technical specifications FIAT DOBLO COMBI 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2012, Model line: DOBLO COMBI, Model: FIAT DOBLO COMBI 2012Pages: 283, PDF Size: 6.31 MB

Page 117 of 283

113

KNOW

YOUR

VEHICLE

SAFETY

STAR

TING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

PROTECTING THE ENVIRONMENT

The devices for reducing petrol engine emissions are the

following:

❒three-way catalytic converter;

❒Lambda sensors;

❒evaporation prevention system.

In addition, do not let the engine run, even for a test, with

one or more spark plugs disconnected.

The following devices are used for reducing diesel fuel en-

gine emissions:

❒oxidising catalytic converter;

❒exhaust gas recirculation system (EGR);

❒diesel particulate filter (DPF) (for versions/markets

where provided).

To close

1) Fit the cap (complete with key) and turn it clockwise

until it clicks once or more.

2) Turn the key clockwise and extract it, then close the

flap.

The hermetic seal may cause a slight increase in pressure

in the tank. A suction noise when you release the cap is

therefore entirely normal.

Do not place naked flames or lit cigarettes

near to the fuel tank opening: fire risk. Keep

your face away from the fuel tank open-

ing to avoid breathing in harmful vapours.

Page 118 of 283

114

KNOWYOUR

VEHICLE

SAFETY

ST AR

TING AND

DRIVING

WARNING

LIGHTS AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DIESEL PARTICULATE FILTER (DPF)

(for versions/markets where provided)

The Diesel Particulate Filter is a mechanical filter, inte-

gral with the exhaust system, that physically traps carbon

particles present in the exhaust gases of Diesel engines.

It is needed to eliminate almost all carbon particles in com-

pliance with current/future legislation. During normal use

of the vehicle, the engine management control unit records

a set of data (e.g. journey time, type of route, tempera-

tures, etc.) and it will then calculate how much particu-

late has been trapped by the filter. Since the filter is a collecting system, it should be regular-

ly regenerated (cleaned) by burning the carbon particles.

The regeneration procedure is controlled automatically by

the engine management control unit according to the fil-

ter conditions and vehicle use conditions.

During regeneration, the following may occur: a limited in-

crease in the engine speed, activation of the fan, a limited

increase in fumes and high temperatures at the exhaust.

These are not faults; they do not impair vehicle perfor-

mance or damage the environment. If the dedicated mes-

sage is displayed, refer to the “Warning lights and mes-

sages” section.

Page 133 of 283

129

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0024mfig. 123F0V0025mfig. 124

The airbags are not deployed in the event of small head-

on collisions (for which the withholding action of the seat

belts is sufficient). Seat belts must always be worn. In the

event of head-on collisions, they ensure the correct po-

sitioning of the occupant.

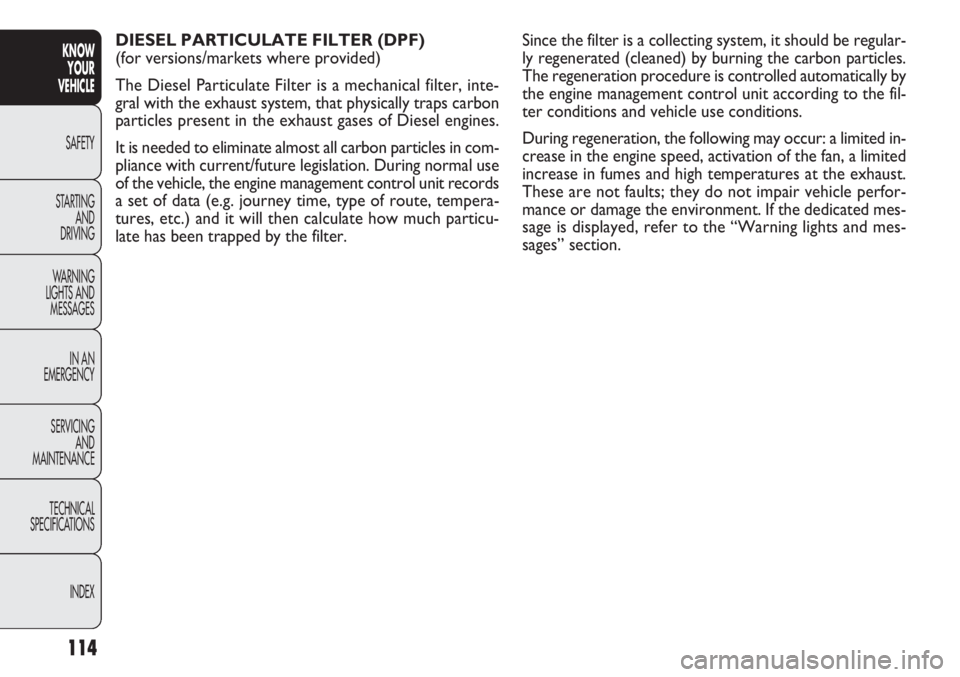

FRONT AIRBAG ON DRIVER’S SIDE fig. 123

This consists of an instant-inflating bag contained in a spe-

cial compartment in the centre of the steering wheel.

FRONT AIRBAG ON PASSENGER’S SIDE

fig. 124 (for versions/markets where provided)

This consists of an instant-inflating bag contained in a spe-

cial compartment in the dashboard: this bag has a larger

volume than that of the driver’s.

Do not put cradle seats facing backwardson the front seat if the passenger airbag

is activated. Deployment of the airbag in

an accident could cause fatal injuries to

the child. Always deactivate the passen-

ger airbag when placing a child seat on the front

seat. Also, the passenger seat should be as far back

as possible to avoid contact between the child seat

and the dashboard. Although this is not manda-

tory by law, the airbag should be immediately re-

activated when children are no longer carried to

ensure better protection for adults.

WARNING

Page 144 of 283

140

KNOWYOUR

VEHICLE

SAFETY

ST ARTING

AN

D

DRIVING

WARNING

LIGHTS AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICA TIONS

INDEX

SNOW TYRES

A Fiat Dealership will be happy to provide advice con-

cerning the most suitable type of tyre for the customer’s

requirements.

For the type, pressures and specifications of the snow tyre

to be used, follow carefully the instructions given in the

“Wheels” paragraph of the “Technical specifications” sec-

tion.

The winter performance of these tyres is considerably re-

duced when the tread thickness is less than 4 mm. If this

is the case, replace them.

Due to their specific features, the performance of snow

tyres is much lower than that of standard tyres in normal

conditions or on long motorway stretches. You should

therefore use them only in the conditions for which they

were designed.

IMPORTANT When using snow tyres with a maximum

speed index below the one that can be reached by the

vehicle (increased by 5%), place a notice in the passenger

compartment, plainly in view, which states the maximum

speed allowed by the snow tyres (as per EC Directive).

All four tyres should be the same (brand and profile) to

ensure greater safety when driving and braking as well as

making the car more responsive.

Remember that you should not change the rotation di-

rection of the tyres.The ABS with which the vehicle may be

equipped will not control the braking sys-

tem of the trailer. Particular caution is therefore

required on slippery roads.

WARNING

Never modify the braking system of the ve-

hicle to control the trailer brake. The trail-

er braking system must be fully independent from

the hydraulic system of the vehicle.

WARNING

Page 159 of 283

155

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0147mfig. 128

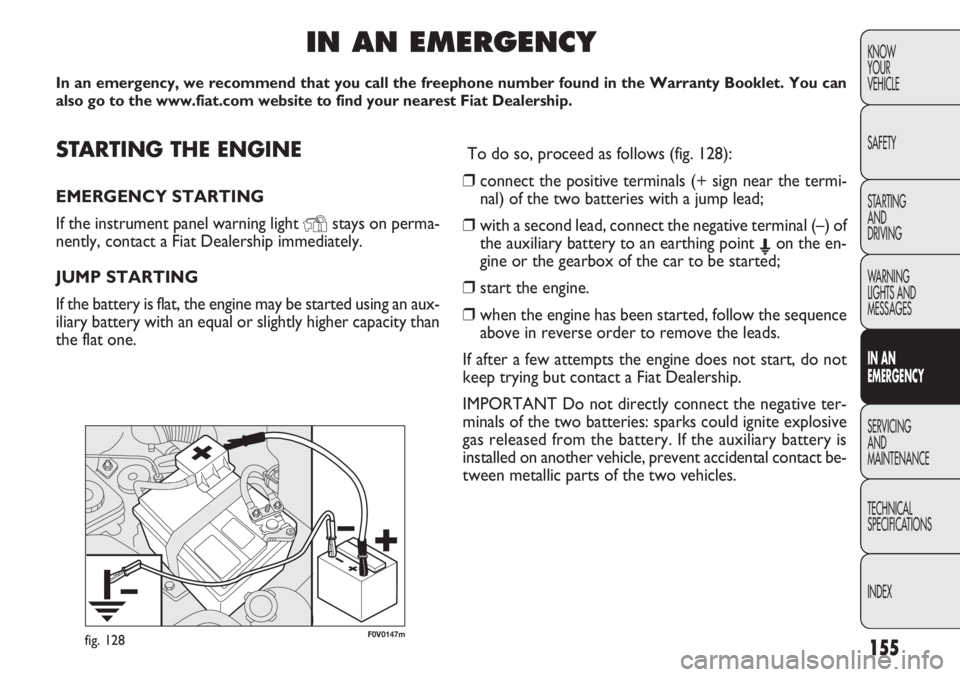

STARTING THE ENGINE

EMERGENCY STARTING

If the instrument panel warning light

Ystays on perma-

nently, contact a Fiat Dealership immediately.

JUMP STARTING

If the battery is flat, the engine may be started using an aux-

iliary battery with an equal or slightly higher capacity than

the flat one.

IN AN EMERGENCY

In an emergency, we recommend that you call the freephone number found i\

n the Warranty Booklet. You can

also go to the www.fiat.com website to find your nearest Fiat Dealership\

.

To do so, proceed as follows (fig. 128):

❒ connect the positive terminals (+ sign near the termi-

nal) of the two batteries with a jump lead;

❒ with a second lead, connect the negative terminal (–) of

the auxiliary battery to an earthing point E on the en-

gine or the gearbox of the car to be started;

❒ start the engine.

❒ when the engine has been started, follow the sequence

above in reverse order to remove the leads.

If after a few attempts the engine does not start, do not

keep trying but contact a Fiat Dealership.

IMPORTANT Do not directly connect the negative ter-

minals of the two batteries: sparks could ignite explosive

gas released from the battery. If the auxiliary battery is

installed on another vehicle, prevent accidental contact be-

tween metallic parts of the two vehicles.

Page 161 of 283

157

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEXUse your hazard lights, warning triangle,

etc to show that your car is stationary.

Passengers should get out of the car, particularly

if it is heavily loaded, and wait for the wheel to be

changed away from the traffic. If you are on a

steep slope or uneven surface, place wedges or

other suitable objects under the wheels to secure

the vehicle. Repair and refit the standard wheel

as soon as possible. Do not grease the bolt threads

before you fit them, because they could sudden-

ly come loose.

WARNING

Use the jack only to replace wheels on the

vehicle with which it is supplied or on oth-

er vehicles of the same model. Never use the jack

for other purposes, such as lifting other models.

Never use the jack to carry out repairs under the

vehicle. Incorrect positioning of the jack may

cause the lifted vehicle to fall. Do not use the jack

for loads higher than the one shown on its label.

WARNING

Incorrect hub cap assembly may cause it

to come off when the car is moving. Nev-

er tamper with the inflation valve. Never intro-

duce tools of any kind between the rim and the

tyre. Check tyre and spare wheel pressures regu-

larly, referring to the values shown in the “Tech-

nical specifications” section.

WARNING

Note for one-way tyres

One-way tyres have a few arrows on the side indicating

the rotation direction. If a wheel is changed (when punc-

tured, for example) the direction of the arrows on the spa-

re wheel tyre may not coincide with the rotation direc-

tion of the wheel to be replaced. In these conditions, too,

the tyre still maintains its safety features.

Anyway, it is recommended to have the wheel repaired

and refitted as soon as possible, as the best performance

is achieved when the rotation direction of all tyres coin-

cides with the one indicated by the arrows.

Page 163 of 283

159

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0193mfig. 133

F0V0151mfig. 132

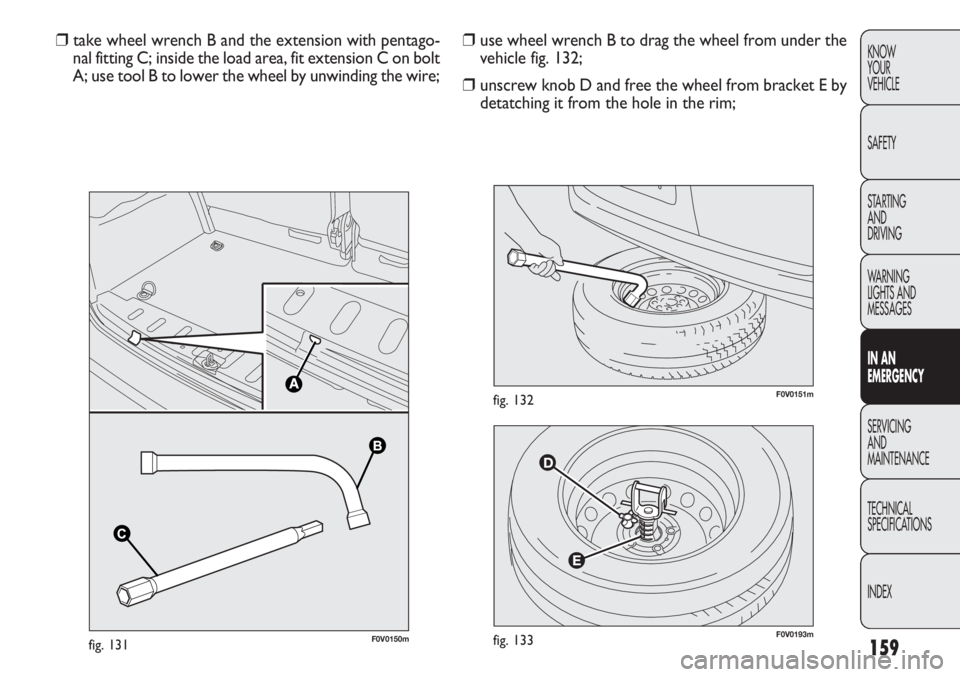

❒ use wheel wrench B to drag the wheel from under the

vehicle fig. 132;

❒ unscrew knob D and free the wheel from bracket E by

detatching it from the hole in the rim;

❒

take wheel wrench B and the extension with pentago-

nal fitting C; inside the load area, fit extension C on bolt

A; use tool B to lower the wheel by unwinding the wire;

BB

CC

F0V0150mfig. 131

Page 165 of 283

161

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

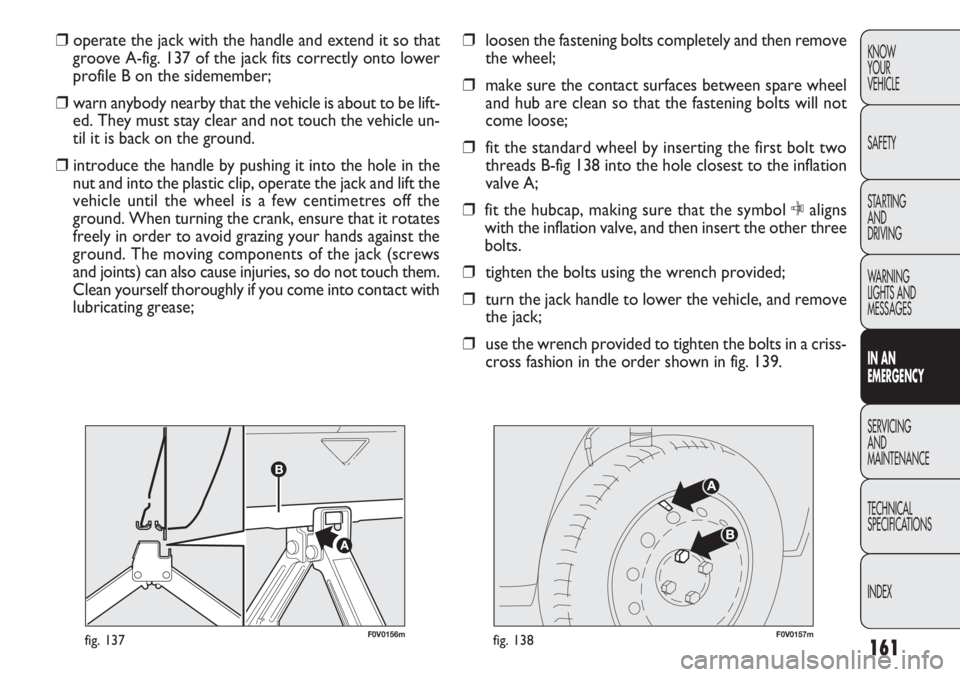

F0V0156mfig. 137F0V0157mfig. 138

❒ loosen the fastening bolts completely and then remove

the wheel;

❒ make sure the contact surfaces between spare wheel

and hub are clean so that the fastening bolts will not

come loose;

❒ fit the standard wheel by inserting the first bolt two

threads B-fig 138 into the hole closest to the inflation

valve A;

❒ fit the hubcap, making sure that the symbol Caligns

with the inflation valve, and then insert the other three

bolts.

❒ tighten the bolts using the wrench provided;

❒ turn the jack handle to lower the vehicle, and remove

the jack;

❒ use the wrench provided to tighten the bolts in a criss-

cross fashion in the order shown in fig. 139.

❒

operate the jack with the handle and extend it so that

groove A-fig. 137 of the jack fits correctly onto lower

profile B on the sidemember;

❒ warn anybody nearby that the vehicle is about to be lift-

ed. They must stay clear and not touch the vehicle un-

til it is back on the ground.

❒ introduce the handle by pushing it into the hole in the

nut and into the plastic clip, operate the jack and lift the

vehicle until the wheel is a few centimetres off the

ground. When turning the crank, ensure that it rotates

freely in order to avoid grazing your hands against the

ground. The moving components of the jack (screws

and joints) can also cause injuries, so do not touch them.

Clean yourself thoroughly if you come into contact with

lubricating grease;

Page 167 of 283

163

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

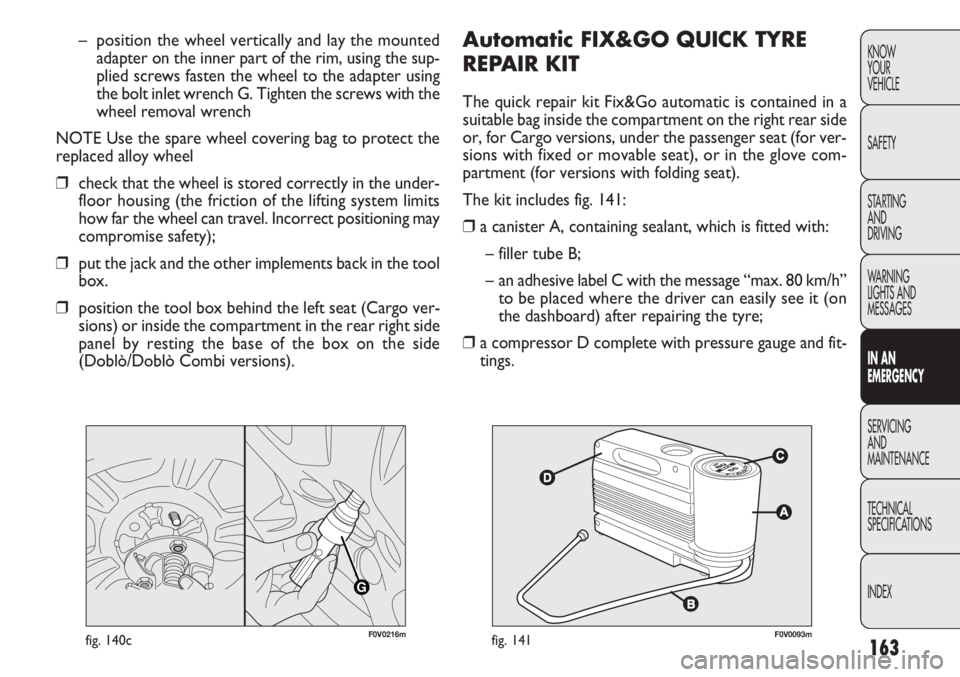

INDEXAutomatic FIX&GO QUICK TYRE

REPA I R KIT

The quick repair kit Fix&Go automatic is contained in a

suitable bag inside the compartment on the right rear side

or, for Cargo versions, under the passenger seat (for ver-

sions with fixed or movable seat), or in the glove com-

partment (for versions with folding seat).

The kit includes fig. 141:

❒a canister A, containing sealant, which is fitted with:

– filler tube B;

– an adhesive label C with the message “max. 80 km/h” to be placed where the driver can easily see it (on

the dashboard) after repairing the tyre;

❒ a compressor D complete with pressure gauge and fit-

tings.

– position the wheel vertically and lay the mounted

adapter on the inner part of the rim, using the sup-

plied screws fasten the wheel to the adapter using

the bolt inlet wrench G. Tighten the screws with the

wheel removal wrench

NOTE Use the spare wheel covering bag to protect the

replaced alloy wheel

❒ check that the wheel is stored correctly in the under-

floor housing (the friction of the lifting system limits

how far the wheel can travel. Incorrect positioning may

compromise safety);

❒ put the jack and the other implements back in the tool

box.

❒ position the tool box behind the left seat (Cargo ver-

sions) or inside the compartment in the rear right side

panel by resting the base of the box on the side

(Doblò/Doblò Combi versions).

G

F0V0216mfig. 140cF0V0093mfig. 141

Page 169 of 283

165

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

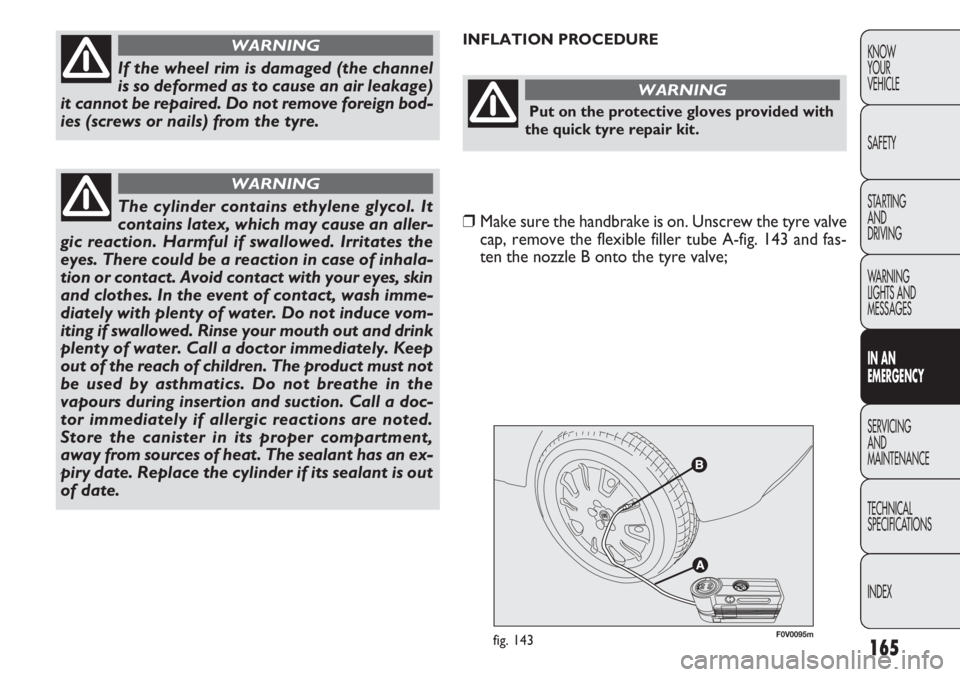

F0V0095mfig. 143

INFLATION PROCEDURE

If the wheel rim is damaged (the channel

is so deformed as to cause an air leakage)

it cannot be repaired. Do not remove foreign bod-

ies (screws or nails) from the tyre.

WARNING

The cylinder contains ethylene glycol. It

contains latex, which may cause an aller-

gic reaction. Harmful if swallowed. Irritates the

eyes. There could be a reaction in case of inhala-

tion or contact. Avoid contact with your eyes, skin

and clothes. In the event of contact, wash imme-

diately with plenty of water. Do not induce vom-

iting if swallowed. Rinse your mouth out and drink

plenty of water. Call a doctor immediately. Keep

out of the reach of children. The product must not

be used by asthmatics. Do not breathe in the

vapours during insertion and suction. Call a doc-

tor immediately if allergic reactions are noted.

Store the canister in its proper compartment,

away from sources of heat. The sealant has an ex-

piry date. Replace the cylinder if its sealant is out

of date.

WARNING

Put on the protective gloves provided with

the quick tyre repair kit.

WARNING

❒ Make sure the handbrake is on. Unscrew the tyre valve

cap, remove the flexible filler tube A-fig. 143 and fas-

ten the nozzle B onto the tyre valve;