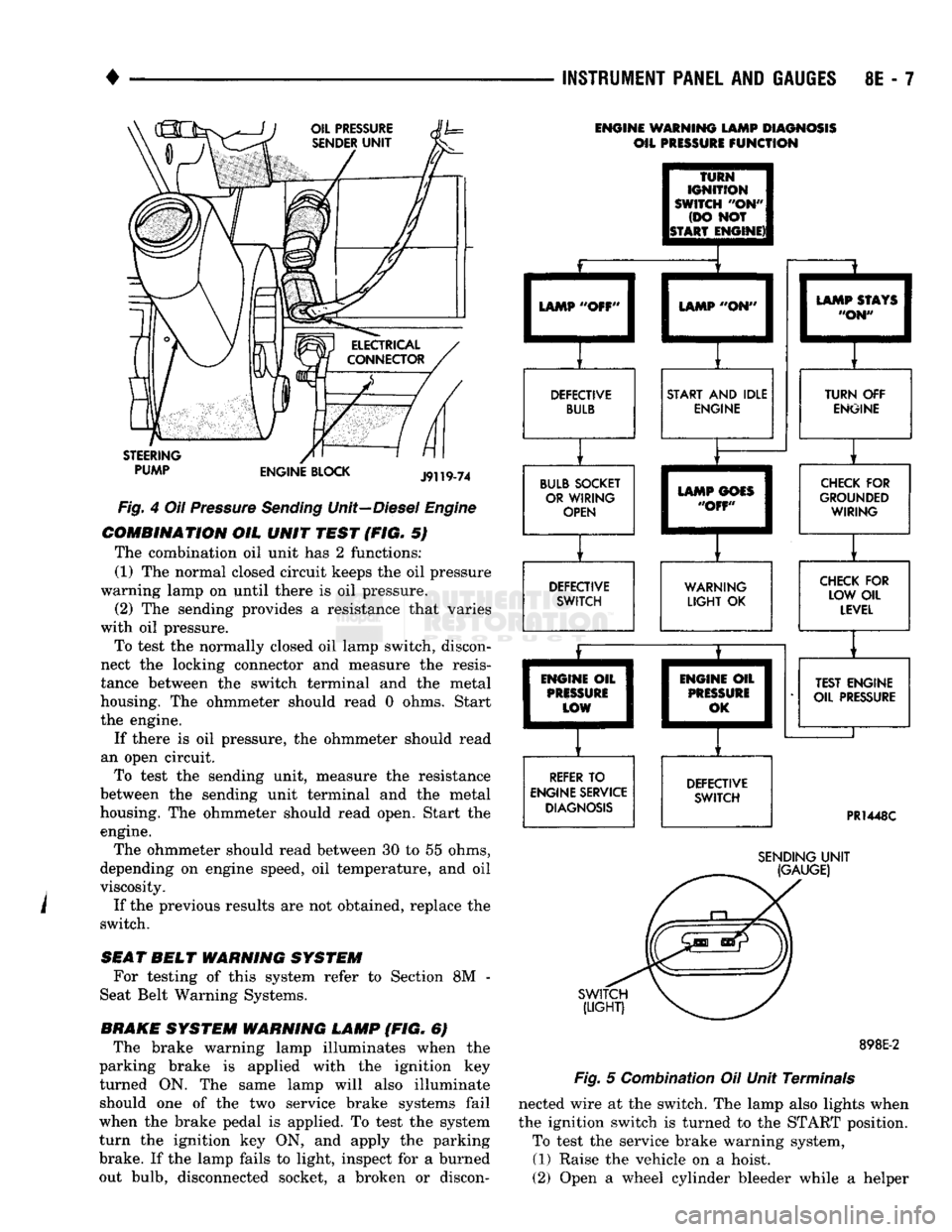

ENGINE WARNING LAMP DIAGNOSIS

OIL PRESSURE

FUNCTION

TURN

IGNITION

SWITCH

"OH"

(DO NOT

ISTART ENGINE)! LAMP "OFF'

LAMP "ON"

DEFECTIVE BULB START AND IDLE

ENGINE

BULB SOCKET OR WIRING OPEN LAMP STAYS

"ON" TURN OFF

ENGINE LAMP GOES

"OFF" DEFECTIVE

SWITCH CHECK FOR

GROUNDED WIRING

WARNING

LIGHT

OK CHECK FOR

LOW OIL LEVEL

ENGINE OIL

PRISSURi

LOW

REFER TO

ENGINE SERVICE DIAGNOSIS ENGIM

PRES

0

IE OIL

1

SURE

1

,K I

DEFECTIVE SWITCH TEST ENGINE

OIL PRESSURE

PR1448C

SWITCH

(LIGHT)

SENDING

UNIT

(GAUGE)

898E-2

Fig.

5 Combination Oil Unit Terminals

nected wire at the switch. The lamp also lights when

the ignition switch is turned to the START position. To test the service brake warning system,

(1) Raise the vehicle on a hoist.

(2) Open a wheel cylinder bleeder while a helper

Page 389 of 1502

8E

- 8 INSTRUMENT PANEL AND GAUGES

•

BRAKE

WARNING

LAMP

SWITCH TO BRAKE

WARNING LAMP

PR!

451

Fig.

6

Brake Warning

Lamp

Switch

depresses

the

brake pedal

and

observes

the

warning

lamp.

If

the

lamp fails

to

light, inspect

for:

•

a

burned

out

bulb

• disconnected socket

•

a

broken

or

disconnected wire

at the

switch. If

the

bulb

is not

burned

out and the

wire continu

ity

is

proven, replace

the

brake warning switch.

The

switch

is in the

brake line

Tee

fitting mounted

on

the frame rail

in the

engine compartment below

the

master cylinder.

CAUTION:

If

wheel cylinder bleeder

was

opened

check

master cylinder fluid level.

On Diesel Models

The

Brake light

is

also con

nected

to a

sensor that monitors vacuum

in the

brake booster system.

The

Brake light when

lit

indi cates

LOW

VACUUM. Refer

to

Group

5 -

Brakes

for

more information.

TEMPERATURE

GAUGE CIRCUIT TEST

(1) Remove temperature gauge. Refer

to

Gauge

Re

placement. (2) Check continuity

in the

wire between

the

tem

perature sensor

and the

temperature gauge (sensor

input

pin)

(Figs.

7, 8 and 9).

(3) With

the

ignition switch

in the ON

position,

check

for

battery voltage across

the B + pin and the

Ground

pin.

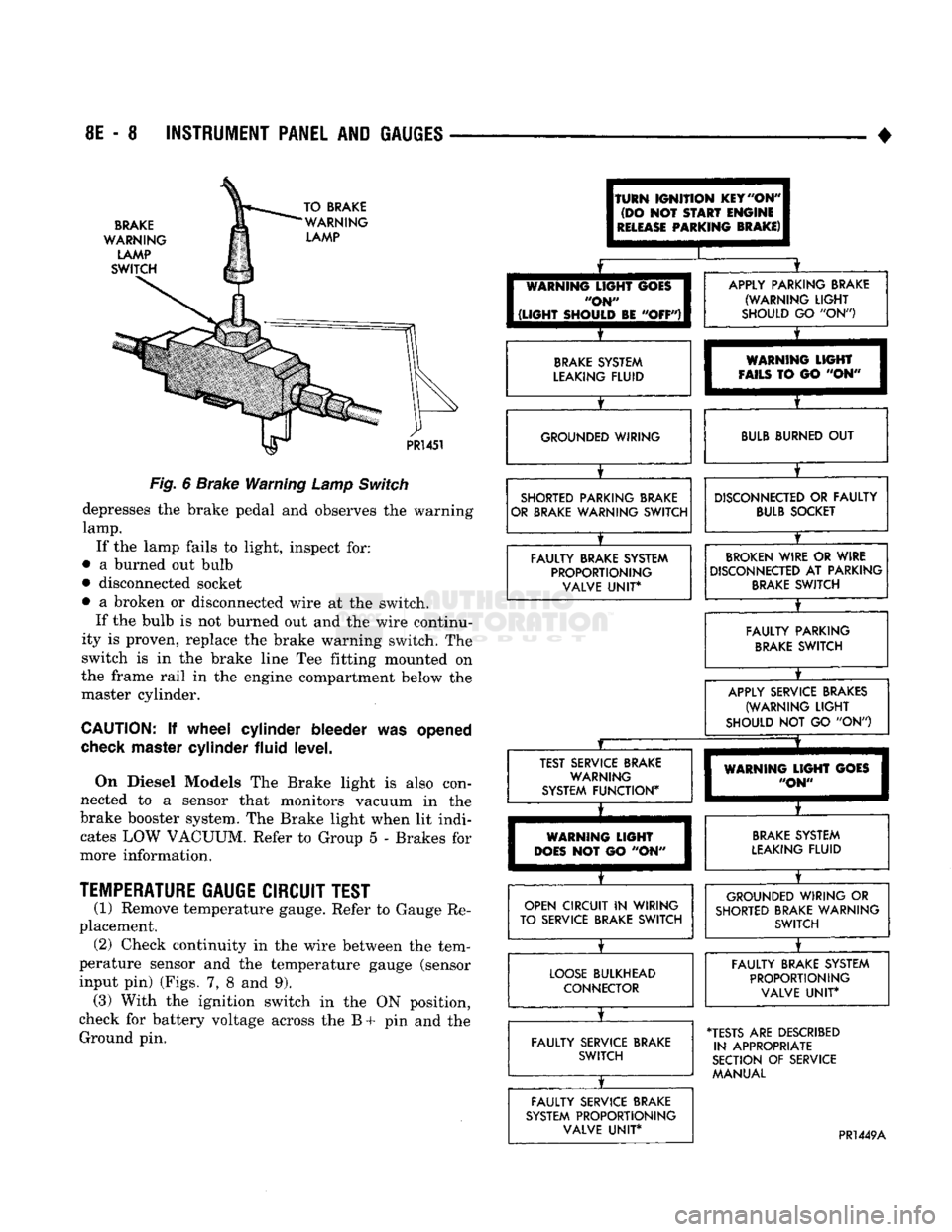

(TURN

IGNITION

KEY

"ON"

(DO

NOT

START

ENGINE

I

RELEASE

PARKING

BRAKE)

I

I

[

WARNING

LIGHT

GOES

I

"ON"

I

1

(LIGHT

SHOULD

BE

"OFF")!

X

APPLY PARKING BRAKE (WARNING

LIGHT

SHOULD

GO "ON")

BRAKE

SYSTEM

LEAKING FLUID

X

WARNING

LIGHT

FAILS

TO GO "ON" GROUNDED WIRING

BULB

BURNED

OUT

SHORTED PARKING BRAKE

OR BRAKE WARNING SWITCH

X

DISCONNECTED

OR

FAULTY

BULB

SOCKET

FAULTY BRAKE SYSTEM PROPORTIONING VALVE

UNIT*

BROKEN

WIRE

OR

WIRE

DISCONNECTED

AT

PARKING

BRAKE

SWITCH

X

FAULTY PARKING

BRAKE

SWITCH

X

APPLY SERVICE BRAKES

(WARNING

LIGHT

SHOULD

NOT GO "ON")

JZ

X

TEST SERVICE BRAKE WARNING

SYSTEM FUNCTION*

X

WARNING

LIGHT

GOES

"ON"

WARNING

LIGHT

DOES

NOT GO "ON"

BRAKE

SYSTEM

LEAKING FLUID

OPEN CIRCUIT

IN

WIRING

TO SERVICE BRAKE SWITCH

X

GROUNDED WIRING

OR

SHORTED BRAKE WARNING SWITCH

LOOSE

BULKHEAD CONNECTOR

X

FAULTY BRAKE SYSTEM

PROPORTIONING VALVE

UNIT*

FAULTY SERVICE BRAKE SWITCH

X

•TESTS

ARE

DESCRIBED

IN APPROPRIATE

SECTION

OF

SERVICE MANUAL

FAULTY SERVICE BRAKE

SYSTEM PROPORTIONING VALVE

UNIT*

PR1449A

Page 390 of 1502

INSTRUMENT

PANEL

AND

GAUGES

8E - S

J938E-34

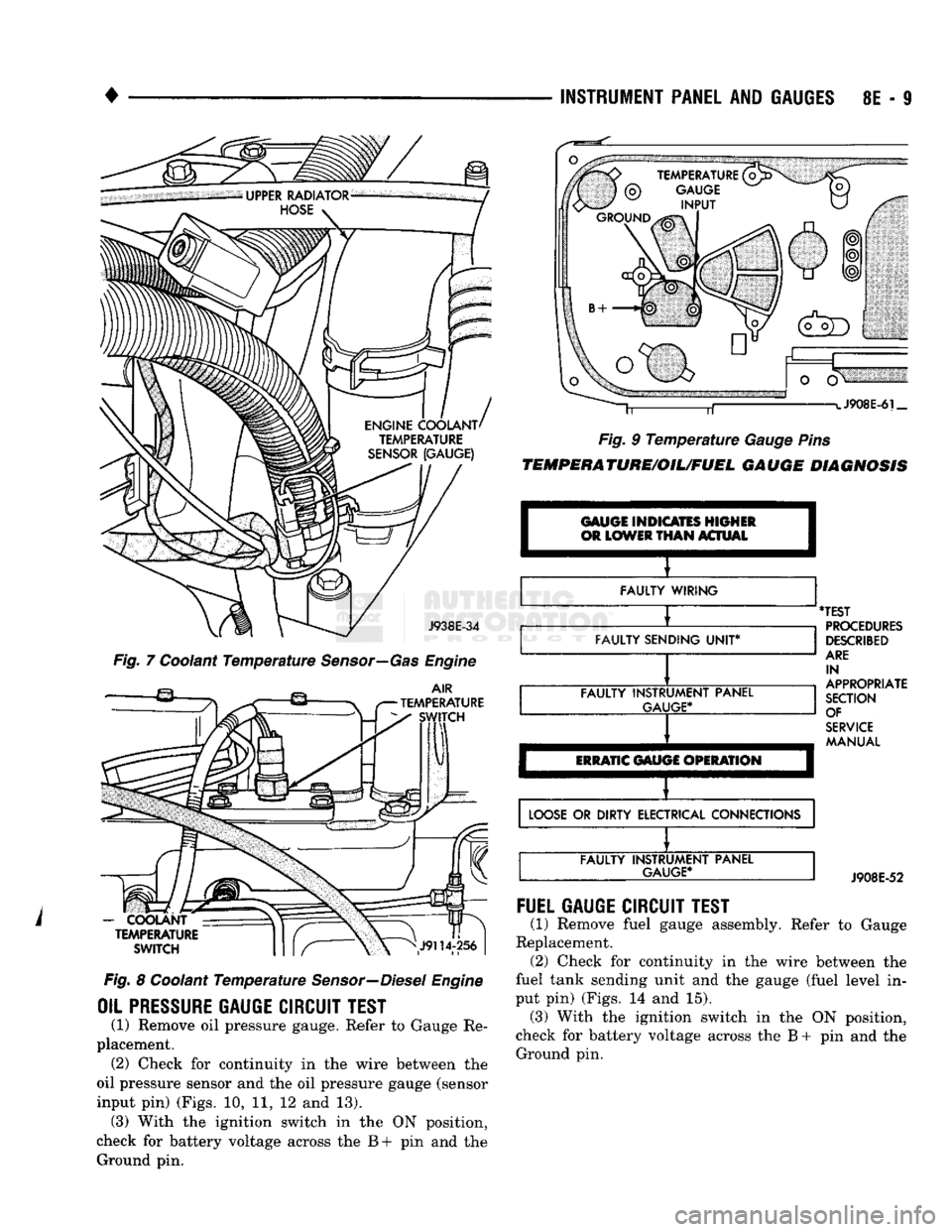

Fig. 7 Coolant Temperature Sensor—Gas Engine

AIR

TEMPERATURE SWITCH

-

COOLANT TEMPERATURE

SWITCH

Fig. 8 Coolant Temperature Sensor—Diesel Engine

OIL PRESSURE

GAUGE

CIRCUIT

TEST

(1) Remove oil pressure gauge. Refer to Gauge Re

placement. (2) Check for continuity in the wire between the

oil pressure sensor and the oil pressure gauge (sensor

input pin) (Figs. 10, 11, 12 and 13). (3) With the ignition switch in the ON position,

check for battery voltage across the B+ pin and the Ground pin. J908E-6i_

Fig. 9 Temperature Gauge Pins

TEMPERATURE/OIL/FUEL

GAUGE

DIAGNOSIS

GAUGE INDICATES HIGHER

OR

LOWER

THAN

ACTUAL I

FAULTY WIRING

FAULTY SENDING

UNIT*

FAULTY INSTRUMENT PANEL

GAUGE*

ERRATIC

GAUGE OPERATION

'TEST

PROCEDURES

DESCRIBED

ARE

IN

APPROPRIATE

SECTION OF

SERVICE

MANUAL

LOOSE

OR DIRTY ELECTRICAL CONNECTIONS FAULTY INSTRUMENT PANEL

GAUGE*

J908E-52

FUEL

GAUGE

CIRCUIT

TEST

(1) Remove fuel gauge assembly. Refer to Gauge

Replacement. (2) Check for continuity in the wire between the

fuel tank sending unit and the gauge (fuel level in

put pin) (Figs. 14 and 15). (3) With the ignition switch in the ON position,

check for battery voltage across the B + pin and the Ground pin.

Page 391 of 1502

8E

- 10

INSTRUMENT

PANEL

AND

GAUGES

GROUND

OIL

PRESSURE

SENSOR

INPUT

J908E-70

Fig.

10 Oil Pressure

Sending

Unit—Gas Engine

STEERING

PUMP

ENGINE

BLOCK

J9119-74

Fig.

11 Oil Pressure

Sending

Unit—Diesel Engine

SENDING

UNIT

(GAUGE)

SWITCH

(LIGHT)

898E-2

Fig.

12 Combination Oil Unit Terminals

VOLTAGE

GAUGE

CIRCUIT

TEST

(1) Remove voltage gauge. Refer to Gauge Replace

ment.

Fig.

13 Oil Pressure

Gauge

Pins

r— FUEL

PUMP

SUPPLY

0 INPUT TO

GAUGE

-SENDING

UNIT

GROUND

-FUEL

PUMP

GROUND

J928E-49

Fig.

14 Fuel Tank

Sending

Connector Terminals

FUEL

GAUGE

INPUT

^

GROUND

y

J908E-71

Fig.

15 Fuel

Gauge

Pins

(2) With the ignition switch in the ON position,

check for battery voltage across the B+ pin and the Ground pin (Fig. 16).

The instrument panel voltmeter indicates elec

trical system battery voltage.

SPEEDOMETER

(1) Remove speedometer assembly. Refer to Gauge

Replacement.

Page 396 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 15

PRND21 INDICATOR

REMOVAL

(1) Remove bezel. Refer to Cluster Bezel Removal.

(2)

Remove cluster mask and lens. Refer to Cluster

Mask and Lens Removal. (3) Remove cluster assembly. Refer to Instrument

Cluster Removal. (4) Remove screws attaching PRND21 mechanism

to cluster housing.

(5)

Remove PRND21 mechanism.

INSTALLATION (1) Position PRND21 mechanism to cluster hous

ing. (2) Install mounting screws.

(3)

Install cluster assembly. (4) Install mask-lens.

(5)

Install bezel.

LAMP BULBS

CLUSTER ILLUMINATION LAMPS TURN SIGNAL INDICATOR LAMPS

LOW OIL PRESSURE INDICATOR LAMP

HIGH BEAM INDICATOR LAMP CHECK ENGINE LAMP

SEAT BELT WARNING LAMP

REMOVAL (1) Disconnect negative cable from battery.

(2) Remove instrument cluster. See cluster re

moval.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket.

(2) Install socket assembly into printed circuit

board.

(3)

Position cluster into place in panel. See cluster

installation. (4) Connect battery negative cable.

LAMP BULB REPLACEMENT—MESSAGE CENTER

REMOVAL (1) Disconnect battery negative cable.

(2) Remove instrument cluster bezel assembly. Re

fer to Instrument Cluster removal.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket assembly. (2) Install lamp socket assembly into printed cir

cuit board.

(3)

Install Instrument Cluster bezel assembly to

instrument panel. Refer to Instrument Cluster instal

lation.

(4) Connect negative cable from battery.

FOUR WHEEL DRIVE INDICATOR LAMP (1) Pull bulb and socket assembly from rear of

housing. (2) Remove bulb from socket.

(3)

Reverse removal procedures to install.

SPECIFICATIONS

Fuel

Gauge Calibration

Mntar Position Resistance

Empty Graduation 90

ohms

± 3

ohms

Empty Stop

Greater

than

96.5 ohms

Full

Graduation 12 ohm

± 3

ohms

Full

Stop

Less

than

8

ohms

1/2

45.3 ohms

± 3

ohms

Temperature

Gauge

Calibration

Pointer

Position Resistance

Cold Graduation 655 ohms

Hot Graduation 64 ohms

Oil Pressure Gauge Calibration

Pointer

Position Resistance

Low Graduation 100 ohms

High Graduation 12 ohms

J908E-58