FIAT 500L 2015 2.G User Guide

Manufacturer: FIAT, Model Year: 2015, Model line: 500L, Model: FIAT 500L 2015 2.GPages: 148, PDF Size: 3.77 MB

Page 101 of 148

CAUTION!

Driving with a hot cooling system could damage your vehicle.If the temperature gauge

reads hot, pull over and stop the vehicle.Idle the vehicle with the air conditioner

turned off until the pointer drops back into the normal range.If the pointer remains

on hot, turn the engine off immediately and call for service.

WARNING!

You or others can be badly burned by hot engine coolant (antifreeze) or steam from

your radiator.If you see or hear steam coming from under the hood, do not open the

hood until the radiator has had time to cool.Never try to open a cooling system pres-

sure cap when the radiator or coolant bottle is hot.

JACKING AND TIRE CHANGING

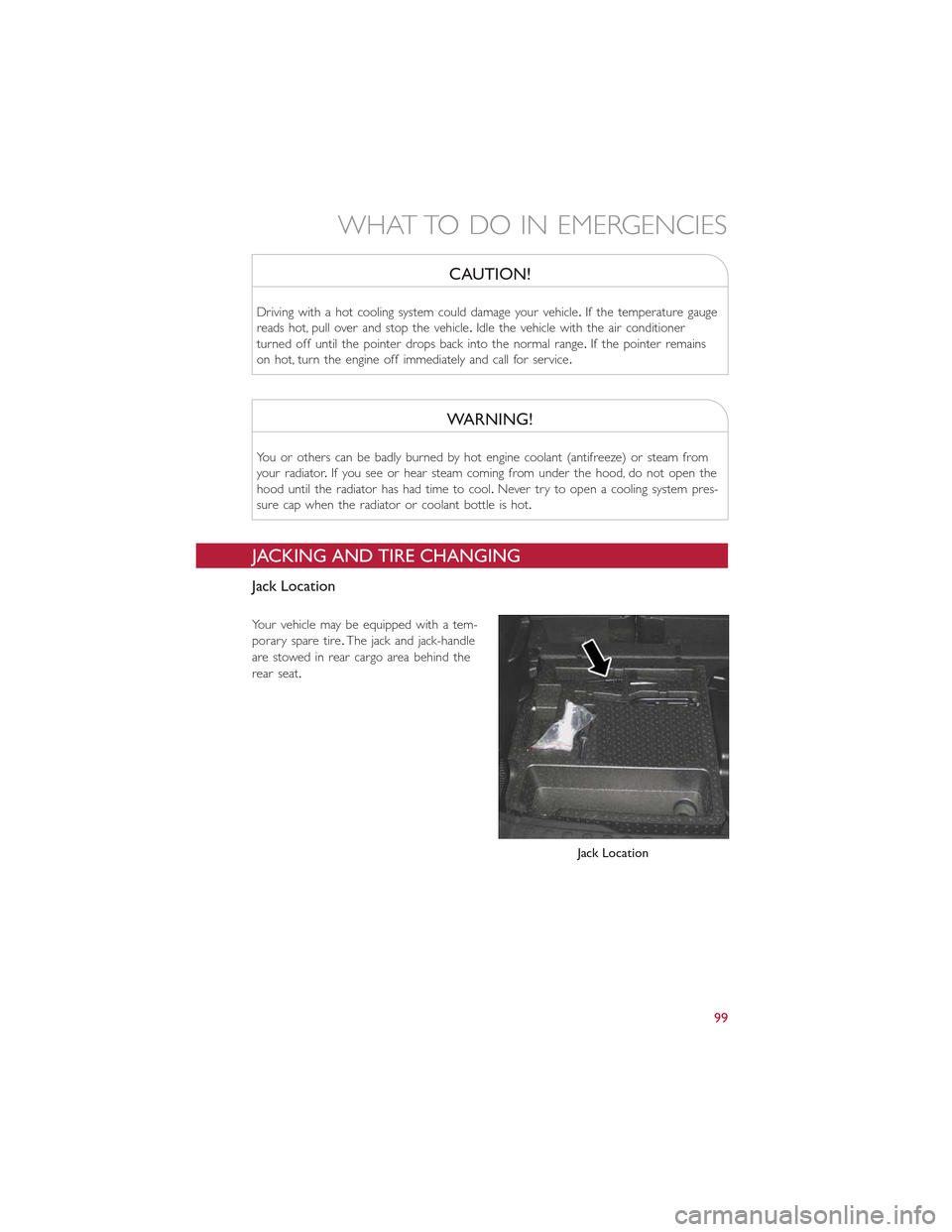

Jack Location

Your vehicle may be equipped with a tem-

porary spare tire.The jack and jack-handle

are stowed in rear cargo area behind the

rear seat.

Jack Location

WHAT TO DO IN EMERGENCIES

99

Page 102 of 148

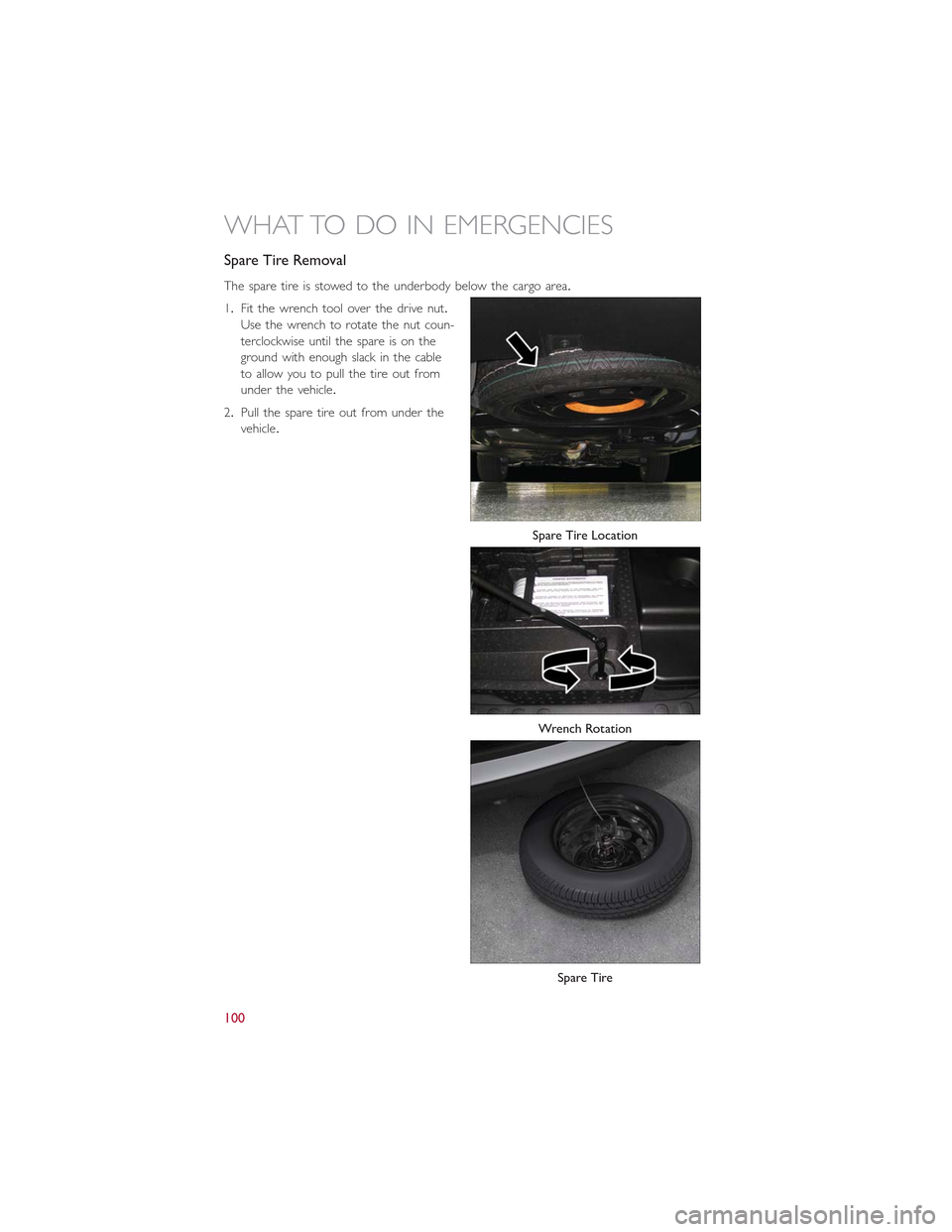

Spare Tire Removal

The spare tire is stowed to the underbody below the cargo area.

1.Fit the wrench tool over the drive nut.

Use the wrench to rotate the nut coun-

terclockwise until the spare is on the

ground with enough slack in the cable

to allow you to pull the tire out from

under the vehicle.

2.Pull the spare tire out from under the

vehicle.

Spare Tire Location

Wrench Rotation

Spare Tire

WHAT TO DO IN EMERGENCIES

100

Page 103 of 148

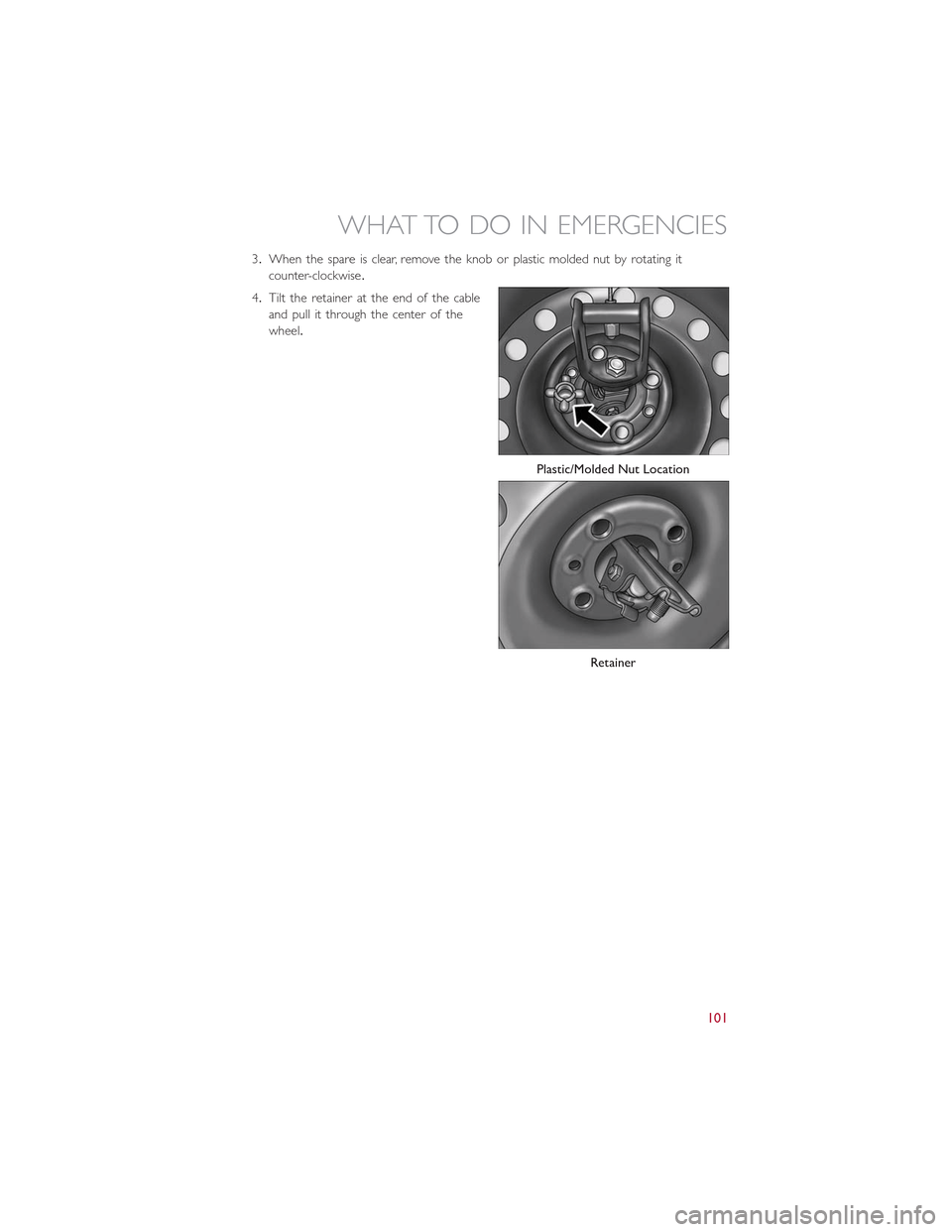

3.When the spare is clear, remove the knob or plastic molded nut by rotating it

counter-clockwise.

4.Tilt the retainer at the end of the cable

and pull it through the center of the

wheel.

Plastic/Molded Nut Location

Retainer

WHAT TO DO IN EMERGENCIES

101

Page 104 of 148

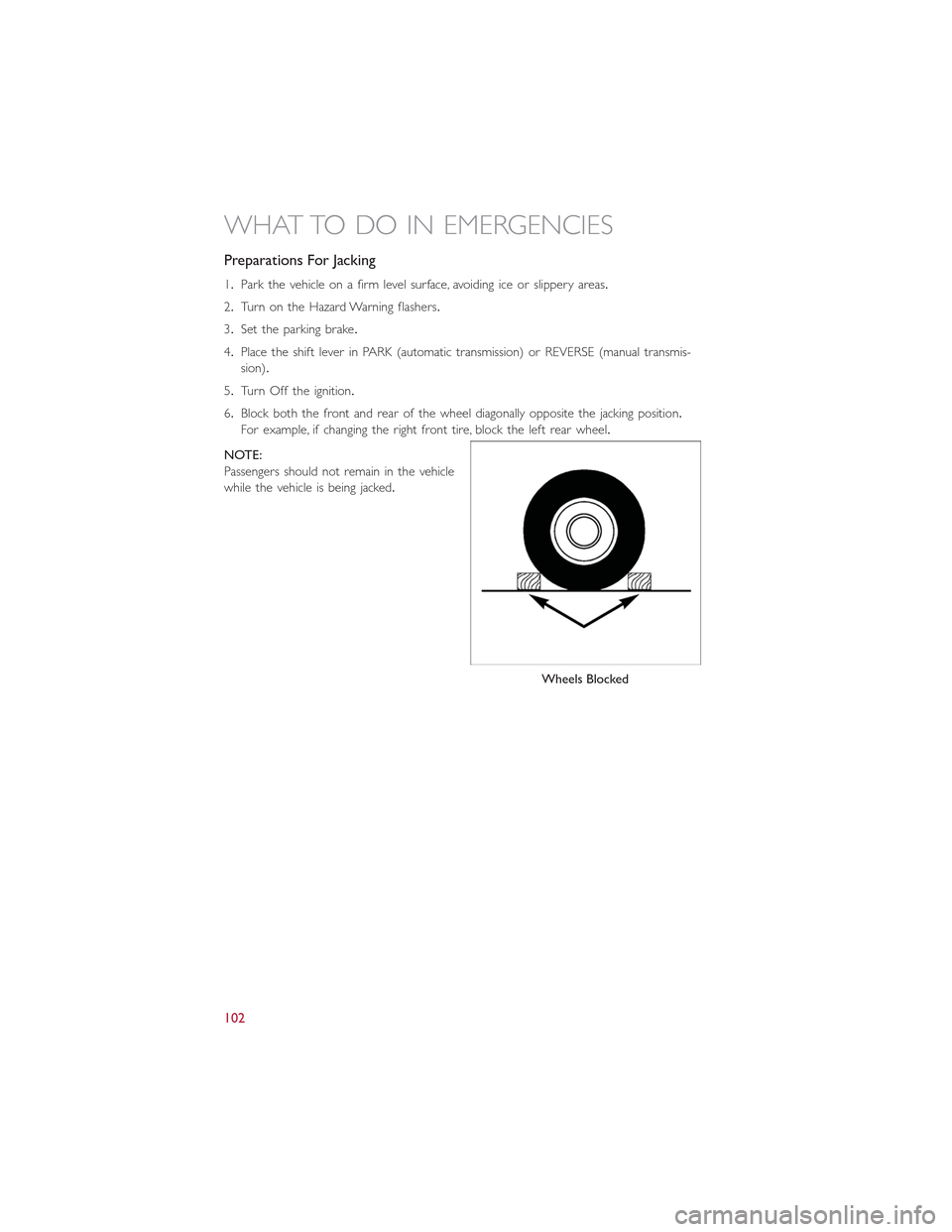

Preparations For Jacking

1.Park the vehicle on a firm level surface, avoiding ice or slippery areas.

2.Turn on the Hazard Warning flashers.

3.Set the parking brake.

4.Place the shift lever in PARK (automatic transmission) or REVERSE (manual transmis-

sion).

5.Turn Off the ignition.

6.Block both the front and rear of the wheel diagonally opposite the jacking position.

For example, if changing the right front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

while the vehicle is being jacked.

Wheels Blocked

WHAT TO DO IN EMERGENCIES

102

Page 105 of 148

Jacking Instructions

NOTE:

Refer to the “Compact Spare Tire” section

of the “Tires-General Information” under

“Starting And Operating” in your Owner’s

Manual on the DVD for more information

about the spare tire, it's use, and operation.

1.Remove the scissors jack and wheel

wrench from the rear storage area.

2.Loosen, but do not remove, the wheel

bolts by turning them to the left one

turn while the wheel is still on the

ground.

NOTE:

There are front and rear jacking locations on each side of the body (as indicated by the

triangular lift point symbol on the sill molding).

Do not raise the vehicle until you are sure the jack is securely engaged.

Warning Label

WHAT TO DO IN EMERGENCIES

103

Page 106 of 148

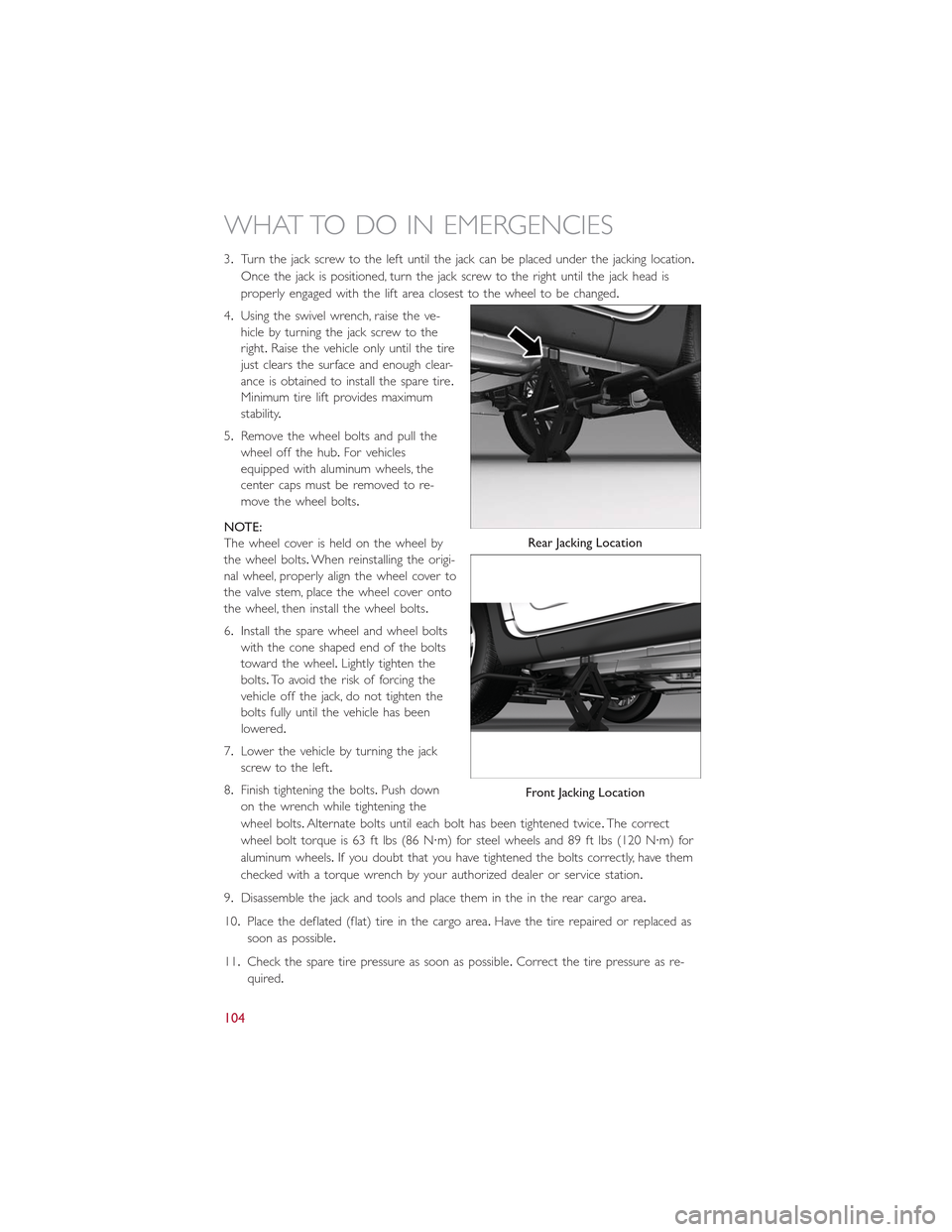

3.Turn the jack screw to the left until the jack can be placed under the jacking location.

Once the jack is positioned, turn the jack screw to the right until the jack head is

properly engaged with the lift area closest to the wheel to be changed.

4.Using the swivel wrench, raise the ve-

hicle by turning the jack screw to the

right.Raise the vehicle only until the tire

just clears the surface and enough clear-

ance is obtained to install the spare tire.

Minimum tire lift provides maximum

stability.

5.Remove the wheel bolts and pull the

wheel off the hub.For vehicles

equipped with aluminum wheels, the

center caps must be removed to re-

move the wheel bolts.

NOTE:

The wheel cover is held on the wheel by

the wheel bolts.When reinstalling the origi-

nal wheel, properly align the wheel cover to

the valve stem, place the wheel cover onto

the wheel, then install the wheel bolts.

6.Install the spare wheel and wheel bolts

with the cone shaped end of the bolts

toward the wheel.Lightly tighten the

bolts.To avoid the risk of forcing the

vehicle off the jack, do not tighten the

bolts fully until the vehicle has been

lowered.

7.Lower the vehicle by turning the jack

screw to the left.

8.Finish tightening the bolts.Push down

on the wrench while tightening the

wheel bolts.Alternate bolts until each bolt has been tightened twice.The correct

wheel bolt torque is 63 ft lbs (86 N·m) for steel wheels and 89 ft lbs (120 N·m) for

aluminum wheels.If you doubt that you have tightened the bolts correctly, have them

checked with a torque wrench by your authorized dealer or service station.

9.Disassemble the jack and tools and place them in the in the rear cargo area.

10.Place the deflated (flat) tire in the cargo area.Have the tire repaired or replaced as

soon as possible.

11.Check the spare tire pressure as soon as possible.Correct the tire pressure as re-

quired.

Rear Jacking Location

Front Jacking Location

WHAT TO DO IN EMERGENCIES

104

Page 107 of 148

Spare Tire Stowage

•Reverse instructions of the spare removal section.

•Rotate the jack wrench tool on the winch drive nut clockwise until effort becomes

heavy and an audible click is heard indicating the spare is properly stowed.

CAUTION!

•The winch mechanism is designed for use with the jack extension tube only.Use

of an air wrench or other power tools is not recommended and they can damage

the winch.

•Do not attempt to raise the vehicle by jacking on locations other than those indi-

cated in the Jacking Instructions for this vehicle.

•Be sure to mount the spare tire with the valve stem facing outward.The vehicle

could be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

105

Page 108 of 148

WARNING!

•Do not attempt to change a tire on the side of the vehicle close to moving traffic.

Pull far enough off the road to avoid the danger of being hit when operating the

jack or changing the wheel.

•Being under a jacked-up vehicle is dangerous.The vehicle could slip off the jack

and fall on you.You could be crushed.Never put any part of your body under a

vehicle that is on a jack.

•Never start or run the engine while the vehicle is on a jack.if you need to get

under a raised vehicle, take it to a authorized dealer where it can be raised on a

lift.

•The jack is designed to use as a tool for changing tires only.The jack should not be

used to lift the vehicle for service purposes.The vehicle should be jacked on a

firm, level surface only.Avoid ice or slippery areas.

•After using the jack and tools, always reinstall them in the original carrier and loca-

tion.While driving you may experience abrupt stopping, rapid acceleration, or

sharp turns.A loose jack, tools, bracket or other objects in the vehicle may move

around with force, resulting in serious injury.

•Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

•Always park on a firm, level surface as far from the edge of the roadway as pos-

sible before raising the vehicle.

•Turn on the Hazard Warning flasher.

•Block the wheel diagonally opposite the wheel to be raised.

•Set the parking brake firmly and set an automatic transmission in PARK; a manual

transmission in REVERSE.

•Do not let anyone sit in the vehicle when it is on a jack.

•Do not get under the vehicle when it is on a jack.

•Only use the jack in the positions indicated and for lifting this vehicle during a tire

change.

•If working on or near a roadway, be extremely careful of motor traffic.

•To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

•Raising the vehicle higher than necessary can make the vehicle unstable and cause

a collision.It could slip off the jack and hurt someone near it.Raise the vehicle

only enough to remove the tire.

•A loose tire or jack thrown forward in a collision or hard stop could injure some-

one in the vehicle.Always stow the jack parts and the extra tire and wheel in the

places provided.

WHAT TO DO IN EMERGENCIES

106

Page 109 of 148

TIRE SERVICE KIT

Your vehicle may be equipped with a Tire Service Kit.

Small punctures up to 1/4” (6 mm) in the tire tread can be sealed with the Tire Service

Kit.Foreign objects (e.g., screws or nails) should not be removed from the tire.The Tire

Service Kit can be used in outside temperatures down to approximately -4°F (-20°C).

This kit will provide a temporary tire seal, allowing you to drive your vehicle up to 100

miles (160 km) with a maximum speed of 55 mph (90 km/h).

Tire Service Kit Storage

The Tire Service Kit is located in the rear trunk area on the left side.

Tire Service Kit Components And Operation

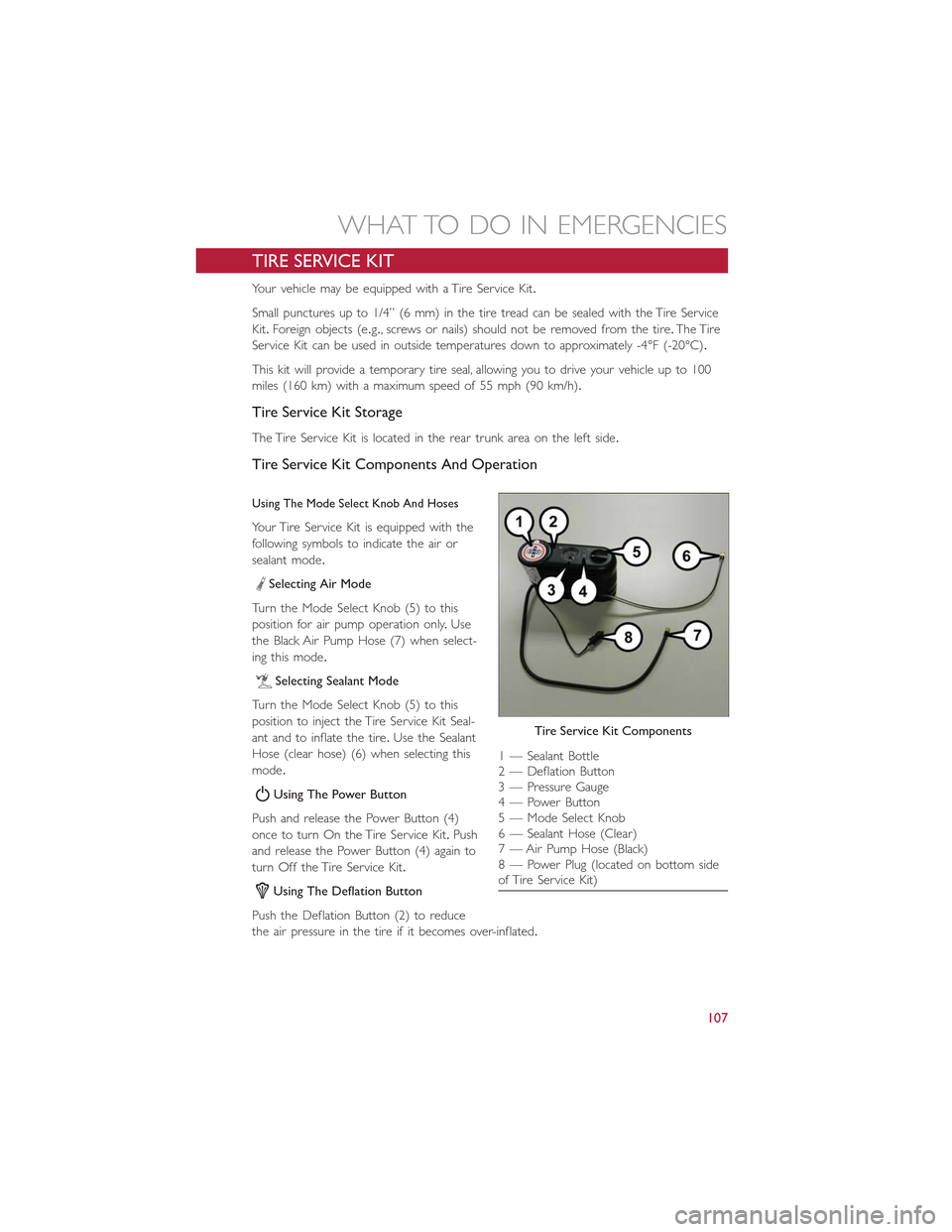

Using The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the

following symbols to indicate the air or

sealant mode.

Selecting Air Mode

Turn the Mode Select Knob (5) to this

position for air pump operation only.Use

the Black Air Pump Hose (7) when select-

ing this mode.

Selecting Sealant Mode

Turn the Mode Select Knob (5) to this

position to inject the Tire Service Kit Seal-

ant and to inflate the tire.Use the Sealant

Hose (clear hose) (6) when selecting this

mode.

Using The Power Button

Push and release the Power Button (4)

once to turn On the Tire Service Kit.Push

and release the Power Button (4) again to

turn Off the Tire Service Kit.

Using The Deflation Button

Push the Deflation Button (2) to reduce

the air pressure in the tire if it becomes over-inflated.

Tire Service Kit Components

1 — Sealant Bottle2 — Deflation Button3 — Pressure Gauge4 — Power Button5 — Mode Select Knob6 — Sealant Hose (Clear)7 — Air Pump Hose (Black)8 — Power Plug (located on bottom sideof Tire Service Kit)

WHAT TO DO IN EMERGENCIES

107

Page 110 of 148

Tire Service Kit Usage Precautions

•Replace the Tire Service Kit Sealant Bottle (1) and Sealant Hose (6) prior to the expi-

ration date (printed on the bottle label) to assure optimum operation of the system.

Refer to “Sealing A Tire With Tire Service Kit” section (F) “Sealant Bottle and Hose

Replacement.”

•The Sealant Bottle (1) and Sealant Hose (6) are a one tire application use.After each

use, always replace these components immediately at an authorized dealer.

•When the Tire Service Kit sealant is in a liquid form, clean water, and a damp cloth will

remove the material from the vehicle or tire and wheel components.Once the sealant

dries, it can easily be peeled off and properly discarded.

•For optimum performance, make sure the valve stem on the wheel is free of debris

before connecting the Tire Service Kit.

•You can use the Tire Service Kit air pump to inflate bicycle tires.The kit also comes

with two needles, located in the Accessory Storage Compartment (on the bottom of

the air pump) for inflating sport balls, rafts, or similar inflatable items.However, use

only the Air Pump Hose (7) and make sure the Mode Select Knob (5) is in the Air

Mode when inflating such items to avoid injecting sealant into them.The Tire Service

Kit Sealant is only intended to seal punctures less than 1/4 inch (6 mm) diameter in

the tread of your vehicle.

•Do not lift or carry the Tire Service Kit by the hoses.

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1.Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2.Verify that the valve stem (on the wheel with the deflated tire) is in a position that is

near to the ground.This will allow the Tire Service Kit Hoses (6) and (7) to reach the

valve stem and keep the Tire Service Kit flat on the ground.This will provide the best

positioning of the kit when injecting the sealant into the deflated tire and running the

air pump.Move the vehicle as necessary to place the valve stem in this position be-

fore proceeding.

3.Place the transmission in PARK (auto transmission) or in Gear (manual transmission)

and cycle the ignition to the OFF position.

4.Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1.Turn the Mode Select Knob (5) to the Sealant Mode position.

2.Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of

the hose.

3.Place the Tire Service Kit flat on the ground next to the deflated tire.

4.Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (6) onto the valve stem.

WHAT TO DO IN EMERGENCIES

108